Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

350 results about "Cobalt base alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt based materials are alloyed with chrome, nickel, and tungsten. Due to the high cost of these alloys, they are used where severe conditions prevail and require high temperature strength and hardness, excellent wear, galling, corrosion, and/or erosion resistance. R30021.

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

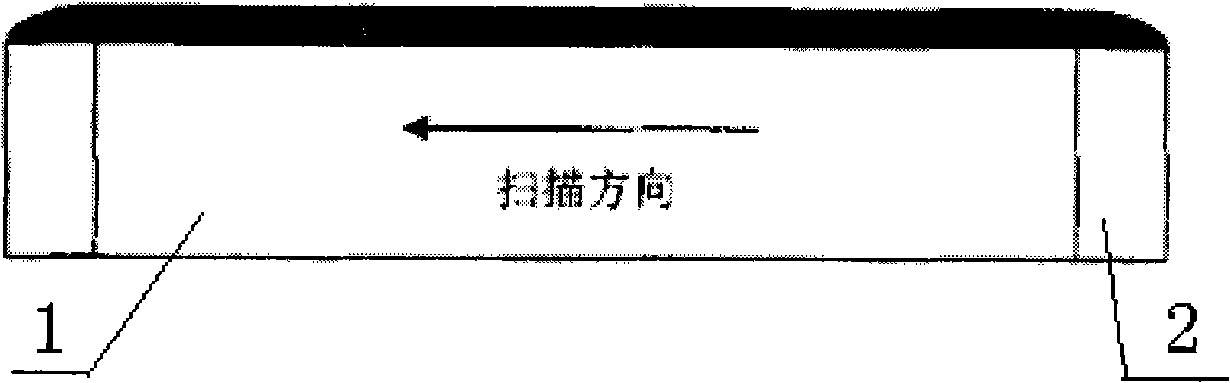

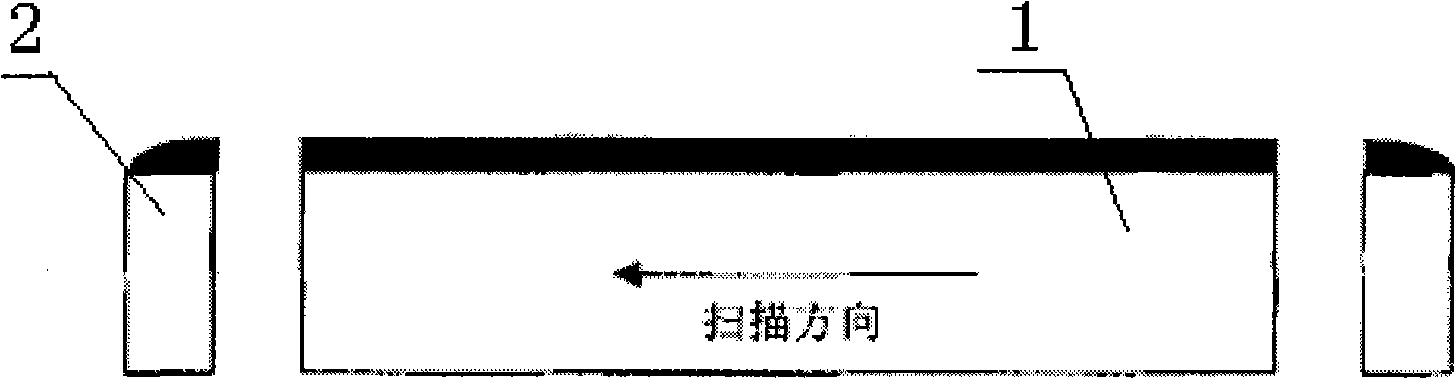

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Cobalt-base alloy with high heat resistance and high strength and process for producing the same

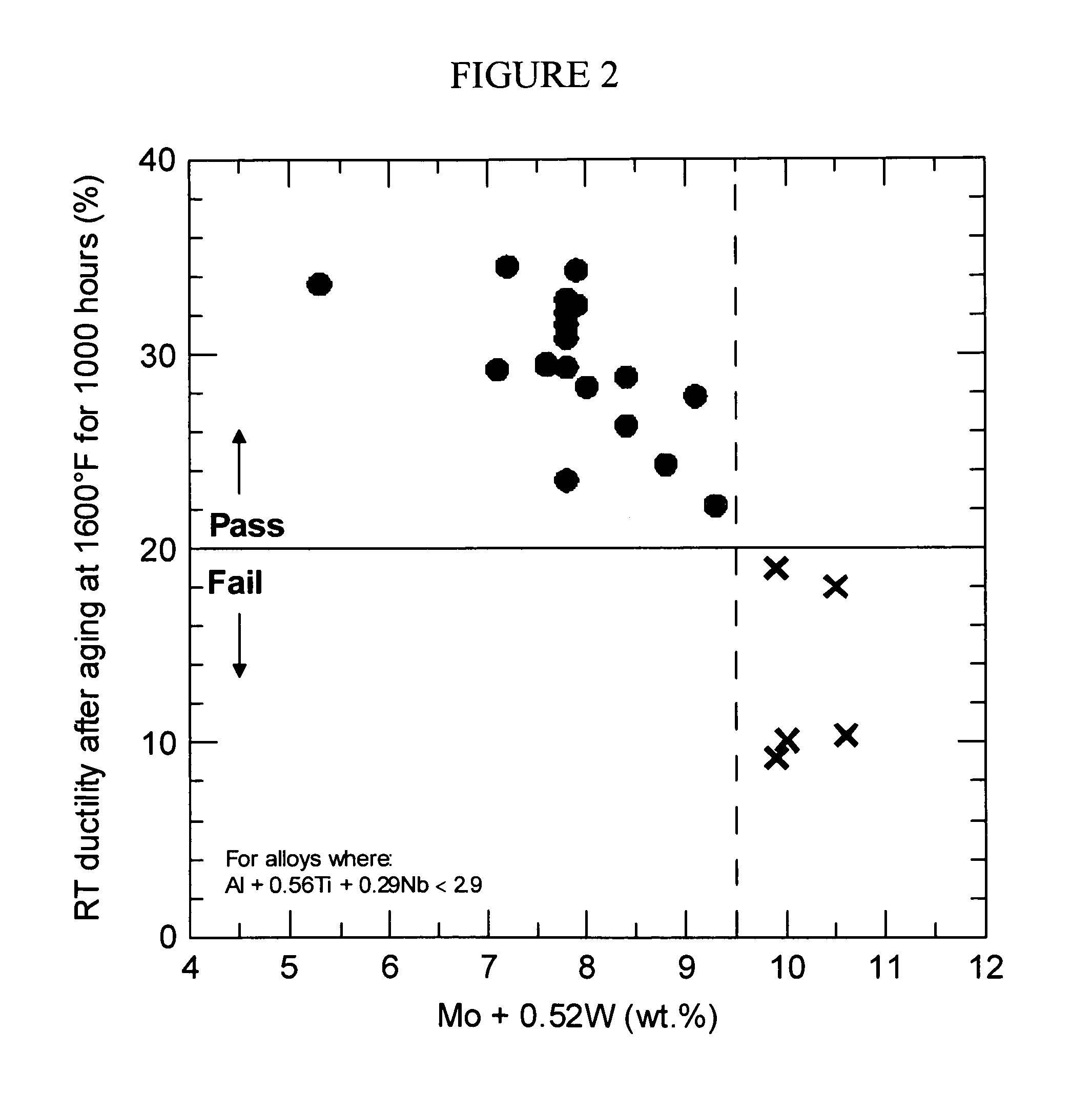

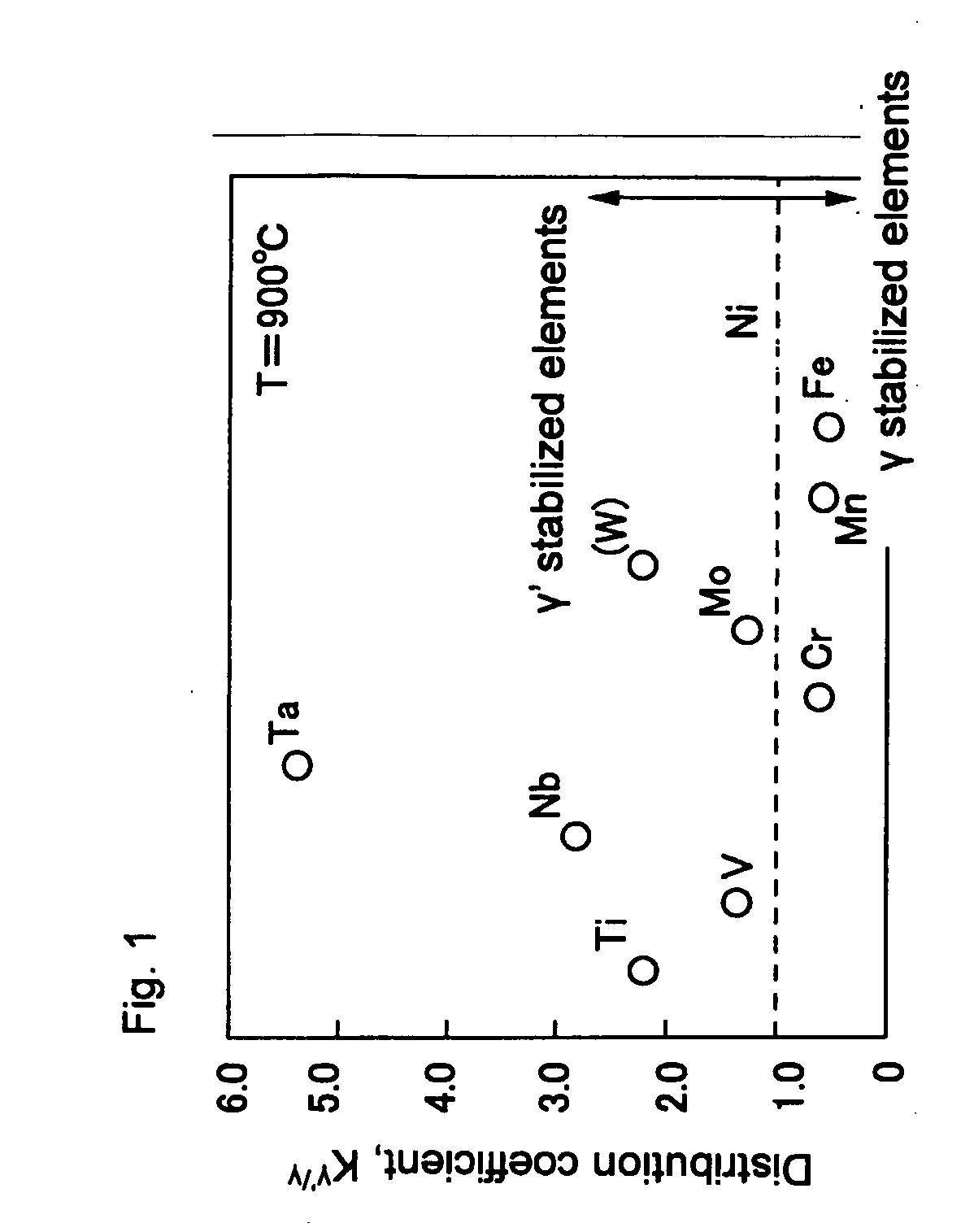

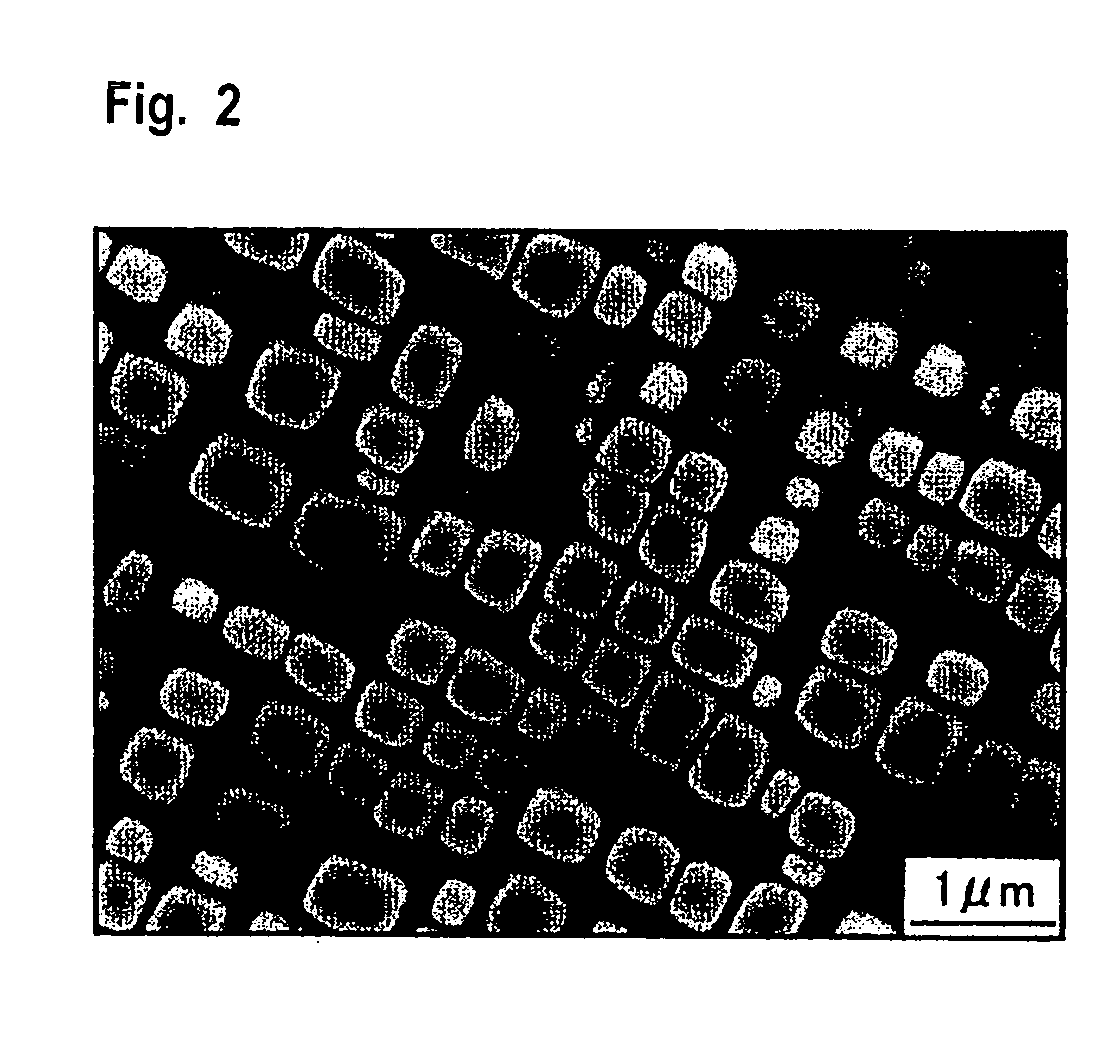

A Co-base alloy which has a basic composition including, in terms of mass proportion, 0.1%-10% Al, 3.0-45% W, and Co as the remainder and has an intermetallic compound of the Ll2 type [Co3(Al,W)] dispersed and precipitated therein. Part of the Co may be replaced with Ni, Ir, Fe, Cr, Re, or Ru, while part of the Al and W may be replaced with Ni, Ti, Nb, Zr, V, Ta or Hf. The intermetallic compound [Co3(Al, W)] has a high melting point, and this compound and the matrix are mismatched little with respect to lattice constant. Thus, the cobalt-base alloy can have high-temperature strength equal to that of nickel-base alloys and excellent structure stability.

Owner:JAPAN SCI & TECH CORP

Method for measuring contents of aluminum, titanium, manganese, nickel, tungsten and iron in cobalt-base alloy

ActiveCN101718689AEasy to handlePromote precipitationPreparing sample for investigationColor/spectral properties measurementsManganeseMaterials science

The invention belongs to a technique for analyzing elements of an alloy, and relates to a method for measuring the contents of aluminum, titanium, manganese, nickel, tungsten and iron in a cobalt-base alloy. The method adopts an inductively coupled plasma atomic emission spectrometer and is different according to different measured elements and different tungsten contents; when high-content tungsten is dissolved, the volume of test solution needs to be maintained between 20 and 40 mL, or the tungsten is easy to be separated out; by performing interference experiments and spectrogram analyses, the method finds the optimal analytical line, overcomes the interferences caused by a plurality of elements such as major elements of cobalt, chromium, tungsten and the like in the cobalt-base alloy, and improves the measuring accuracy; the sample dissolving speed is accelerated, and the sample dissolving time is shortened to 2 hours from about two or three days; and the method has wide measuring ranges including: 0.05 to 0.30 percent of the aluminum, 0.05 to 0.30 percent of the titanium, 0.05 to 1.00 percent of the manganese, 0.05 to 24.00 percent of the nickel, 0.05 to 20.00 percent of the tungsten, and 0.05 to 3.00 percent of the iron.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

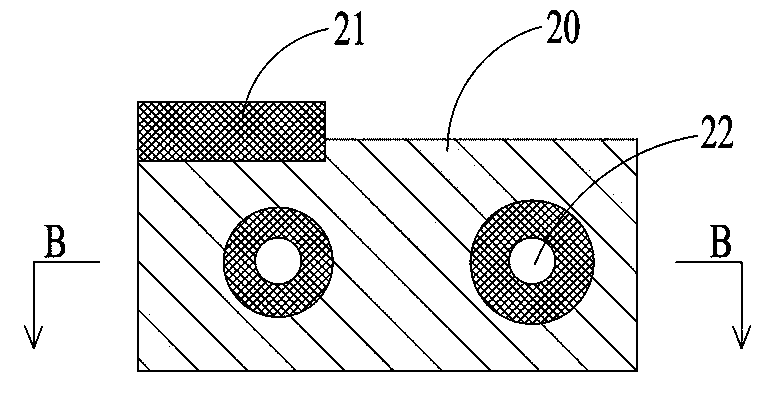

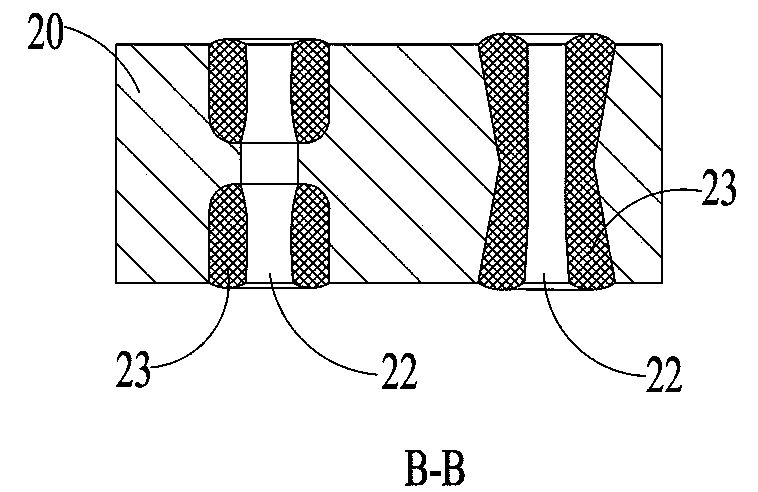

Binary alloy coating seamless steel tube top and manufacture method thereof

InactiveCN101596551AReduce stress concentrationEliminates crack-prone problemsMandrelsFurnace typesBinary alloyLaser coating

A binary alloy coating seamless steel tube top and a manufacture method belong to the field of laser processing. Aiming at solving the easy peel-off of molybdenum alloy of a molybdenum alloy top, prolonging service life and reducing cost, the invention melts and coats nickel-base or cobalt-base alloy coating at the nose or working part of the top, melts and coats iron-base alloy coating at the straightening part and the parallel part to obtain a binary alloy coating seamless steel tube top; the preparation of the top has the following steps of manufacturing the top by adopting a casting manner, performing mechanical processing on the cast top and reserving melt thickness of 1.0-3.0mm on the external surface of the top for laser melt process; using nickel-base or cobalt-base alloy to perform laser melt on the top end of the nose part; performing laser melt on the lateral of the nose part as well as the working part with nickel-base or cobalt-base alloy as melt powder, finishing laser melt on the straightening part and the parallel part with iron-base alloy incessantly; performing strain-removal treatment, namely performing mechanical processing of top nose spiracle and finishing laser coating polishing and grinding.

Owner:BEIJING UNIV OF TECH

Method for preparing wear-resistant coating on surface of driving sheave race of elevator by laser cladding

ActiveCN102453904AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesLaser beam welding apparatusHigh power lasersWear resistant

The invention relates to a method for preparing a wear-resistant coating on the surface of a driving sheave race of an elevator by laser cladding. A rendering transition layer with good toughness, which is clad on the surface of the race and forms metallurgical bonding with a base body, is rapidly scanned by laser through high-power laser; and a wear-resistant cobalt-base alloy which has good corrosive resistance and a frication coefficient in fit with that of a steel wire rope is prepared on a rendering alloy surface through laser cladding. The method is characterized by comprising the following special steps of: firstly, pre-treating the surface of the race; secondly, selecting alloy powder and an automatic powder sending device; thirdly, carrying out the laser cladding on the rendering alloy and the cobalt-base alloy powder with the frication coefficient in fit with that of the steel wire rope so that a wear-resistant coating with the thickness of 0.5-1.2 mm is formed on the surface of the race; and finally, carrying out flaw detection after cladding. The method provided by the invention has the characteristics of high productivity, lower energy consumption, small machining allowance of a cladding layer, high field, low combined cost and the like.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

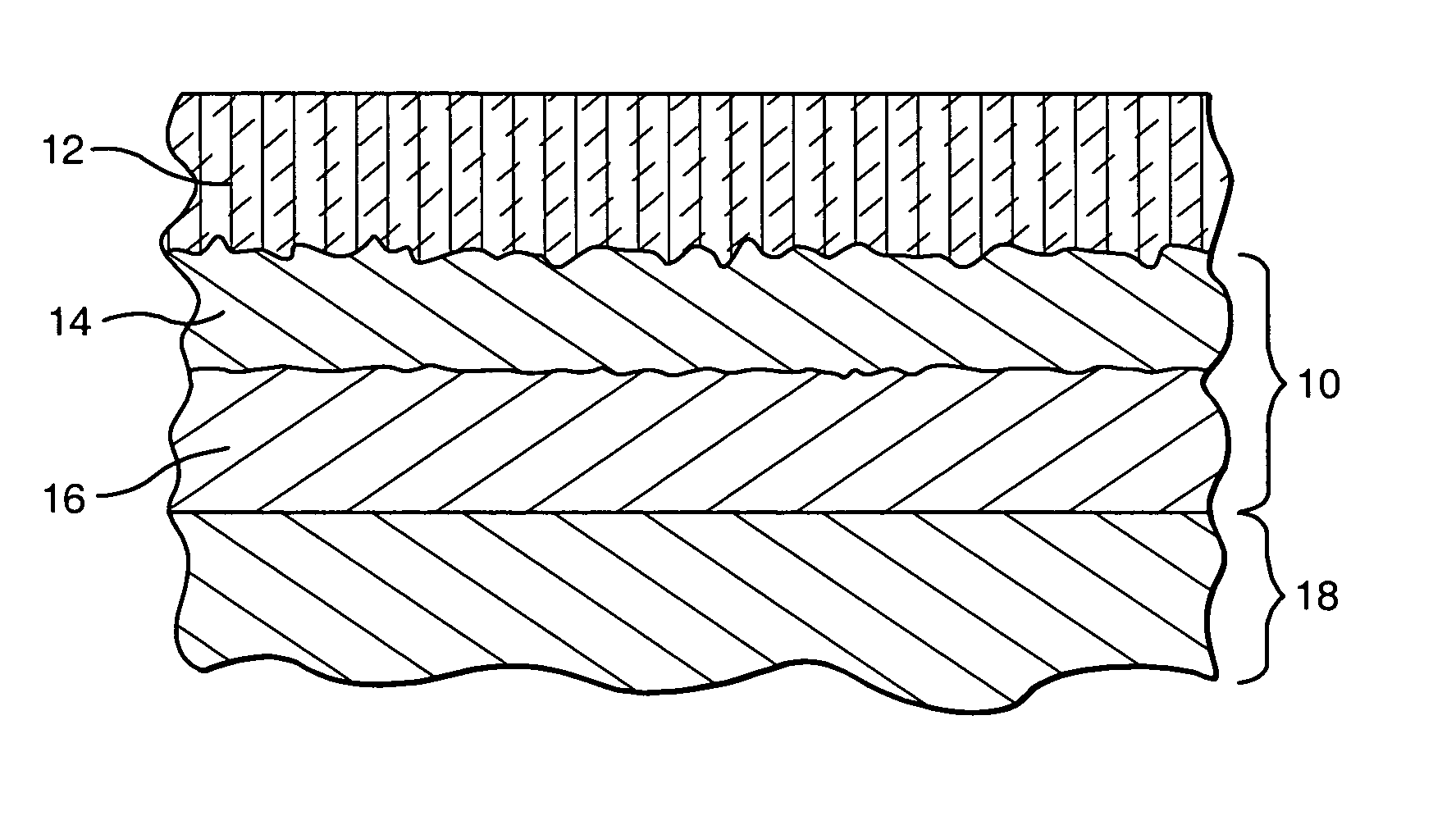

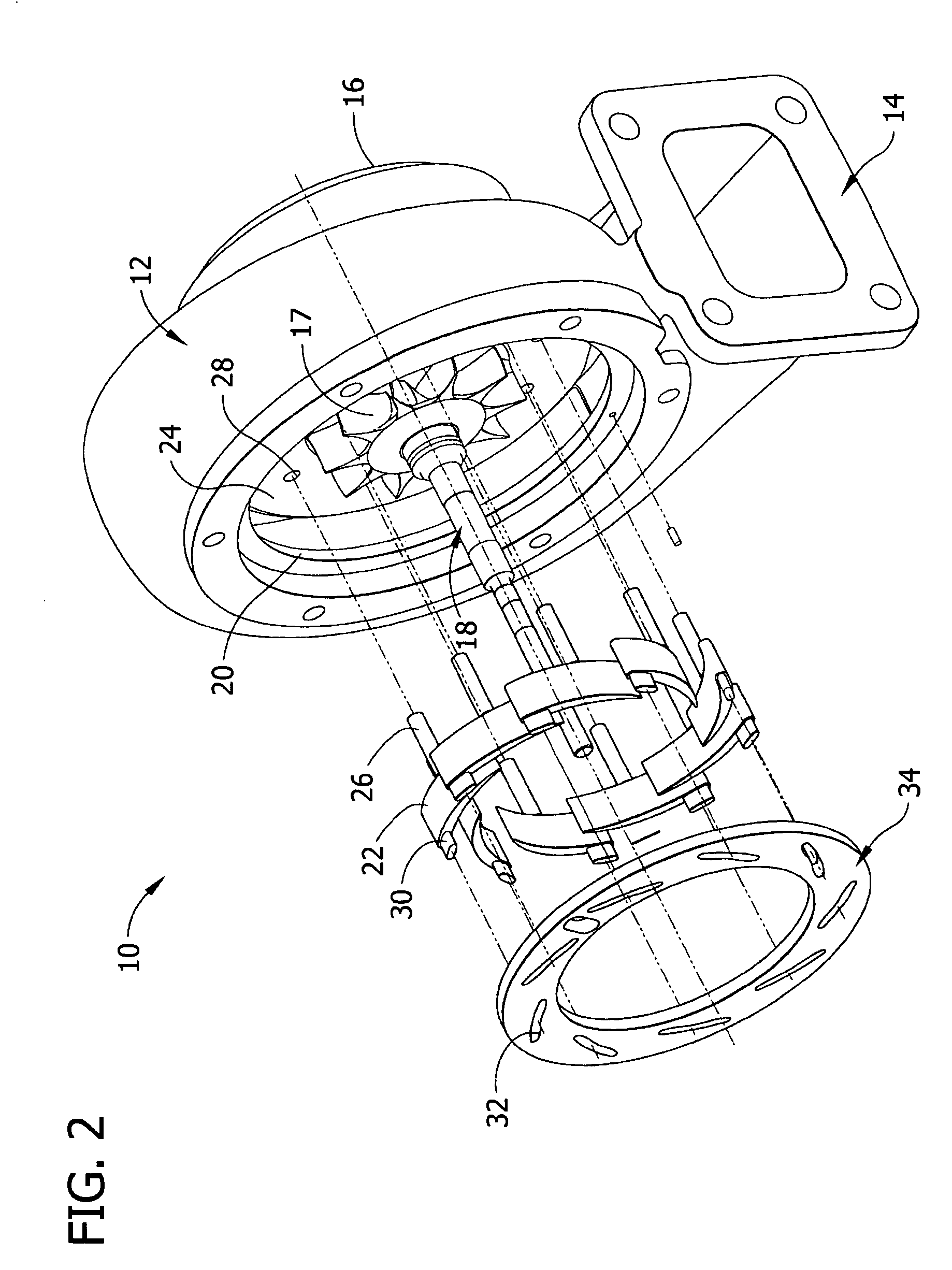

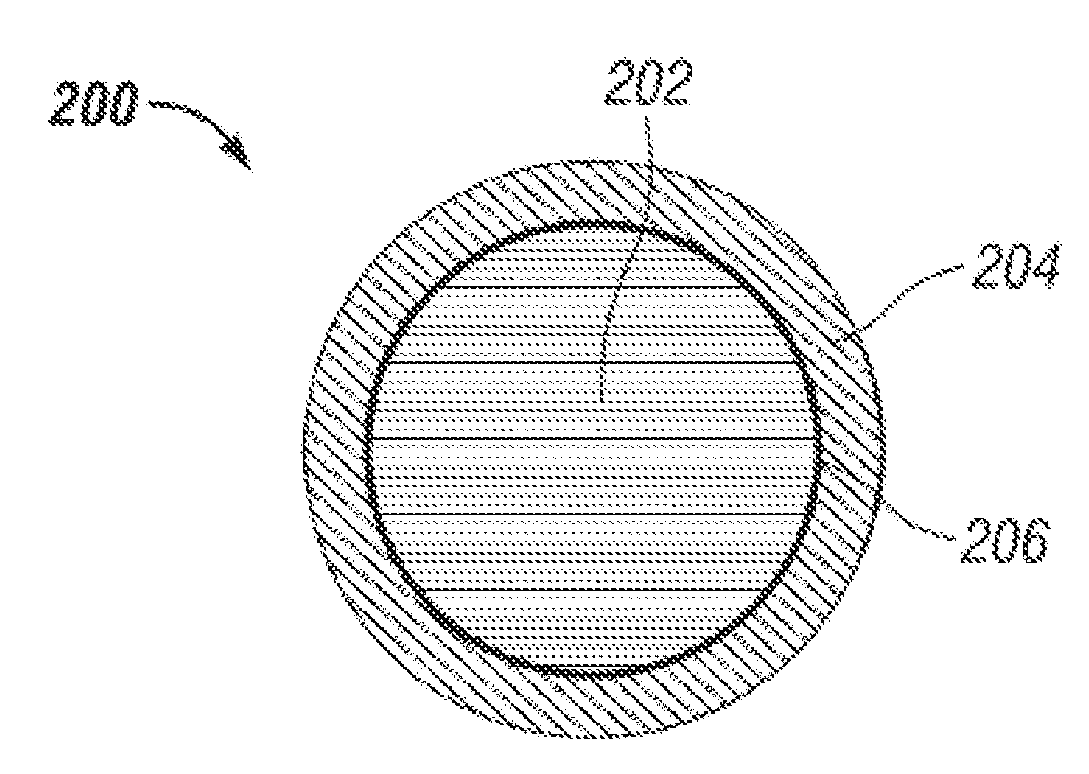

Bi-layer HVOF coating with controlled porosity for use in thermal barrier coatings

InactiveUS7150921B2Increase roughnessImprove ductilityMolten spray coatingPretreated surfacesPorosityPolyester

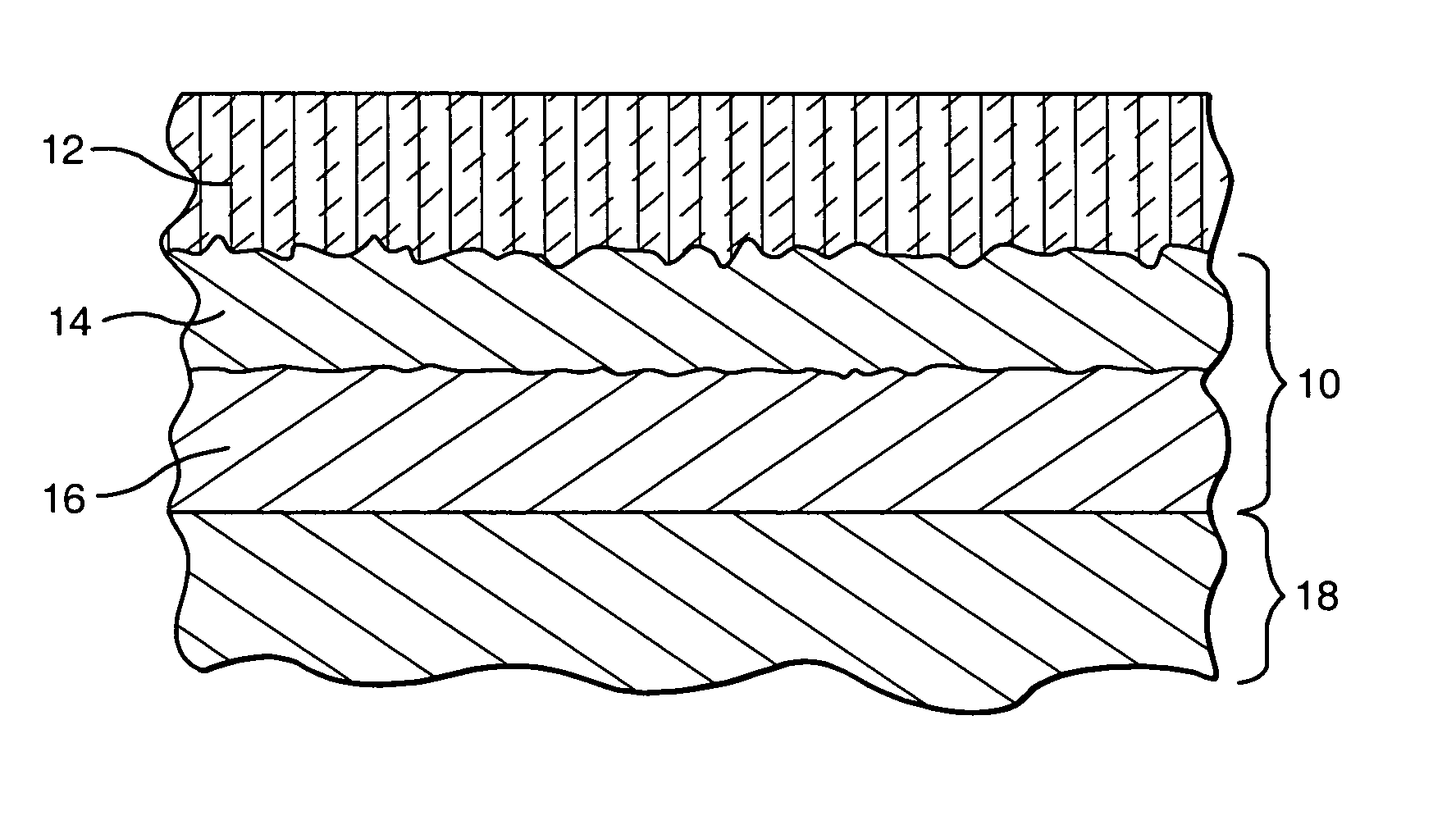

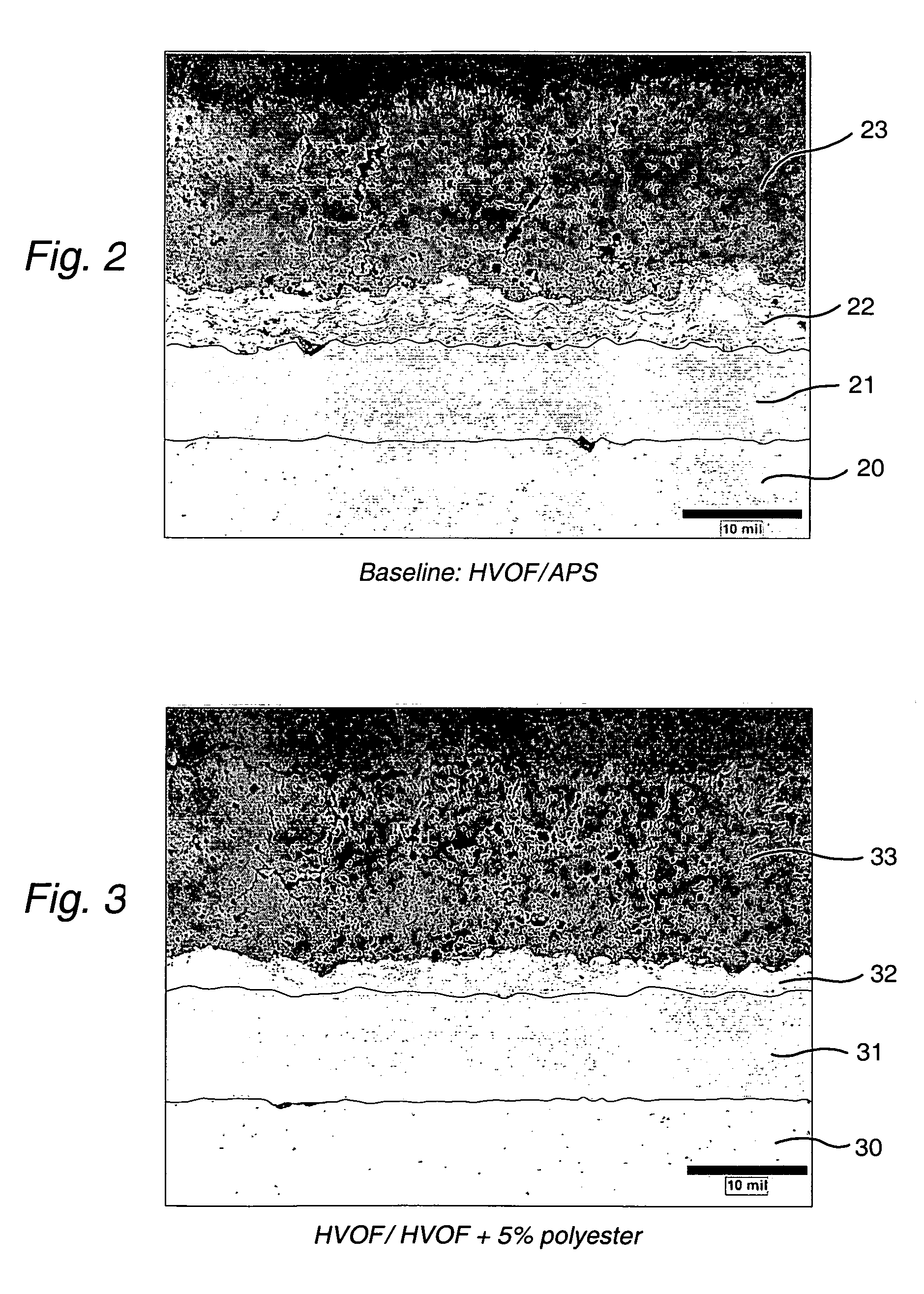

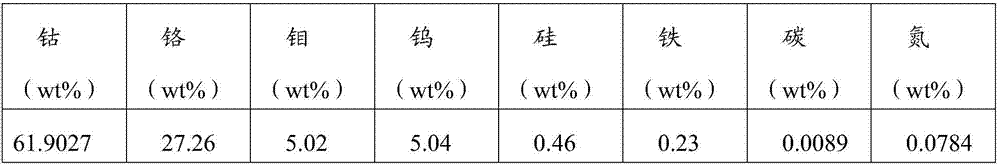

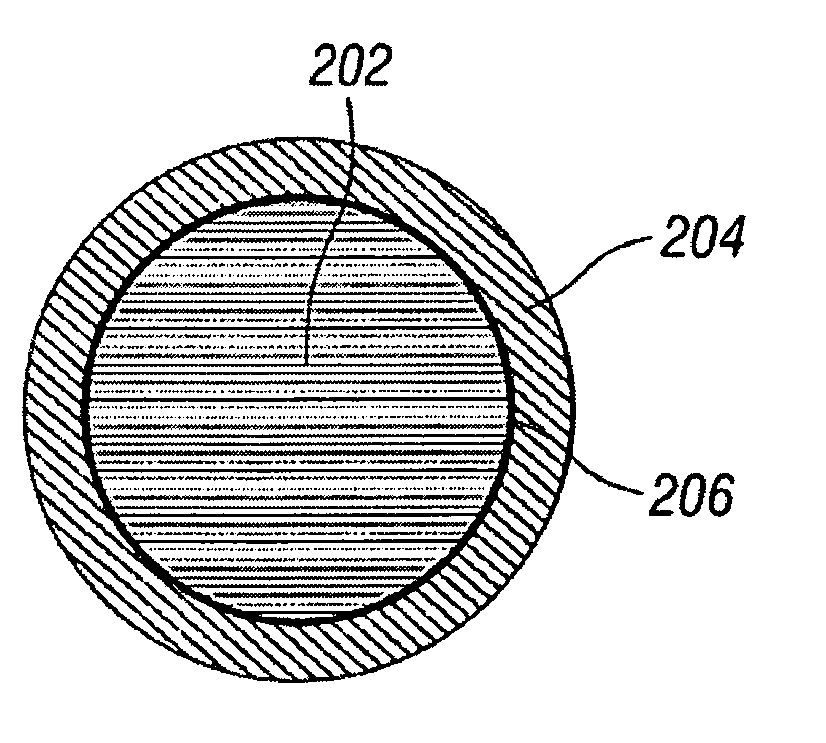

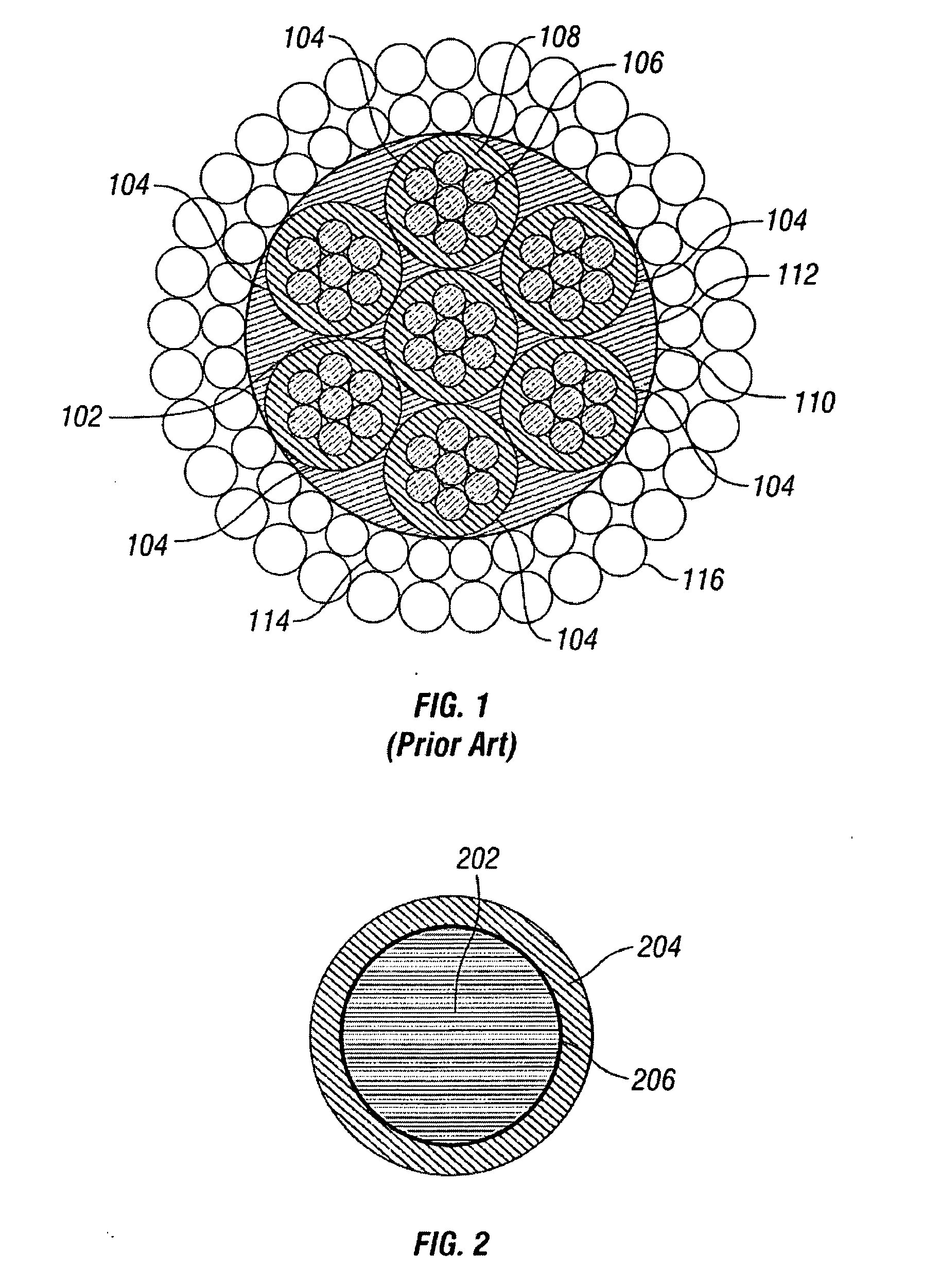

A bi-layer bond coating for use on metal alloy components exposed to hostile thermal and chemical environment, such as a gas turbine engine, and the method for applying such coatings. The preferred coatings include a bi-layer bond coat applied to the metal substrate using high velocity oxy-fuel (HVOF) thermal spraying. Bi-layer bond coatings in accordance with the invention consist of a dense first inner layer (such as iron, nickel or cobalt-based alloys) that provides oxidation protection to the metal substrate, and a second outer layer having controlled porosity that tends to promote roughness, mechanical compliance, and promotes adherence of the thermal barrier coating (TBC). Preferably, the outer, less dense layer of the bi-layer bond coat is formed from a mixture of metallic powder and polyester to adjust and control the porosity, but without sacrificing mechanical compliance.

Owner:GENERAL ELECTRIC CO

Bi-layer HVOF coating with controlled porosity for use in thermal barrier coatings

InactiveUS20050260434A1Increase roughnessImprove ductilityPropellersMolten spray coatingPolyesterPorosity

A bi-layer bond coating for use on metal alloy components exposed to hostile thermal and chemical environment, such as a gas turbine engine used to generate electricity and the method for applying such coatings. The preferred coatings include a bi-layer bond coat applied to the metal substrate, with both layers being applied using high velocity oxy-fuel (HVOF) thermal spraying. In one embodiment, bond coatings in accordance with the invention can be used in combination with a thermal barrier coating (“TBC”). However, the invention can also take other forms, such as a stand alone overlay coating. Bi-layer bond coatings in accordance with the invention consist of a dense first inner layer (such as iron, nickel or cobalt-based alloys) that provides oxidation protection to the metal substrate, and a second outer layer having controlled porosity that tends to promote roughness, mechanical compliance, and promotes adherence of the TBC. Preferably, the outer, less dense layer of the bi-layer bond coat is formed from a mixture of metallic powder and polyester to adjust and control the porosity, but without sacrificing mechanical compliance. Together, the layers enhance adherence to the substrate and improve the overall life of the coating system.

Owner:GENERAL ELECTRIC CO

Laser cladding wear-resisting and heat fatigue-resisting alloy coating process for manufacturing hot rolled seamless steel tube rolling mill retained mandrel

InactiveCN101994114AStrong metallurgical bondEnabling Laser ManufacturingMetallic material coating processesSurface cleaningAlloy coating

The invention discloses a laser cladding wear-resisting and heat fatigue-resisting alloy coating method for manufacturing a hot rolled seamless steel tube rolling mill retained mandrel, which is characterized by comprising the following steps: carrying out surface cleaning on greasy dirt and rustyscale of a retained mandrel; selecting cobalt-base alloy powder; adopting laser equipment and an automatic powder delivering device; carrying out laser cladding processing on the surface of the retained mandrel so as to form a 0.2-2mm coating with high-temperature oxidation resistance, heat fatigue resistance and heat abrasion resistance; and carrying out high temperature tempering processing on the retained mandrel after being subject to the laser cladding processing so as to decrease the coating after being subject to the laser cladding processing and the residual stress after the gene matrix is transformed. The laser cladding alloy coating of the invention is even and compact, has the characteristics of high production efficiency, low energy consumption, small machining allowance of a cladding layer, high yield and low comprehensive cost and the like.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Cobalt-based alloy powder and preparation method and application thereof

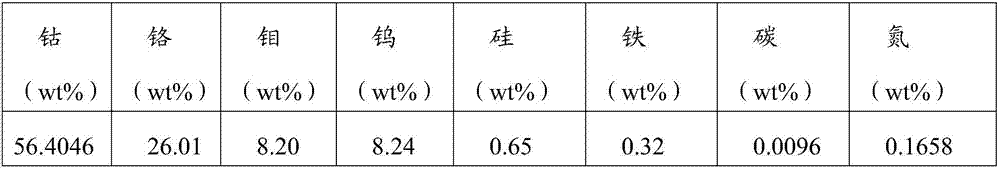

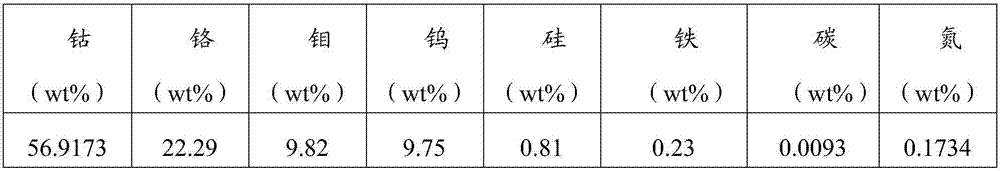

ActiveCN107513642AImprove liquiditySmall particle sizeAdditive manufacturing apparatusTransportation and packagingChemical compositionNitrogen

The invention relates to cobalt-based alloy powder and a preparation method and application thereof. The cobalt-based alloy powder is prepared from, by weight percentage, 22-32% of chromium, 4-10% of molybdenum, 4-10% of tungsten, 0-1% of silicon, 0-0.75% of iron, 0-0.35% of carbon, 0.05-0.2% of nitrogen and the balance cobalt. The cobalt-based alloy powder is good in fluidity, small in particle size and concentrated in particle size distribution; the mechanical performance of a cobalt-based alloy material prepared through the cobalt-based alloy powder can reach the 5 type / type 5 of the GB17168 / ISO 22674 requirement, the tensile strength reaches 1326 MPa, and the non-proportional extension strength reaches 948 MPa; and the elastic modulus reaches 206 GPa, and the fracture elongation rate reaches 13.8%.

Owner:GUANGZHOU NALIAN MATERIAL TECH CO LTD

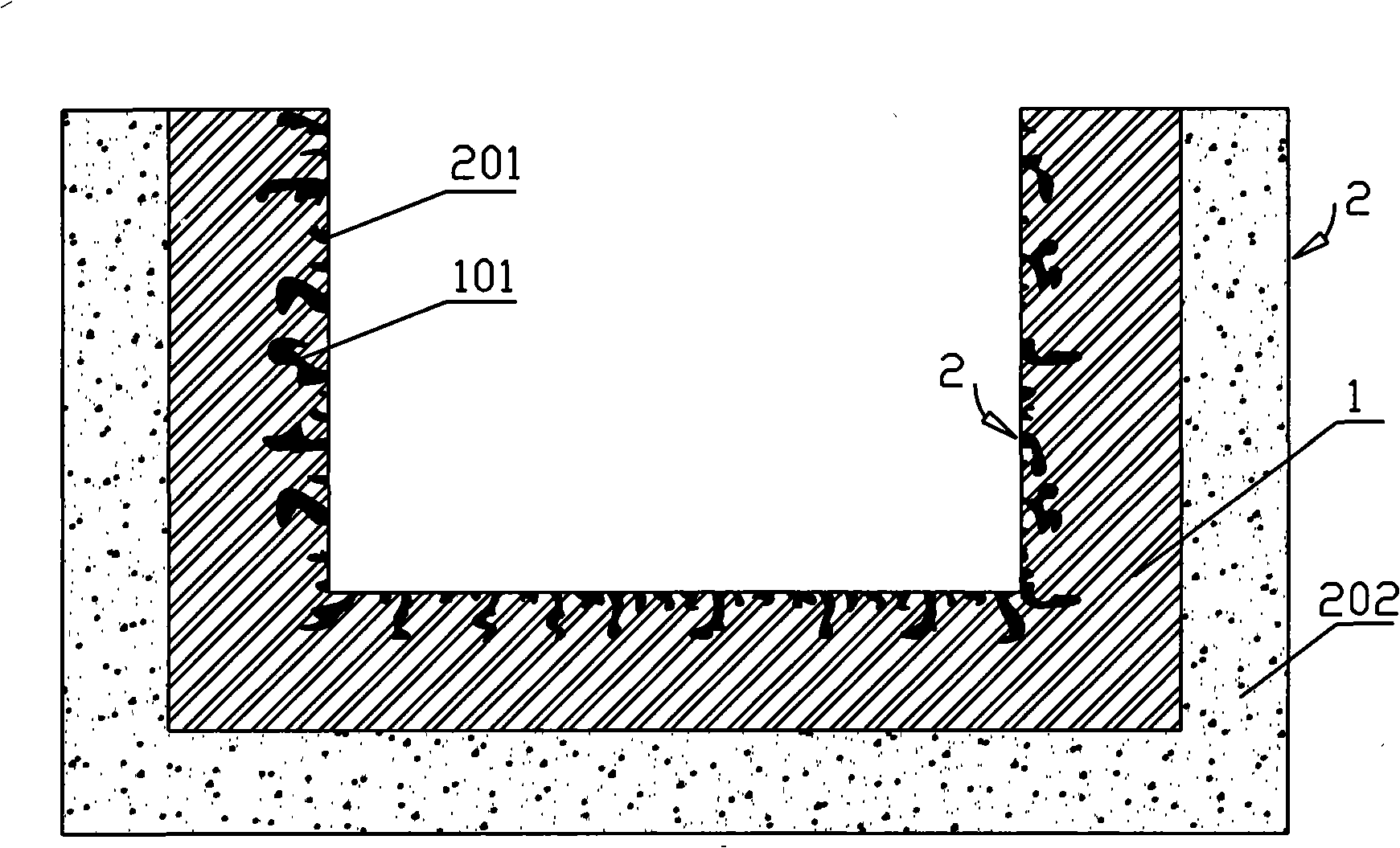

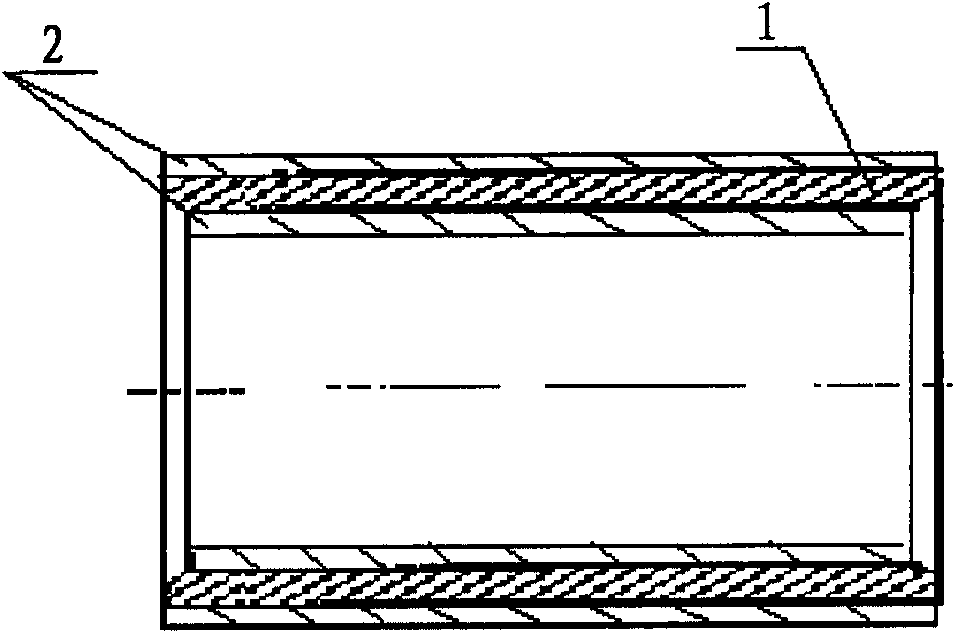

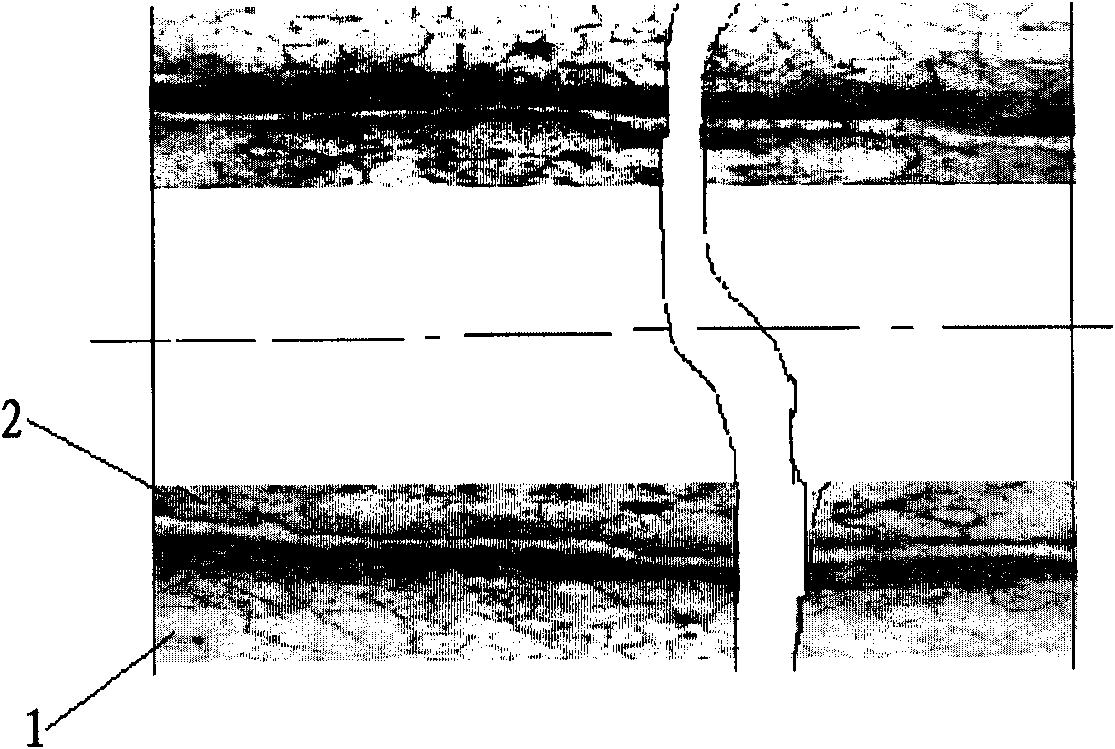

Laser cladding cobalt-base alloy coating material of continuous casting crystallizer copperplate and process

InactiveCN101775525AEnough widthDense tissueMetallic material coating processesSocial benefitsAutomatic control

The invention relates to a laser cladding cobalt-base alloy coating material of a continuous casting crystallizer copperplate and a process, which is characterized in that the cobalt-base alloy coating is a cobalt-base alloy and contains the components by weight percent: 0.6-1.2 percent of C, 20-30 percent of Cr, 13-20 percent of W, 3-5 percent of Mo, 0.8-1.2 percent of Si, 0.4-1.0 percent of Fe, 7-9 percent of Ni, 5 percent of Nb and the balance of Co. The cladding coating has compact tissue and does not have cracks or air holes and forms good metallurgical bonding with the surface of a crystallizer copperplate, and a cladding layer which is 2mm thick or above can be formed. The process can accurately control the thickness of the coating and realize automatic control on the whole process and has the advantages of low energy consumption, no pollution, high efficiency and low cost. Consequently, the invention can improve the disadvantages of the original crystallizer coating technology and has obvious economic benefits and social benefits.

Owner:QINHUANGDAO SHOUGANG CHANGBAI MOLD +1

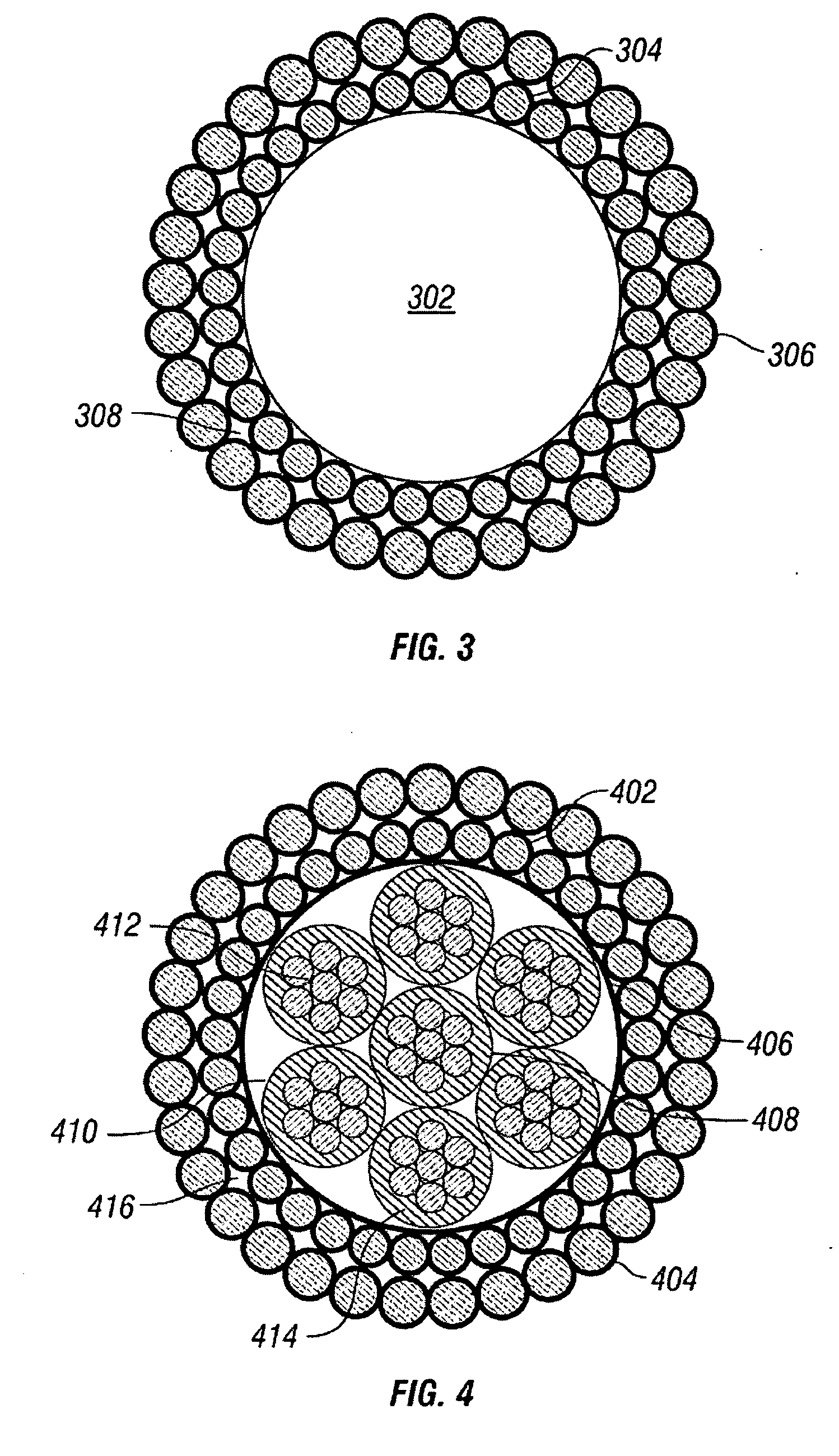

Lightweight armor wires for electrical cables

ActiveUS20070158095A1Simple designHigh strengthNon-insulated conductorsPlastic/resin/waxes insulatorsElectrical conductorTitanium alloy

Disclosed are electric cables with improved armor wires used with wellbore devices to analyze geologic formations adjacent a wellbore. The cables include at least one insulated conductor, and one or more armor wires surrounding the insulated conductor. The armor wires include a low density core surrounded by a corrosion resistant alloy clad, where the alloy clad includes such alloys as beryllium-copper based alloys, nickel-chromium based alloys, superaustenitic stainless steel alloys, nickel-cobalt based alloys, nickel-molybdenum-chromium based alloys, and the like. The low density core may be based upon titanium or titanium alloys. The cables of the invention may be any useful electric cable design, including monocables, quadcables, heptacables, quadcables, slickline cables, multiline cables, coaxial cables, or seismic cables.

Owner:SCHLUMBERGER TECH CORP

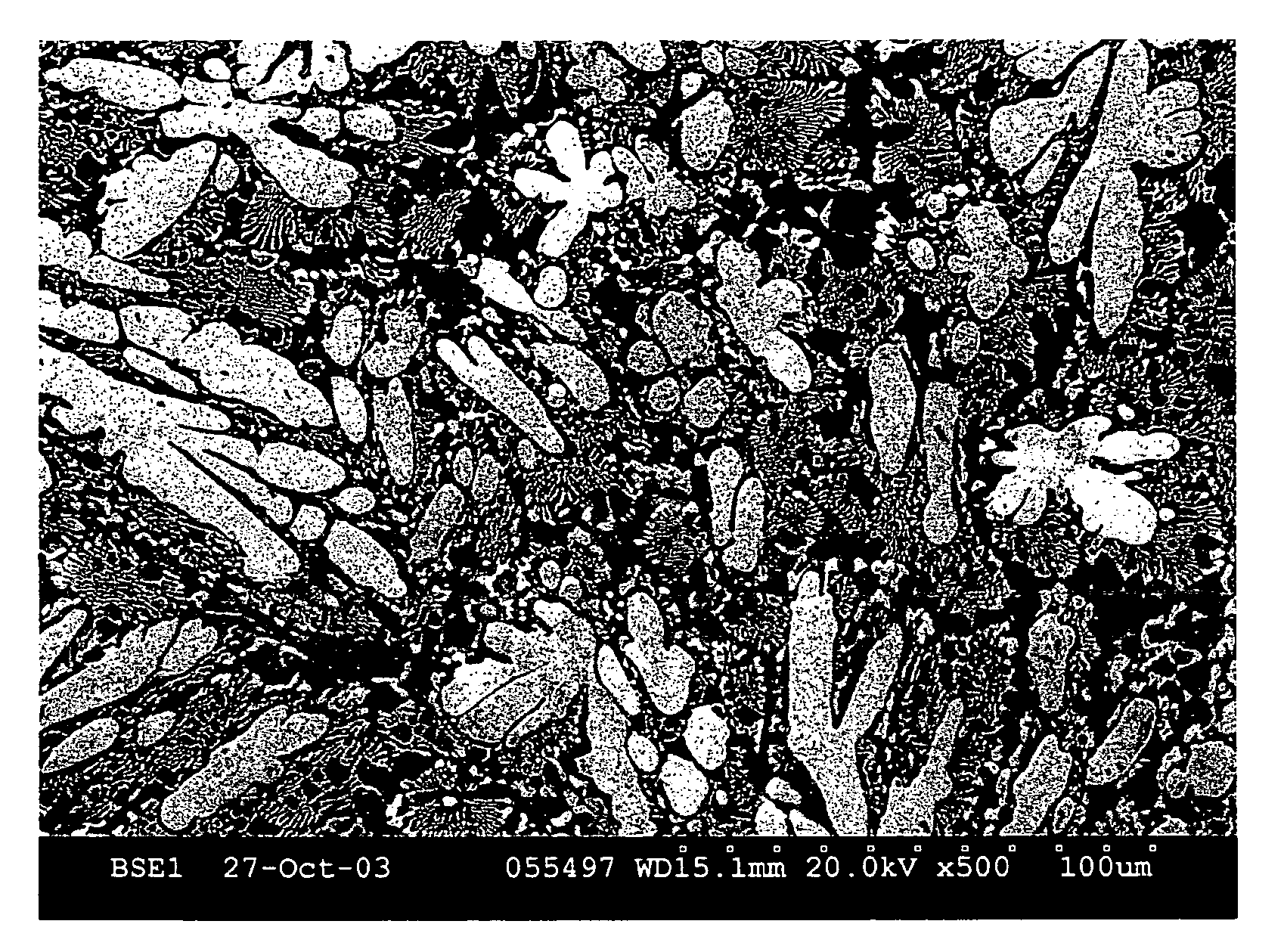

Imparting high-temperature degradation resistance to components for internal combustion engine systems

ActiveUS20060134455A1Impart resistancePretreated surfacesSolid state diffusion coatingSlurryAlloy coating

A method of imparting high-temperature, degradation resistance to a component associated with an internal combustion engine involving applying a metal slurry comprising a Co-based metallic composition, a binder, and a solvent to a surface of the component, and sintering the Co-based metallic composition to form a substantially continuous Co-based alloy coating on the surface of the body. An internal combustion engine component comprising a metallic substrate and a Co-based metallic coating thereon which has a thickness between about 100 and about 1000 microns.

Owner:KENNAMETAL INC

Composite overlaying method for bush and sleeve of rolls for hot dipping

InactiveCN101596634AImprove wear resistanceAccelerated corrosionHot-dipping/immersion processesArc welding apparatusWear resistantRoom temperature

The invention discloses a composite overlaying method for a bush and a sleeve at both ends of a sink roll and a stabilization roll for hot dipping. A substrate adopts a stainless steel iron-based material, and a cobalt-based alloy material working face is overlaid on the substrate. The method comprises the following steps of: preheating the manufactured substrate of the bush and the sleeve to 500 to 650 DEG C, keeping temperature for 1 to 3 hours, and slowly cooling to 250 to 350 DEG C at a speed of 50 to 150 DEG C per hour; overlaying cobalt-based alloy materials on the substrate; heating the overlaid bush and sleeve to 500 to 650 DEG C, keeping temperature for 1 to 3 hours, and slowly cooling to a room temperature at a speed of 10 to 50 DEG C per hour; and finally, roughing and finishing the overlaid bush and sleeve. The bush and the sleeve for the sink roll and the stabilization roll in the invention work under the condition of hot-dipping of aluminum, aluminum zinc, zinc, zinc aluminum, pure aluminum liquid, and the like, have enough bonding strength of the substrate and the working face and good corrosion resistant and wear resistant performance, and improve the service life and reliability of the bush and the sleeve for the sink roll and the stabilization roll.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

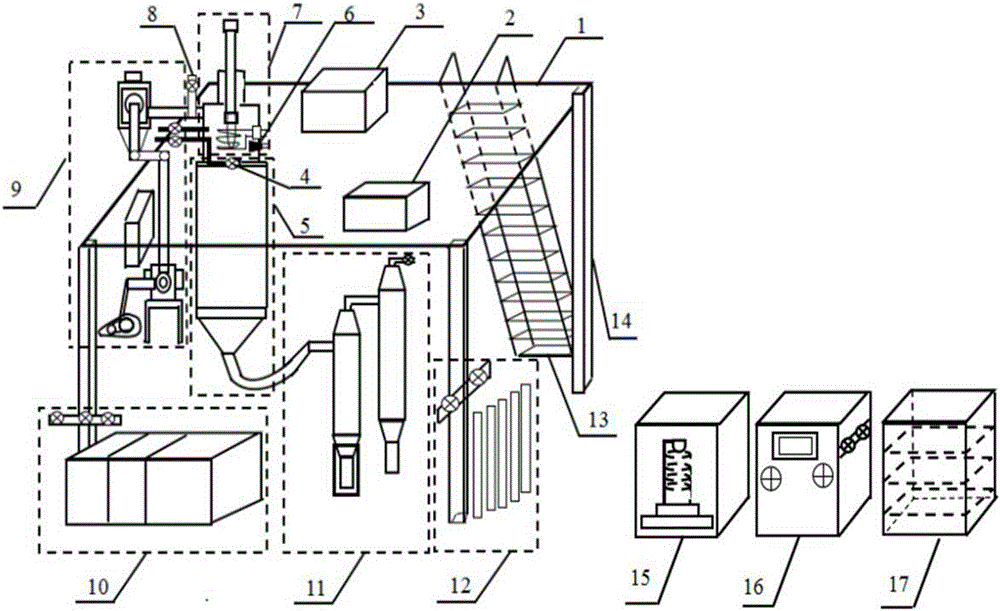

Alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing

InactiveCN106424748AWith mechanical controlWith automatic controlAdditive manufacturing apparatusTransportation and packagingAutomatic controlCollection system

The invention relates to a high-performance alloyed spherical powder preparation device and method for laser 3D (three-dimensional) printing. The device comprises a vacuum acquirement and inflation system, an induction smelting system, an atomization powder preparation system, a power collection system and a power system. The preparation method includes that: (1) the induction smelting system selects a non-crucible induction system or a crucible induction system; (2) alloy bars are fixed on a continuous feeder, or nickel-based / cobalt-based alloy bars are put in a smelting chamber; (3) the smelting chamber, an atomizing chamber and a power collection device are vacuumized prior to be fed with inert gas; (4) induction smelting is started, when alloy reaches preset temperature, alloy droplets are enabled to enter the atomization powder preparation system, and nozzles are started to perform atomization powder preparation; alloyed power prepared in the atomization chamber is collected through the powder collection device. The device can realize mechanical control, automatic control and real-time monitoring; the prepared alloy powder is high in yield, uniform in particle size distribution, good in degree of sphericity, uniform in chemical component, good in mobility, low in oxygen content and low in hollow sphere rate.

Owner:NORTHEASTERN UNIV

Copper-base crystallizer surface laser cladding method

ActiveCN101532133AHigh hardnessImprove wear resistanceMolten spray coatingSuperimposed coating processHardnessCo2 laser

A copper-base crystallizer surface laser cladding method is characterized in that the method comprises the following steps in sequence: (1) preparing a nickel-base transition layer with thickness of 0.3-0.5mm; (2) melting the transition layer by using a mixing mode CO2 laser beam; (3) preparing a nickel-base or cobalt-base alloy work layer with thickness of 0.6-1.0mm by ultrasonic spraying; (4) melting transition layer by using the mixing mode CO2 laser beam; and (5) processing a laser cladding layer into a smooth surface. By the method of the invention, excellent metallurgically bonded cladding layers are formed on copper-base materials. The hardness and wearing resistance experiments show that the hardness of the work layer is above Hv350, which is improved by more than 3 times compared with the hardness of copper alloy; the wear loss of the laser cladding nickel-base or cobalt-base work layer is about 10mg and the high temperature wearing resistance is over 5 times as high as that of the copper alloy, thus having the effect of strengthening the copper alloy. The method of the invention is suitable for not only strengthening the copper-base crystallizer but also strengthening various copper-base alloy surfaces.

Owner:GUANGDONG INST OF NEW MATERIALS

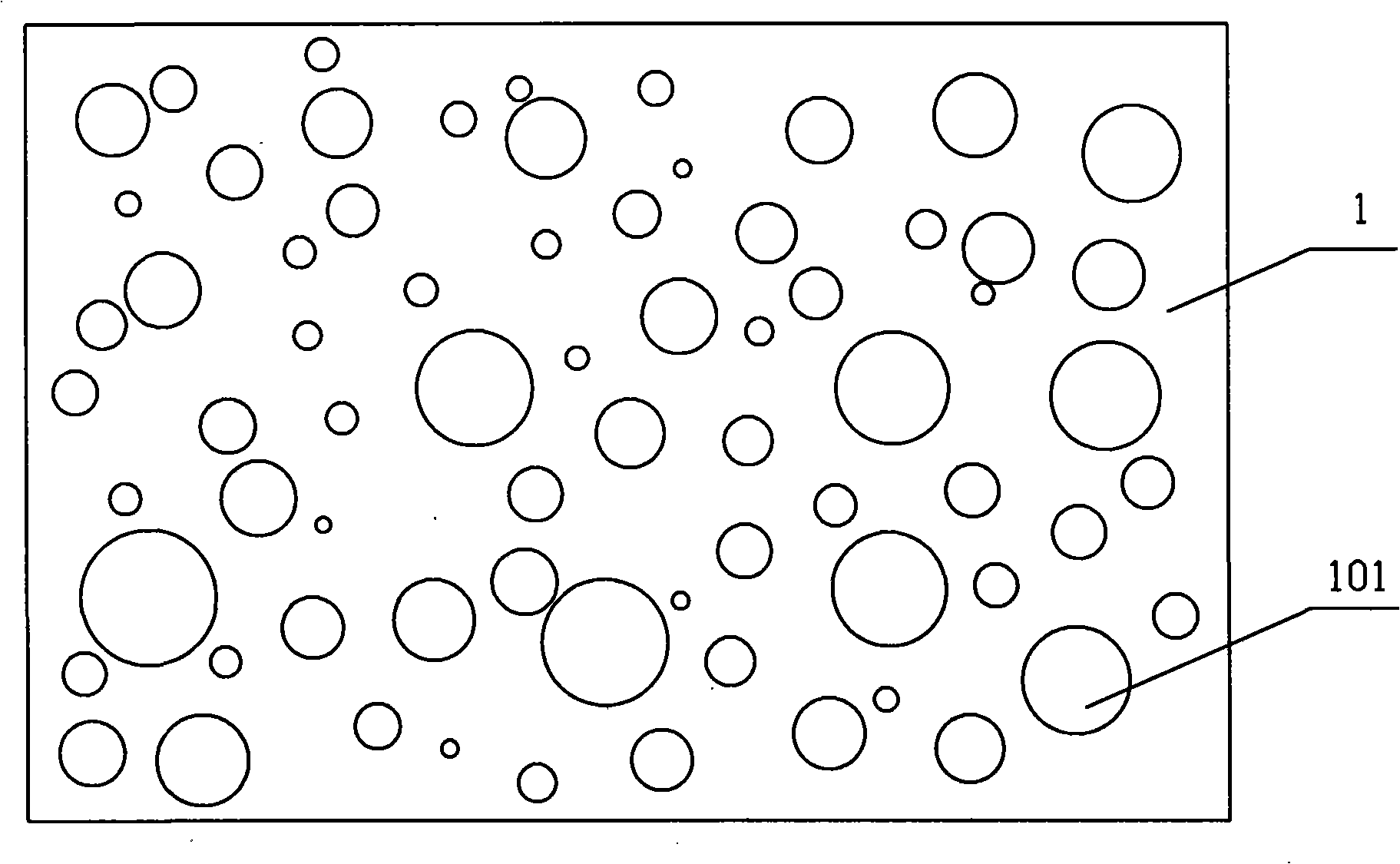

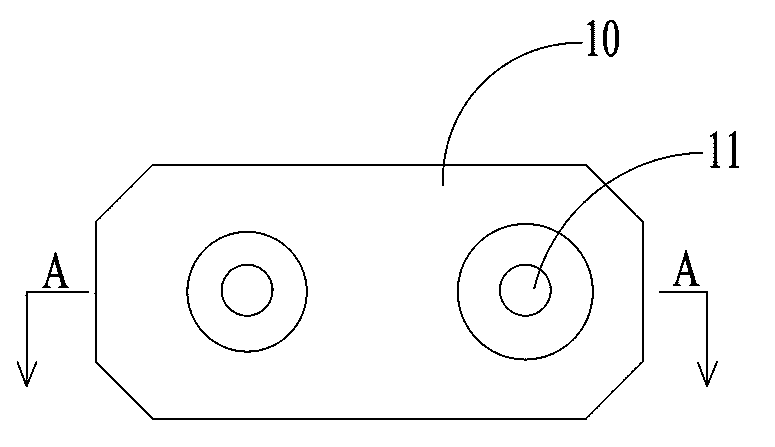

Metal composite material capable of inducing bone growth and application thereof

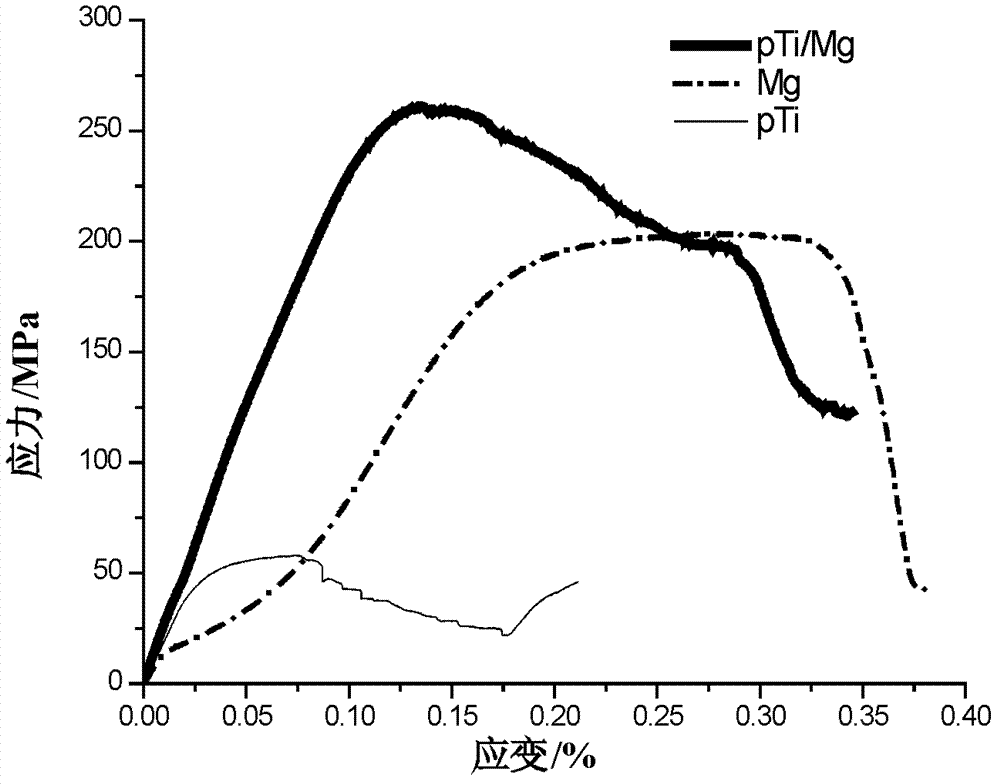

ActiveCN103357063AHigh bonding strengthImprove biological activityProsthesisBone structureMetallic materials

The invention discloses a metal composite material capable of inducing bone growth and an application thereof. The metal composite material is especially suitable for biomedical engineering for human hard tissue defect, comprising an artificial joint, artificial bone, a dental implant, a plastic surgery medical apparatus and instrument, a bone marrow cavity implant and the like. Specifically a double-phase composite material capable of inducing bone growth is provided, a cellular structure is prepared on a clinical medical metal material (titanium, titanium alloy, stainless steel, cobalt-base alloy, nickel-titanium shape memory alloy and the like), magnesium or a magnesium alloy capable of inducing bone growth is filled in the cellular structure, and the composite material in the structure can be used as a solid material, and as the surface / partial structure of a solid metal material. By virtue of the design of the composite material, the bioactivity of an existing medical metal implantable device can be improved; along with the continuous decomposition and bone induction effect of the magnesium or the magnesium alloy in a human body environment, and the bone structure is gradually induced to grow into the cellular structure to enhance the binding strength of the bone tissue with the implant so as to prevent the implant from getting separated, achieve good biological immobilization, and greatly improve the bone integration effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ni-Cr-Co alloy for advanced gas turbine engines

Owner:HAYNES INTERNATIONAL

Cobalt-based alloy powder for laser cladding of steam turbine last-stage blade

InactiveCN102021559AImprove performanceHigh hardnessMetallic material coating processesHardnessWear resistance

The invention discloses cobalt-based alloy powder for the laser cladding of a steam turbine last-stage blade. The powder comprises Cr, W, Co, Zr and Hf and is characterized by also comprising Ni, Mn, Si and C, wherein the powder comprises the following components in percentage by mass: 0.4 to 0.9 percent of C, 24 to 30 percent of Cr, 6 to 10 percent of W, 8 to 14 percent of Ni, 0.3 to 0.8 percent of Mn, 0.5 to 1.0 percent of Si, 0.02 to 0.06 percent of Zr, 0.25 to 0.5 percent of Hf and the balance of Co. The powder is cladded on a disabled steam turbine last-stage blade by a laser cladding processing method to form a cobalt-based alloy coating with high hardness, oxidation resistance, corrosion resistance, erosive wear resistance, high strength and high cladding performance so as to solve the technical problem of the repair of the steam turbine last-stage blade.

Owner:成都大陆激光技术有限公司

Bimetallic materials for oilfield applications

Corrosion resistant and / or lightweight bimetallic cylinders used in tools and electric cables, including core surrounded by corrosion resistant alloy outer cladding materials, where the alloy clad may include such alloys as beryllium-copper based alloys, nickel-chromium based alloys, superaustenitic stainless steel alloys, nickel-cobalt based alloys, nickel-molybdenum-chromium based alloys, and the like. The core may be a low density core based substantially upon titanium or titanium alloys.

Owner:SCHLUMBERGER TECH CORP

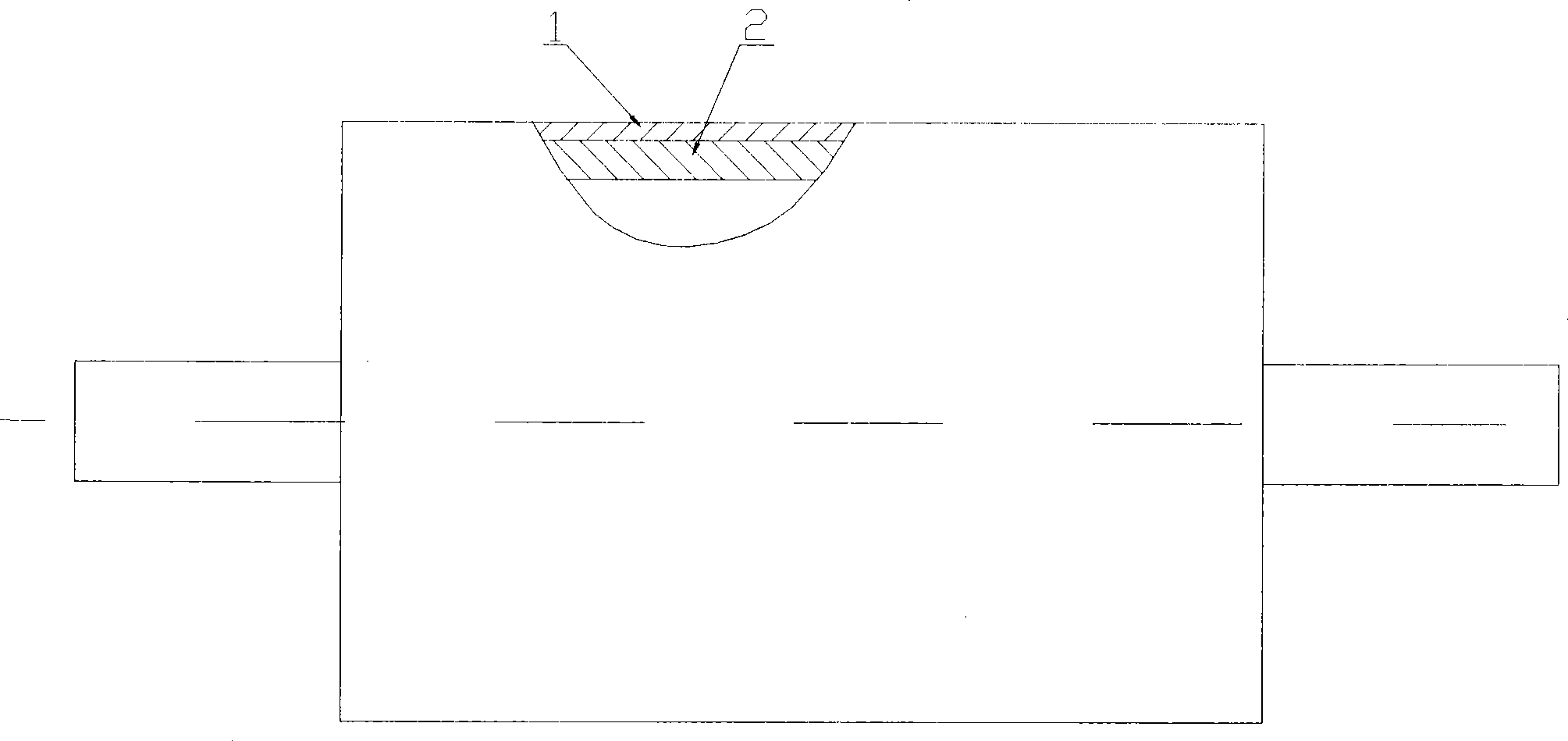

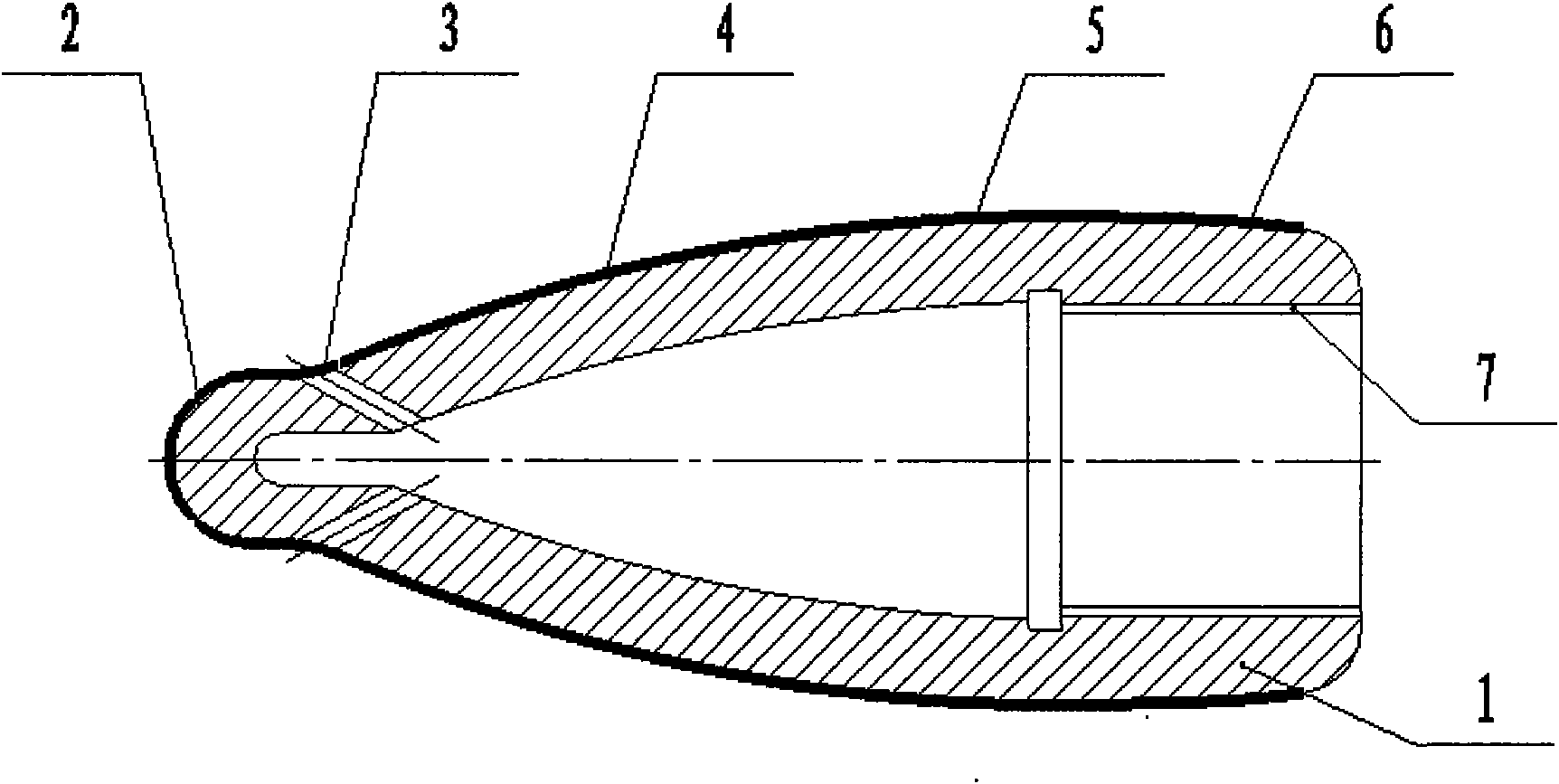

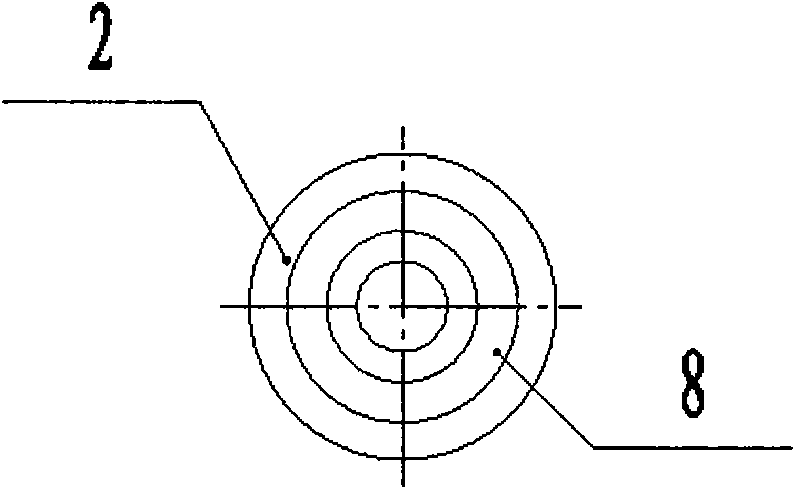

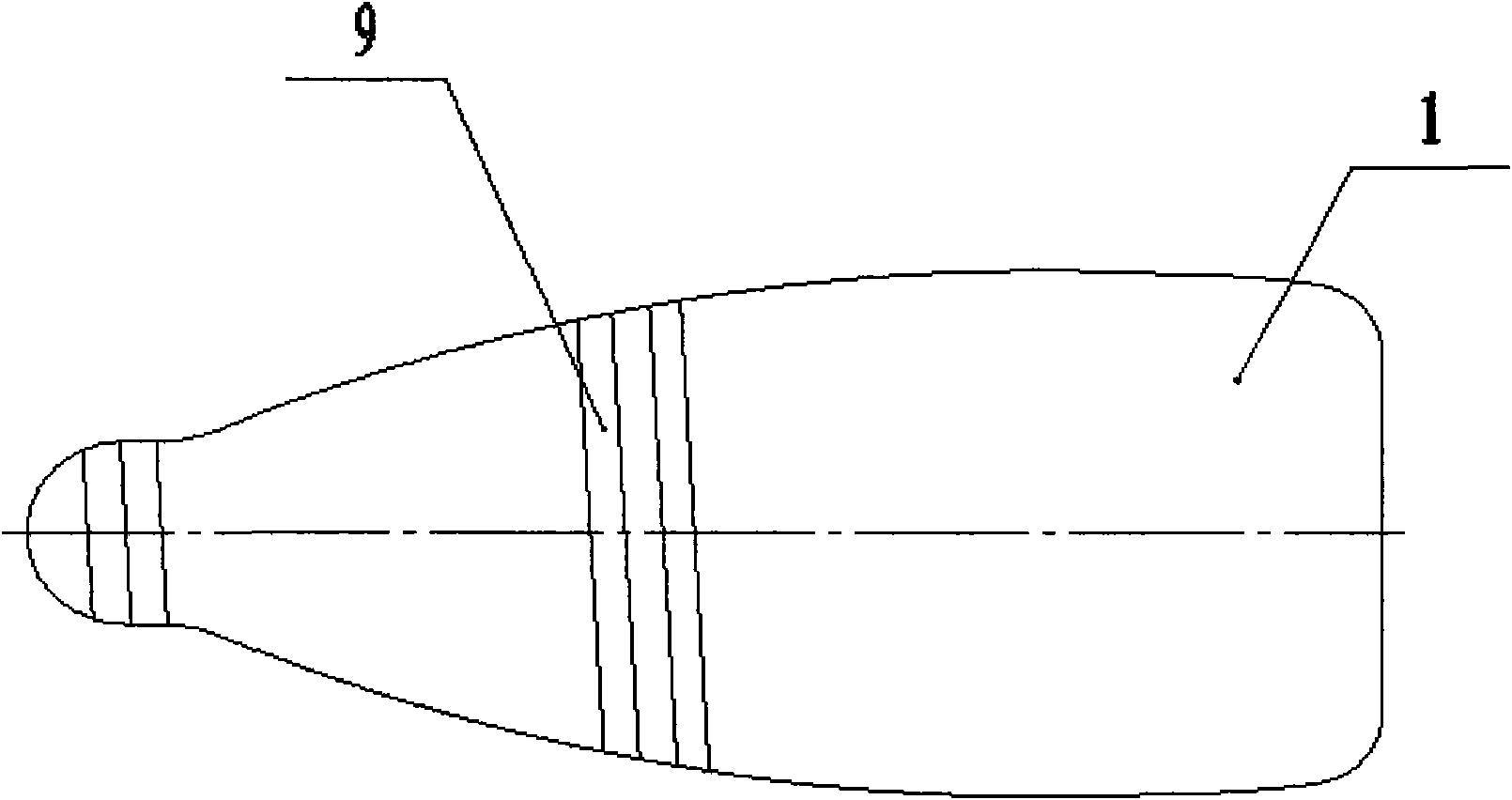

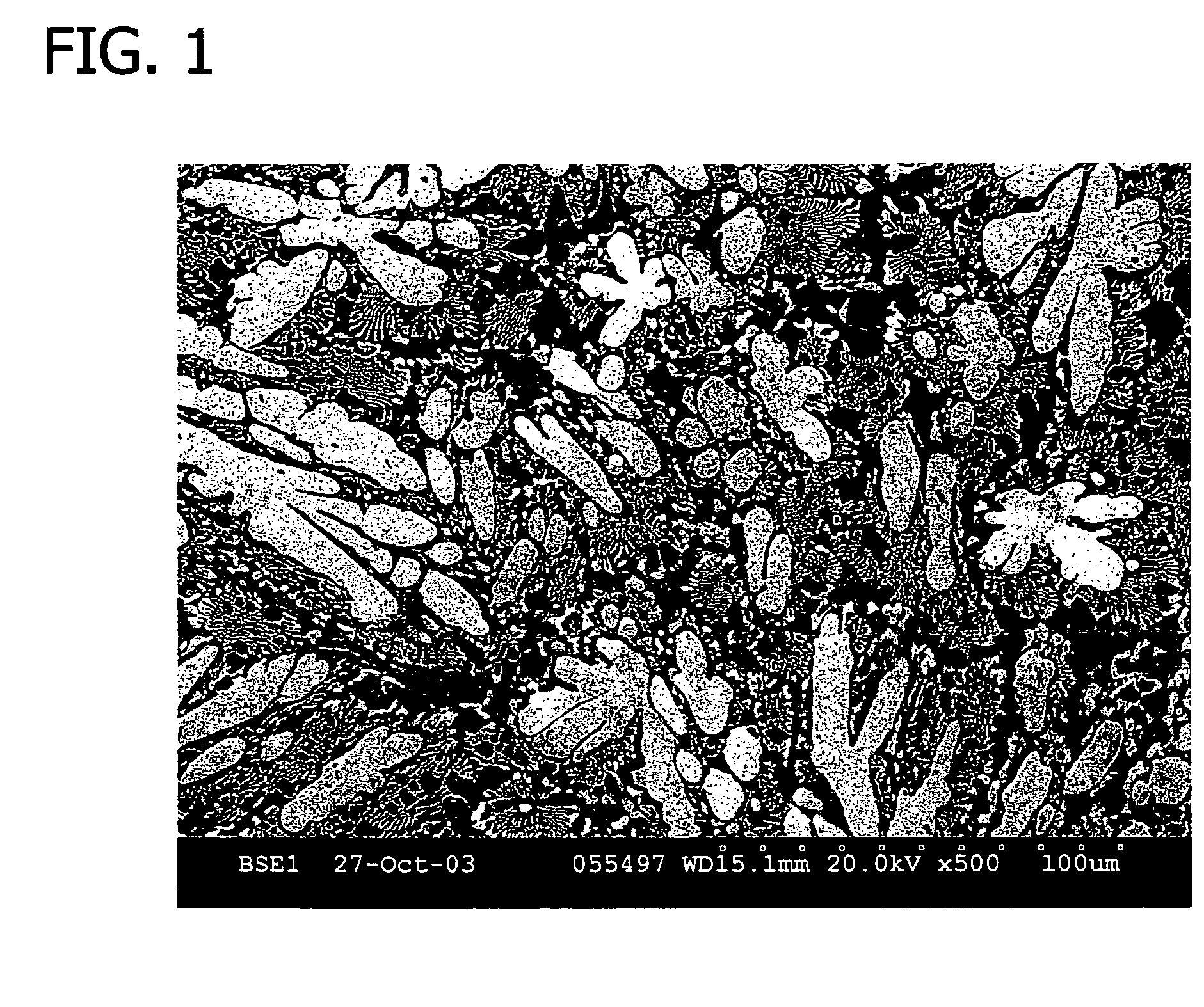

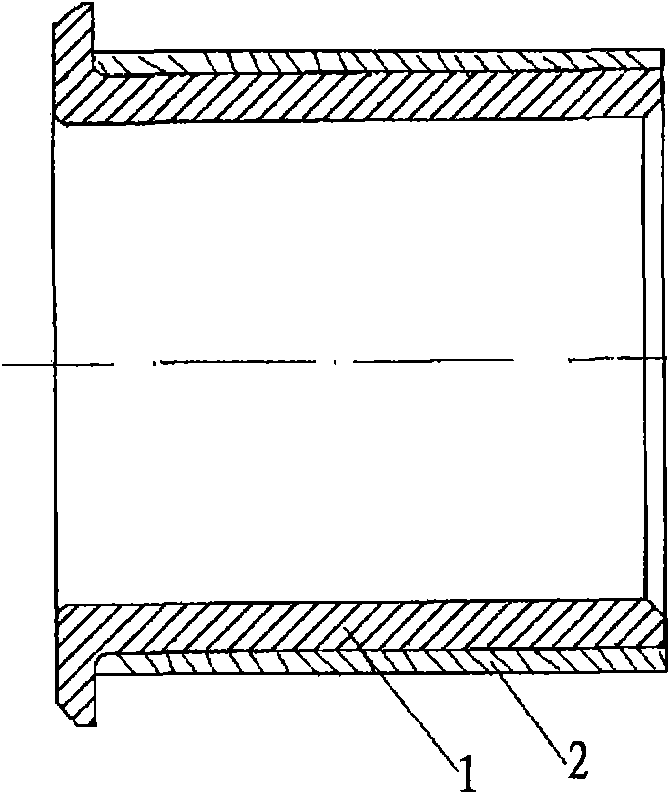

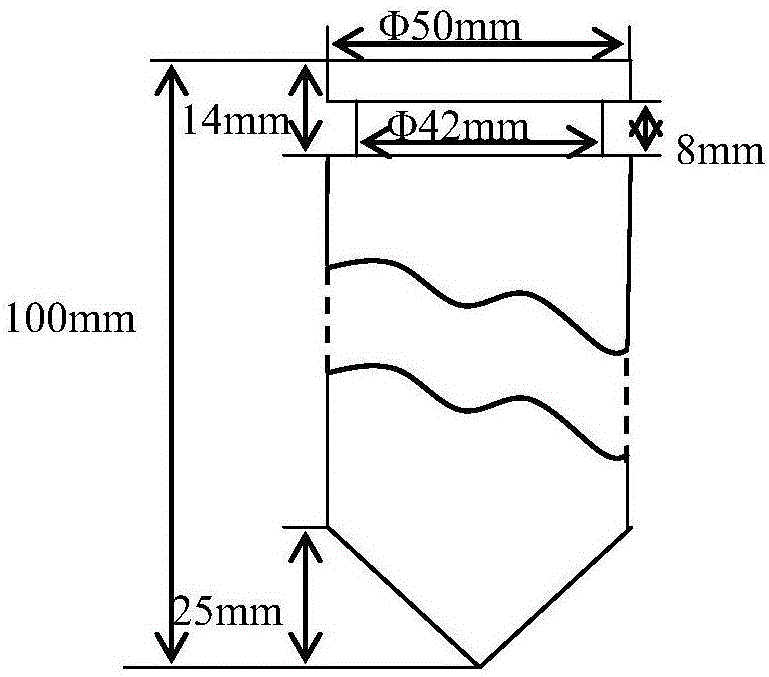

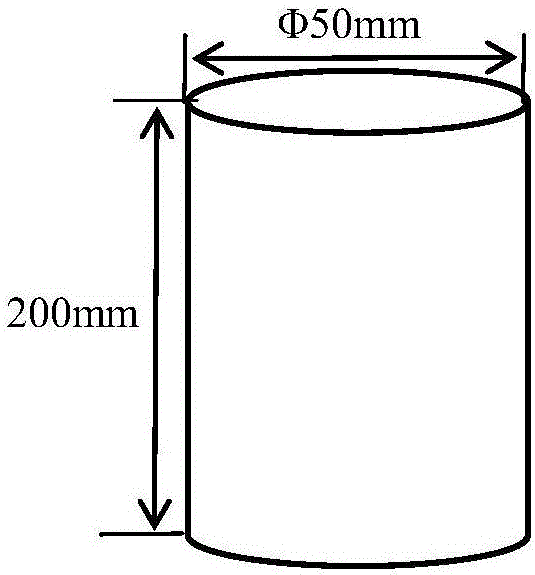

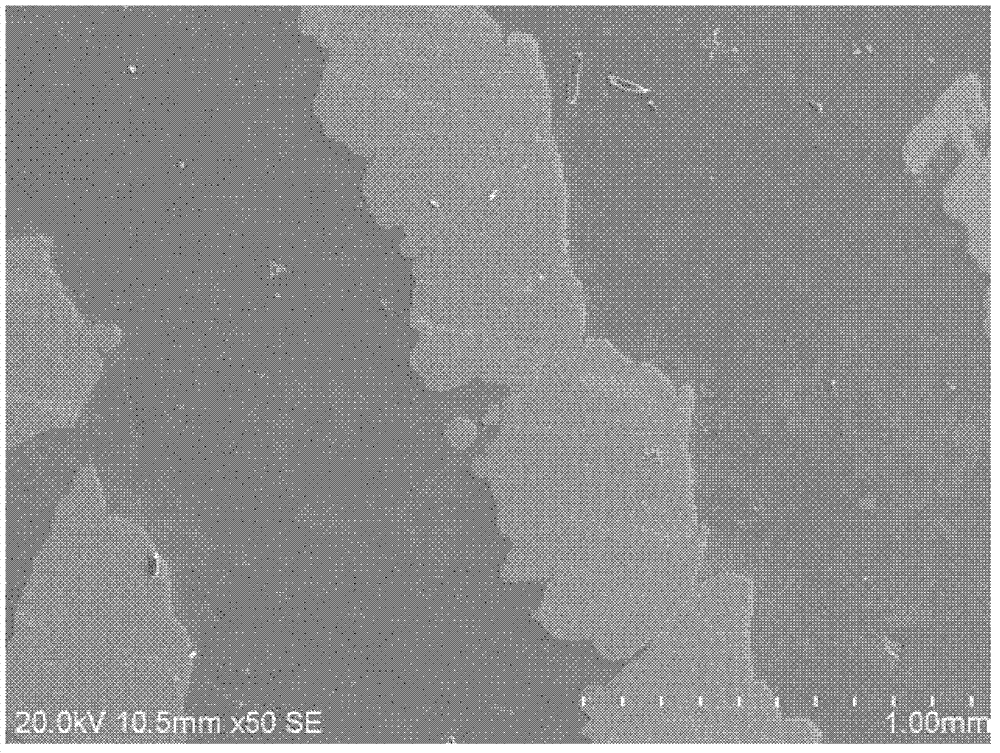

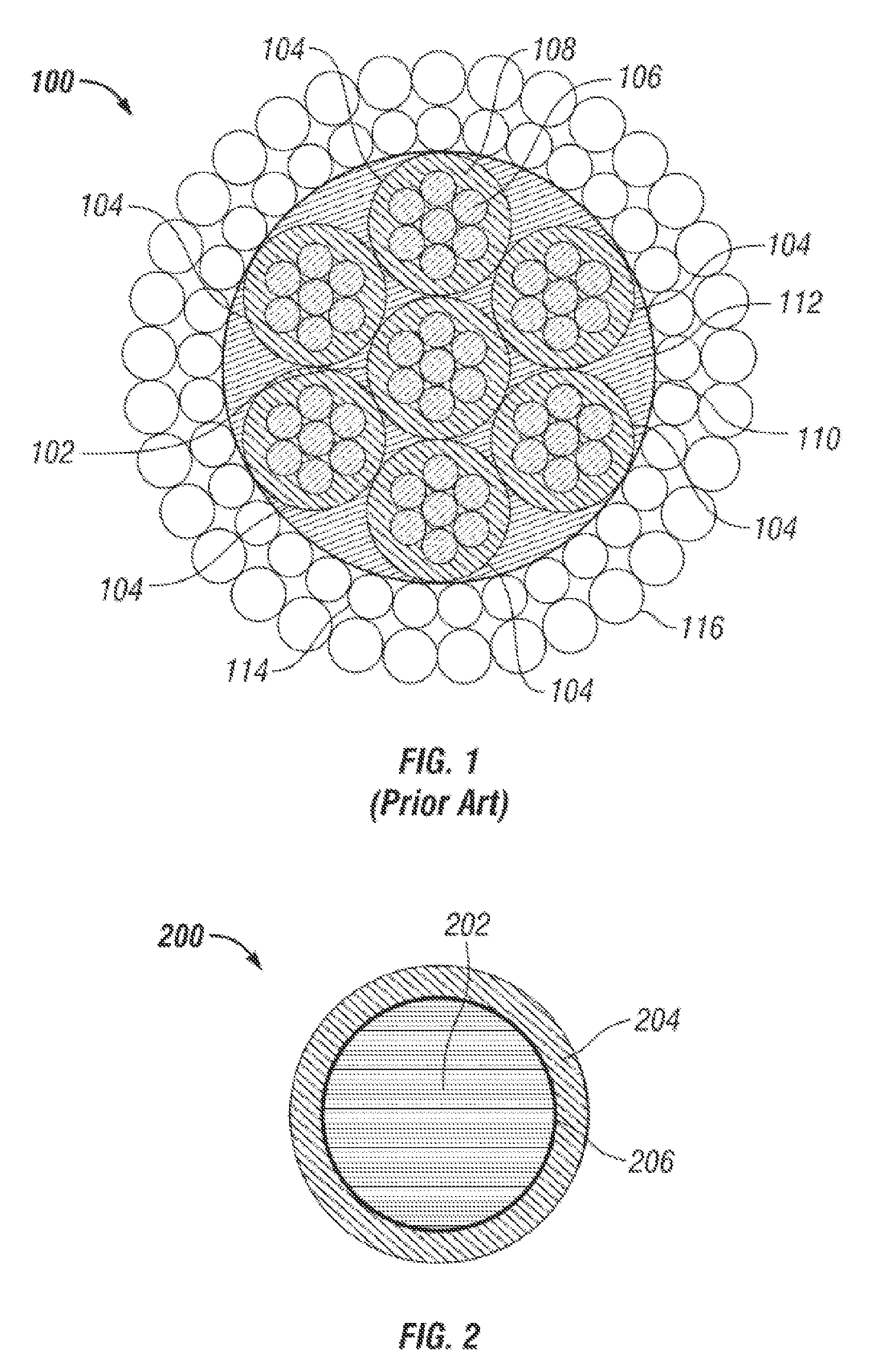

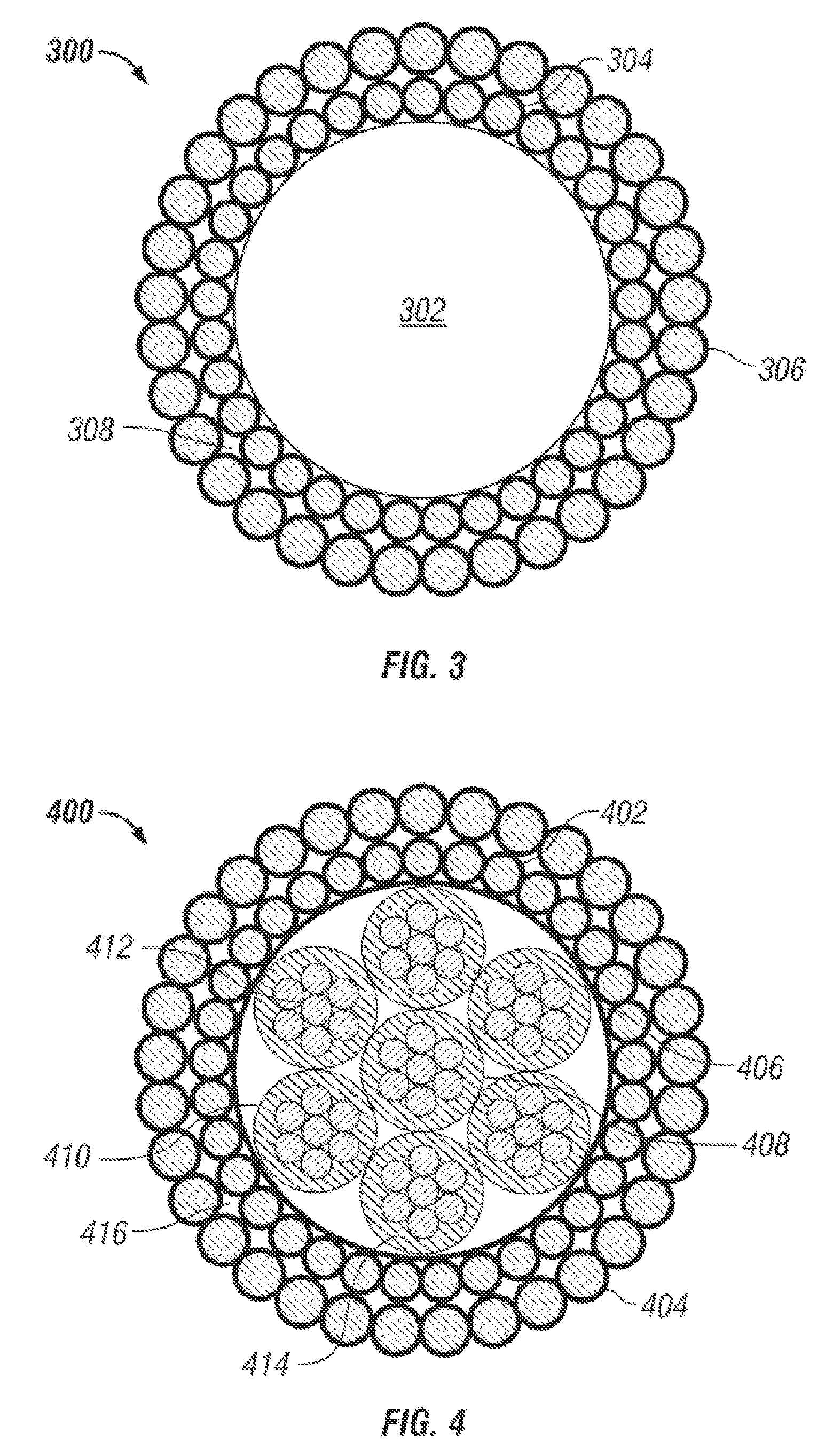

Target foil for use in the production of [18f] using a particle accelerator

InactiveUS20090052628A1High strengthConversion outside reactor/acceleratorsX-ray tube electrodesParticle acceleratorNiobium

The invention is directed to a novel foil for use as an entrance window foil during the production of [18F] by irradiation of [18O] using a particle accelerator. The foil is a high strength cobalt based alloy foil, thin film coated with an inert and refractory metal such as niobium.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA +1

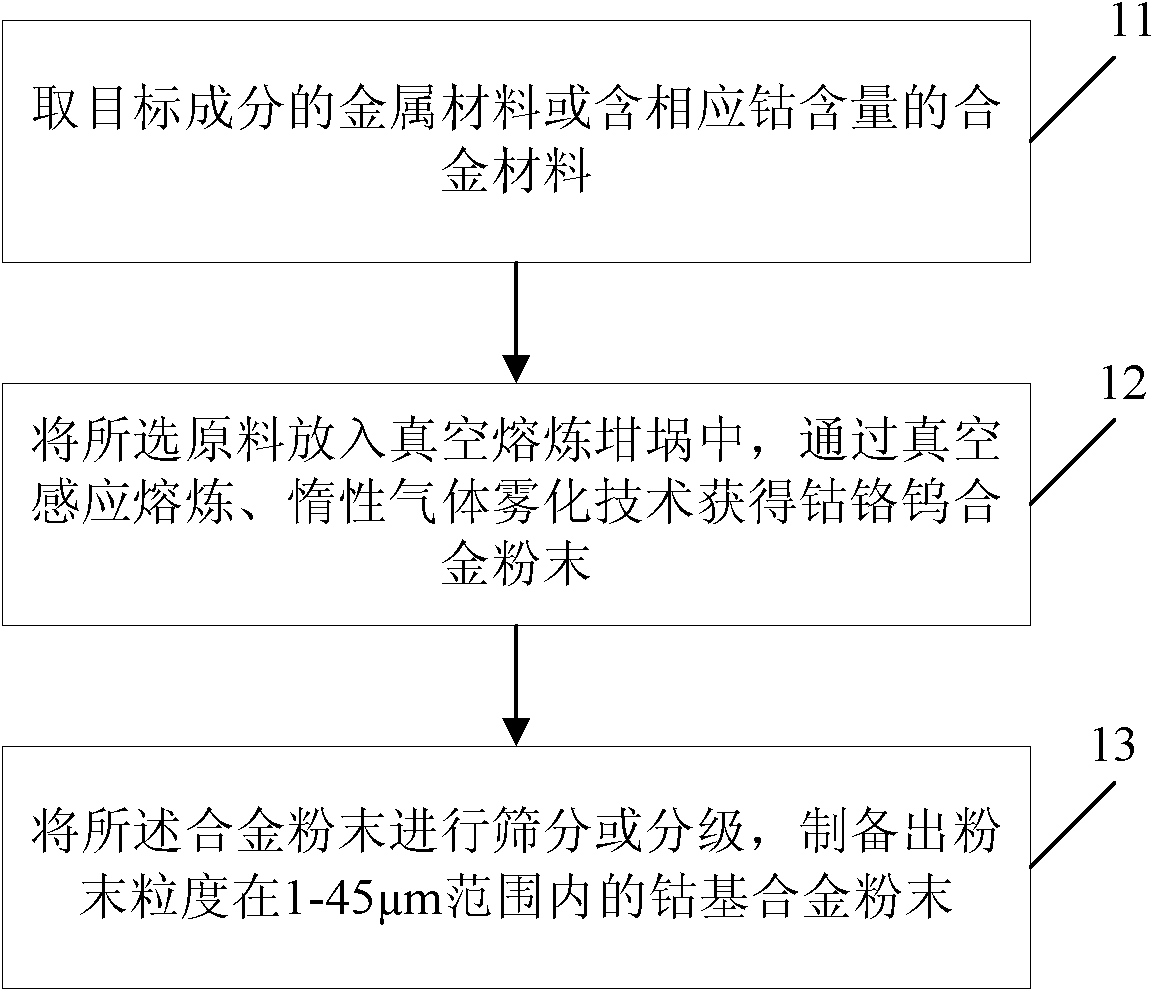

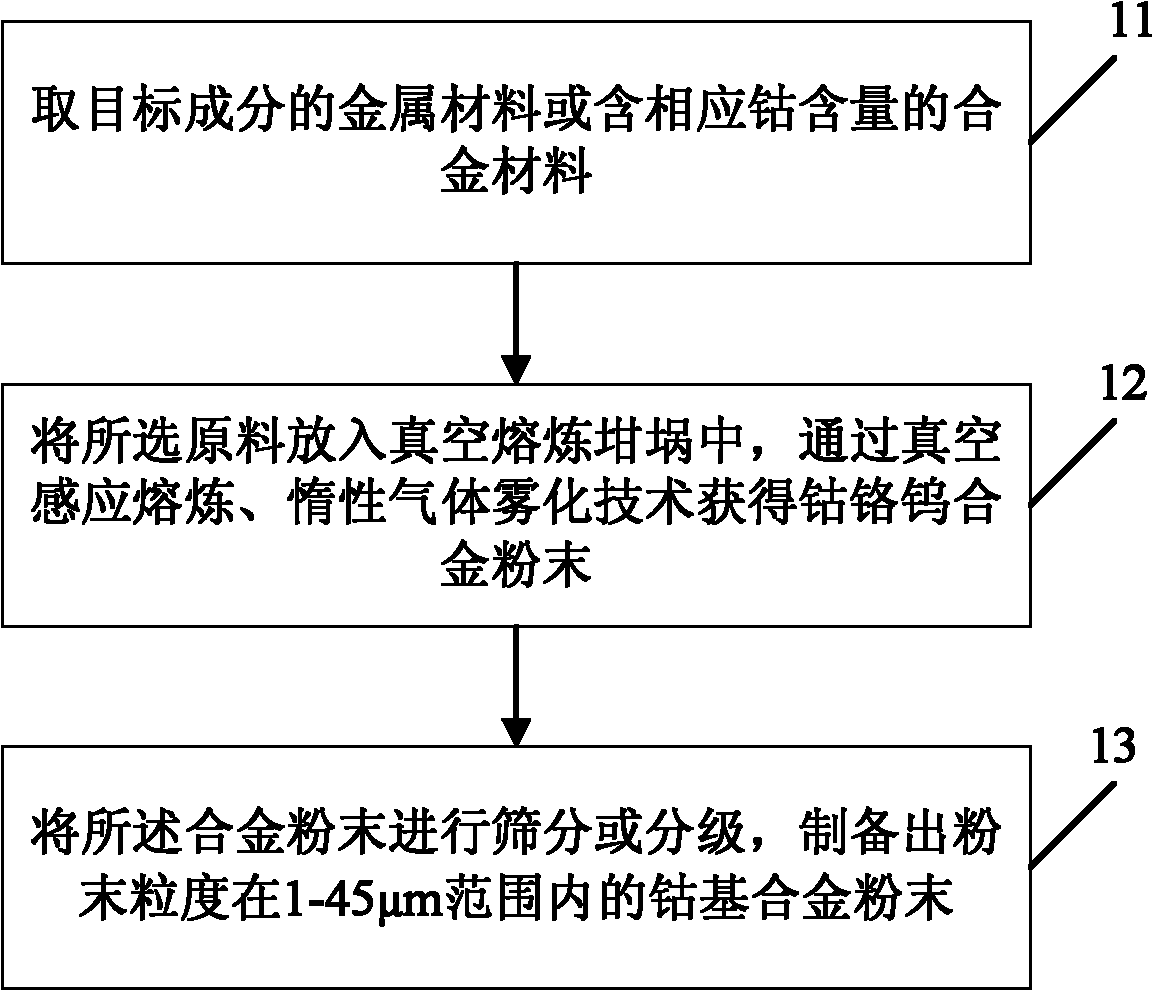

Production method of fine particle sized cobalt-base alloy powder

The invention relates to a production method of fine particle sized cobalt-base alloy powder, which comprises the steps that: firstly, metal materials of targeted components or alloy materials which contain the corresponding cobalt content are taken; the selected raw materials are placed into a crucible, and the cobalt-base alloy powder is obtained through the vacuum induction melting and inert gas atomization technologies; and screening or grading is carried out, so the cobalt-base alloy powder with the powder size within 1-45mu m is produced. The problems of high oxygen content of fine powder, bad apparent density and fluidity, low powdering rate during the coating, low coating density and bonding strength and the like of the existing fine particle sized cobalt-base alloy powder are solved, and the quality of a cobalt-base alloy powder product is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Compound medicament intravascular stent and preparation method thereof

ActiveCN101327343ANo effect on mechanical propertiesEffect on mechanical propertiesStentsSurgeryBiocompatibility TestingThrombus

The invention relates to a composite drug stent and a preparation method thereof. The stent includes a stent body and active drugs; wherein, the stent body is a perforated medical material with good biocompatibility, which can be made by optionally using stainless steel, cobalt-based alloy, titanium alloy, nickel-titanium alloy, or polylactic acid bio-polymer material; the active drugs include special endothelial progenitor cell antibody drug and anti-smooth muscle cell proliferation drug. The internal surface of the perforated stent body is fixedly provided with the special endothelial cell antibody drug, while the external surface of the perforated stent body is coated with the anti-smooth muscle cell proliferation drug. The preparation method includes as follows: (1) pretreating the surface of the stent body; (2) making holes; (3) post-treating the surface of the stent body; (4) dispensing medicines; (5) coating the external surface; (6) fixing the internal surface; (7) drying at low temperature. The preparation method can selectively absorb endothelial progenitor cells and facilitate in repairing endodermis, and can effectively inhibit the proliferation and migration of vascular smooth muscle cells, persistently and effectively reduce the newborn endangium, effectively prevent the stent from narrowing, and avoid the risk of tardive thrombosis.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

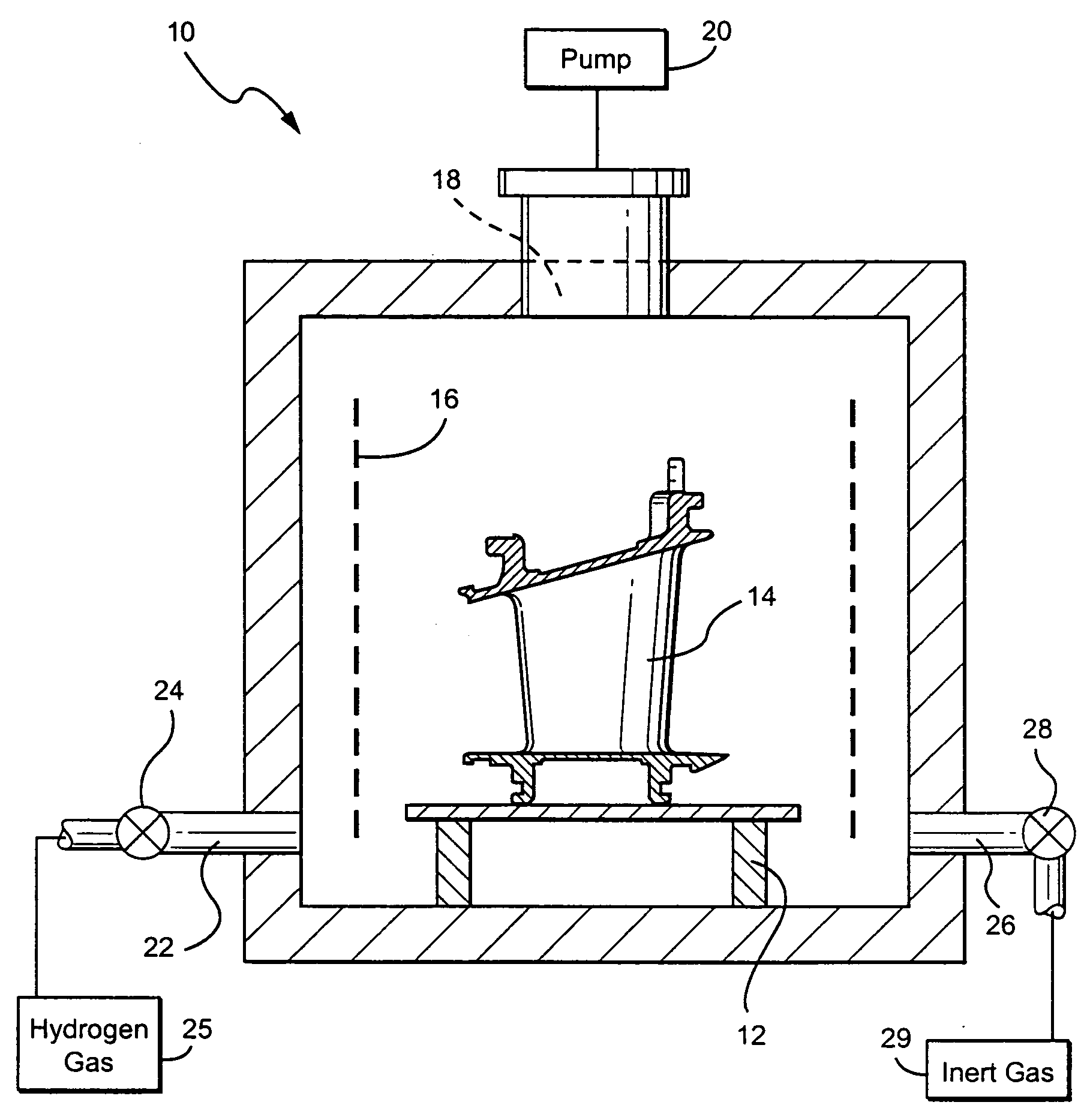

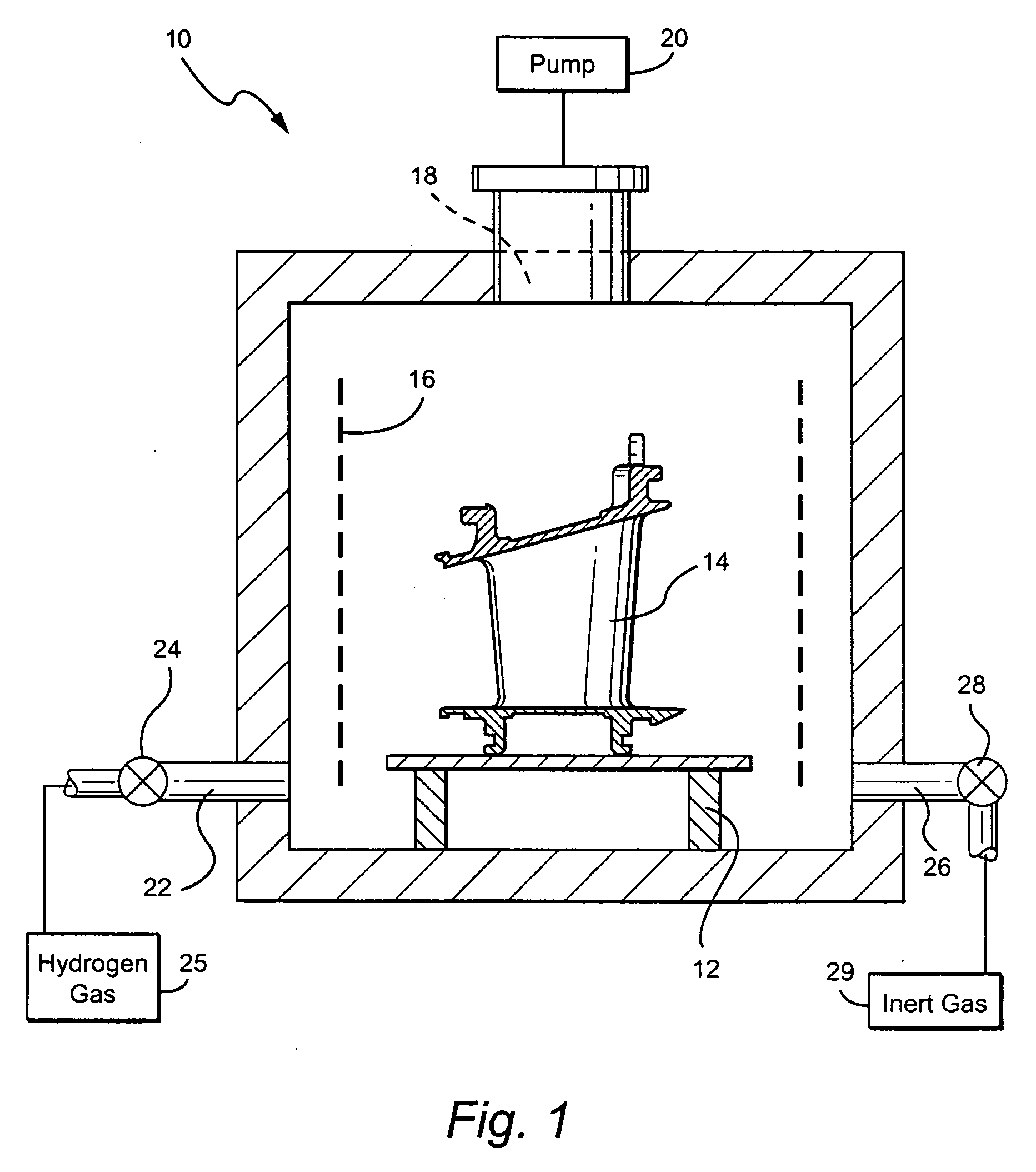

Methods of hydrogen cleaning of metallic surfaces

The pulsed partial pressure hydrogen cleaning of cobalt-based alloys in turbine components is achieved by disposing the component within a vacuum furnace and heating the component. Upon heating to about 1400° F., a partial pressure hydrogen gas and a vacuum are repetitively cycled within the furnace by supplying in each cycle a fresh supply of hydrogen gas, followed by removal of reaction products between the hydrogen gas and surface contaminants and substantially all residual hydrogen gas from within the furnace. The repetitious cycling renders the surfaces clean, enabling refurbishment thereof by activated diffusion healing repair.

Owner:GENERAL ELECTRIC CO

Cobalt-base alloy material and manufacturing method thereof

InactiveCN104141066AExcellent wear resistanceExcellent corrosion resistanceInjection molding machineWear resistance

The invention discloses a cobalt-base alloy material. The cobalt-base alloy material is prepared from the following raw materials in percentage by mass: 40-70% of Co, 20-30% of Cr, 1-10% of Ni, 0.5-10% of Mo, 1-20% of W, 1-5% of Fe, 0.2-0.5% of Mn, 0.5-4% of Si and 0.4-2% of C. The invention also provides a manufacturing method of the cobalt-base alloy material. The method comprises the following steps: preparing an alloy material with corresponding content according to the weight percentages of chemical components of the alloy; performing ball-milling on the alloy material to obtain powder; then adding a forming agent; stirring and cooling; crushing an obtained material into particles; injecting to obtain a product green blank by virtue of an injection molding machine; putting the green blank into a vacuum degumming integrated furnace, and sintering to obtain a product. The cobalt-base alloy material disclosed by the invention is easy to process, has more excellent wear resistance and corrosion resistance than those of stainless steel, and can be widely applied to the field of clocks and watches and jewelries.

Owner:ZHUZHOU FULIDA CEMENTED CARBIDE CO LTD

Method for measuring content of boron in cobalt-base alloy

ActiveCN101718688AAvoid interferenceImprove accuracyPreparing sample for investigationColor/spectral properties measurementsElement analysisMaterial resources

The invention belongs to a technique for analyzing trace elements of an alloy, and relates to a method for measuring the content of boron in a cobalt-base alloy. By adopting an inductively coupled plasma emission spectrometer and treating a sample of the cobalt-base alloy in particular a high-tungsten sample by using 20mL of hydrochloric acid, nitric acid and hydrofluoric acid, the method solves the puzzling problems that the past dissolved sample has large reagent dosage and high reagent blank and cannot be measured normally by an instrument; by performing interference experiments and spectrogram analyses, the method finds the optimal analytical line, overcomes the interferences caused by a plurality of elements such as major elements of cobalt, chromium, tungsten and the like in the cobalt-base alloy, and improves the measuring accuracy; the method has wide measuring ranges, the measuring lower limit is 0.002 percent, and the measuring upper limit is 0.20 percent and is 101 times of the measuring lower limit; and the method can perform measurement quickly, is simple and convenient to operate, and saves a large quantity of manpower and material resources.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Laser forming electro-galvanizing wire conducting roller and manufacturing method thereof

InactiveCN101457378AImprove wear resistanceImprove corrosion resistanceElectrolysis componentsMetallic material coating processesWear resistanceCo2 laser

A laser forming electrogalvanizing line conducting roll comprises a substrate. The surface of the substrate is coated with a laser cladding layer, the thickness of the laser cladding layer is 3-10mm, the laser cladding layer and the substrate are bonded in a metallurgical manner, and the laser cladding layer is a nickel base alloy powder layer or a cobalt base alloy powder layer or a combination of the nickel base alloy powder layer and the cobalt base alloy powder layer. A manufacturing method of the laser forming electrogalvanizing line conducting roll comprises the following working procedures: A. fabricating the substrate of the conducting roll; and B. cladding an intermediate transition layer by laser: firstly cladding a layer of the nickel base alloy powder or the cobalt base alloy powder on the substrate of the conducting roll for rendering by a transverse-flow continuous CO2 laser device as the intermediate transition layer; removing surface laser cladding oxide scale by machining, and then cladding the nickel base alloy powder or the cobalt base alloy powder with better wear resistance and corrosion resistance on the intermediate transition layer by the transverse-flow continuous CO2 laser device as a surface functional layer. The manufacturing method has the advantages of strong adaptability, simple convenient operation, high normativeness, low production cost and great practical value.

Owner:SHENYANG DALU LASER TECH

Cobalt-base alloy welding wire, hook claw using welding wire, connection rod and surfacing method

InactiveCN103921013AEffective control of hardnessMeet the hardnessConnecting rod bearingsConnecting rodsChemical compositionHardness

The invention discloses a cobalt-base alloy welding wire, a hook claw using the welding wire, a connection rod and a surfacing method. The cobalt-base alloy welding wire comprises chemical components including, by mass, 0.9-1.05% of C, 26.0-32.0% of Cr, 3.0-6.0% of W, less than or equal to 3.0% of Ni, less than or equal to 1.0% of Mo, less than or equal to 1.0% of Mn, less than or equal to 2.0% of Si, less than or equal to 3.0% of Fe, and the balance Co. By controlling the content of C, deposited metal meets the requirements of hardness and nondestructive testing.

Owner:SICHUAN HUADU NUCLEAR EQUIP MFR

Anticorrosive and antiwear cast cobalt-base alloy

The present invention relates to Co-base alloy, especially, an anticorrosive and antiwear cast Co-base alloy. The alloy consists of C 1.0-2.5 wt%, Cr 20-35 wt%, W 5-20 wt%, Mo 1-6 wt%, Nb 1-8 wt%, Cu0.5-2.0 wt%, Si 0.5-3.0 wt%, Ni 2-15 wt% and Co 35-65 wt%. It has excellent anticorrosive performance and average hardness of about 48 HRC, and may be used in making cutter of water flow type chemical fiber cutting machine. Substituting partial Co with Ni can reduce the cost of the alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

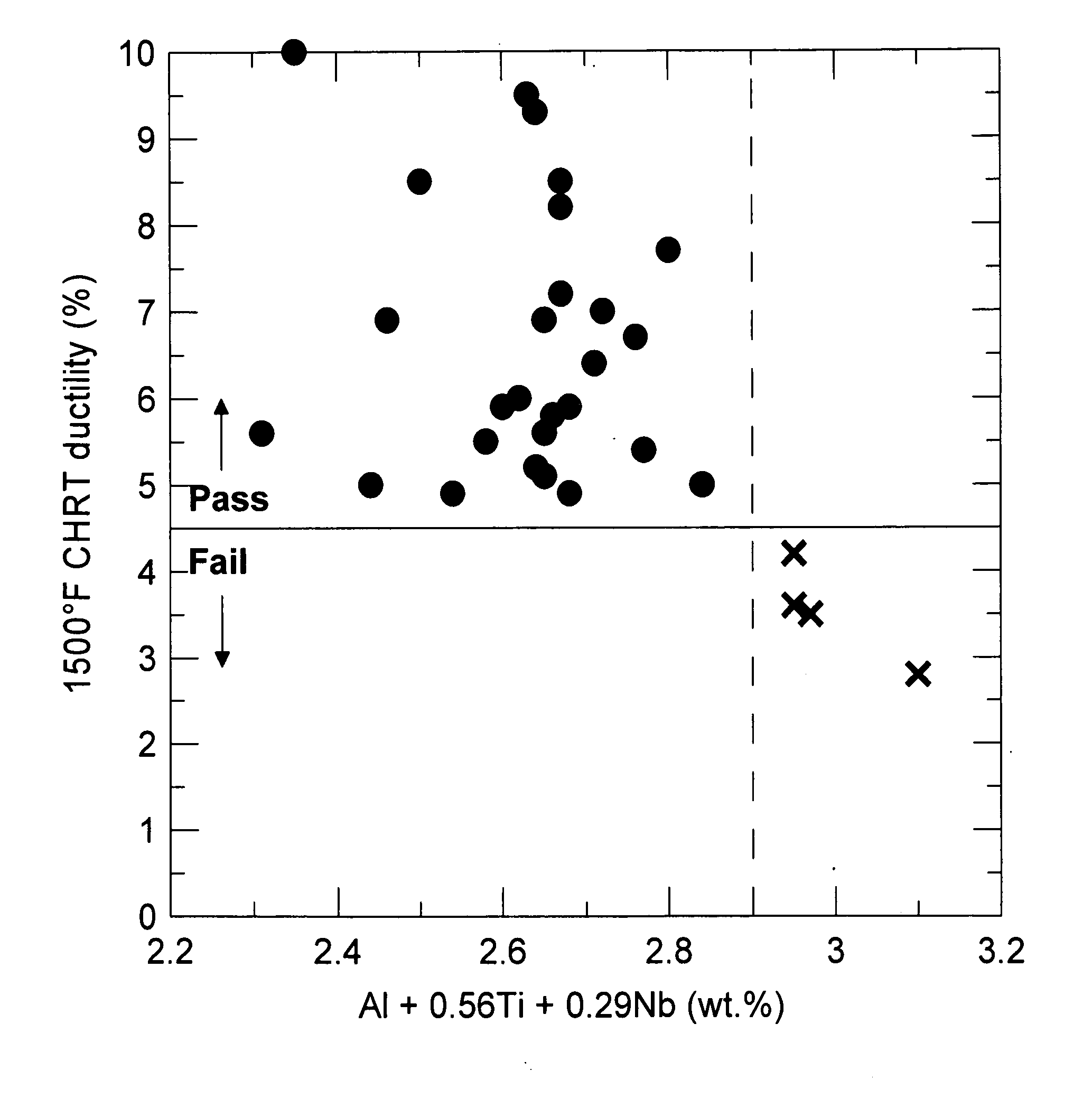

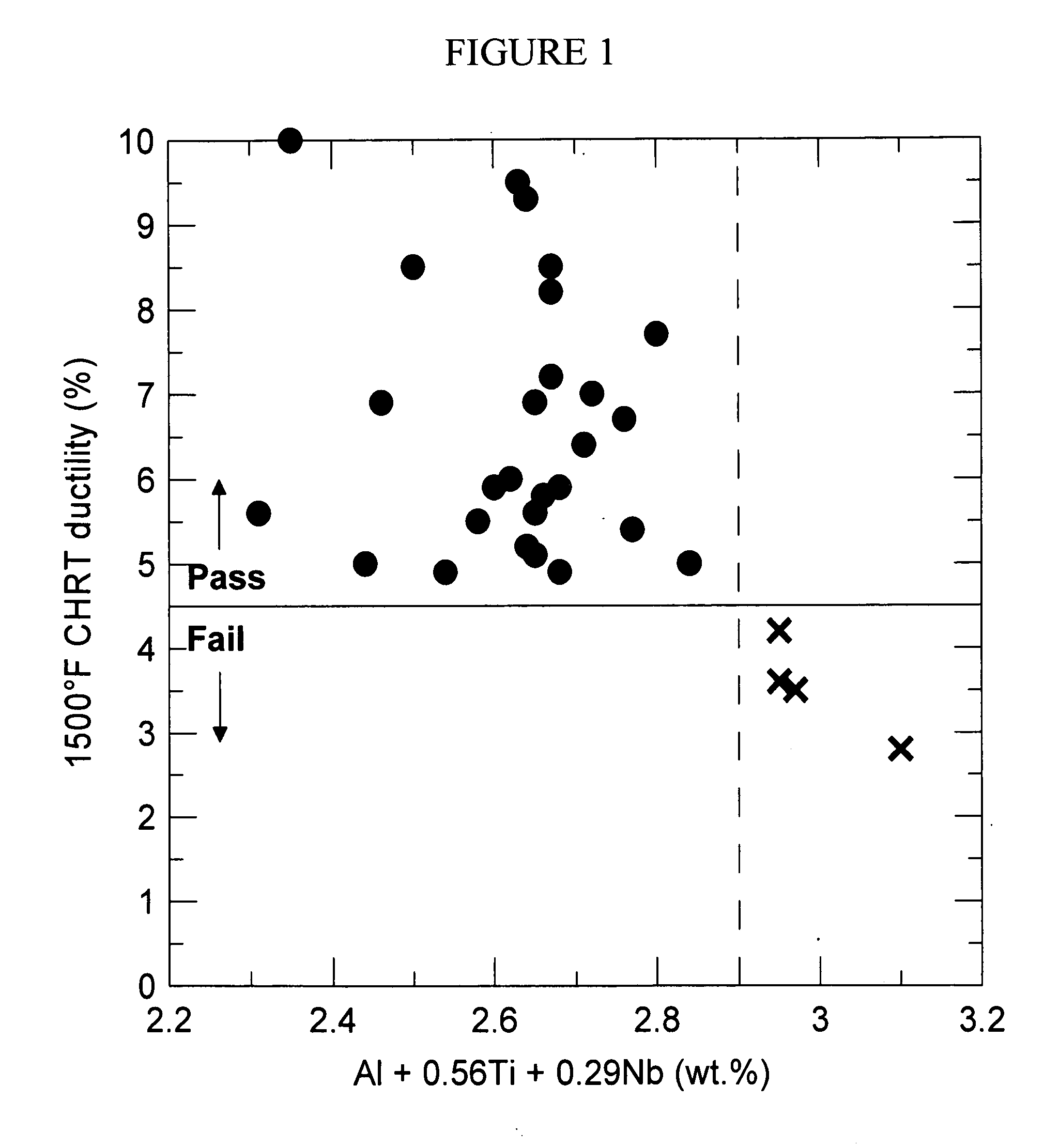

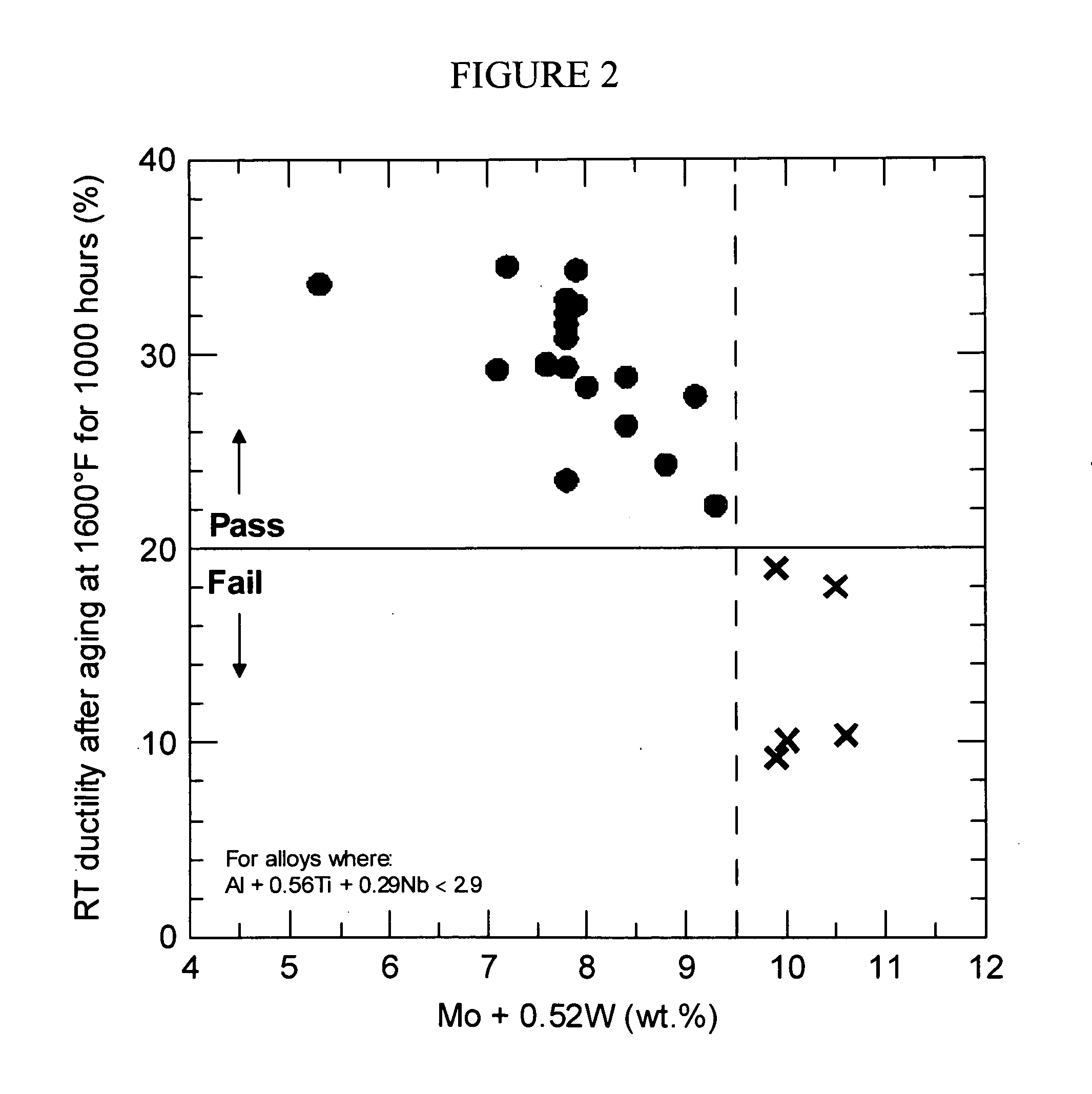

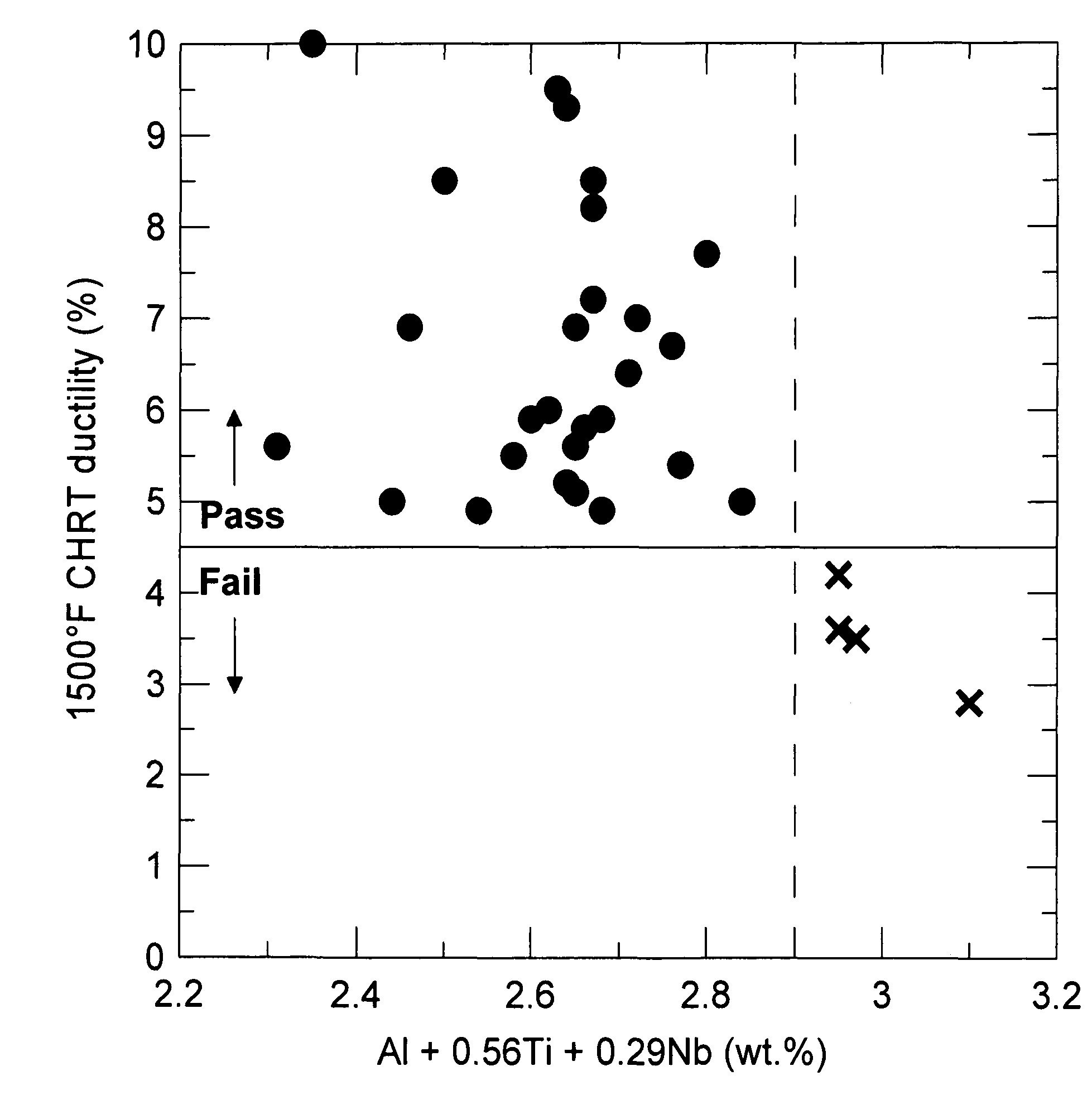

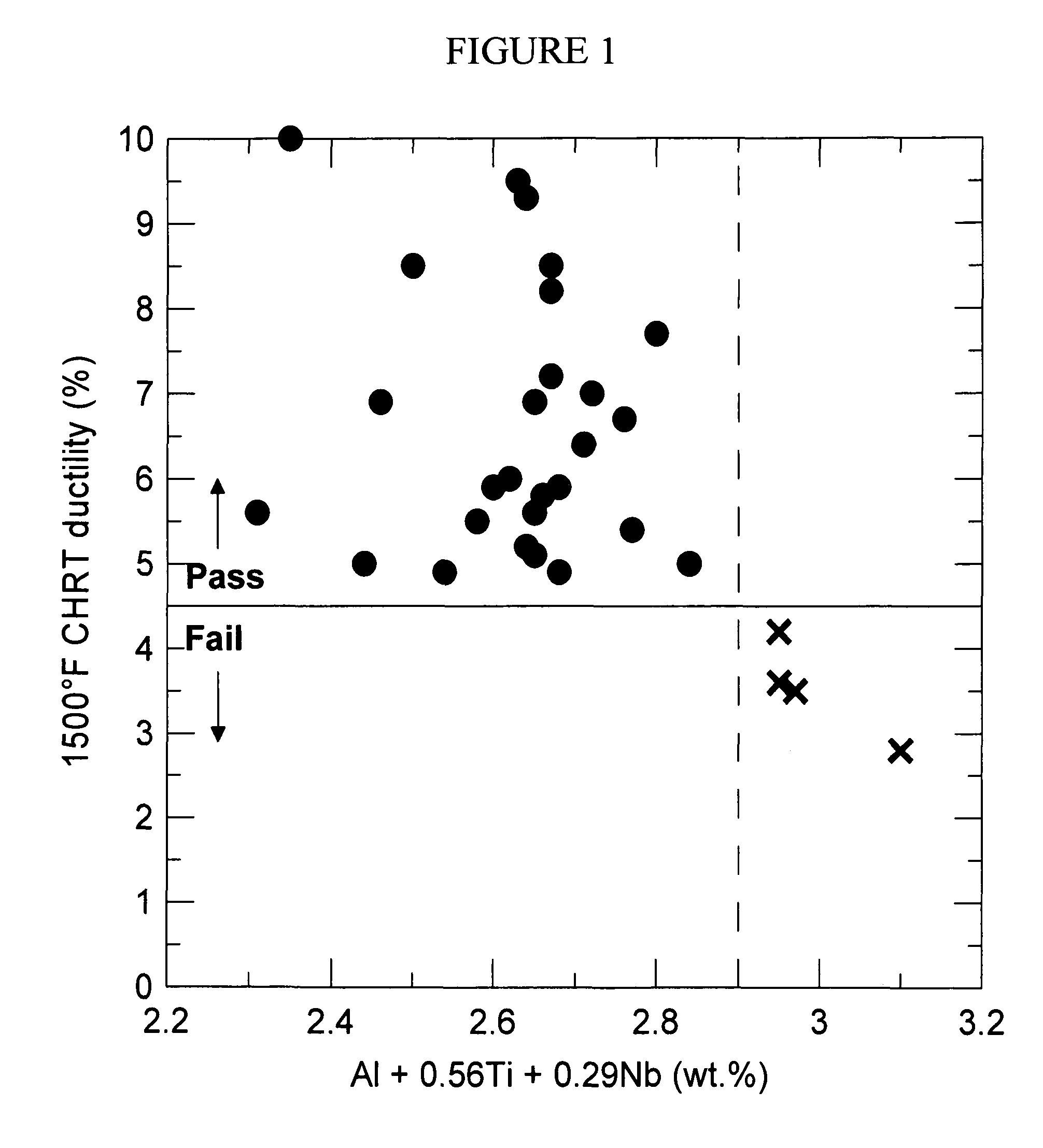

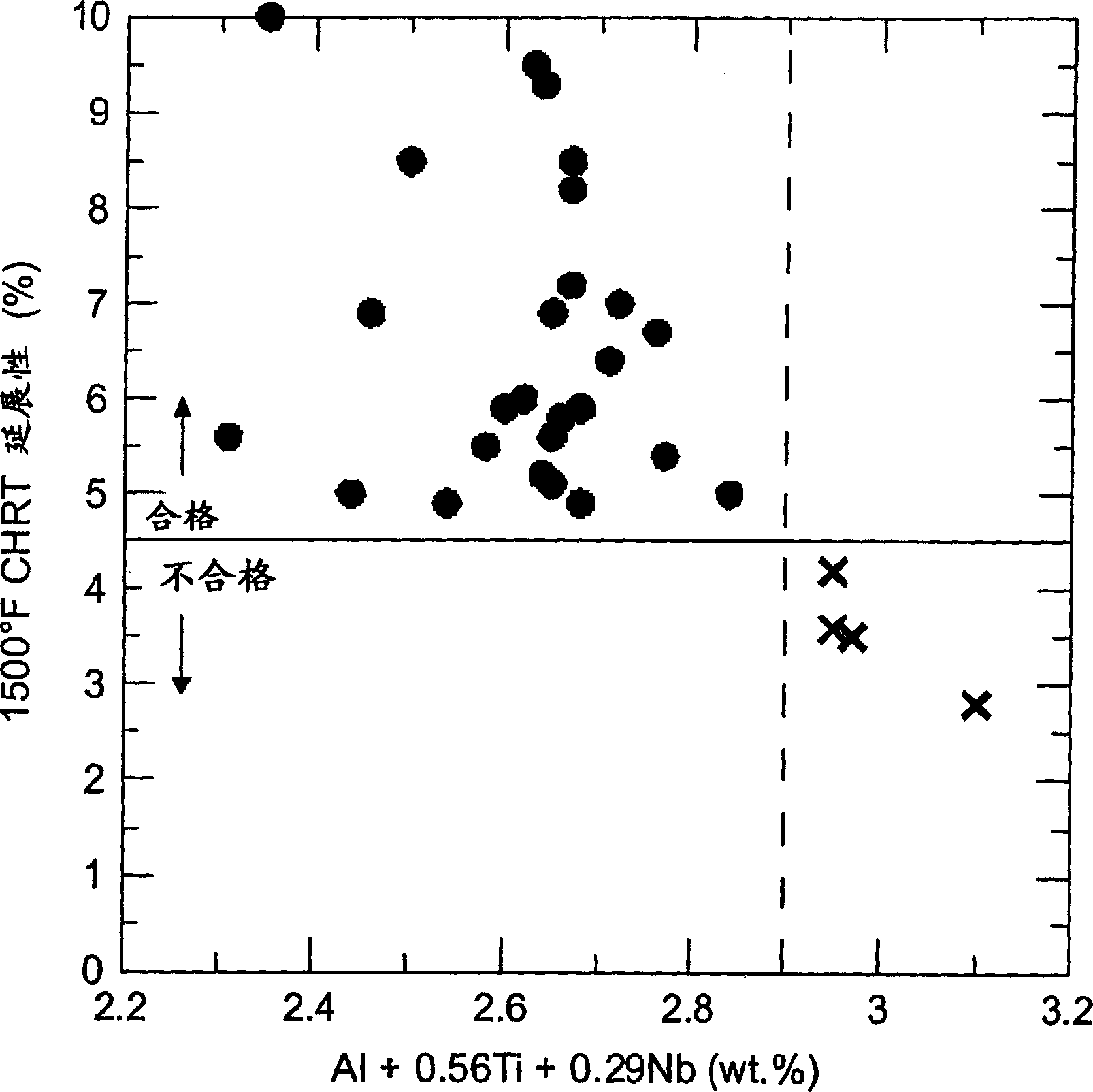

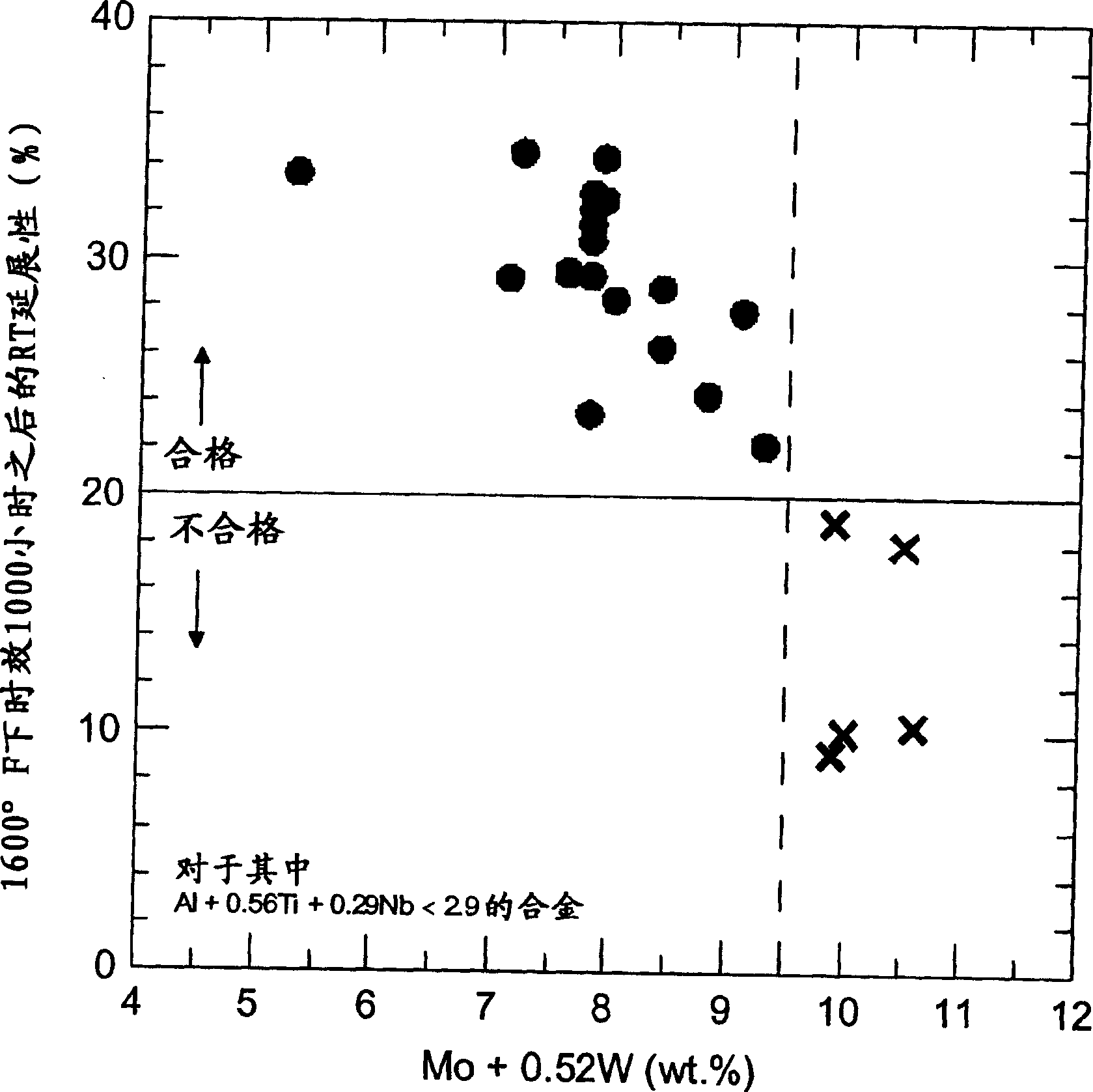

Ni-Cr-Co alloy for advanced gas turbine engines

A wrought age-hardenable nickel-chromium-cobalt based alloy suitable for use in high temperature gas turbine transition ducts possessing a combination of three specific key properties, namely resistance to strain age cracking, good thermal stability, and good creep-rupture strength contains in weight percent 17 to 22 chromium, 8 to 15 cobalt, 4.0 to 9.1 molybdenum, up to 7 tungsten, 1.39 to 1.65 aluminum, 1.50 to 2.30 titanium, up to 0.80 niobium, 0.01 to 0.2 carbon, up to 0.01 boron, up to 3 iron, up to 1.5 tantalum and less than 0.02 zirconium, with a balance of nickel and impurities. Certain alloying elements must be present in amounts according to two equations here disclosed.

Owner:HAYNES INTERNATIONAL

Ni-Cr-Co alloy for advanced gas turbine engines

Owner:HAYNES INTERNATIONAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00000.png)

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00001.png)

![Target foil for use in the production of [18f] using a particle accelerator Target foil for use in the production of [18f] using a particle accelerator](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/608e22dd-af99-4217-bcfe-89a8d80b969b/US20090052628A1-20090226-D00002.png)