Production method of highly dimensionally accurate half shells

A bearing pad and height technology, applied in the field of deep-drawn bearing pads, can solve problems such as uneven bearing pad edges and welding difficulties, and achieve the effects of saving investment costs, high economic performance, and good deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

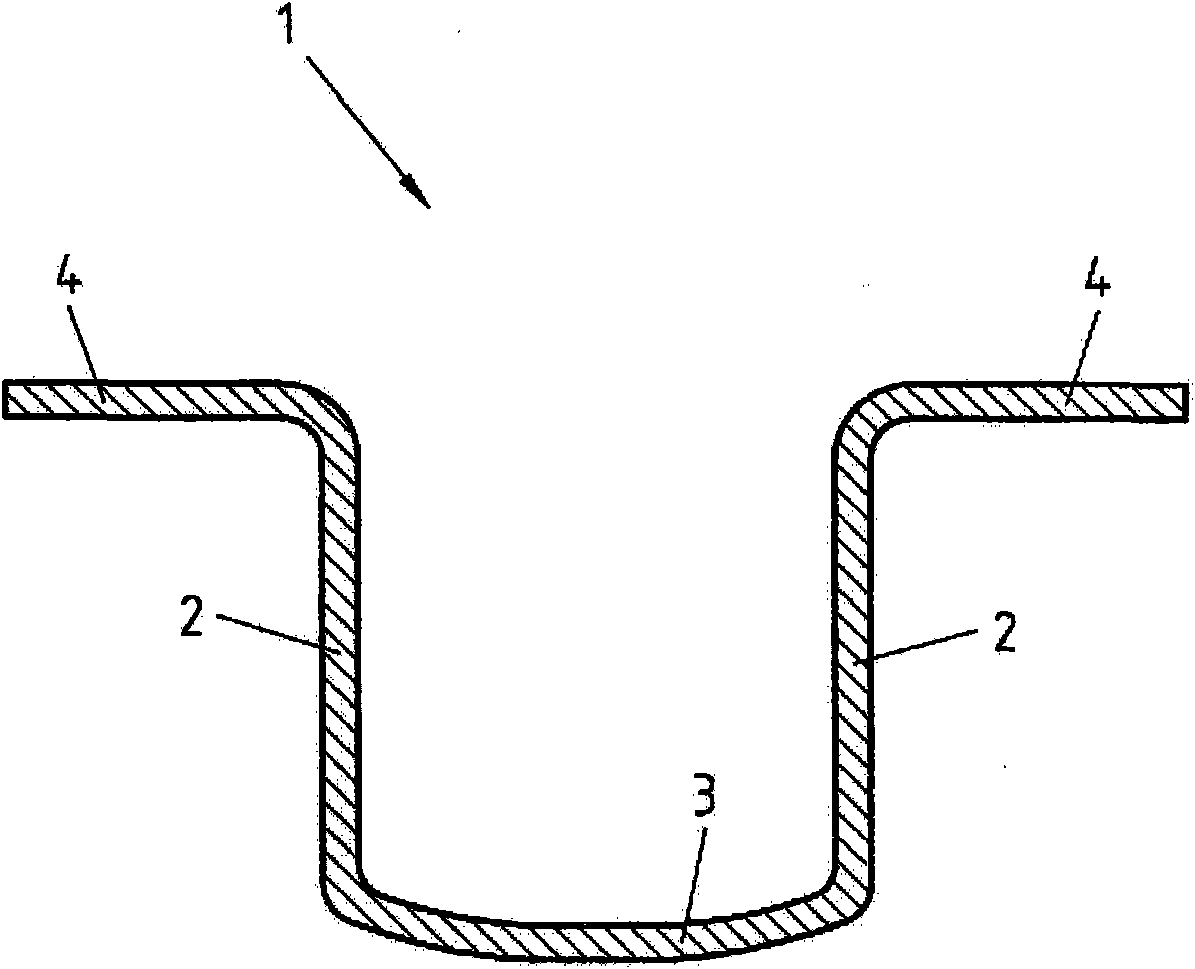

[0021] figure 1 A schematic cross-sectional view of a preformed bearing shell 1 is first shown in . The bearing shell comprises side panels 2 and a bottom region 3 . further by figure 1 It can be seen that the bottom region 3 is slightly arched and that the bearing shell is additionally provided with a collar 4 .

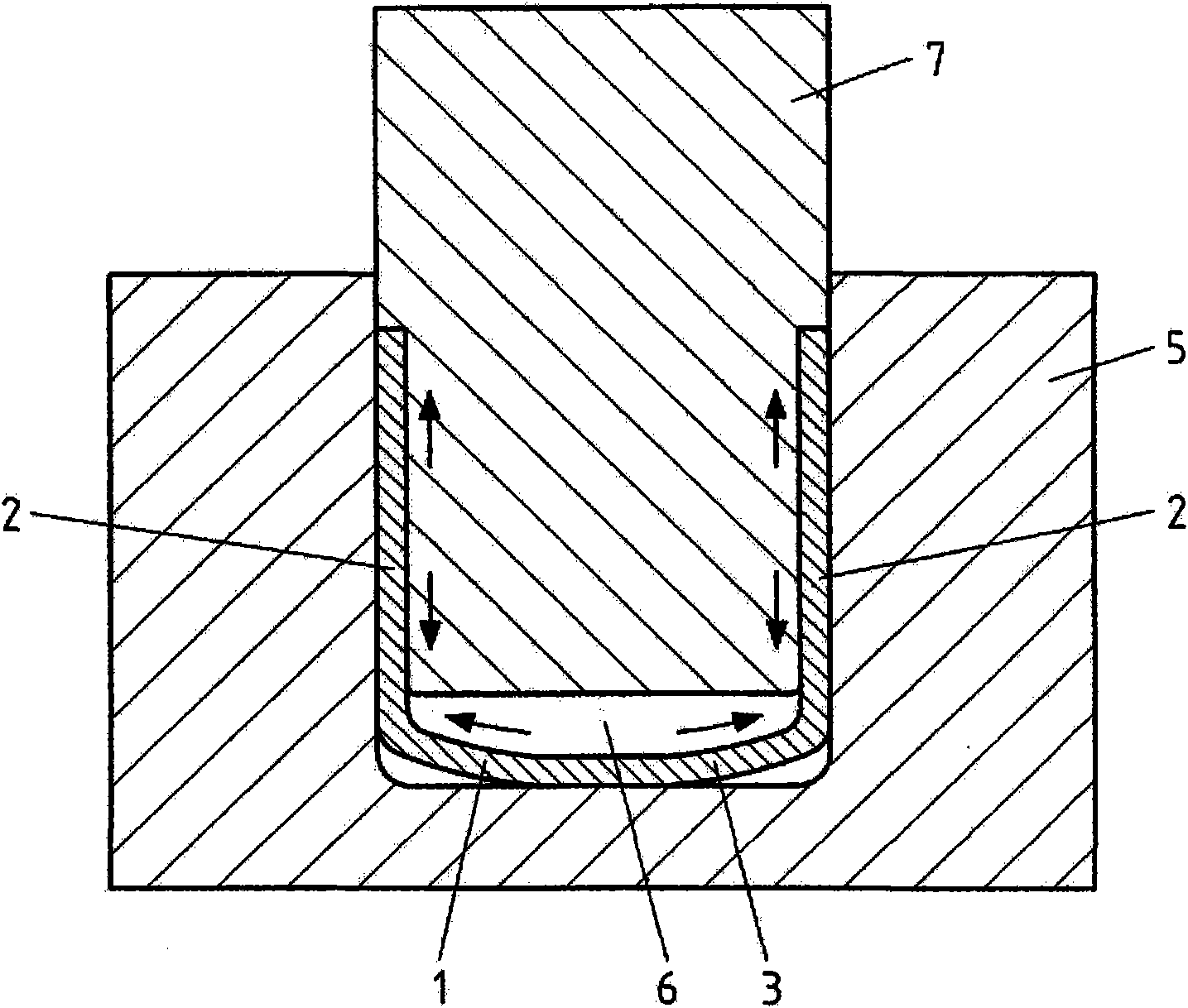

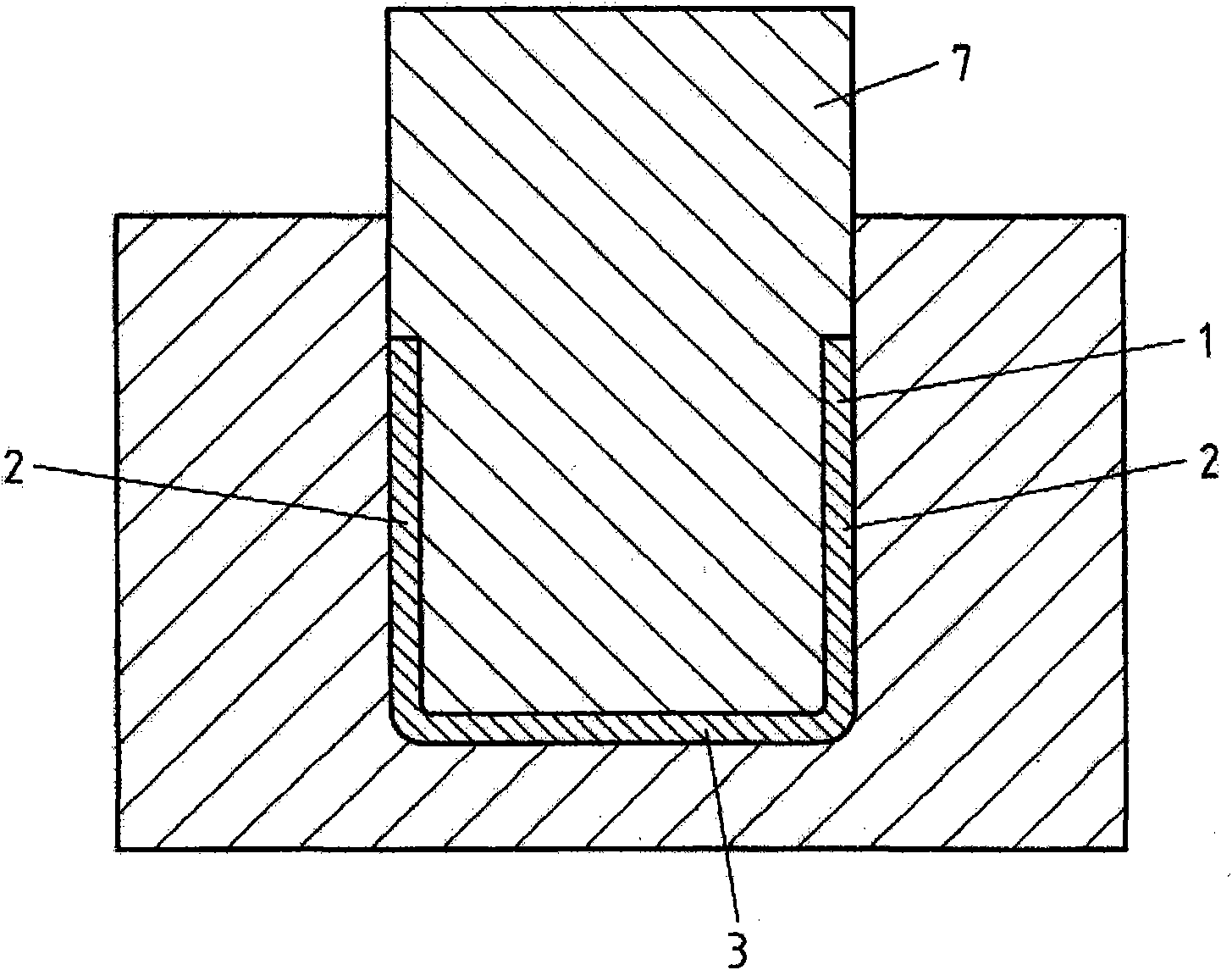

[0022] Figure 2a ) and 2b) a first embodiment of the method according to the invention is shown. Firstly, the drawing schematically shows a die 5 with a die 6 which, together with a punch 7 , can deform the bearing shell 1 , which is now already flangeless, into its final shape. Depend on Figure 2a ) shows that the punch 7 presses the bottom region 3 and the side plate 2 on the bearing shell 1 during the deformation process due to the preforming of the bearing shell 1 . As a result of this calendering process a material flow is formed which roughly corresponds to the Figure 2a ) shows the direction of the arrow. On the one hand, the wall thickness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com