Automatic control system and method for high-precision straightening machine

An automatic control system and straightening machine technology, which is applied to the program control and electrical program control in the sequence/logic controller, can solve the problem of high straightness, which can only reach about 0.5mm/m and cannot meet high straightness. Requirements, straightening accuracy stays in etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

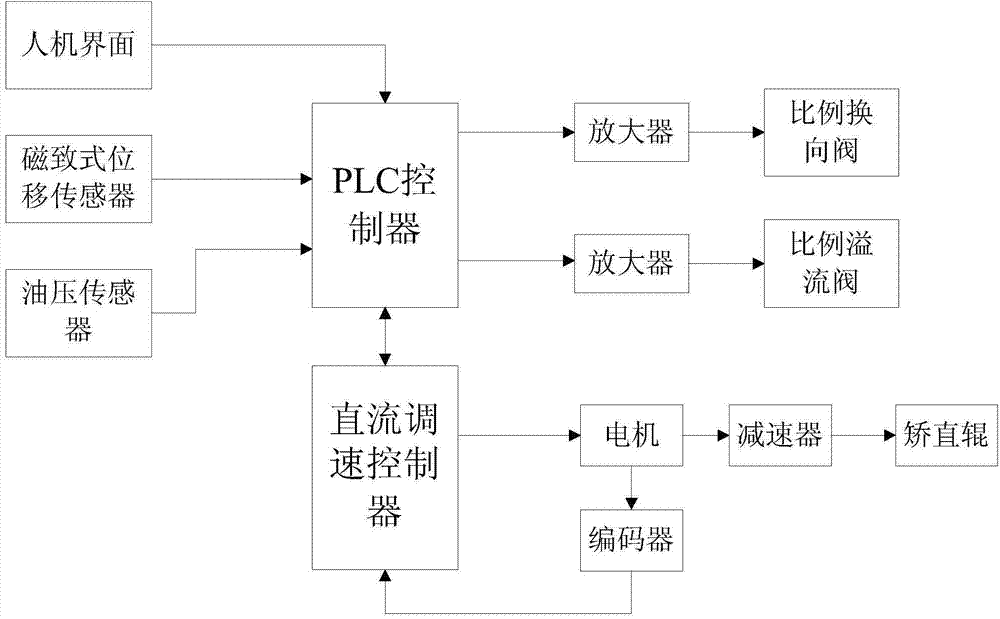

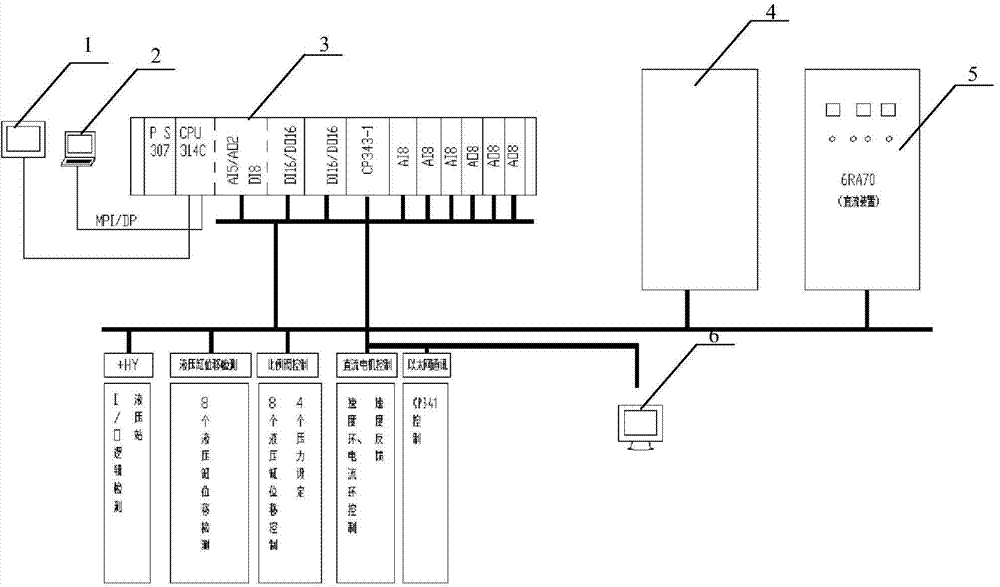

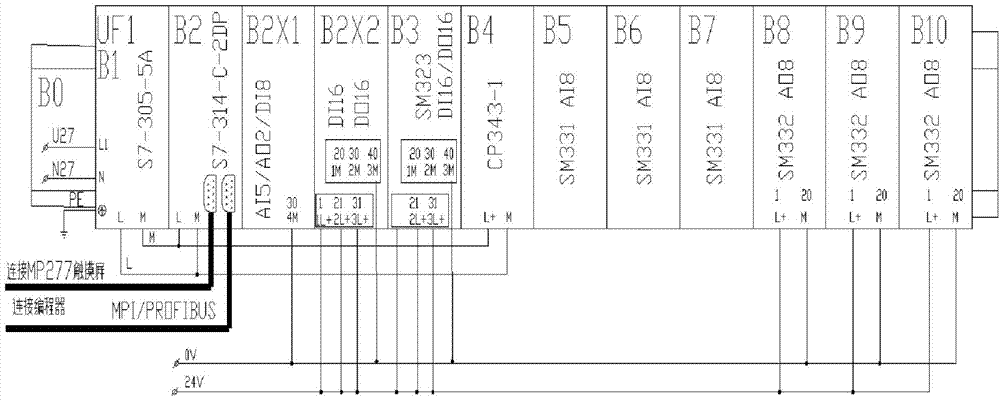

[0039] In the embodiment of the present invention, such as figure 1 As shown, the high-precision straightening machine automatic control system includes a magnetic displacement sensor, an oil pressure sensor, a human-machine interface (HMI), a PLC controller, an amplifier, a DC speed controller (6RA70), a DC motor, a reducer, Incremental photoelectric encoder, proportional reversing valve, proportional overflow valve and their corresponding amplifiers, wherein the magnetic displacement sensor is installed at the piston connecting rod of the oil cylinder of the straightening machine, and the oil pressure sensor is arranged at the hydraulic pressure On the valve block, it is used to detect the pressure of the straightening roller cylinder. The output signal of the magnetic displacement sensor is connected to the first channel analog input terminal IW3 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com