Method and device for sealing steel wire framework plastic composite pipe

A technology of steel wire framework and sealing equipment, which is applied in the field of composite pipes, and can solve problems such as no sealing equipment, deformation, and rusting of steel wire mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

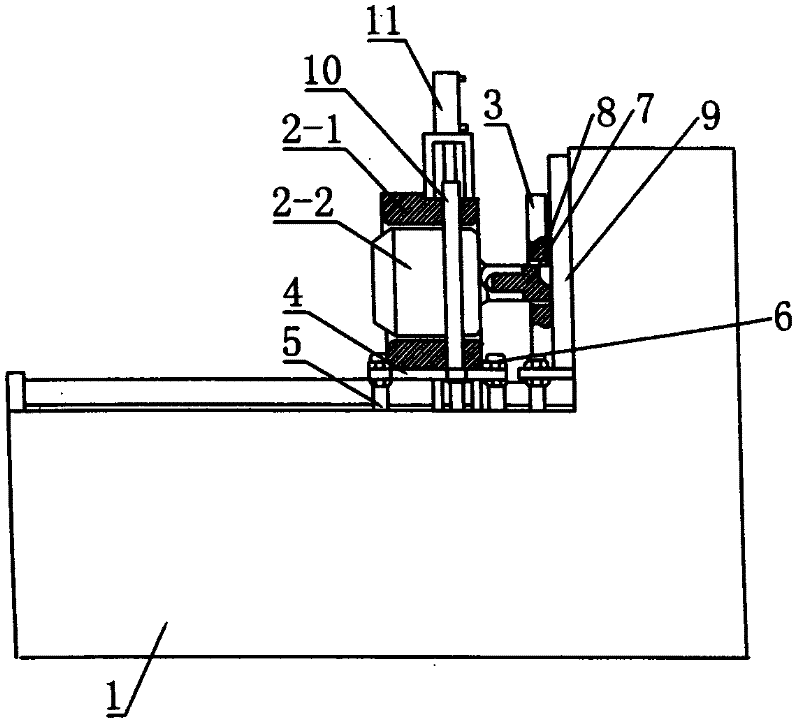

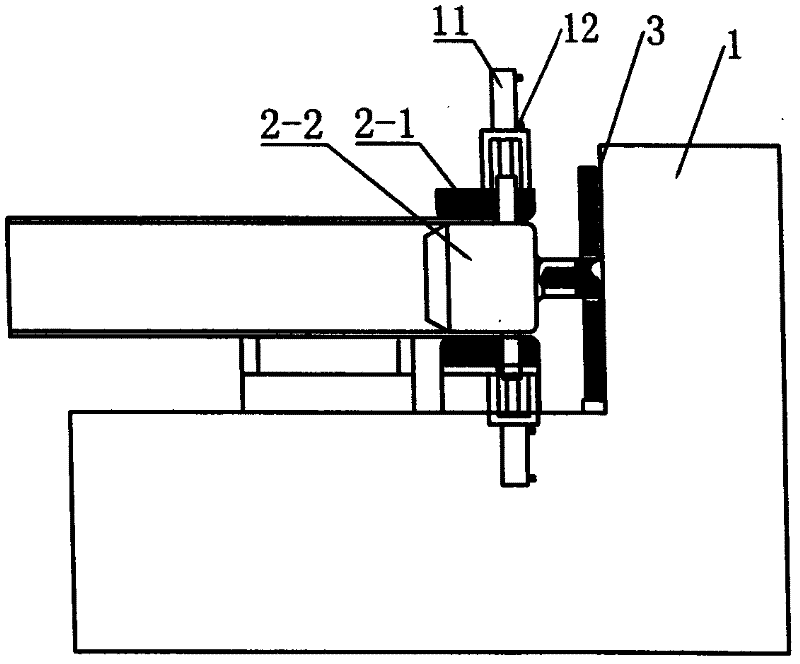

[0020] The invention discloses a sealing method for a plastic composite pipe with a steel wire frame, which uses the plastic sealing method of the pipe itself, first heats the port of the composite pipe, and then wraps the steel wire with the plastic that is turned inside out after the composite pipe is heated by an external force. Wherein, after the port of the composite pipe is heated, the composite pipe is put into a mold with a good specification, and the composite pipe or mold is moved to restore the plastic flanged out after heating, and then the composite pipe and mold are moved to repair The end of the good pipe is squeezed against a pre-prepared flat plate, and after cooling, the composite pipe is taken out to complete the sealing process. The process of putting the composite pipe into the mold with a good specification is to cover the outer wall of the composite pipe through the outer mold, and to restore and shape the plastic that has been turned out of the composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com