Ultra-high strength steel hot-stamping die for car door anticollision beam

A hot stamping die and ultra-high-strength steel technology, applied in the field of hot stamping, can solve the problems of severe springback, low strength, and inability to achieve, and achieve the effects of weight reduction, good surface quality, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

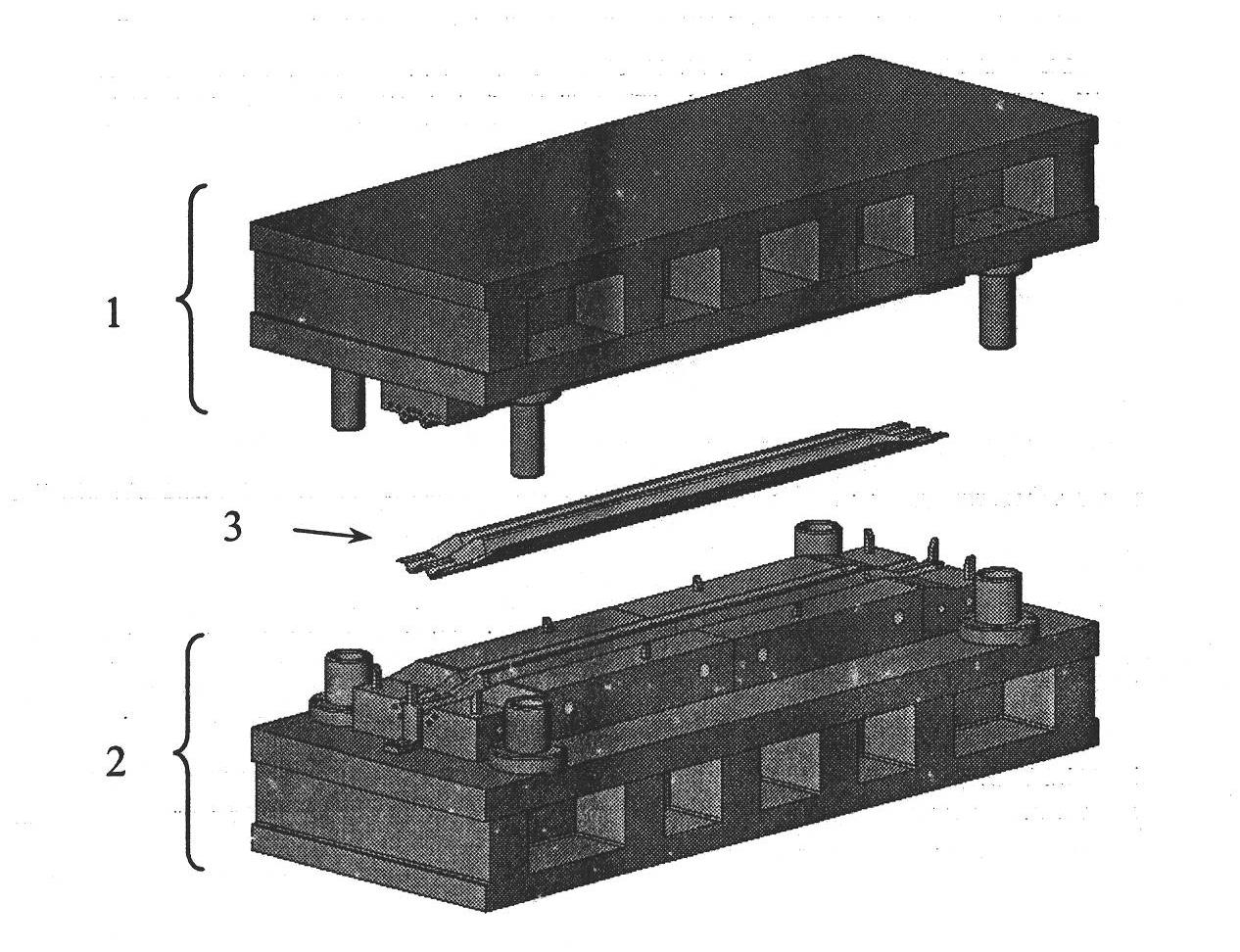

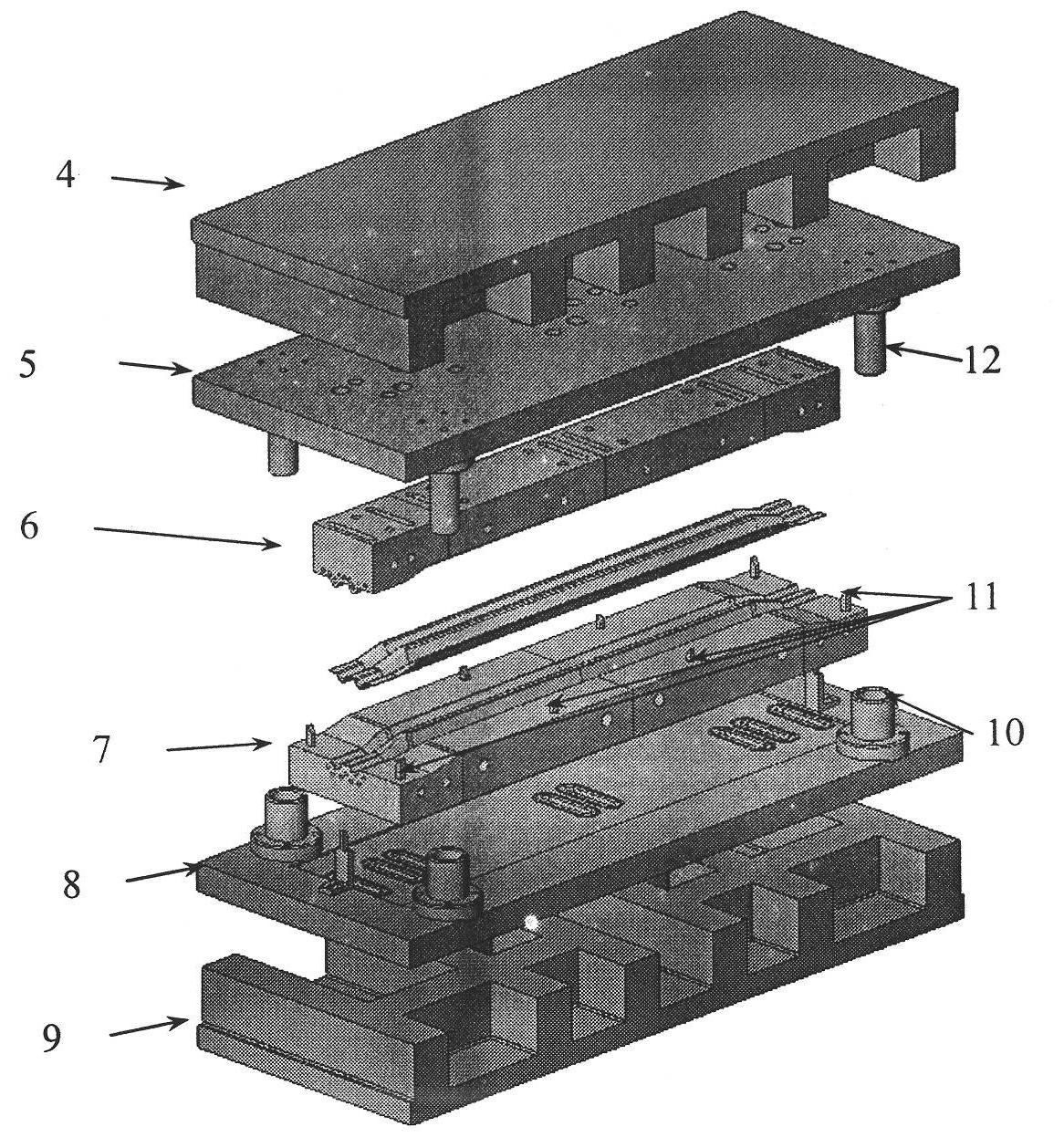

[0028] Attached below figure 1 ~ attached Figure 4 The example shown illustrates a hot stamping die for an ultra-high strength steel door impact beam.

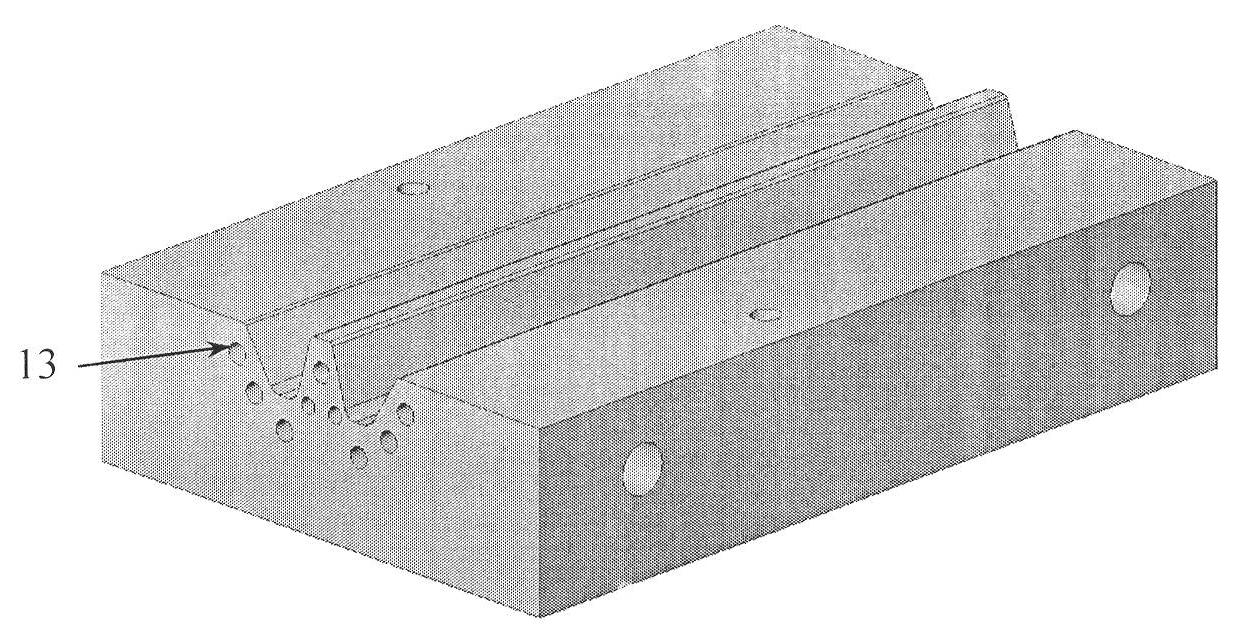

[0029] The mold for preparing the door anti-collision beam of the present invention includes an upper mold 2 and a lower mold 3 . The upper die 2 is mainly composed of a combination punch 6, cooling system, sealing ring, guide post 12, punch mounting plate 5, and upper mounting frame 4; the lower die is mainly composed of a combination die 7, a cooling system , Seal groove 14, guide sleeve 10, die mounting plate 8, lower mounting frame 9, sheet metal positioning device 11.

[0030] attached figure 1 In order to ensure the smooth progress of the forming process, so that no forming defects appear at the position of the mold block, and to optimize the cooling effect of the cooling system, the blocks of the combined punch 6 and the combined die 7 avoid the corners of the formed part, And the corresponding blocks of the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com