Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Realize continuous punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

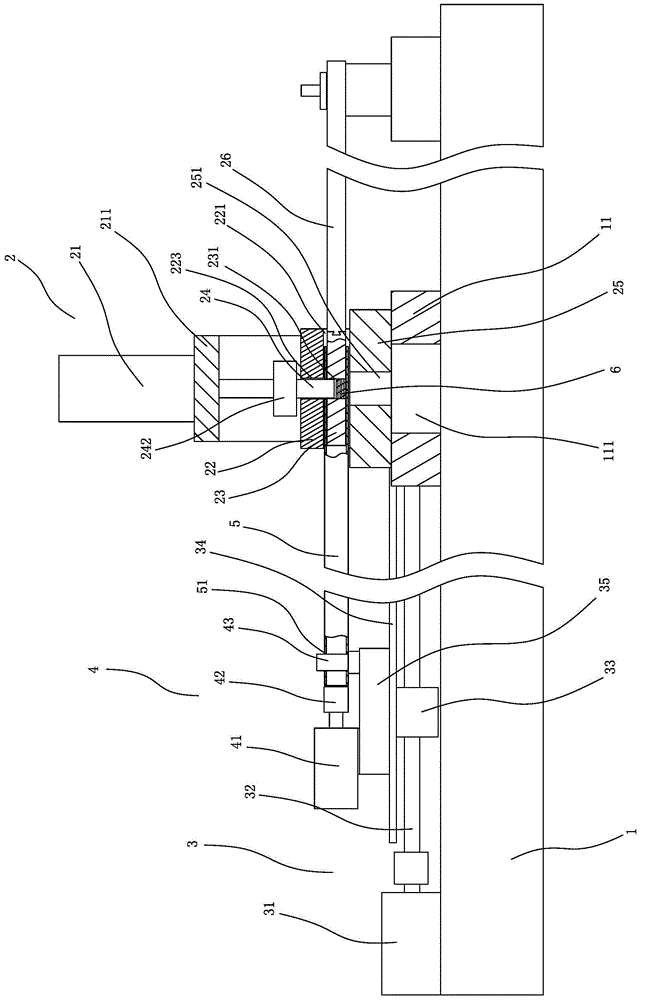

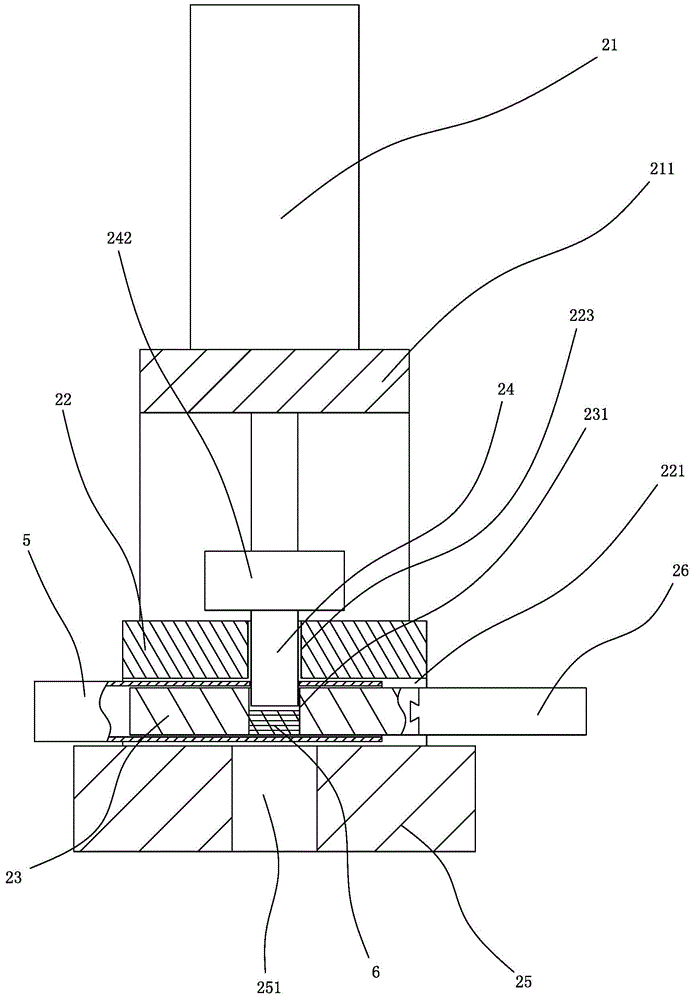

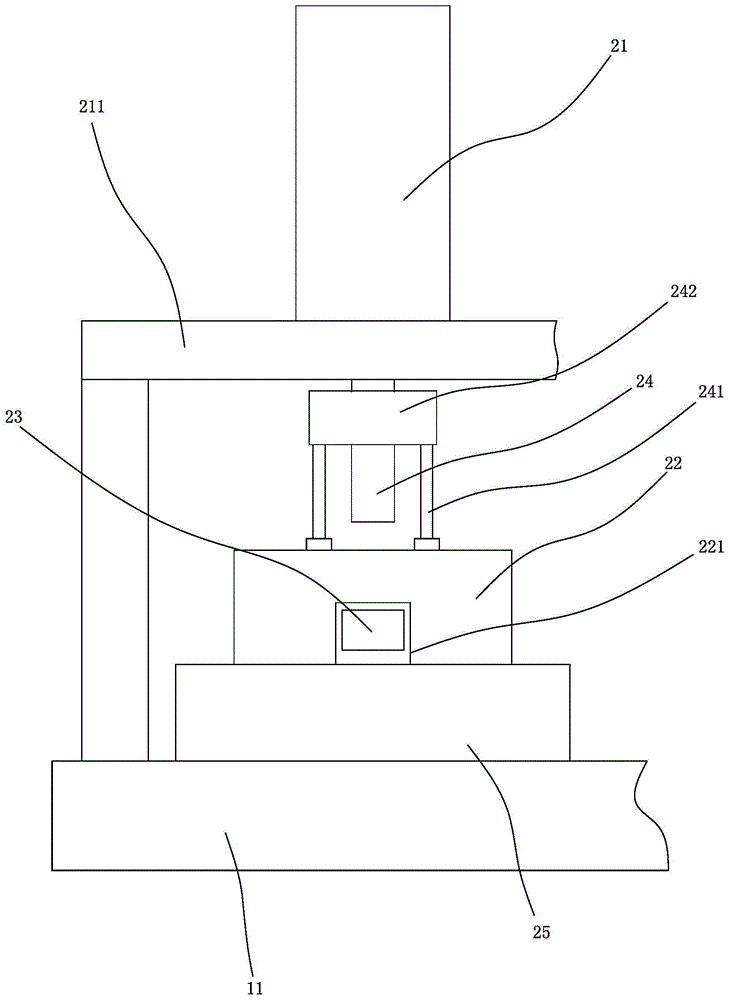

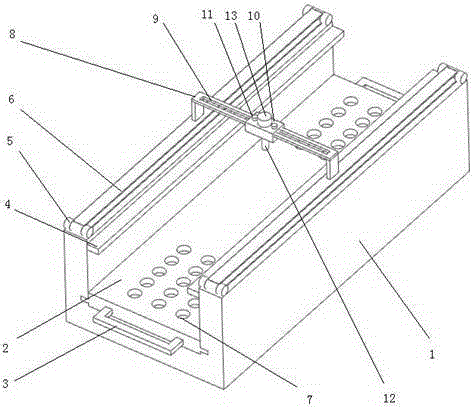

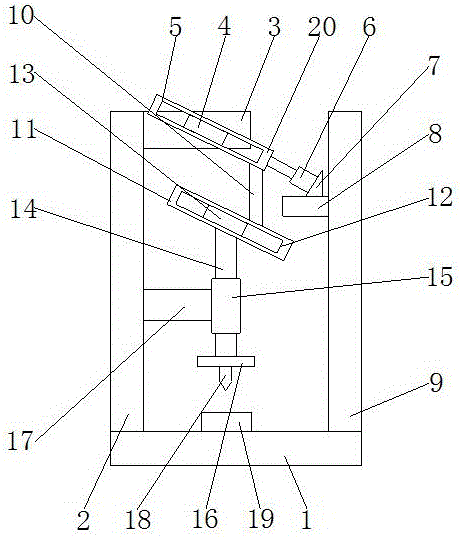

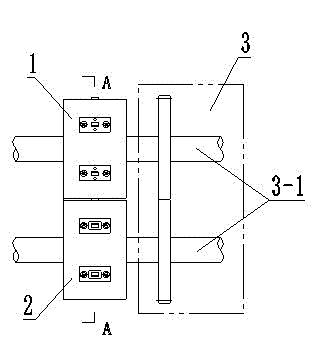

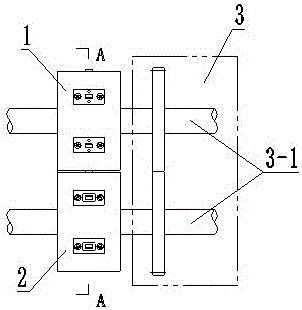

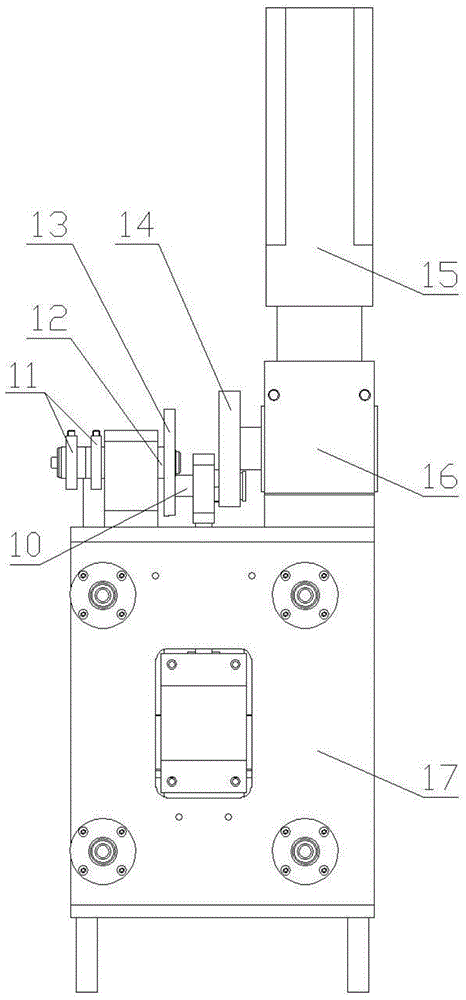

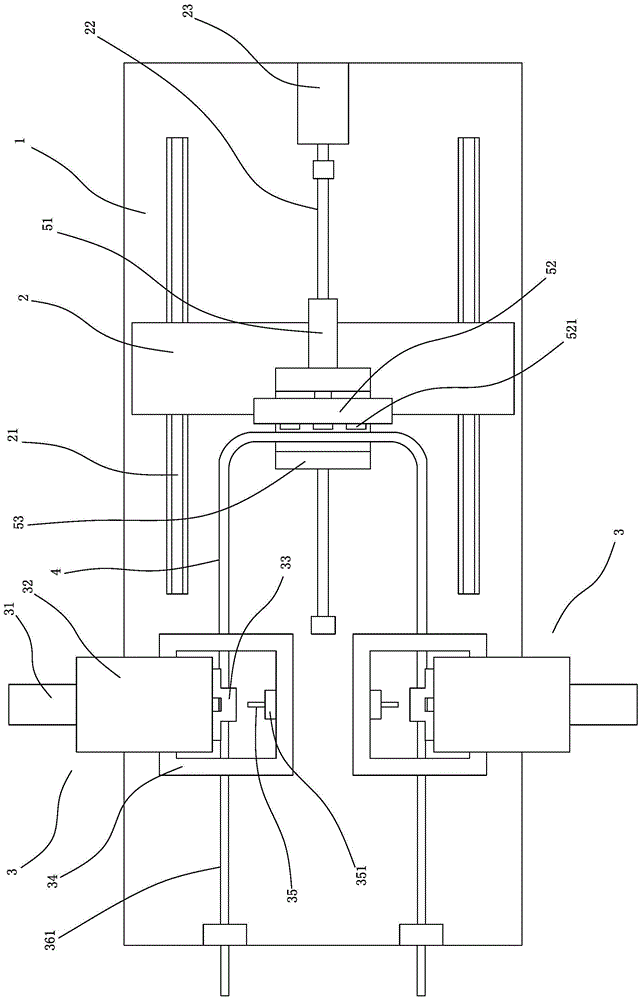

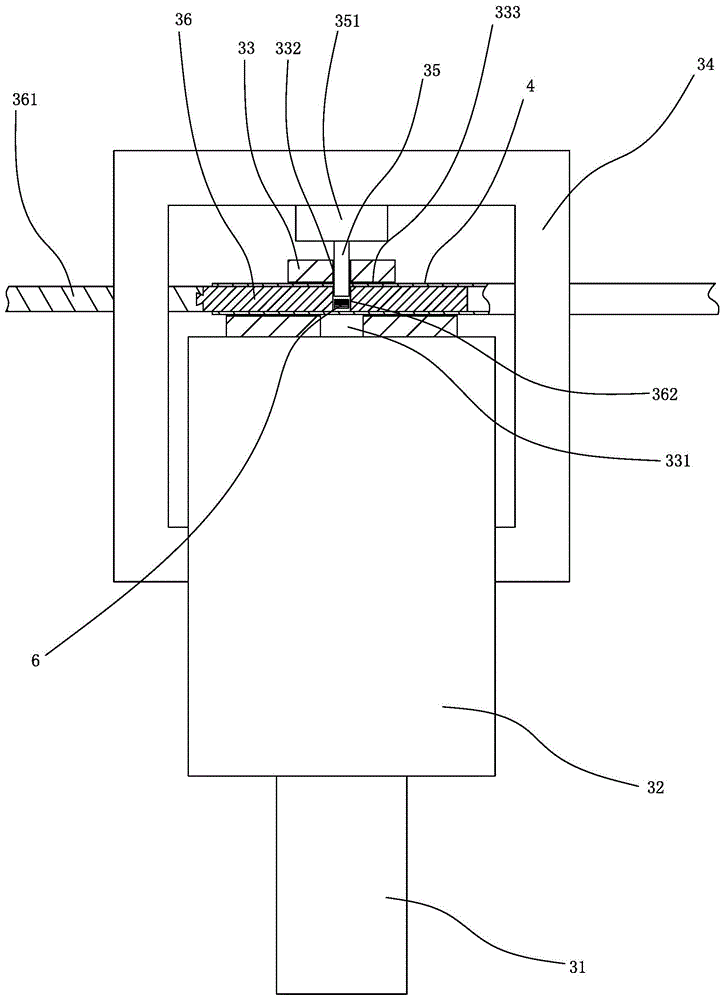

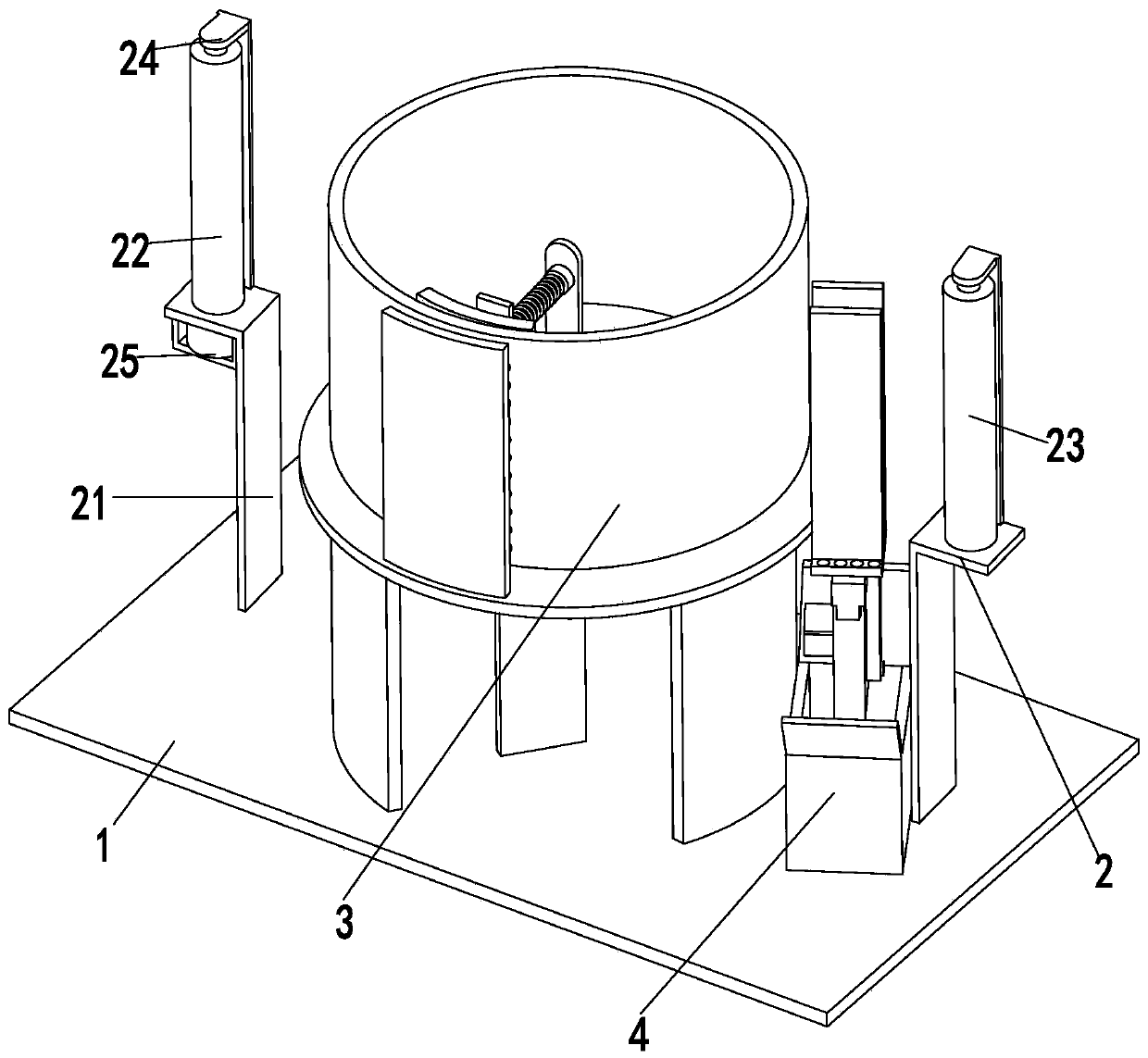

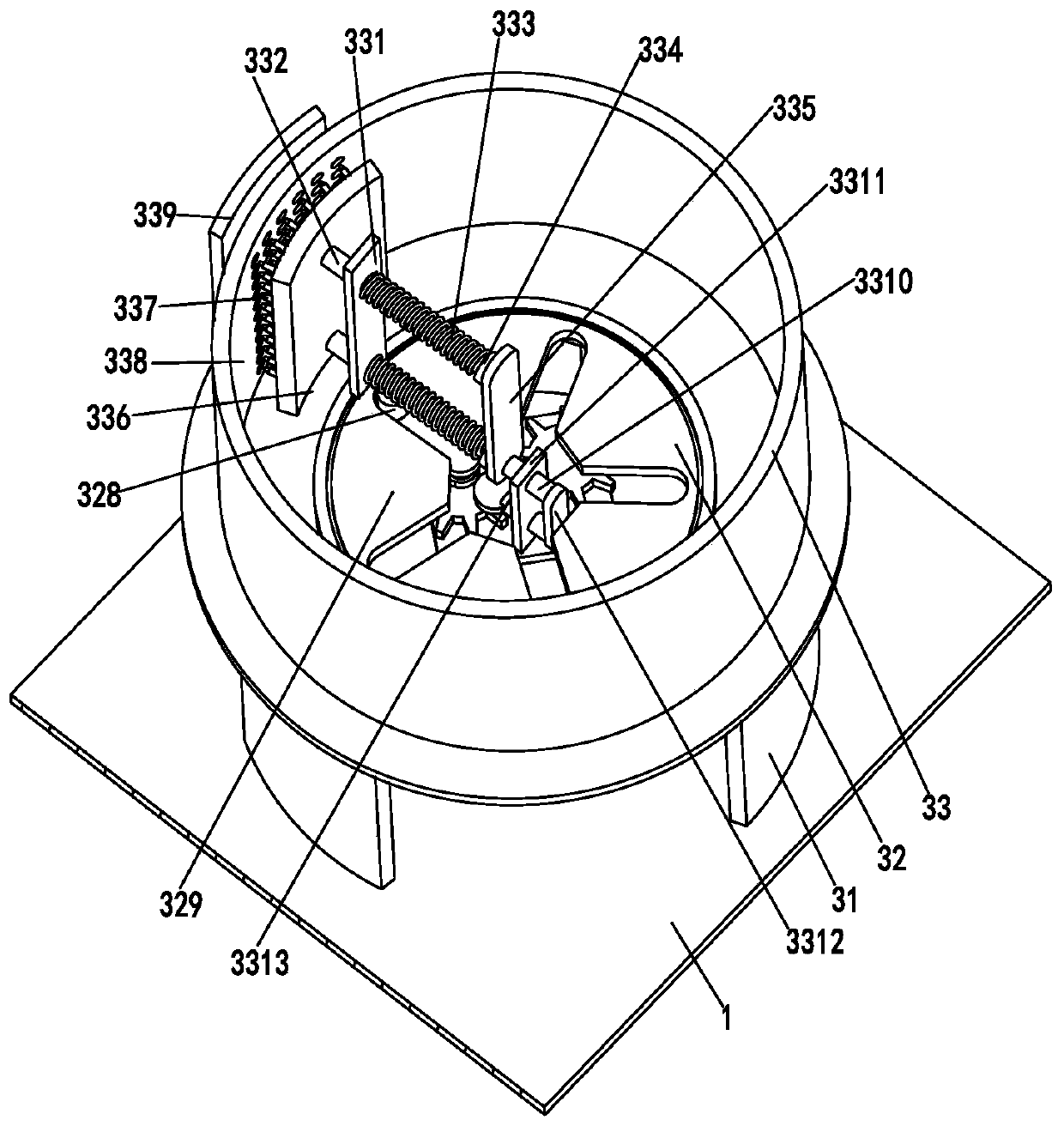

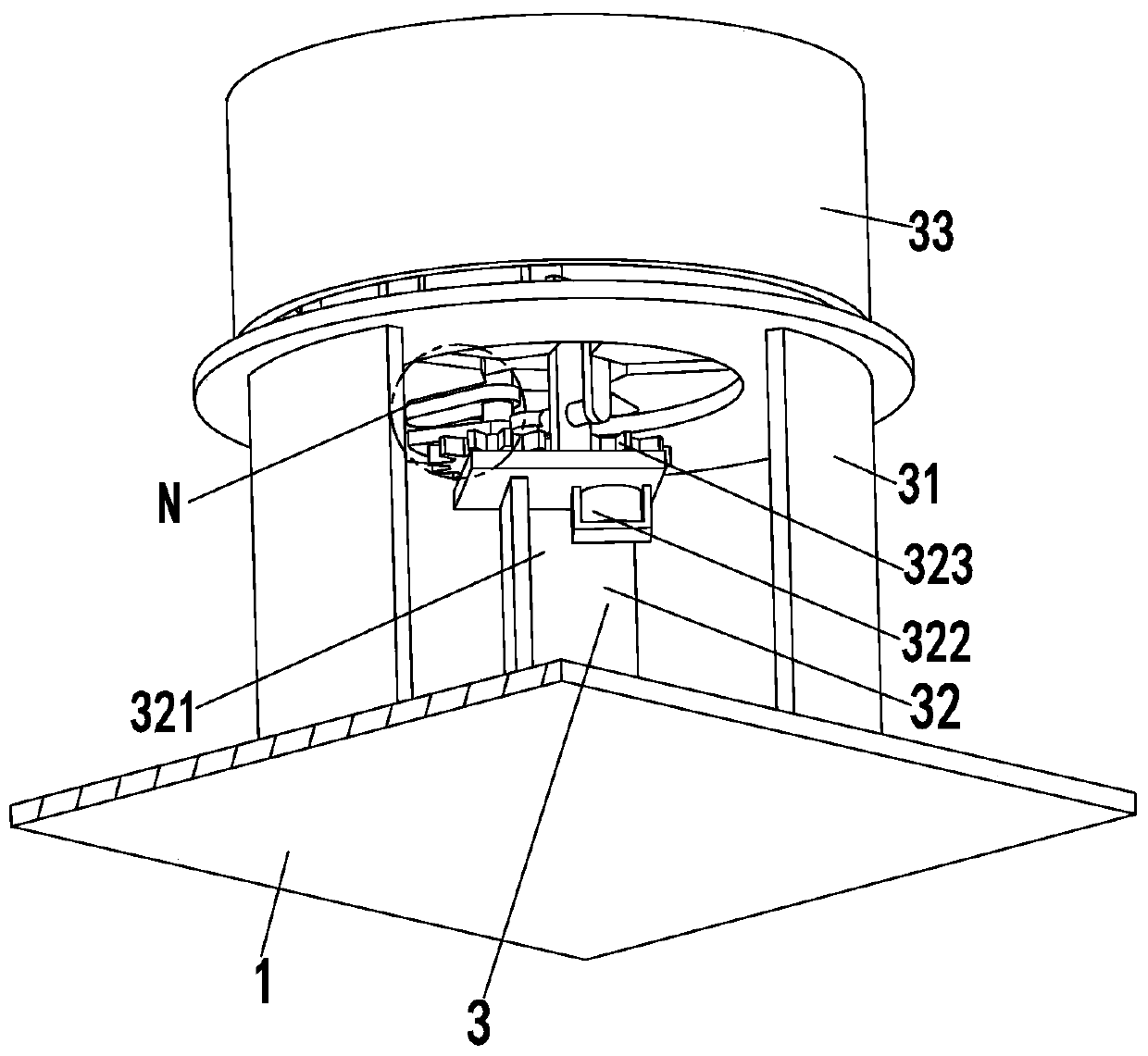

Continuous punching device for linear pipes

ActiveCN104128434ARealize continuous punchingImprove punching efficiencyPerforating toolsMetal-working feeding devicesPunchingLateral extension

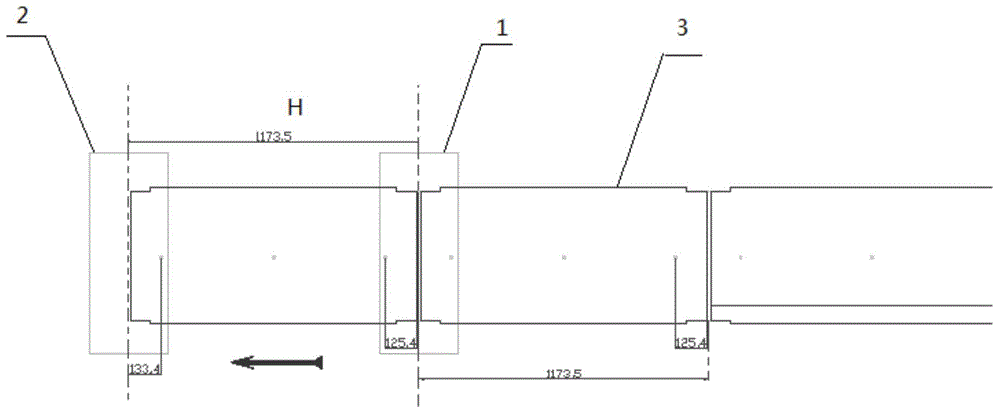

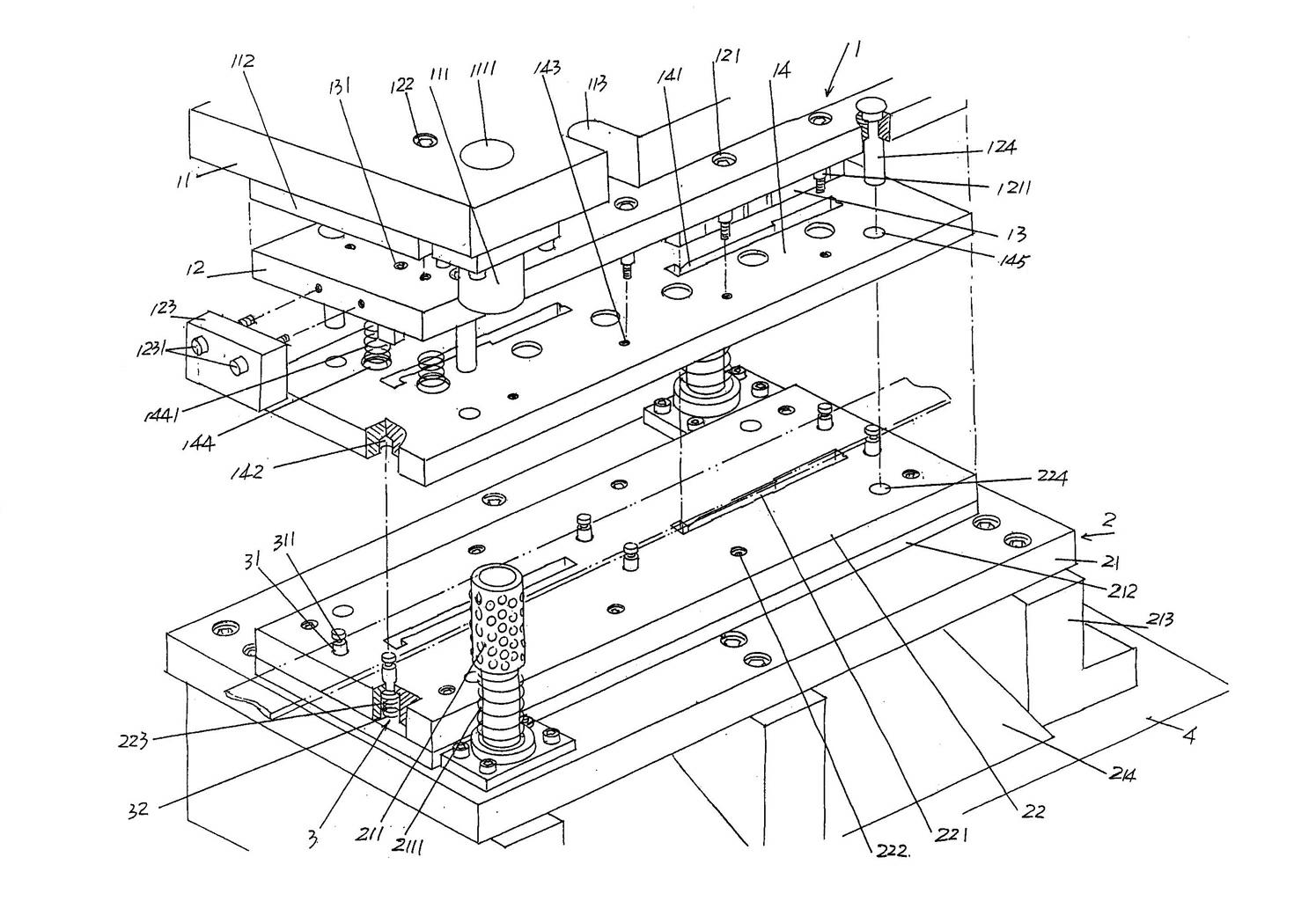

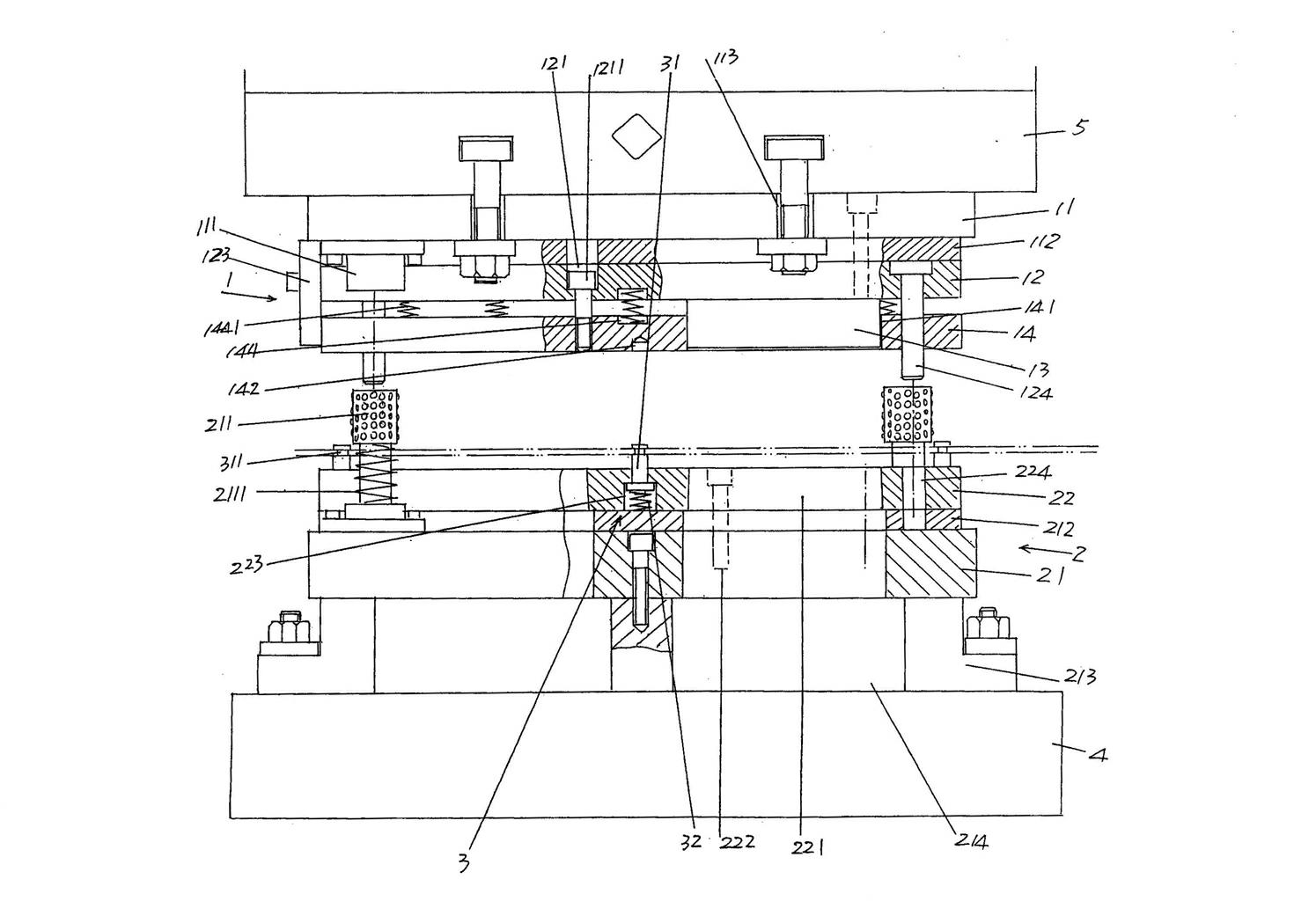

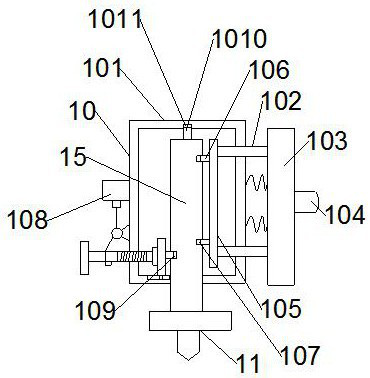

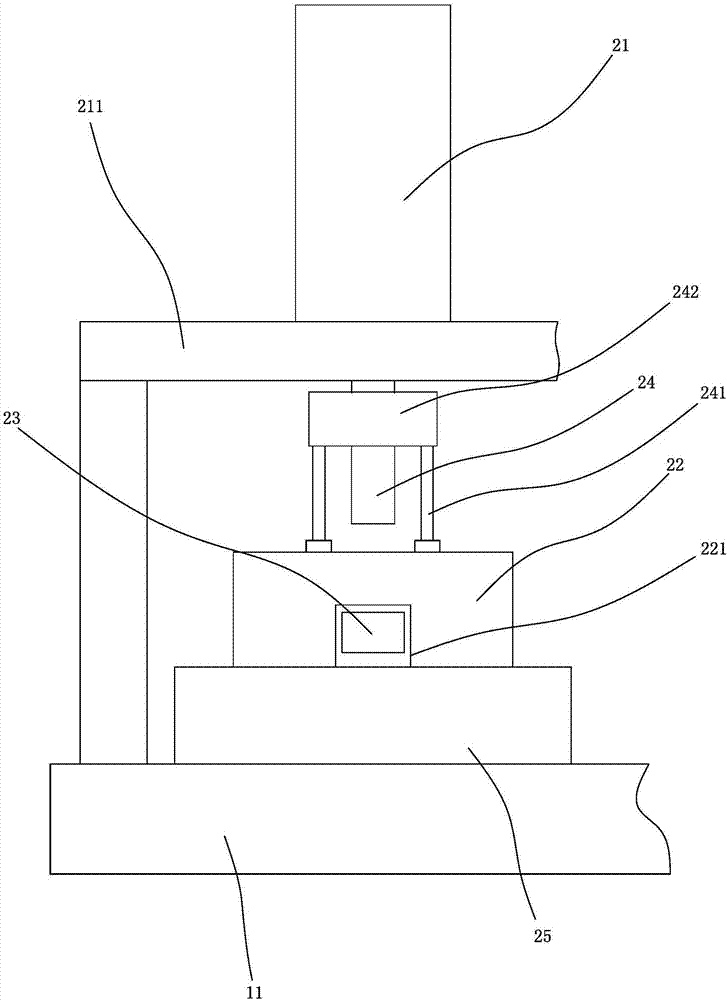

A continuous punching device for linear pipes comprises a base, punching mechanisms, a sliding base, a transverse moving mechanism, clamping mechanisms and a control device, wherein the punching mechanisms are arranged on the base; the sliding base is arranged on the base in a horizontal moving mode in the transverse direction; the transverse moving mechanism drives the sliding base to move in the transverse direction; each clamping mechanism is arranged on the sliding base and used for clamping one end of one linear pipe; the control device is respectively connected with the punching mechanisms and the transverse moving mechanism; each punching mechanism comprises a die holder, a core die and a stamping mechanism; the die holders are arranged on the base, a through hole extending in the transverse direction and allowing one linear pipe to stretch in is formed in the side face of each die holder, a first punched hole communicated with the corresponding through hole is formed in the top face of each die holder, and a discharge hole communicated with the corresponding through hole is formed in the bottom face of each die holder; each core die is arranged in the through hole of the corresponding die holder through a die rod which extends in the transverse direction, and a second punched hole opposite to the first punched hole is formed in each core die; each stamping mechanism comprises a punch which can move up and down relative to the corresponding first punched hole and the corresponding second punched hole and a driving part which can drive the punch to move up and down. The continuous punching device has the advantages of being simple in structure, convenient to operate, high in punching efficiency and the like.

Owner:冠达星股份有限公司

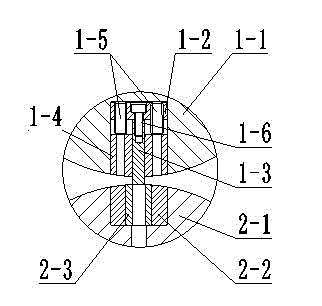

Stampings bonding prevention device for stamping die

ActiveCN103157728AAvoid it happening againAvoid downtime for cleaningShaping toolsCleaning using toolsPunchingTerete

The invention discloses a stampings bonding prevention device for a stamping die and is suitable for punching of coiled materials. The stampings bonding prevention device for the stamp die comprises two rotary cylinders which are located on one side of the die, and the coiled materials go in from the side. The two rotary cylinders are tightly attached to each other and arranged up and down. Each rotary cylinder comprises an oil storage drum with two sealed ends and an oil impregnating layer which is arranged on the outer side of the oil storage cylinder. The oil impregnating layer has elasticity. A plurality of oil impregnating holes are uniformly formed in the circumferential surface of each oil storage cylinder. One ends of the oil storage cylinders are connected with a punching oil conveying system through pipelines. A damping layer with elasticity is arranged between each oil storage cylinder and each oil impregnating layer. A plurality of oil impregnating cylinders are uniformly arranged on the circumferential surface of each damping layer and embedded in each oil impregnating layer. Oil outlet holes which penetrate through the inner surface of each damping layer are formed in each oil impregnating cylinder. Kerfs which are communicated with the oil outlet holes are uniformly arranged on the circumferential surface of each oil impregnating cylinder. The stampings bonding prevention device for the stamp die can prevent stampings from bonding with the die, and therefore continuous punching can be achieved, and influence of machine halt on production efficiency is avoided. Besides, the stampings bonding prevention device for the stamp die is beneficial for prolonging service life of the die and improving punching quality of products.

Owner:WANXIANG 123 CO LTD

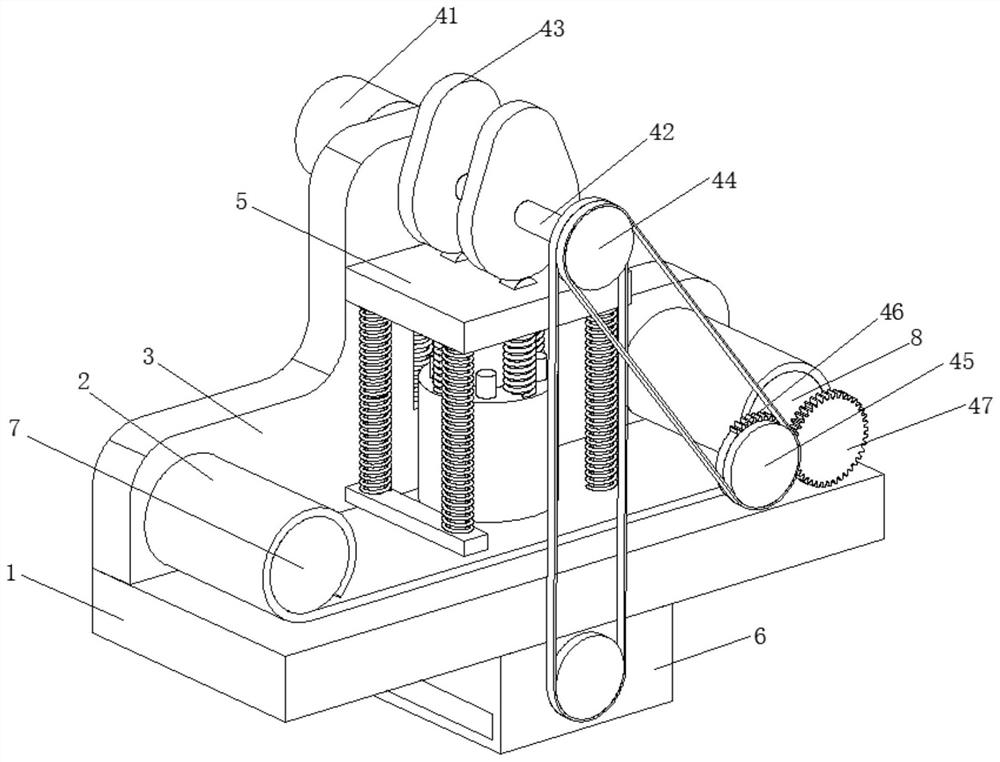

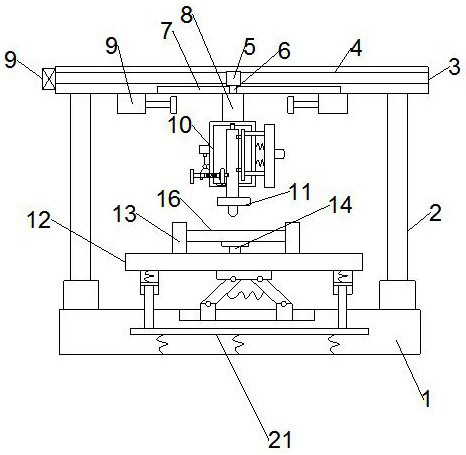

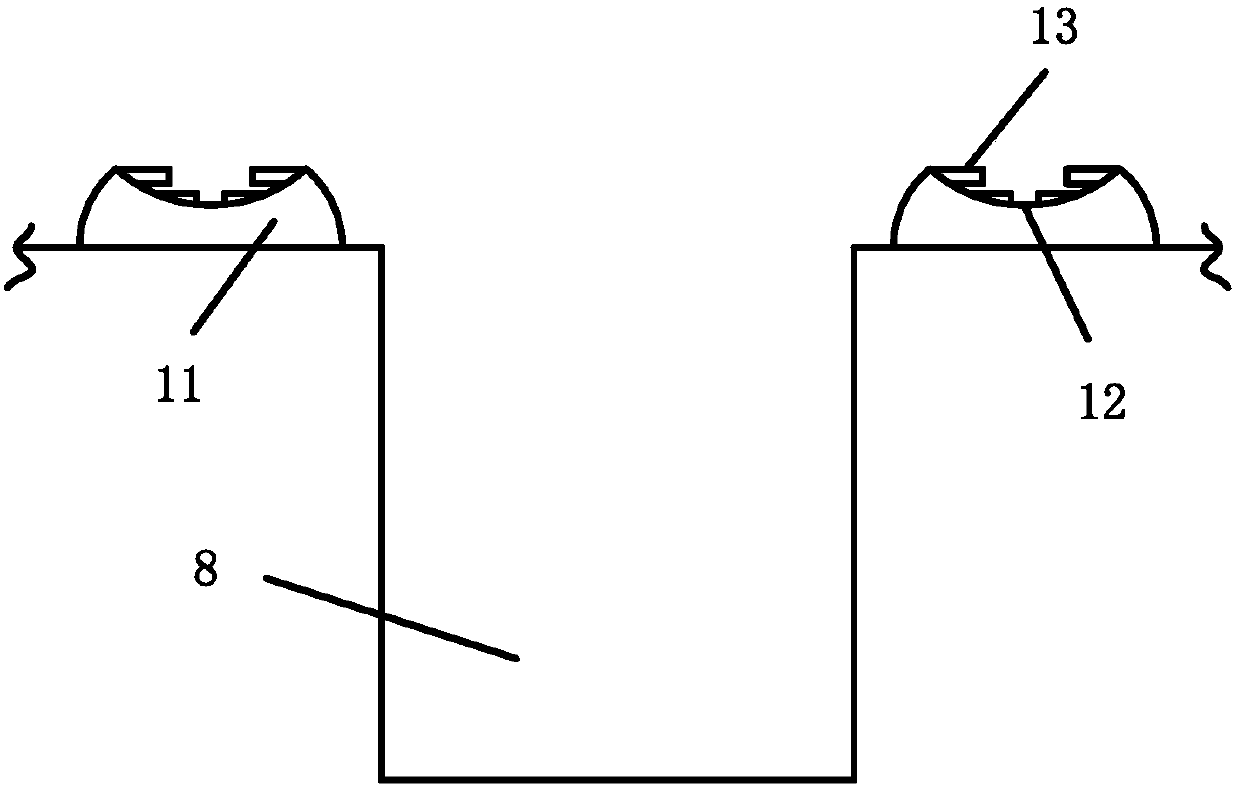

Full-automatic punching die

InactiveCN105268828APrecise punchingRealize continuous punchingPerforating toolsMetal working apparatusPunchingElectric machinery

The invention discloses a full-automatic punching die. The section of a bottom frame of the full-automatic punching die is U-shaped; inner walls of two side ends of the bottom frame are provided with guide rails; two ends of a pulling plate are clamped into the guide rails; the upper parts of the two side ends of the bottom frame are each provided with a pair of primary motors; two transmission belts are respectively arranged on rotary shafts of corresponding primary motors; two side bottom ends of a bracket are fixed on the corresponding transmission belts; two groups of fixing holes are formed in the pulling plate; each group of fixing holes comprises at least two rows of fixing holes; a guide rail slot is formed in the bracket; a movable bracket is arranged on the bracket in a sleeving mode; the bottom of the movable bracket is provided with a punch; the movable bracket is provided with a movable motor; a rotary shaft of the movable motor penetrates through the movable bracket to the guide rail slot; a limiting part is arranged at each of two sides of the movable motor; and the limiting parts penetrate through the movable bracket to the guide rail slot. According to the full-automatic punching die provided by the invention, full-automatic movement of punching equipment is realized by virtue of the corresponding structures, so that precise punching and positioning are guaranteed, and punching effect is good.

Owner:滁州市成业机械制造股份有限公司

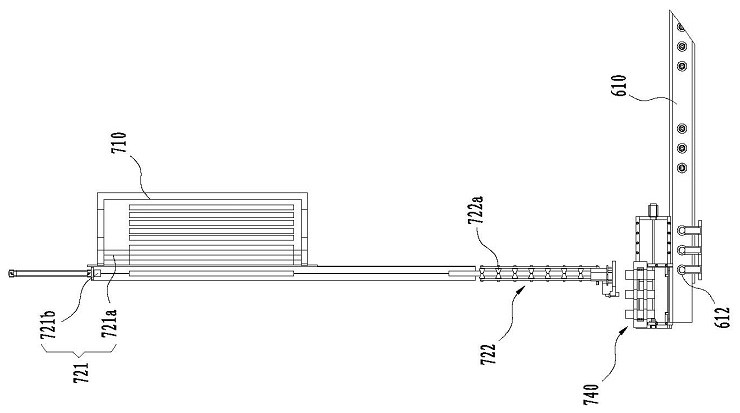

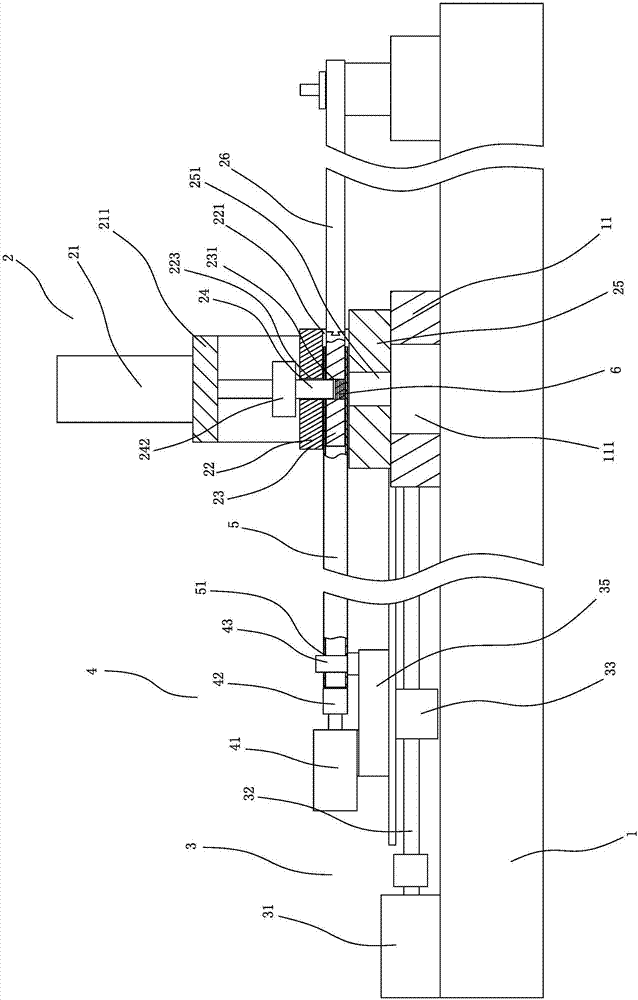

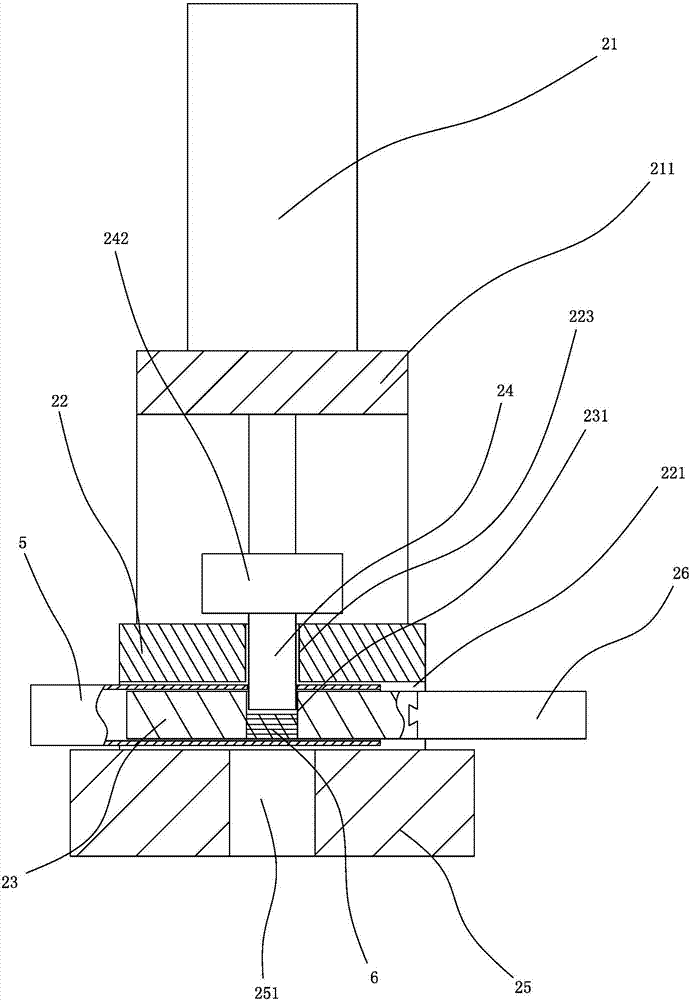

Online continuous punching method and equipment in cold roll forming

ActiveCN104959455AAutomatically realize continuous productionRealize continuous punchingMetal-working feeding devicesMetal working apparatusPunchingRoll forming

The invention relates to online continuous punching method and equipment in cold roll forming. The method includes the steps that information of products to be produced is input; in production, after a punching die and a gap punching die act each time, the die which acts after next feeding is finished is determined; the feeding length a of a next hole and the feeding length b of a next gap are calculated according to the length of fed materials and the information of the products to be produced, the two distance values are compared, if the a is smaller, the punching die is the die which acts after next feeding is finished, and if the b is smaller, the gap punching die is the die which acts after next feeding is finished. By means of the mode, the products of various specifications can be produced automatically and continuously.

Owner:XINXIANG TIANFENG MACHINERY MFG

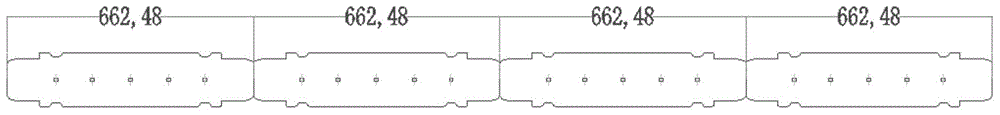

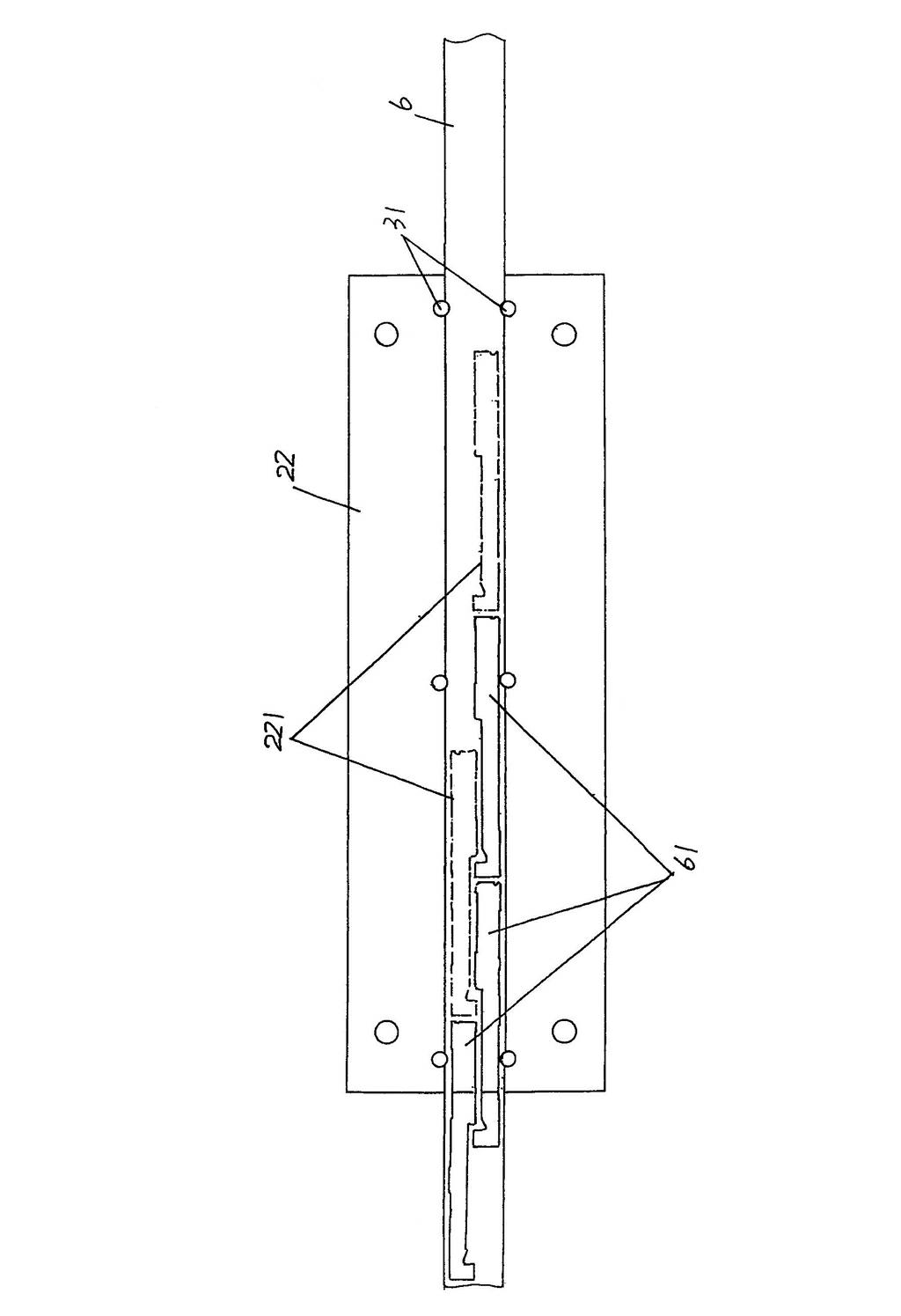

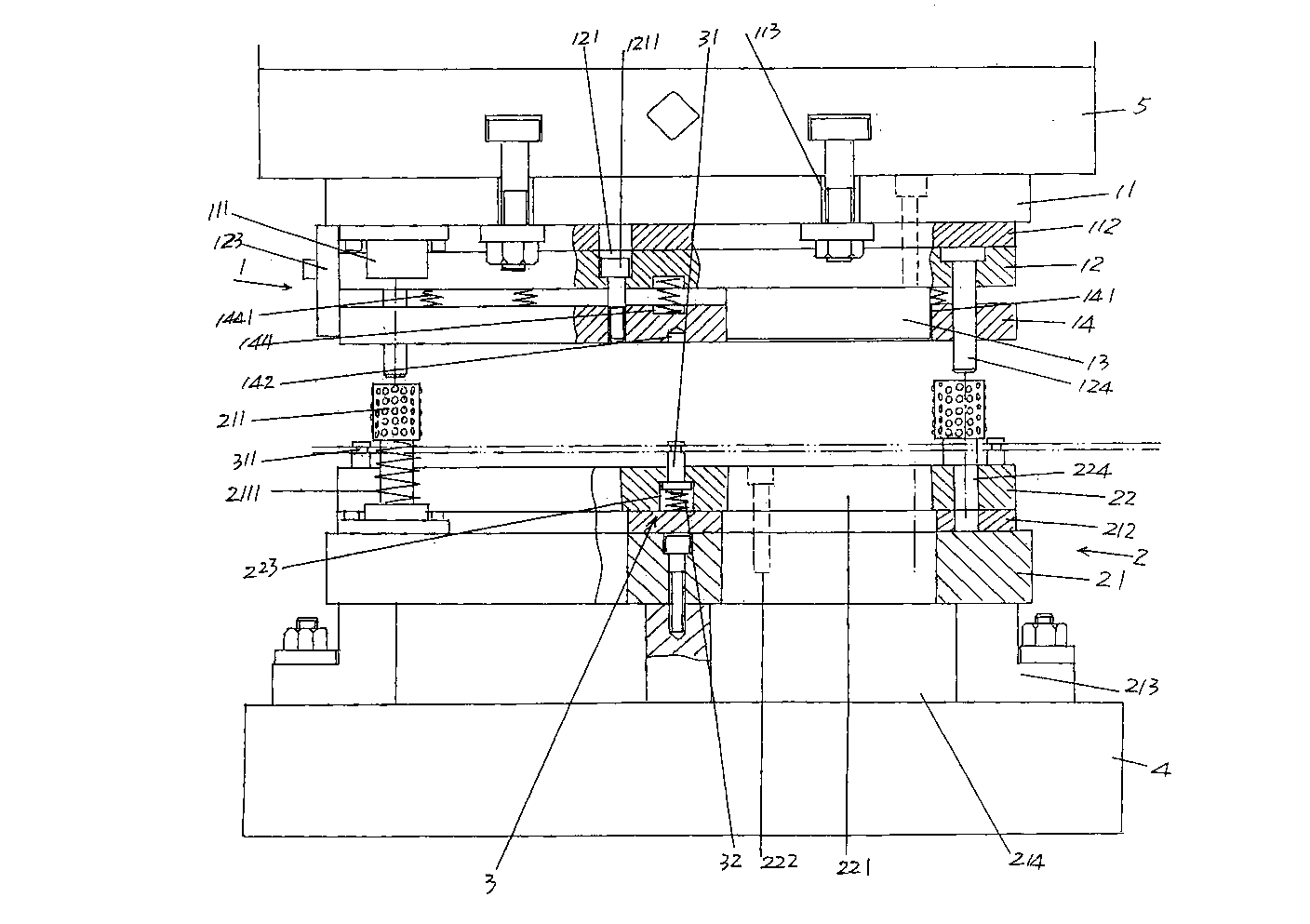

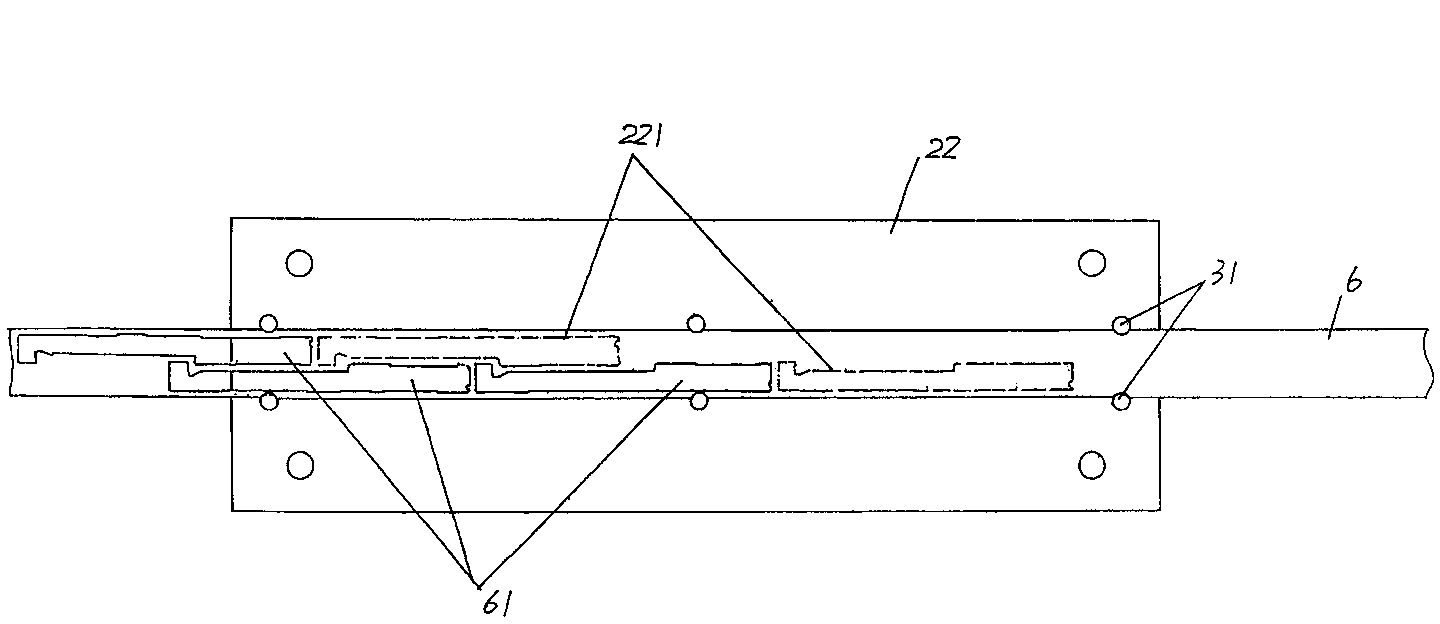

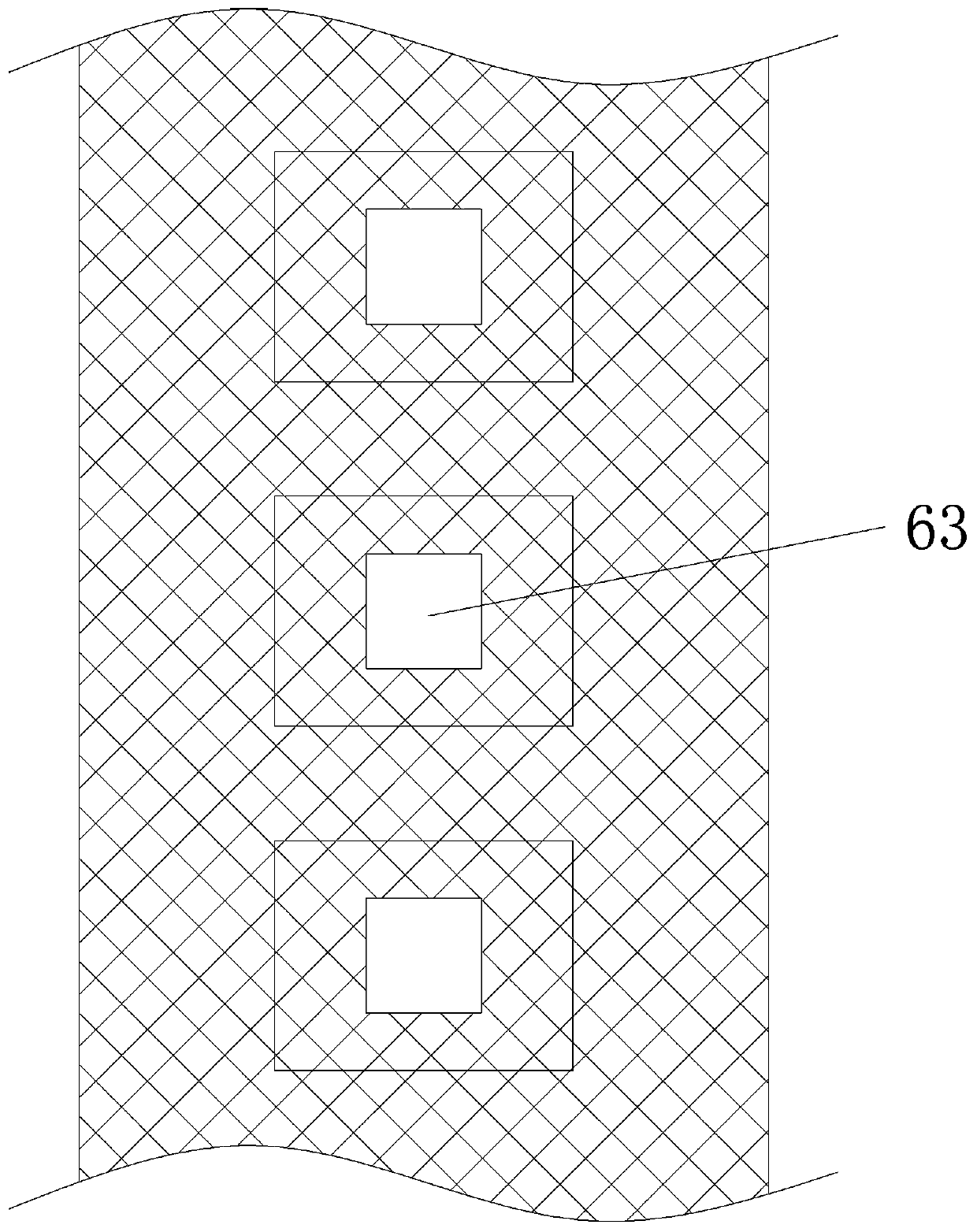

Mold for punching needle bed insert blank used in computer knitting flat knitting machine

InactiveCN102672052AAvoid interferenceRealize continuous punchingShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a mold for punching a needle bed insert blank used in a computer knitting flat knitting machine, belonging to the technical field of molds; the mold comprises an upper mold mechanism and a lower mold mechanism; the upper mold mechanism comprises an upper template holder, an upper template and an insert male punching mold; the lower mold mechanism comprises a lower template holder and a lower template; the mold is characterized in that the upper mold mechanism further comprises a material press plate connected with one side of the upper template; a mold guide hole is arranged on the material press plate; one side of the lower template, and two sides of a mold cavity corresponding to tool edges are provided with a group of thin steel strip guiding and limiting mechanisms for guiding and limiting the thin steel strips, respectively; each thin steel strip guiding and limiting mechanism is matched with the material press plate; a material cutter is fixed on the upper template; and the material cutter corresponds to the left end of the mold guide hole. The mold has the advantages that the mold is helpful to realize the continuous punching, so as to enhance the efficiency and satisfy the industrialization amplification production requirements; the thin steel strip is prevented from offset or up-warping, so that the punching quality is ensued, the fault is avoided so as to save materials and reduce cost; and the operation field is protected from interference.

Owner:常熟市尚湖镇冶塘伟东模具厂

Blanking device of reinforced backflow hollow-square-shaped HY fiber felt in flat heat pipe

PendingCN112371830AReduce labor intensityIncrease productivityMetal-working feeding devicesGrain treatmentsFiberStructural engineering

The invention relates to the technical field of fiber felt material post-treatment forming preparation, and discloses a blanking device of a reinforced backflow hollow-square-shaped HY fiber felt in aflat heat pipe. The blanking device comprises a workbench, two side plates are welded to the top of the workbench, a transmission mechanism is arranged at the left sides of the side plates, and a blanking mechanism is arranged between the two side plates; and a collecting mechanism is arranged at the bottom of the workbench, a discharging roller and a winding roller are rotationally connected between the two side plates correspondingly, and the surface of the discharging roller and the surface of the winding roller are both movably connected with a fiber felt body. According to the blanking device, the transmission mechanism and the blanking mechanism are used in a matched manner, so that the fiber felt can be directly and continuously blanked and automatically fed, manual cutting production by workers is not needed, the production efficiency can be greatly improved, and the labor intensity of the workers is reduced; and the collecting mechanism can be used for crushing and collectingleftover materials, the leftover materials can be conveniently recycled, and waste can be prevented.

Owner:德清宏业晶体纤维有限公司

Industrial equipment punching machine

InactiveCN106825661ASolve the situation that the hole cannot be punched continuouslyRealize continuous punchingBoring/drilling machinesPunchingIndustrial equipment

The invention discloses an industrial equipment punching machine, comprising a base, the top of the base is fixedly connected with a first support rod, one side of the first support rod is fixedly connected with a first support plate, and the front of the first support plate is fixedly connected with a A first slider, the surface of the first slider is slidably connected to the first slot on the first slider, and one end of the first slider is fixedly connected to one end of the electric telescopic rod. In this industrial equipment punching machine, through the setting of the first slider, the first card slot and the electric telescopic rod, the first sliding plate can slide better, so that the connecting rod can drive the second sliding plate to slide, so that the punching needle can Moving up and down, this solves the situation that the punching machine cannot continue to punch holes, which improves the work efficiency, and the second sliding plate can move better through the setting of the second card slot and the second slider, so that the punching needle can realize Moving up and down, this new type of utility model has simple structure and low cost, making it easier for operators to get started.

Owner:陈婷

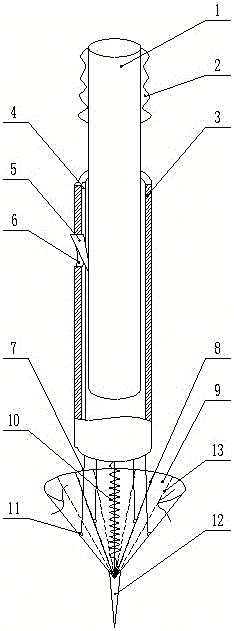

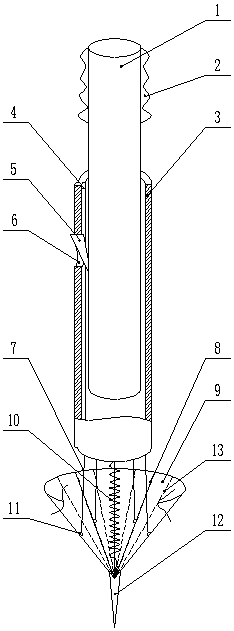

Novel perforator for vegetable transplanting

The invention belongs to the field of vegetable transplanting and relates to a novel perforator for vegetable transplanting. The novel perforator comprises a pressure bar, a casing pipe and a digging bucket. The pressure bar is provided with a wedge-shaped clamp with a downward wedge-shaped structure. Upper and lower ends of the casing pipe are respectively provided with an opening and an enclosed port. The upper end of the casing pipe sleeves the lower end of the pressure bar. The side wall of the casing pipe is provided with a clamping hole. Multiple movable rods are hinged to the lower end of the casing pipe. The other ends of the movable rods are respectively hinged to and uniformly distributed on the same circumference in the digging bucket. The top of the digging bucket is uniformly provided with multiple extending-retracting folding lines connected to the bottom of the digging bucket and the bottom of the digging bucket is provided with a conical cap. In use, a handle is held, the novel perforator is downward inserted into soil and then the pressure bar is lifted so that the soil is dug up along with the digging bucket and thus soil does not fall off and labor efficiency is improved.

Owner:南通腾舟船舶机械有限公司

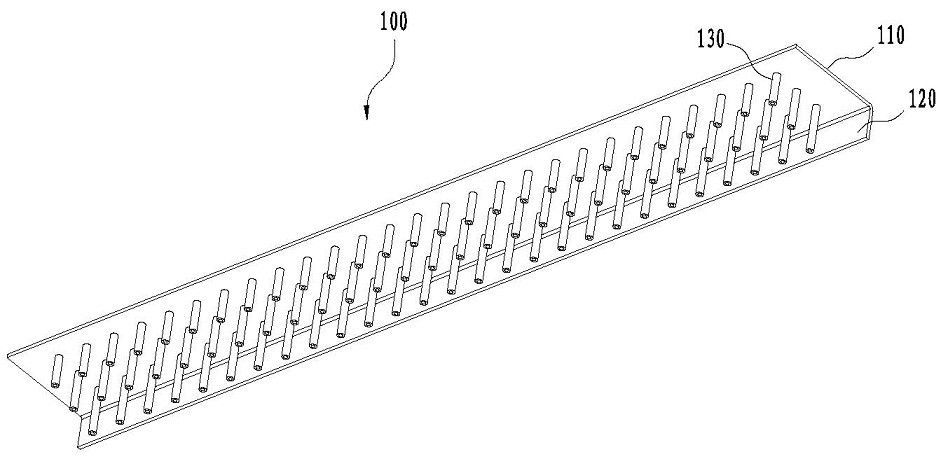

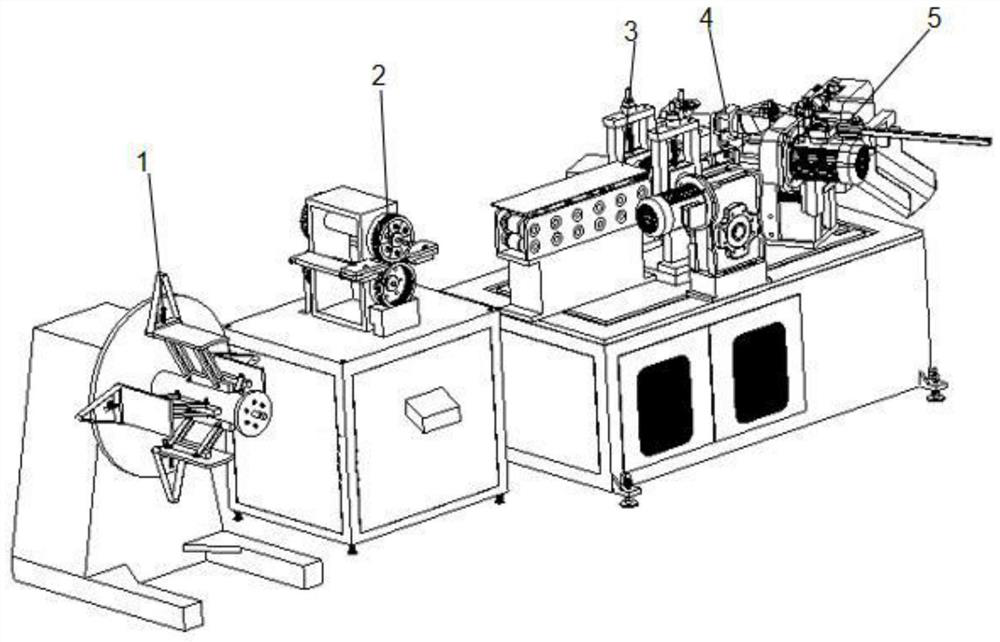

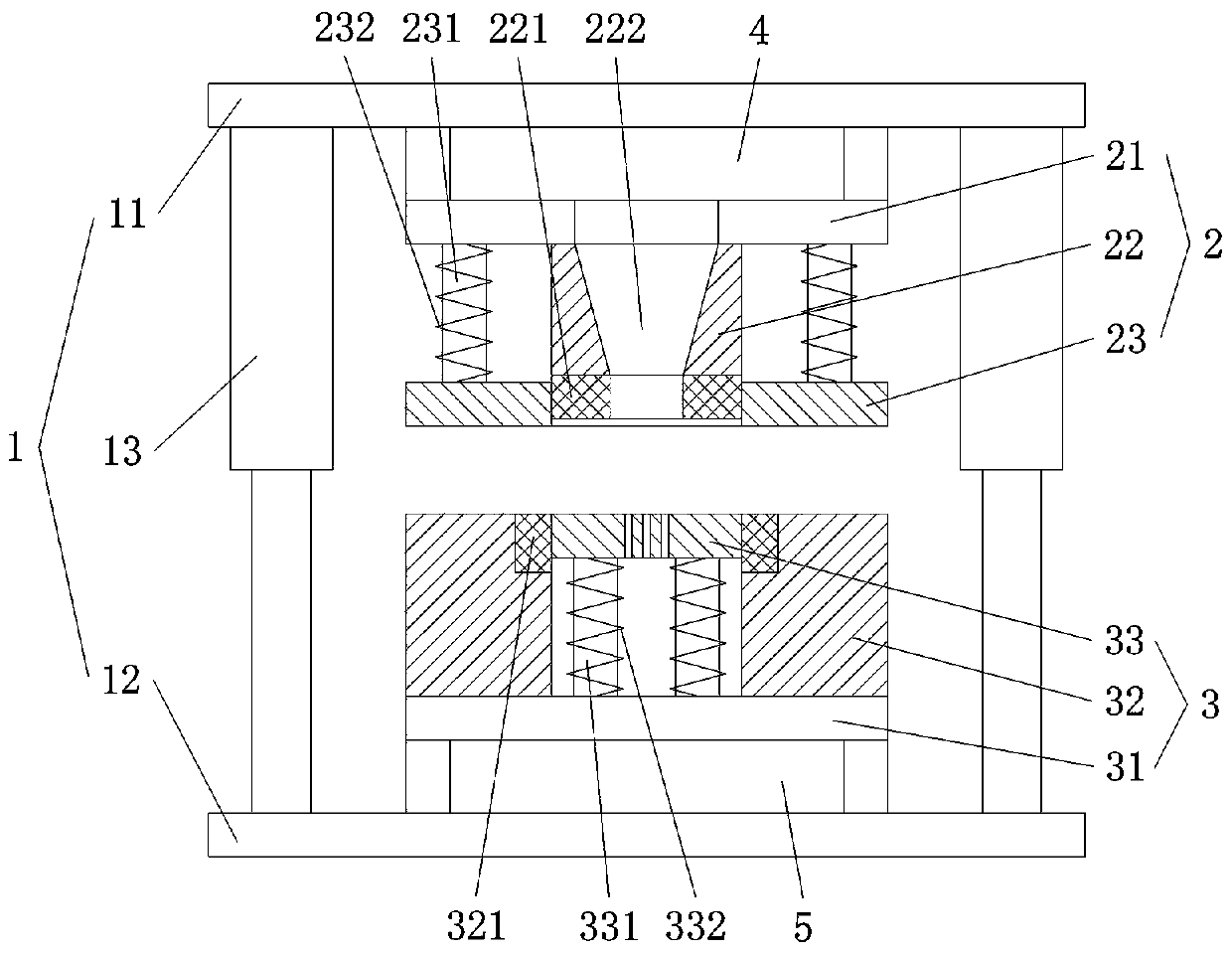

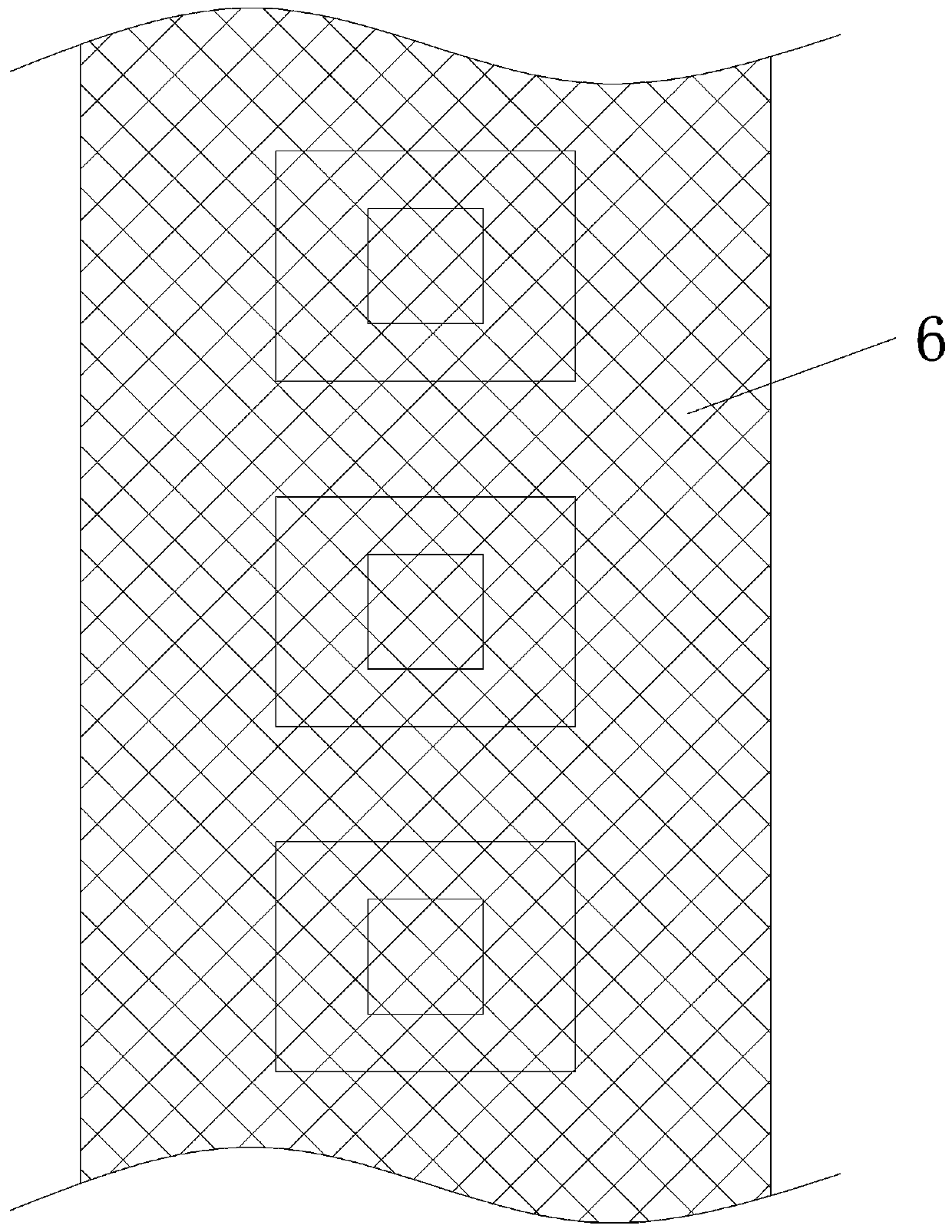

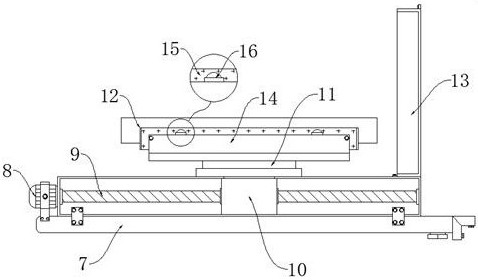

Strip punch forming unit

InactiveCN112108559ARealize continuous punchingImprove processing efficiencyShaping toolsPerforating toolsPunchingStructural engineering

The invention relates to a strip punch forming unit. The strip surface of a strip is composed of an air pipe plate surface part and a non-porous plate surface part which are arranged in the strip width direction, air distribution holes distributed in an array mode are formed in the air pipe plate surface part, and the strip punch forming unit comprises a strip conveying mechanism for conveying thestrip. The conveying direction of the strip conveying mechanism is consistent with the body length direction of the strip, the front end of the strip conveying mechanism is provided with a storage mechanism used for storing a strip coil and an uncoiling mechanism used for uncoiling the strip coil and flattening the strip coil into a plate, and a punching station is arranged on a conveying path ofthe strip conveying mechanism. A punching mechanism is arranged on one outer side of the plate at the punching station and used for punching the air pipe plate surface part on the plate. By the adoption of the scheme, continuous punching machining of the plate can be achieved, the punched plate is continuously provided for subsequent machining of an air distribution plate, the machining efficiency of the air distribution plate can be improved, and the labor cost can be reduced.

Owner:王小华

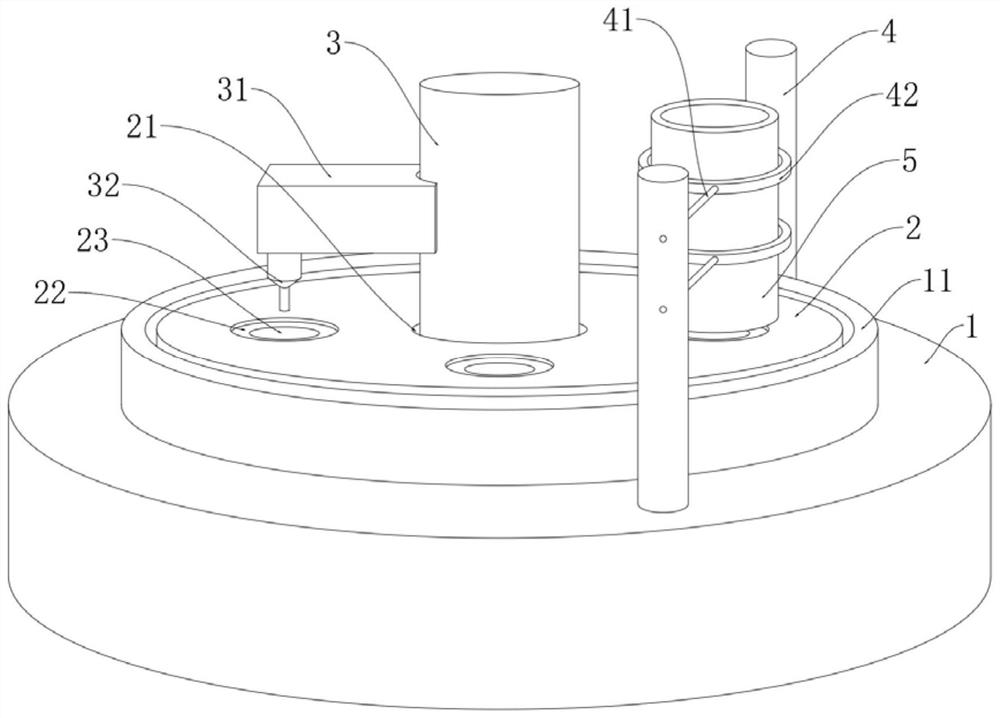

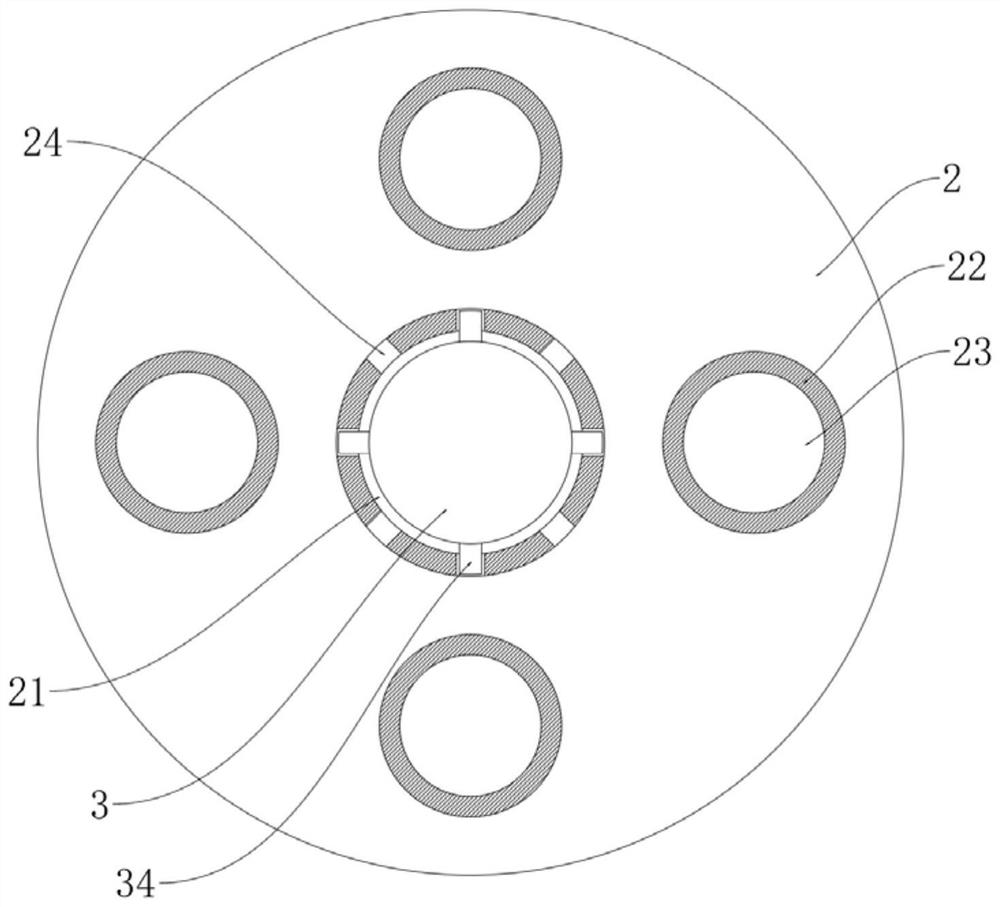

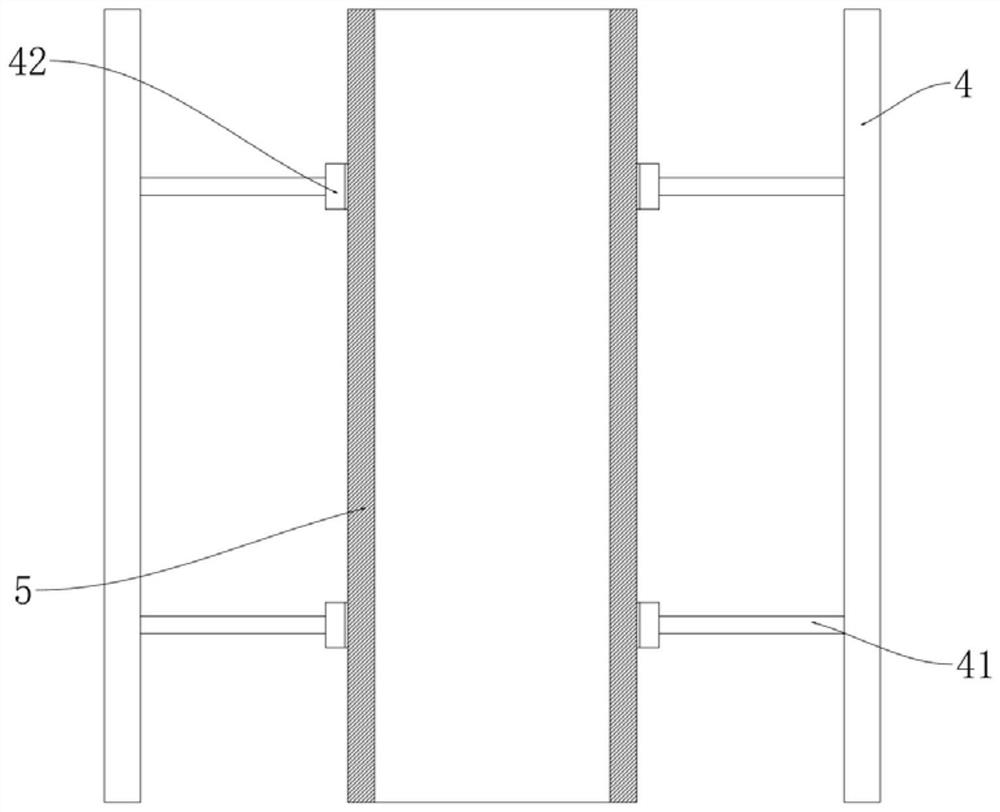

Automatic feeding and discharging punching die for automobile parts

InactiveCN112605248AAccurate and timely automatic feedingIncrease productivityPerforating toolsMetal-working feeding devicesPunchingStructural engineering

The invention discloses an automatic feeding and discharging punching die for automobile parts. The automatic feeding and discharging punching die comprises a base, wherein a backing ring is mounted on the upper surface of the base, a punching die disc is rotatably mounted on the backing ring, a plurality of material grooves are symmetrically formed in the upper surface of the punching die disc, and a punching hole channel is formed in the groove bottom of each material groove; and a control hole is formed in the center of the punching die disc, a control hydraulic cavity is formed in the center of the base, a hydraulic rod is inserted into the control hydraulic cavity in a sliding mode, the upper end of the hydraulic rod does not penetrate through the control hole in a contact mode, extends to the position above the punching die disc and is provided with a cross arm, and a punching drill is mounted on the lower surface of the cross arm. The punching die disc intermittently rotates and a discharging rod vertically moves through vertical movement of the hydraulic rod, so that the material grooves can cooperate with material barrels to achieve automatic feeding, a discharging rod can cooperate with the punching hole channel and the material grooves to achieve automatic discharging, extra equipment does not need to be added, the production efficiency is improved, more energy is saved, and the cost is lower.

Owner:YUHUAN QIYUAN TECH CO LTD

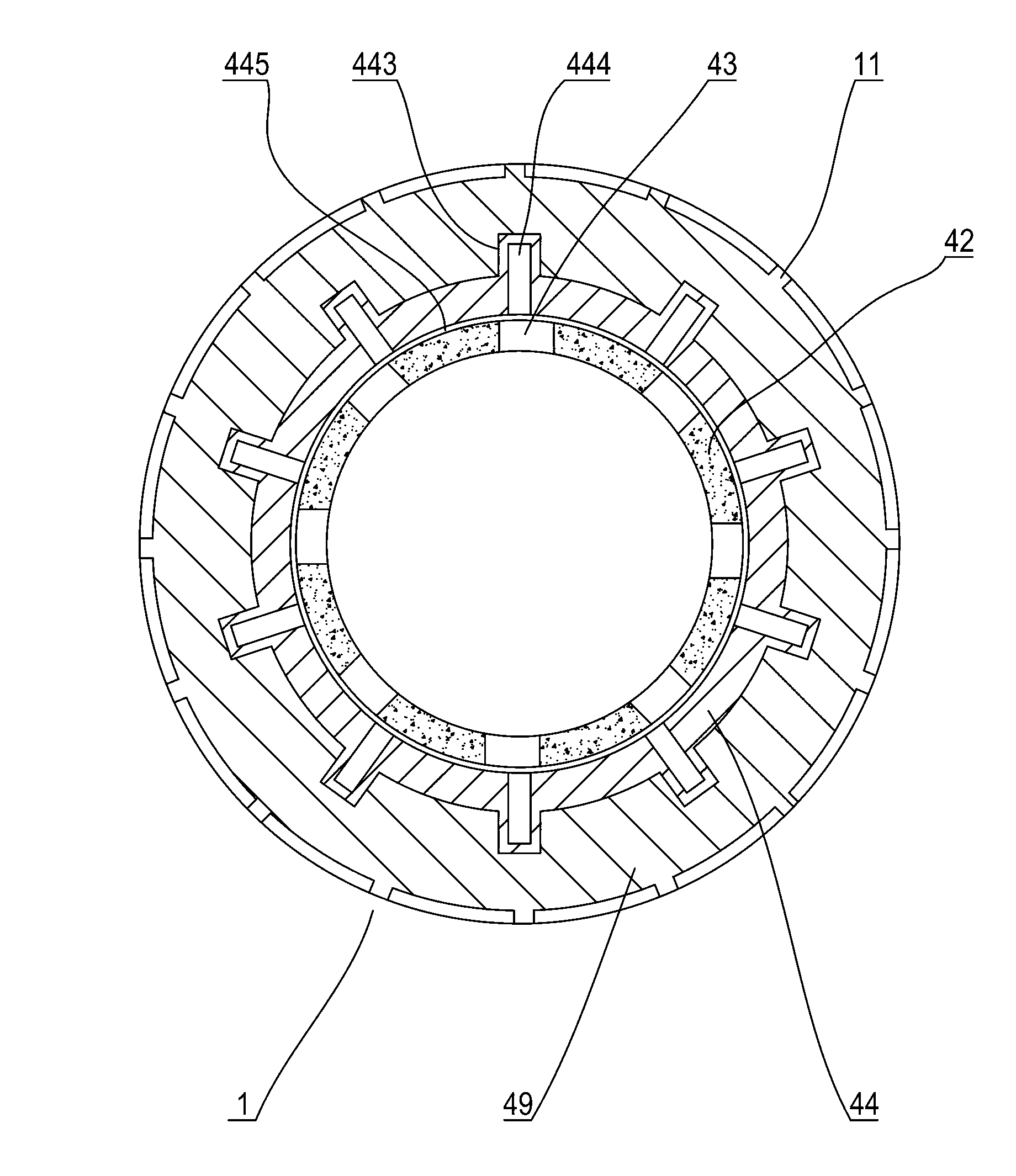

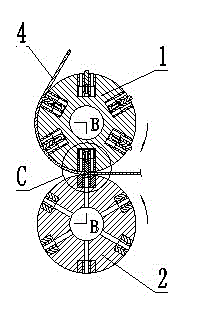

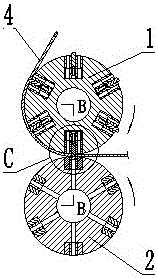

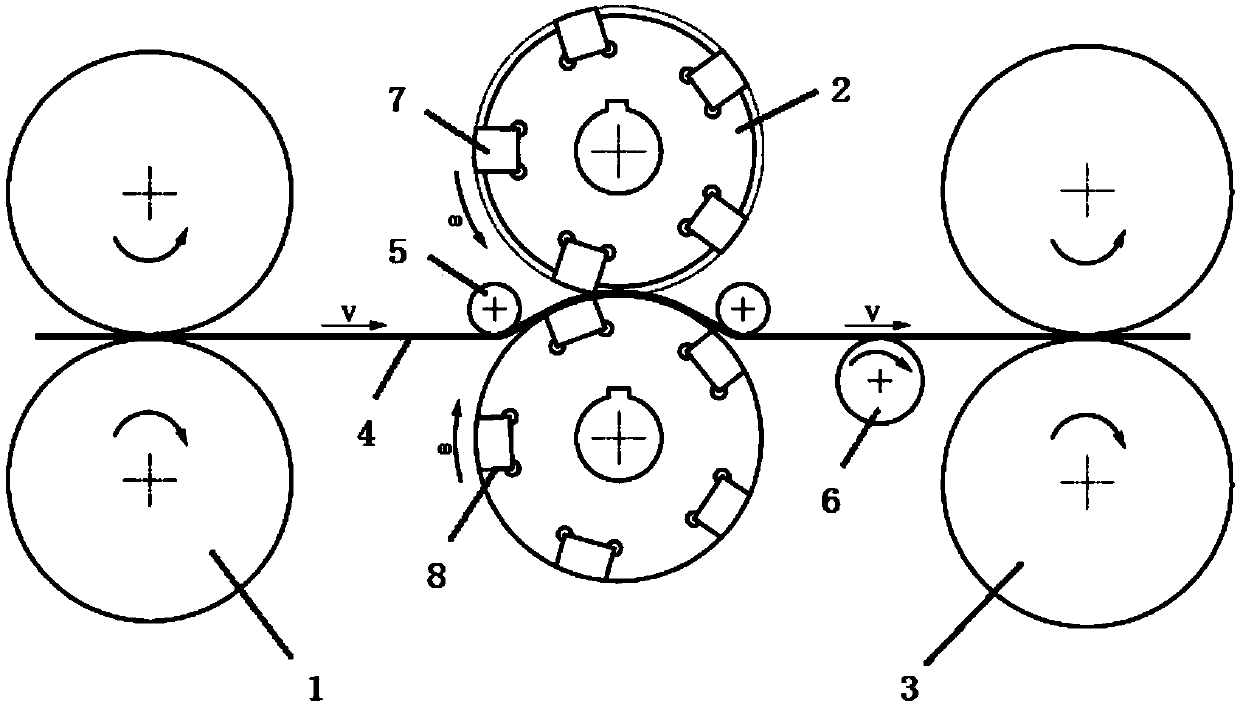

Assembled rotary blanking die

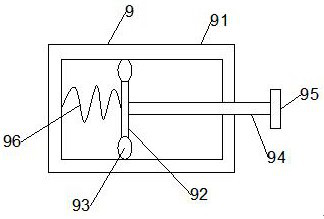

ActiveCN102873180ARealize blankingRealize continuous punchingPerforating toolsGear wheelGear transmission

Disclosed is an assembled rotary blanking die. The problem that the a reciprocate blanking die is low in work efficiency because of limited motion efficiency is solved. The assembled rotary blanking die comprises a punch component, a matrix component and a gear transmission mechanism. The gear transmission mechanism is a pair of external meshed gears which are equal in number of teeth and number of modes. The punch component and the matrix component are fixedly assembled with central shafts of the two external meshed gears respectively, and the punch component and the matrix component match with each other. Rotation of the punch component and rotation the matrix component can simultaneously achieve blanking and feeding of workpieces. Compared with the conventional reciprocate blanking die, the assembled rotary blanking die has greatly improved production efficiency.

Owner:BAODING GOLDEN SUNLIGHT POWER EQUIP TECH

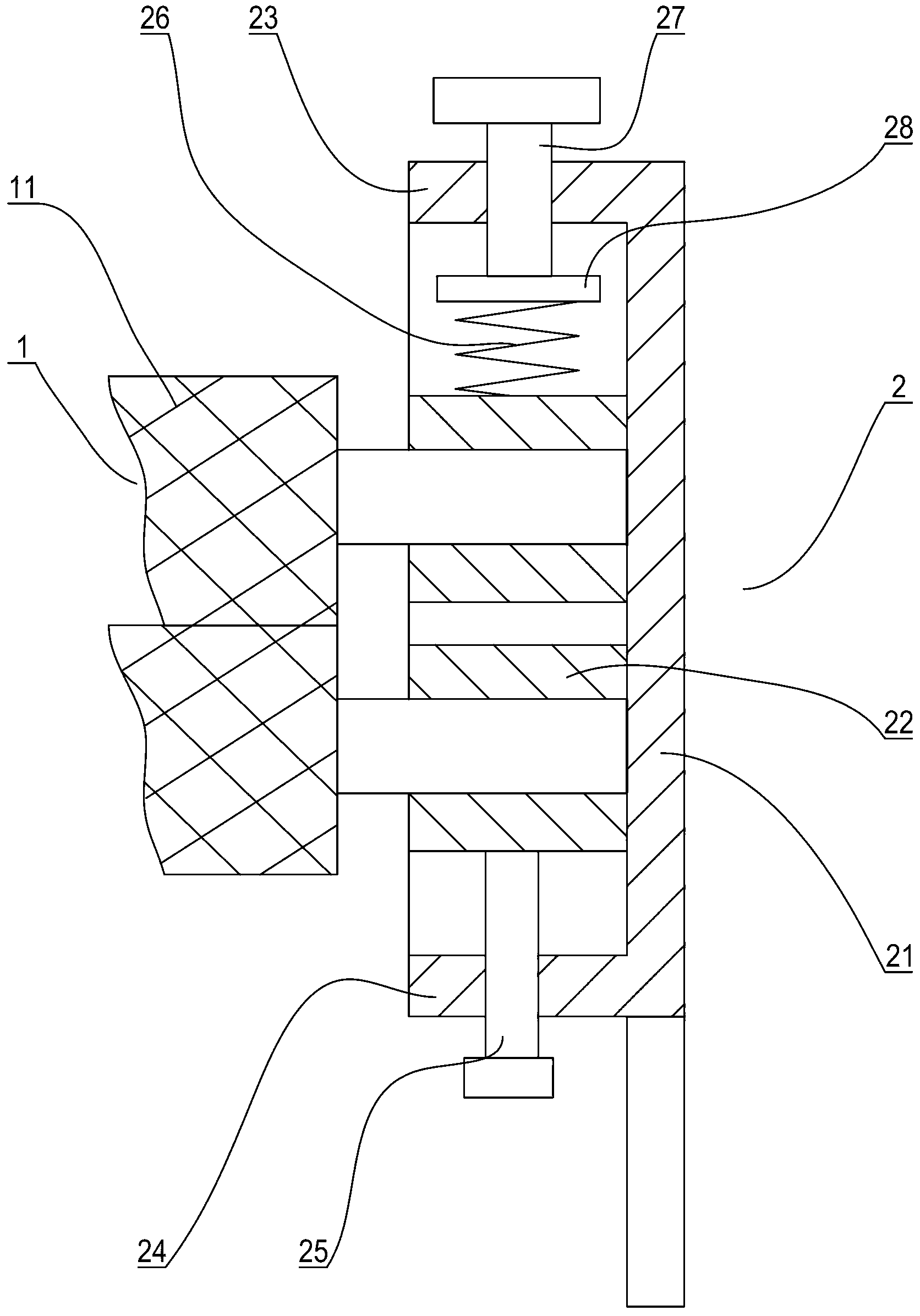

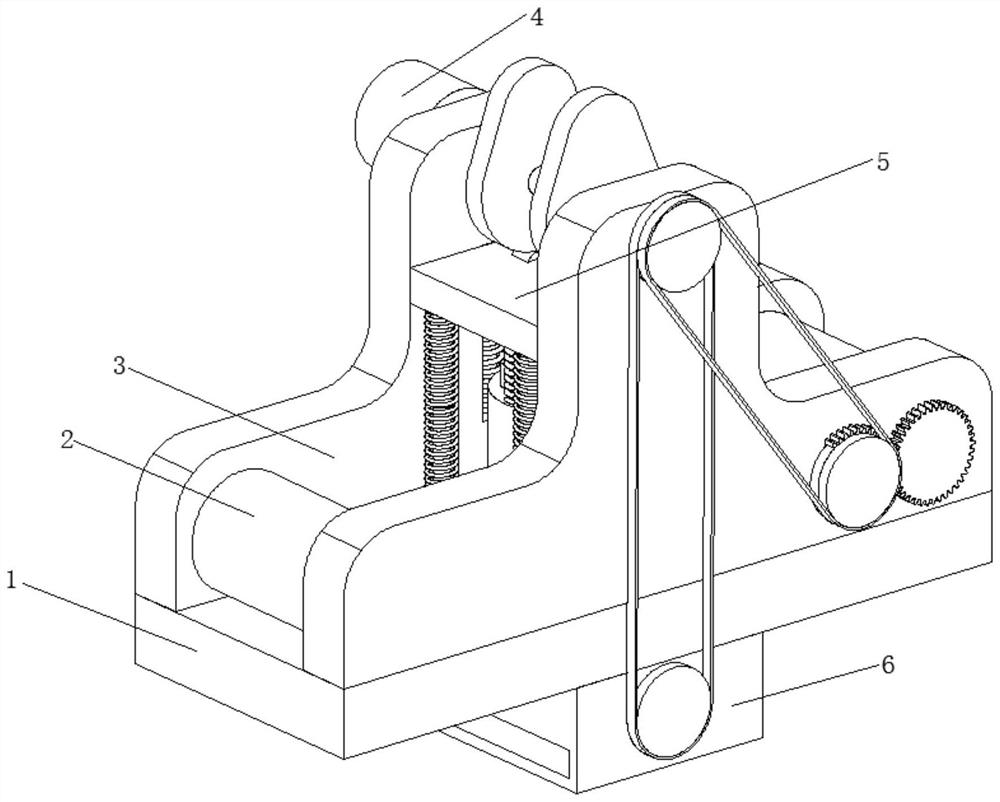

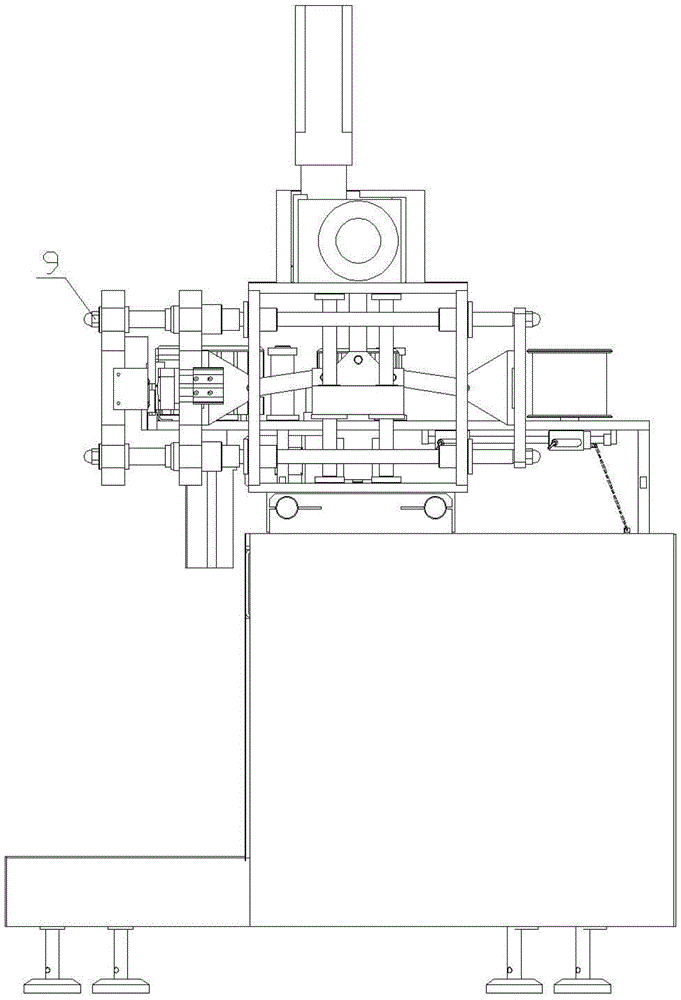

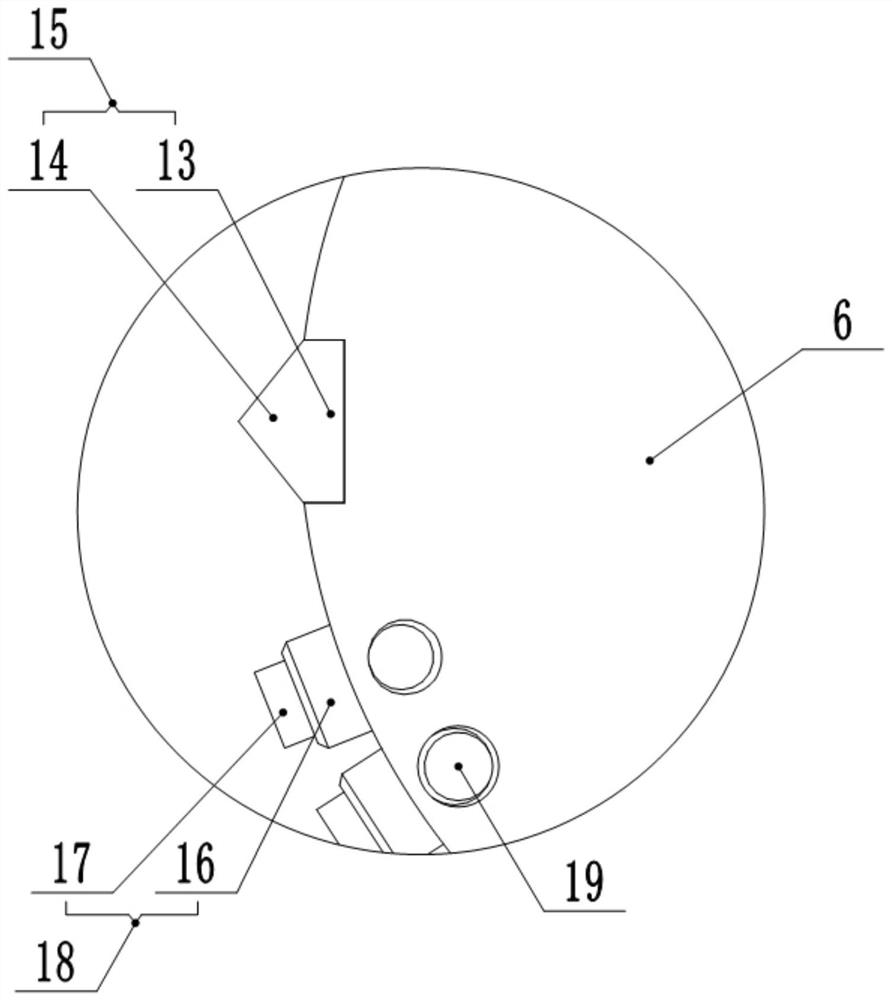

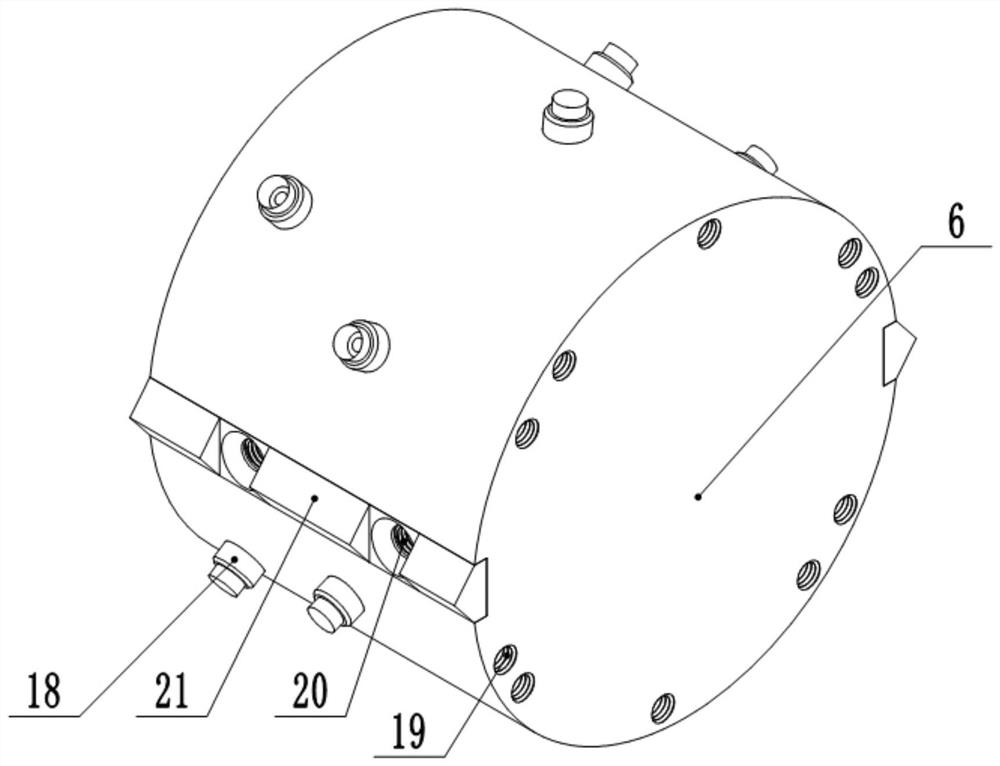

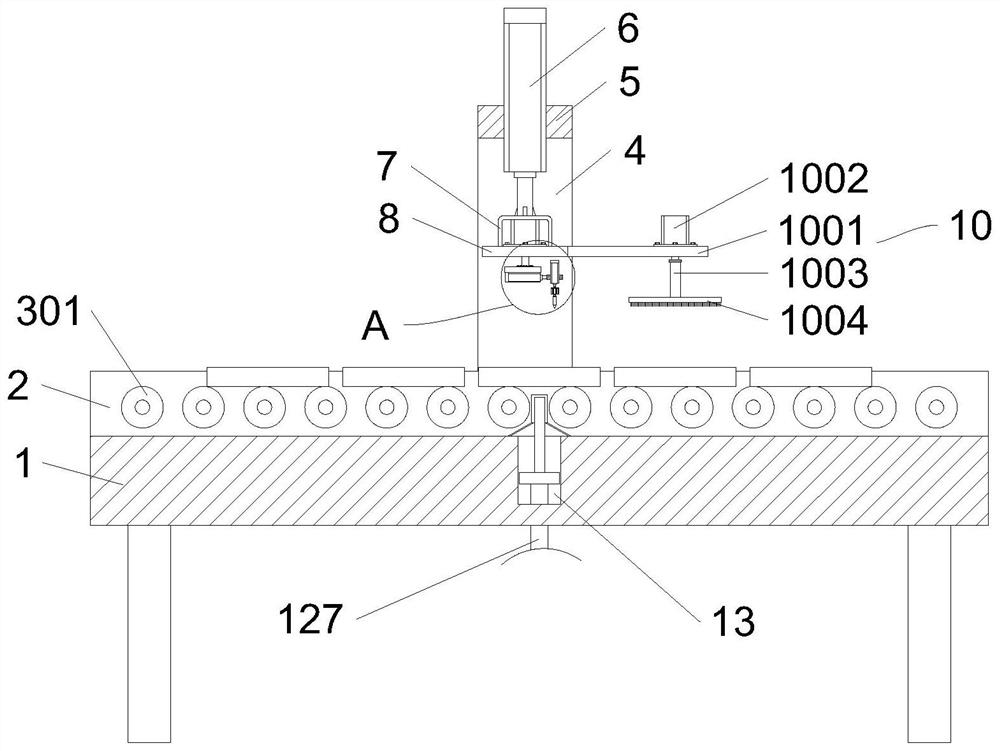

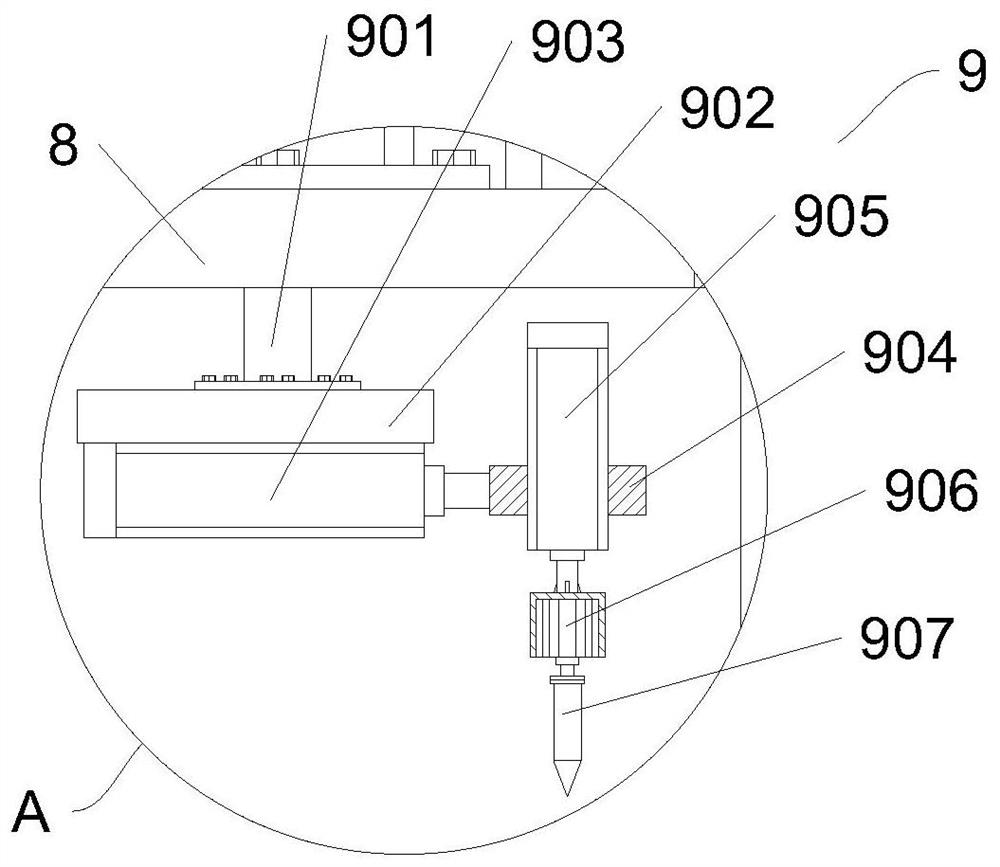

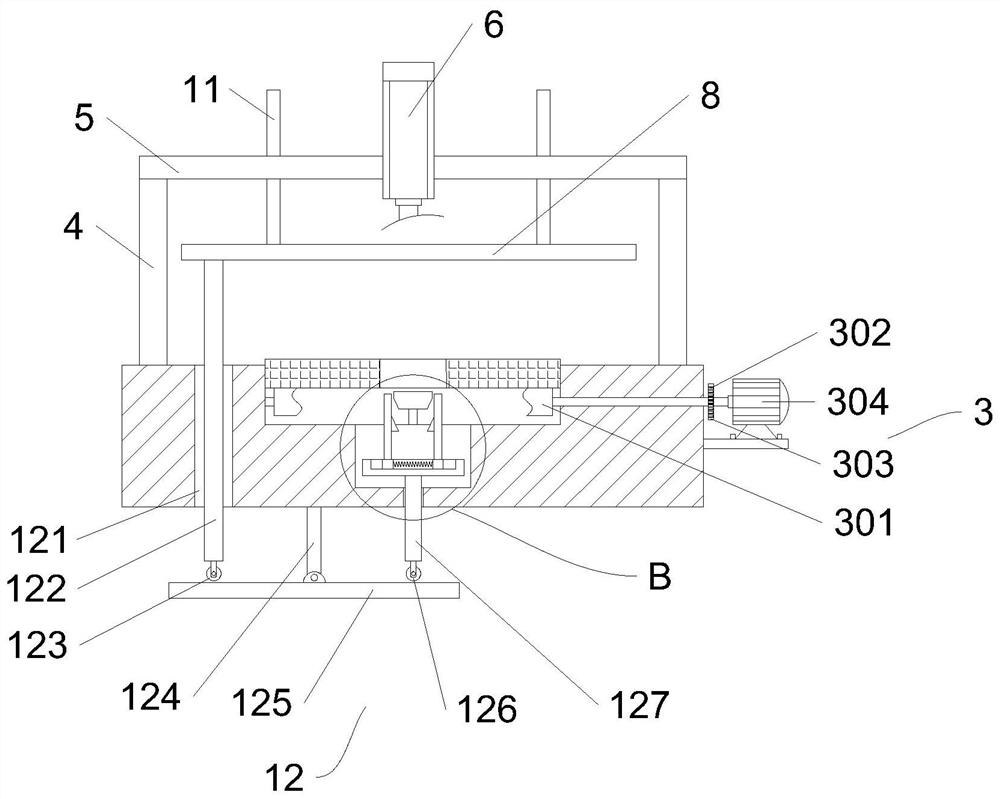

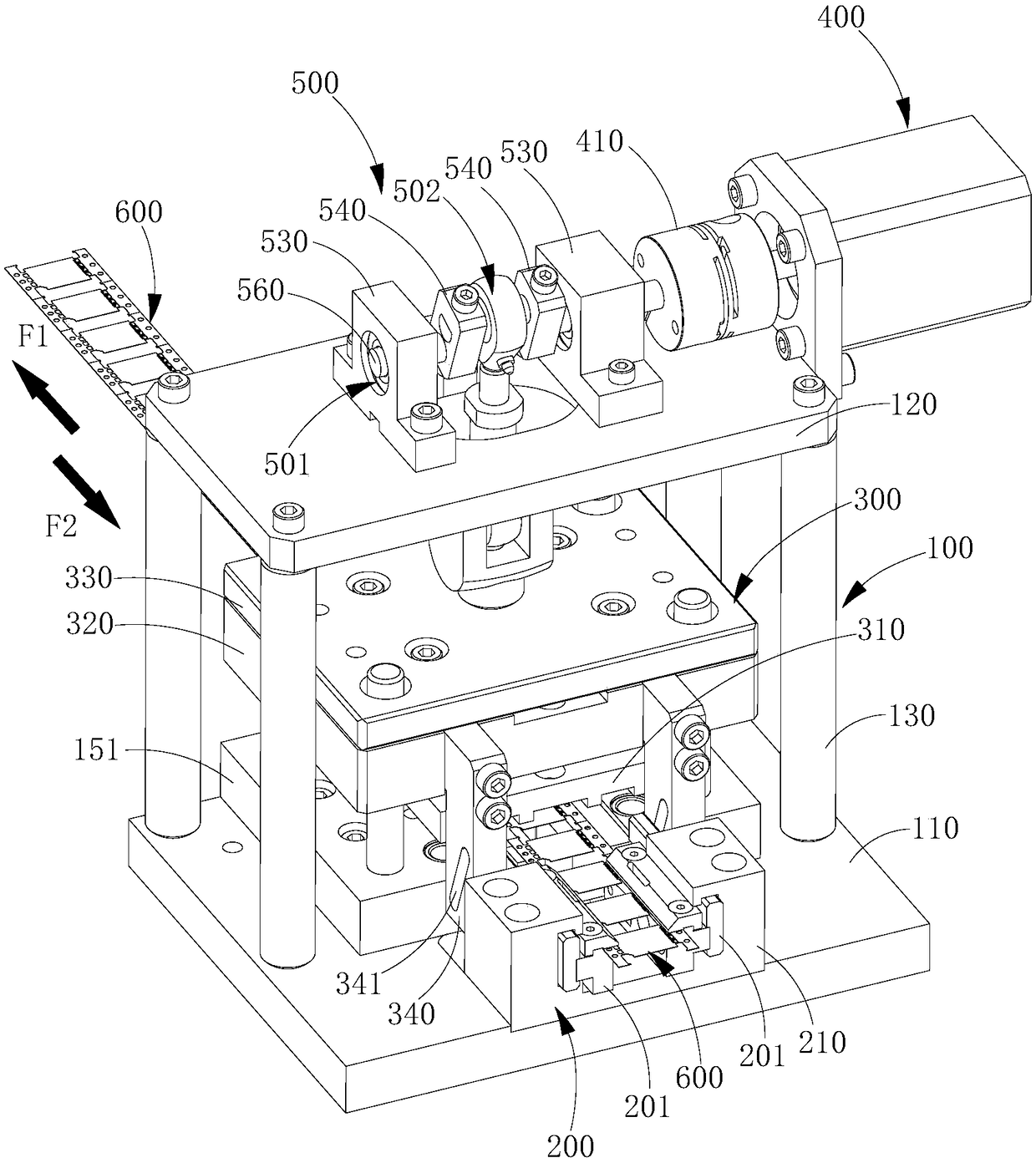

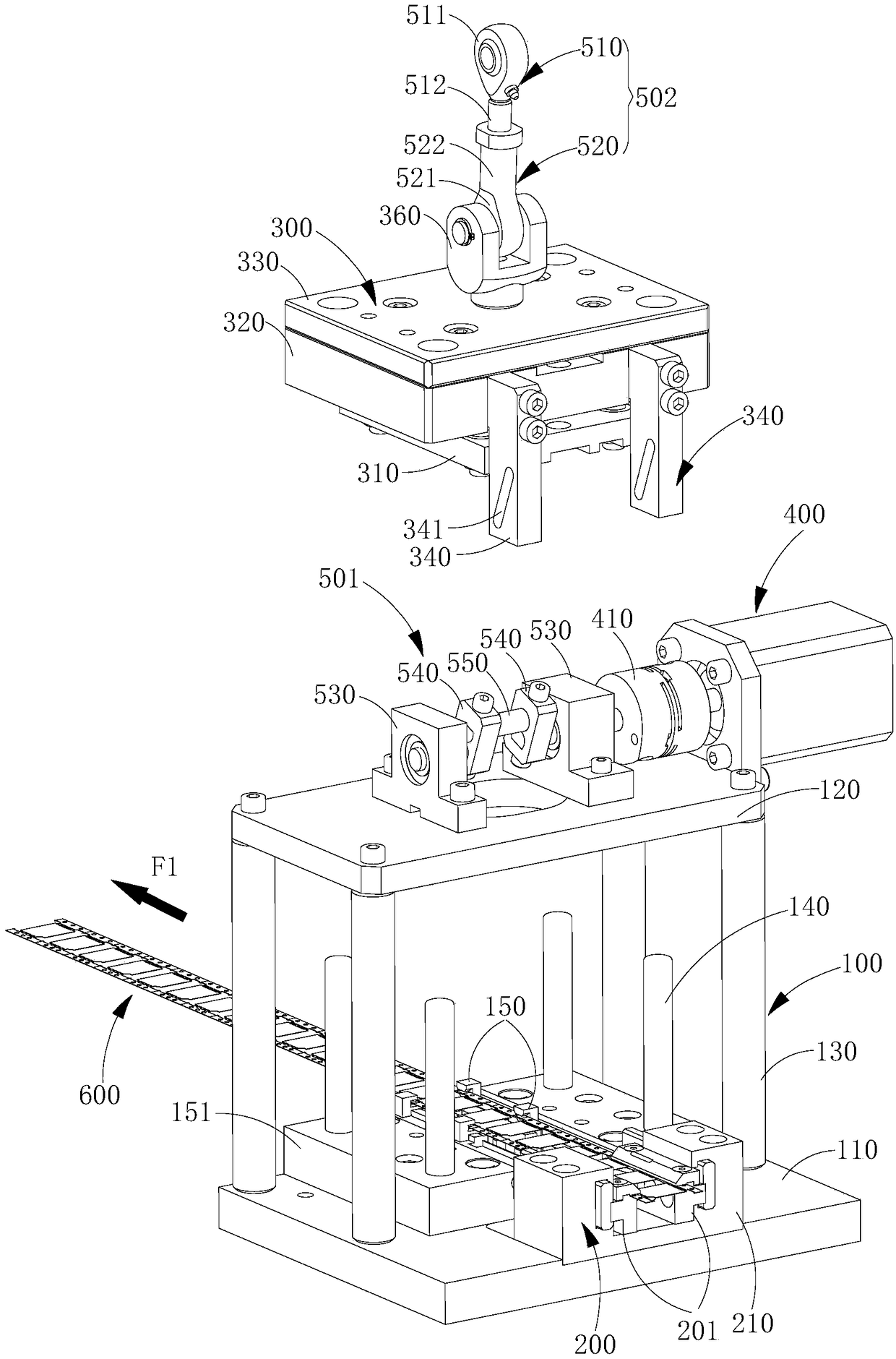

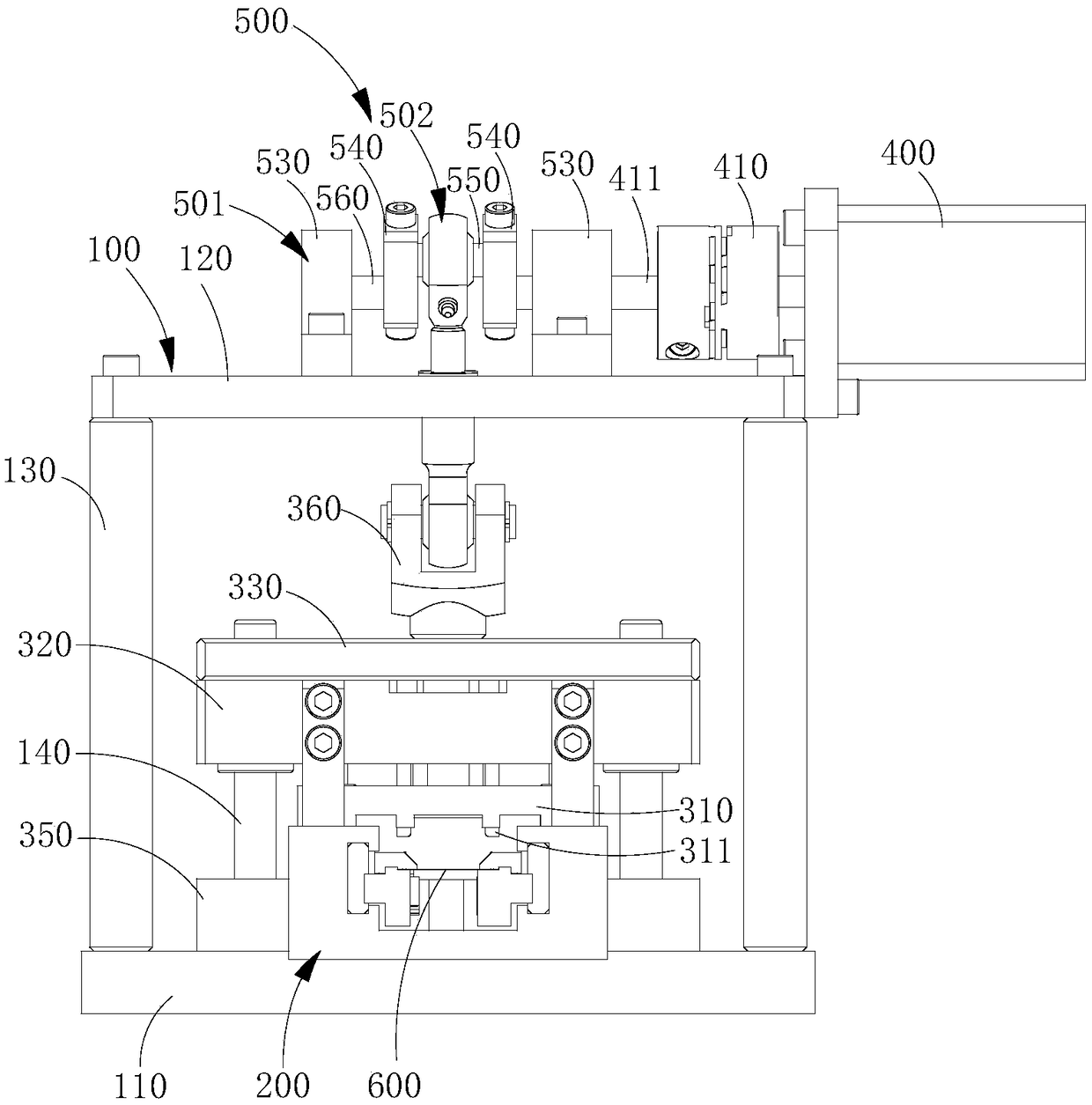

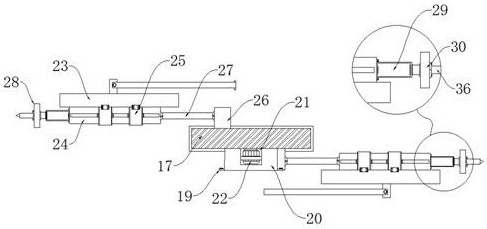

Continuous punching equipment for pipe fitting

InactiveCN113399547AAchieve left and right movementRealize continuous punchingPerforating toolsShaping safety devicesPunchingPipe fitting

The invention provides continuous punching equipment for a pipe fitting. The equipment comprises a punching base and a pipe fitting body, air cylinders are symmetrically arranged on the upper portion of the punching base, the free ends of the two air cylinders are connected with an adjusting base, an adjusting screw shaft is rotationally arranged in a cavity of the adjusting base, an adjusting screw block is in threaded connection with the interior of the adjusting screw shaft, and the adjusting screw shaft is connected with an output shaft of a forward and reverse rotation motor. The forward and reverse rotation motor is started, the adjusting screw shaft rotates to drive the adjusting screw block to move, then an adjusting through column moves, a balance block is driven to move, then a punching head moves, through forward and reverse rotation of the forward and reverse rotation motor, left-right movement of the punching head is achieved, and continuous punching of the pipe fitting is achieved.

Owner:YANGZHOU YUXIN PIPE IND CO LTD

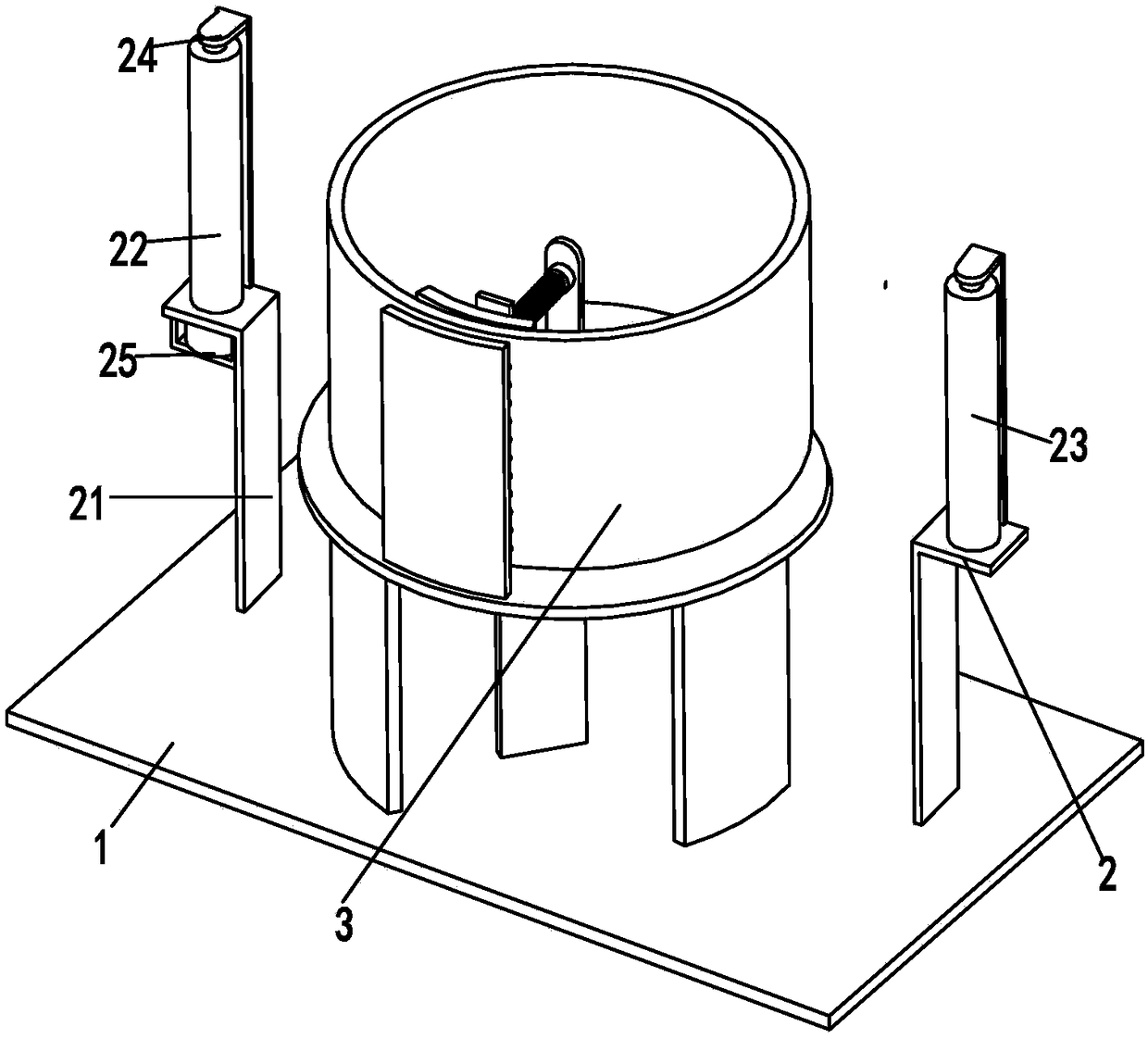

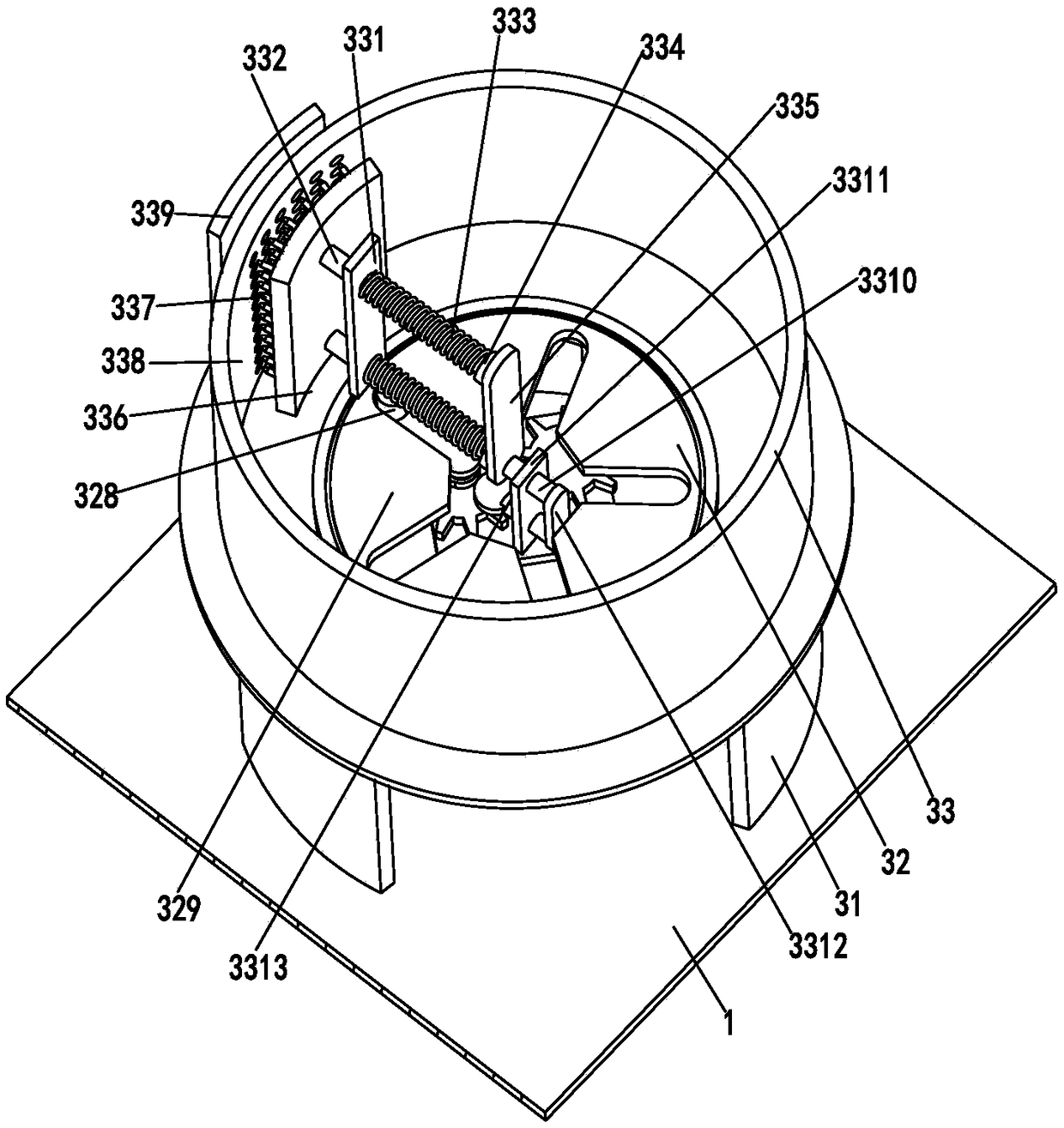

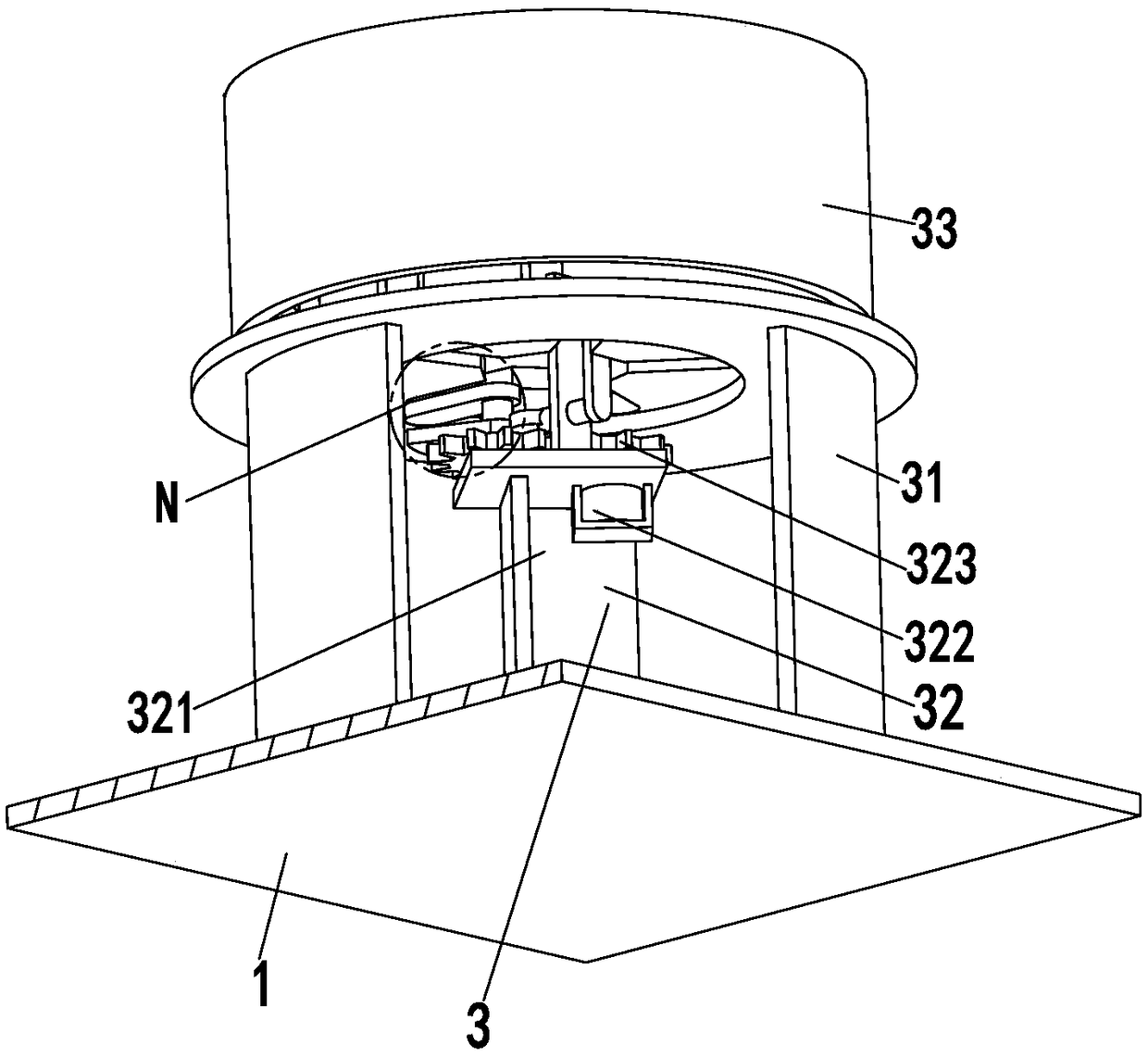

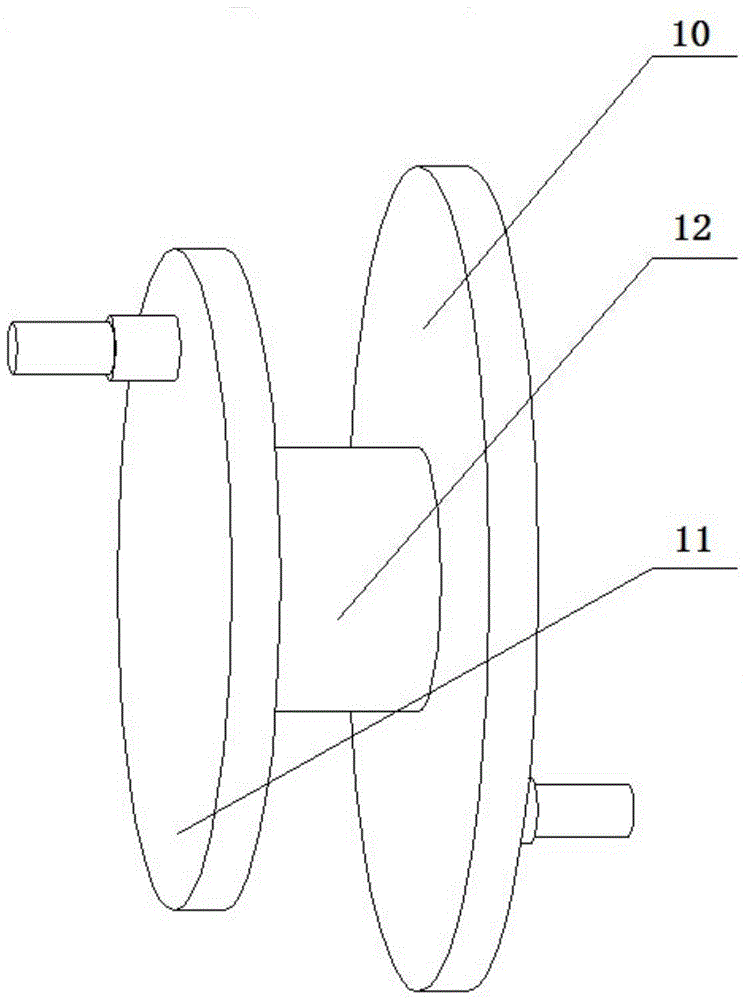

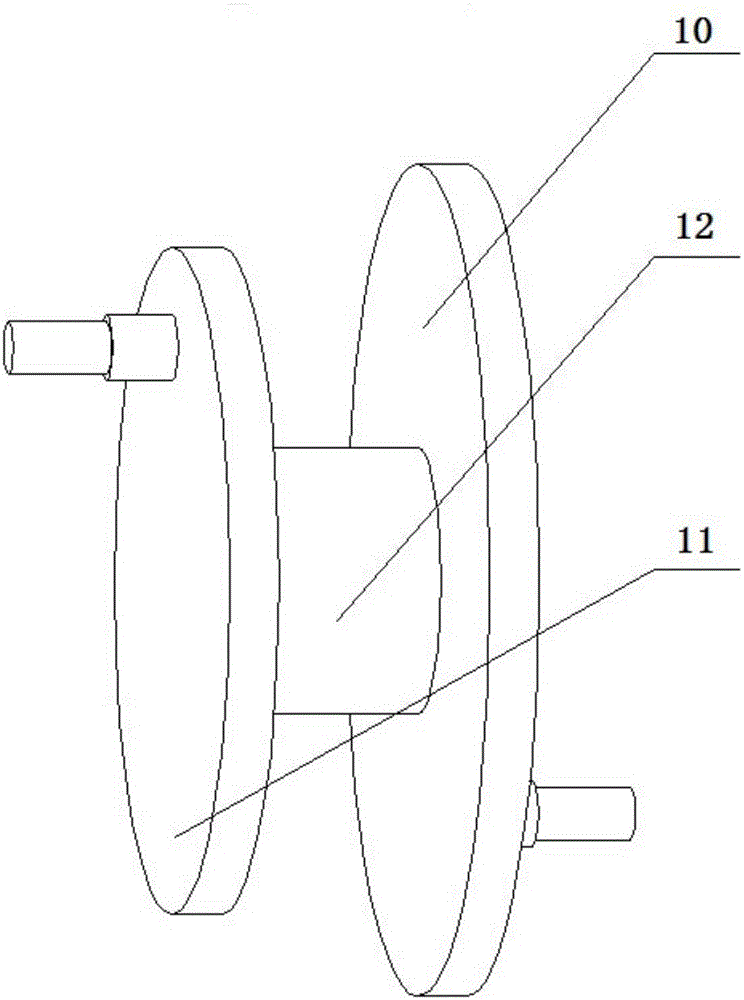

A continuous punching device for straight pipe

ActiveCN104128434BRealize continuous punchingImprove punching efficiencyPerforating toolsMetal-working feeding devicesPunchingLateral extension

Owner:冠达星股份有限公司

A synthetic fiber leather auxiliary processing textile machine

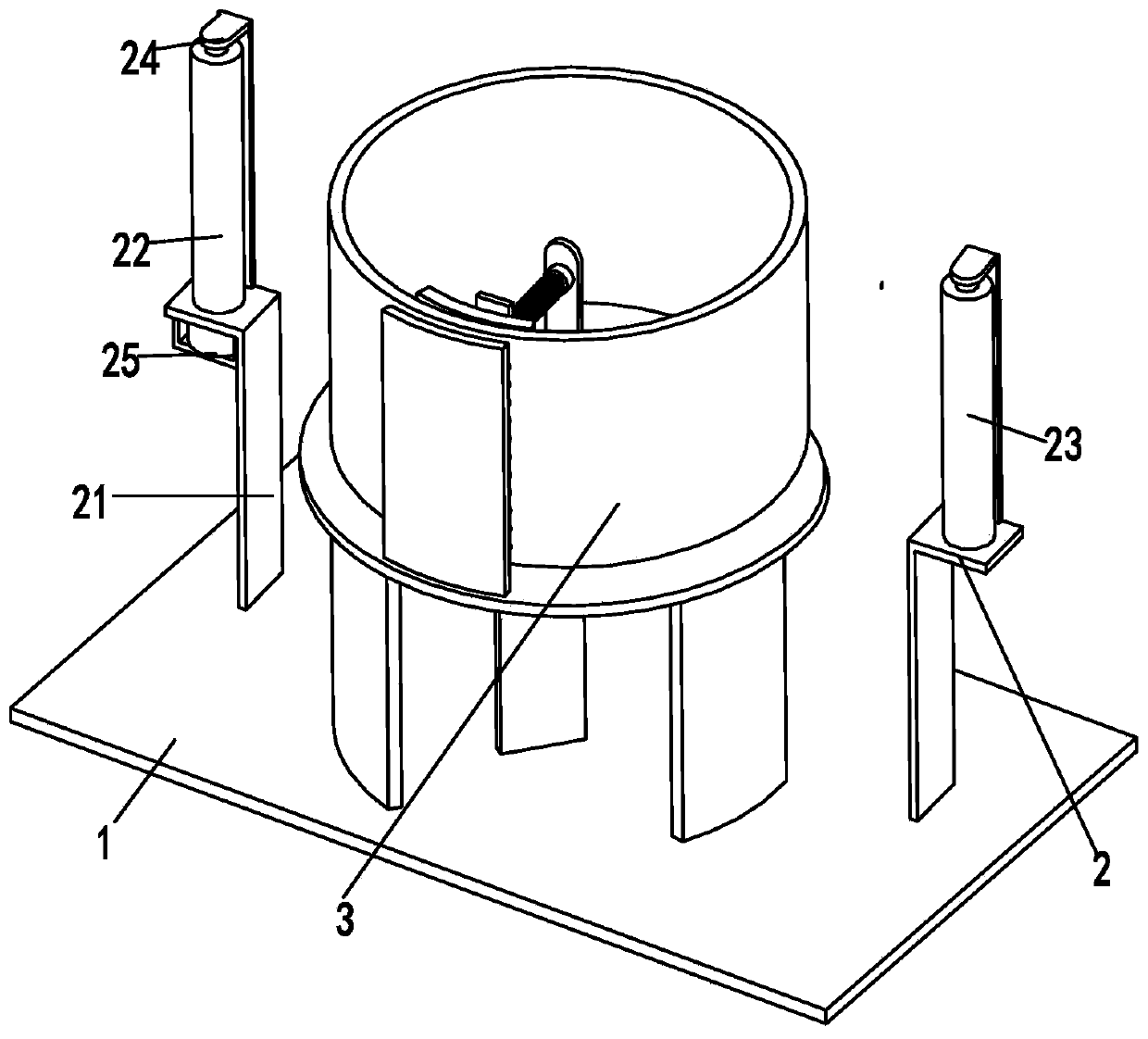

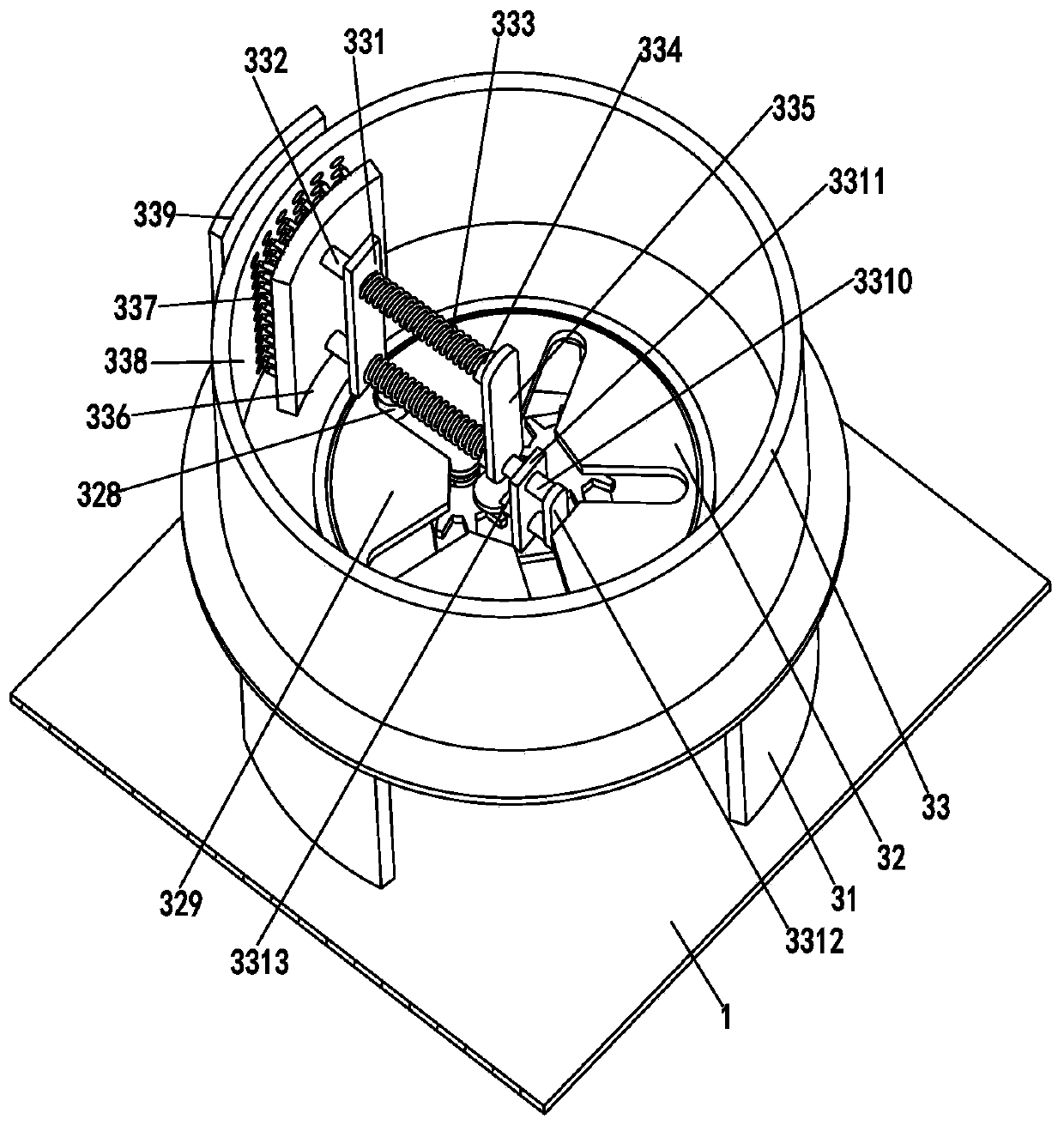

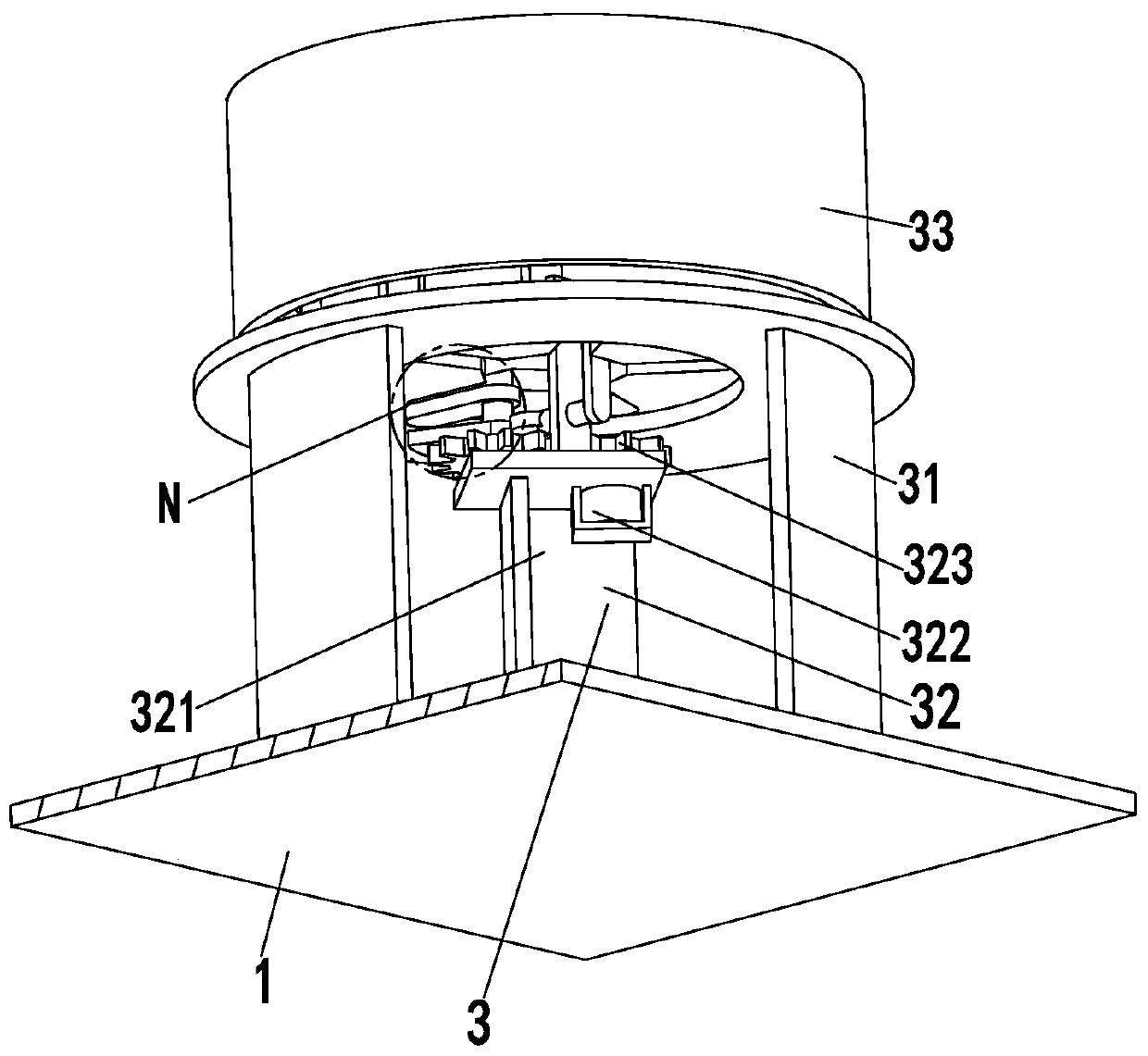

ActiveCN108908481BRealize the function of automatic punchingRealize continuous operationLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusRotational axisGear wheel

The invention relates to a synthetic fiber leather auxiliary processing textile machinery. The synthetic fiber leather auxiliary processing textile machinery comprises a bottom plate, a material placing device and a perforating device; the perforating device is mounted in the middle of the bottom plate, the material placing device is arranged on the outer side of the perforating device, the material placing device is mounted on the bottom plate, the material placing device comprises a mounting frame, a driving material placing roller, an auxiliary material placing roller, a connection frame and a rotary motor, the perforating device comprises a supporting frame, a power mechanism and a perforating mechanism, and the power mechanism comprises a working frame, a working motor, a driving gear, a driven gear, a rotary shaft, an adjusting block, a rotary plate, a concave boss and a rotary round plate. The synthetic fiber leather auxiliary processing textile machinery can solve the problemsof poor continuity, low working efficiency and poor stability exists in the existing leather perforating process, can achieve the function that the leather is automatically perforated, and has the advantages of continuous operation, high working efficiency and good stability.

Owner:SHEYANG COUNTY HUARUI TECTILE MACHINERY CO LTD

A hole puncher for vegetable transplanting

ActiveCN106171156BRealize continuous punchingImprove support strengthManure treatmentArchitectural engineeringWedge shape

The invention belongs to the field of vegetable transplanting and relates to a novel perforator for vegetable transplanting. The novel perforator comprises a pressure bar, a casing pipe and a digging bucket. The pressure bar is provided with a wedge-shaped clamp with a downward wedge-shaped structure. Upper and lower ends of the casing pipe are respectively provided with an opening and an enclosed port. The upper end of the casing pipe sleeves the lower end of the pressure bar. The side wall of the casing pipe is provided with a clamping hole. Multiple movable rods are hinged to the lower end of the casing pipe. The other ends of the movable rods are respectively hinged to and uniformly distributed on the same circumference in the digging bucket. The top of the digging bucket is uniformly provided with multiple extending-retracting folding lines connected to the bottom of the digging bucket and the bottom of the digging bucket is provided with a conical cap. In use, a handle is held, the novel perforator is downward inserted into soil and then the pressure bar is lifted so that the soil is dug up along with the digging bucket and thus soil does not fall off and labor efficiency is improved.

Owner:南通腾舟船舶机械有限公司

An Assembled Rotary Blanking Die

ActiveCN102873180BRealize blankingRealize continuous punchingPerforating toolsEngineeringMechanical engineering

Disclosed is an assembled rotary blanking die. The problem that the a reciprocate blanking die is low in work efficiency because of limited motion efficiency is solved. The assembled rotary blanking die comprises a punch component, a matrix component and a gear transmission mechanism. The gear transmission mechanism is a pair of external meshed gears which are equal in number of teeth and number of modes. The punch component and the matrix component are fixedly assembled with central shafts of the two external meshed gears respectively, and the punch component and the matrix component match with each other. Rotation of the punch component and rotation the matrix component can simultaneously achieve blanking and feeding of workpieces. Compared with the conventional reciprocate blanking die, the assembled rotary blanking die has greatly improved production efficiency.

Owner:BAODING GOLDEN SUNLIGHT POWER EQUIP TECH

Synthetic fiber leather auxiliary processing textile machinery

ActiveCN108908481ARealize the function of automatic punchingRealize continuous operationLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringMechanical engineering

The invention relates to a synthetic fiber leather auxiliary processing textile machinery. The synthetic fiber leather auxiliary processing textile machinery comprises a bottom plate, a material placing device and a perforating device; the perforating device is mounted in the middle of the bottom plate, the material placing device is arranged on the outer side of the perforating device, the material placing device is mounted on the bottom plate, the material placing device comprises a mounting frame, a driving material placing roller, an auxiliary material placing roller, a connection frame and a rotary motor, the perforating device comprises a supporting frame, a power mechanism and a perforating mechanism, and the power mechanism comprises a working frame, a working motor, a driving gear, a driven gear, a rotary shaft, an adjusting block, a rotary plate, a concave boss and a rotary round plate. The synthetic fiber leather auxiliary processing textile machinery can solve the problemsof poor continuity, low working efficiency and poor stability exists in the existing leather perforating process, can achieve the function that the leather is automatically perforated, and has the advantages of continuous operation, high working efficiency and good stability.

Owner:SHEYANG COUNTY HUARUI TECTILE MACHINERY CO LTD

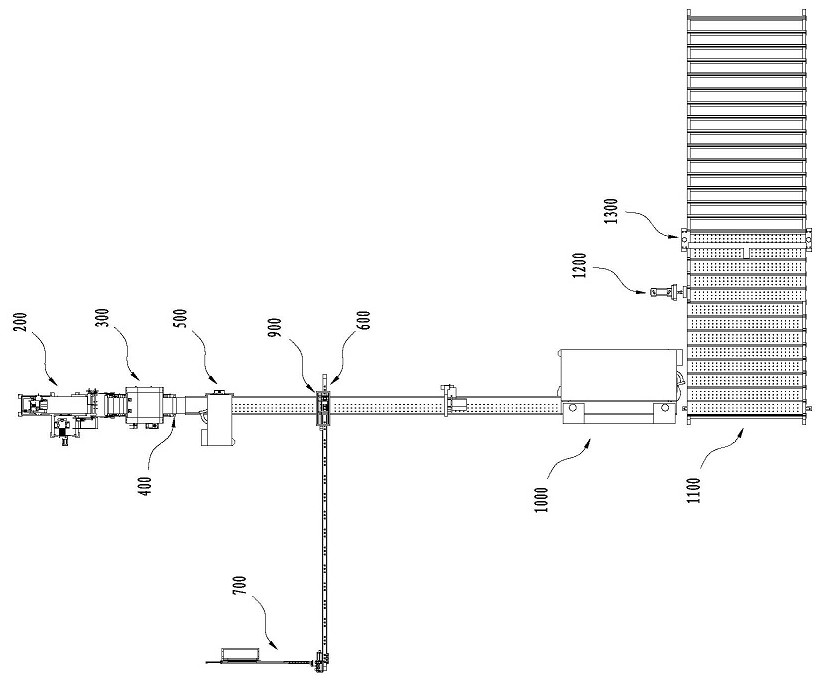

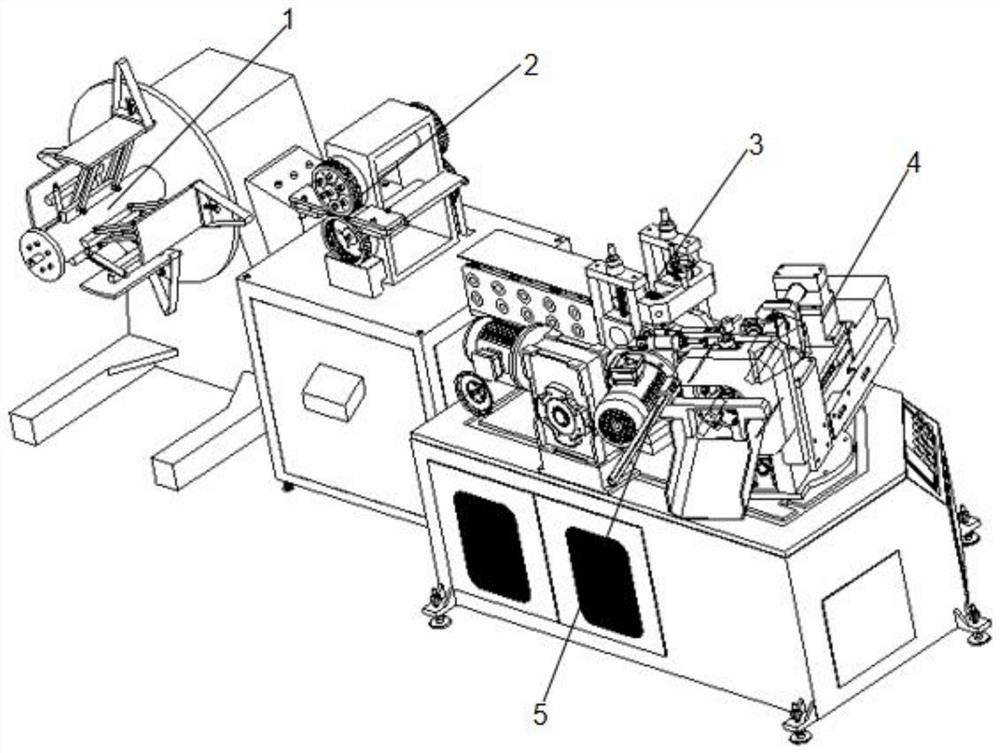

A continuous molding device for filter center pipe

ActiveCN112475026BRealize continuous processing and formingImprove processing efficiencyPunchingEngineering

The invention provides a continuous forming device for a central tube of a filter, comprising an unwinding device; a punching device installed on the right side of the unwinding device; a pushing device installed on the right side of the punching device; and a pushing device installed on the right side of the pushing device The coiling device; the cutting device installed at the front end of the coiling device, the cutting device includes a rotating shell, the center of the rotating shell is provided with a center hole matching the coiling shaft, and the cutting wheel is fixed on the On the installation shaft, one end of the installation shaft is fixed on the rotating shell, the positioning guide wheel is installed on one side of the center hole of the rotating shell, and the pneumatic pull rod is installed on one side of the rotating shell, the pneumatic pull rod and the rotating shell They are fixedly connected by a tie rod shaft. The continuous forming device of the central tube of the filter can realize automatic unwinding, punching, stable feeding, automatic coiling and cutting of the coiled plate, realize continuous processing and forming of the central tube, and greatly improve the processing efficiency and quality of the central tube.

Owner:佛山市豹王滤芯制造有限公司

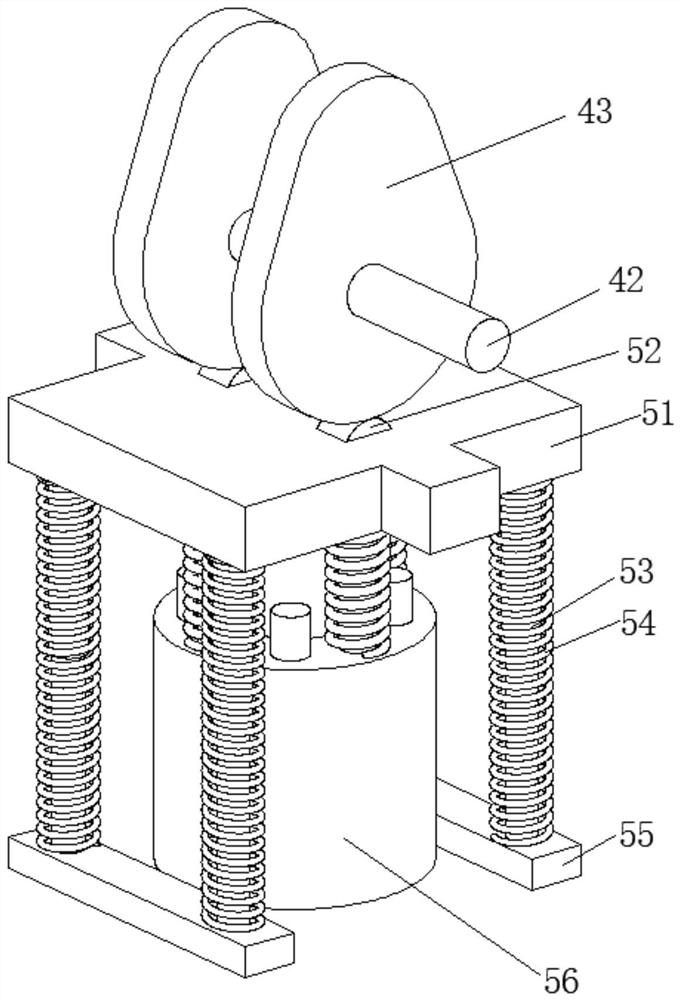

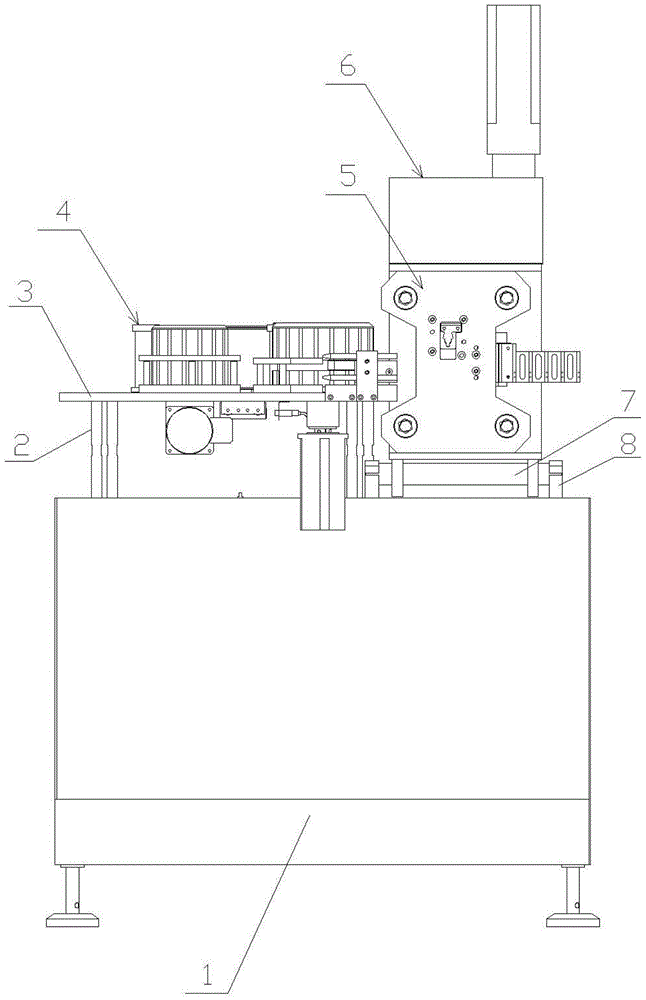

Automatic liquid filling machine single punching device

ActiveCN104925332BReasonable structureWork reliablyPackaging automatic controlPackaging machinesPunchingSlide plate

The invention discloses a single punching device of a full-automatic liquid filling machine. The single punching device comprises a machine body, a feeding mechanism and a punching mechanism. The punching mechanism comprises a rectangular frame. A sliding block is installed in the frame through guiding pillars. The frame is provided with a driving device connected with the sliding block. Four long transmission shafts penetrate through the frame. The two ends of the long transmission shafts are provided with a punching head and a rear fixing plate. The punching head comprises a front plate and a sliding plate, wherein the front plate is fixed to the front ends of the four long transmission shafts, and the sliding plate is arranged on the four long transmission shafts in a sleeving mode. The sliding block is hinged to the rear fixing plate and the sliding plate through connecting rods respectively. The opposite faces of the front plate and the sliding plate are provided with a female die and a male die respectively and a pair of slitting cutters respectively. The sliding plate is provided with a removing air cylinder, a removing plate is arranged at the front end and a piston rod of the removing air cylinder, and a removing cutting plate corresponding to the removing plate is arranged on the front plate. The single punching device has the advantages that the structure is reasonable, work is reliable, single or multiple punching can be achieved, and the production efficiency is high.

Owner:LIAONING CHUNGUANG PHARMA EQUIP CORP LTD

A continuous punching device for u-shaped pipe

ActiveCN104084478BRealize continuous punchingImprove punching efficiencyPerforating toolsMetal-working feeding devicesPunchingFixed frame

Owner:冠达星股份有限公司

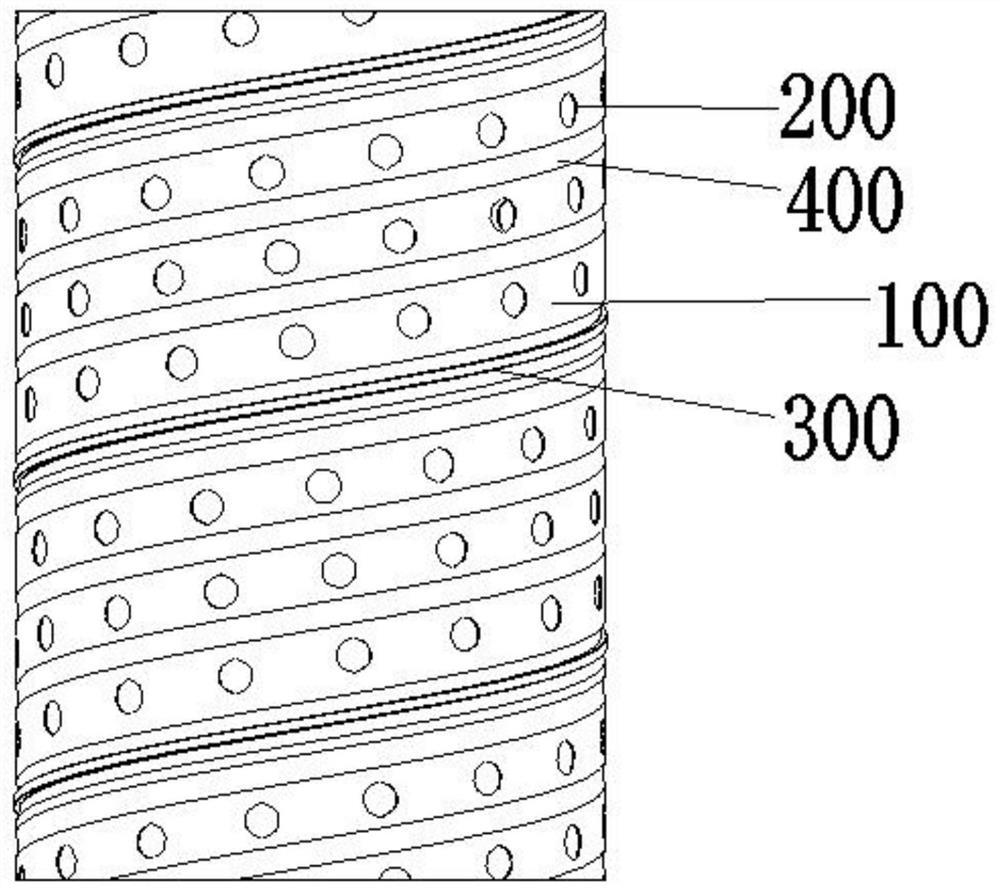

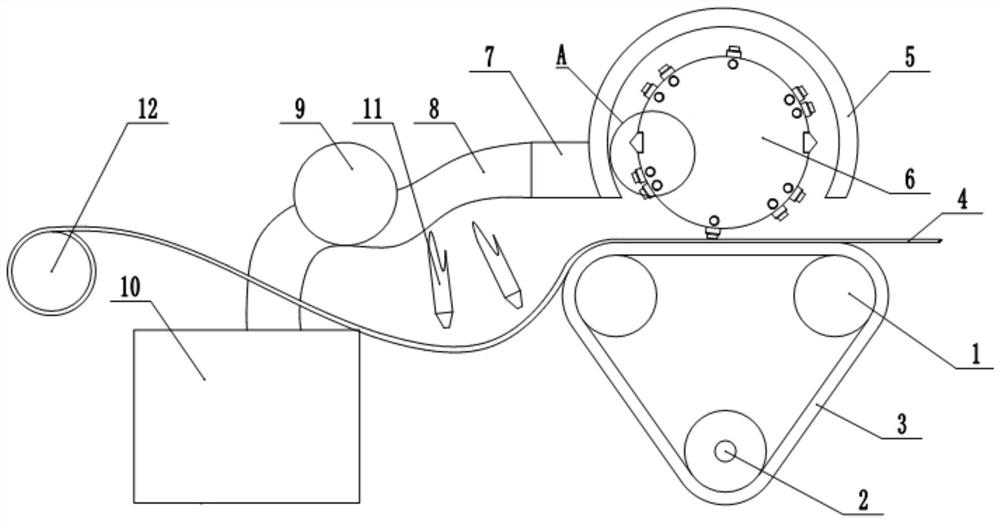

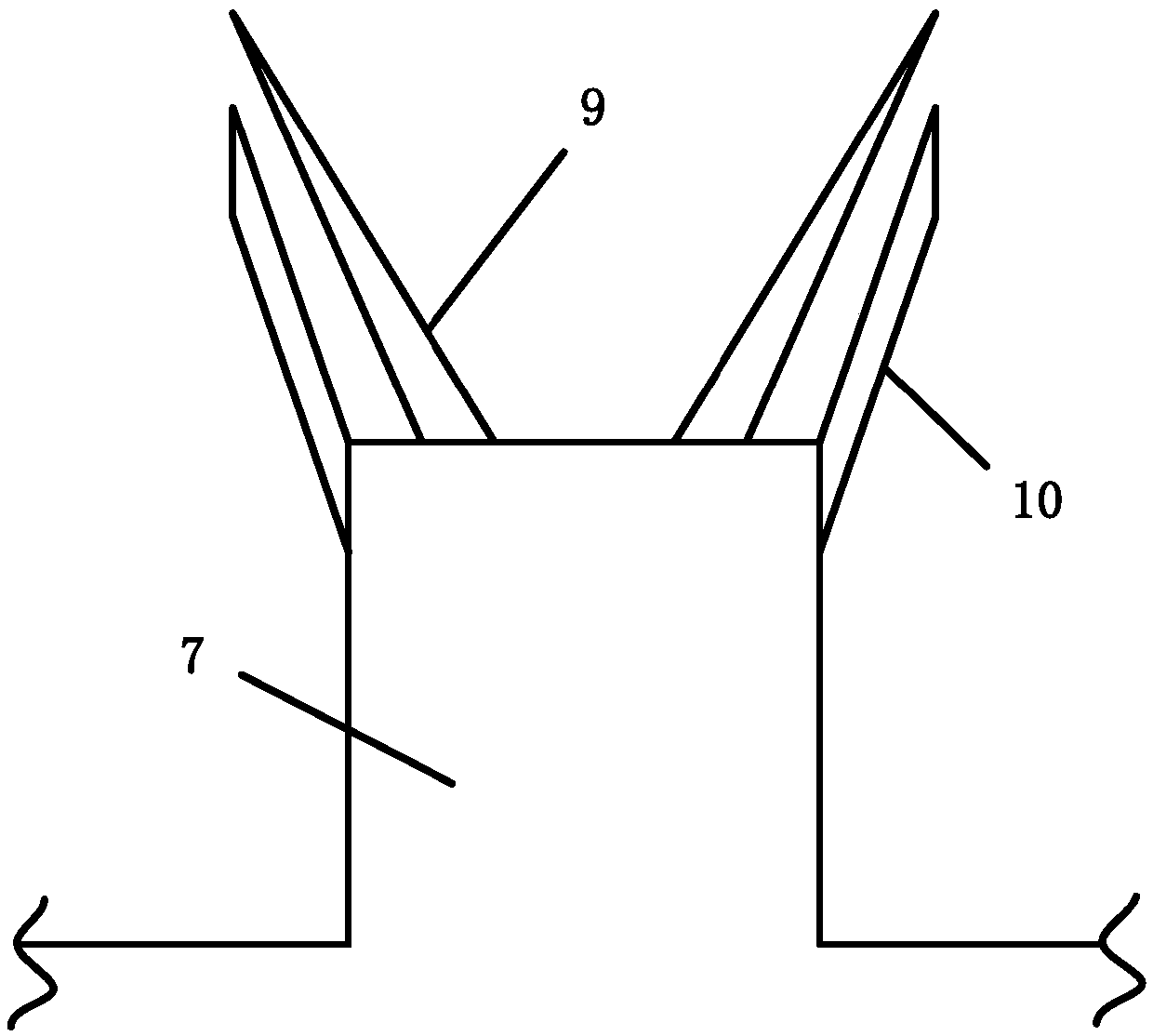

Film continuous punching tool and its punching process

ActiveCN112847574BControl punch spacingRealize continuous punchingCleaning using gasesMetal working apparatusPunchingStructural engineering

The invention belongs to the technical field of sealing strip processing, and specifically discloses a film continuous punching tool and its punching process, including a frame, on which a punching mechanism and a transmission mechanism are arranged, and the transmission mechanism is used to transmit the film to be punched. The film, the punching mechanism is located above the transmission mechanism, the punching mechanism includes a rotating cylinder connected to the frame, the outer wall of the rotating cylinder is evenly distributed with multiple groups of punching components along the circumference, the punching components include punching parts and shearing parts, punching The hole piece includes a punching nail detachably connected to the outer wall of the drum. The punching nail includes a mounting part for connecting with the drum and a punching part for punching holes. The punching part is in the shape of a ring; the shearing part includes The connecting part for connecting with the outer wall of the drum and the shearing part for cutting the film, the length direction of the connecting part is parallel to the axial direction of the drum, and the shearing part includes several triangular prism-shaped shears distributed along the length direction of the connecting part. Cutting blocks, with spacing between adjacent cutting blocks. By adopting the scheme of the invention, the problem of continuous punching of the film can be solved.

Owner:萨固密渝锦(重庆)橡塑制品有限公司 +2

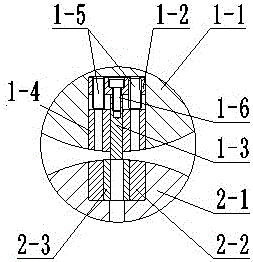

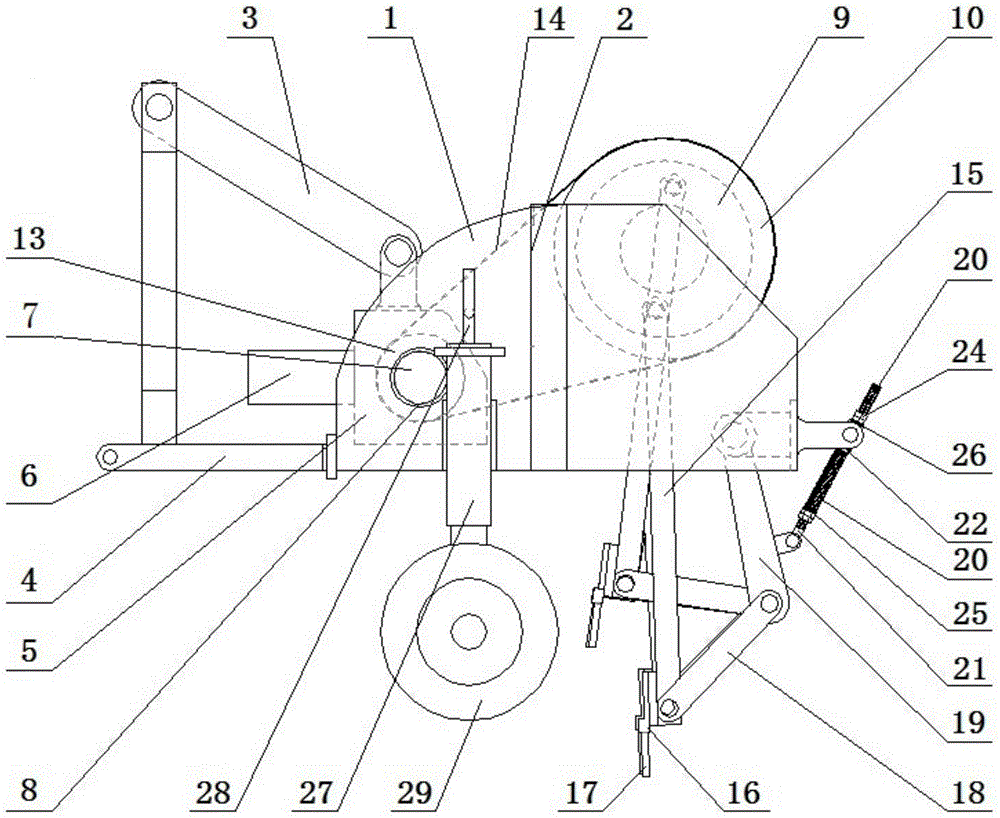

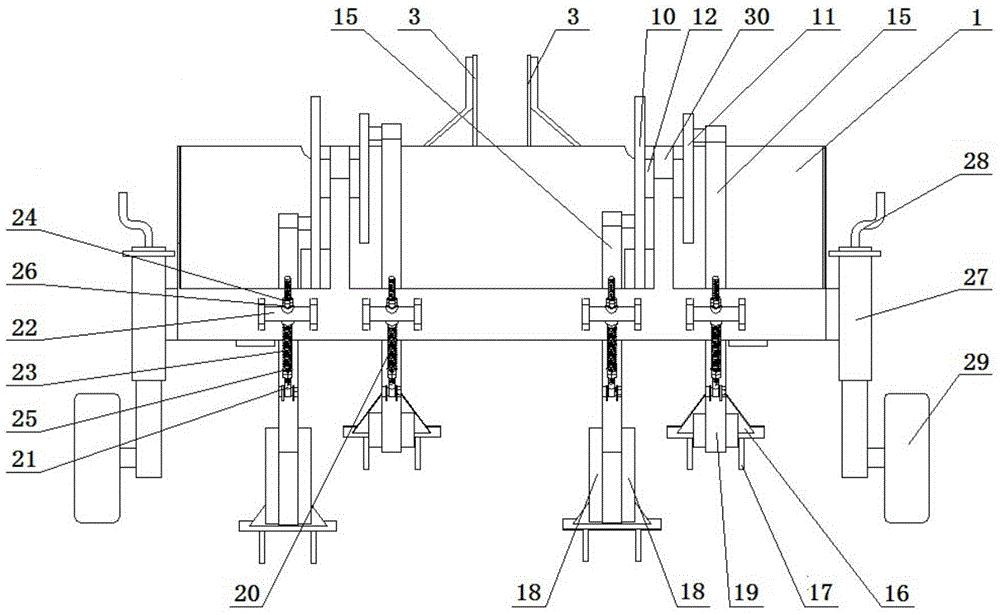

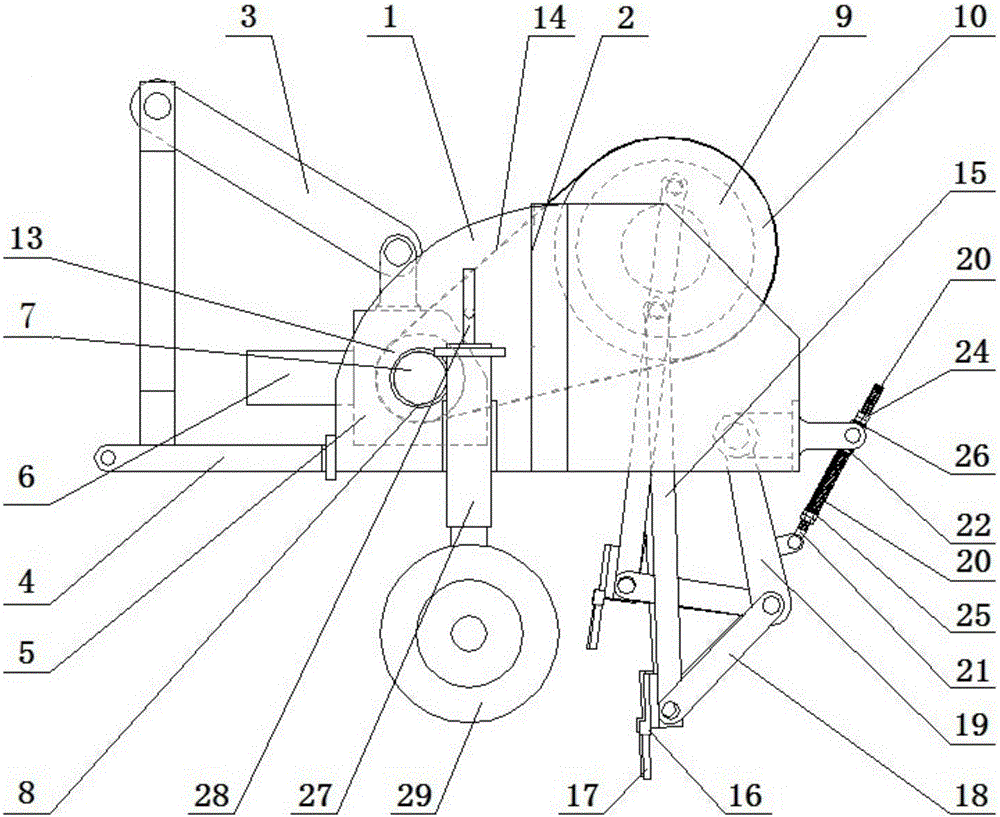

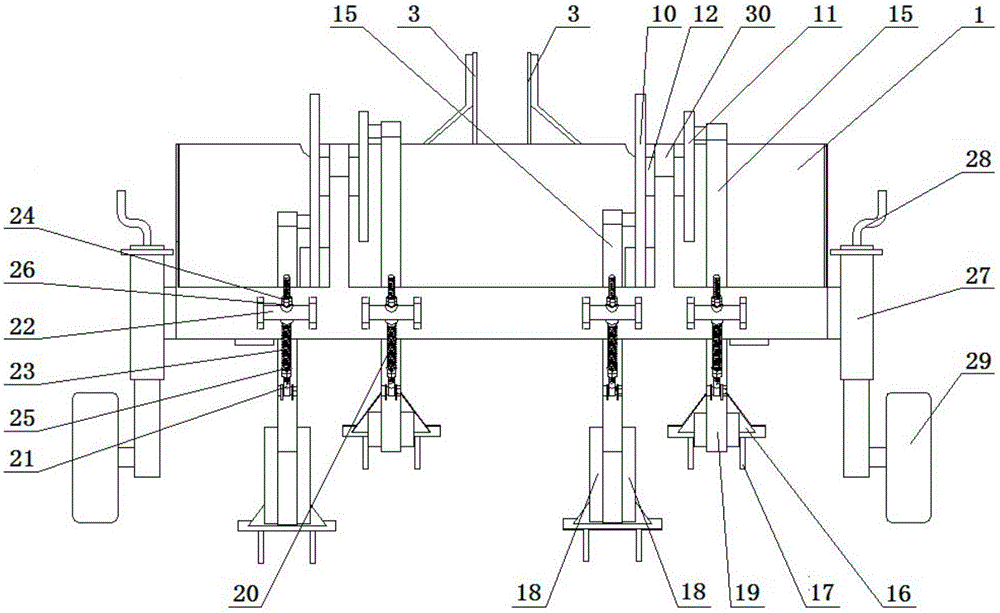

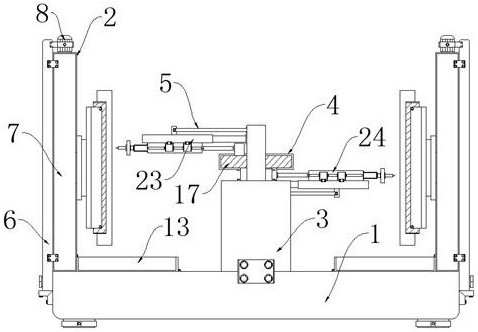

Traction type hole depth adjustable punching machine

ActiveCN105075442BRealize continuous punchingImprove job stabilitySoil lifting machinesDepth limitPower transmission

A pull-type hole-depth-adjustable perforating machine comprises a rack (1), a power transmission device, perforating devices, a returning device and depth limiting wheels (27), wherein the rack (1) comprises a rack main beam (2), two upper hanging frames (3) and two lower hanging frames (4); the power transmission device comprises a gearbox (5) and a belt transmission mechanism, and the perforating devices are distributed symmetrically and respectively connected to the belt transmission mechanism; the returning device comprises a supporting arm (19), a returning connection rod (18) and a spring rod (20); and the two depth limiting wheels (27) are distributed symmetrically and respectively firmly connected on two sides of the rack main beam (2) and comprise rocker arms (28) and wheels (29).

Owner:CHINA AGRI UNIV

Pull-type hole-depth-adjustable perforating machine

A pull-type hole-depth-adjustable perforating machine comprises a rack (1), a power transmission device, perforating devices, a returning device and depth limiting wheels (27), wherein the rack (1) comprises a rack main beam (2), two upper hanging frames (3) and two lower hanging frames (4); the power transmission device comprises a gearbox (5) and a belt transmission mechanism, and the perforating devices are distributed symmetrically and respectively connected to the belt transmission mechanism; the returning device comprises a supporting arm (19), a returning connection rod (18) and a spring rod (20); and the two depth limiting wheels (27) are distributed symmetrically and respectively firmly connected on two sides of the rack main beam (2) and comprise rocker arms (28) and wheels (29).

Owner:CHINA AGRI UNIV

Punching equipment for continuous production of disc brushes

ActiveCN113400406ARealize continuous punchingImprove drilling efficiencyCleaning using toolsMetal working apparatusPunchingEngineering

The invention relates to the field of disc brush production, in particular to punching equipment for the continuous production of disc brushes. The punching equipment comprises a workbench, wherein a through groove is formed in the top end of the workbench; a conveying mechanism is mounted in the through groove; a hydraulic rod I is arranged above the middle of the top end of the workbench; a moving plate is fixed at the telescopic end of the hydraulic rod I; a drilling mechanism used for punching holes in the disc brushes is arranged on the moving plate; a cleaning mechanism used for cleaning the disc brushes is arranged at the end, in the conveying direction of the conveying mechanism, of the moving plate; a groove is formed in the position, corresponding to the lower part of the conveying mechanism, of the middle of the workbench; and a clamping mechanism is arranged in the groove. Through the addition of the conveying mechanism, the drilling mechanism, the clamping mechanism and the like, the disc brushes are conveyed by the conveying mechanism to the position below the drilling mechanism, the clamping mechanism is controlled to clamp the disc brushes, and the drilling mechanism is controlled to punch the holes in the disc brushes; then, the clamping mechanism is divorced from the disc brushes, and the punched disc brushes are driven by the conveying mechanism and conveyed to the cleaning mechanism; and consequently, the continuous punching in the disc brushes is achieved and the punching efficiency is relatively high.

Owner:安徽环美刷业股份有限公司

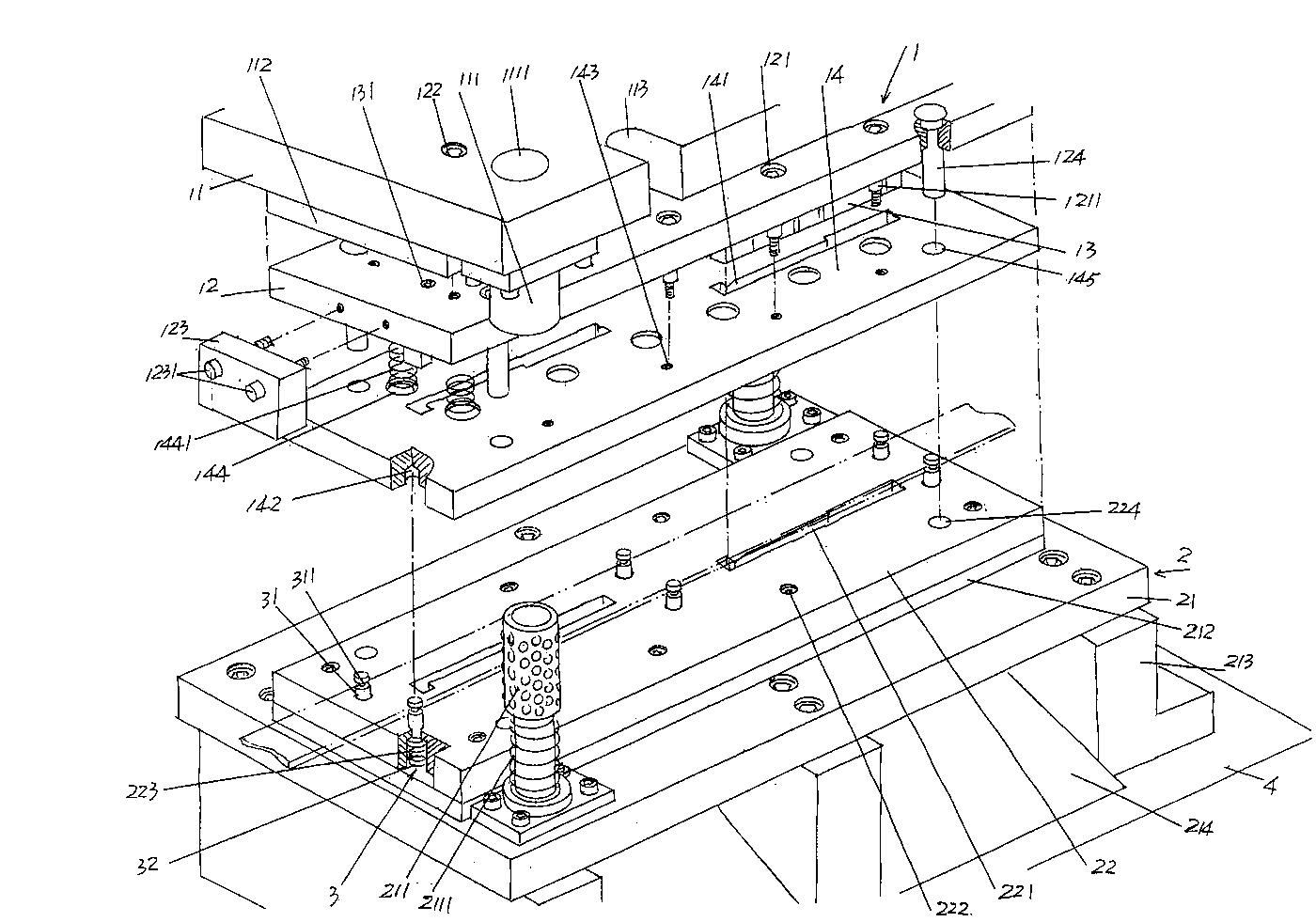

Die for forming needle bed insert blank

InactiveCN102699197AImprove efficiencyGuarantee stamping qualityShaping toolsStampingStructural engineering

The invention discloses a die for forming a needle bed insert blank and belongs to the technical field of dies. The die comprises an upper die mechanism and a lower die mechanism, wherein the upper die mechanism comprises an upper die plate frame, an upper die plate and insert male stamping dies; and the lower die mechanism comprises a lower die plate frame and a lower die plate. The die is characterized in that the upper die mechanism also comprises a pressing plate; the pressing plate is connected with one side of the upper die plate; die guiding holes matched with the insert male stamping dies are formed in the pressing plate opposite to the insert male stamping die; a group of thin steel strip guiding and limiting mechanisms for guiding and limiting thin steel strips are arranged on one side, which faces the pressing plate, of the lower die plate and on two sides of the lower die plate, which correspond to the cutting edge die cavities, in the length direction at intervals in a floating mode; and the thin steel strip guiding and limiting mechanisms are matched with the pressing plate. The die has the advantages that continuous stamping can be realized, so that the efficiency is improved, and the industrial expanded production requirement is met; the thin steel strips cannot deviate or cannot be unwarped, so that the stamping quality can be guaranteed; and the unqualified products cannot be manufactured, so that materials are saved, and the cost is reduced.

Owner:常熟市尚湖镇冶塘伟东模具厂

Ferrite sheet blanking die

InactiveCN110027042ARealize continuous punchingNo waste requiredMetal working apparatusEngineeringWork in process

The invention provides a ferrite sheet blanking die comprises a die set, an upper die assembly and a lower die assembly, wherein the die set comprises an upper die set and a lower die set, and the upper die set and the lower die set are connected through guide pillars; the upper die assembly is installed below the upper die set, and an upper waste discharging space is formed between the upper dieassembly and the upper die set; the lower die assembly is installed above the lower die set and provided with a lower waste discharging space between the lower die assembly and the lower die set; andthe upper die assembly has a downward movement blanking action with relative to the lower die assembly. According to the ferrite sheet blanking die,the blanking mode of blanking an annular semi-finished product inside the whole material of a long strip sheet is improved, the waste discharging space is adopted to eliminate the internal waste, and a flat material discharging plate is adopted to ensure that the annular semi-finished product can be embedded into the long strip-shaped integral waste after being blanked, continuous blanking is realized without taking materials and discharging waste,and the blanking efficiency is greatly improved.

Owner:TDG HLDG CO LTD

A special automatic punching machine for the production and processing of finished artificial leather

InactiveCN108858430BRealize continuous operationWith continuous operationMetal working apparatusPunchingPulp and paper industry

The invention relates to a special automatic perforating machine for finished product artificial leather production and processing. The special automatic perforating machine for finished product artificial leather production and processing comprises a bottom plate, a material placing device, a perforating device and a waste collecting device. The perforating device is mounted in the middle of thebottom plate, the waste collecting device is arranged on the outer side of the perforating device, the material placing device is arranged on the outer side of the waste collecting device, and the waste collecting device and the material placing device are mounted on the bottom plate. The material placing device comprises a mounting rack, an active material placing roller, an auxiliary material placing roller, a connecting rack and a rotating motor. The perforating device comprises a supporting rack, a power mechanism and a perforating mechanism. The waste collecting device comprises a collecting box, a supporting plate, a working plate, a rotating motor, a rotating disc, a rotating column, a rotating rack, a moving column, a moving plate and a swinging rack. The special automatic perforating machine for finished product artificial leather production and processing provided by the invention can solve the problems that in the leather perforating process, the continuity is poor, the working efficiency is low and the stability is poor and wastes need to be collected manually and the like, and can achieve the function of perforating the leather automatically.

Owner:绍兴缤众进出口有限公司

punching device

ActiveCN107186040BPrecise processingImprove processing efficiencyMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates a blanking device. The blanking device comprises a rack, a blanking mechanism, a feeding mechanism, a driving mechanism and a transmission mechanism, wherein the rack is provided with a support platform for supporting a material strap; the blanking mechanism is movably arranged on the rack, can ascend and descend relative to the rack and blanks and bends materials on the material strap on the support platform when descending; the feeding mechanism is arranged on the rack and linked with the blanking mechanism; and the driving mechanism is arranged on the tack, the transmission mechanism is connected between the driving mechanism and the blanking mechanism, the driving mechanism drives the blanking mechanism to ascend and descend through the transmission mechanism, and the feeding mechanism is driven to clamp and drive the material strap to move forwards when the blanking mechanism ascends, so that the blanking mechanism can continually blank and bend the materials on the material strap. According to the blanking device, the blanking mechanism and the feeding mechanism are linked and share the same power source, and the blanking device is accurate in processing and high in processing efficiency.

Owner:GUANGDONG EVERWIN PRECISION TECH

Punching equipment for processing control equipment

InactiveCN114101467ARealize continuous punchingRealize continuous cycle punching workMetal working apparatusWood punching outPunchingControl engineering

The punching equipment for control equipment machining comprises a workbench, two lifting assemblies, a center table, a transmission assembly and two punching assemblies, the lifting assemblies are symmetrically installed on the two sides of the upper surface of the workbench in a locked mode, the center table is installed at the center of the upper surface of the workbench in a locked mode, and the transmission assembly is installed at the top of the center table. The punching assemblies are symmetrically installed on the two sides of the center table and connected with the upper surface and the lower surface of the transmission assembly, and the output ends of the punching assemblies face the lifting assembly. The two sets of control equipment elements are symmetrically installed on the two sides of the workbench, the transmission assembly is installed in the center of the two sets of control equipment elements, the transmission assembly serves as a power source, the punching assembly is driven to conduct corresponding circulating reciprocating extension to achieve punching treatment on the control equipment elements on the two sides, the overall punching efficiency is improved, and meanwhile under cooperation of the lifting assembly, the punching efficiency is improved. In the punching process, control equipment elements are driven to move and feed, continuous punching is achieved, and operation and use of workers are facilitated.

Owner:徐州安荣机械制造有限公司

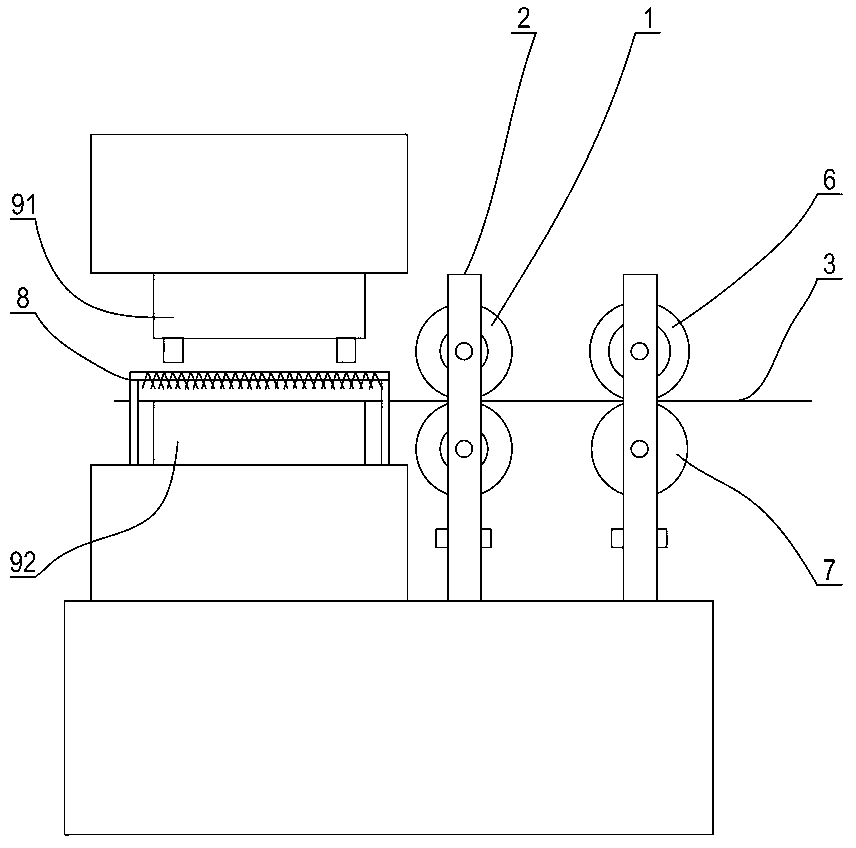

Device and method for adjusting roller type punching distance

ActiveCN107855404AGood cross section qualityReduce manufacturing costMetal-working feeding devicesMetal working apparatusPunchingEngineering

The invention discloses a device for adjusting the roller type punching distance. The device comprises two guide press rollers in up-and-down compression joint, two punching press rollers in up-and-down compression joint and two correction press rollers in up-and-down compression joint. A plate sequentially penetrates the guide press rollers, the punching press rollers and the correction press rollers. Pressing rollers are arranged on the two sides of the punching press rollers correspondingly. A speed measurement roller is arranged between the punching press rollers and the correction press rollers. Convex molds are evenly arranged on the surface of the punching press roller located on the upper portion. Concave molds in one-to-one correspondence to the convex molds are arranged on the surface of the punching press roller located on the lower portion. Cutting strips are arranged at the tops of the convex molds. Rubber outer edges are fixed to the outer sides of the cutting strips. Thecutting strips and the rubber outer edges are attached to the inner side walls of the concave molds in a sliding manner. Rubber flanges are arranged at the tops of the concave molds. A groove is formed in the top of each rubber flange. Multiple annular rubber pieces are arranged on the inner wall of each groove. According to the device, the defects in the prior art can be overcome, and the punching position accuracy is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com