Cobalt-based spray powder used for aero-engine abrasion-resistant parts and preparation method thereof

An aero-engine and powder-spraying technology, applied in the field of wear-resistant coating materials, can solve the problems of poor grinding and polishing performance, weak adhesion of ultra-fine powder coatings, prone to cracks and delamination, and achieve excellent resistance to Abrasive wear, good coating grinding and polishing performance, surface smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

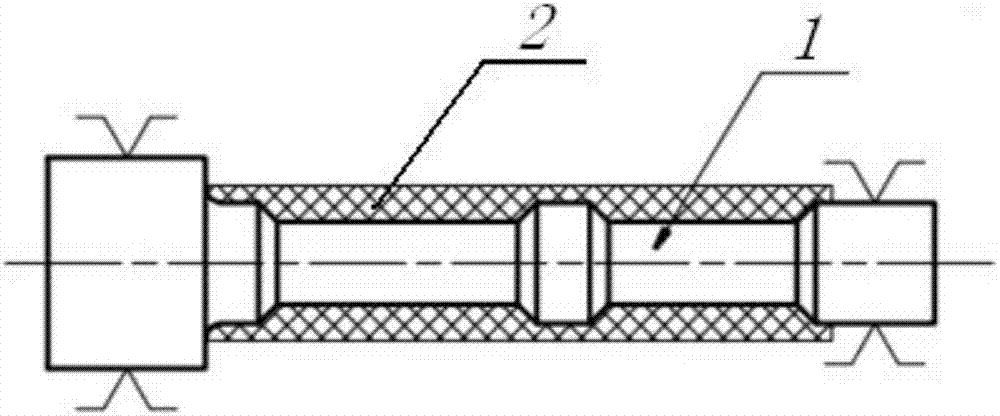

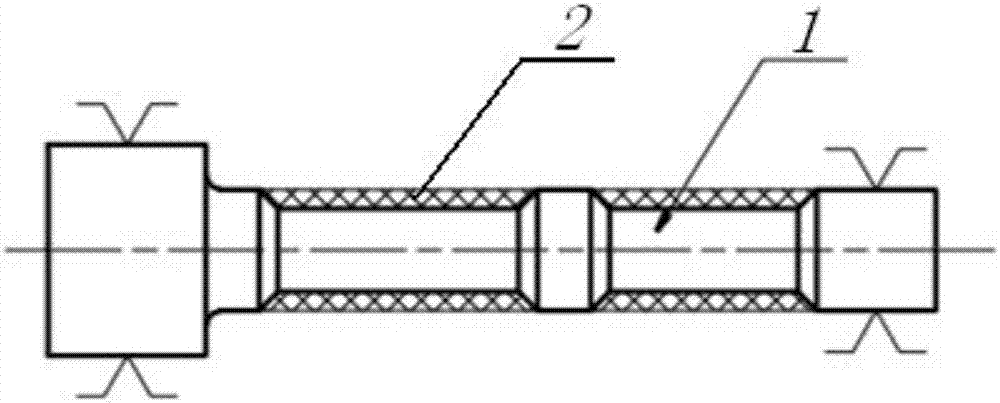

Image

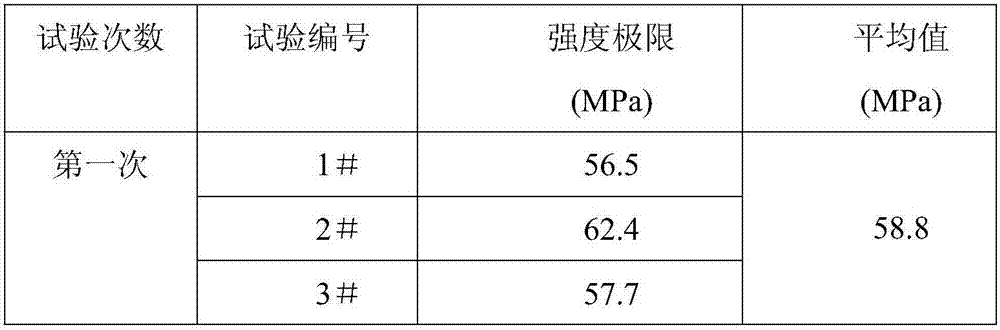

Examples

Embodiment Construction

[0025] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

[0026] In the present embodiment, the composition and weight percentage of the spray powder are respectively:

[0027] Chromium: 25.5%

[0028] Nickel: 10.5%

[0029] Tungsten: 7.5%

[0030] Carbon: 0.5%

[0031] Cobalt: 56%.

[0032] The particle size range of spray powder is 5μm~45μm.

[0033] The preparation method of the above-mentioned spraying powder comprises the following steps: a, batching: batching the components of chromium, nickel, tungsten, carbon, and cobalt according to the weight ratio, and fully mixing the components; b, smelting: mixing the above The raw materials are heated and melted in the crucible, and the melting temperature is 1280 ° C ~ 1320 ° C. The molten alloy liquid flows out from the guide tube at the bottom of the crucible and enters the atomization chamber; c. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com