A continuous molding device for filter center pipe

A molding device and center tube technology, applied in the field of air filters, can solve the problems of low production efficiency of intermittent processing, difficulty in meeting modern processing, waste of manpower and material resources, etc., to improve processing quality, compact structure, and prevent surface localization deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

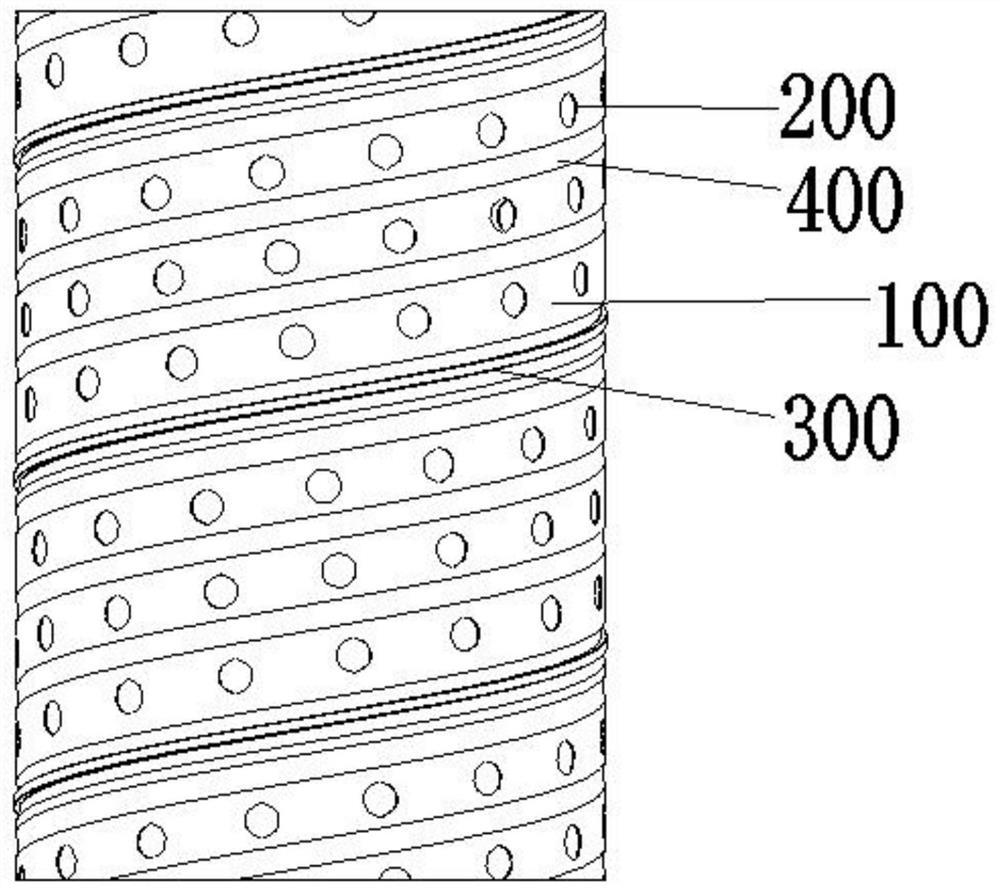

[0035] Embodiment: A continuous molding device for a central pipe of a filter.

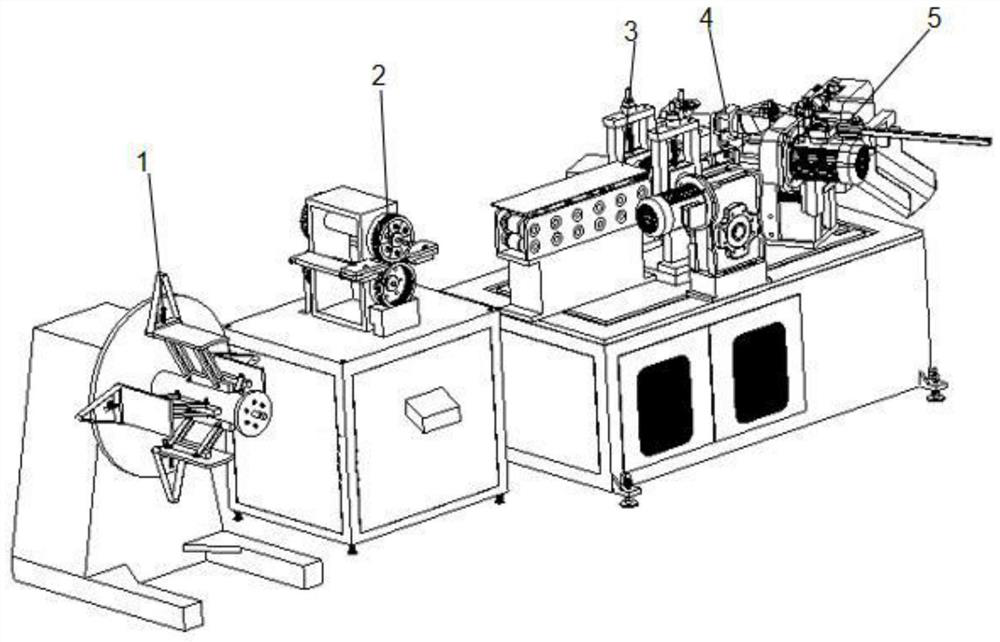

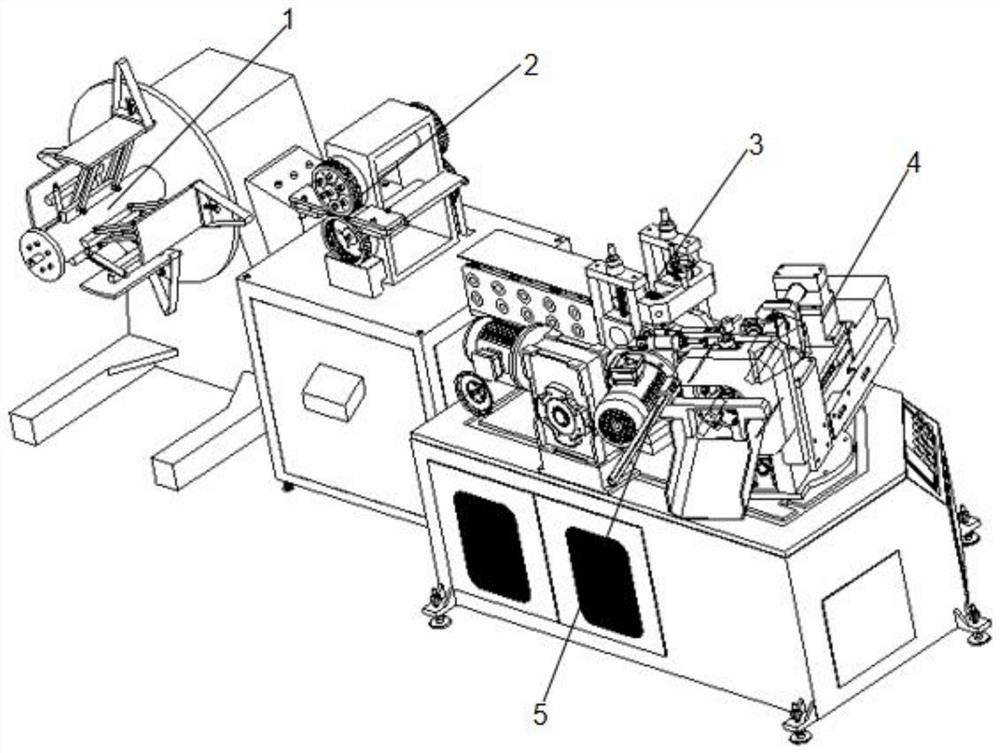

[0036] refer to Figure 1 to Figure 14 As shown, a continuous molding device for filter center pipe, including:

[0037] Unwinding device 1, described unwinding device 1 comprises unwinding frame 11, and unwinding shaft 13 is installed on the described unwinding frame 11, and rotating disk 12 is fixed on the afterbody of unwinding shaft 13, and is installed on described unwinding shaft 13 There are four fixed installation blocks 14 that are distributed in a circular array around the center of the unwinding shaft 13, each fixed installation block 14 is correspondingly equipped with a support 15, the top of the support 15 is equipped with a support plate 16, and the tail of the support plate 16 is equipped with End block 17, the front end of unwinding shaft 13 is equipped with a front sealing plate 18; in the actual work process, the metal strip roll is placed on the support plate 16 and positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com