Film continuous punching tool and its punching process

A technology of film and tooling, which is applied in the field of film continuous punching tooling and its punching technology, can solve the problems of manual punching troubles, etc., and achieve the effect of improving punching efficiency and facilitating transmission and winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

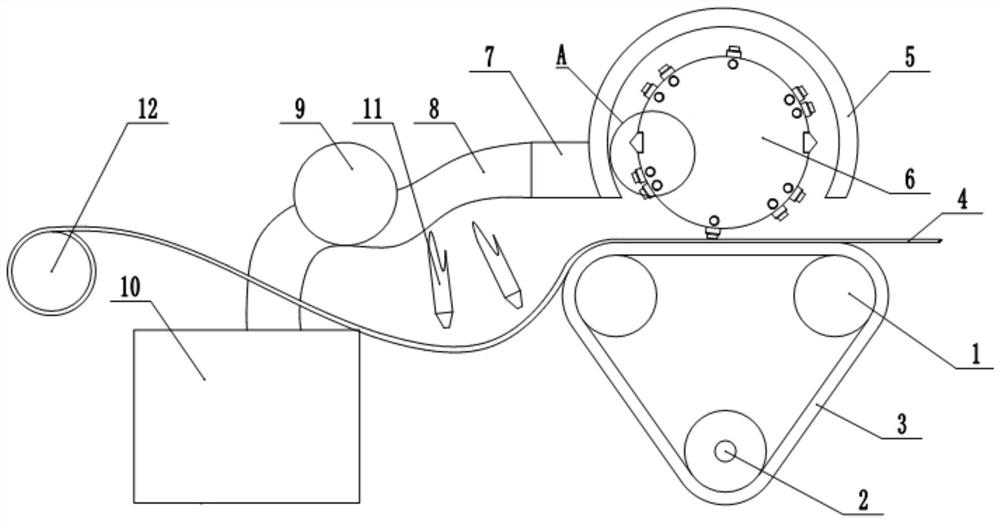

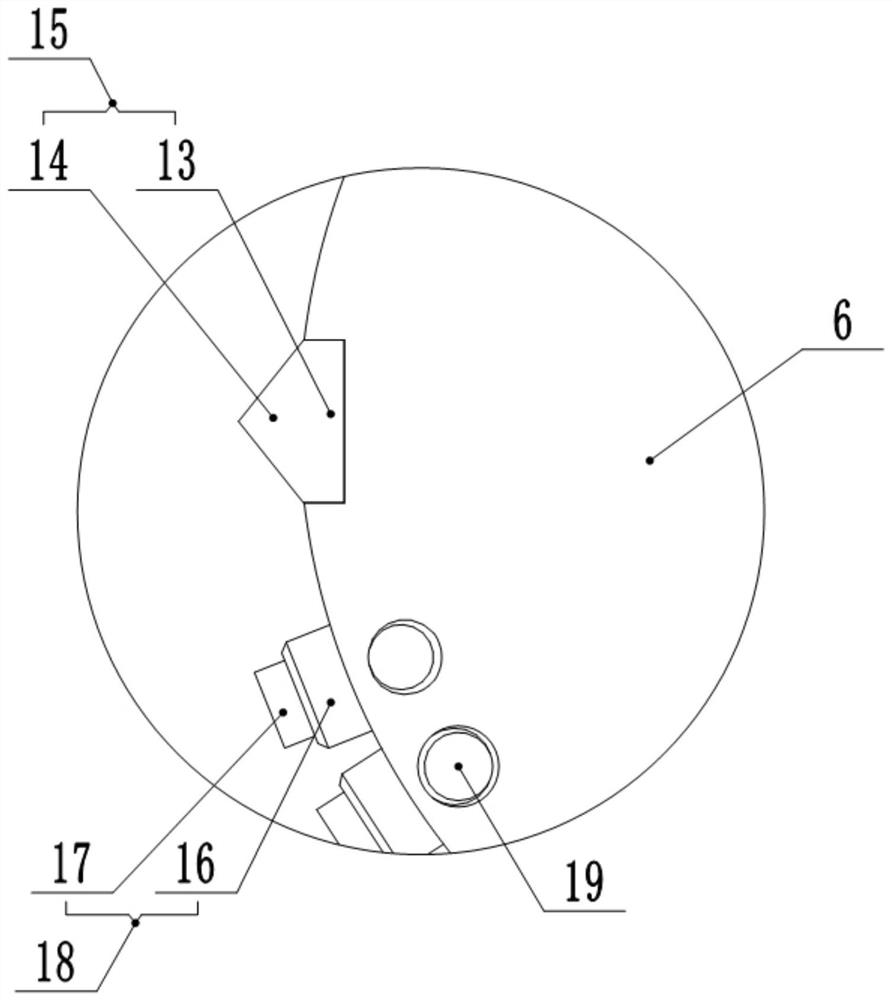

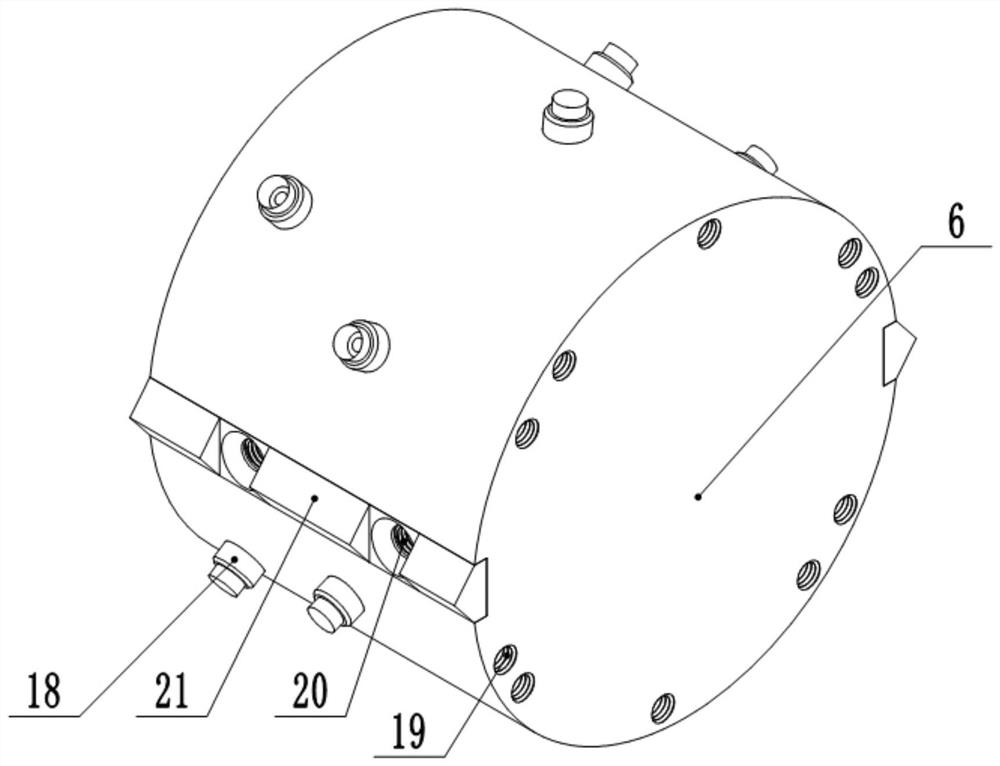

[0017] Such as figure 1 As shown, the film continuous punching tool includes a frame, and the frame is provided with a transmission mechanism, a punching mechanism, a dust removal mechanism and a cooling mechanism. The transmission mechanism includes three transmission wheels 1 that are rotatably connected to the frame. The wheels 1 are distributed in a triangle. Specifically, the three transmission wheels 1 are distributed in an inverted isosceles triangle. The outer sides of the three transmission wheels 1 are provided with a conveyor belt 3. A motor A for driving one of the transmission wheels 1 to rotate is fixed on the frame. , the output shaft of the motor A is fixed to the transmission wheel 1, and the transmission wheel 1 drives the other two transmission wheels 1 to move through the transmission belt 3 to realize the transmission of the transmission belt 3. During actual use, in order to ensure transmission stability, the transmission wheel 1 can be selected for use w...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is that, in combination with Figure 4 As shown, the dust suction fan 9, the cooling fan and the collection box 10 are not provided. Specifically, the drum 6 is coaxially fixed with a cam 22, and two piston barrels 27 are symmetrically fixed above and below the cam 22 on the frame. The barrel 27 is vertically slidably connected with a piston 24, the piston 24 is fixed with a piston rod 23, and one end of the piston rod 23 stretches out from the piston barrel 27 and is slidably connected with the outer wall of the cam 22, and the cam 22 and the piston rod 23 form a cam mechanism. 22 rotations drive the piston rod 23 to slide vertically. The sealing end of the piston barrel 27 is provided with an air inlet 28 and an air outlet 29, the air inlet 28 communicates with the dust suction pipe 8, the air outlet 29 communicates with the blowing pipe 11, and the air inlet 28 is equipped with a gas unidirectionally entering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com