Production system for thistle board

A technology of plasterboard and production system, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve problems such as insufficient drying, waste, energy waste, etc., achieve simple control modules, increase operating speed, and optimize The effect of dry mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

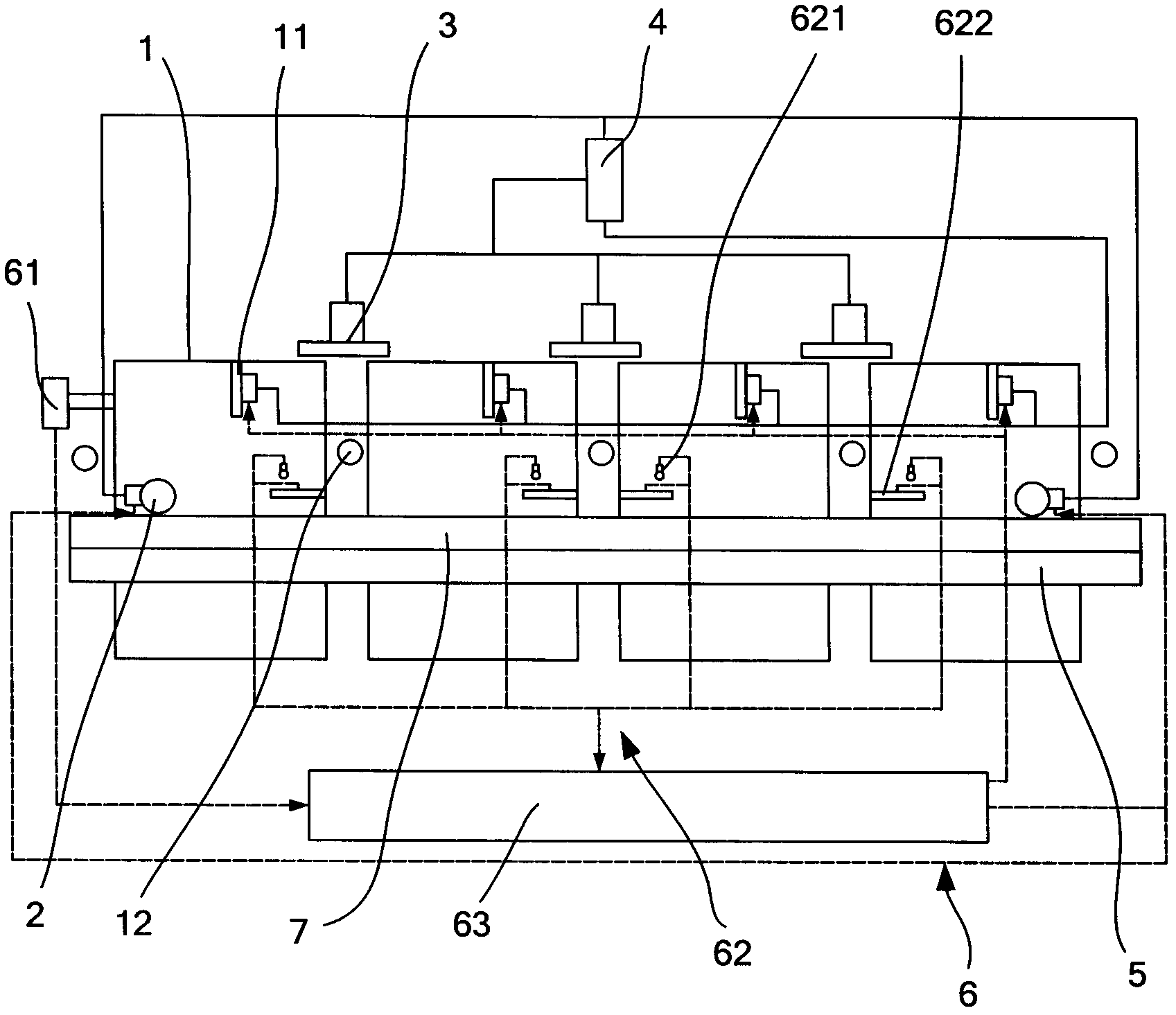

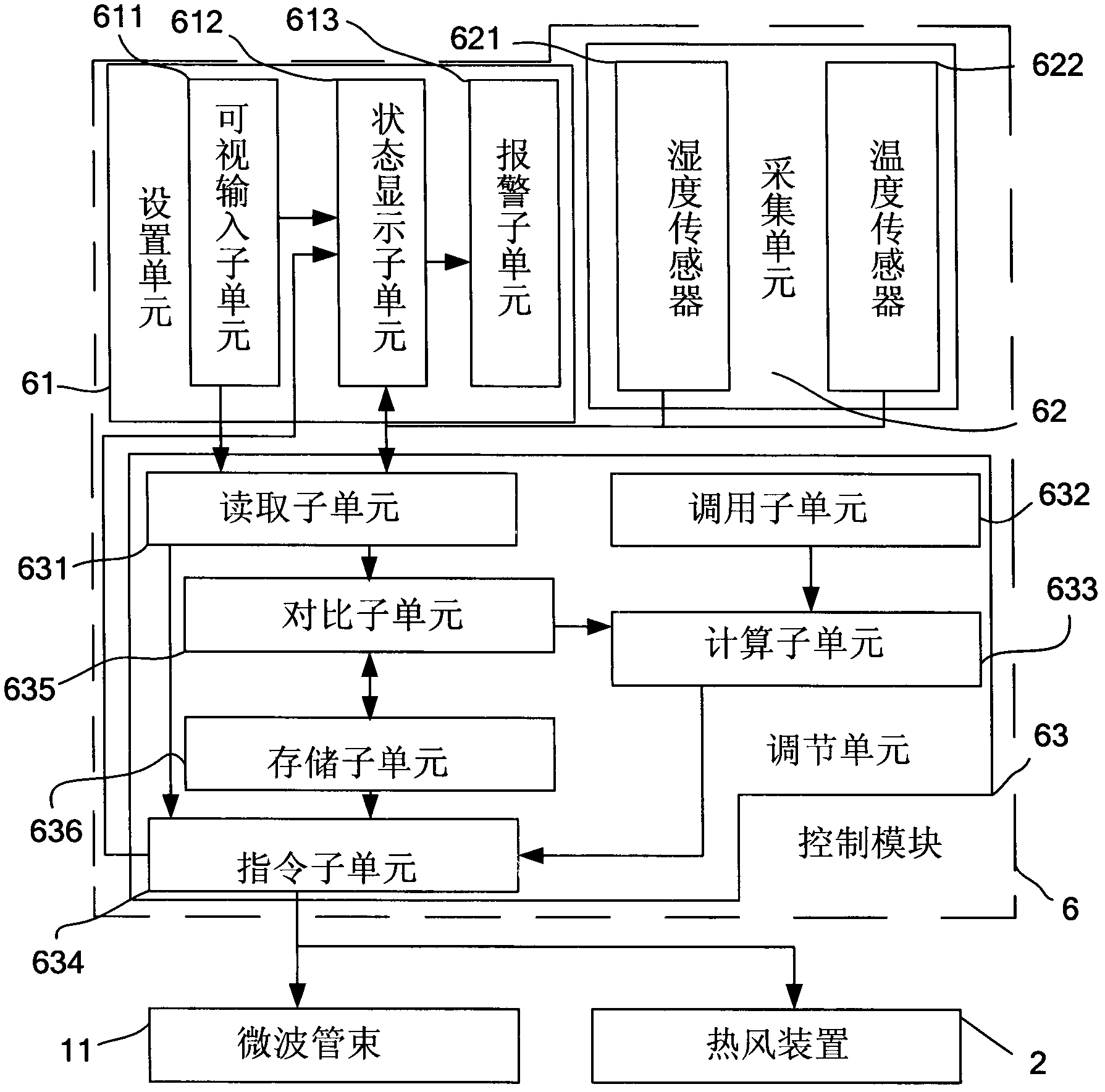

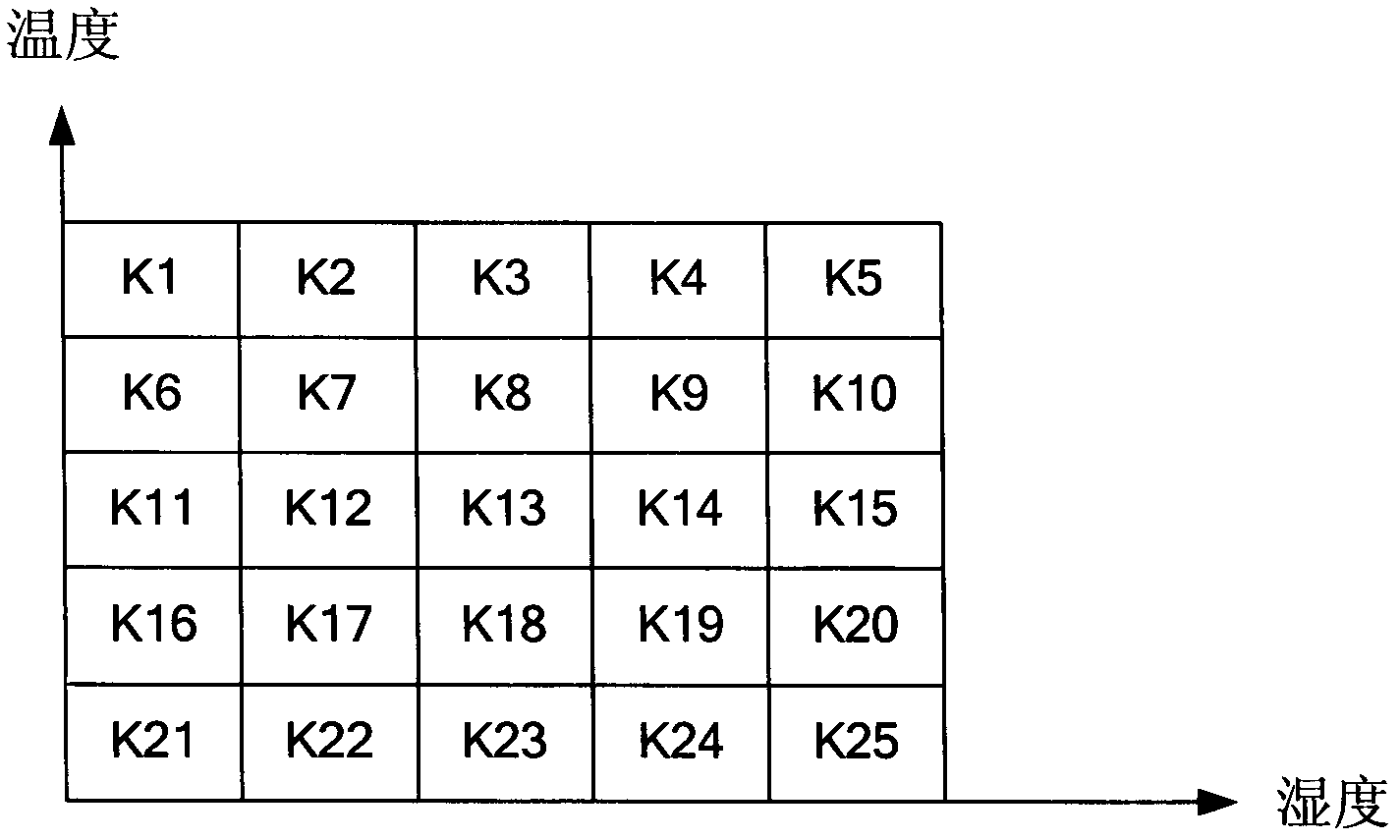

[0035] Working principle of the present invention: the gypsum board is porous, and the contained moisture includes chemically bound water, adsorbed water and free water. Among them, chemically bound water is also called crystal water, and adsorbed water and free water are also called physical water. Drying of plasterboard is the process of eliminating free water and adsorbed water. The convective heat exchange between the circulating hot air and the gypsum board is mainly used to heat up the board and evaporate excess water; microwave is a kind of electromagnetic wave that can generate a high-frequency electromagnetic field. Under the action of the electromagnetic field, the polar molecules (water molecules) change from the original random distribution state to the polar arrangement orientation of the electric field. Under the action of the high-frequency electromagnetic field, the molecules move and rub against each other to generate energy, which makes the gypsum board heat u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com