Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

197 results about "Microwave tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cu-Al2O3 nano strengthened dispersion alloy and preparation method thereof

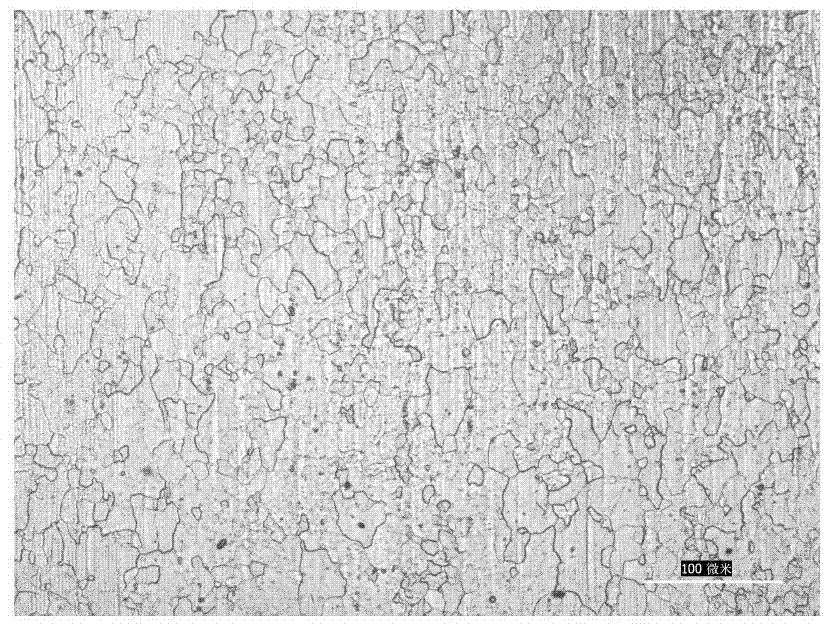

The invention relates to a Cu-Al2O3 nanometer dispersion strengthening alloy and preparation thereof. The preparation includes the steps of Cu-Al alloy vacuum smelting, pulverizing, screening, internal oxidizing, hydrogen reducing, vacuum hot pressing, canned hot extruding, etc. Comparing with oxygen-free copper, sigma of the alloy of the invention is 2 to 6 times higher that of the oxygen-free copper, the anti-annealing softening temperature is up to over 900 DEG C, the conductivity is up to 96% IACA and more. The process of the invention is simple, the prepared Cu-Al2O3 nanometer dispersion strengthening alloy has high strength, high conductivity, electrical conductivity higher than 96% IACA, and is anti-annealing and antimagnetic. The alloy can not only used for large-scale integrated circuit lead frame, manufacturing of controlled thermonuclear reaction heat sink components, and is expecially suitable for manufacturing of microwave tube grid mesh, inertial instrument sensor, particle accelerator and other high-precise parts.

Owner:CENT SOUTH UNIV

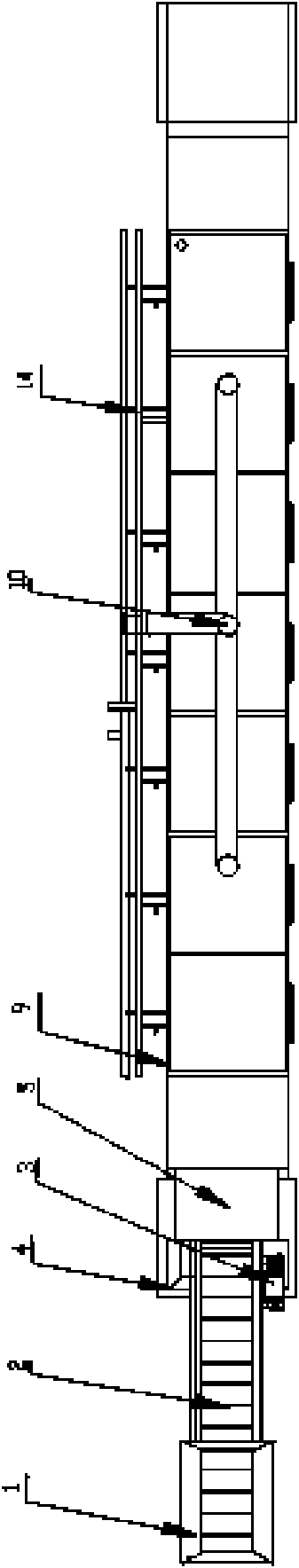

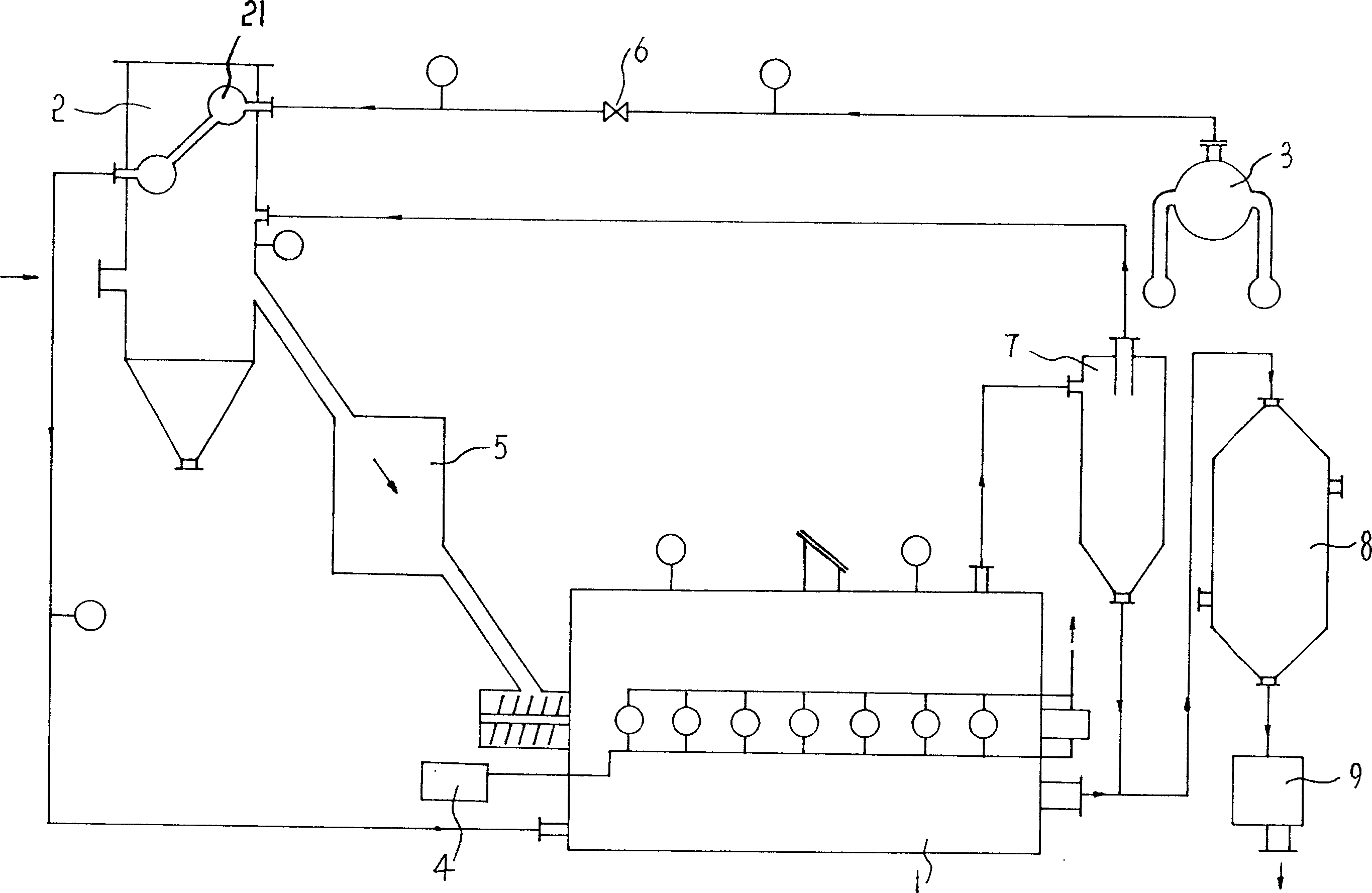

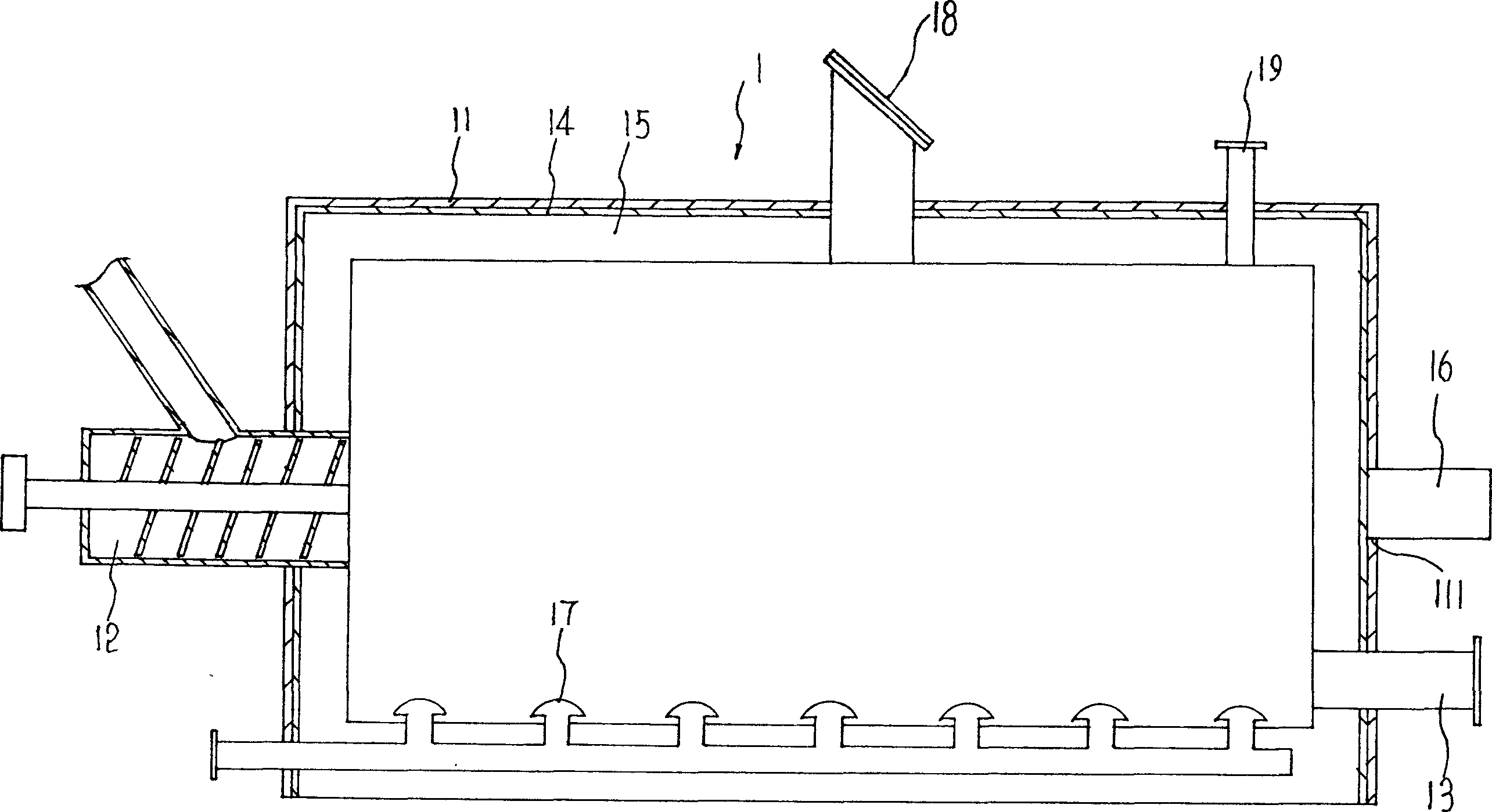

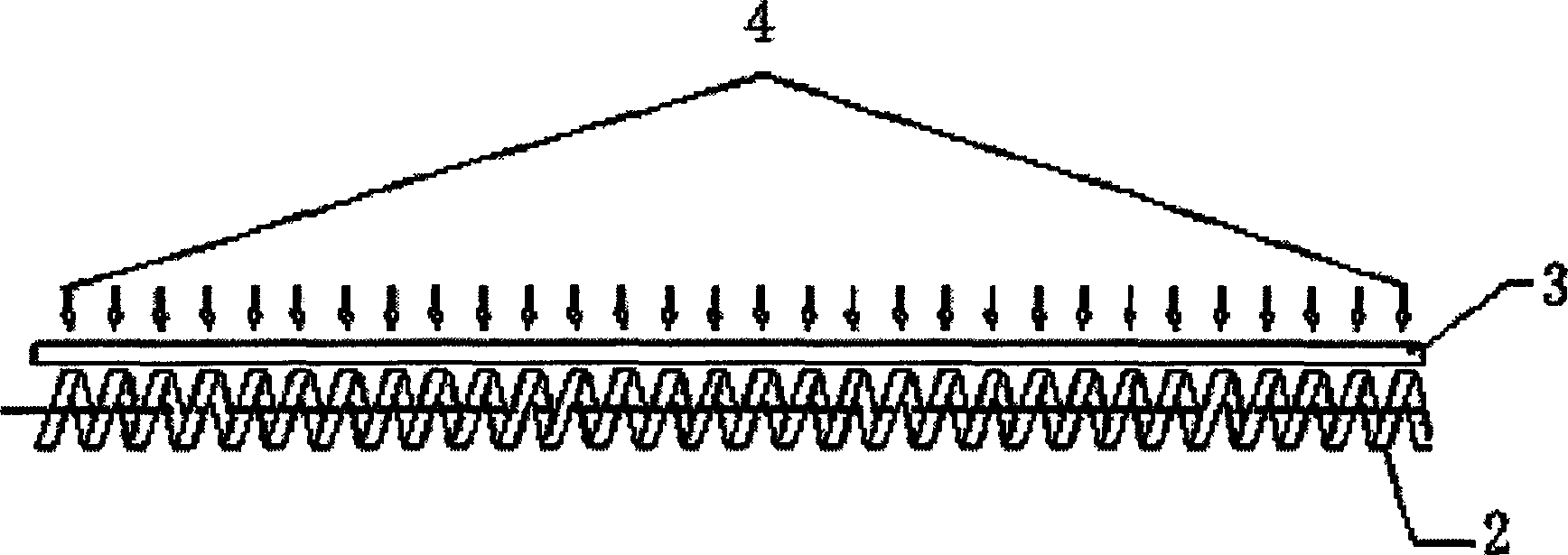

Continuous-type microwave hot air combined drying equipment

InactiveCN101581534AImprove efficiencySlow heatingSludge treatment by de-watering/drying/thickeningDrying solid materials with heatMicrowave tubeEngineering

The invention relates to continuous-type microwave hot air combined drying equipment which comprises a material lifting device, a lower hopper auxiliary device, an upper layer conveyer belt, a lower layer conveyer belt, a microwave case, a humidity-discharging device, a hot-air device; the upper layer conveyer belt and the lower layer conveyer belt are arranged in the microwave case in parallel; the microwave case is internally provided with a microwave tube; a discharge port of the material lifting device is arranged above the lower hopper auxiliary device which is positioned above the loading end of the upper layer conveyer belt; the discharge end of the upper layer conveyer belt is provided with a guide plate which is positioned above the loading end of the under layer conveyer belt; a humidity-discharging device is arranged on the top of the microwave case; and the hot-air device is arranged at the bottom of the microwave case. The equipment achieves the effect of energy-saving and high efficient by adopting the structure.

Owner:WENZHOU UNIVERSITY

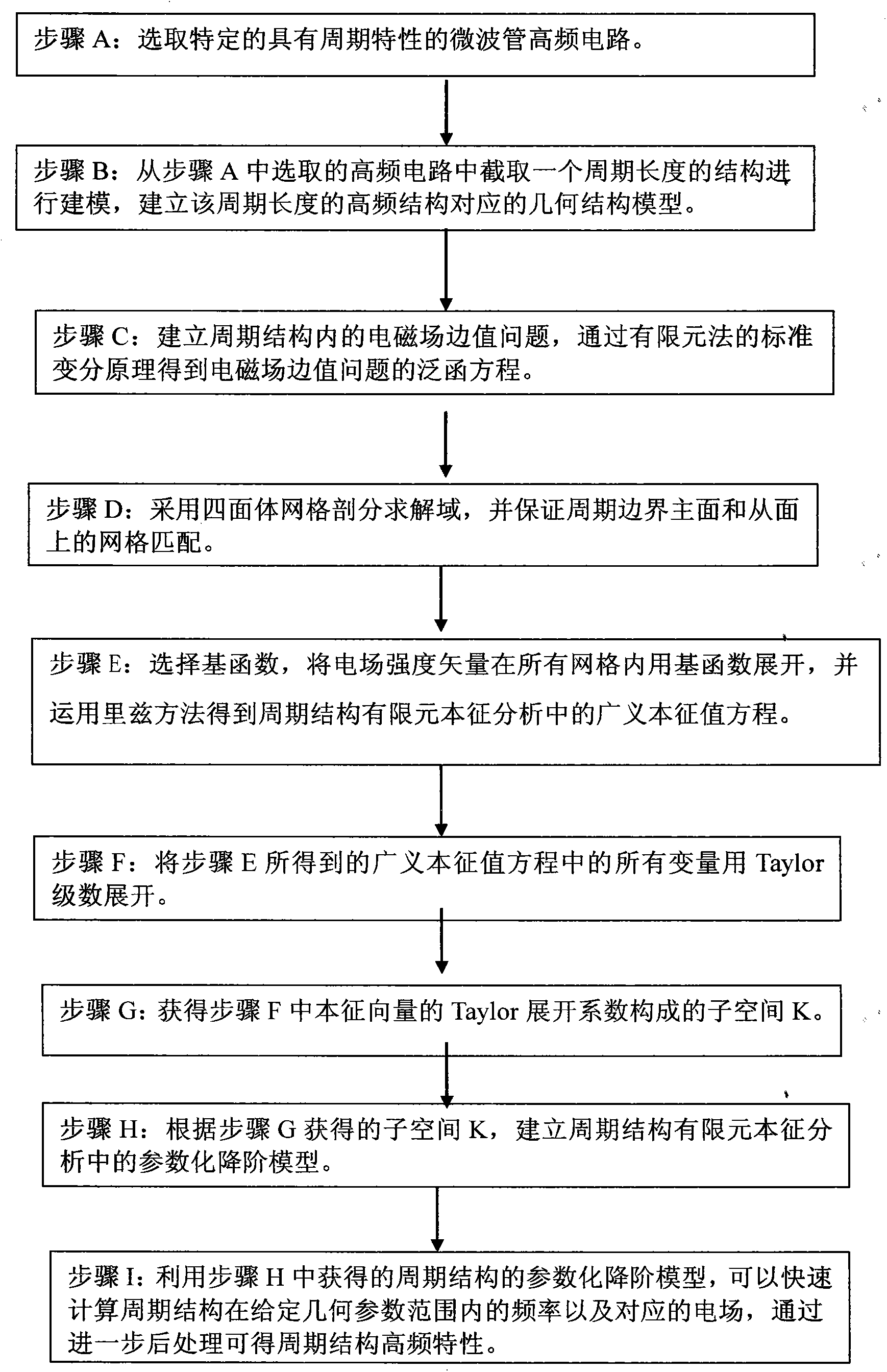

Parameterized reduced model based three-dimensional electromagnetic field simulation method of periodic structure

ActiveCN103412989AAccurately obtainedSpecial data processing applicationsWave structureReduced model

The invention discloses a parameterized reduced model based three-dimensional electromagnetic field simulation method of a periodic structure. Geometric parameters, needing optimization, of the periodic structure are set to be variables, finite-element eigen analysis of the microwave-tube periodic structure is performed after a group of data is fetched in a geometric parameter variation range for modeling, and then all high-frequency characteristic curves of the microwave-tube periodic structure in variation ranges of multiple geometric parameters such as pitch of a helix slow-wave structure, internal diameter of a helix and clamping rod width can be acquired rapidly and accurately, so that quick optimized simulation of the microwave-tube periodic structure is realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

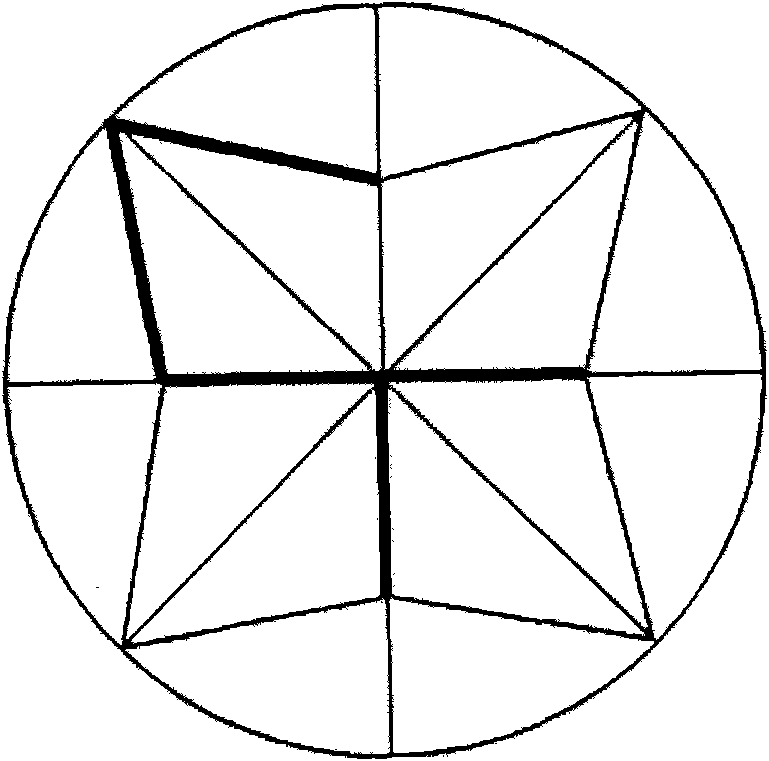

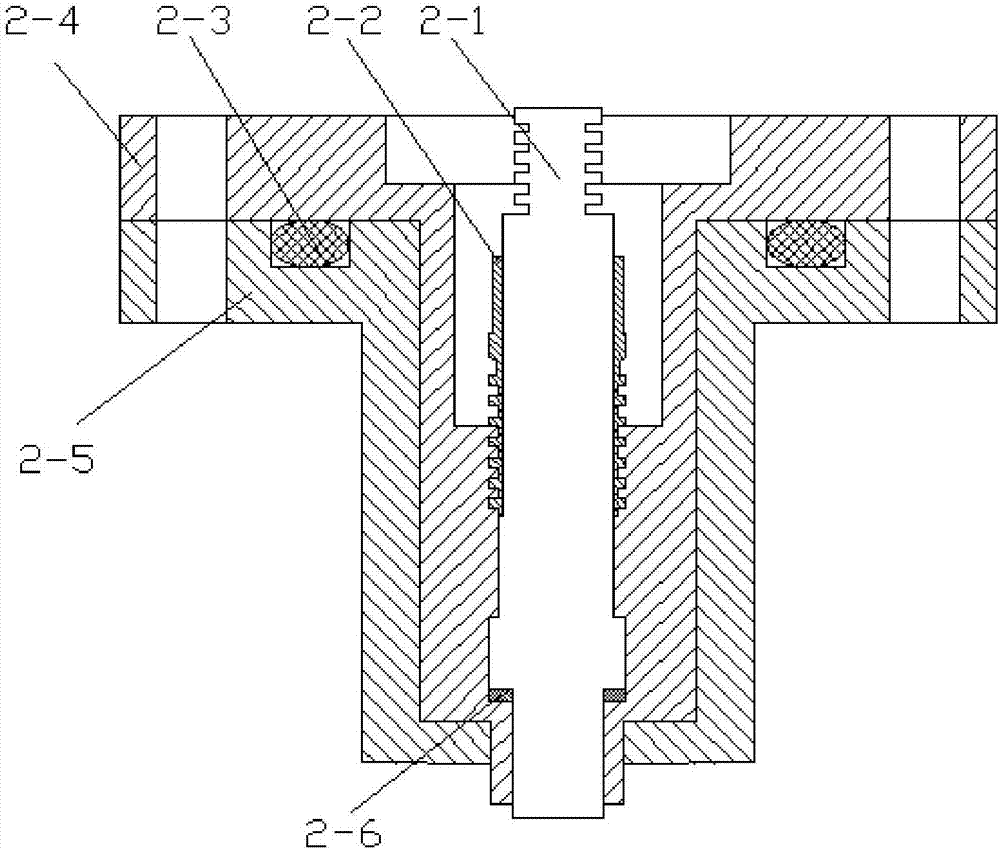

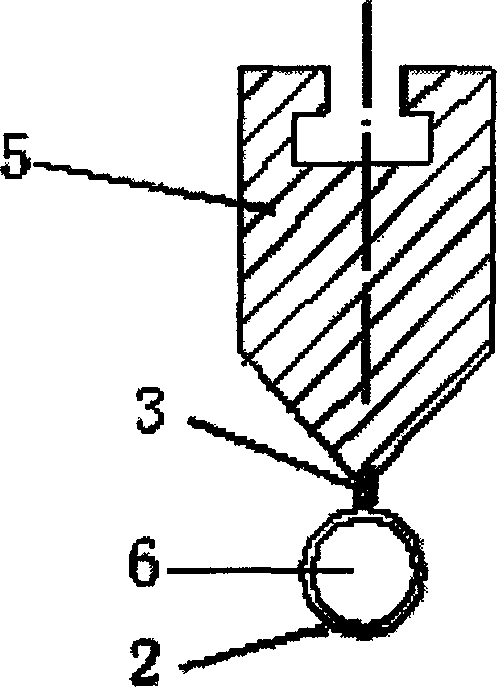

Microwave catalytic reactor system

InactiveCN102133516AScientific and reasonable structureEnergy based chemical/physical/physico-chemical processesMicrowave cavityReactor system

The invention relates to a microwave catalytic reactor system comprising a feeding hole, a measuring controller, a mixing chamber, a microwave reactor and a discharging hole which are sequentially connected, wherein a reaction tube (3) and a microwave cavity (5) are installed in a reactor body (1) of the microwave reactor; a microwave tube (6) is installed in the microwave cavity (5); a catalyst (4) with a microwave absorption characteristic is filled in the reaction tube (3); a temperature sensor is arranged in the catalyst (4); and the measuring controller, a control circuit of the microwave tube (6) and the temperature sensor are electrically connected with a central control unit. A forced circulation cooling water chamber (2) is arranged between the outer wall of the reaction tube (3) and the reactor body (1), a water tank for holding forced circulation cooling water is installed outdoors, and the cooling water chamber (2) and the water tank are connected with a water pump through pipelines. An outlet of the microwave reactor can be selectively connected with a cooler and a separator. The microwave catalytic reactor system can be used for continuous flowing air (liquid) and solid catalytic reaction, and can be used for treating waste water, waste gas and the like.

Owner:XIANGTAN UNIV

Method and device for manufacturing reduced iron using microwave fluid bed

InactiveCN1733943AGood for balance controlReduce consumptionFluidised-bed furnacesWater vaporReaction temperature

The invention discloses a method to prepare reduced iron with microwave fluid bed. Wherein, mixing smashed iron ore and coal with proper proportion, preheating to reaction temperature on first fluid bed to convey into second microwave fluid bed; using water vapor to drive material as fluidized state; iron reacts with vapor to generate water-gas to reduce ferric oxide; cooling, magnetic separating, and obtaining the product; the feeding mechanism pipes of two beds connect with each other; arranging microwave tube with independent air cooling mechanism on out shell of the bed and windshield connected to steam boiler pipe on bottom of microwave fluid bed. This invention distributes technological in reason, and needs low cost.

Owner:孔凡逸 +1

Method and device for exploiting seabed surface layer natural gas hydrate

InactiveCN104948143AThe principle is practicalSimple structureFluid removalOcean bottomSurface layer

The invention relates to a method and device used for exploiting seabed surface layer natural gas hydrate and used for the field of natural gas exploitation. The method and device for exploiting the seabed surface layer natural gas hydrate solves the problems that during the exploitation at present, a reagent is expensive, an instrument is complex, the lifting needs to consume plenty of energy, and complex three-phase flowing is involved in the lifting. The technical scheme is that first an exploitation device on a mining vehicle is started to drive a cutting head to cut the seabed surface layer natural gas hydrate; then natural gas hydrate slurry is sucked into a particle thinning device through a conveying pipe B and pumped into a right transfer chamber through a slurry pump; a control center is started, solid-fluid-gas three-phase hydrate enters a right heating chamber, a sensor B is triggered to be started, a microwave tube performs heating, the natural gas hydrate is decomposed, natural gas is collected through a gas collecting device on a working ship; and water and gravels are discharged to the seabed through a waste discharge pipe. The exploiting method is simple in principle and practical and can achieve continuous exploitation of the natural gas hydrate. The exploiting device is simple in structure and small in energy consumption and is used for exploiting the seabed natural gas hydrate.

Owner:SOUTHWEST PETROLEUM UNIV

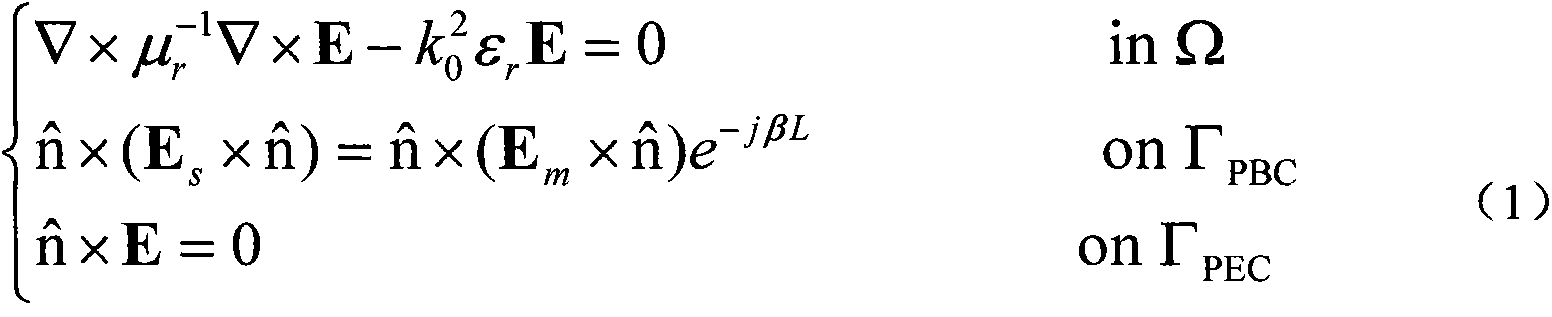

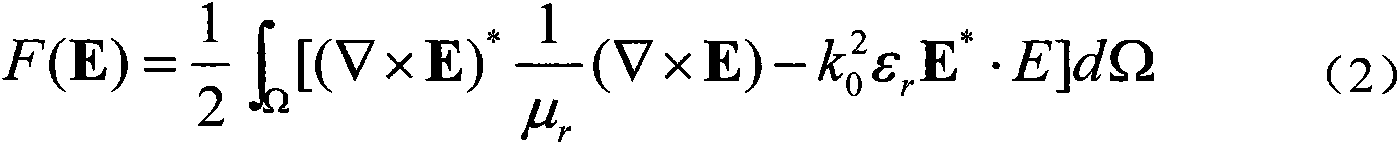

Finite element simulation method capable of removing microwave tube high-frequency circuit in pseudo-DC mode

InactiveCN101944145AEfficient designFast and Efficient UWB Parametric SweepSpecial data processing applicationsMicrowave tubeClassical mechanics

The invention relates to a finite element simulation method capable of removing a microwave tube high-frequency circuit in a pseudo-DC mode, comprising the flowing steps: (A) using a zero electric displacement vector as an electric field constraint equation and acquiring an integrated form of the electric field constraint equation according to an boundary value problem of an electromagnetic field in a microwave tube high-frequency circuit and acquiring a functional equation of the boundary value problem of the electromagnetic field through a standard variation principle of a finite element method; and (B) necessarily ensuring the match between grids on a main surface and grids on a secondary surface on a peripheral boundary when solving a solution domain and considering a pseudo-periodic boundary condition by adopting a dissection solution domain of tetrahedral grids. The invention has the advantages that the finite element simulation method can greatly improve the accuracy, the efficiency and the robustness of microwave tube high-frequency system simulation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

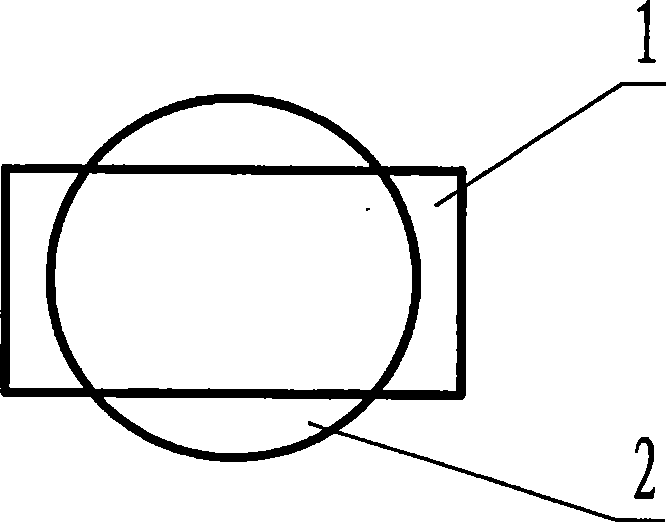

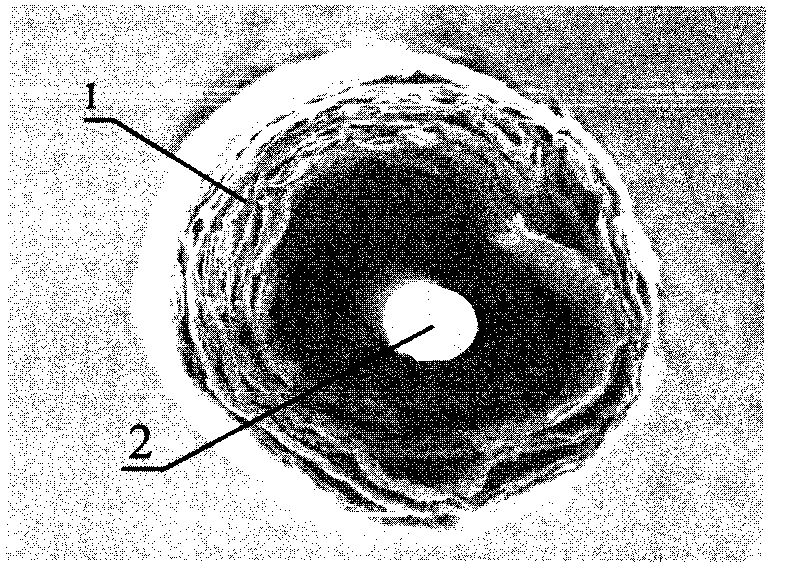

Wide-band micro-wave kit shaped energy delivery window

A boardband microwave box-shaped energy transporting window, which belongs to the technical field of microwave device, relates to a microwave energy transporting window in microwave tubes. The microwave energy transporting window is composed of two rectangular waveguide segments (1), a circular waveguide segment (2) and a dielectric window disk (3), wherein the rectangular waveguide segments (1) are respectively connected to both ends of the circular waveguide segment (2); the dielectric window disk (3) is hermetically welded at the middle of the circular waveguide segment (2); and the diameter of the circular waveguide segment (2) is determined according to the cutoff frequency formula of TE11'O'mode to make the cutoff frequency of the TE11'O' mode in the work band range of the box-shaped energy transporting window. The boardband microwave box-shaped energy transporting window can work in the transmission state of the circular waveguide TE11'O'mode and can work in cutoff state, thereby greatly widening the work bandwidth of the box-shaped window. Meanwhile, the size and the volume of the box-shaped window is greatly reduced, and the generation of high-order mode can effectively suppressed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

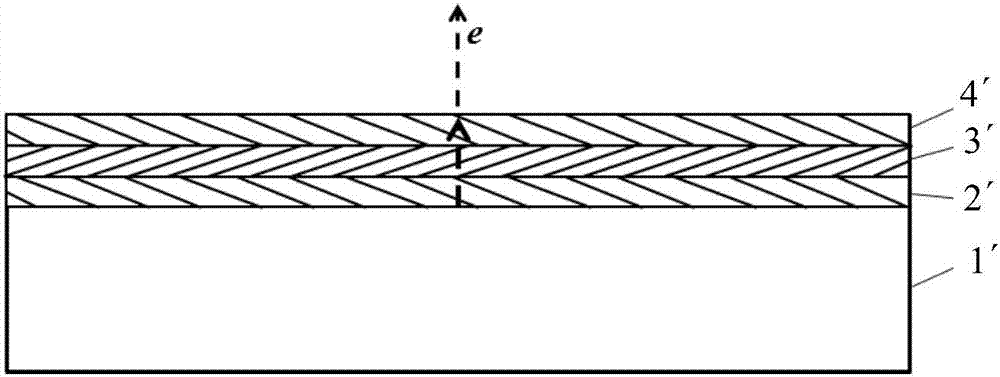

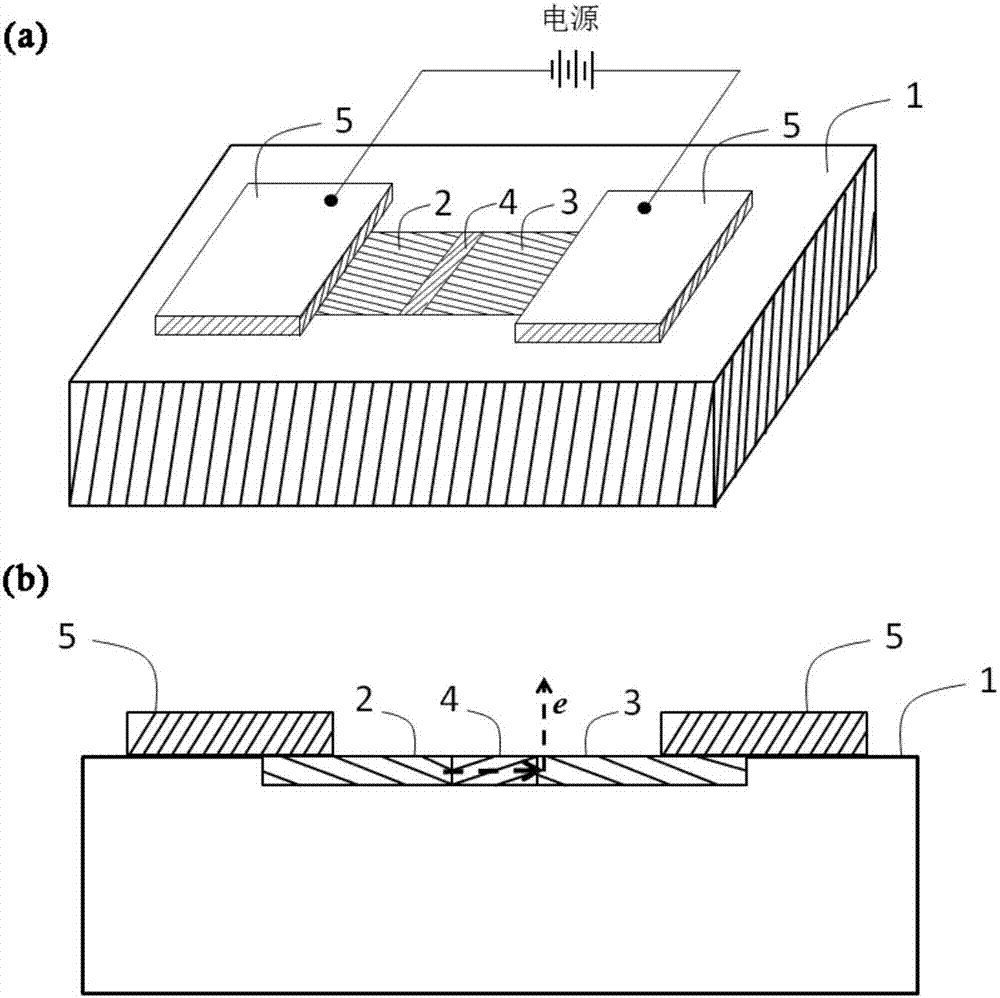

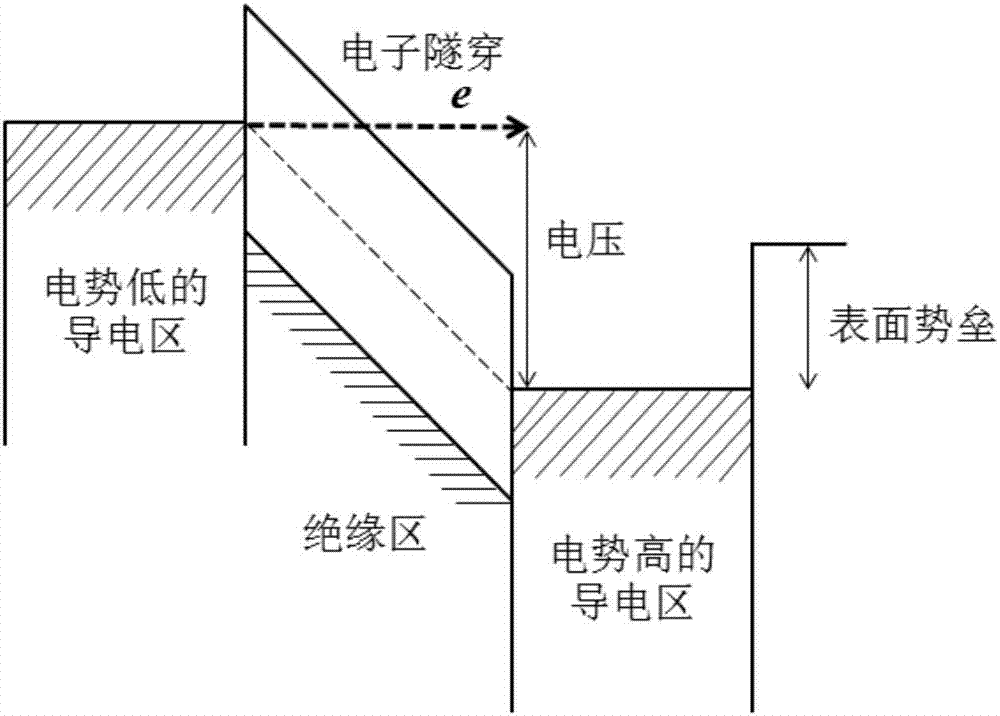

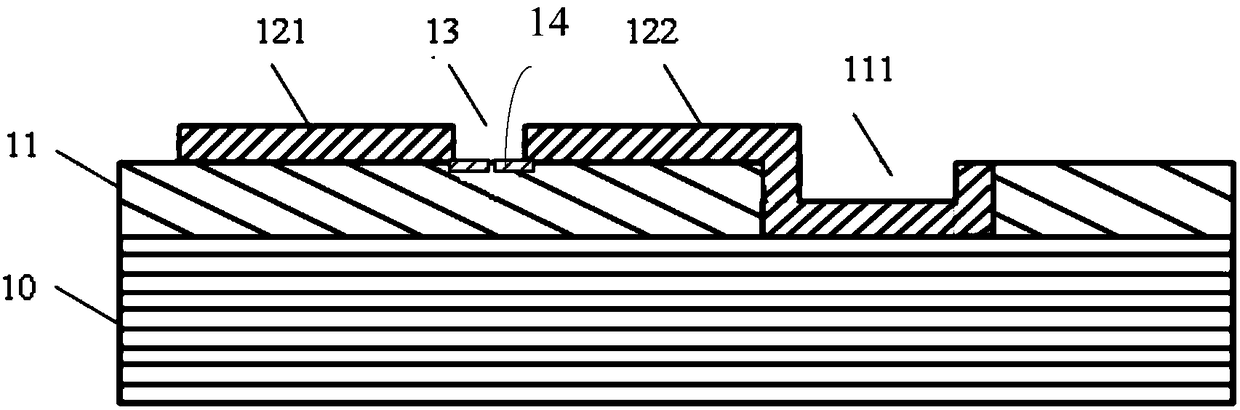

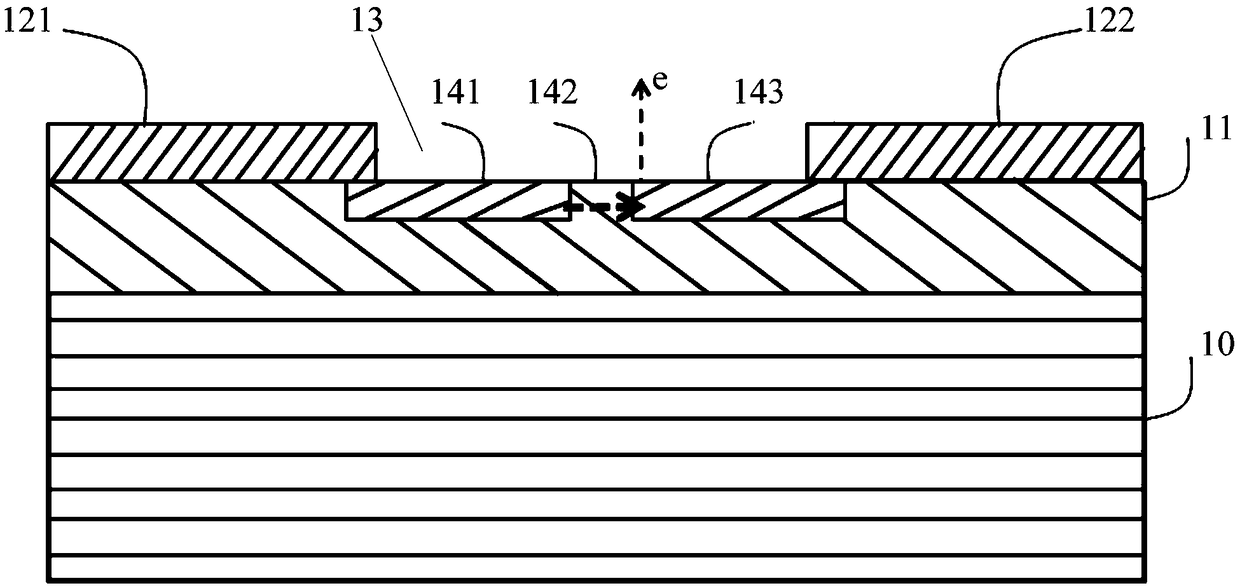

Surface tunneling miniature electron source, array thereof and implementation method of array

ActiveCN107248489ASimple structureImprove electron emission efficiencyCathode ray tubes/electron beam tubesTransit-tube cathodesElectron sourceMicrowave tube

Owner:PEKING UNIV

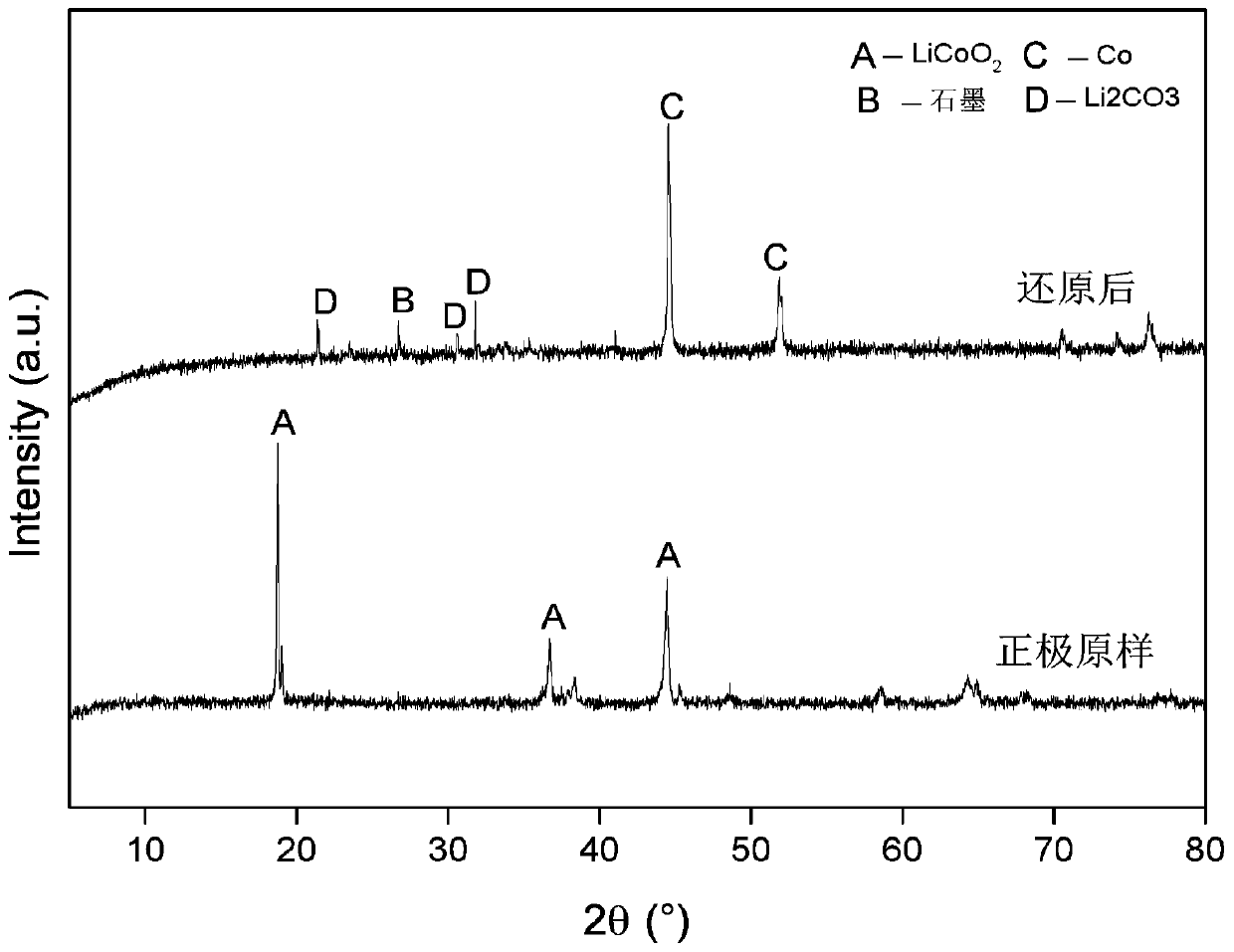

Method for assisting recovery of lithium and cobalt in waste electrode material through microwave roasting

ActiveCN110343864AOptimizing Pickling PropertiesReduce consumptionWaste accumulators reclaimingProcess efficiency improvementOrganic acidLithium

The invention discloses a method for assisting recovery of lithium and cobalt in a waste electrode material through microwave roasting. The method comprises the following steps of, step (1), crushingand screening a positive plate to obtain electrode material powder; step (2), putting the obtained positive electrode active material into a microwave tube furnace filled with inert protective gas forroasting, and collecting the roasted solid-phase product; step (3), mixing the solid-phase product with excess organic acid, preparing an acid leaching solution, and recovering cobalt salt precipitate; and step (4), adding any one of phosphoric acid, phosphate or carbonate into the leaching solution, and recovering the precipitate of the lithium. According to the method, the electrode material ispre-reduced in a microwave roasting mode, a binder PVDF plays a role of a reducing agent, the acid leaching characteristic of the lithium and the cobalt in the positive electrode material is optimized, the energy consumption and the gent consumption in the recovery process are reduced, and the pretreatment process is simplified; and the method has the advantages of high efficiency, low energy consumption, environmental friendliness and the like.

Owner:CHINA UNIV OF MINING & TECH

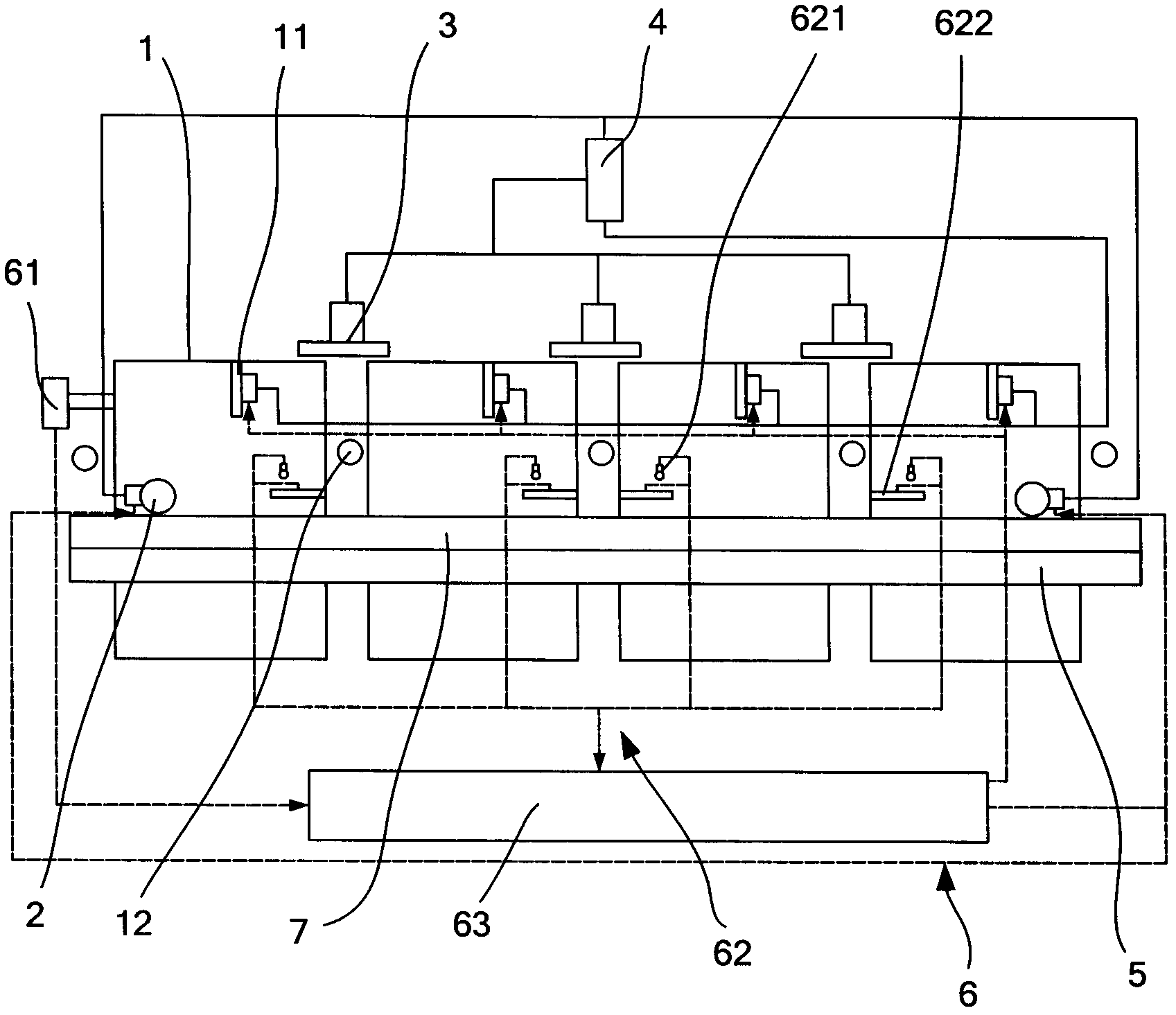

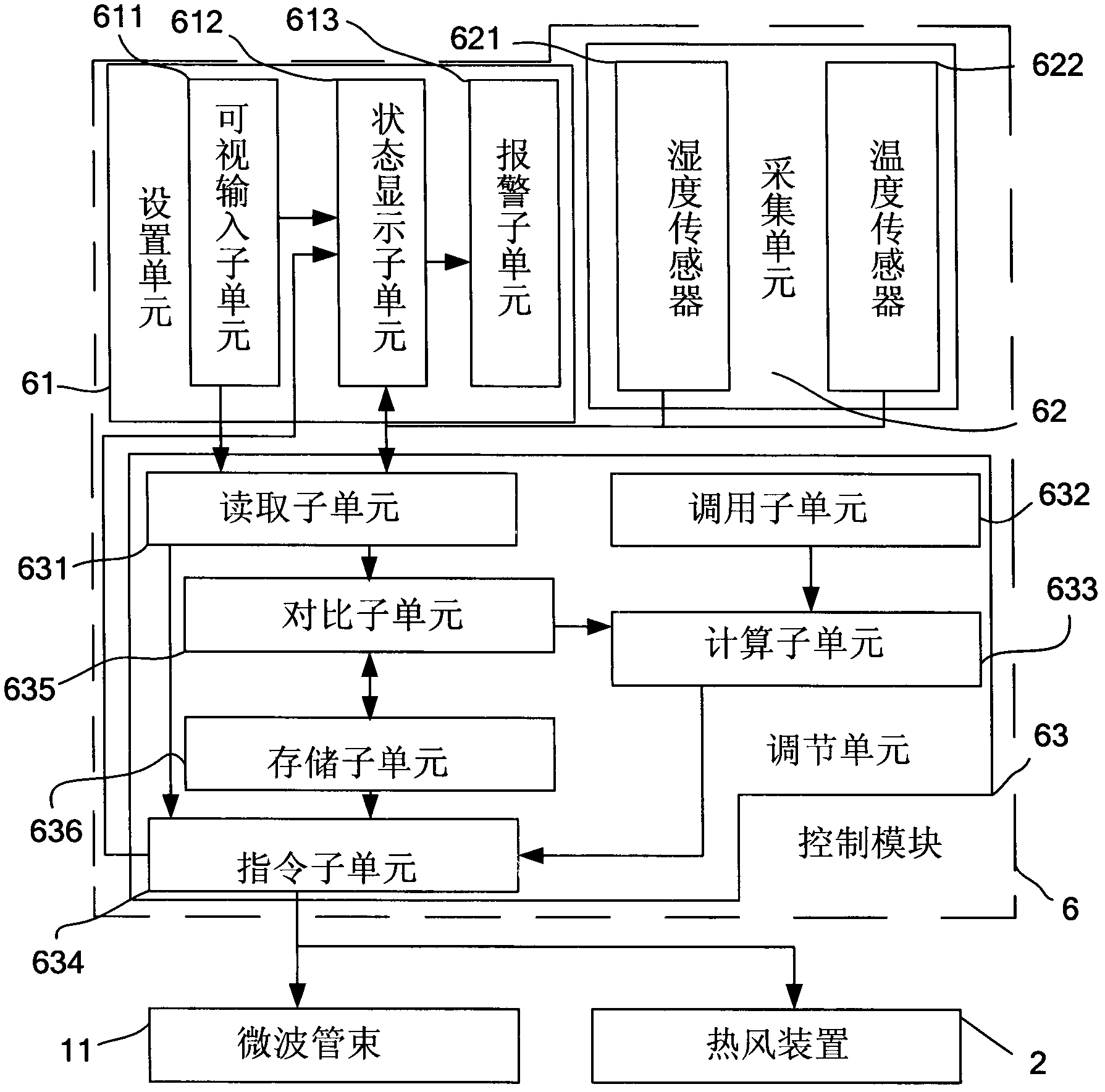

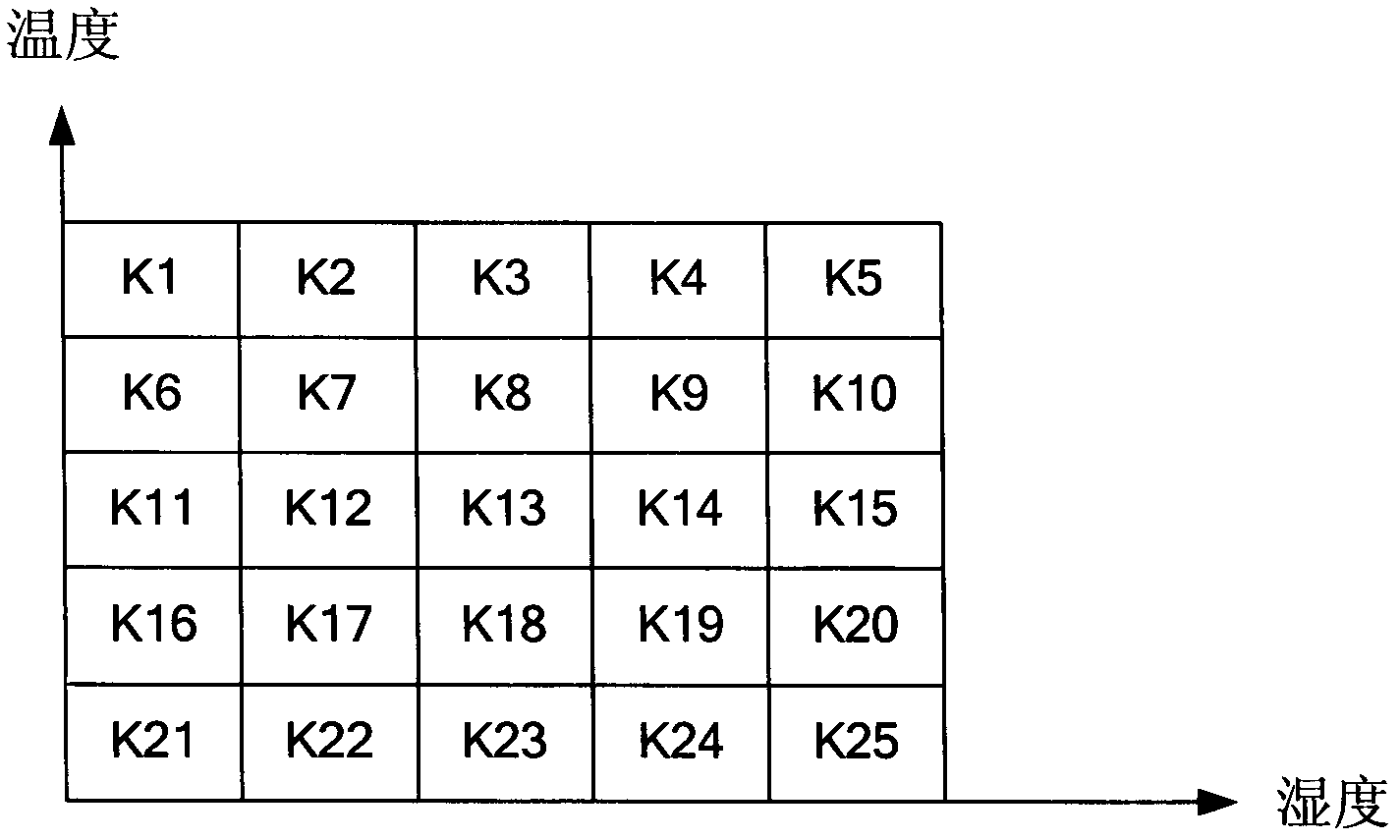

Production system for thistle board

ActiveCN102371621AQuality improvementSave energyCeramic shaping plantsProduct inspectionMicrowave tube

The invention discloses a production system for a thistle board. The production system comprises a raw material preparing section, an extruding forming section, a panel cutting section, a drying section and an end-product inspection storing section, which are arranged in turn. The drying section further comprises more than one box body, and the box bodies are sequentially arranged in parallel, wherein microwave tube bundles are arranged in the box bodies; microwave restrainers are arranged between the box bodies; hot air devices are arranged in the box bodies and are used for blowing hot air to the thistle board; dehumidification devices are arranged on top parts between the box bodies and are used for sucking wet hot air; a heat circulating device is connected to the hot air devices, the dehumidification devices and the microwave tube bundles and is used for circulating heat; conveying devices are connected to each other in the box bodies and are used for conveying the thistle board; and a control module comprises a setting unit, an acquiring unit and an adjusting unit. The production system can be used for detecting the humidity and temperature variation of the thistle board in real time and adjusting the power of the microwave tube bundles and the strength of the hot air devices according to detected data.

Owner:肇庆北新建材有限公司

Preparation method of ultrathin Ta-W alloy foil

The invention provides a preparation method of ultrathin Ta-W alloy foil, and belongs to the technical field of Ta-W alloy machining. The preparation method includes the steps that cyclic operation of alloy billet prepared through a powder metallurgy method, cold rolling cogging, and cold rolling and vacuum annealing, 3-5 micrometer foil annealing, and the like. The thickness of the prepared foil can reach 3-5 micrometers. The preparation method is simple in process, the prepared foil is high in precision, and compared with pure Ta foil and other Ta-W alloy foil, the ultrathin Ta-W alloy foil has the advantages of being high in strength, good in surface quality, and the like. The prepared Ta-(5.0-7.5 wt%)W alloy foil with the thickness of 3-5 micrometers is suitable for high-power microwave tubes, traveling wave tubes, and other vacuum devices of electronic components, aerospace, and other industries. The preparation method has great significance on achieving high-power high-performance microwave tube localization, improving microwave tube using performance, prolonging service life, and the like.

Owner:CENT SOUTH UNIV

Preparation process of melamine foam

The invention relates to a preparation process of melamine foam. The preparation process mainly consists of a (foaming liquid) distributing section, a foaming section, a transition section and high-temperature crosslinking, drying and a shaping section. A crude foam product is cut and secondarily processed to prepare a melamine foam product. A special device of the foaming section consists of microwave tube sets, wherein each of the microwave tube sets can be independently controlled and used; the power of the device can be variably modulated within 10-100%; and the total microwave power is 100-500 KW, preferably 150-350 KW.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

X-waveband high-impedance relativity theory klystron amplifier adopting annular beam cold cathode

ActiveCN105810537AAvoid backflow phenomenonReduce field strength in non-emitting areasTransit-tube cathodesKlystronsKlystronDrift tube

The invention relates to a microwave source apparatus in the technical field of high-power microwaves, in particular an X-waveband high-impedance relativity theory klystron amplifier adopting an annular beam cold cathode. The X-waveband high-impedance relativity theory klystron amplifier is composed of a cathode, a cathode shielding ring, an anode outer cylinder, a high frequency signal injection port, injected waveguide, a resonant cavity, a drift tube, a coaxial extracting structure, a collector, a studdle and a permanent magnetic field; the disadvantages that the traditional high-impedance RKA electronic optical system based on a hot cathode needs an extra heating device and is large in energy consumption, and the system is huge, complex and bad for processing and experimenting are overcome, and the traditional foilless diode is hard to produce the high-impedance annular electronic beam in kOmega level; an annular beam cold cathode with the shielding ring is designed to apply to the X-waveband high-impedance RKA adopting the permanent magnet package, so that the electronic optical system of the microwave tube is simple and compact in structure and easy to process and experiment.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of dispersion strengthened copper and oxygen-free copper composite bars

ActiveCN108057732AStrong resistance to high temperature softening abilityImprove high temperature resistanceTransportation and packagingMetal-working apparatusElectronic informationOxygen

The invention relates to a preparation method of dispersion strengthened copper and oxygen-free copper composite bars. The preparation method comprises the preparation process steps of nitrogen atomizing powdering, oxygen source preparation, powder mixing, cold isostatic pressing machining, the short flow path, integrated heat treatment, squeezing machining, finishing and decrustation, preparationof dispersion strengthened copper and oxygen-free copper composite copper ingots, secondary squeezing of the dispersion strengthened copper and oxygen-free copper composite copper ingots, stretchingmachining of the dispersion strengthened copper and oxygen-free copper composite bars, and checking and detecting. Through a powder metallurgy and pressure machining technology, Cu-Al2O3 nano dispersion strengthened copper and oxygen-free copper are composited to be prepared into the Cu-Al2O3 nano dispersion strengthened copper and oxygen-free copper composite bars, through the high-temperature, high-strength and high-grade oxygen-free copper characteristic of the Cu-Al2O3 nano dispersion strengthened copper, the requirements of large-power microwave tubes in the electronic information industry, large-current high-voltage relays in the electrical industry and the like for key materials are met.

Owner:中铝洛阳铜加工有限公司

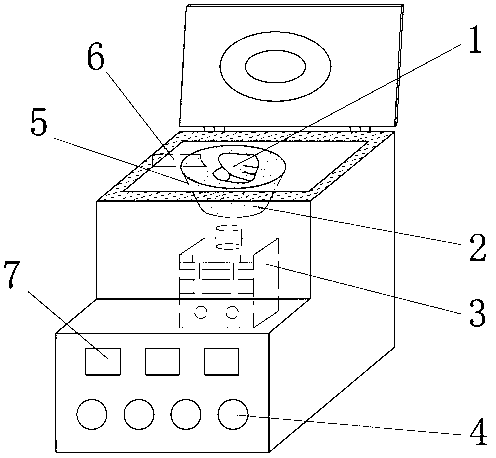

Microwave tube experiment device

PendingCN107014950APrevent fallingImprove the degree of sealingChemical analysis using combustionMaterial analysis by optical meansMicrowave tubeLow voltage

The invention discloses a microwave tube experiment device. A microwave tube is arranged on an optical platform and a support, and comprises an experiment section, a low voltage section, a mediate voltage section and a high voltage section which are arranged in sequence; microwave tube end caps are arranged at two ends of the microwave tube; a pressure sensor, a mixed gas chamber and a tap are arranged on the low voltage section; a molecular pump extraction section and a capsule device are arranged on the mediate voltage section; the experiment section comprises an experiment section tube body, and observing windows are symmetrically formed in front and rear walls of the experiment section tube body; the pressure sensor comprises a PCB pressure sensor, a pressure sensor gland, a first connecting part, a second connecting part and a copper ring; a seal ring is arranged on the plane, matched with the second connecting part, of the first connecting part; two flanges for connecting are arranged on the capsule device, and a capsule holder is arranged between the two flanges. The microwave tube experiment device is smart in idea, compact in structure, convenient and quick to assemble and safe and stable to use, and is convenient for observing experiment effects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A method and device for exploiting natural gas hydrate in the surface layer of the seabed

InactiveCN104948143BThe principle is practicalSimple structureFluid removalMicrowave tubeEnergy consumption

The invention relates to a method for exploiting seabed surface natural gas hydrate and an exploiting device thereof, which are used in the field of natural gas exploitation. It overcomes the problems of expensive reagents, complex instruments and equipment, large energy consumption for lifting and complex three-phase flow involved in the current mining. Its technical plan: first start the development device on the mining vehicle to drive the cutting head to cut the natural gas hydrate on the surface of the seabed; then suck the natural gas hydrate slurry into the particle refinement device through the delivery pipe B, and then use the slurry pump to pump it into the right transfer chamber ;Start the control center, the solid-flow gas three-phase hydrate enters the right heating chamber, trigger sensor B to start, the microwave tube is heated, the natural gas hydrate decomposes, and the natural gas is collected by the gas collecting device on the working ship through the gas pipeline; The pipe discharges into the seabed. The mining method is simple in principle and practical, and can conveniently realize the continuous mining of natural gas hydrate; the mining device has a simple structure and low energy consumption, and is used for seabed natural gas hydrate mining.

Owner:SOUTHWEST PETROLEUM UNIV

Microwave photocatalytic fluidized bed waste water treatment device and treatment method

ActiveCN104045124AHigh activityPromote degradationWater/sewage treatment by irradiationMultistage water/sewage treatmentRefluxDiaphragm pump

The invention relates to a microwave photocatalytic fluidized bed waste water treatment device and treatment method. A diaphragm pump is arranged on the upstream of a circulating water pipe between a buffer reflux tank and a fluidized bed, a microwave conduit is arranged on one side of the top of the fluidized bed and communicated with a magnetron, the magnetron is electrically connected with a microwave tube power supply, a photocatalytic reaction device is arranged on the outer side of the fluidized bed and consists of an outer cover and an ultraviolet lamp, the ultraviolet lamp is arranged in the outer cover, the fluidized bed is filled with photocatalyst, pretreating waste water flows in the buffer reflux tank and flows in the fluidized bed from bottom to top through the diaphragm pump, the magnetron and the ultraviolet lamp are simultaneously turned on, the temperature of waste water in the fluidized bed can be maintained at 80 DEG C below. The microwave photocatalytic fluidized bed waste water treatment device and the treatment method thereof have the beneficial effects that the ultraviolet lamp is arranged on two axial sides of the fluidized bed, so as to be beneficial to internal transmission flight in the fluidized bed, microwave is radiated and introduced by adopting a waveguide manner, so that the photocatalyst activity and the photocatalytic waste water degradation efficiency can be improved, and industrialization can be easily realized.

Owner:JINING UNIV

Preparation method and application of fluorescent carbon dot for specifically identifying Cr<6+> and vitamin C

ActiveCN109054824AStrong fluorescence emissionRapid responseNanoopticsNano-carbonChromatographic separationVitamin C

Owner:ZHENGZHOU UNIV

Biomass microwave cracking gasification unit

InactiveCN102504878ASolve the reuse problemDesign scienceChemical industryCombustible gas productionMicrowave tubeSlag

The invention provides a biomass microwave cracking gasification unit, which comprises a microwave gasification unit, a gas cooling device and an electric fishing decoking device. The microwave gasification unit comprises a furnace body, a vaporizing furnace installed in the furnace and a microwave generator installed on the furnace, an insulation material is provided between the furnace inner wall and the vaporizing furnace outer wall, a feed inlet is arranged at the top of the vaporizing furnace, a gas sealing valve is installed at the feed inlet, a discharge duct is arranged at the upper part of the vaporizing furnace, a slag hole is arranged at the bottom of the vaporizing furnace, an air inlet pipe is arranged at the lower part of the vaporizing furnace, an regulating valve is installed on the air inlet pipe and a microwave tube of the microwave generator is arranged corresponding vaporizing furnace outer wall. The exhaust pipe of the microwave gasification unit connects with the inlet of a cooling device and the outlet of the gas cooling device connects with a decoking air inlet pipe of the electric fishing decoking device. The unit has the advantages of scientific design, reasonable structure, fast gas making, energy saving, environmental protection, safety and reliability.

Owner:ZHUMADIAN HUAXUAN INDS

Automatic dish cooking machine

The automatic dish cooking machine includes a material storage with material outlet in the lower part, a cooking microwave heating tub, a microwave tube with controllable temperature and time set beside the cooking tub, and a thin film bag connected to the material outlet and contacting closely with the inner wall of the cooking tub. The present invention has the materials sealed inside thin film bag and heated and cooked inside the cooking microwave heating tub, and completes the cooking process automatically. The present invention has material amount, heating time and temperature well controlled, and the cooked dish is delicious. The present invention is suitable for use in restaurant and household.

Owner:李峰

Sintering method and sintering furnace of zirconium oxide all-ceramic tooth

InactiveCN103340693AReduce manufacturing costSimple structureArtificial teethFluidised-bed furnacesZirconium hydrideMicrowave sintering

The invention provides a sintering method and a sintering furnace of a zirconium oxide all-ceramic tooth. The method is mainly characterized in that a layer of zirconium oxide powder which has been sintered once, repulverized and can be fritted no longer at the temperature of 1500 DEG C is adhered to a tooth crown blank by utilizing dextrin; then the tooth crown blank is embedded in silicon carbide powder of a silicon carbide powder microwave sintering furnace; microwaves are generated by microwave tubes and the silicon carbide absorbs the microwaves to produce heat; when the heating temperature is 1300-1500 DEG C, the temperature is accurately controlled to rise in a ladder shape, so that the tooth crown blank is converted into a high-density and high-strength zirconium oxide ceramic body; the sintering furnace comprises a silicon carbide powder heating body device, a furnace body heat insulating device, a microwave generator, a temperature sensor, control switches and instruments, and the structure of the sintering furnace is simple and durable. By adopting the sintering method provided by the invention, the production cost of the zirconium oxide all-ceramic tooth can be greatly lowered, and the zirconium oxide all-ceramic tooth is easy to produce in a large scale, and the practice of zirconium oxide ceramic tooth sintering technology also can be generally carried out among stomatology department students in medical colleges and universities.

Owner:NANNING YUEYANG TECH

Cathode salt, preparation method thereof, barium-tungsten cathode containing cathode salt and preparation method of barium-tungsten cathode

ActiveCN102768928AGuaranteed emission currentGuaranteed lifeTransit-tube cathodesCold cathode manufactureSubstance amountMicrowave tube

The invention discloses cathode salt, a preparation method thereof, a barium-tungsten cathode containing the cathode salt and a preparation method of the barium-tungsten cathode. The cathode salt contained in the cathode comprises BaCO3, CaCO3 and Al2O3, the substance amount ratio among the BaCO3, the CaCO3 and the Al2O3 is 4-5:0.4-0.7:1, and the preparation method of the cathode salt includes the steps of weighing, ball milling, briquetting and sintering. The preparation method of the barium-tungsten cathode containing the cathode salt includes: preparing a cathode substrate, preparing the cathode salt, dipping the cathode salt, lathing the cathode and laminating the emitting surface of the cathode. The barium-tungsten cathode prepared by the cathode salt is resistant to ion bombardment, the service life of microwave tubes is long, and each technical index can meet design requirements.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

High thermal conductivity aln for microwave tube applications

InactiveUS20010053739A1Improve thermal conductivityLoss of characteristicHigh resistivityThermal transmittance

Dense, high thermal conductivity AIN ceramic is described (along with a method of manufacture) which can be used in microwave tubes as collector rods, Helix support rods, T rods, etc. instead of BeO ceramic. High thermal conductivity, vacuum compatibility, low dielectric loss tangent at microwave frequencies, high electrical resistivity and dielectric strength are AIN properties allowing the material to be used in traveling wave tubes, particle accelerators or as laser bores and in other similar applications. These materials allow the replacement of BeO, which is a toxic material with diminishing availability in the United States and on the world market.

Owner:CERADYNE

Method for producing nano graphite field emission vacuum electronic cathode

InactiveCN101764007ACathode cross-sectional area is smallSimple production processCold cathode manufactureElectronPotassium permanganate

The invention belongs to the field of vacuum electronic element and device production and a method for producing field emission microwave vacuum electronic cathode by using a nano graphite material. The method comprises: processing industrial expanded graphite sheets at high temperature to produce wormlike expanded graphite; processing the wormlike expanded graphite with solution of concentrated sulfuric acid and potassium permanganate to produce nano graphite sheets; washing the nano graphite sheets to remove acid and purifying the nano graphite sheets by using ultrasonic waves and centrifugation; filtering and drying the nano graphite sheets and forming a film; rolling up the film to produce a nano graphite cylinder; and subjecting the nano graphite column to calcining and post treatment to obtain the nano graphite cylindrical cathode. The method has the characteristics that: the production process is simple, reliable, low in energy consumption and high in production efficiency; the produced electronic cathode has a small cross section and high stability, can emit high-intensity current in use, makes the industrial production realized easily; and the like. The method overcome the drawbacks of the prior art such as difficult use in field emission microwave tubes, digital tubes, projection tubes and other tube vacuum electronic elements, complicated production process, low production efficiency, high production cost and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

On-chip micro electron source and manufacturing method thereof

PendingCN109285740AImprove cooling effectLarge emission currentDischarge tube electron gunsCold cathode manufactureSingle electronMicrowave tube

The invention discloses an on-chip micro electron source and a manufacturing method thereof. The on-chip micro electron source is provided with a heat conducting layer, and at least one electrode in the same pair of electrodes is connected with the heat conducting layer via a through hole of an insulating layer, so that heat generated by the on-chip micro electron source can be dissipated throughthe electrode and the heat conducting layer, and thus the heat dissipation ability of the on-chip electron source is significantly improved. Therefore, the on-chip micro electron source can integratemultiple single electron sources on the same substrate so as to form an electron source integration array with a high integration level, so that the on-chip electron source is enabled to have high overall emission current, and more application requirements are met. For example, the on-chip micro electron source provided by the invention can be widely applied to various electronic devices involvingan electron source such as X-ray tubs, microwave tubes and flat-panel displays.

Owner:PEKING UNIV

Microwave tube system and microwave tube

ActiveUS7071624B2Prevention of unnecessary haltHigh outputTravelling-wave tubesAmplifiers with transit-time effectHelical lineMicrowave tube

Owner:NEC NETWORK & SENSOR SYST

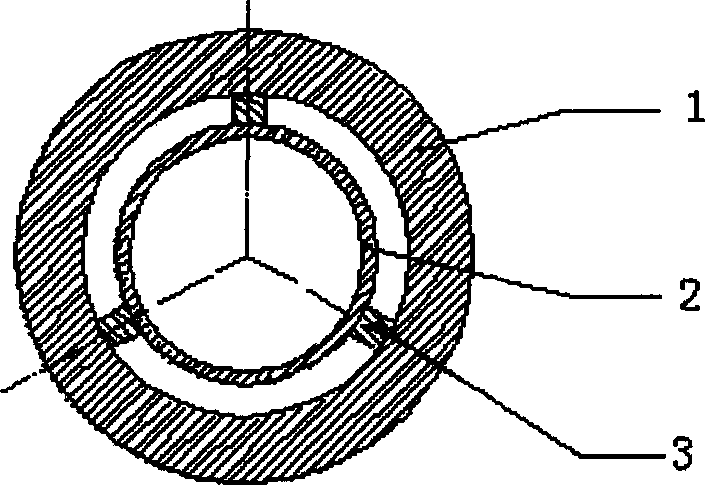

New bonding and assembling process for slow wave circuit of microwave tube and its bonding agent cleaning system

InactiveCN1805680AImprove high frequency characteristicsEven contactWork holdersCleaning using liquidsInterference fitMicrowave tube

The invention relates to a microwave slow-wave circuit adhere installment technique, which also discloses relative cleaning system of said adhesive. The inventive microwave slow-wave circuit can improve the high-frequency property of microwave tube. The inventive cleaning system can clear the adhesive and save the consumed solvent, with simple structure, continuous operation, and high safety. The inventive technique comprises: first sticking three ceramic clamping rods with adhesive on the integration of screw line and core rod in 120 degree; then abrading the outer round of integration; pushing the integration and the microwave tube in interference fit with special device into the tube case; and removing the adhesive.

Owner:NANJING UNIV OF TECH

Method for preparing low-sulfur expandable graphite from medium-low carbon fine flake graphite

The invention relates to the field of preparation of expandable graphite, in particular to a method for preparing low-sulfur expandable graphite in the room temperature atmospheric environment by using low-concentration sulfuric acid as an intercalation reagent by a mild and easily-controlled chemical intercalation method in accordance with medium-low carbon fine flake graphite. The method is simple in equipment, safe, controllable, free from gas protection and special protection, and suitable for mass preparation of low-sulfur fine flake graphite expandable graphite with low cost. The method comprises the following steps of (1) adopting natural fine flake graphite as a raw material, wherein the percentage by mass of carbon is 50-90%, and the size of graphite is 45-180 <mu>m; (2) under the condition of room temperature, using potassium permanganate as an oxidant, adopting the sulfuric acid of which the percentage by mass is 30-85% as an intercalation agent, and performing effective intercalation on the graphite raw material under the condition of room temperature, wherein heating is not needed in the process, and after uniform stirring is performed, the process can be completed under the standing condition; and (3) adopting a microwave tube furnace for rapidly expanding the expandable graphite, and finally, obtaining a low-sulfur fine flake expandable graphite powder material with a high-expandable volume.

Owner:黑龙江省宝泉岭农垦帝源矿业有限公司

Manufacturing method for dispersion strengthened oxygen-free copper alloy board

The invention discloses a manufacturing method for a dispersion strengthened oxygen-free copper alloy board. A technological process of the manufacturing method comprises the following steps: atomizing nitrogen gas to prepare powder, preparing an oxygen source, mixing powder, performing cold isostatic pressing and processing, performing short-process integrated thermal treatment, extrusion-processing, performing hot-rolling on an extruded board or a sheared billet into a board, straightening and face-milling, cold-rolling, and straightening and finishing. The manufacturing method breaks through the history that only bars can be supplied for dispersion oxygen-free copper, increases a utilization rate of a dispersion oxygen-free copper material, improves the processing efficiency of the dispersion oxygen-free copper material, solves the hot-rolled cracking problem and the oxygen control problem of dispersion oxygen-free copper very well, ensures stability of the material dimension, manufactures the dispersion strengthened oxygen-free copper alloy board which is 1.0-5 mm thick, and meets needs of key materials such as an electronic information industry large-power microwave tube cavity and an electric industry overhead high-voltage switch contact sheet.

Owner:中铝洛阳铜加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com