Multi-station progressive die for punching of electric appliance contact support and blanking process

A multi-station progressive die and contact technology, applied in the field of stamping die, can solve the problems of reduced production efficiency, low production efficiency, low safety, etc., and achieve the effects of improving production efficiency, shortening production cycle, and improving stamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

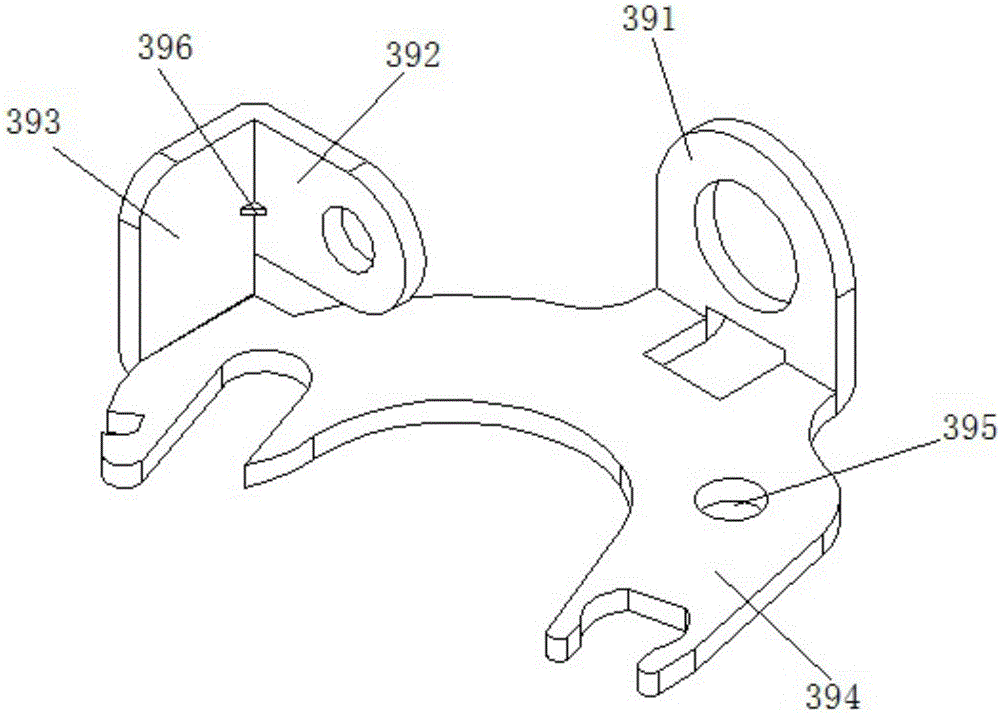

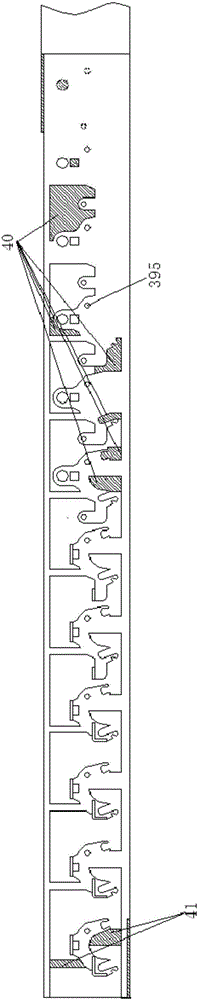

[0035] The electrical contact support of this implementation, such as figure 1 As shown, it includes a curved portion and a non-bent portion 394, the non-bent portion 394 is provided with at least one circular hole, and the curved portion includes a first curved portion 391, a second curved portion 392 and a third curved portion perpendicular to the non-bent portion 394, respectively. part 393, the first curved part 391 is connected to the non-bent part 394, the second curved part 392 is vertically connected to the third curved part 393, and a reinforcing rib 396 is provided between the second curved part 392 and the third curved part 393, and the second curved part 392 is connected to the third curved part 393. The three bent portions 393 are connected to the non-bent portion 394 .

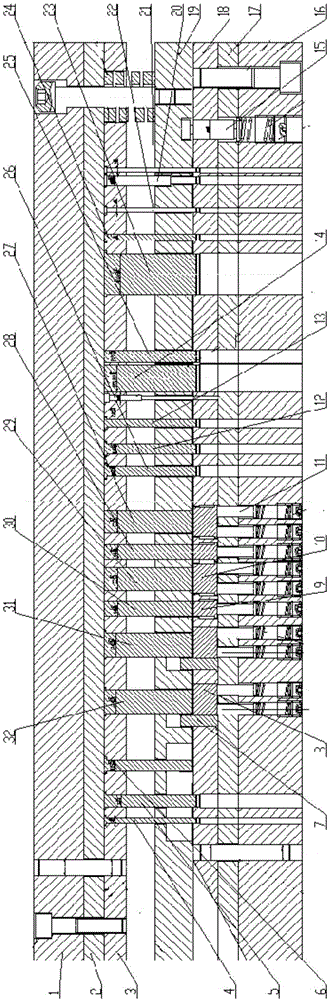

[0036] A multi-station progressive die for stamping an electrical contact support, such as figure 2 As shown, it includes an upper die, a lower die, a working assembly, and a fixed-distance pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com