Corrugated plate punching device

A stamping device and corrugated plate technology, applied in the field of punches, can solve problems such as unsatisfactory stamping effect, difficulty in setting positioning tools, and inability to guarantee accuracy, etc., to achieve good practical value, improve work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

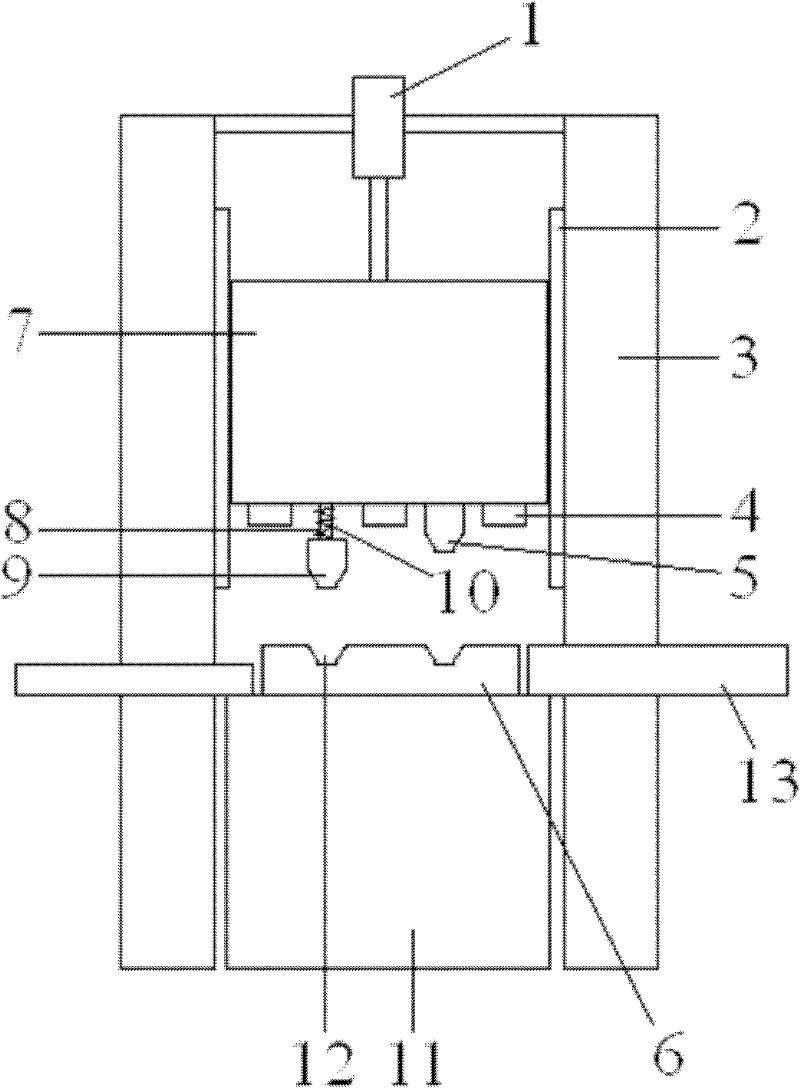

[0012] see figure 1 , a corrugated plate stamping device, including a bracket 3, two parallel vertical guide rails 2 are arranged on the bracket 3, and a slider 7 is installed on the two parallel vertical guide rails 2 through sliding fit, and is located on the two A cylinder 1 is installed on the support above the parallel vertical guide rail 2, and the front end of the piston rod of the cylinder 1 is fixedly connected with the end of the slide block 7; Guide rod 8, the bottom end of guide rod 8 is fixedly welded with left stamping block 9, is covered with spring 10 on the guide rod 8, and the bottom that is positioned at the slide block 7 right side of left stamping block 9 is fixedly installed with right stamping block 5; The bottom of right stamping block 9,5 is provided with workbench 11, and lower mold 6 is fixedly installed on the workbench 11, and lower mold 6 is respectively provided with two die cavities 12, and left and right stamping block 9,5 are positive respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com