Blanking device of reinforced backflow hollow-square-shaped HY fiber felt in flat heat pipe

A technology of flat heat pipes and fiber mats, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of low manual production efficiency and high labor intensity of workers, and achieve the goal of reducing the number of placements, reducing labor intensity, and facilitating recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

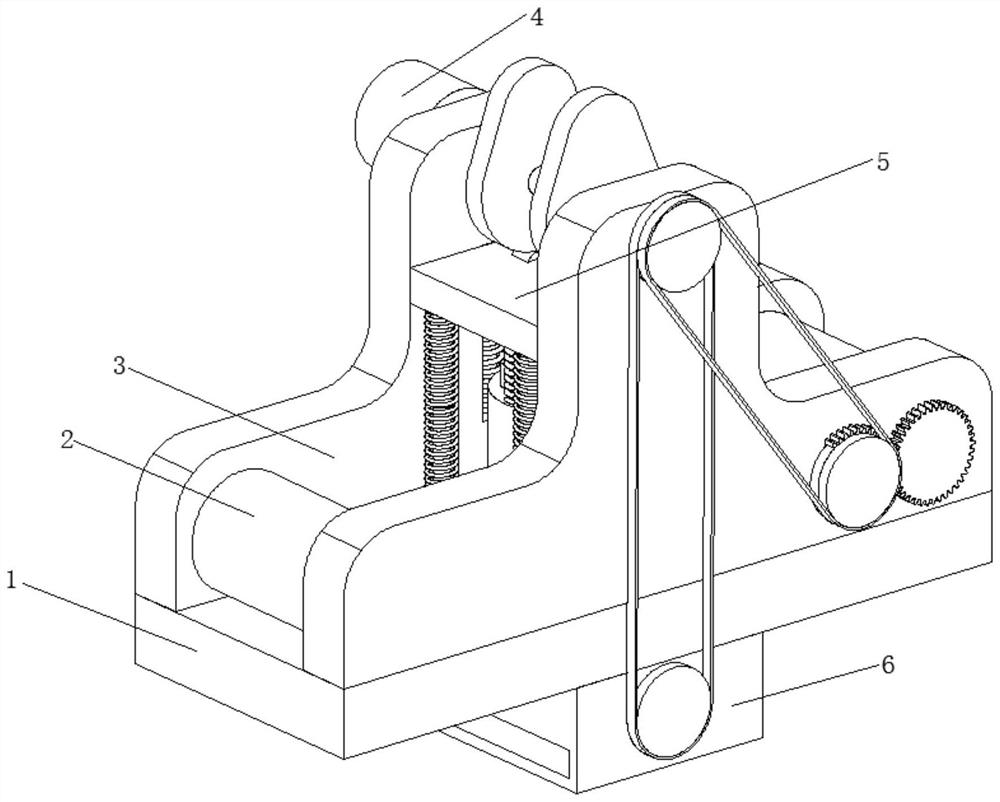

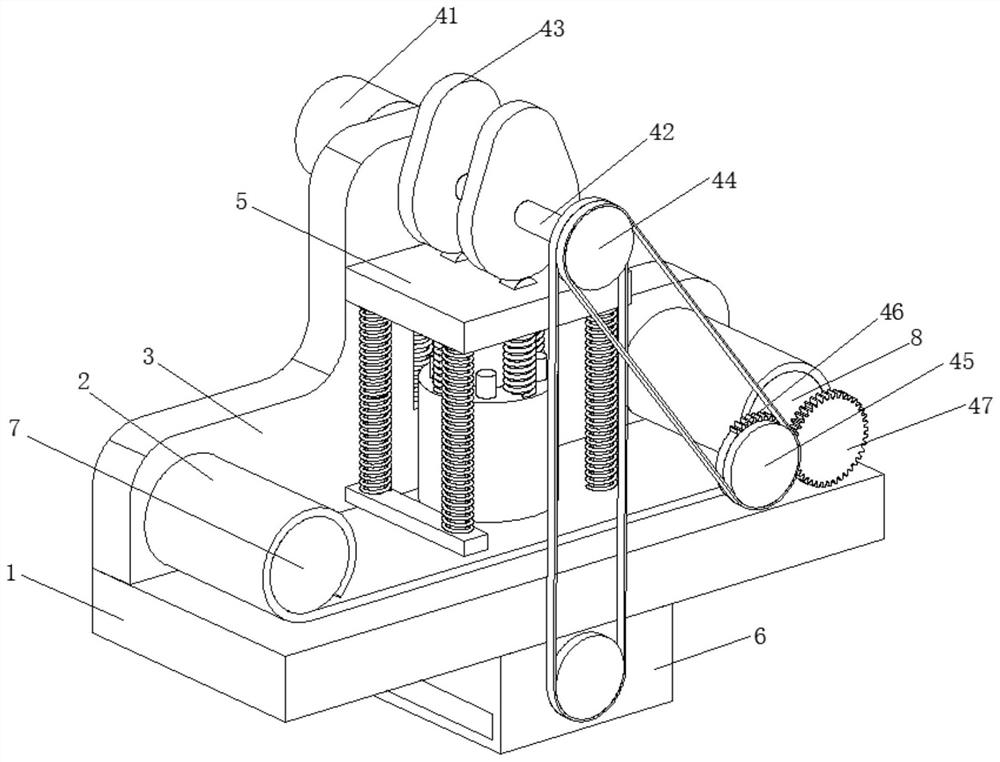

[0031] A kind of HY fiber mat punching device with enhanced reflow in the flat heat pipe, such as Figure 1-Figure 6 As shown, including a workbench 1, two side plates 3 are welded on the top of the workbench 1, a transmission mechanism 4 is arranged on the left side of the side plate 3, a punching mechanism 5 is arranged between the two side plates 3, and the workbench 1 The bottom of the bottom is provided with a collection mechanism 6, and the discharge roller 7 and the winding roller 8 are respectively rotated and connected between the two side plates 3, and the punching mechanism 5 is located between the discharge roller 7 and the winding roller 8, and the discharge roller 7 and the surfaces of the winding roller 8 are movably connected with the fiber felt body 2 .

[0032] In this embodiment, the transmission mechanism 4 includes a motor 41, the output end of the motor 41 is welded with a rotating shaft 42, the surface of the rotating shaft 42 is clamped with two cams 43...

Embodiment 2

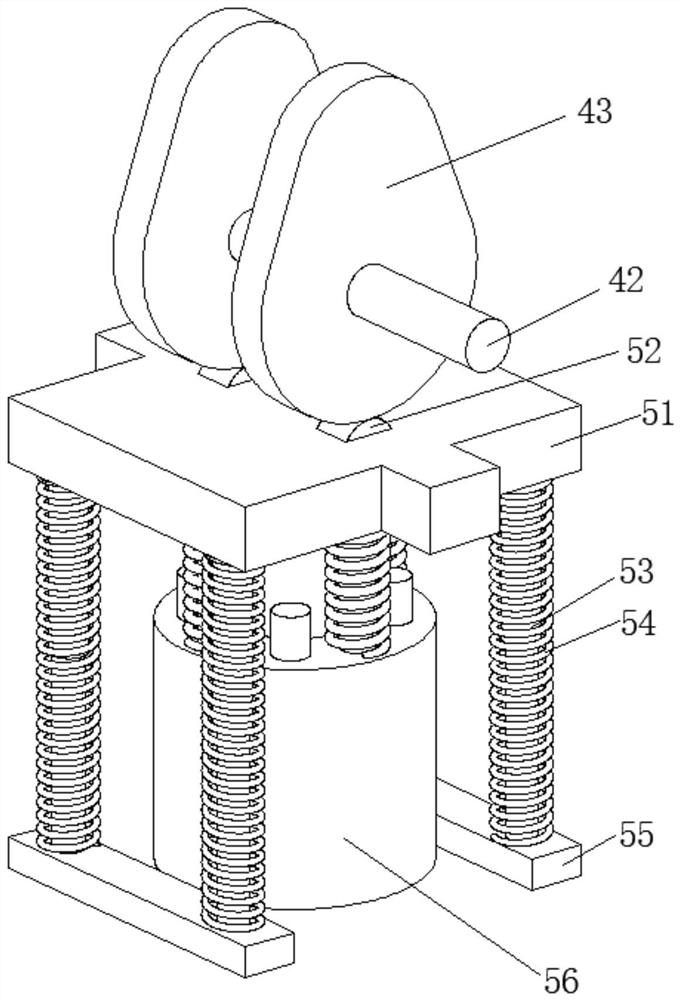

[0043] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the top ends of the inner column 561 and the connecting rod 563 are welded and fixed with the bottom of the fixed plate 51, and the two ends of the No. 4 spring 564 are respectively connected with the bottom of the fixed plate 51 and The tops of the jackets 562 are in contact with each other.

[0044] The outer jacket 562 and the inner column 561 can punch the fiber mat twice successively, which can realize the back shape of the fiber mat after punching, and successive punching can prevent the fiber mat from being cut when they are punched together, resulting in unqualified products There is no need for separate punching of the fiber mat twice, which can reduce the process and thus reduce the cost input.

[0045] It is worth noting that the collection mechanism 6 includes a collection box 61, the inner wall of the collection box 61 is rotatably connected with a connecting shaft 62, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com