Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

304results about How to "No rebound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gongbu ointment

InactiveCN1354014AQuick eliminationNormal bloodAerosol deliveryDigestive systemSide effectDioscorea polystachya

The present invention relates to a Chinese medicine Gongbugao ointment containing no any hormone without toxic side effect. The prescription of said Chinese medicine ointment is formed from 63 Chinese medicinal materials of american ginseng, Chinese angelica root, Chinese yam, salvia root, astragalus root, ganoderma coix seed, pipe-fish, notoginseng root, sea horse and others. Said invented ointment is a pure Chinese medicine preparation, has no any hormones and has no any toxic side effect, and possesses stable and long-period curing and health-care effect, and has internal regulation action, and can quickly relieve, reduce and eliminate toxic side effect due to chemotherapy, so that it is a good oral tonic product for all people.

Owner:廖干甫

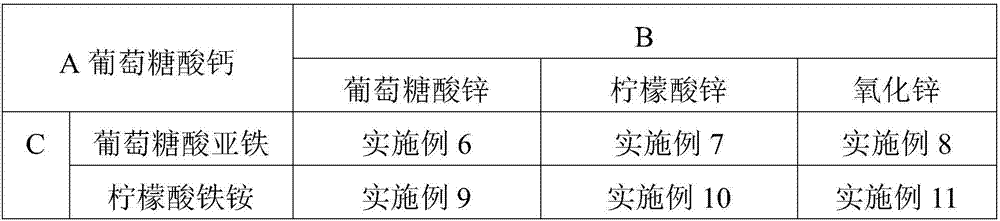

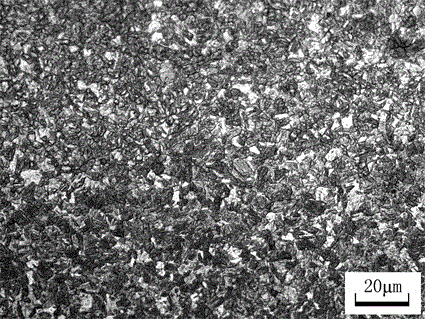

Steel with 1,300MPa-level tensile strength for automobile safety piece and production method thereof

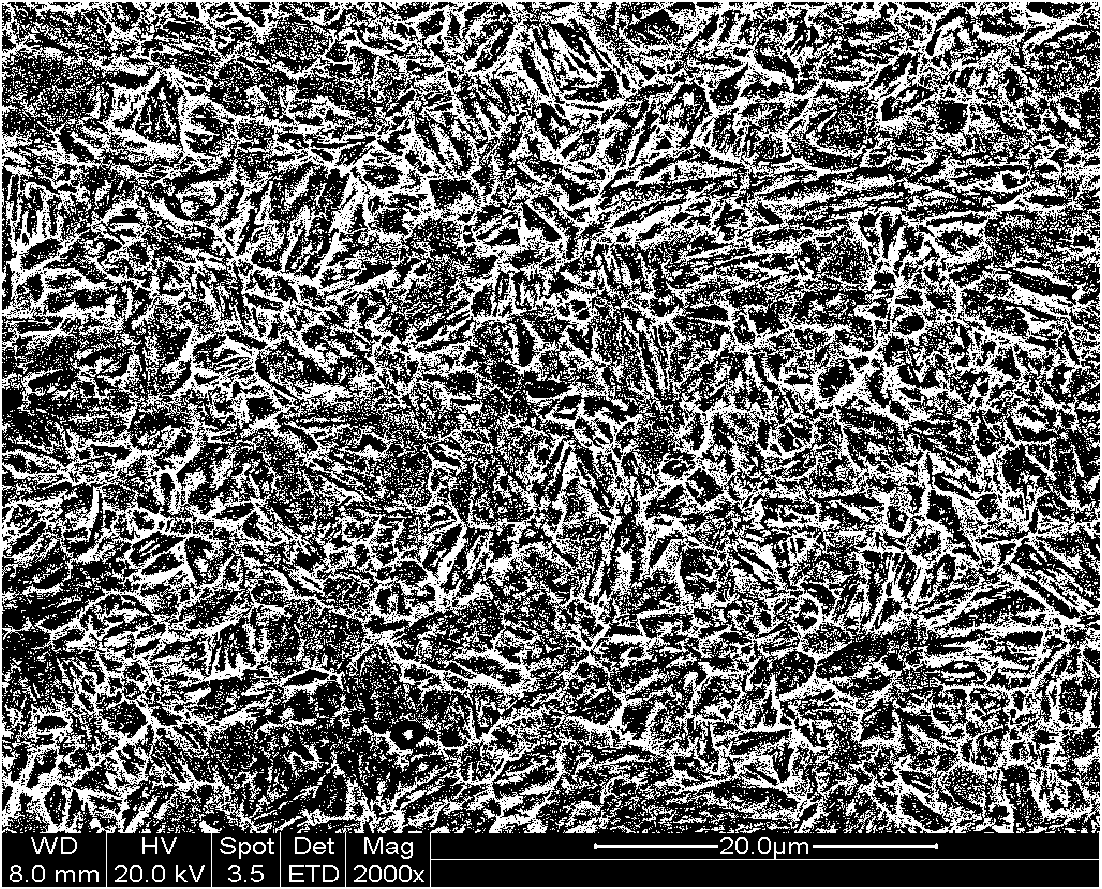

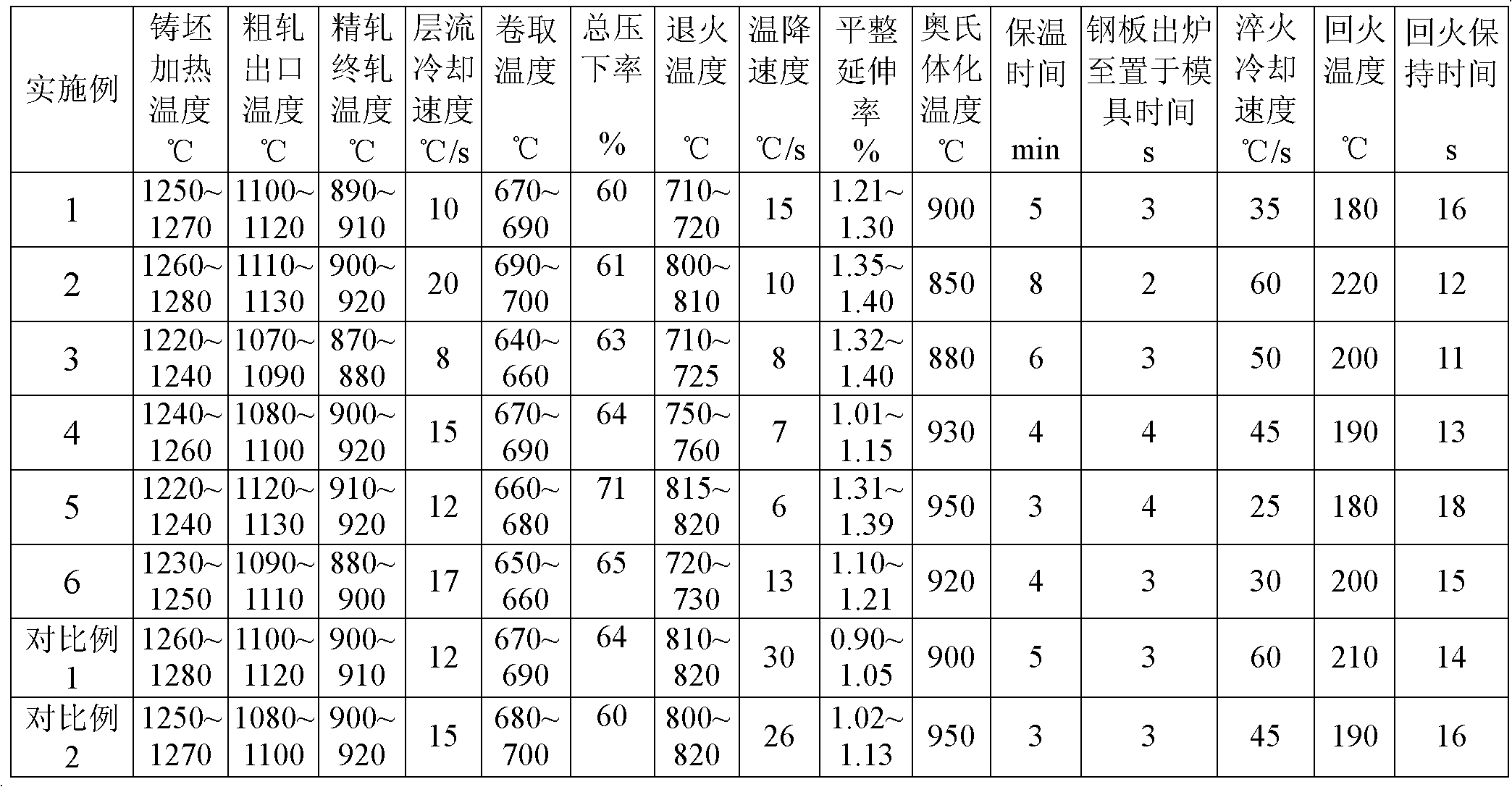

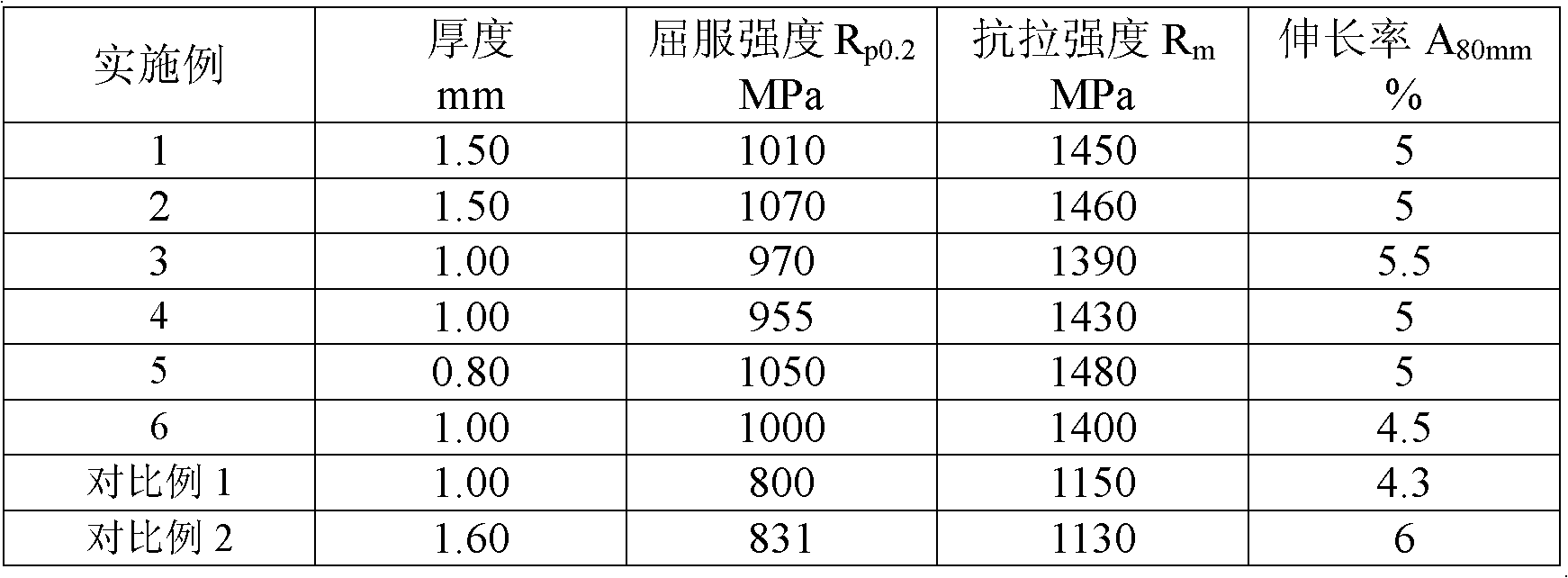

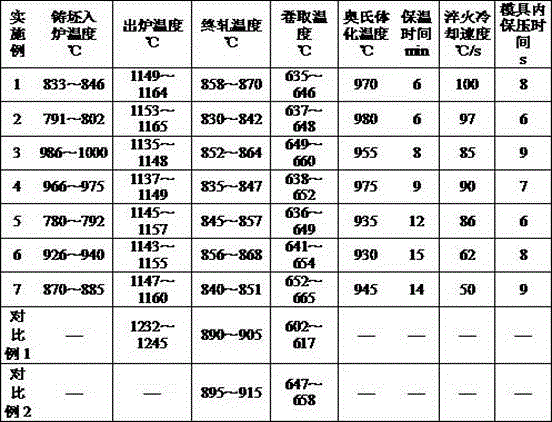

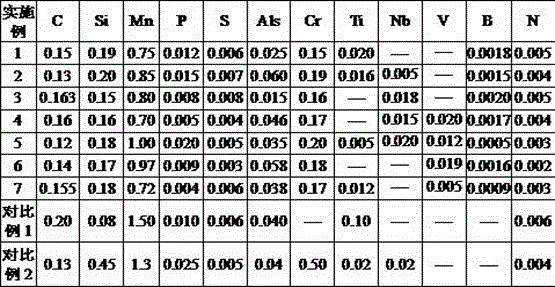

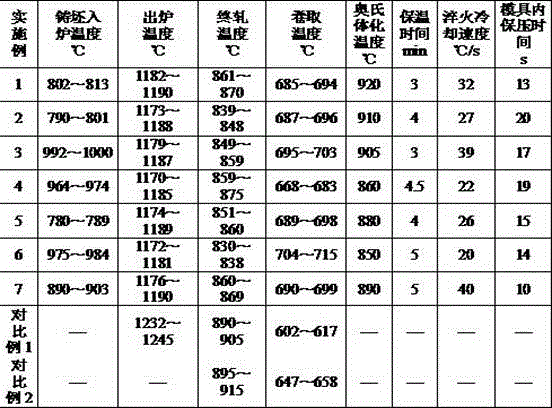

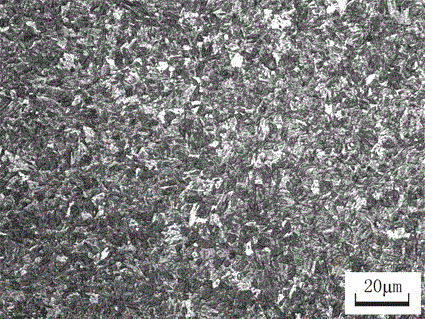

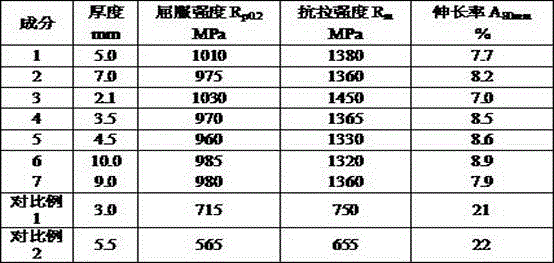

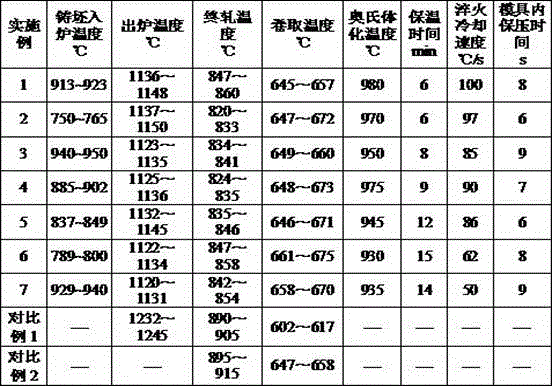

The invention relates to steel with 1,300MPa-level tensile strength for an automobile safety piece and a production method thereof. The steel comprises the following components in percentage by weight: 0.12 to 0.22 percent of C, 0.10 to 0.40 percent of Si, 1.00 to 1.60 percent of Mn, 0.10 to 0.45 percent of Cr, 0.01 to 0.10 percent of Ti, 0.0005 to 0.005 percent of B, 0.01 to 0.06 percent of Als,less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S and less than or equal to 0.008 percent of N. The production method comprises the following steps of: smelting by using a converter; alloying; performing vacuum treatment and component fine turning; continuously casting; heating a casting blank to the temperature of between 1,220 and 1,280 DEG C; performing rough rolling; performing fine rolling; performing laminar flow cooling; reeling; performing acid-washing; performing cold rolling; annealing; smoothing; finishing; cutting; heating and austenitizing under the protective atmosphere of nitrogen; forming a mold; quenching; tempering; and taking a member out for later use. The steel has ultrahigh intensity, meets the requirements of an automobile industry on the intensity and the rigidity of the safety piece of a vehicle body, can be complicatedly deformed without resilience, has high dimensional accuracy of parts and can be industrially produced on common large production equipment.

Owner:武汉钢铁有限公司

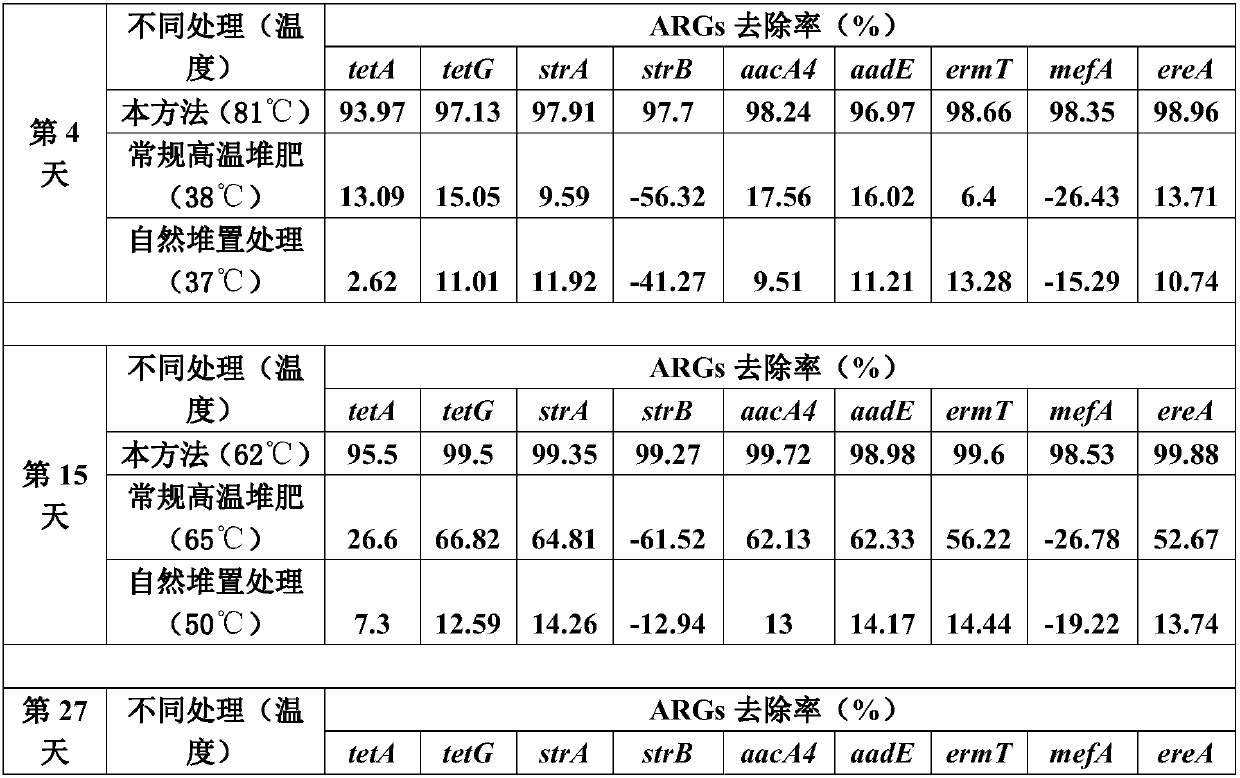

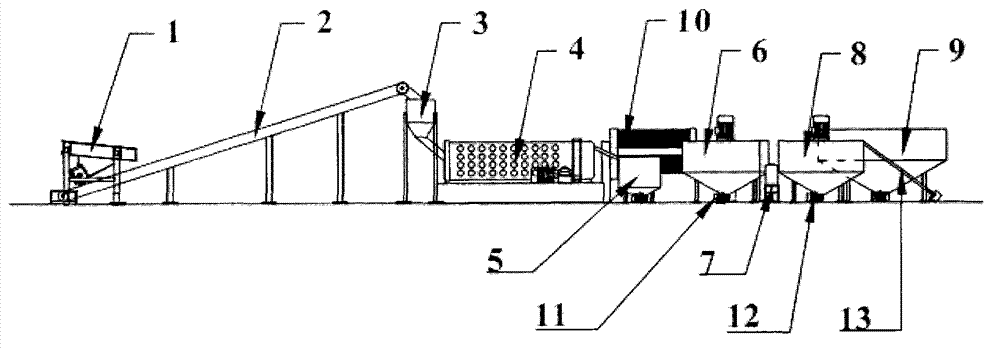

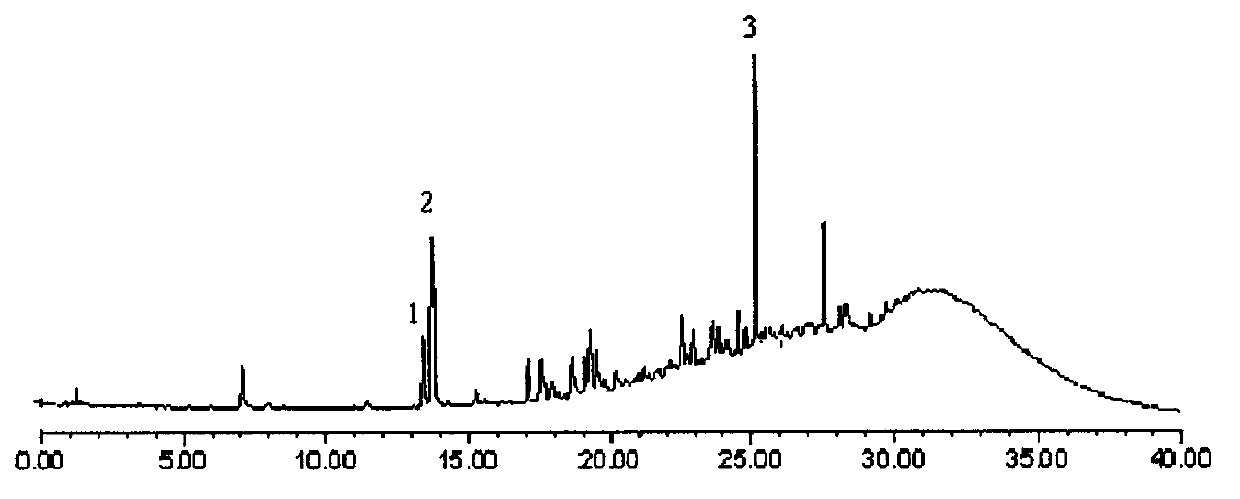

Method for quickly reducing antibiotics and resistance genes in organic solid waste

ActiveCN108033817AReduce the risk of gene transferNo reboundBio-organic fraction processingBacteriaGene transferBacteroidetes

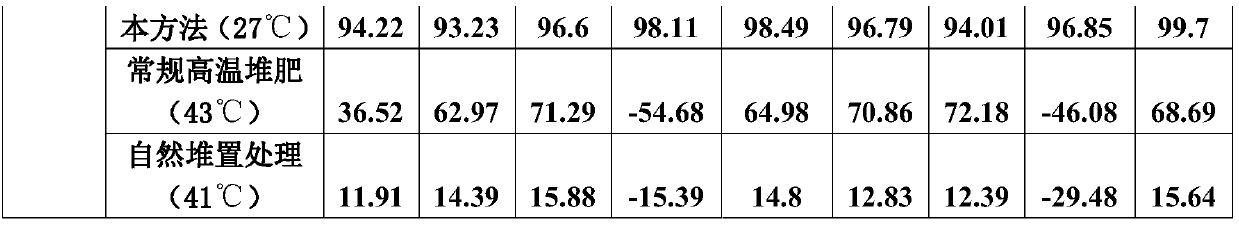

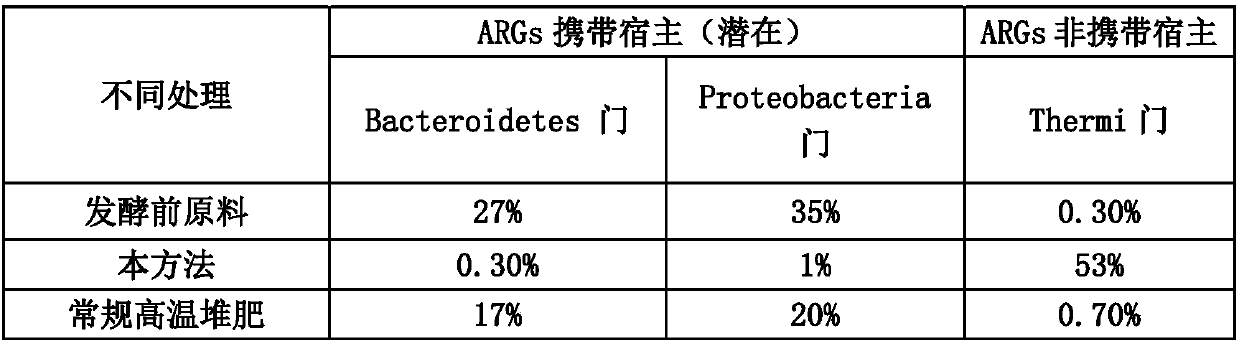

The invention discloses a method for quickly reducing antibiotics and resistance genes in organic solid waste, and belongs to the field of organic solid waste treatment. The method has the advantagesthat ultrahigh-temperature aerobic fermentation is carried out on the organic solid waste by the aid of aerobic zymocyte capable of tolerating the temperatures of at least 80 DEG C under the conditionthat pile temperatures are not lower than 80 DEG C under the control for at least 5-7 days, and accordingly effects of quickly and stably reducing the antibiotics and the resistance genes in the organic solid waste can be realized; the antibiotics and the ARGs (antibiotic resistance genes) can be quickly degraded by means of ultrahigh-temperature aerobic fermentation, integral microbial communitystructures in piles further can be changed, 90% of microorganisms (mainly including Proteobacteria and Bacteroidetes) which carry the ARGs can be killed, risks of gene transfer of the ARGs can be reduced, diffusion of the ARGs can be controlled from the source, and the ARGs can be guaranteed against rebounding; the organic solid waste can be treated, and double effects of efficiently removing antibiotic residues and resistance gene pollution can be realized; exogenous heating can be omitted, energy can be produced only by the aid of metabolism of thermophilic microorganisms to reach the highfermentation temperatures, and accordingly the method is low in energy consumption and is environmentally friendly.

Owner:FUJIAN AGRI & FORESTRY UNIV

Refractory castable for blast furnace tapping trench and preparation method thereof

InactiveCN109293375AImprove liquidityImprove room and medium temperature strengthAluminiumMicrostructure

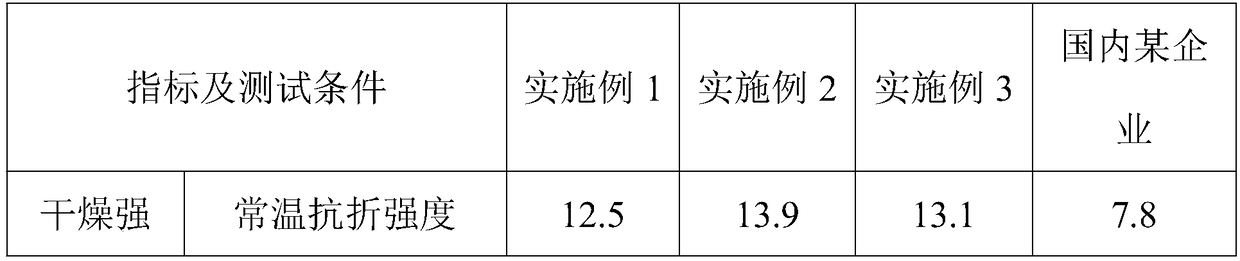

The invention discloses method of preparing a refractory castable used for large blast furnace iron runners, and the refractory castable has the advantages of green environmental protection, energy saving and emission reduction, good construction performance, high strength, high temperature volume stability, thermal shock stability and slag corrosion resistance. The method adopts Shanxi high-quality high bauxite (Al2O3 is greater than equal to 88%), fused brown corundum, fused white corundum and 97 silicon carbide as main raw materials, and high bauxite and fused brown corundum are composed ofcertain particles, fused white corundum powder, calcined alumina powder, 95 silicon micropowder, spherical asphalt, metal silicon powder and pure calcium aluminate cement are composition of a matrix,and an appropriate amount of an anti-explosive agent and a high-efficiency dispersant are added for the preparation. The calcined alumina powder used in the long-life environment-friendly tapping trench castable prepared by the method of the invention has uniform microstructure, high fineness, good sinterability and fluidity, and reacts with silicon oxide to form a high-temperature phase of mullite at high temperature, which improves the internal microstructure of the material and improves the thermal shock stability of the material.

Owner:洛阳润昌窑业有限公司

Cereal diet meal replacement powder and making method thereof

PendingCN106889521AKeep the tasteRetain nutrientsFood mechanical treatmentFood dryingMeal replacementRed bean

The invention discloses cereal diet meal replacement powder and a making method thereof. The cereal diet meal replacement powder includes raw materials yam, red dates, Chinese wolfberry fruits, oats, red beans, black beans, black sesame, walnut kernels, dried apples, chia seeds, quinoa and probiotics. The cereal diet meal replacement powder has the effects of moderating, nourishing and tonifying qi, nourishing the kidney, nourishing the blood, nourishing the intestines and detoxifying the intestines and expelling toxin, is suitable for all people, is homological in medicine and food, natural and health-care and can replace the three meals.

Owner:北京幸福人生健康科技发展有限公司

Method for preparing biological filler for injectable soft tissue

A process for preparing the biologic filler able to be injected in soft tissue for repairing it or beautifying skin includes such steps as providing the fresh skin of piglet, removing subcutaneous fat, immersing in defatting liquid for defatting, defatting again, alkali treating, removing alkali, cutting for layering, softening by enzyme liquid, cross-linking, water washing, bleaching, cutting to become particles, packing and Co-60 irradiation.

Owner:SHANDONG UNIV

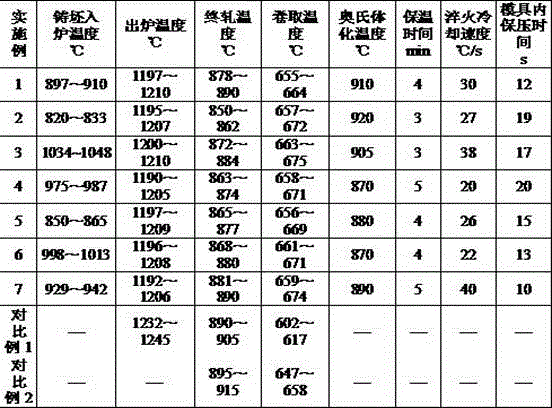

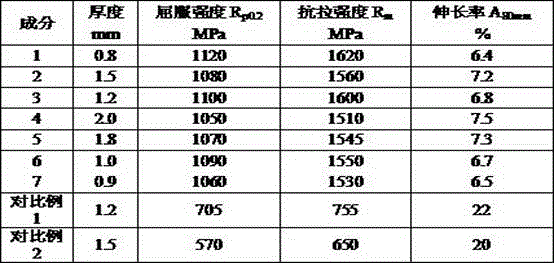

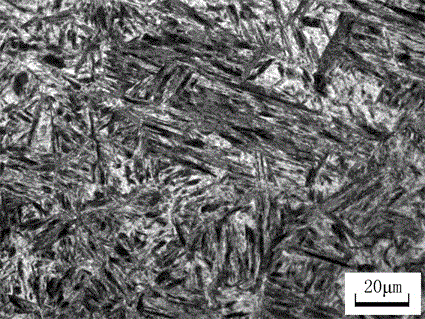

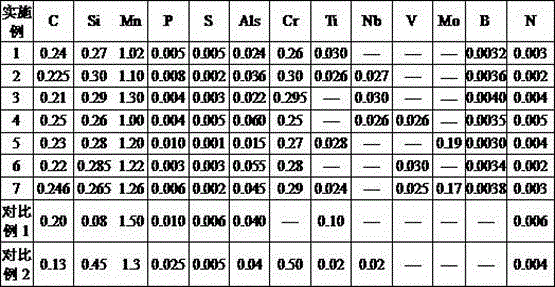

Thin hot forming steel rolled directly through sheet billet and with tensile strength being larger than or equal to 1500MPa and production method

ActiveCN106086685AImprove surface qualityUniform tissueWork treatment devicesMetal rolling arrangementsThin slabHigh pressure water

The invention discloses thin hot forming steel rolled directly through a sheet billet and with the tensile strength being larger than or equal to 1500MPa. The thin hot forming steel comprises, by weight, 0.21%-0.25% of C, 0.26%-0.30% of Si, 1.0%-1.3% of Mn, 0-0.01% of P, 0-0.005% of S, 0.015%-0.060% of Als, 0.25%-0.30% of Cr, 0.026%-0.030% of Ti or 0.026%-0.030% of Nb or 0.026%-0.030% of V or a mixture of any two of the above components, 0.003%-0.004% of B and 0-0.005% of N. The production method includes the production steps of molten iron desulphurization, smelting and refining through an electric furnace or converter, continuous casting, dephosphorization treatment before entering a soaking pit, soaking, heating, high pressure water dephosphorization before entering a rolling mill, rolling, cooling, coiling, austenitizing, mold stamping forming and quenching. The thin hot forming steel is short in process, good in surface quality and high in thickness precision; the quality requirement of cold-rolled products can be met, and complex deformation can be achieved smoothly; and moreover, no resilience exists after deformation, and dimensional accuracy of parts is high.

Owner:武汉钢铁有限公司

Hot forming steel directly rolled through medium and thin slab and having tensile strength larger than or equal to 1500 MPa and production method

ActiveCN106119692AHigh dimensional accuracyMeet quality requirementsWork treatment devicesFurnace typesPunchingThin slab

Hot forming steel directly rolled through a medium and thin slab and having tensile strength larger than or equal to 1500 MPa comprises components including, by weight percent, 0.21% to 0.25% of C, 0.26% to 0.30% of Si, 1.0% to 1.3% of Mn, not larger than 0.01% of P, not larger than 0.005% of S, 0.015% to 0.060% of Als, 0.25% to 0.30% of Cr, 0.026% to 0.030% of Ti or 0.026% to 0.030% of Nb or 0.026% to 0.030% of V or mixing of two or more of Ti, Nb and V with the any proportion, 0.003% to 0.004% of B, 0.17% to 0.19% of Mo and not larger than 0.005% of N. Production steps comprise molten iron desulfuration, electric furnace or converter smelting and refining, continuous casting, descaling treatment before the steel enters a soaking pit furnace, uniform heating, heating, high-pressure water descaling before the steel enters a rolling mill, rolling, cooling, reeling, austenitizing, mold punching molding and quenching. The flow is short, the product surface quality is good, the thickness precision is high, the quality requirement of a cold rolled product can be met, the complex deformation can be smoothly completed, no springback exists after deformation, and the size precision of parts is high.

Owner:武汉钢铁有限公司

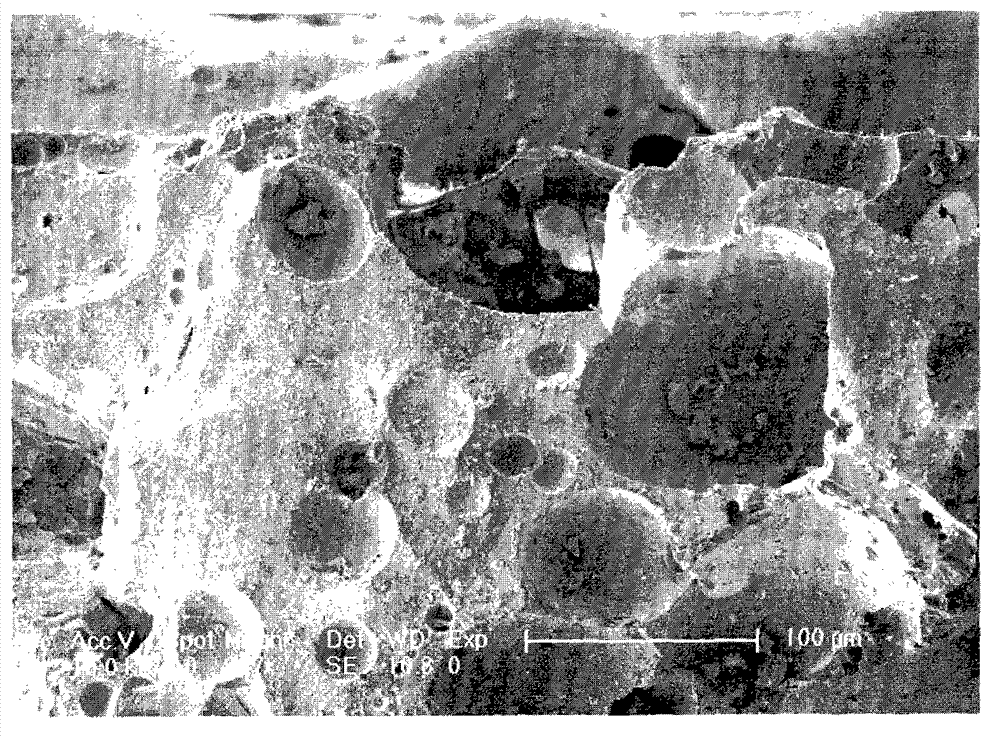

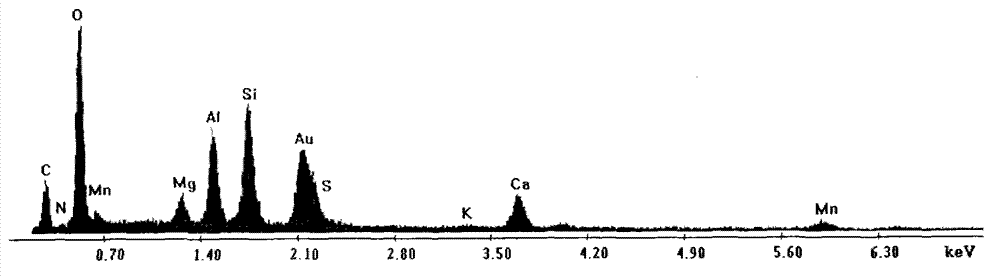

Repairation method of chromium-polluted soil and corresponding equipment thereof

InactiveCN103084385ANo reboundProtect environmentContaminated soil reclamationEcological environmentAfter treatment

The invention relates to a repairation method of chromium-polluted soil and corresponding equipment of the repairation method. After a traditional repairation method of chromium-polluted soil is used for treating the soil, the dissolving of hexavalent chromium in the soil after treatment rebounds along with time. The repairation method of chromium-polluted soil takes manganese slag as a curing agent, and comprises the following steps of: crushing and screening: crushing and screening the chromium-polluted soil, so that the particle diameter of more than 90% of chromium-polluted soil is less than or equal to 20mm; regulating the pH value: adding sulfuric acid in the chromium-polluted soil after treatment in step (1) until the pH value of the chromium-polluted soil is 5-6; carrying out reduction reaction: adding a reducing agent in chromium-polluted soil after treatment in step (2), adding sufficient water so as to guarantee that the soil water content is higher than 40%, stirring uniformly, and standing for more than 20 hours; and carrying out curing reaction: adding a manganese slag curing agent in the soil obtained in step (3), and stirring uniformly, thereby obtaining the repaired soil. The repairation method of chromium-polluted soil and the corresponding equipment provided by the invention have the beneficial effects that the chromium-polluted soil is treated thoroughly and does not rebound, certain practical significance is brought to ecological environment protection, the equipment can operate continuously and automatically and the like.

Owner:韩清洁

Method and device of laser impact sheet metal mouldless shaping based on liquid crystal mask

InactiveCN100999038ARealize three-dimensional distributionDifferent transmittanceLaser beam welding apparatusManufacturing technologyMetallic materials

The present invention belongs to the field of machinery manufacture technology, in particular, it relates to a laser impacted sheet formation method base on liquid crystal mask and its equipment. It is applicable to precision formation of metal sheet (whose thickness is 50 micrometers-4 mm). The invented equipment includes successively-connected laser generator control device, laser generator, beam-expanding system, liquid crystal display screen and display screen control device, focusing system, workpiece clamping apparatus system and digital control system connected with laser generator control device. Display screen control device and working table control device.

Owner:JIANGSU UNIV

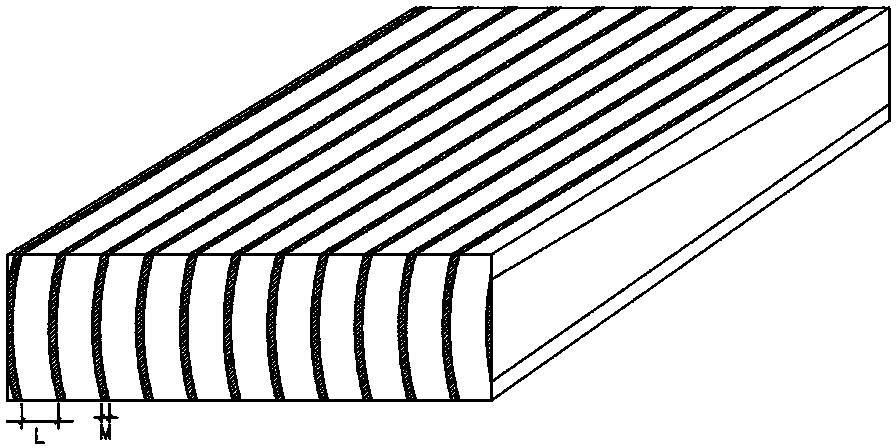

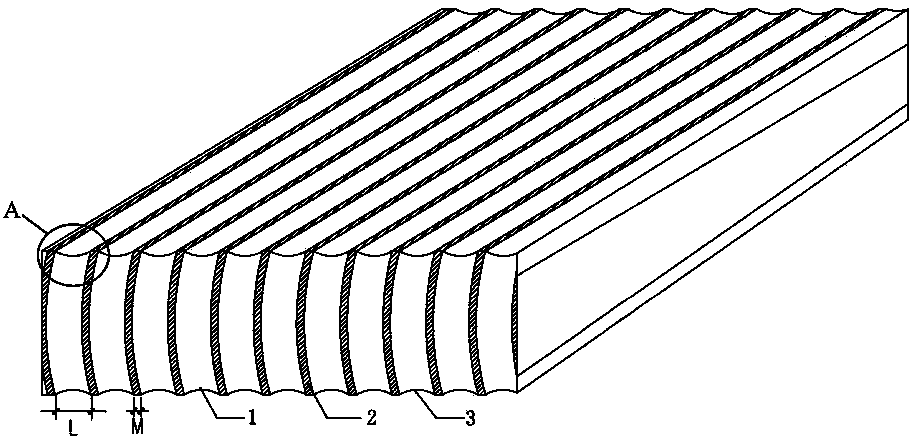

Surface strengthening ancient-Chinese-fir-imitation floor base material and manufacturing method thereof

InactiveCN103522384AGood dimensional stabilityHigh strengthWood treatment detailsPressure impregnationUltimate tensile strengthMachining

The invention discloses a surface strengthening ancient-Chinese-fir-imitation floor base material and a manufacturing method thereof. The surface strengthening ancient-Chinese-fir-imitation floor base material is mainly manufactured by using Chinese-fir converted timbers as raw materials, the surface layer density is 0.6g / cm<3>-0.8g / cm<3>, the hardness is improved by one time to be maximum and is larger than that of the Chinese-fir converted timbers, the wear loss is reduced by 50% to the maximum and is less than that of the Chinese-fir converted timbers, concave-convex grains are arranged on the surface of the base material, the depth of a groove is 1mm-3mm, and the manufacturing method comprises the steps of one-time drying, converted timber fine machining, immersion treatment, secondary drying and sizing treatment. The surface strengthening ancient-Chinese-fir-imitation floor base material is high in surface hardness and strength, has the three-dimensional relief and antiquing effects, and is good in size stability, green and environmentally-friendly. The manufacturing method is easy to operate, small in equipment investment, wide in raw material source, and low in cost.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Anti-hepatitis B virus composition taken from fresh dandelion and application of anti-hepatitis B virus composition in preparation of anti-hepatitis B virus drug

InactiveCN103099838AHas anti-HBV activityHigh development valueOrganic active ingredientsDigestive systemCaffeic acidIsochlorogenic acid

The invention relates to an anti-hepatitis B virus composition taken from fresh dandelion and an application of the anti-hepatitis B virus composition in preparation of an anti-hepatitis B virus drug and belongs to the field of traditional Chinese medicines. The anti-hepatitis B virus composition provided by the invention comprises a fresh dandelion polysaccharide component, a phenolic acid component and a flavone component and is characterized in that the weight ratio of the fresh dandelion polysaccharide component to the phenolic acid component to the flavone component is (2-40): (3-70): (2-50). According to an optimized scheme, the phenolic acid component takes caffeic acid, chlorogenic acid and isochlorogenic acid A as typical ingredients; the flavone component takes galuteolin, quercetin and luteolin as typical ingredients; and the weight ratio of the caffeic acid to the chlorogenic acid to the isochlorogenic acid A to the galuteolin to the quercetin to the luteolin is (0.25-10): (2-40): (0.25-20): (0.5-20): (0-10): (1.5-20). According to the invention, the fresh dandelion is taken as raw material, effective ingredients are separated, purified and enriched by macroporous resin, the effective ingredients are mixed to obtain the fresh dandelion anti-hepatitis B virus composition, a process is simple and convenient, related diseases caused by hepatitis B viruses can be effectively treated, cost is low, and mass production can be achieved.

Owner:苏州艾费堂医药科技有限公司

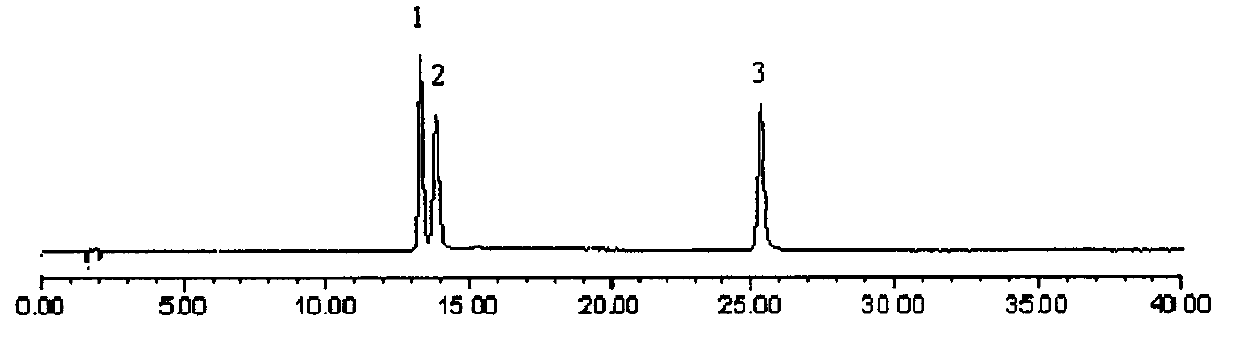

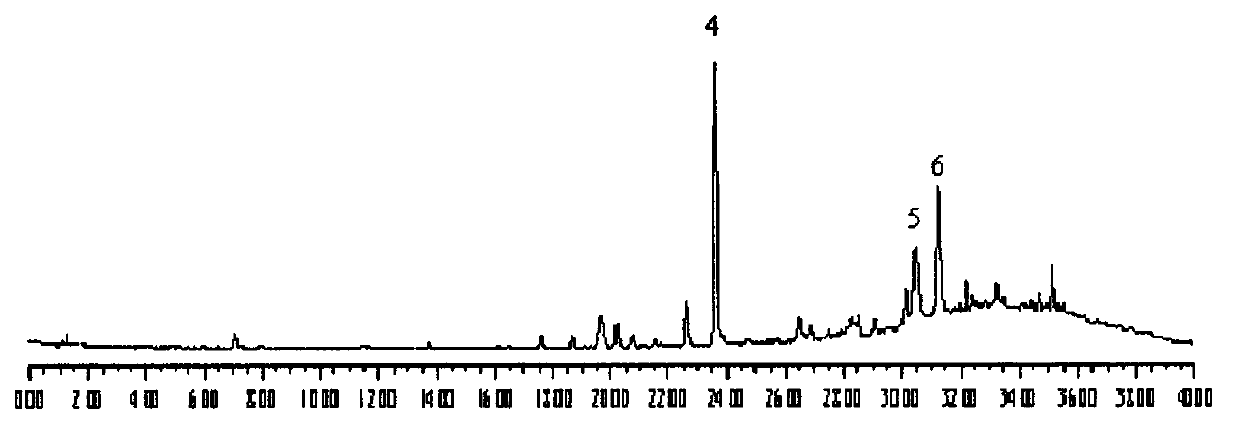

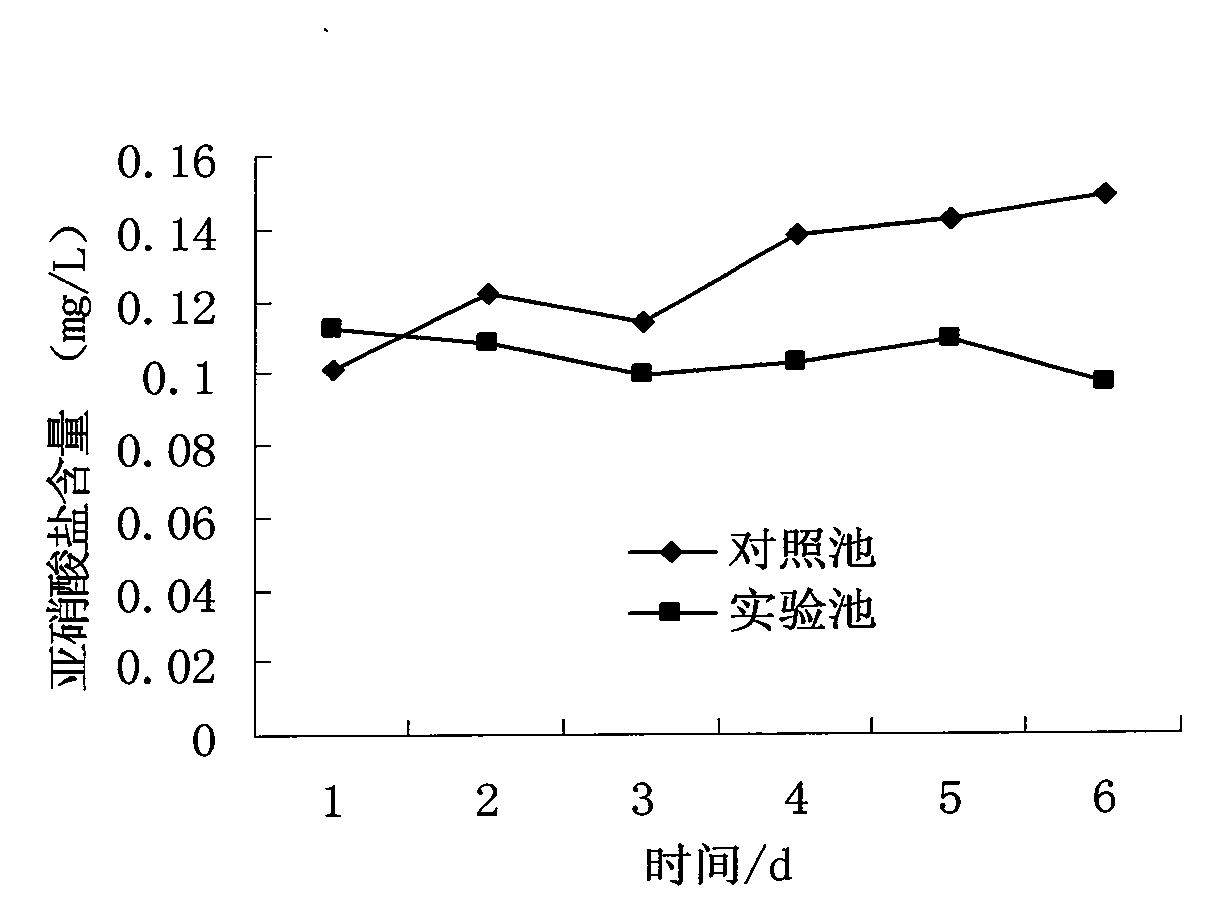

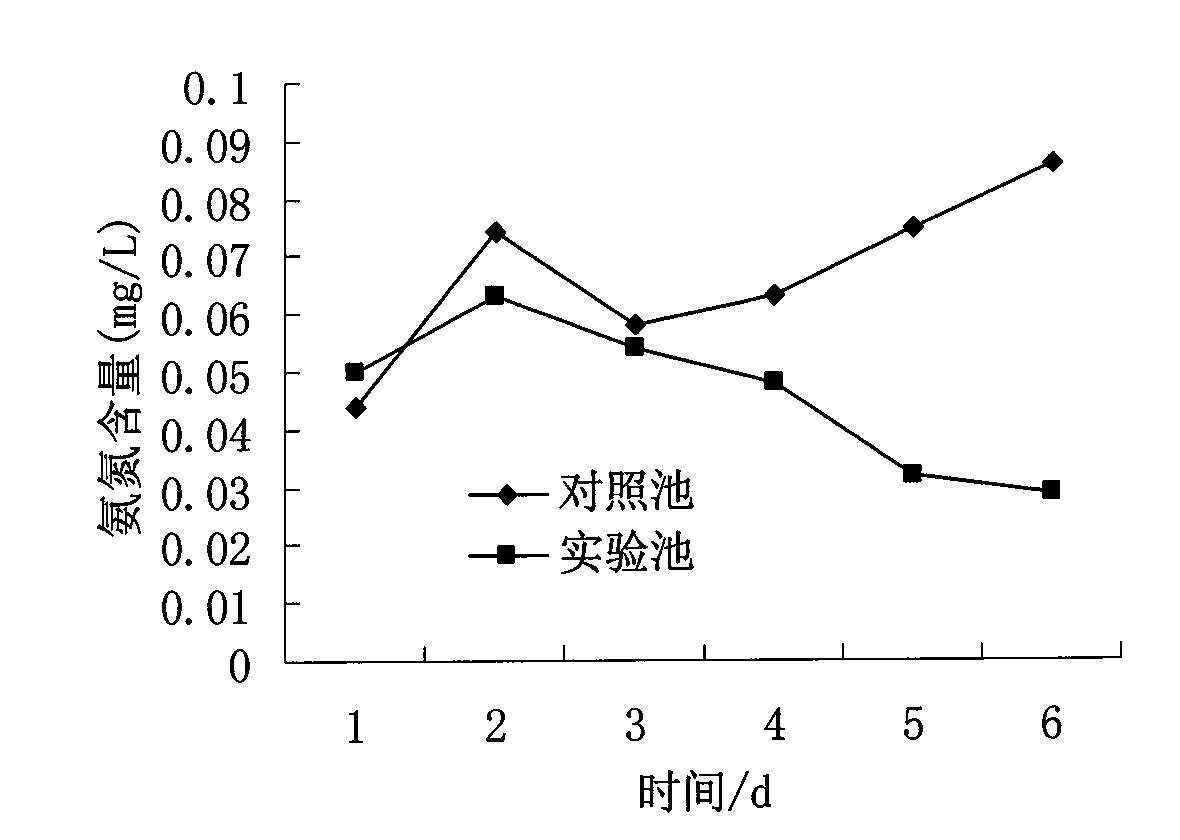

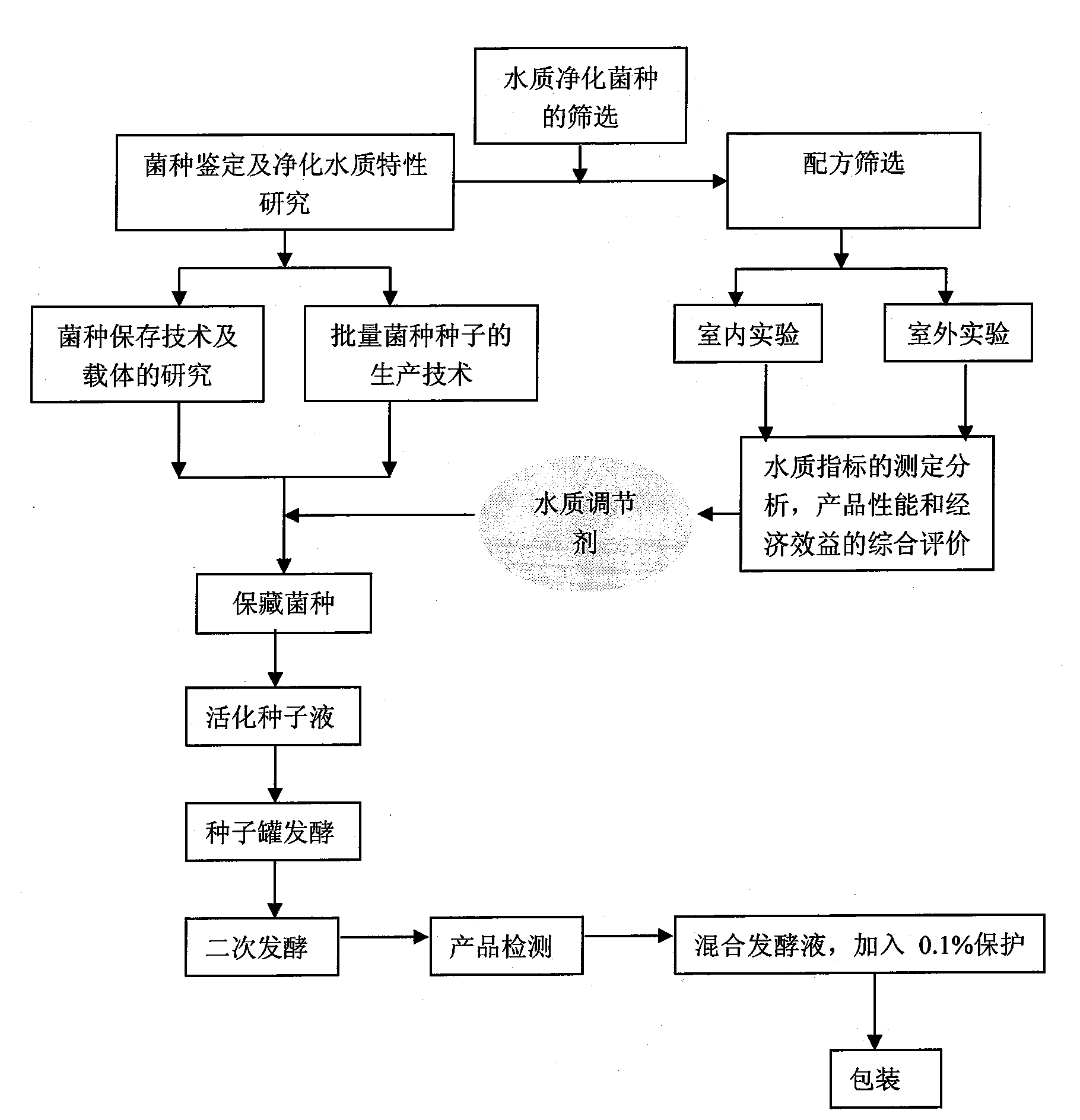

Microorganism water treatment agent in culturing water and preparation technique thereof

InactiveCN101624234APromote degradationNo reboundBacteriaMicroorganism based processesEnvironmental resistanceWater quality

The invention relates to a microorganism water treatment agent in culturing water and a preparation technique thereof, belonging to the technical field of animal farming. The microorganism water treatment agent comprises (Klebsiella) AN-4, bacillus subtilis, Rhodospirillum, and Lactobacillus plantarum. Bean cake powder and molasses are used as raw materials and deeply fermented to produce water treatment agent which has lots of living bacterial and can effectively purify water quality. The product has low cost and environmental protection, overcomes problems that the current water quality purifying agent has poor stability and weak stress resistance and the like, can be used for large-scale industrial production and provides a new microorganism preparation for aquaculture water body.

Owner:NANJING AGRICULTURAL UNIVERSITY

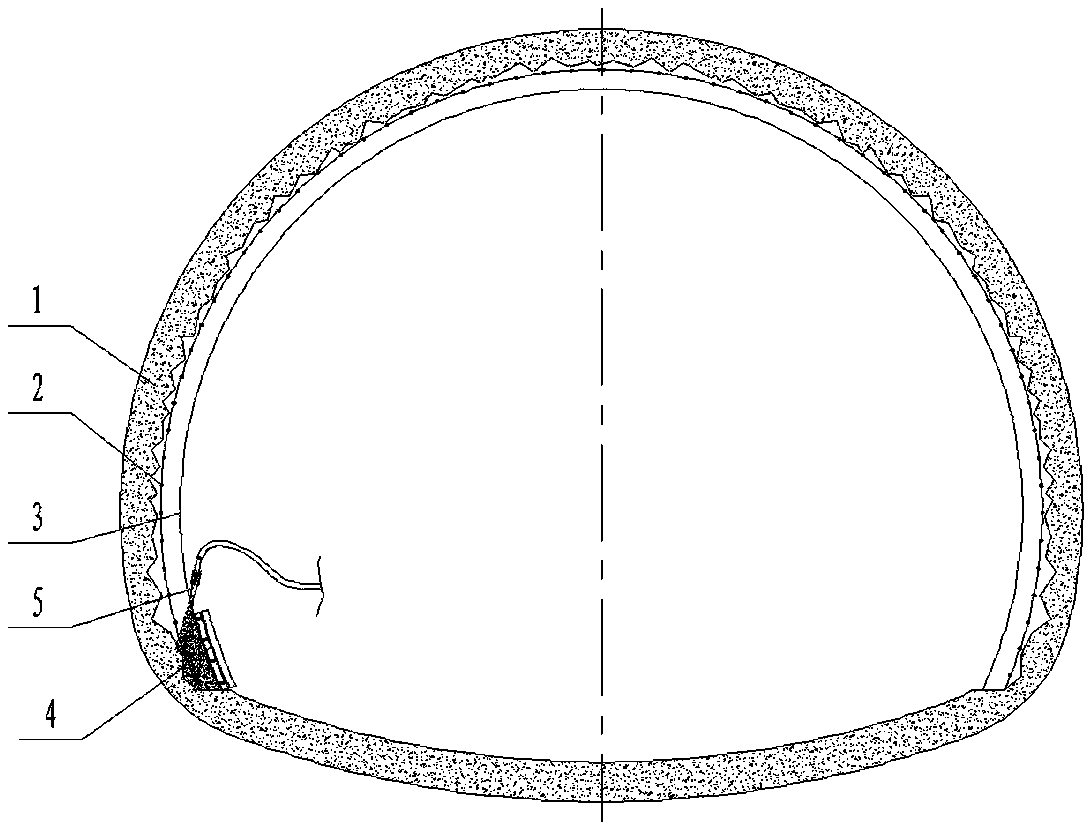

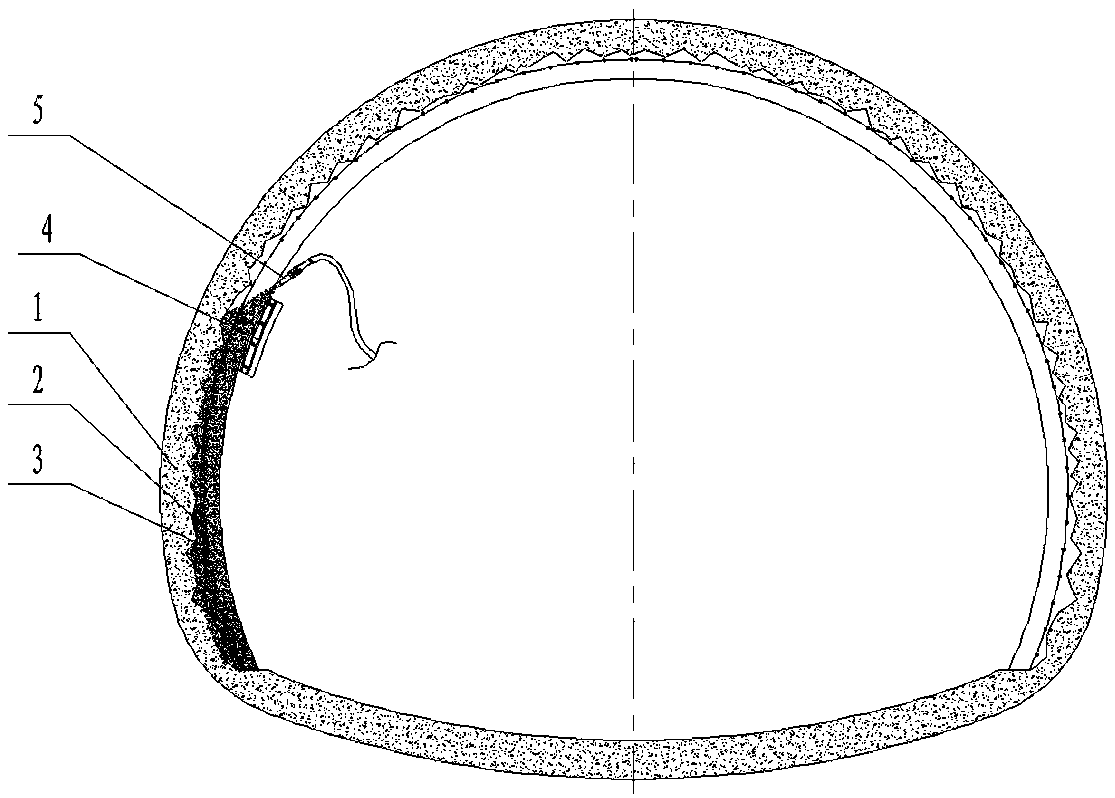

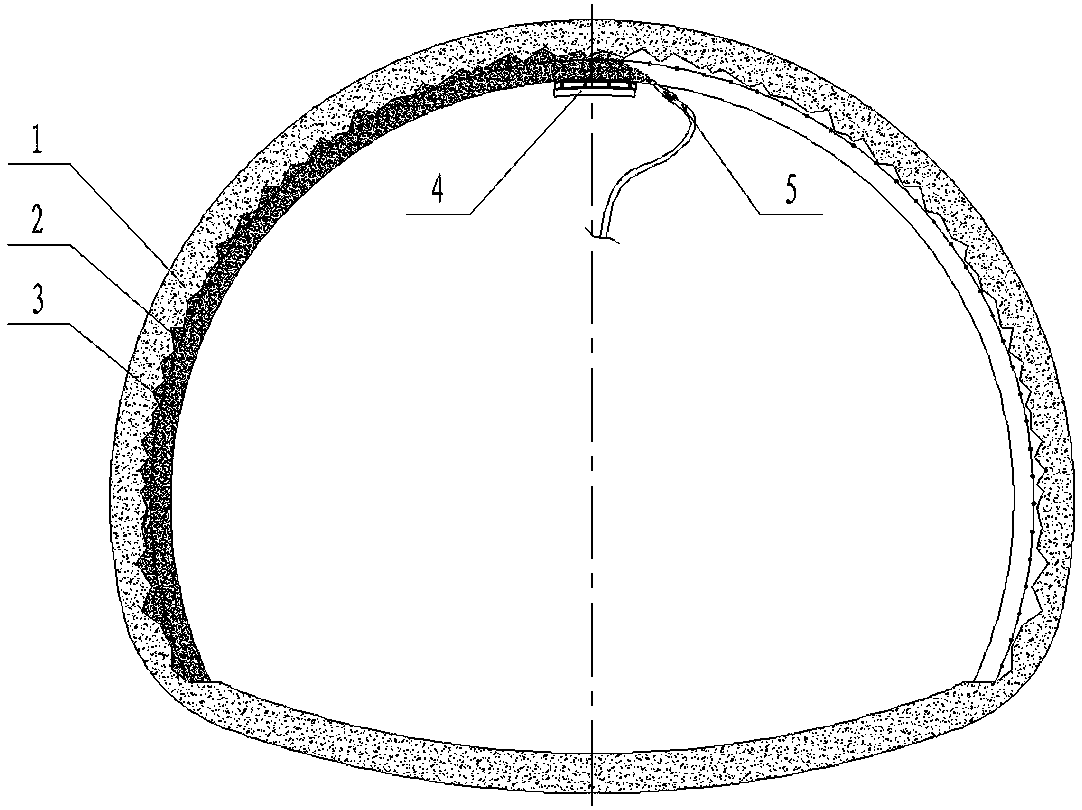

Construction method and support mould for tunnel primary support

The invention provides a construction method and support mould for tunnel primary support. The movable support mould is adopted in tunnel primary support construction; a mould cavity is formed betweenthe support mould and the tunnel excavation face; the support mould moves with the outline of the tunnel excavation face as the moving track; the mould cavity used for forming a tunnel primary support concrete layer is formed through joint cooperation of the movable support mould and the tunnel excavation face; the mould cavity is filled with concrete added with an accelerator, and after the concrete at the bottom of the mould cavity is initially solidified, the support mould moves towards a next station step by step; when the support mould moves, a mould cavity which is newly formed by the support mould in the moving process and the tunnel excavation face is continuously filled with concrete added with an accelerator; and finally, the whole tunnel primary support concrete layer is formed. The construction method and support mould have the beneficial effects that the working time is short, efficiency is high, the using quantity of the accelerators is small, springback is avoided, flatness is high, smoothness is achieved, unevenness is avoided, attractiveness is achieved, and after-treatment is not needed.

Owner:SICHUAN LANHAI ENG EQUIP MFG CO LTD

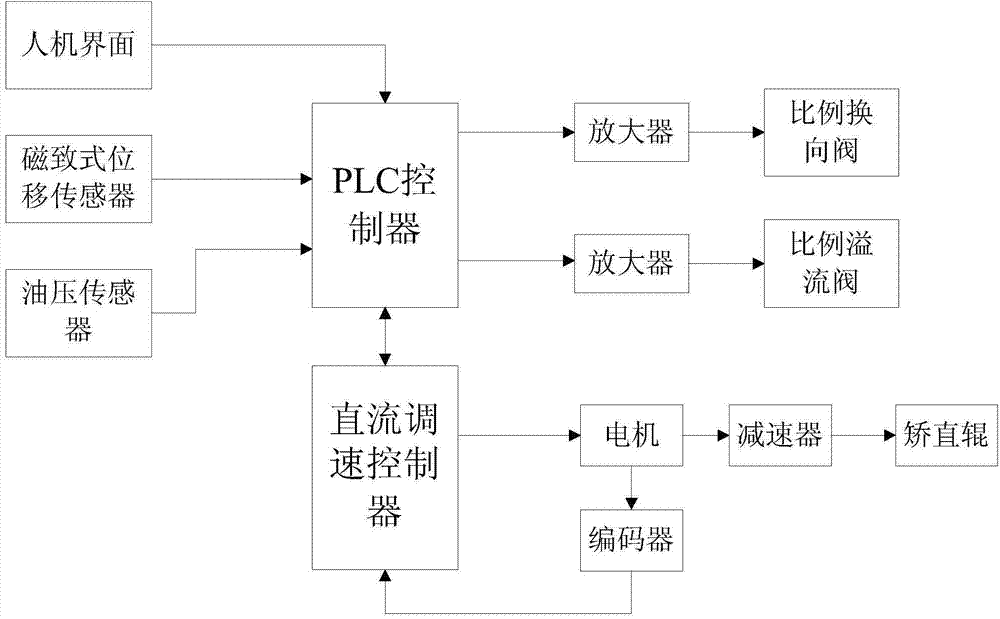

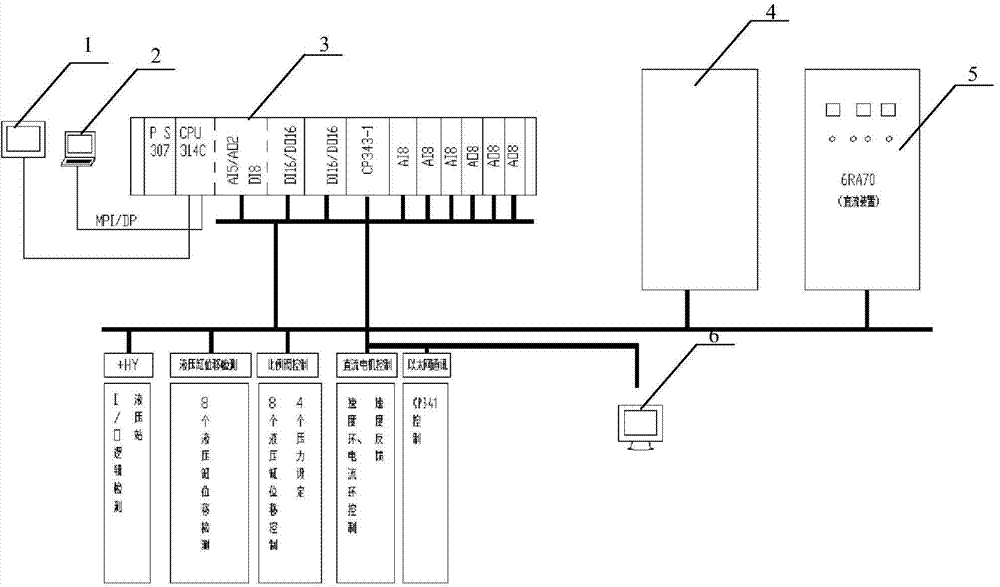

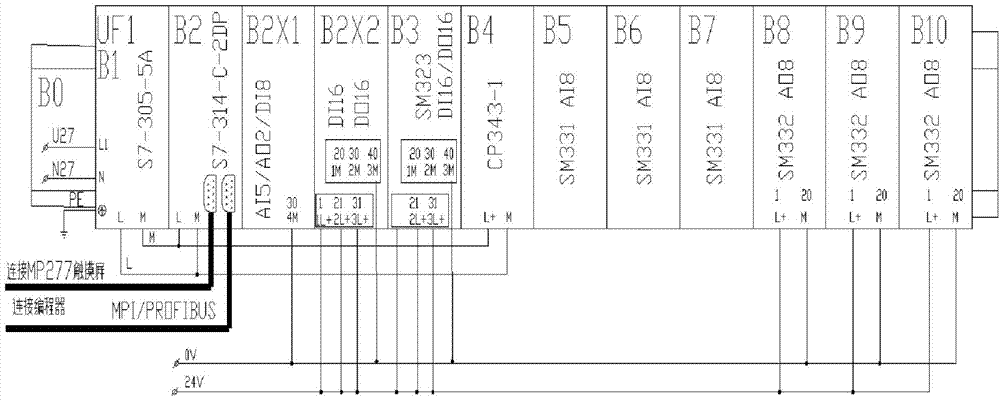

Automatic control system and method for high-precision straightening machine

ActiveCN104117554AEnsure consistencyNo dead zoneProgramme control in sequence/logic controllersPistonAutomatic control

The invention relates to an automatic control system and method for a high-precision straightening machine and belongs to the field of automatic control. Through the automatic control system and method, the straightness (curvature) reaches over 0.3 mm / m according to the straightening precision of the high-precision straightening machine; a hardware structure and a software method of the automatic control system for the high-precision straightening machine are designed considering closed-loop control of oil source pressure and oil cylinder piston displacement of a hydraulic system of the high-precision straightening machine, continuous detection of straightening operation process data, stepless speed regulation control for calibrating transmission of all sets of straightening rollers and the like, the international advanced level of three-dimensional rotation straightening under high-precision automatic control is reached, consistency of roller gap precision in the straightening process, stability of evenly distributed and balanced straightening force and reliability of nonlinear variable gain automatic compensation can be guaranteed, the straightness is improved to 0.2 mm / m from 0.3 mm / m according to the straightening precision of the high-precision straightening machine, and the straightening target that straightened materials have no blind area or tiny crack or scratch or oval or bounce is achieved.

Owner:辽宁银捷装备科技股份有限公司

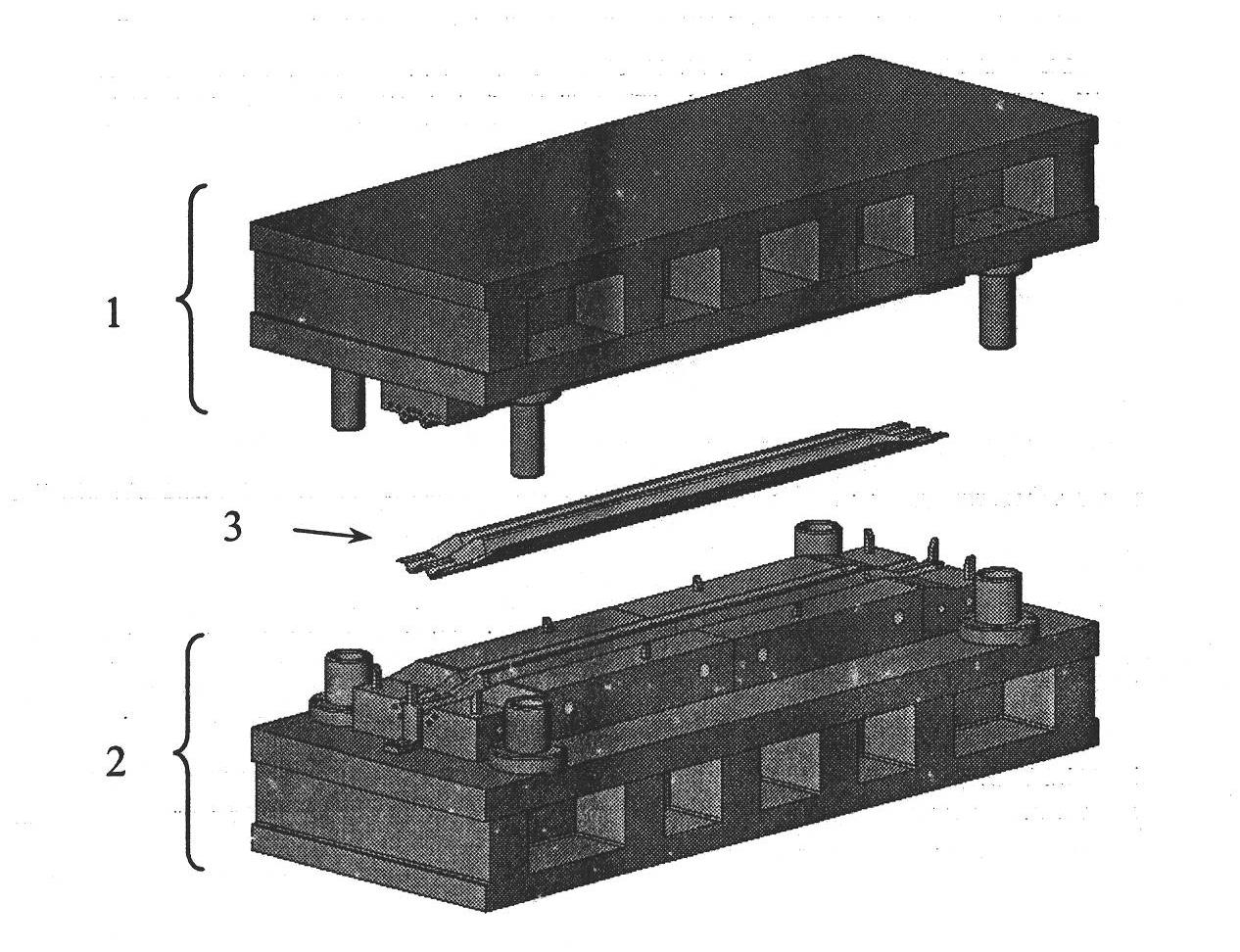

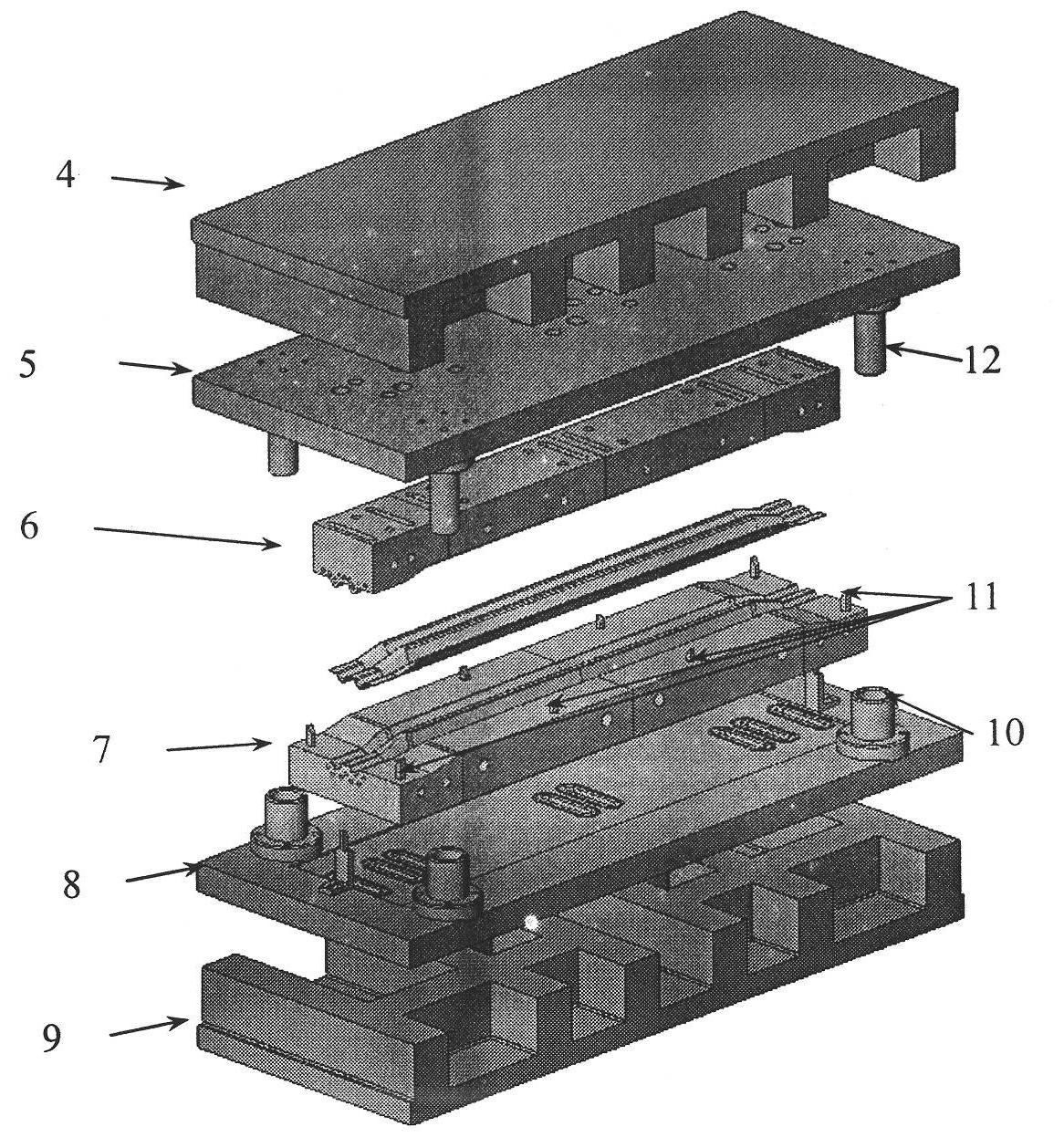

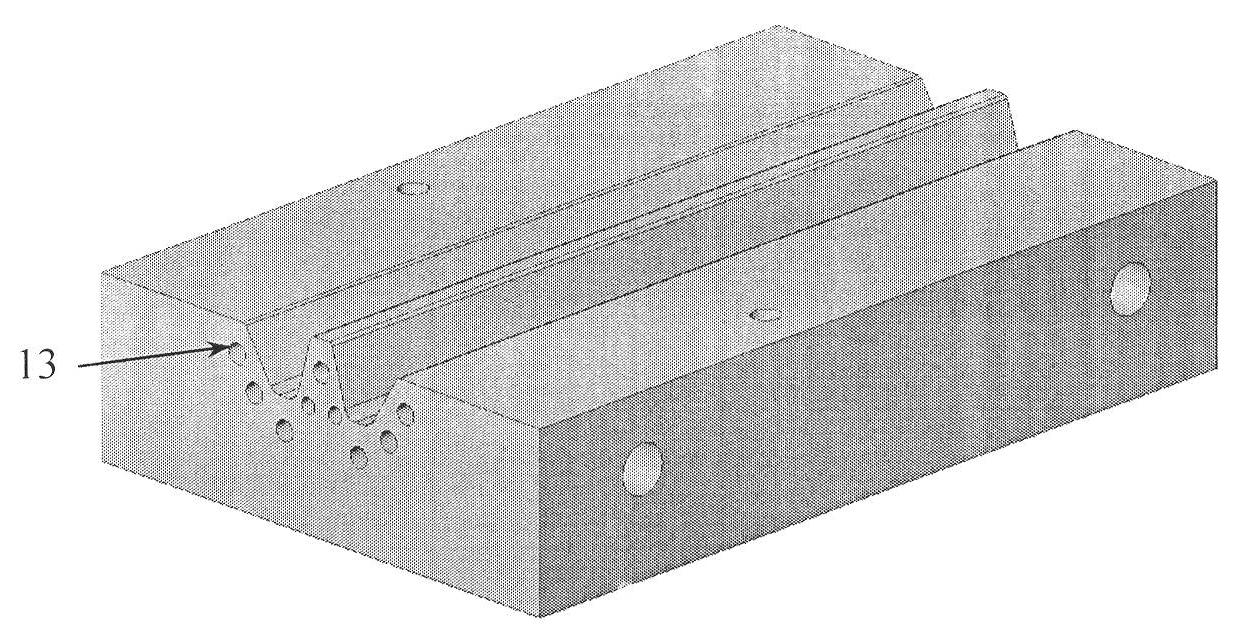

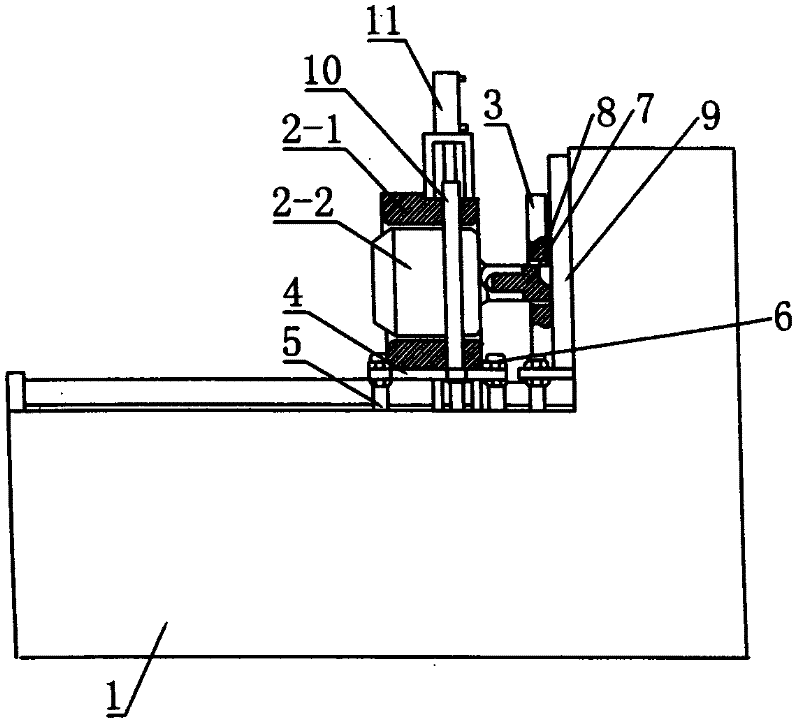

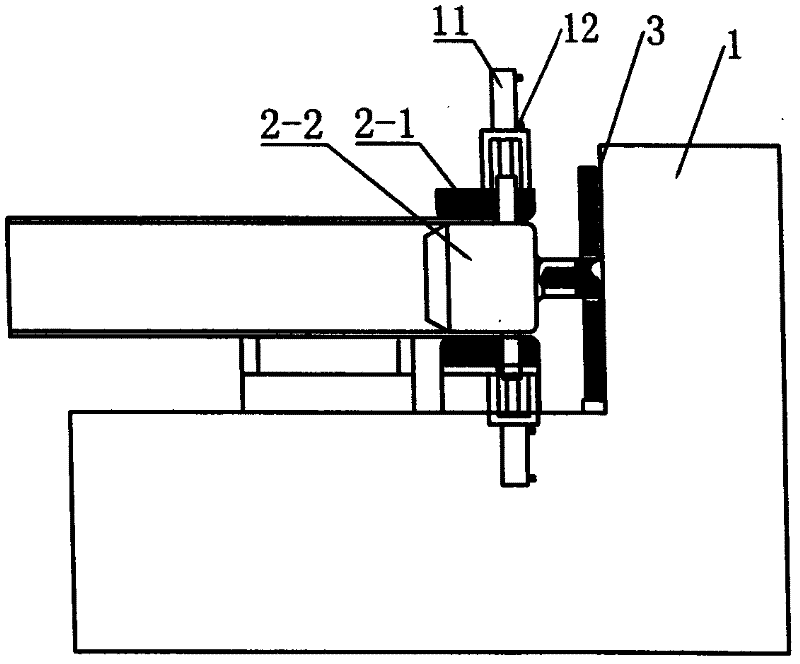

Ultra-high strength steel hot-stamping die for car door anticollision beam

InactiveCN101972814AHigh strengthReduce weightShaping toolsLoad-supporting pillarsHot stampingEngineering

The invention provides a hot-stamping die for an anticollision beam, comprising an upper die and a lower die, wherein the upper and lower dies mainly comprise combined convex / concave dies, cooling systems and a cooling seal ring. The blocks of the combined convex / concave dies avoid the corners and are staggered relatively. The cooling systems adopt drill holes, wherein the diameter of the holes is 8-30mm and the peaks of the holes are 3-10mm distant from the profiles; the two ends of the holes are sealed after hole drilling; runway type water troughs are processed near the places where the block dies are 10-50mm distant from the two end faces; the cooling water enters from one water trough and flows out of the other water trough; and seal grooves are arranged on the cooling water troughs and the cooling water troughs are provided with the seal ring and are externally connected with cooling water pipes.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Method and device for sealing steel wire framework plastic composite pipe

The invention discloses a method and a device for sealing steel wire framework plastic composite pipe. The method comprises the following steps of: heating end opening of a composite pipe by a way of self plastic sealing of pipe material, and wrapping a steel wire with plastics turned out from inside and outside of the heated composite pipe by effect of external force. The device comprises a sealing rack and a mould disposed on the sealing rack for fixing the composite pipe; and a heating plate corresponding to the end opening of the composite pipe is disposed out of the mould. The plastics of the pipe material can be wrapped on the steel wire for sealing, and good promotional value is realized.

Owner:GUANGDONG EAST PIPES

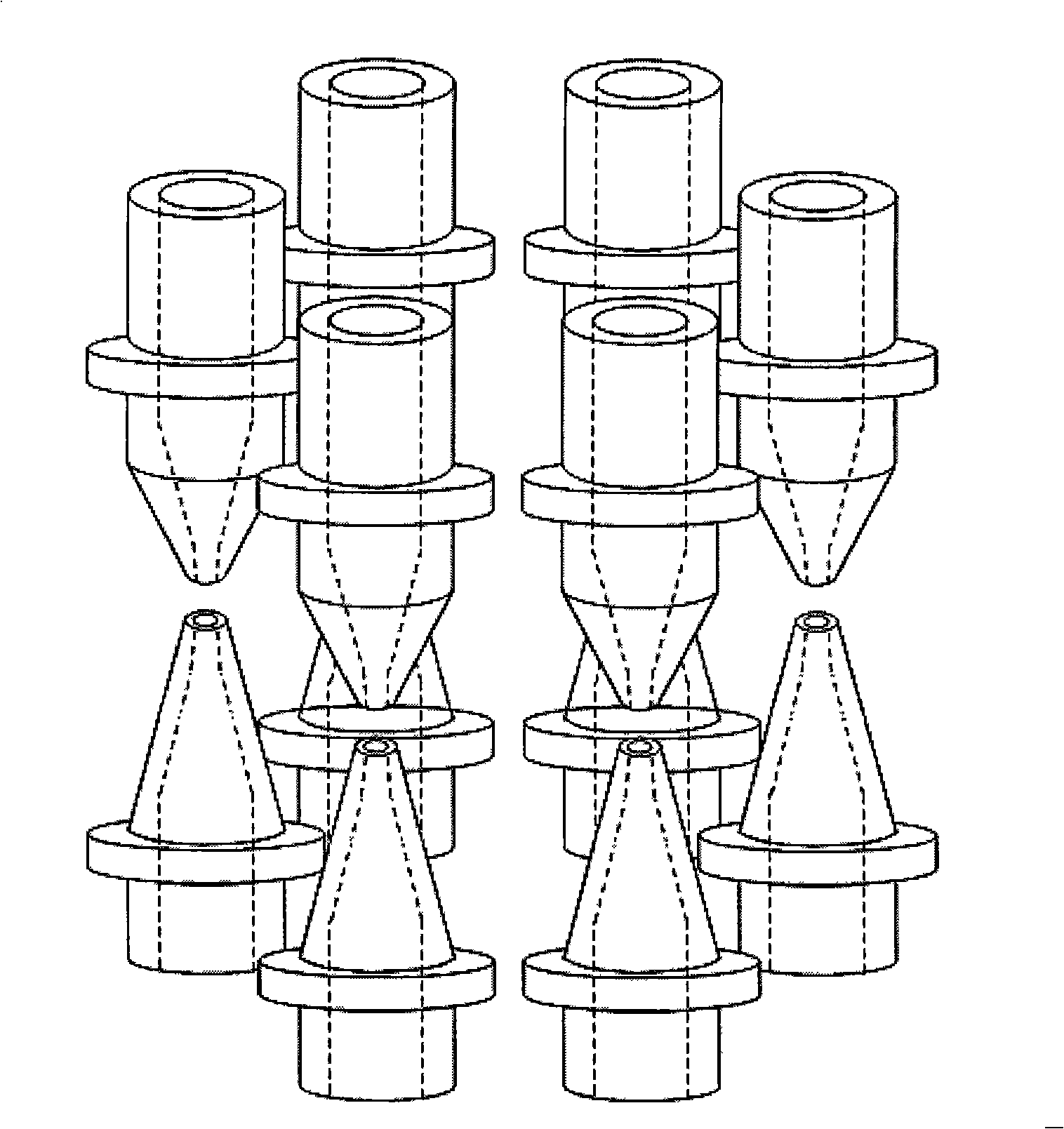

Aerosol virtual impact concentrating separator

ActiveCN101322891AEvenly distributedFree from lossDispersed particle separationThree stageEngineering

The invention relates to an aerosol virtual impacting concentration separator which is characterized in that the separator comprises an outer drum; one side of the lower part of the outer drum is provided with an exhaust port and an exhaust fan which is connected with the exhaust end of the exhaust port; the outer drum is internally provided with three stages of separation inlet components from top to bottom; the first stage component comprises an aerosol air intake, the front end of the first stage component is provided with a waterproof and inset resistant net cover, the first stage component is internally provided with a flow limit column and a ring gap is arranged between the flow limit column and the first stage component; the second stage component comprises a large particle collection port and a second stage separation intake board, the large particle collection port is correspondingly arranged under the aerosol air intake and a plurality of second stage spouts are cut evenly at the periphery of the second stage separation intake board; the third stage component comprises a tank which is connected under the second stage separation intake board, the third stage spouts are cut at the bottom of the tank and a third stage collection port is arranged under the third stage spouts. By utilizing the flying inertia of aerosol particle and adopting the virtual impacting principle, the separator of the invention separates the respirable particle with the diameter of 2 microns to 12 microns, which contains microorganism, from great air flow and concentrates the respirable particle to comparatively small air flow.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI +1

Liver protecting and kidney invigorating bean

The liver protecting and kidney invigorating bean is one kind of health food prepared with black bean and 12 kinds of Chinese medicinal materials including rehmannia root, white atractylodes rhizome, Yunling, etc and salt in certain weight proportion. The preparation process includes decocting the Chinese medicinal materials, filtering, adding black bean into the filtrate, boiling, stoving black bean, and packing. The liver protecting and kidney invigorating bean has the health functions of protecting liver, invigorate spleen and stomach, promoting urination, tranquilizing, balancing yin-yang, etc.

Owner:覃玉兰

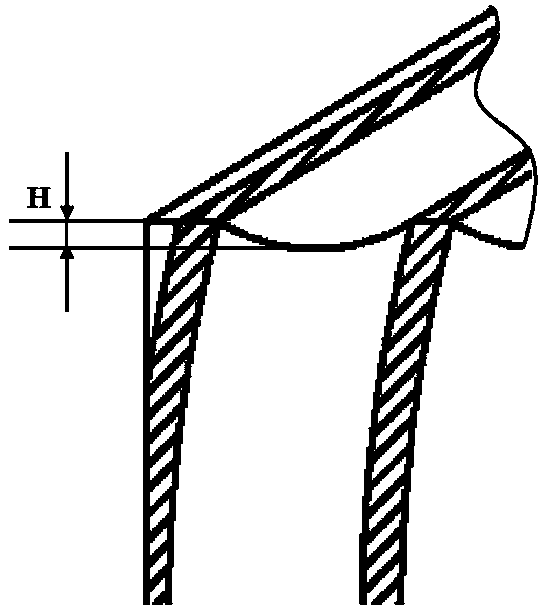

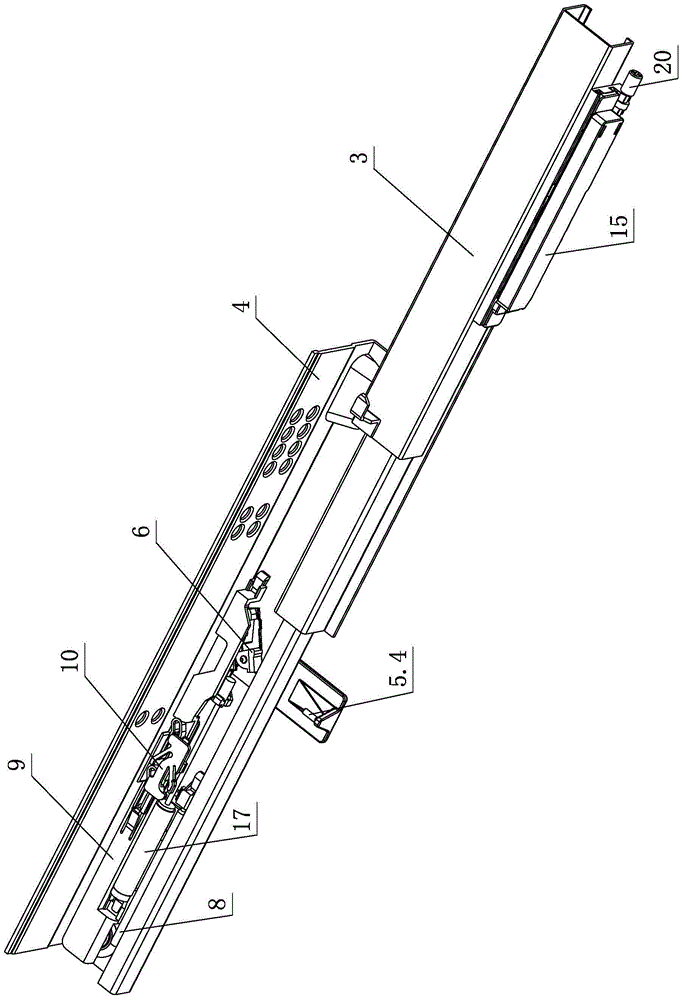

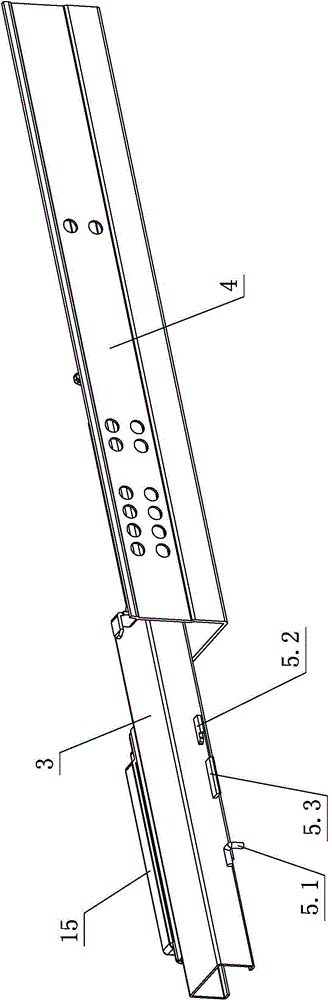

Drawer slide rail which is closed in damping mode and opened in pressing mode

A drawer slide rail which is closed in a damping mode and opened in a pressing mode comprises a slide rail assembly arranged on a cabinet side plate. A drawer is arranged on the slide rail assembly and is at least composed of a bottom plate and a front panel. The slide rail assembly is at least composed of a movable slide rail and a fixed slide rail, and the movable slide rail and the fixed slide rail are both provided with a pressing rebounding device, a damping device, a shifting part A and a shifting part B which interact with one another. Each damping device makes contact with the corresponding shifting part A when the drawer is closed by at least a segment of travel, and the drawer is automatically closed through the acting force of each damping device. The front panel automatically pauses at a pre-pause distance H relative to the cabinet side plate through the pressing rebounding devices when the drawer is automatically closed, the front panel is pressed in the closing direction in the opening process, and the drawer is automatically opened through the acting force of the pressing rebounding devices. Due to the structural improvement, the drawer slide rail has the advantages of being simple and reasonable in structure, safe, reliable, small in size, long in service life, steady and smooth in the pulling process, small in exerted force, convenient to operate, and humanized in design and is high in practicability.

Owner:伍志勇

Thin thermoformed steel with tensile strength being not lower than 1100 MPa directly rolled by sheet billet and production method of thin thermoformed steel

The invention provides thin thermoformed steel with tensile strength being not lower than 1100 MPa directly rolled by a sheet billet. The thin thermoformed steel with tensile strength being not lower than 1100 MPa directly rolled by the sheet billet comprises the following components, in percentage by weight, 0.12-0.16% of C, 0.15-0.20% of Si, 0.7-1.0% of Mn, not higher than 0.02% of P, not higher than 0.008% of S, 0.015-0.060% of Als, 0.15-0.20% of Cr, 0.005-0.02% of Ti or 0.005-0.02% of Nb or 0.005-0.02% of V or a mixture mixed by more than two of the three components in any proportion, 0.0005-0.0020% of B and not higher than 0.005% of N. The production method of the thin thermoformed steel comprises the steps of desulfurizing molten iron; smelting the molten iron by an electric furnace smelting or a rotating furnace and refining the molten iron; performing continuous casting; performing descaling treatment before putting the molten iron into a soaking pit furnace; performing soaking; performing heating; performing high pressure water descaling before putting the molten iron into a rolling mill; performing rolling; performing cooling; performing coiling; performing austenitizing; performing mould stamping forming; and performing quenching. The steel is short in process, good in quality of product surface, high in accuracy of thickness, capable of meeting the quality requirements of cold-rolled products and realizing complicated deformation smoothly without resilience after deformation, and high in accuracy of part size.

Owner:武汉钢铁有限公司

Large-package zero-twist winding machine

The invention relates to a winding machine, in particular to a large-package zero-twist winding machine which mainly solves the technical problems that the winding machine can not satisfy the requirements of especially large package quantity, automatic cylinder disassembly after a cylinder is full, manipulator operation, and the like of a glass-fiber winding automatic production line in the prior art; and the whole mechanism basically uses a mechanical structure mainly, only can realize functions, such as compression, unidirectional locking, and the like, has the defects of uncompleted control, and the like in operation, can not digitally and electronically control and can not realize accurately control of a device, and other technical programs. The large-package zero-twist winding machine comprises a frame (1) and is characterized in that a head yarn gripper is arranged on the frame (1) and connected with a yarn-ball tension curved control device, and the yarn-ball tension curved control device is connected to a cross compression curved control device.

Owner:杭州天启机械有限公司

Traditional Chinese preparation for treating Menieres disease

The invention discloses a traditional Chinese preparation for treating Menieres disease, and the traditional Chinese preparation comprises the following components in parts by weight: 1-10 parts of hairyvein agrimony, 1-5 parts of cassia seed, 0-8 parts of the root of red-rooted salvia, 0-6 parts of Tuckahoe, 0-4 parts of rhizoma gastrodiae and 0-3 parts of bighead atractylodes rhizome. In the traditional Chinese preparation provided by the invention, the traditional Chinese medicines such as the hairyvein agrimony, the cassia seed and the other traditional Chinese medicines are compatible and are decocted into a decoction for oral administration. Thus, all the clinical symptoms such as dizziness, nausea, vomit, nystagmus and the like of patients disappear, and no patient recurs through a follow-up visit for three years. The traditional Chinese preparation for treating the Menieres disease disclosed by the invention has the advantages of simple preparation method, low expense, good treatment effects, no toxic or side effect, no recurrence and no rebound.

Owner:张明兰 +1

Hot-formed steel directly rolled from medium-thin sheet billet and having tensile strength equal to or higher than 1300 MPa and production method

ActiveCN106222556AHigh dimensional accuracyMeet quality requirementsWork treatment devicesMetal rolling arrangementsThin slabHigh pressure water

The invention provides hot-formed steel directly rolled from a medium-thin sheet billet and having the tensile strength equal to or higher than 1300 MPa. The hot-formed steel comprises, by weight, 0.17%-0.20% of C, 0.21%-0.25% of Si, 1.0%-1.3% of Mn, 0-0.01% of P, 0-0.008% of S, 0.015%-0.060% of Als, 0.19%-0.24% of Cr, 0.021%-0.025% of Ti, or 0.021%-0.025% of Nb, or 0.021%-0.025% of V or the mixture of any two of Ti, Nb and V according to any proportion, 0.002%-0.003% of B, 0.14%-0.16% of Mo, and 0-0.005% of N. A production method comprises the steps of molten iron desulphurization, smelting and refining in an electric furnace or a converter, continuous casting, descaling treatment before molten iron enters a soaking pit, soaking, heating, high-pressure water descaling before the molten iron enters a rolling mill, rolling, cooling, reeling, austenitizing, stamp-forming through a die, and quenching. According to the hot-formed steel directly rolled from the medium-thin sheet billet and having the tensile strength equal to or higher than 1300 MPa and the production method, the procedure is short, the surface quality of a product is good, the thickness precision is high, the requirement for the quality of cold-rolled products can be met, and complex deformation can be completed successfully; and in addition, restoration after deformation is avoided, and the dimensional precision of parts is high.

Owner:武汉钢铁有限公司

Roller coating type simulated face brick coating and construction method

The invention relates to the technical field of coatings, and particularly relates to a roller coating type simulated face brick coating and a construction method. The roller coating type simulated face brick coating is prepared by dispersing the following components in parts by weight in a dispersing kettle: 10-20 parts of ethylene glycol, 2-6 parts of dispersing agents, 1-2 parts of AMP 95, 50-100 parts of 2% hydroxy ethyl cellulose solutions, 30-50 parts of 10% inorganic gels, 1-2 parts of wetting agents, 3-9 parts of defoaming agents, 500-600 parts of natural rock flour, 50-100 parts of rigid polymer emulsions, 50-100 parts of elastic polymer emulsions, 5-10 parts of film forming auxiliary agents, 5-10 parts of hydrophobic modified alkali swelling thickening type thickening agents, 1-6 parts of hydrophobic modified alkali swelling associating type thickening agents, 1-2 parts of sterilizing agents and 110-240 parts of water. According to the invention, a coated film grain obtained after roller coating is more similar to that of an exterior wall tile.

Owner:BAOJI JIALILAI BUILDING DECORATION

Cambered displayer backboard manufacturing method and structure

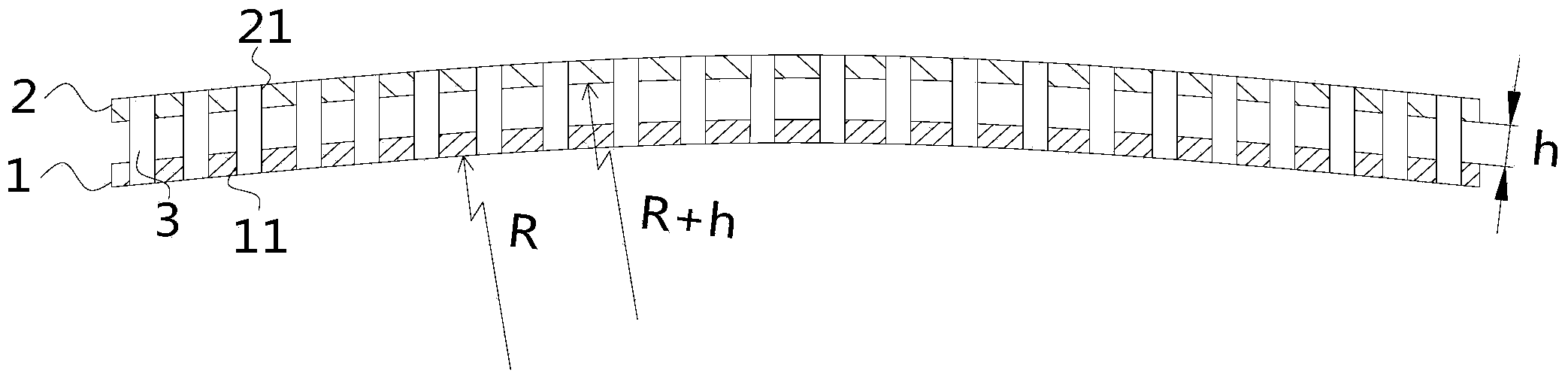

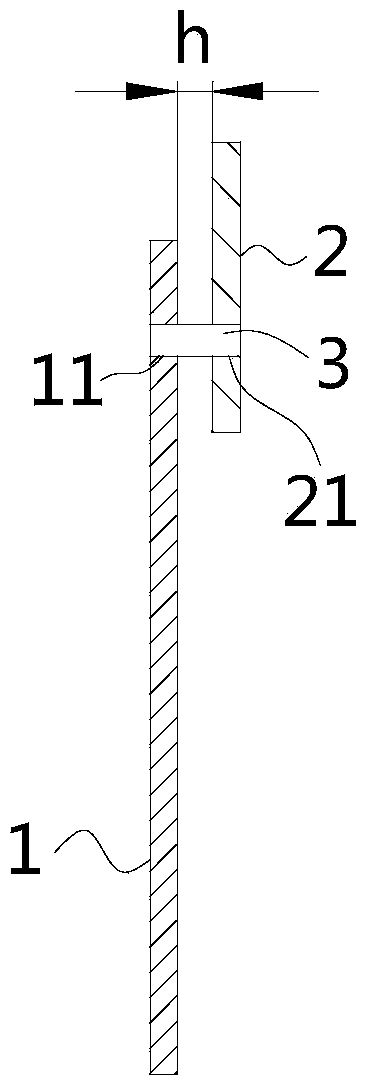

ActiveCN103934319ANo reboundExtended service lifeIdentification meansDisplay deviceAgricultural engineering

The invention relates to a cambered displayer backboard manufacturing method and structure. The cambered displayer backboard manufacturing method and structure can prevent rebound deformation of a cambered backboard. The method involves a bearing plate, and comprises the following steps that (a), the bearing plate and a connection plate are selected; (b), bearing plate installing holes are formed in the bearing plate at same intervals; (c), connection plate installing holes are formed in the connection plate at same intervals; (d), fastening screws are arranged on the bearing plate installing holes of the bearing plate and the connection plate installing holes of the connection plate, it is guaranteed that the distance between the bearing plate and the connection plate is h, the bearing plate and the connection plate are firmly fixed through a tool, a fastening device, the fastening screws and fastening nuts, the bearing plate and the connection plate naturally bend, and a bearing plate curved surface with the radian equal to the circular arc radius R of the bearing plate is formed. The cambered displayer backboard manufacturing method is applied to cambered backboard process for manufacturing cambered displayers.

Owner:四川长虹技佳精工有限公司

High-pressure gas bulging thermoforming die of boron steel pipe

InactiveCN104438878AHigh strengthBig spaceShaping toolsQuenching devicesHydraulic cylinderHigh pressure

The invention relates to a high-pressure gas bulging thermoforming die of a boron steel pipe. The die comprises an upper die base and a lower die base, and is characterized in that an upper die forming insert is mounted on the lower surface of the upper die base; a lower die forming insert is mounted on the upper surface of the lower die base; the lower surface of the upper die forming insert and the upper surface of the lower die forming insert are the forming surface of a workpiece of the boron steel pipe; seal heads are arranged at the two ends of the workpiece of the boron steel pipe respectively; the front ends of the seal heads are in contact with the pipe ends of the workpiece of the boron steel pipe; an axial hydraulic cylinder or an air cylinder is connected to the rear ends of the seal heads; vent holes are formed in the centers of the seal heads; the front ends of the vent holes are communicated with the interior of the workpiece of the boron steel pipe; a high-pressure gas station is connected to the rear ends of the vent holes; cooling passages are arranged at the lower part of the upper die forming insert and the upper part of the lower die forming insert respectively and directly connected with a water pipe or connected with the water pipe through the upper die base and the lower die base. According to the die, the workpiece which has the material mechanical strength of 1,500 MPa and is variable in cross-section shape and circumference can be produced.

Owner:WUXI LANGXIAN LIGHTWEIGHT TECH CO LTD

Herbal compound deodorant and preparation method thereof

InactiveCN107020011AGood effectNo secondary pollutionGas treatmentDispersed particle separationBiotechnologyMentha spicata extract

The present invention relates to a deodorant preparation method, which is particularly used for removing benzene-based substance, TVOC, ammonia and other harmful gases in indoor air, wherein the deodorant comprises the following raw materials: a plant extract (preferably a lemon extract, a green tea extract, a peppermint extract or a mixture of a lemon extract, a green tea extract and a peppermint extract), a deep sea biological extract (preferably a deep sea shell extract, a seaweed extract or a mixture of a deep sea shell extract and a seaweed extract), cellulase (preferably xylanase), protease (preferably papain), a catalyst carrier (preferably nanometer tourmaline powder), powder for carrier doping (preferably a nanometer negative ion additive), a photocatalyst (preferably nanometer titania), and the balance of distilled water. According to the present invention, the production process is simple and environmentally friendly; the deodorant is prepared at the normal temperature under the normal pressure, and the preparation equipment is the normal non-toxic hard plastic (such as PV) or the stainless steel metal container; and the used catalyst carrier doping, the used carrier doping and the used photocatalyst loading are directly completed in the distilled water with the normal temperature and the normal pressure.

Owner:张志红 +1

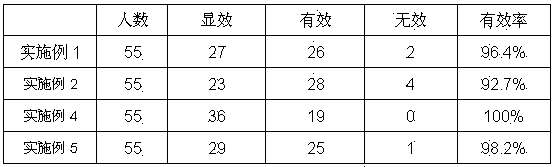

Traditional Chinese medicine composition for treating obesity

InactiveCN103735778AQuick effectNo reboundMetabolism disorderPlant ingredientsPharmaceutical formulationBiology

The invention discloses a traditional Chinese medicine composition for treating obesity. The traditional Chinese medicine composition is characterized by comprising 8-12 parts of poria cocos, 8-15 parts of pinellia ternata, 8-12 parts of rhizoma atractylodis, 8-12 parts of rhizoma cyperi, 2-5 parts of dried orange peel, 8-15 parts of medicated leaven, 8-12 parts of ligusticum wallichii and 1-3 parts of semen pharbitidis by weight. The traditional Chinese medicine composition is scientific in pharmaceutical formulation, convenient to take, good to absorb and low in side effect; the traditional Chinese medicine composition has the effects of invigorating spleen to remove phlem, regulating qi-flowing to resolve depression, and promoting blood circulation to remove blood stasis, and is quick in taking effect on the obesity without rebound, and stable and accurate in curative effect.

Owner:王本东

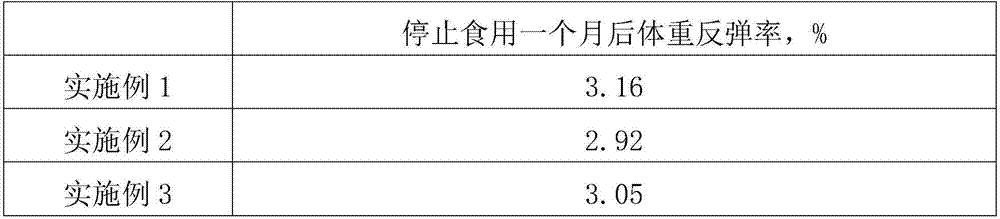

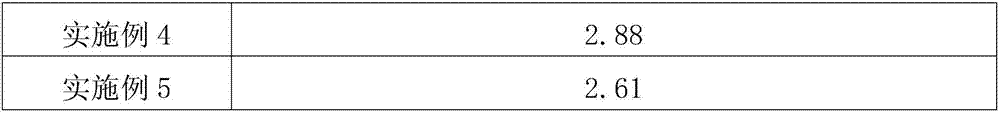

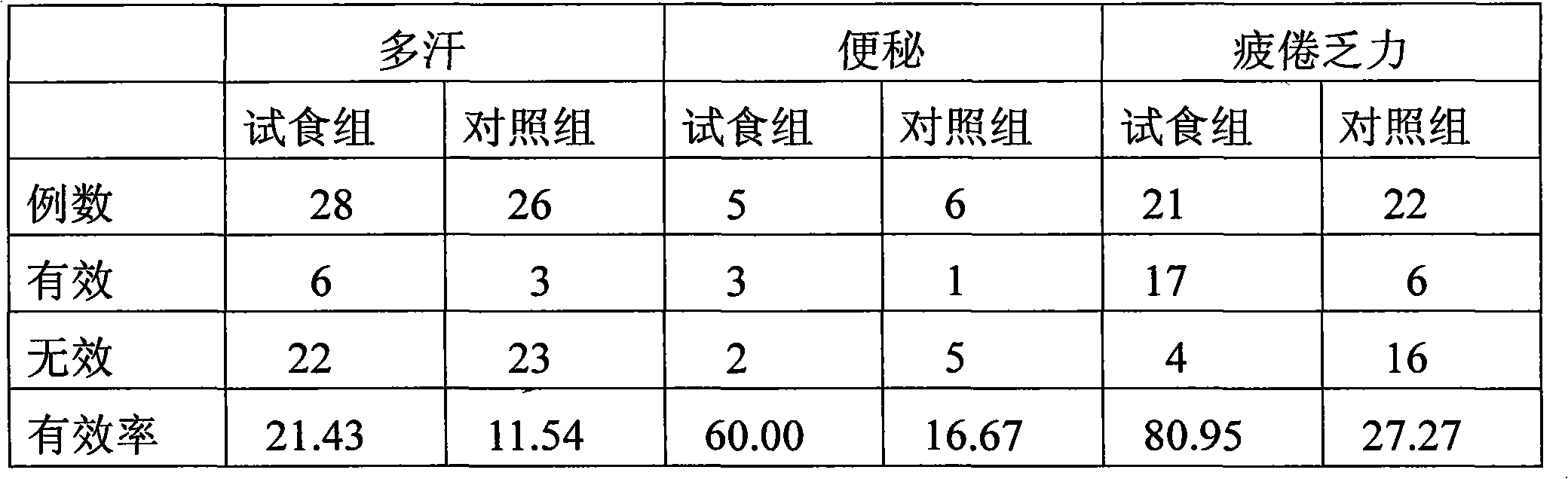

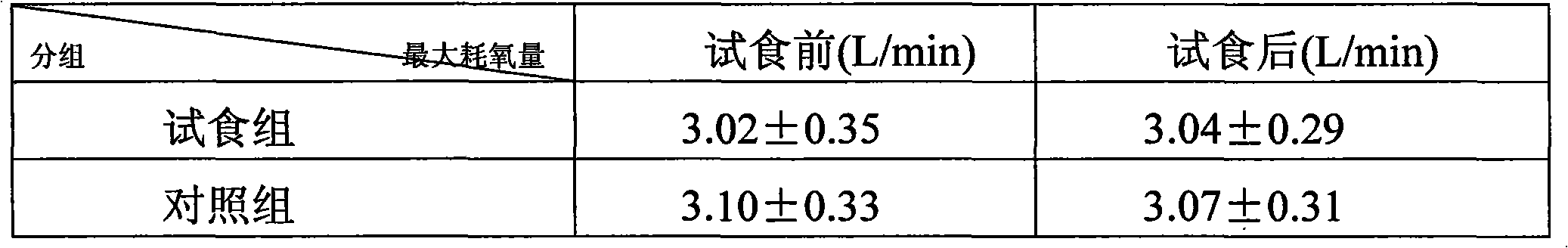

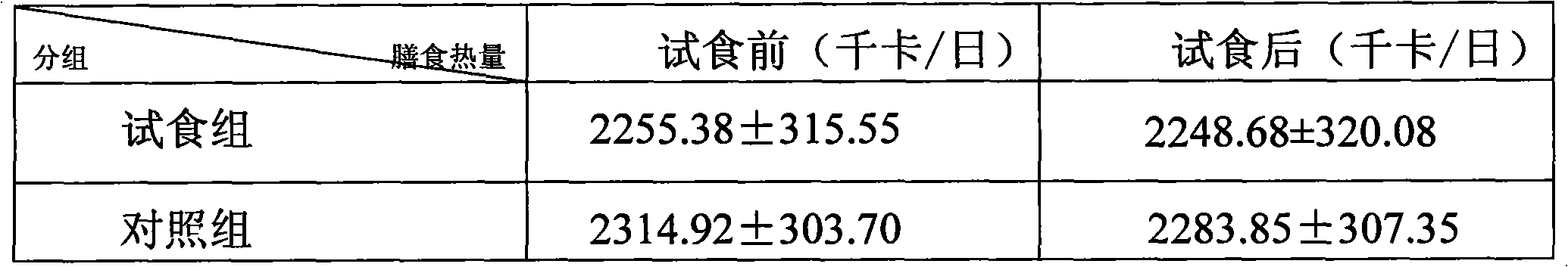

Health products for reducing fat

A weight-losing and lipid-lowering health care product relates to a health care product. The weight-losing and lipid-lowering health care product can solve the problems of gastrointestinal functional disorders, anemia, diabetes, renal dysfunction, weight rebound phenomenon and toxic and side effects of drugs when in administration of the existing weight-losing health care products or the lipid-lowering health care products by a person. The weight-losing and lipid-lowering health care product is composed of a tablet A and a table B; wherein, the tablet A is composed of chitosan, L-carnitine, chromium picolinate, calcium pyruvate and excipients; and the tablet B is composed of mixed vitamins, mixed minerals, linolenic acid and the excipients. The weight-losing and lipid-lowering drug of the invention can reduce the body weight for 3.17 plus or minus 1.56Kg after 45 days, lower the body fat for 2.83 plus or minus 1.19Kg and significantly reduce the subcutaneous fat of other parts; the average decrease rate of cholesterol is 10.48 plus or minus 5.11 percent, the average decrease rate of triglyceride is 19.57 plus or minus 8.12 percent, the total effective rate is 52.94 percent, the effects of weight-losing and lipid-lowering are significant, the weight-losing and lipid-lowering drug has no toxicity or side effects and no weight rebound.

Owner:HARBIN MEDICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com