Novel suction head variable in spacing and packaging machine using same

A packaging machine, a new type of technology, applied in the field of stamping product packaging, can solve the problems of human factors affecting positioning accuracy, difficulty in continuous large-scale operation, and inability to realize variable-pitch adsorption, etc., achieve accurate and reliable reciprocating motion, and reduce maintenance utilization rate , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

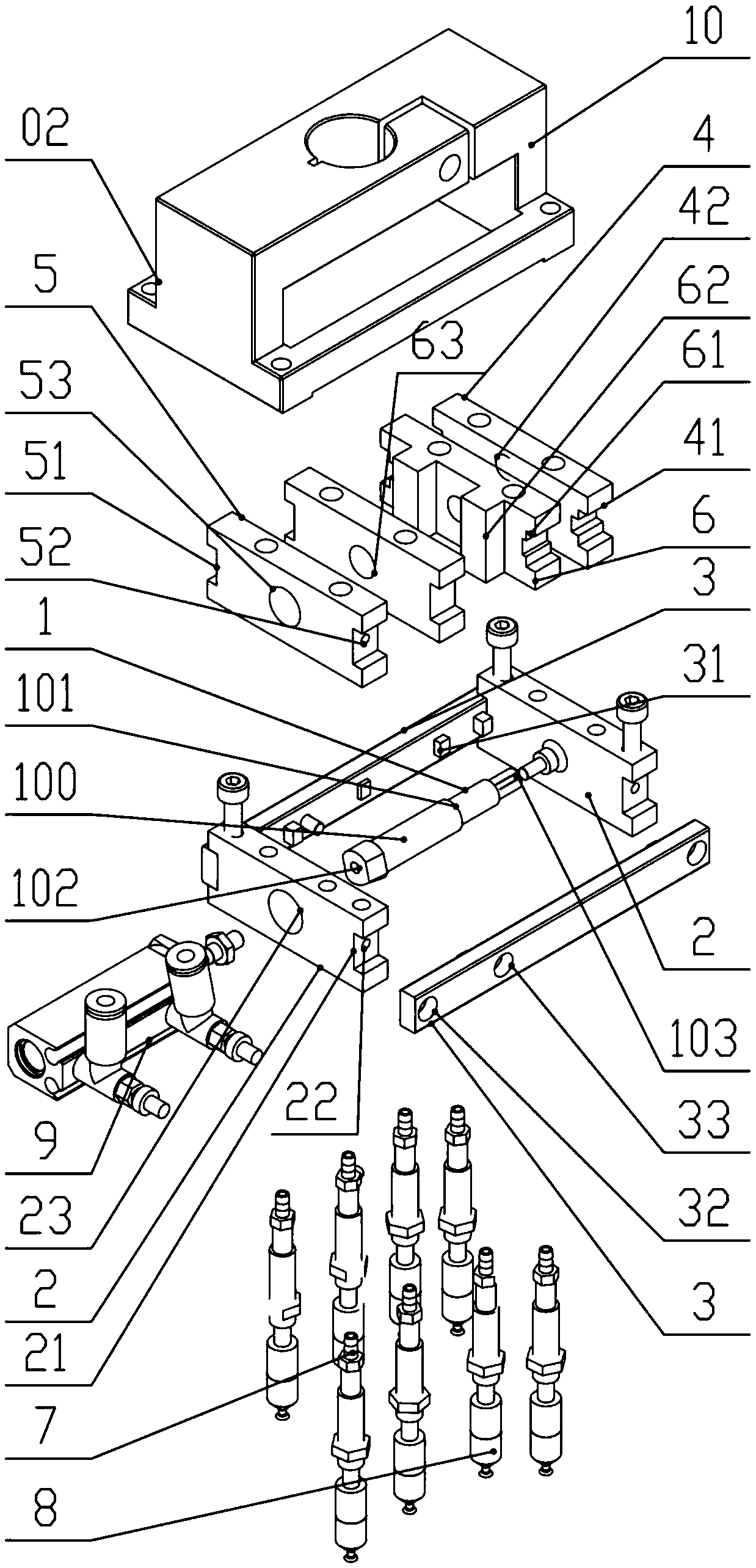

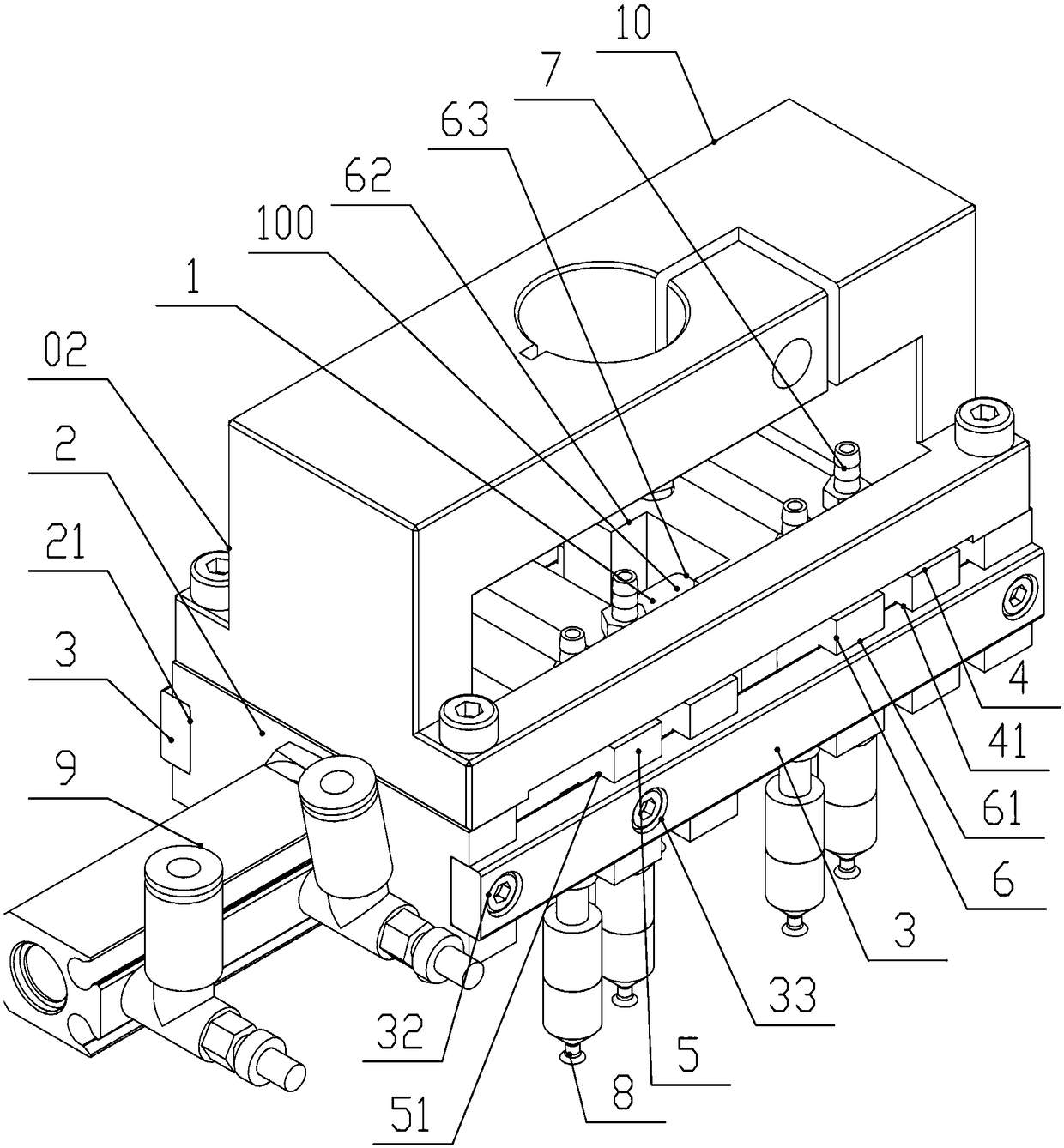

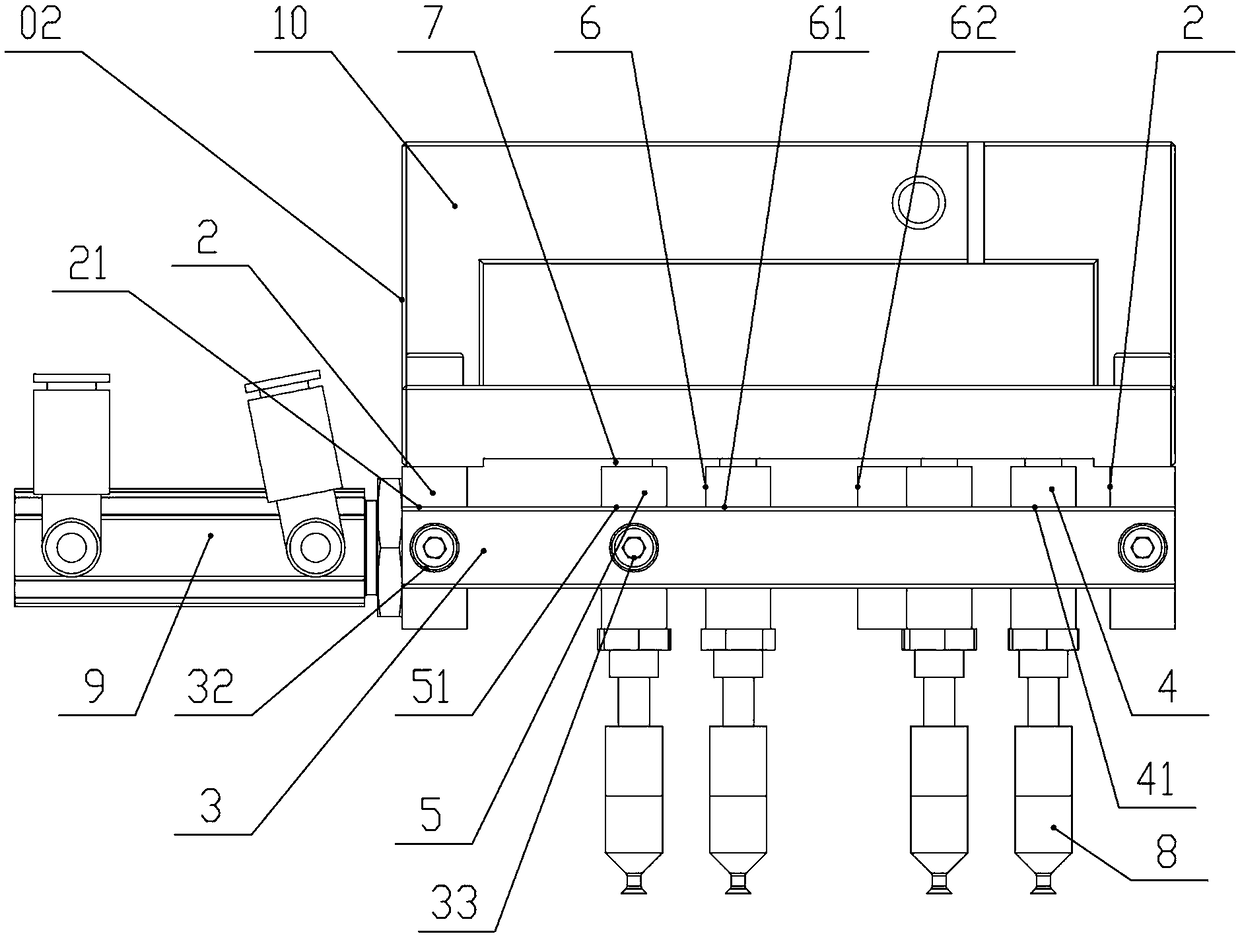

[0049] Figure 1 to Figure 7 A novel variable pitch suction head according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a push rod 1. The push rod 1 is a multi-step shaft. There are several shaft sections 100 on the push rod 1. One end of each shaft section 100 forms a shaft shoulder 101. The front end of the push rod 1 is fixed and slides forward. Block 4, the rear end of the push rod 1 wears the rear slider 5, and each shaft segment 100 wears a middle slider 6,

[0050] The two ends of two parallel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com