Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "No crack phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

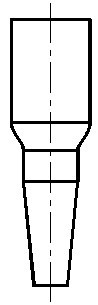

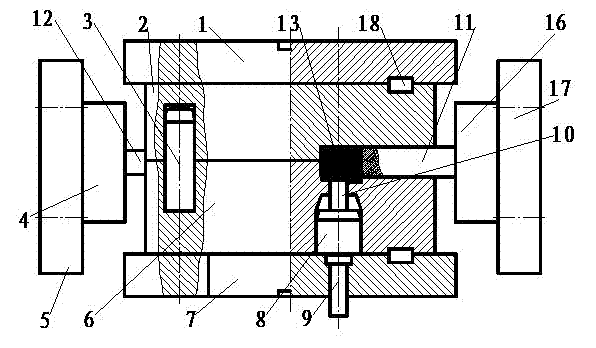

Precision die forging and shaping technical method for automobile steering knuckle rough type parts

InactiveCN102672096ALow forming speedNo crack phenomenonRailway componentsMetal-working apparatusEngineeringMaterial distribution

The invention provides a precision die forging and shaping technical method for automobile steering knuckle rough type parts. The precision die forging and shaping technical method mainly comprises the process steps of blanking, heating, extruding and drawing out a rod part, pre-forging, upsetting, performing material distribution and performing multi-way precision die forging and shaping and is specifically as follows: blanking through a cutting device, and heating to the temperature of 1080 DEG C-1180 DEG C in a medium-frequency induction furnace; placing a round bar which is well heated into a female die of an extruding and drawing-out die to form a stock comprising a cylindrical surface and a steering knuckle rough rod part; placing the stock after upsetting and material distribution into a multi-way die forging die, firstly enabling an upper male die and an upper die seat in the vertical direction to move downwards, and closing the upper male die and a lower female die for forging; and then using male dies on the symmetrical left side and right side in the horizontal direction to perform extrusion precision forging and shaping. According to the method provided by the invention, as the die forging is performed on a multi-way die forging hydraulic machine, the shaping speed is much lower than that of die forging on a hammer, thus the occurrence of the phenomenon of forming cracks on the surface due to strong speed sensitivity caused by too-high speed can be avoided; and the contact friction resistance between a forged piece and the surface of a die cavity during the processes of die forging, shaping and ejection of the forced piece can be greatly reduced, the surface quality of the forged piece is further improved, and the utilization rate of the material of the forged piece is improved.

Owner:CHONGQING UNIV OF TECH

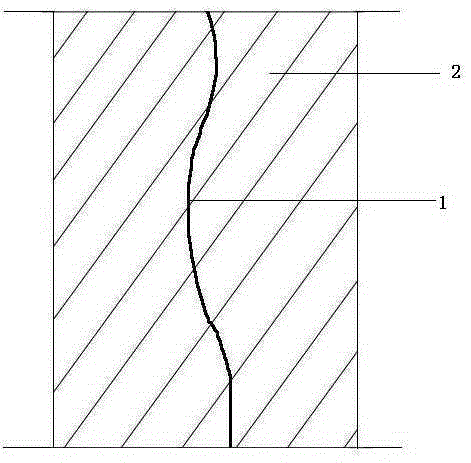

Construction process for plugging and consolidating concrete crack through chemical grouting

InactiveCN105239789ACrack works wellUniform thicknessBuilding repairsFoundation repairChemical groutingMaterials science

The invention relates to a construction process for plugging and consolidating a concrete crack through chemical grouting, which belongs to the technical field of concrete consolidation engineering and in particular relates to a concrete crack plugging and consolidating method. The construction process for plugging and consolidating the concrete crack through the chemical grouting comprises the following steps of the first step, opening a V-shaped groove, which is 20 mm wide at the upper part and at least 20mm deep, along the concrete crack; the second step, flushing the V-shaped groove; the third step, plugging the V-shaped groove; the fourth step, drilling a grouting hole; the fifth step, mounting a grouting head; the sixth step, performing grouting; and the seventh step, removing the grouting head. The construction process for plugging and consolidating the concrete crack through the chemical grouting, provided by the invention, is advantaged in that the grouting process is simple and convenient, the operation of the process is convenient, the crack is closely plugged without a gap, the plugged concrete crack is durable and fatigue-proof and not prone to crack again, the concrete crack plugging effect is good, the concrete surface is completely dry, leakage and moist are avoided, the thickness of a plugging and finishing coating on the surface of the crack is uniform, no missed brushing, no base exposure, no peeling, no swelling and no crack are achieved. And moreover, the process causes no pollution to the environment.

Owner:赵涛

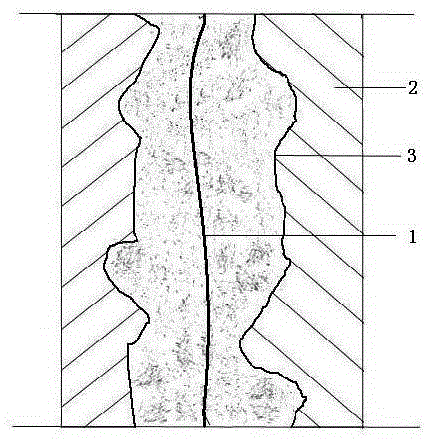

Laser cladding and manual arc welding combined repairing method for abraded TRT hub

InactiveCN107813051AImprove fusion rateHigh creep limitLaser beam welding apparatusShielded metal arc weldingSilicon alloy

Disclosed is a laser cladding and manual arc welding combined repairing method for an abraded TRT hub. The method includes the six steps of preparation before laser cladding, research of crack problems during cladding, determining of cladding materials, laser cladding, manual welding of the TRT rotor hub, heat treatment, detection and machining. Iron-based self-fluxing alloy powder nickel-boron-silicon alloy serves as the cladding materials. The abraded TRT hub is repaired through the process combining manual arc welding and laser cladding, the repaired TRT hub is free of cracks and high in rate of fusing with raw materials, the abrasion resistance, corrosion resistance and comprehensive mechanical performance of the repaired TRT hub all reach or are higher than those of base metal, and the service life is greatly prolonged. The abrasion resistance of the repaired TRT hub is 1.3-1.5 times that of the raw materials, the corrosion resistance of the repaired TRT hub is 1.5-1.8 times thatof the raw materials, and the service life of the repaired TRT hub is 1.2-1.4 times that of the raw materials. The deformation amount can be controlled within 0.5 mm, meanwhile, heat damage to the base metal is quite small, and the overall mechanical performance is not lower than that of new products.

Owner:河北瑞兆激光再制造技术股份有限公司

Cobalt-based spray powder used for aero-engine abrasion-resistant parts and preparation method thereof

InactiveCN106975742AExcellent resistance to abrasive wearExcellent hard surface wearMolten spray coatingWear resistantSpray coating

The invention belongs to the technical field of wear-resistant coating materials, and in particular relates to a cobalt-based spraying powder for aero-engine wear-resistant parts, and also relates to a method for preparing the above-mentioned spraying powder. The composition and weight percentage of the spray powder are: chromium: 20%~30%; nickel: 7%~15%; tungsten: 5%~12%; carbon: 0.1%~1%; cobalt: 45%~65% %; the particle size range of the above spray powder is 5 μm to 45 μm; the coating obtained by using the spray powder is suitable for working at high temperature, and has excellent anti-abrasive wear, hard surface wear, fretting wear and particle erosion wear performance ;After spraying, the bonding strength is high, and it is not easy to fall off; after spraying, the coating has a uniform texture, smooth surface, no delamination and cracks; at the same time, the cobalt content in the material determines that the coating is an excellent anti-oxidation coating; in addition , the powder coating also has good coating grinding and polishing properties and high coating hardness, and can be widely used in the application of engine parts.

Owner:TIANJIN CHENGLI AVIATION TECH CO LTD

Castable material for aluminum melting furnace

InactiveCN101597168AMeet the requirements of the conditions of useEasy to sinterBreaking strengthCoesite

The invention relates to a castable material for an aluminum melting furnace. The castable material comprises the following components of 70-88 percent of I-level bauxite, 5-15 percent of clay, 3-10 percent of kyanite and 4-8 percent of binding agent, wherein the I-level bauxite with the grain size of 5-3 mm accounts for 35-45 percent, the I-level bauxite with the grain size of 3-1 mm accounts for 20-30 percent, the I-level bauxite with the grain size of 1-0 mm accounts for 15-25 percent, and the I-level bauxite with the grain size lower than 0.09 mm accounts for 15-25 percent. All the physical performance indexes of the refractory castable material inner lining produced according to the grain size and the mixture ratio are as follows: the breaking strength is 15.6MPa, the compression strength is 41.3MPa, the linear change rate is 0.18 percent, the volume density is 2.81 g.cm, and the actual application shows that all the physical performance indexes can fully meet the requirements of service conditions of the inner lining of the aluminum melting furnace, no crack phenomenon occurs, the problem of alumetizing is eliminated, and the service life can reach more than 4 years.

Owner:刘杰

Matt acrylic resin film for thermoforming, process of its production and laminated body

InactiveCN101044023AStable productionNo crack phenomenonSynthetic resin layered productsVehicle componentsPolymer scienceCrazing

A matt acrylic resin film which develops an unprecedented design and is excellent in handleability and which does not cause cracking in the matt layer even when subjected to insert molding or in-mold molding or deeply stretch-formed and exhibits mar resistance, surface hardness, heat resistance and mattness; a process for the production thereof; and laminates each comprising the film and a substrate. More specifically, a matt acrylic resin film comprising an acrylic resin filmy substrate and a matt layer formed on one surface of the substrate which layer comprises a matting agent and a binder resin and has a thickness of 0.1 to 5[mu]m. The matt acrylic resin film is produced by applying a coating material comprising a matting agent and a binder resin as the essential components to one surface of an acrylic resin filmy substrate by printing or coating in such a way as to give a dry film thickness of 0.1 to 5[mu]m.

Owner:MITSUBISHI CHEM CORP

Housing quality detecting device for electric meter production

InactiveCN109374226AHigh speedQuality improvementMachine part testingMeasurement of fluid loss/gain rateElectric machineEngineering

The invention relates to the technical field of electric meter production, in particular to a housing quality detecting device for electric meter production. The housing quality detecting device comprises a base, an opening and closing degree detecting device, a gas tightness detecting device, a collecting device and a main control cabinet. The opening and closing degree detecting device and the gas tightness detecting device are fixedly connected to the left side and the right side of the top of the base; the collecting device is fixedly connected to the right end of the base; and the main control cabinet is fixedly connected to the left side of the rear end of the base. According to the invention, since a photoelectric sensor, a rotating plate, a cross bar, a first clamping band, a firsttransition plate and a fifth motor are arranged, a first cover plate rotates under the effect of an electromagnet; whether the opening / closing degree is qualified is determined based on the effect ofthe photoelectric sensor and the disqualified product is rejected; and with the gas tightness detecting device, a first ventilating pipe, a push rod, and a connecting plate, the air tightness of thebox body is detected quickly by the gas tightness detecting device to avoid crack existence, so that the safety of the box body is improved.

Owner:怀化智信能源科技有限公司

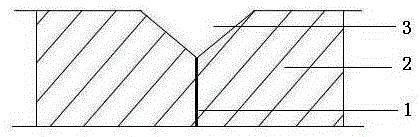

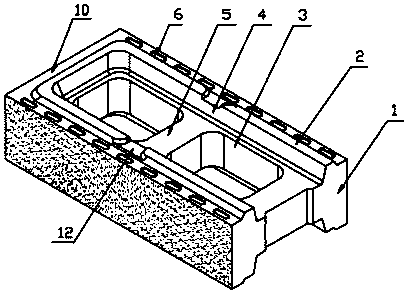

Cylinder liner spinning and flanging processing method and special fixture thereof

InactiveCN1544176AEasy to processReduce labor intensityCylinder headsCylindersEngineeringMechanical engineering

The invention discloses a cylinder case rotary pressing-curling processing method and its special clamp, and the method: installing and griping the cylinder case in the clamp and rotating the clamp, adopting a rotary pressing wheel to expand and press the mouth of the cylinder case to form a 120-150 degree bellmouthing, adopting an extrusion wheel to planish the big platform, loosening the cylinder case griped by the clamp and then ejecting the cylinder case and completing the processing, where the special clamp is a clamp: there is a space between the inner and outer bodies, the diameter of one side of the outer body is greater than that of the other side, there is a push-remove case between the inner and outer bodies on one end of the clamp and there is a conical stopper on the other end of the clamp, there is a pull rod set in the center of the inner body, and the pull rod is connected with the conical stopper. It has the characters of simple processing procedures, accurate assembly and positioning, high processing precision, high working efficiency and low labor strength.

Owner:烟台万斯特有限公司

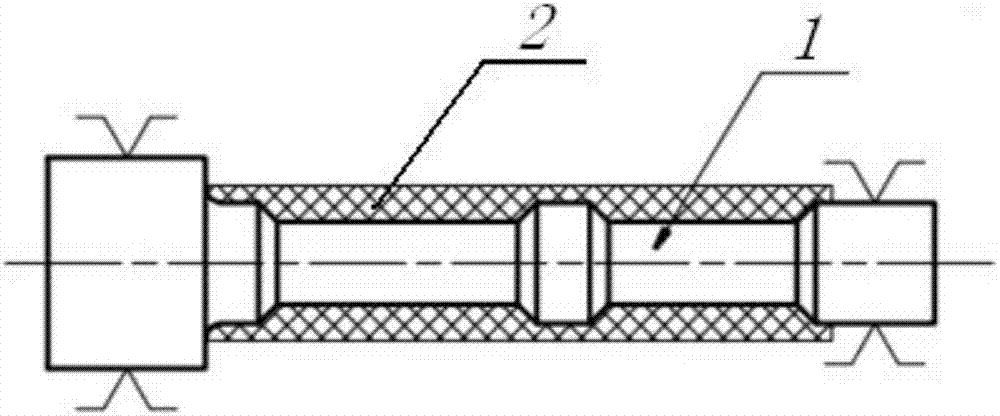

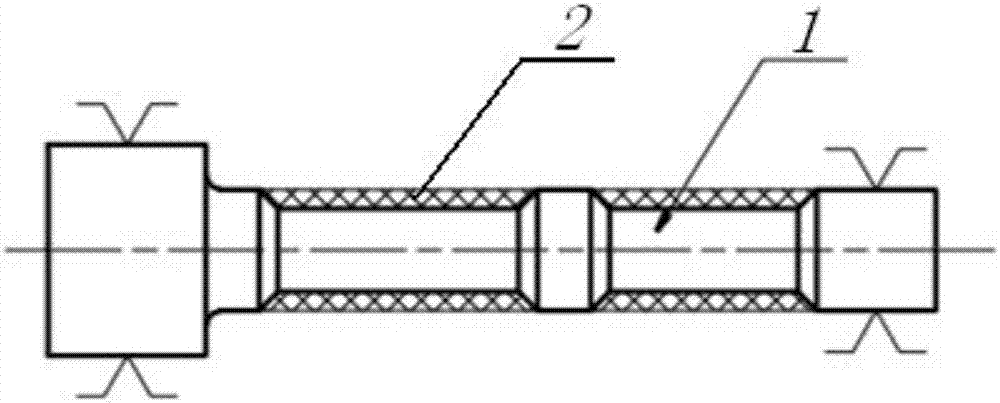

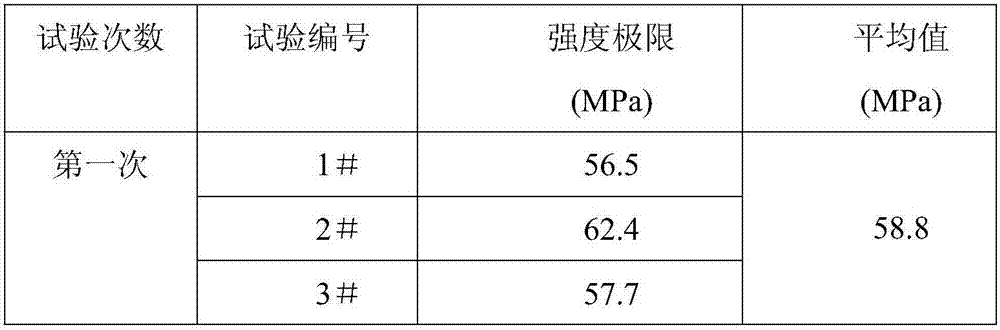

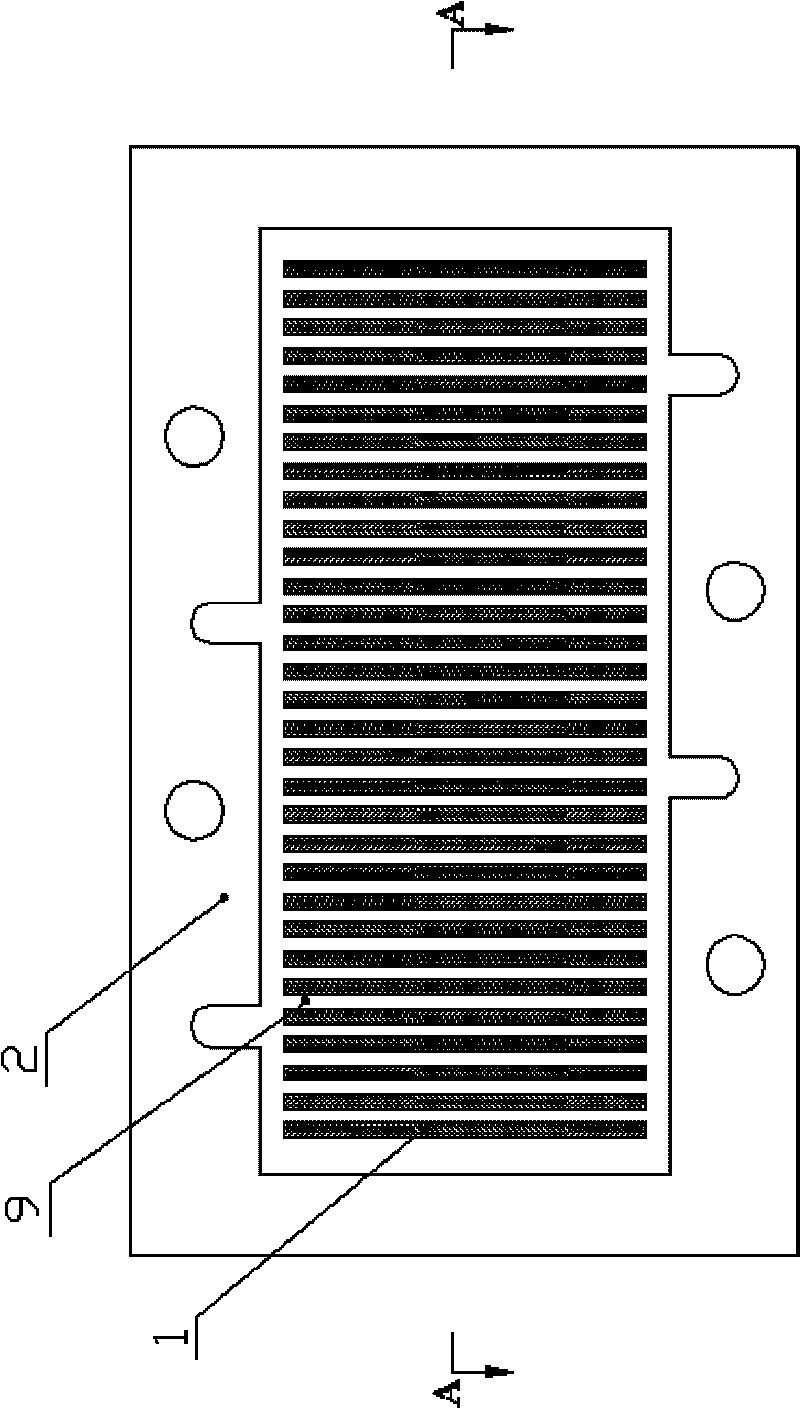

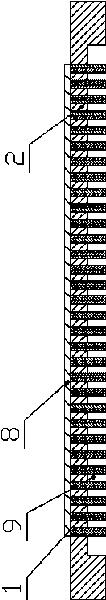

Collector plate of vanadium redox battery and preparation method thereof

The invention discloses a collector plate of a vanadium redox battery and a preparation method thereof, and the collector plate of the vanadium redox battery has the characteristic of improving the charging and discharging performances; the collector plate of the vanadium redox battery comprises an electricity-conduction plastic body which is formed by distributing a plurality of electricity-conduction plastic strips at interval, a flow field plate is arranged between the two adjacent electricity-conduction plastic strips, and the height of the electricity-conduction plastic strips and the height of the flow field plate are unequal to form an electrolyte solution groove; the preparation method is that: a. electricity-conduction fillers are added in a thermoplasticity polymer to obtain thermoplasticity electricity-conduction plastic strips; b. the electricity-conduction plastic strips are arranged and fixed at interval; c. epoxide resin or phenolic resin for forming the flow field plate is cast among the electricity-conduction plastic strips; d. solidification. When the electrolyte solution flows in the electrolyte solution groove, the flowing is unobstructed, and the battery polarization is low; the vanadium redox battery arranged in the collector plate has good charging and discharging performances, thereby being popularized and applied to the vanadium redox battery.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

Self-insulation concrete slab and preparation method thereof

ActiveCN104929306AImprove insulation effectLower heat transfer coefficientSolid waste managementClimate change adaptationInsulation layerSlag

The invention relates to a self-insulation concrete slab. The self-insulation concrete slab comprises a self-insulation layer and a heat insulation layer, wherein the self-insulation layer mainly consists of cement, sandstone, gravel, admixture, a water reducing agent and water; the heat insulation layer mainly consists of cement, micro iron slag powder, pulverized fuel ash, sodium lignin sulfonate, polyurethane, water and silicon dioxide. Through the adoption of the self-insulation manner of the concrete, the wall thickness is reduced, so that the secondary construction is avoided; the phenomena that the wall protection layer is cracked, the insulation material is aged, the insulation layer is loosened and bumped can be avoided while the energy is saved; the insulation layer and the structure are same in service life. The self-insulation concrete slab is small in heat transfer coefficient, excellent in insulation effect, high in crushing resistance and freezing resistance and long in service life; the self-insulation concrete slab is used as a preferred wall material of building.

Owner:CHINA AEROSPACE CONSTR ENG GRP CO LTD

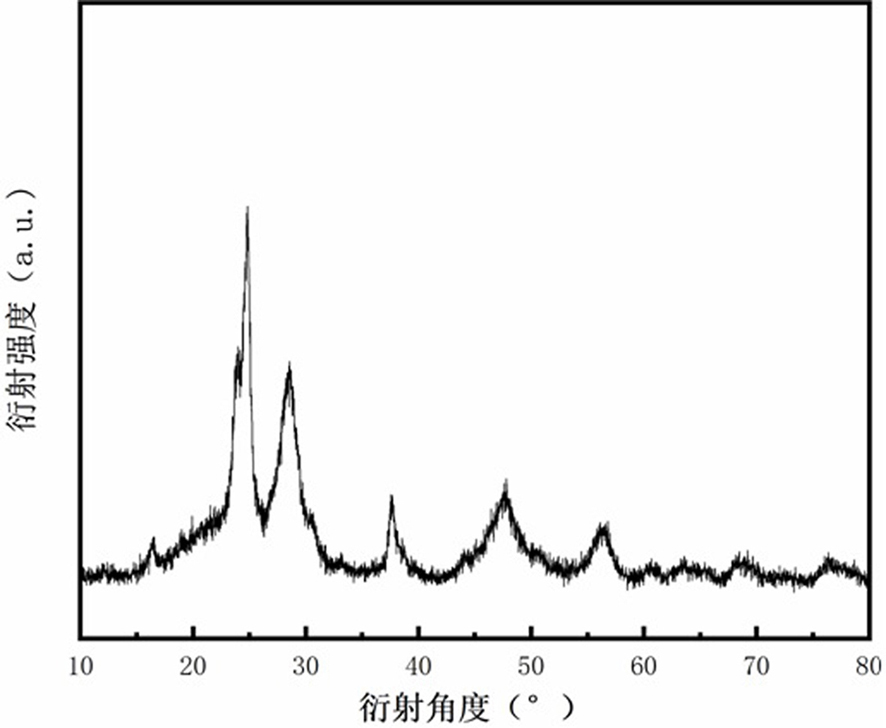

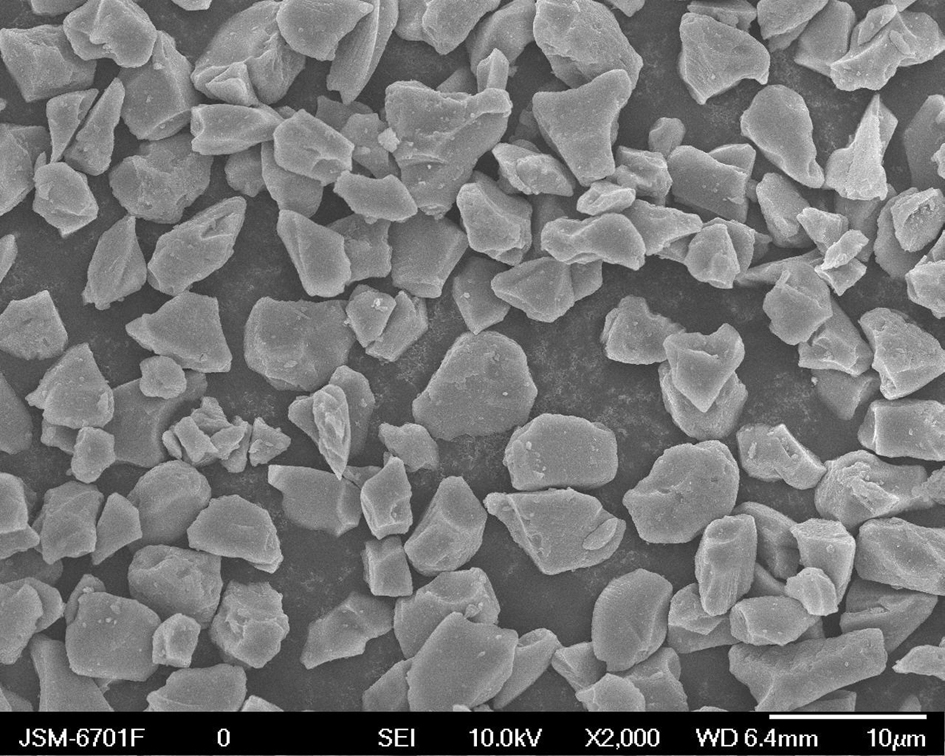

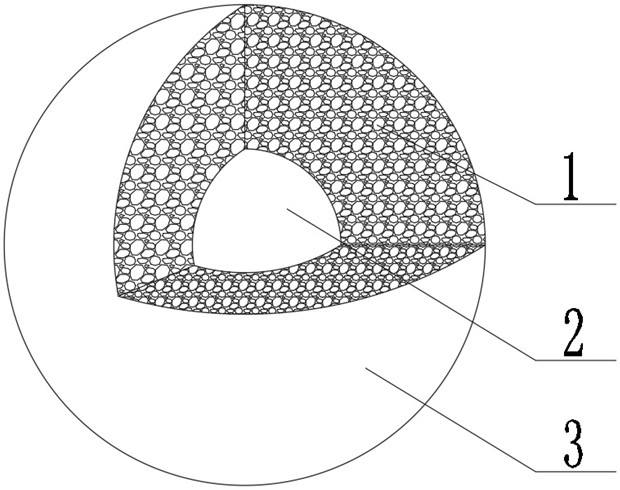

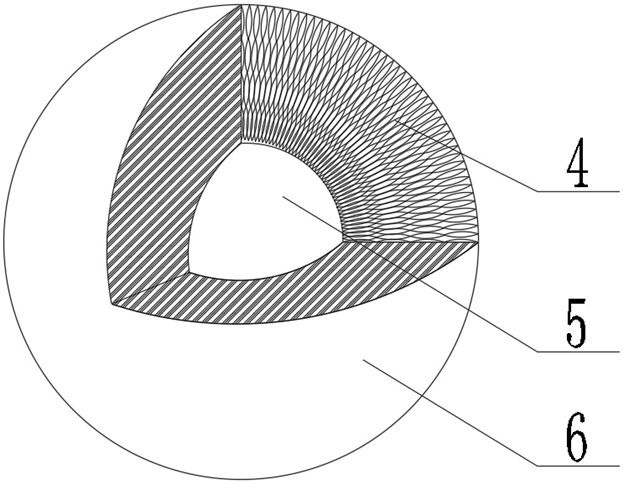

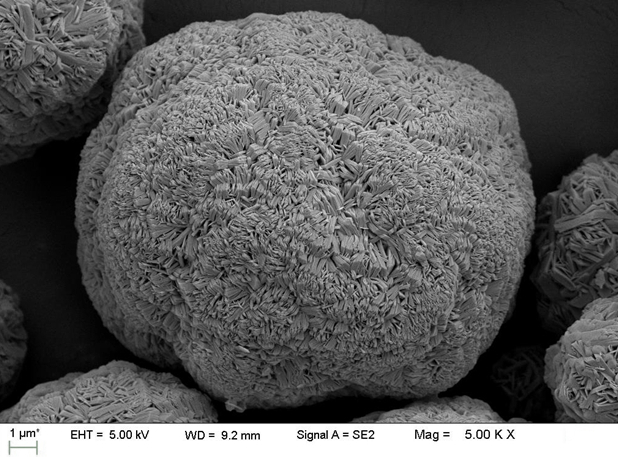

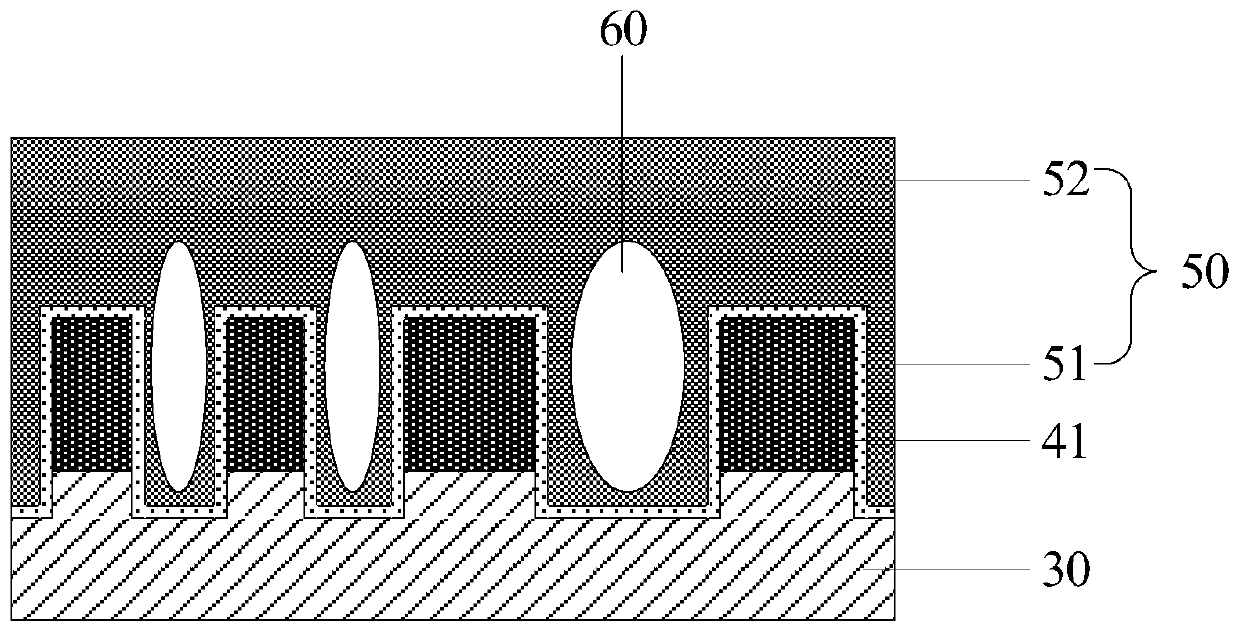

Silicon-based negative electrode material for inhibiting crack formation in lithium intercalation and deintercalation process and preparation method of silicon-based negative electrode material

InactiveCN113394384AFast transmissionImprove the first Coulombic efficiencyNegative electrodesSecondary cellsCarbon coatingPerovskite (structure)

The invention discloses a silicon-based negative electrode material for inhibiting crack formation in a lithium intercalation and deintercalation process and a preparation method of the silicon-based negative electrode material, the silicon-based negative electrode material is of a three-layer composite structure which sequentially comprises a silicon-based material layer, a perovskite coating layer and an amorphous carbon coating layer from inside to outside; the silicon-based material layer is doped with at least one element selected from B, P, Al, Zr, Ti and Mg; and the perovskite is LaMO3, and M = Co and / or Fe. According to the invention, the method of high-temperature sintering element doping, perovskite coating layer coating and carbon coating is adopted to inhibit the formation of cracks in the lithium intercalation and deintercalation process of the silicon-based negative electrode material, so that the huge stress change of the silicon-based negative electrode material in the lithium intercalation and deintercalation process is effectively relieved, and the formation of cracks in particles is inhibited; and relatively high first coulombic efficiency and excellent cycling stability are shown.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

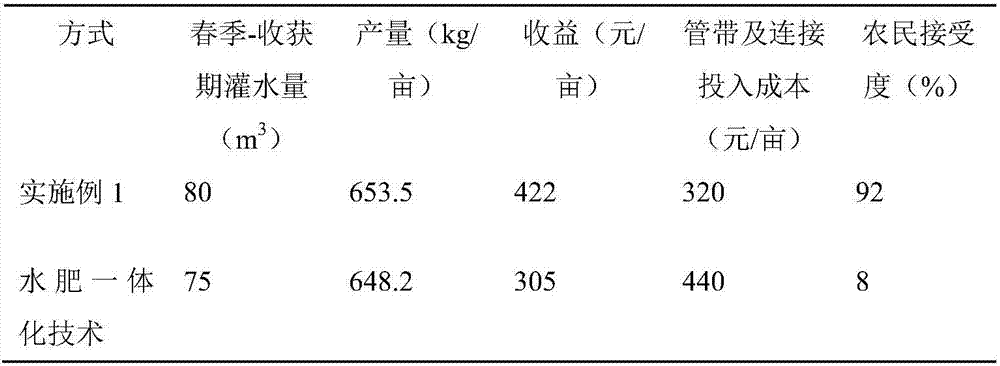

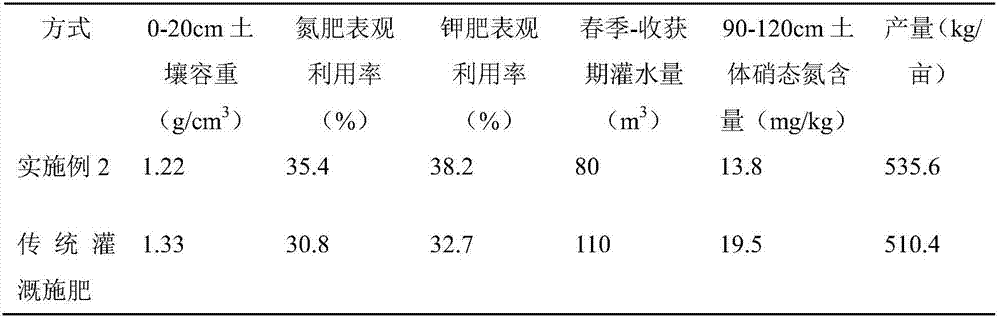

Drought-resisting and water-saving winter wheat spring irrigation and fertilization method

The invention relates to a drought-resisting and water-saving winter wheat spring irrigation and fertilization method. The drought-resisting and water-saving winter wheat spring irrigation and fertilization method is implemented in winter wheat regeneration and jointing stages. The method comprises the following steps of (1) applying nitrogenous fertilizer and potash fertilizer in wheat fields; (2) performing water irrigation through a simple micro-spraying device; (3) starting irrigation from the far end of the wheat fields, after water sprayed by micro-spraying hoses rests on the field surface for 3-5 minutes, removing a section of the micro-spraying hoses to irrigate other areas in sequence until reaching the other end of the fields, and ensuring the irrigation amount to be 35-40 m3 per mu (=0.0667 hectares). The drought-resisting and water-saving winter wheat spring irrigation and fertilization method achieves water irrigation through the simple micro-spraying device, and accordingly is low in cost, simple in installation and field operation, assures years of service, avoids risks of ageing and loss and facilitates water amount control and observation; meanwhile, the drought-resisting and water-saving winter wheat spring irrigation and fertilization method is easy to accept by farmers during production, and by matching fertilization with water irrigation, saves water consumption as well as input of nutrient of nitrogen, phosphorus and potassium, ensures the yield of wheat and improves the utilization rate of nitrogenous fertilizer.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

High alumina castable

InactiveCN105461318AMeet the requirements of the conditions of useEasy to sinterCoesiteCompressive strength

The invention relates to a high alumina castable. The high alumina castable comprises 60-85% of high alumina bauxite, 1-10% of clay, 1-10% of flint clay, 10-30% of zircon sand and 3-7% of a binder. The high alumina bauxite comprises 30-40% of bauxite with the granularity of 5-3mm, 25-35% of bauxite with the granularity of 3-1mm, 20-30% of bauxite with the granularity of 1-0mm, and 10-20% of bauxite with the granularity of 0.09mm or below. The physical performance indexes of the above fireproof castable lining produced according to above granularities and proportions are as follows: the bending strength is 15.5MPa, the compressive strength is 40.5MPa, the linear change rate is 0.20%, and the bulk density is 2.75g.cm<-3>. Practical use proves that the physical performances of the high alumina castable completely meets use condition requirements of fused aluminum furnace linings, has no cracks, and eliminates the aluminising problem, and the service life of the high alumina castable can reach 5 years or above.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

Method for forming an air gap between metal wiring lines and a metal wiring structure

ActiveCN108807339AOvercoming cracksCrack phenomenon avoidSemiconductor/solid-state device detailsSolid-state devicesSilicon dioxideDielectric layer

The invention provides a method for forming an air gap between metal wiring lines and a metal wiring structure. The method comprises the following steps: providing a metal interlayer dielectric layer;forming a metal layer on the interlayer dielectric layer; etching the metal layer to form a plurality of metal lines spaced apart from each other; a metal interlay dielectric layer is etched to forma trench, the depth of the trench is smaller than the thickness of the metal interlayer dielectric layer, a metal layer is sequentially covered with a silicon-rich oxide, a plasma-enhanced tetraethylorthosilicate and fluorine-doped silica or a plasma-enhanced tetraethylorthosilicate and non-fluorine-doped silica to form an interconnected dielectric lay and an air gap between the metal lines. The invention can improve the filling appearance of the side wall of the metal connection and avoid the short circuit phenomenon between the metal connections.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Precursor with hydroxide coated on outer layer of single crystal and preparation method of precursor

PendingCN114436342AImproved magnification performanceHigh tap densityAfter-treatment detailsSecondary cellsElectrical batterySingle crystal

The preparation method comprises the following steps: carrying out acid treatment on a selected single-crystal positive electrode material to form an uneven surface, so that primary particles of the hydroxide generated in a subsequent co-precipitation reaction can be better attached to the surface of the single-crystal positive electrode material, and the surface of the single-crystal positive electrode material is more uniform; precursor particles with a core-shell structure are prepared, each particle is composed of an inner core and an outer shell layer, the inner core is a single-crystal positive electrode material, the outer shell layer of each particle is formed by aggregating nickel-containing composite hydroxide primary particles, and the structure can further improve the cycle performance, the overall packing density and the specific capacity of the material; meanwhile, according to different application fields, the primary particles of the shell layers of the particles are in a sheet shape, a block shape, a spindle shape or a needle shape, so that the tap density of the material is further improved, and meanwhile, the rate capability, the cycle performance and other electrochemical performance of the lithium ion battery are improved.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Raw material applied to butterfly valve rubber lagging

The invention provides a raw material applied to a butterfly valve rubber lagging. The raw material is prepared from the following compositions Epichlorohydrin rubber, nanometer zinc oxide, stearic acid, sulphur, stearic acid, lead oxide, a vulcanizing agent, light calcium, cis-1,4-polybutadiene rubber, zine stearate, transformer oil, glycerin, medium chrome yellow, styrene-butadiene segmented copolymer, basic zinc sulfate, white carbon black, naphthenic oil, a stabilizing agent, azodicarbonamide, tartrazine, zinc oxide, naphthenic oil, azodicarbonamide and zinc oxide according to a certain weight ratio. The provided raw material is good in heat and cold resistance, relatively good in oxidation and acid resistance, and usable under severe conditions for a long time.

Owner:当涂县中澜橡塑制品有限公司

Technological method for welding low-temperature ductile iron and manganese steel plate

ActiveCN106270966AEasy to integrateGood weld shapeArc welding apparatusWelding/soldering/cutting articlesSheet steelManganese

The invention belongs to the technical field of welding, and particularly relates to a technological method for welding low-temperature ductile iron and a manganese steel plate. A NiFe-1 welding rod is selected, an MAG shielded welding technology is adopted, a low-temperature ductile iron material and the manganese steel plate are welded together in an intermittent welding manner, and the low-temperature ductile iron material, the manganese steel plate and the welding rod are not preheated before welding and are not subjected to heat treatment after welding. According to the welding technology, weld joint root fusion is good, weld joint appearance molding is good, and the surface is free of cracks and pores; the low-temperature ductile iron material is free of the phenomena of embrittlement and cracking; the quality of the manganese steel plate is not reduced; and energy consumption is reduced.

Owner:CHANGZHOU HUADE MACHINERY

Positive electrode material with oxide coated on outer layer of single crystal and preparation method of positive electrode material

PendingCN114447328AImproved magnification performanceImprove cycle performanceSecondary cellsPositive electrodesPhysical chemistrySingle crystal

The invention relates to a positive electrode material with oxide coated on the outer layer of single crystal and a preparation method of the positive electrode material, the selected single-crystal positive electrode material is subjected to acid treatment to form an uneven surface, so that hydroxide primary particles can be better attached to the surface of the single-crystal positive electrode material in a subsequent coprecipitation reaction; the positive electrode material particles obtained after sintering with a lithium source are composed of an inner core and a shell layer, the inner core is a single-crystal positive electrode material, and the particle shell layer is formed by primary crystal grain aggregation of a nickel-containing composite oxide; the positive electrode material has good cycle performance, relatively high filling density and relatively high specific capacity; according to different application fields, primary crystal grains of the material have microscopic characteristics similar to cuboids, blocks, strips and sheets, the tap density of the material is further improved, and meanwhile, the rate capability, the cycle performance and other electrochemical performance of the lithium ion battery are improved.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Nut

The invention relates to a nut. The nut comprises a connecting block, a first nut body, and a second nut body; one end of the connecting block is fixedly connected to the first nut body, the other endof the connecting block is fixedly connected to the second nut body, a gap is arranged between the first nut body and the second nut body, and a limiting screw for preventing the nut from shaking isarranged on the connecting block. The nut has the beneficial effects that through the connecting block, rapid connection of the first nut body and the second nut body is achieved, through the connecting block, shaking of the first nut body and the second nut body in the radial direction can be limited, through the limiting screw on the connecting block, limiting of the whole nut in the axial direction is prevented, mounting quality of the whole nut is ensured, a detachable operation rod on the connecting block can achieve rapid rotation of the nut, according to different mounting environments, different models of operation rods can be selected, the mounting efficiency and the mounting quality of the nut can be improved, and the subsequent maintaining can be facilitated.

Owner:平湖巨龙紧固件有限公司

Composite passivation solution and preparation method and application thereof

ActiveCN111621776AImprove anti-corrosion performanceImprove repairabilityMetallic material coating processesOrganic acidFatty alcohol

The invention provides a composite passivation solution and a preparation method and application thereof. The composite passivation solution is prepared from the raw materials in parts by weight: 5-25parts of a silane coupling agent, 10-30 parts of low-grade saturated fatty alcohol, 2-15 parts of an aqueous hydrochloric acid solution with the mass percentage concentration being 2.5%, 0.5-10 partsof an aqueous organic acid solution with the mass percentage concentration being 20%, 0.5-10 parts of a conductive polyaniline butanol solution with the mass percentage concentration being 0.2%-10%,and the balance of water, wherein the total weight parts of the composite passivation solution are 100. The invention further provides a metal surface anticorrosion method utilizing the composite passivation solution. The composite passivation solution enables a metal substrate to have the good anticorrosion property.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

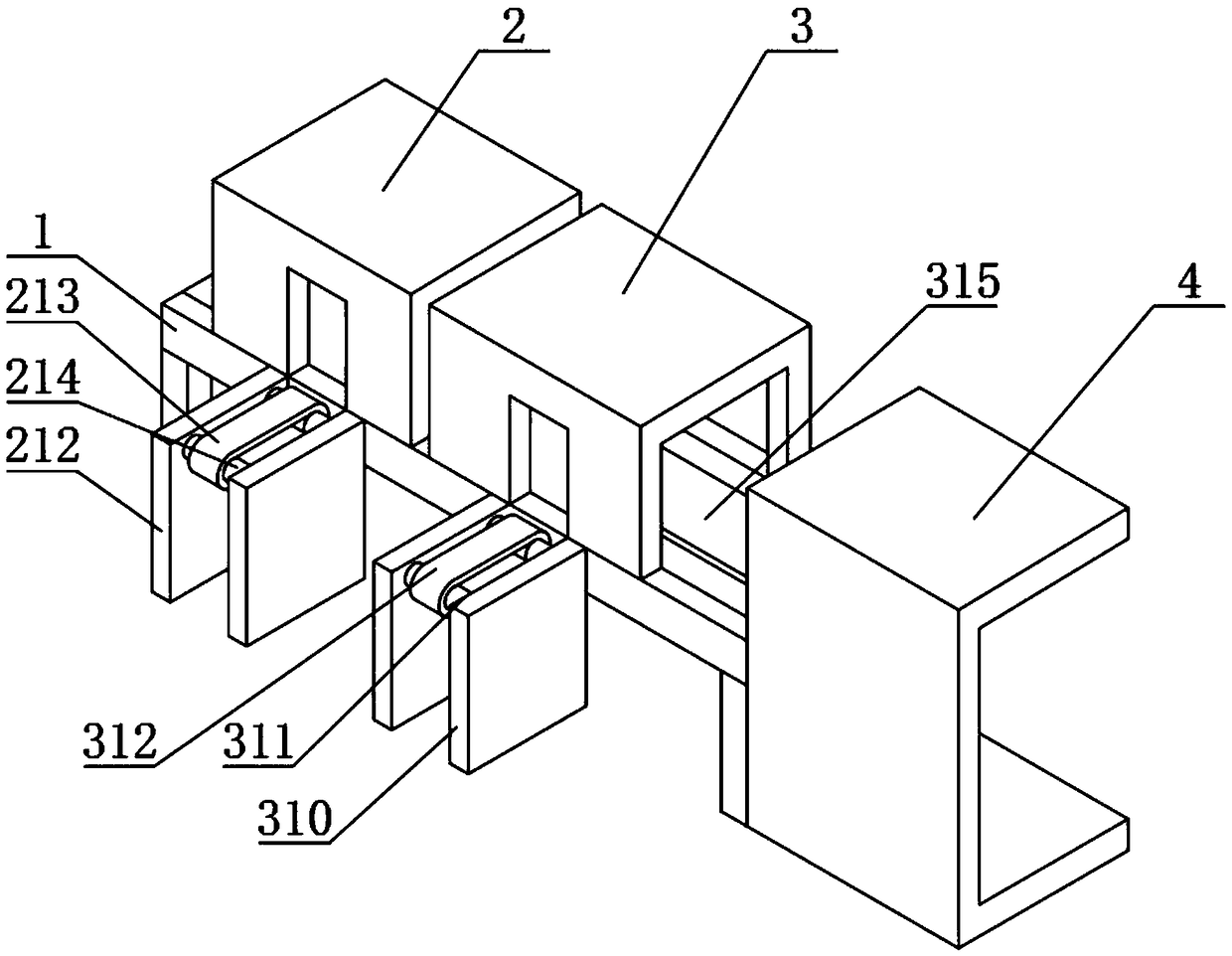

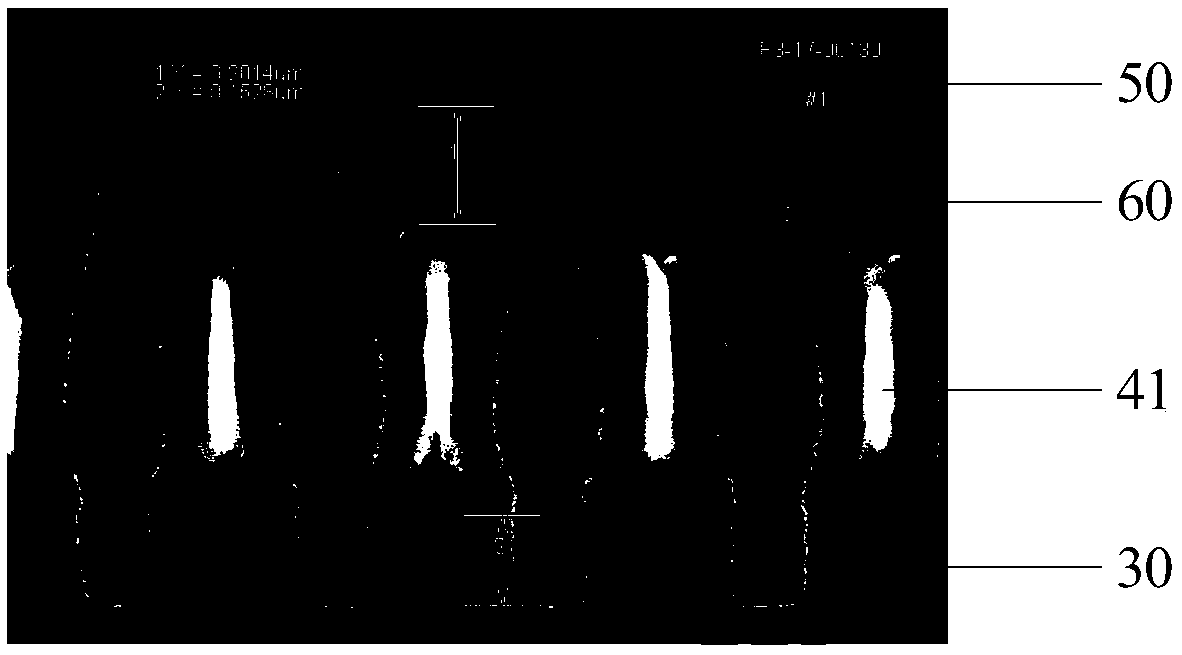

Multi-ram die forging process method and die for 40Cr-steel frame type parts

InactiveCN102049456BIncrease profitImprove plastic forming abilityForging/hammering/pressing machinesIntermediate frequencyMetallic materials

The invention discloses a multi-ram die forging process and a die for 40Cr-steel frame type parts, belongs to the technical field of plastic forming for a metal material, and aims at effectively avoiding the problems in an existing open die forging process and a existing isothermal forging process. The multi-ram die forging process comprises the steps of blanking, heating and multi-ram die forging, wherein, the multi-ram die forging comprises the steps as follows: (1) stocks are heated until the temperature reaches 1000 to 1180 DEG C through intermediate frequency induction; and (2) heated blanks are formed in one step through a multi-ram die forging die. The multi-ram die forging die comprises symmetrical left and right lateral male dies, an upper half male die, a lower half male die, a lateral male die fixing board and a die frame, wherein, the die frame comprises an upper die holder and a lower die holder. The invention has the advantages as follows: the technological process is reasonable, and the processing parameter and the performance are stable; the structure of the die is simple, the die is convenient to manufacture, install and use, and the operation is reliable; the friction resistance between forged pieces and a die cavity can be reduced greatly, the service life of the die is prolonged obviously, the surface quality of the forged pieces can be improved, and the utilization ratio of materials is high; and one-step forming can be achieved, and pre-forging is not required.

Owner:CHONGQING UNIV OF TECH

Method for forming air gap between metal wirings and structure of metal wirings

ActiveCN108807339BOvercoming cracksCrack phenomenon avoidSemiconductor/solid-state device detailsSolid-state devicesSilicon dioxideDielectric layer

The invention provides a method for forming an air gap between metal wiring lines and a metal wiring structure. The method comprises the following steps: providing a metal interlayer dielectric layer;forming a metal layer on the interlayer dielectric layer; etching the metal layer to form a plurality of metal lines spaced apart from each other; a metal interlay dielectric layer is etched to forma trench, the depth of the trench is smaller than the thickness of the metal interlayer dielectric layer, a metal layer is sequentially covered with a silicon-rich oxide, a plasma-enhanced tetraethylorthosilicate and fluorine-doped silica or a plasma-enhanced tetraethylorthosilicate and non-fluorine-doped silica to form an interconnected dielectric lay and an air gap between the metal lines. The invention can improve the filling appearance of the side wall of the metal connection and avoid the short circuit phenomenon between the metal connections.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A kind of technological method of welding low-temperature ductile iron and manganese steel plate

ActiveCN106270966BEasy to integrateGood weld shapeArc welding apparatusWelding/soldering/cutting articlesSheet steelManganese

A process method for welding a low-temperature ductile iron and a manganese steel plate, the method comprising: selecting a NiFe-1 welding rod, and using an MAG active gas shielded welding process to weld the low-temperature ductile iron material and the manganese steel plate together in an intermittent welding manner, wherein the low-temperature ductile iron material, the manganese steel plate and the welding rod are neither preheated before welding, nor are they subjected to a heat treatment after welding. The welding process not only results in a good fusion at the root of the weld, a good weld profile formation, no crack on the surface, no blow hole and no embrittlement and crack phenomenon to the low-temperature ductile iron material, but also causes the quality of the manganese steel plate not to be reduced; furthermore, the energy consumption is saved.

Owner:CHANGZHOU HUADE MACHINERY

Drawing part solid-liquid composite lubricant coating and preparation method thereof

The invention discloses a drawing part solid-liquid composite lubricant coating and a preparation method thereof. The drawing part solid-liquid composite lubricant coating is compounded from a solid lubrication layer and a liquid lubrication layer, wherein the solid lubrication layer is prepared from 10ml of epoxy resin, 10ml of polyamide, 5g of tin bronze, 3-5g of polytetrafluoroethylene, 2-3g of graphite and 5ml of anhydrous alcohol; and the liquid lubrication layer is 10ml of liquid paraffin. The preparation method comprises the following steps: spraying a mixed adhesive coating on a pretreated drawing part surface, and curing in air for 12 hours to obtain the solid lubrication layer; and spreading the 10ml of liquid paraffin on the surface of the solid lubrication layer. The invention can smooth the drawing part surface and lower the friction factor, does not have any crack, has good lubrication action, lowers the cost of the drawing part, and enhances the drawing efficiency.

Owner:南京淳和新材料科技有限公司

Forged and compacted steel wire rope with multi-layer inner layer rope and its manufacturing method

A kind of forged and compacted steel wire rope with multi-layer inner layer rope. The steel wire rope structure is 35W×7. The strands are twisted once and formed by forging and compacting. The manufacturing method is to first twist the inner and outer strands, then use the inner strands to twist the inner rope, then forge and compact the inner rope, and finally use the forged and compacted inner rope and outer strand To close the rope. The steel wire rope strands of the present invention have uniform gaps, no cracks observed with the naked eye, increased contact area between the outer layer strand steel wire and the inner layer rope, reduced early broken wires of the inner layer rope, high fatigue life of the steel wire rope, high breaking tension of the whole rope, and improved the service life of the wire rope.

Owner:GUIZHOU WIRE ROPE

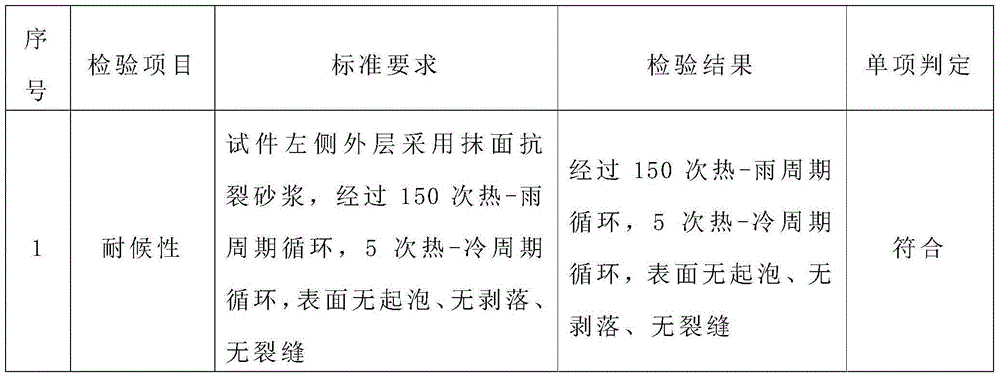

Nickel-iron slag self-insulating autoclaved brick and preparation method thereof

The invention relates to a nickel-iron slag self-heat preservation autoclaved brick and a preparation method for the same. The nickel-iron slag self-heat preservation autoclaved brick comprises nickel-iron slag and a calcium material, wherein the calcium material is preferably carbide slag; the nickel-iron slag comprises powdery nickel-iron slag and granular nickel-iron slag. The nickel-iron slag self-heat preservation autoclaved brick has a low heat transfer coefficient, strong compressive strength and high freezing resistance; the strength grade can reach MU30; the appearance quality and dimensional deviation of the nickel-iron slag self-heat preservation autoclaved brick are consistent with standards; the surface of the self-heat preservation autoclaved brick is detected to be free of bubbling, stripping and cracks by virtue of weather resistance tests; in addition, the aims of treating wastes with wastes and turning the wastes into wealth can be fulfilled, pollution caused by the nickel-iron slag can be reduced, and the ecological environment can be optimized; high added value can be obtained with low cost, so that the self-heat preservation autoclaved brick has great economic and social benefits.

Owner:SHANDONG WEIYE NEW BUILDING MATERIAL

A kind of composite passivation solution and its preparation method and application

ActiveCN111621776BImprove anti-corrosion performanceImprove repairabilityMetallic material coating processesSilanesFatty alcohol

The invention provides a composite passivation solution and a preparation method and application thereof. Taking the total weight of the composite passivation solution to be 100 parts, the raw materials include: 5-25 parts of silane coupling agent, 10-30 parts of lower saturated fatty alcohol, 2-15 parts of hydrochloric acid aqueous solution with a mass percentage concentration of 2.5% , 0.5-10 parts of an organic acid aqueous solution with a concentration of 20% by mass, 0.5-10 parts of a conductive polyaniline butanol solution with a concentration of 0.2%-10% by mass, and the balance of water. The present invention also provides a metal surface anticorrosion method utilizing the above-mentioned composite passivation solution. The composite passivation solution of the present invention can make the metal substrate have good anti-corrosion performance.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Anti-seismic and anti-cracking modular brick for wall and building

PendingCN111593842AGuaranteed to be verticalGuaranteed smoothWallsProtective buildings/sheltersBrickArchitectural engineering

The invention discloses an anti-seismic and anti-cracking modular brick for a wall and a building, and belongs to the technical field of construction engineering. The anti-seismic and anti-cracking modular brick for the wall comprises a brick body. The upper end surface of the brick body is provided with a first convex portion along the length direction, and the bottom surface of the brick body isprovided with a first concave portion which cooperates with the first convex portion. One end surface of the brick body is provided with a second convex portion along the height direction, and the other opposite end surface of the brick body is provided with a second concave portion which cooperates with the second convex portion. The both sides of the upper end surface and the bottom surface ofthe brick body are provided with sink bores arranged along the length direction. The first convex portion and the first concave portion are provided with sink grooves which penetrate through both endsof the brick body along the length direction. A first through hole along the height direction is formed in each sink groove. Horizontal and vertical steel bars and water and electricity network linepipes can be directly placed on the anti-seismic and anti-cracking modular brick for the wall, upright columns, ring beams, structural columns and door and window lintels can be conveniently installed, and formworks are not needed. After stacking, the anti-seismic and anti-cracking modular brick for the wall can form a grid-like invisible concrete frame structure, the whole building can be made into a whole structure, and the anti-seismic and anti-cracking functions and the like are achieved.

Owner:吴胜万

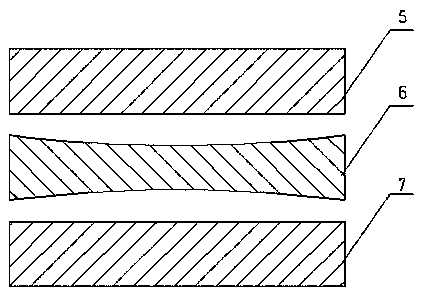

Curved surface compensation conveying belt

PendingCN110712925AReduce manufacturing costExtended service lifeConveyorsAdhesiveStructural engineering

The invention discloses a curved surface compensation conveying belt, and relates to the technical field of conveying belts. The curved surface compensation conveying belt comprises a skeleton layer,an upper covering layer and a lower covering layer, wherein the upper covering layer is positioned on the outward side of the skeleton layer, and comprises a middle upper adhesive section and an edgeupper adhesive section in the width direction; the middle upper adhesive section is thicker than the edge upper adhesive section; the lower covering layer is positioned on the inward side of the skeleton layer, and comprises a middle lower adhesive section and an edge lower adhesive section in the width direction; and the middle lower adhesive section is thinner than the edge lower adhesive section. The service life of easily worn parts of the covering layers is prolonged through a curved surface compensation method, so that the service life of the conveying belt is prolonged.

Owner:江苏凯嘉橡胶科技股份有限公司

Antirust paint for improving brightness of finish and preparation method thereof

The invention discloses antitrust paint for improving the brightness of finish. The antirust paint is the characterized by being prepared from 8-12 parts by weight of copal resin, 32-36 parts by weight of organosilicon epoxy resin, 3-5 parts by weight of tetraethylenepentamine, 5-7 parts by weight of 2-hydroxypropyl acrylate, 1-2 parts by weight of ammonium polyphosphate, 11-14 parts by weight of modified asphalt, 4-7 parts by weight of modified waste clay sand, 1-2 parts by weight of fluorescent pigment, 1-2 parts by weight of borneol, 0.3-0.7 parts by weight of a silane coupling agent, 1-2 parts by weight of polyolefin wax, 2-3 parts by weight of light calcium carbonate, 1-2 parts by weight of titanium dioxide, 2-3 parts by weight of cellulose acetate, 1-2 parts by weight of micaceous iron oxide, 10-13 parts by weight of a gasoline solvent No. 200 and 4-6 parts by weight of butyl acetate. By use of the natural resin copal, the antirust paint has the characteristics of nontoxicity and stable properties. The borneol in the paint has a fragrance and effects of relaxing and raising spirit and restoring consciousness, can effectively reduce the peculiar smell of the paint and smells comfortable. The used polyolefin wax can be uniformly disperse a filler to avoid paint quality influence caused by the formation of dust agglomeration. The used micaceous iron oxide has a strong anti-rust effect. The used fluorescent pigments and titanium dioxide can improve the brightness of the antirust paint and give people a comfortable visual enjoyment.

Owner:TIANCHANG YINHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com