Automatic punching device of car seat sliding rail

A technology for car seat slide rails and stamping devices, which is applied to vehicle parts, transportation and packaging, etc. It can solve the problems of low production efficiency, unfavorable continuous production of the production line, and difficulty in ensuring processing accuracy, etc., and achieves simple structure, continuous and efficient automatic stamping , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

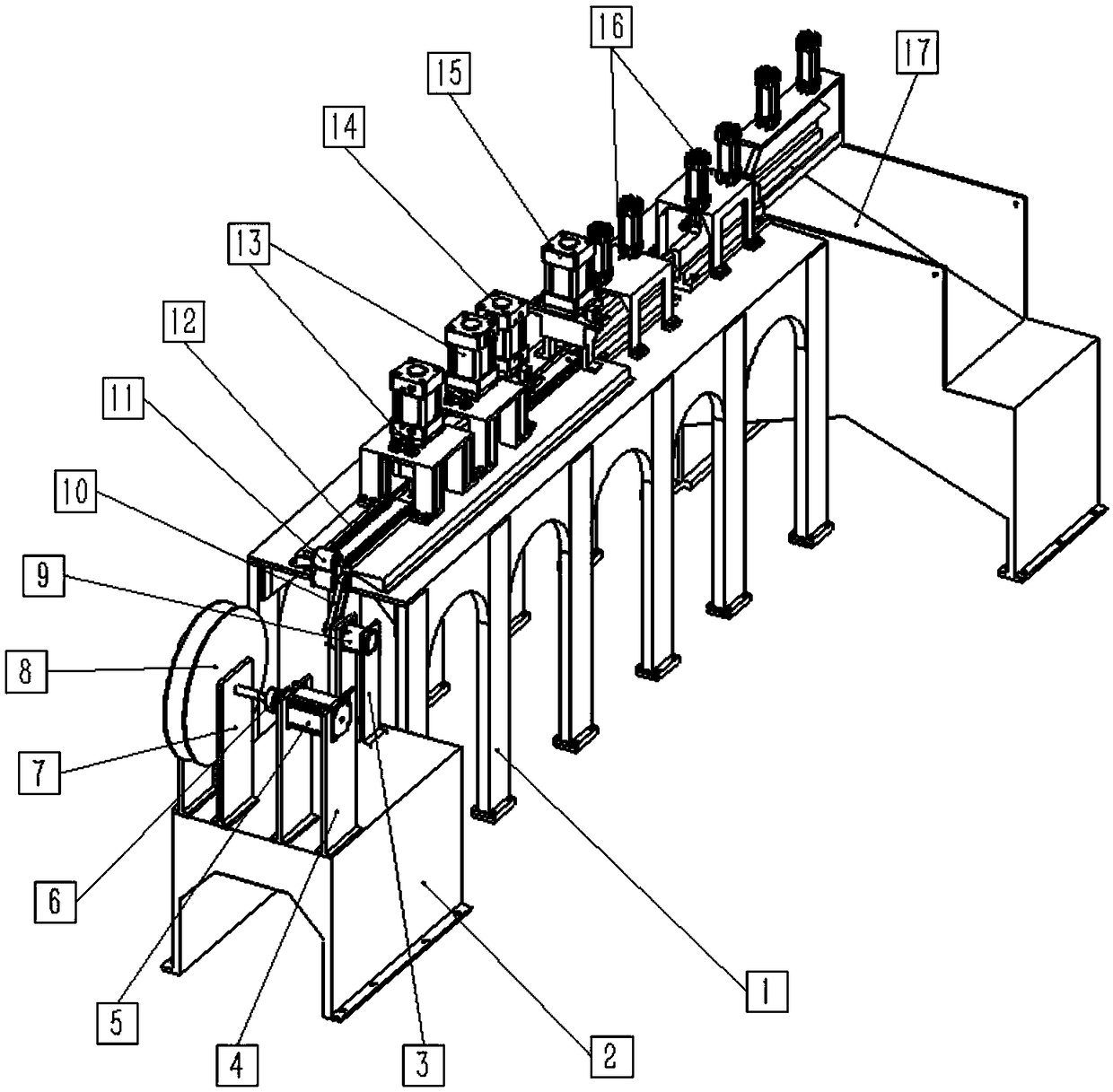

[0039] An automatic stamping device for slide rails of automobile seats, wherein a conveying bracket 1, a feeding bracket 2, and a blanking mechanism 17 are installed on the ground through anchor bolts. Before work, check whether the reel motor 5 and the belt motor 9 are working normally, whether the belt 10 is installed reliably, whether the steel belt on the reel 8 is installed correctly and enters the feeding track 12 by the roller. Check whether there is any foreign matter on the feeding track 12 that hinders the conveyance of the steel strip, and check whether the cylinders of each stamping mechanism are working normally and are in a shrinking state. After checking, start the automatic control system.

[0040] The reel motor 5 drives the reel 8 to rotate through the single diaphragm coupling 6, so that the strip steel wound on the reel 8 is conveyed downward.

[0041] The belt motor 9 drives the pulley to rotate, and the roller 11 rotates through the transmission of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com