High speed stamping die with low temperature lubricating structure

A low-temperature lubrication and high-speed stamping technology, which is applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as splashing of lubricating oil, pollution of molds and machine tools, and inconvenient cleaning, so as to ensure stamping accuracy and production efficiency. Improved service life and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

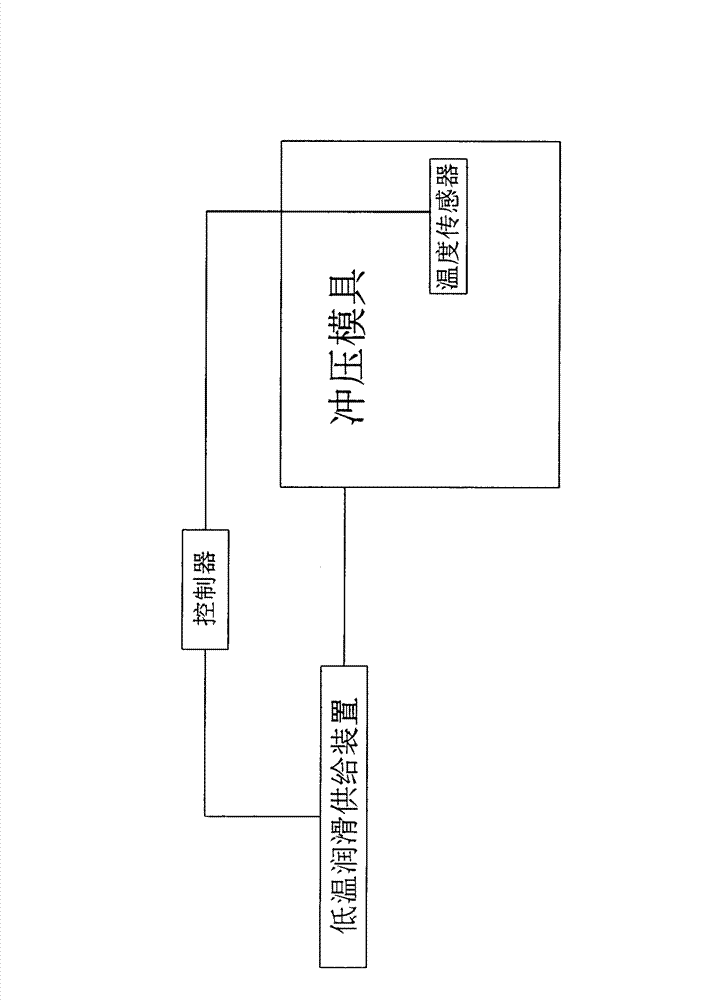

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0031] Such as figure 1 The shown high-speed stamping die with a low-temperature lubricating structure includes an upper die base 10 and a lower die base 11, and an upper die backing plate 12, a punch fixing plate 13, The forming plate set formed by the unloading backing plate 14, the unloading plate 15, the lower template 16 and the lower die backing plate 17, etc., is provided with a forming component in the forming plate set. Such as figure 1 As shown, the forming assembly includes a punching edge 53 provided on the lower template 16, a forming insert 54 of the lower mold, a stripping plate insert 55 and a forming insert 56 located on the stripping plate 15, and a stripping insert 56 located on the stripping plate 15 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com