Automatic feeding and discharging punching die for automobile parts

A technology for auto parts, feeding and discharging materials, applied in the direction of piercing tools, feeding devices, manufacturing tools, etc., can solve the problems of high energy consumption, high cost of transportation equipment, low efficiency of successive punching of fixed molds, etc., and increase production efficiency , Increase reliability, accurate and timely automatic feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

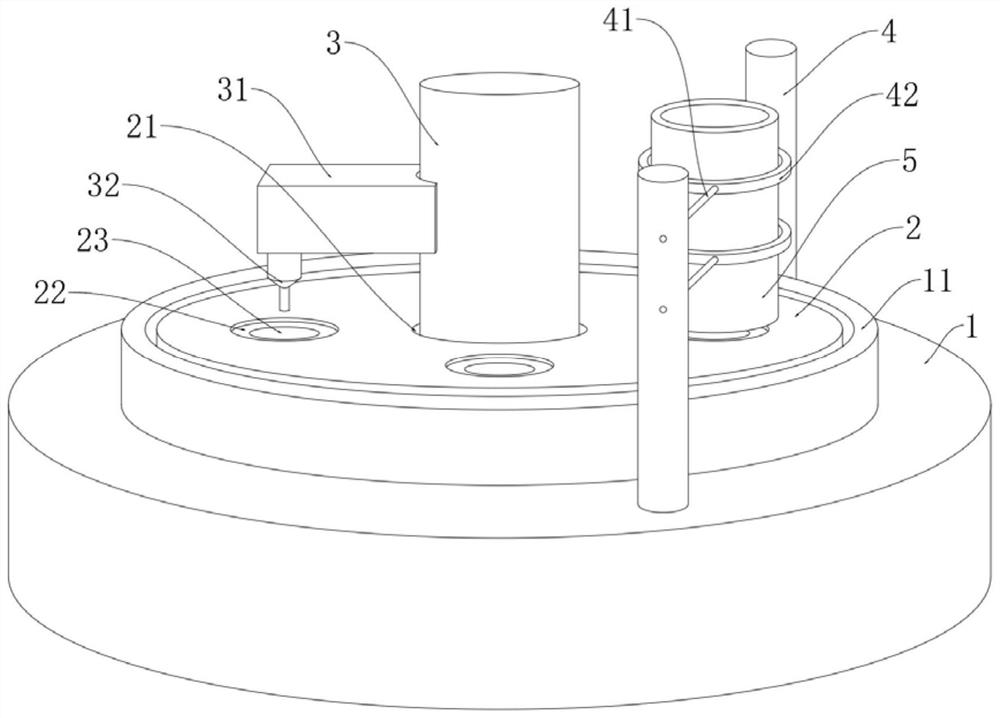

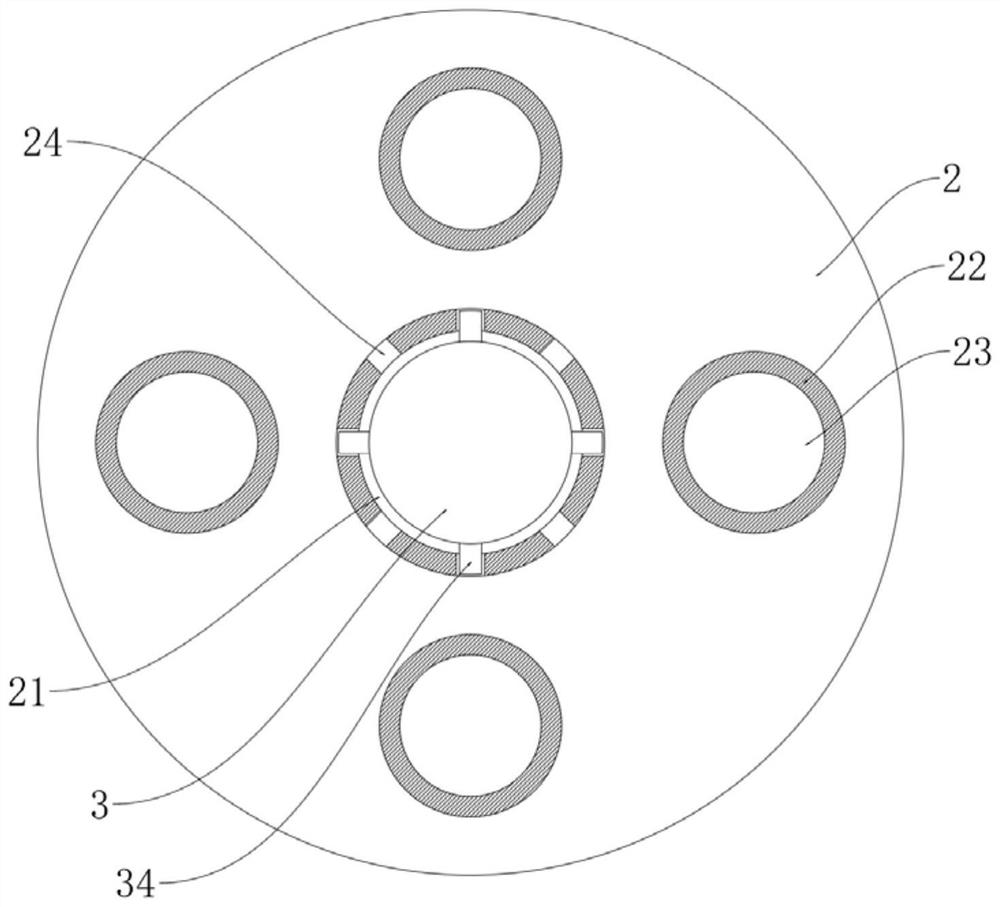

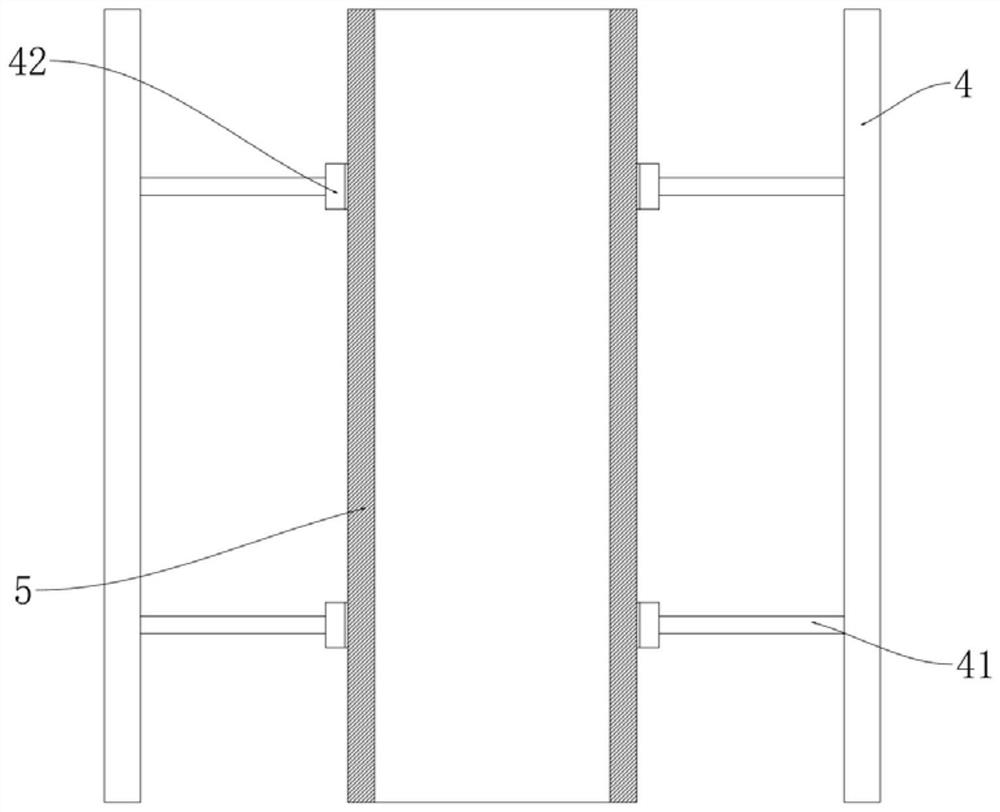

[0026] refer to Figure 1-6 , a kind of punching die for automatic feeding and discharging of auto parts, including a base 1, a support ring 11 is installed on the upper surface of the base 1, a die disc 2 is mounted on the support ring 11, and a plurality of die discs are symmetrically arranged on the upper surface of the die disc 2. The trough 22, the bottom of each trough 22 is provided with a punching hole 23, the center of the die plate 2 is provided with a control hole 21, the center of the base 1 is provided with a control hydraulic chamber 12, and the control hydraulic chamber 12 is slidingly inserted into the hydraulic pressure chamber. Rod 3, the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com