Flat bending mold of round pipe

A flat and curved technology, applied in the field of stamping dies, can solve the problems of increased production costs and low product precision, and achieve the effects of increased production efficiency, reduced resistance, and easy release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

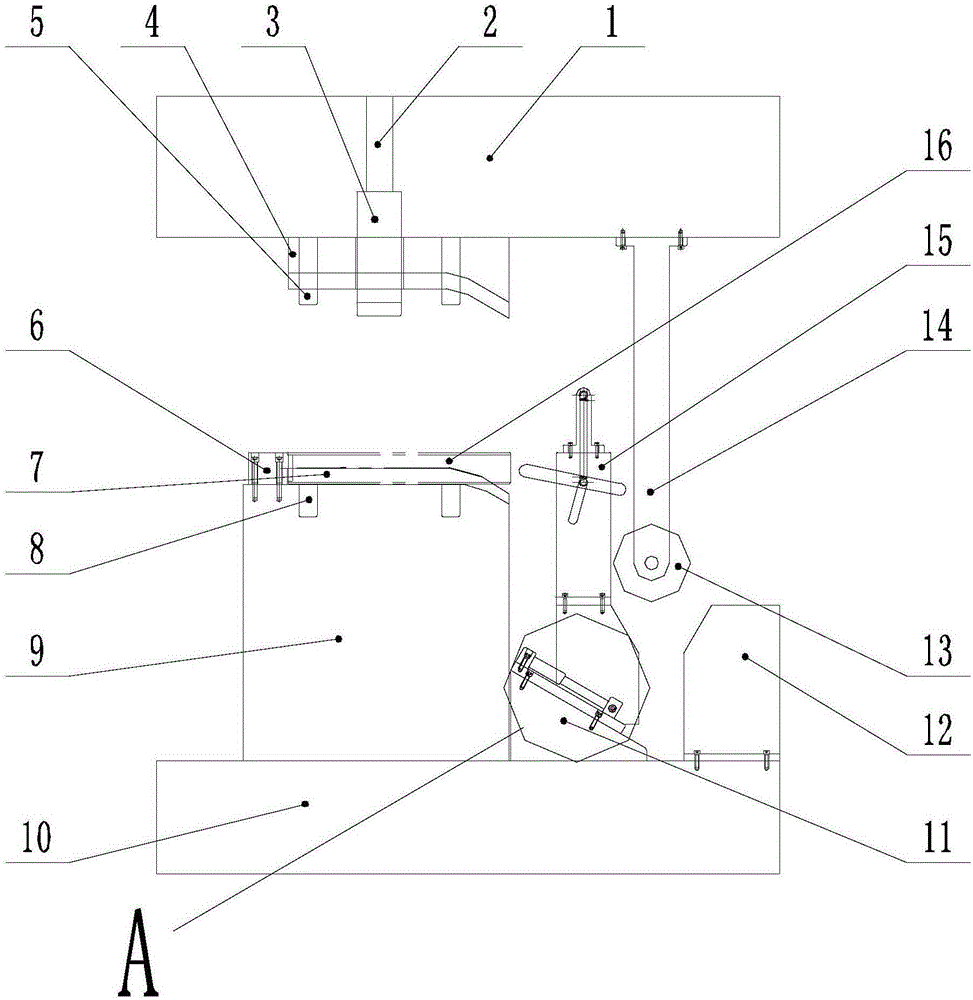

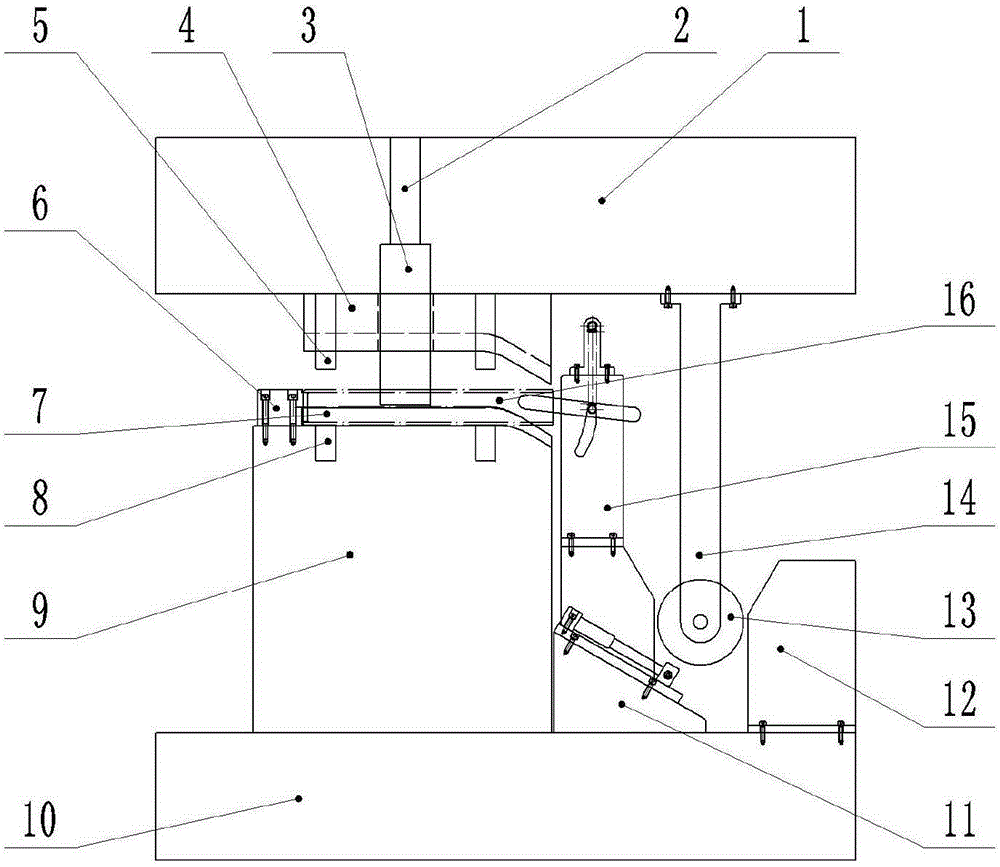

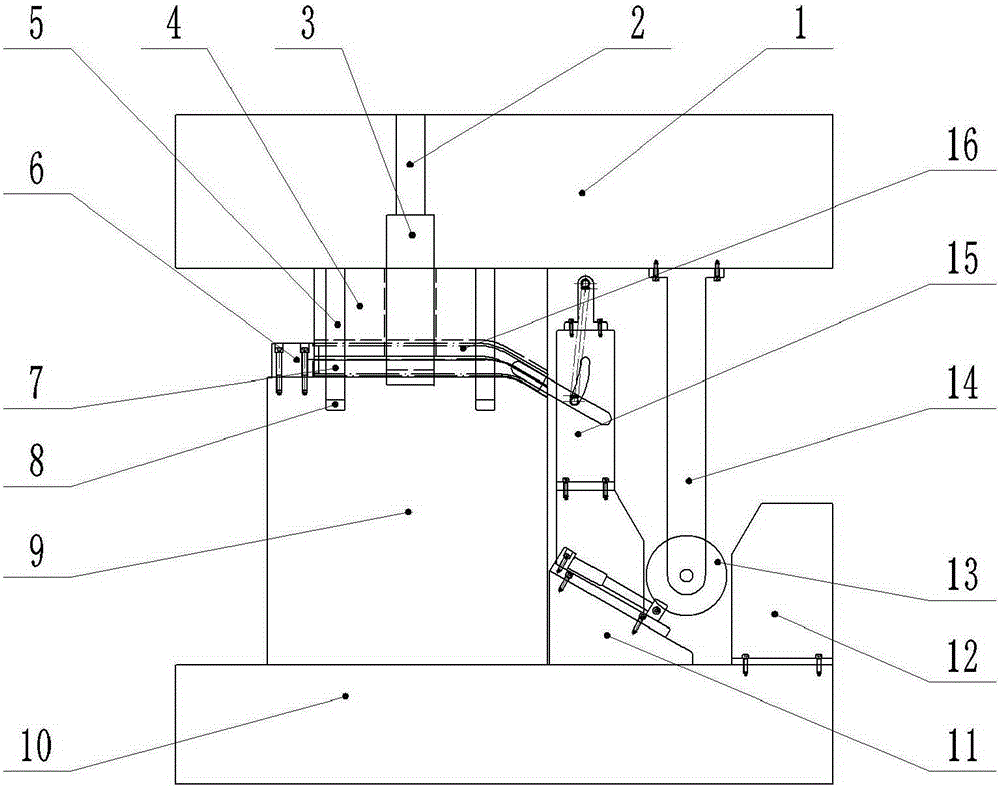

[0030] Such as Figure 1-3 As shown, a round tube flat bending mold according to an embodiment of the present invention includes: an upper mold 4 fixedly mounted on the bottom of the upper mold frame 1 , and a through hole is processed in the middle of the upper mold 4 . Gas spring A2, gas spring A2 is installed in the inside of patrix 1, and the bottom of gas spring A2 installs locating plate 3, and locating plate 3 passes the middle through hole of patrix 4. Positioning block 5, positioning block 5 is installed on both sides of upper mold 4; Lower mold 7, lower mold 7 is installed on the top of lower mold frame 9, corresponds to upper mold 4, and lower mold frame is fixed on the base 10; Rear positioning seat 6 , the rear positioning seat 6 is located at the right rear side of the lower mold 7, and is fixed with the lower mold frame 9 by bolts. Positioning groove 8, positioning groove 8 is positioned at the both sides of lower mold 7, and position corresponds to positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com