Servo motor connecting mode

A technology of servo motors and connection methods, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of reducing the reliability of servo motors and stamping precision, so as to improve reliability and stamping precision, prolong service life and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

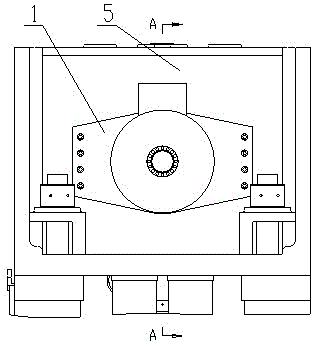

Image

Examples

Embodiment Construction

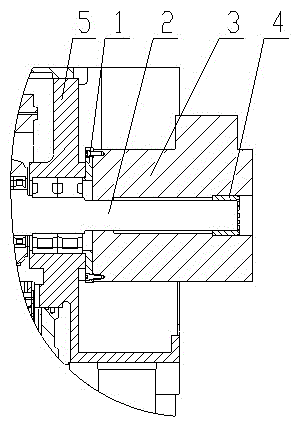

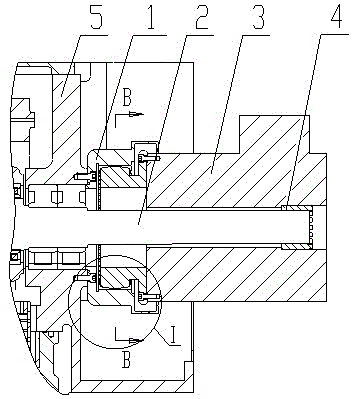

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] Such as image 3 with Figure 4 As shown, the present invention is made up of crankshaft 2, hollow shaft servo motor 3, expansion coupling sleeve 4, upper beam 5, inner gear sleeve seat 7 and external gear motor base 8, and hollow shaft servo motor 3 passes expansion coupling sleeve 4 It is directly fixedly connected with the crankshaft 2, and the outer gear motor base 8 is internally engaged with the inner gear sleeve base 7, and the inner gear sleeve base 7 is fixed on the upper beam 5.

[0015] Such as Figure 5 As shown, in order to enhance the sealing performance between the inner teeth sleeve seat 7 and the upper beam and ensure the stability of the structure, the present invention preferably adds a sealing ring 10 between the two.

[0016] As an improvement of the present invention, the top of the outer tooth of the toothed motor base 8 is made into an elli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com