An aluminum-based electronic packaging material and a processing method thereof

An electronic packaging material, aluminum-based composite technology, used in circuits, electrical components, electrical solid devices and other directions, can solve the problems of long production process, long cycle, high cost, improve thermal conductivity, continuous production process, high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

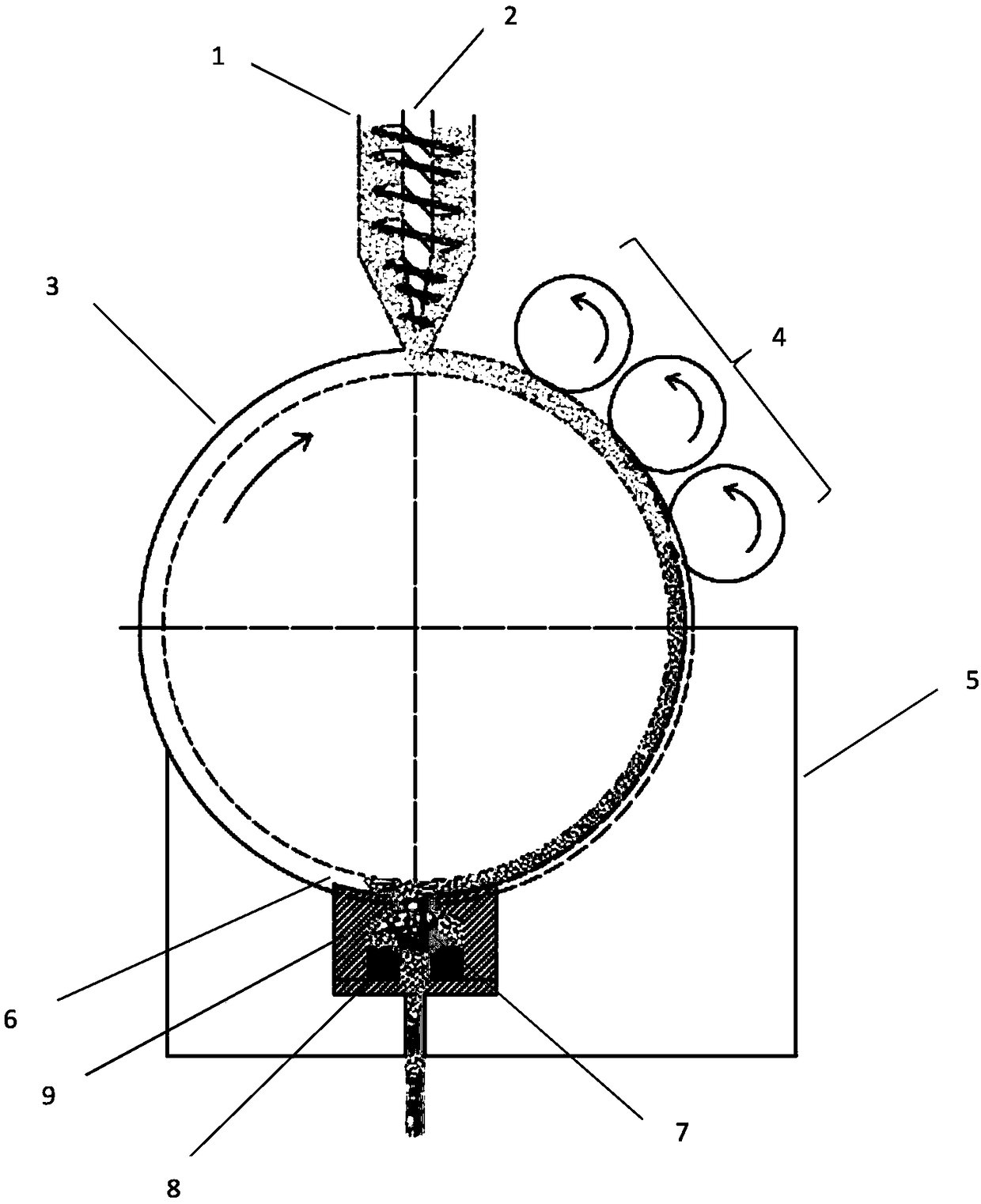

Embodiment 1

[0048] A high thermal conductivity aluminum-based electronic packaging material is prepared, the composition of which is Al: 40.98wt%, graphene: 0.01wt%, carbon nanotube: 0.01wt%, diamond: 1wt%, Si: 58wt%. Raw materials include aluminum powder, graphene powder, carbon nanotube powder, diamond powder and silicon powder. The screw mixer is used for mixing for 30 minutes, and the screw pusher pushes the mixed powder into the groove on the surface of the large roller at a speed of 300g / min. , the large roller and the planetary roller rotate in reverse, and at a line speed of 200mm / min, an aluminum-based electronic packaging composite rod with a diameter of 8mm is extruded. In order to further improve the compactness of the rod, the obtained 8mm rod was again introduced into the mold by the large roller and the planetary roller, and subjected to secondary extrusion to obtain an aluminum matrix composite material plate with a thickness of 2mm and a width of 20mm.

Embodiment 2

[0050] An aluminum-based electronic packaging material with a low thermal expansion coefficient is prepared, the composition of which is Al: 30wt%, graphene: 15wt%, carbon nanotube: 15wt%, Si: 20wt%, SiC: 20wt%. Raw materials include aluminum powder, graphene powder, carbon nanotube powder, silicon powder and silicon carbide powder. The V-shaped machine is used to mix the materials for 40 minutes. Grooves on the surface of the large roller, the large roller and the planetary roller rotate in opposite directions, and at a line speed of 500mm / min, an aluminum-based electronic packaging composite rod with a diameter of 8mm is first extruded. In order to further improve the density of the rod, the obtained The 8mm rod material is introduced into the mold again by the extrusion wheel and the compaction wheel, and the second extrusion is carried out to obtain an aluminum-based composite material rod with a diameter of 8mm. The rod is extruded three times, and the rod with a diameter of...

Embodiment 3

[0052] A high thermal conductivity aluminum-based electronic packaging material is prepared, the composition of which is Al: 80wt%, graphene: 3wt%, carbon nanotube: 2wt%, tungsten: 10wt%, molybdenum: 5wt%. Raw materials include aluminum powder, graphene powder, carbon nanotube powder, tungsten powder and molybdenum powder. The ball mill is used to mix the materials for 60 minutes. The screw pusher pushes the mixed powder into the surface groove of the large roll at a speed of 200g / min. Rotate in reverse with the planetary roll, and extrude an aluminum-based electronic packaging rod with a diameter of 8mm at a line speed of 600mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com