Shape-keeping fine stamping die for stamped part of refrigerator

A technology for stamping parts and refrigerators, applied in the field of stamping dies, can solve the problems of low stamping efficiency, waste of lubricating oil, time-consuming and labor-intensive, etc., and achieve the effects of reducing wear, reducing waste and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

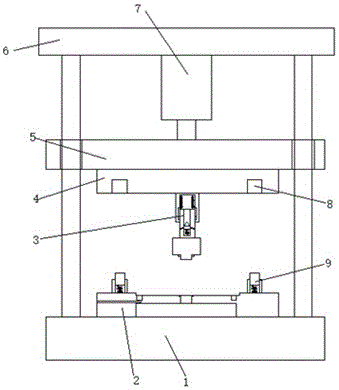

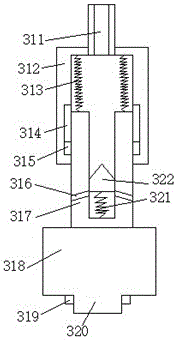

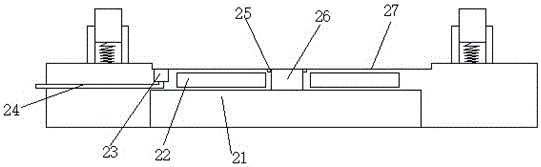

[0019] Embodiment: Place the parts of the refrigerator in the oil storage tank 27 on the lower template 2 and fix them. The punching position is aligned with the punching hole 26, and the hydraulic cylinder 7 is started. The hydraulic cylinder 7 drives the fixed plate 5 and the upper template 4 to move downward, and the upper template 4 moves downward. The template 4 drives the stamping device 3 to move downward, the stamping head 320 contacts the stamping stamping part, drives the second connecting column 317 to move upward in the first groove, the first spring 313 contracts, and pressure is generated in the first groove, driving the third The movable block 322 in the groove 314 moves downward, and the movable block 322 moves to the bottom of the first through hole 316. The lubricating oil in the first groove is sprayed out and falls on the stamping part to lubricate the stamping part and guide it elastically. The column 9 is inserted into the guide hole 8, the stamping head 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com