Continuous-type microwave hot air combined drying equipment

A combination of drying and microwave hot air technology, applied in lighting and heating equipment, heating to dry solid materials, drying solid materials, etc., can solve the problems of difficult heat convection transfer, unsatisfactory drying, slow heating speed, etc., to achieve the drying cycle Longer, shorter drying cycle, slower heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

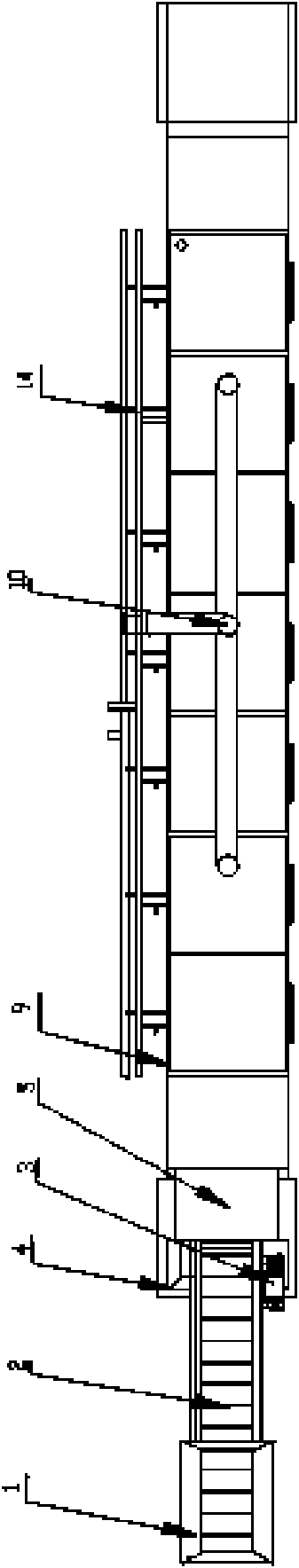

[0018] Such as figure 1 , 2 As shown, the specific embodiment of the present invention is an embodiment of a continuous microwave hot air combined drying equipment, including a material lifting device, a lower hopper auxiliary device 4, an upper conveyor belt 5, a lower conveyor belt 6, and a microwave box 9 , dehumidifying device 10, hot air device 7, described material lifting device is made up of hopper 1, hoisting belt 2, speed-regulating motor 3, and the feeding end of hoisting belt 2 is positioned at the bottom of hopper 1, and hoisting belt 2 is controlled by speed-regulating motor 3 drive, the discharge end of the lifting belt 2 is located above the lower hopper auxiliary material device 4, the upper conveyor belt 5 and the lower conveyor belt 6 are arranged in parallel in the microwave box 9, and the upper conveyor belt 5 and the lower conveyor belt 6 pass through the microwave respectively. The ceramic idler 11 in the box 9 is driven, and the microwave box 9 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com