Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Shorten drying cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

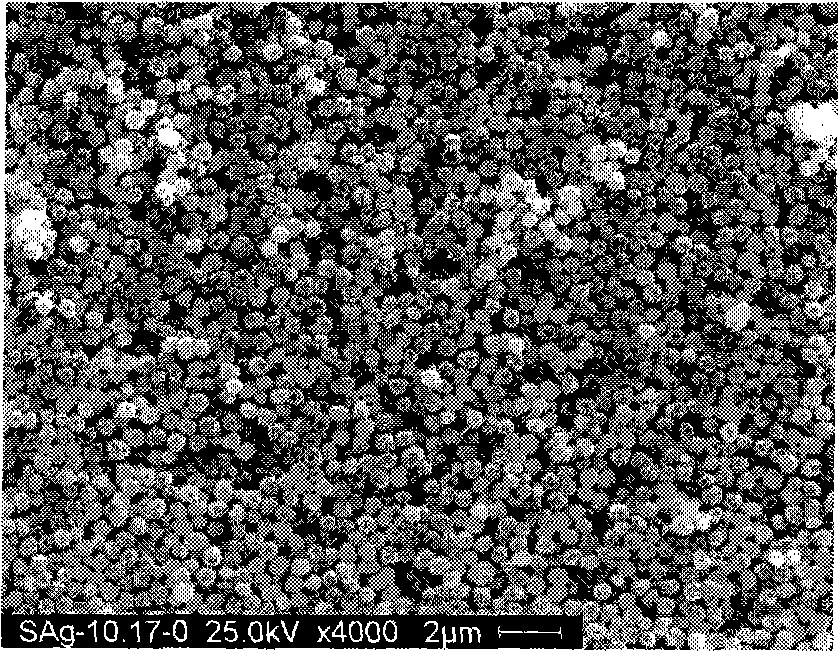

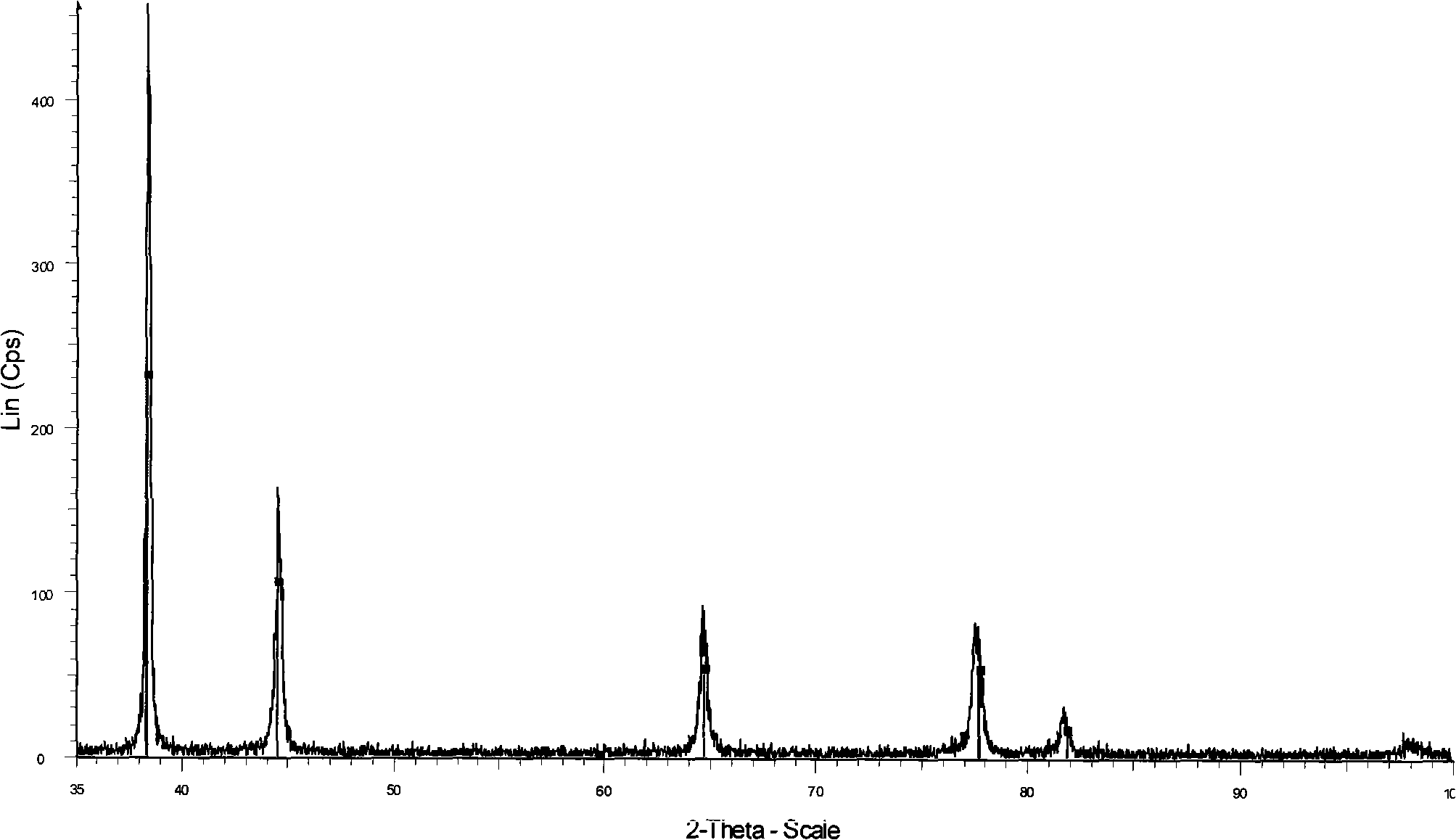

Preparation of high dispersed superfine spherical silver powder for conductive silver slurry

A preparation method of high-dispersion ultra-fine spherical silver powder used for conductive silver paste relates to a preparation method of ultra-fine spherical silver powder, in particular to the preparation method of the high-dispersion ultra-fine spherical silver powder for the conductive silver paste in the electronic industry. The preparation method is characterized in that silver ammonia solution is dropped in a reduction system which consists of a reducing agent of formaldehyde, a dispersant of polyvinyl alcohol PVA and sodium hydroxide solution, thus obtaining high-dispersion ultra-fine silver powder slurry, and the high-dispersion ultra-fine spherical silver powder with the particle size range of 0.3 to 1.0Mum can be obtained by solid-liquid separation and drying. The method of the invention has simple and feasible process flow, low production cost, less equipment investment, stable and reliable process conditions, small particle size of the product silver powder, narrow distribution range, high yield and easy realization of industrial mass production.

Owner:JINCHUAN GROUP LIMITED

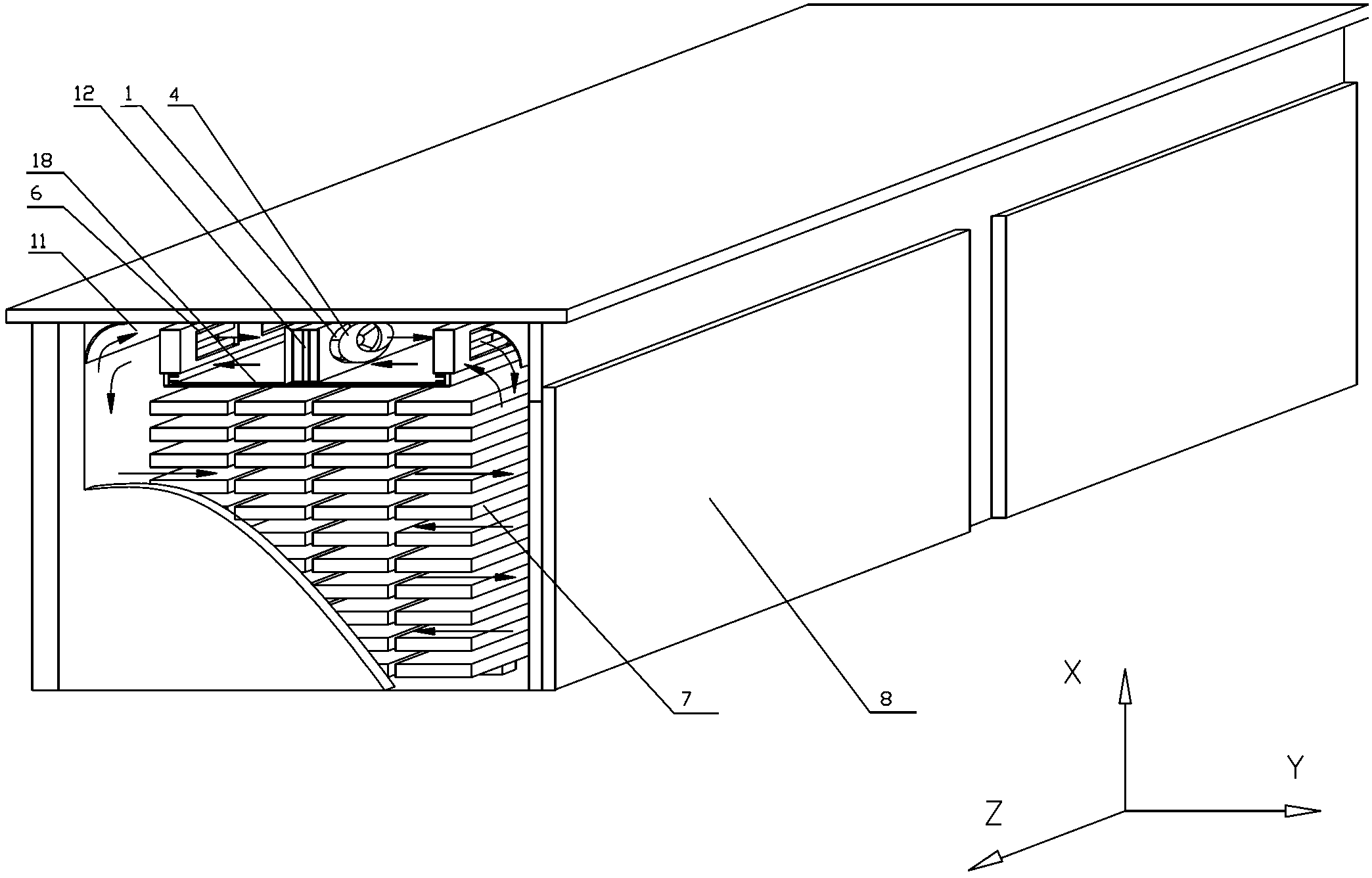

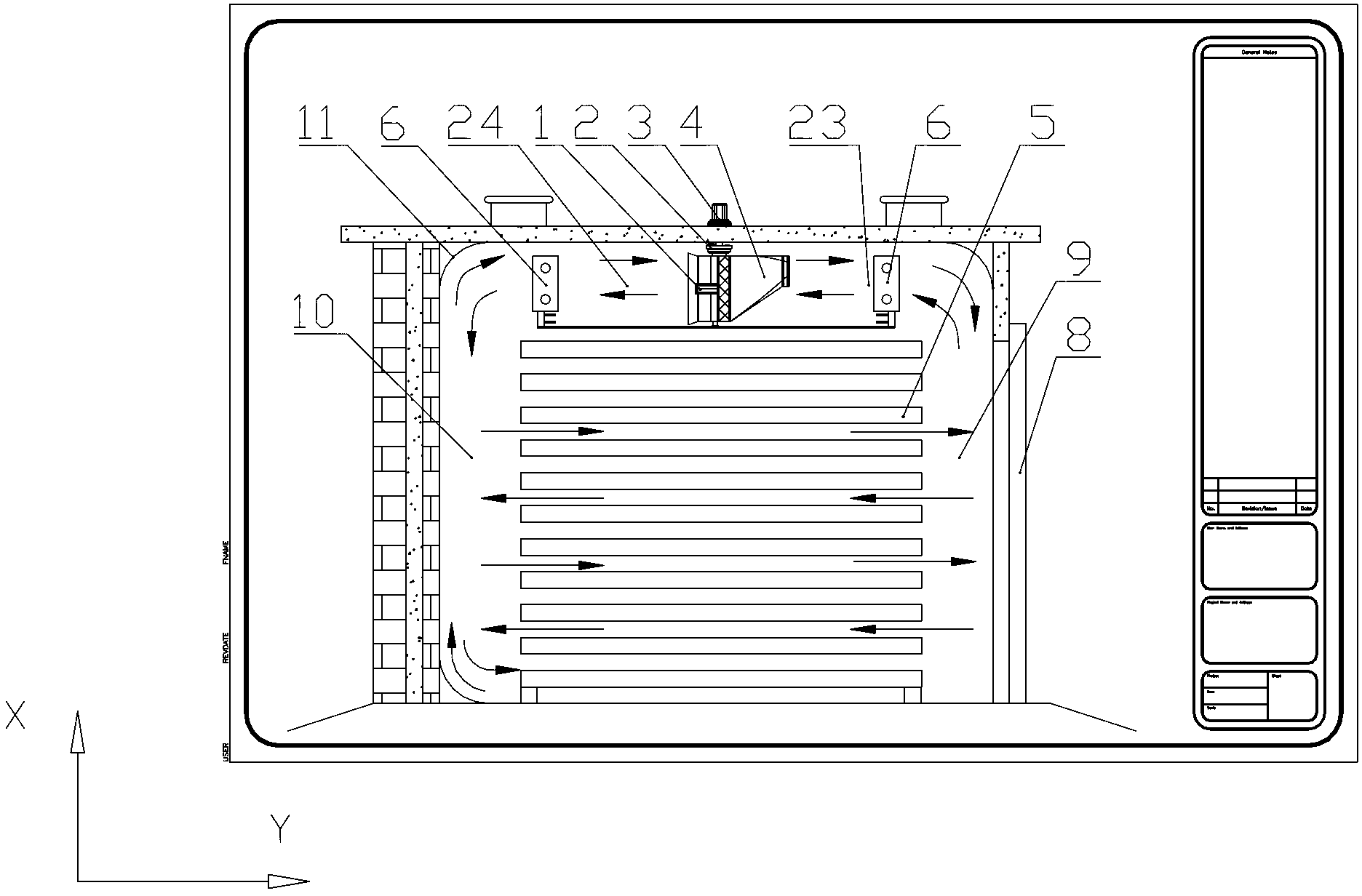

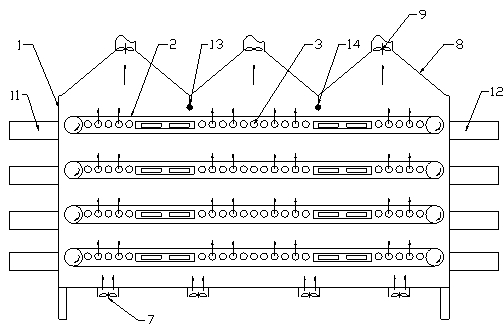

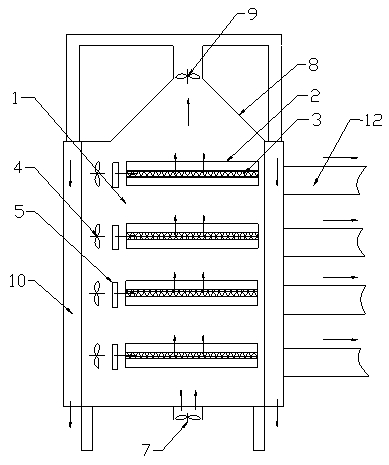

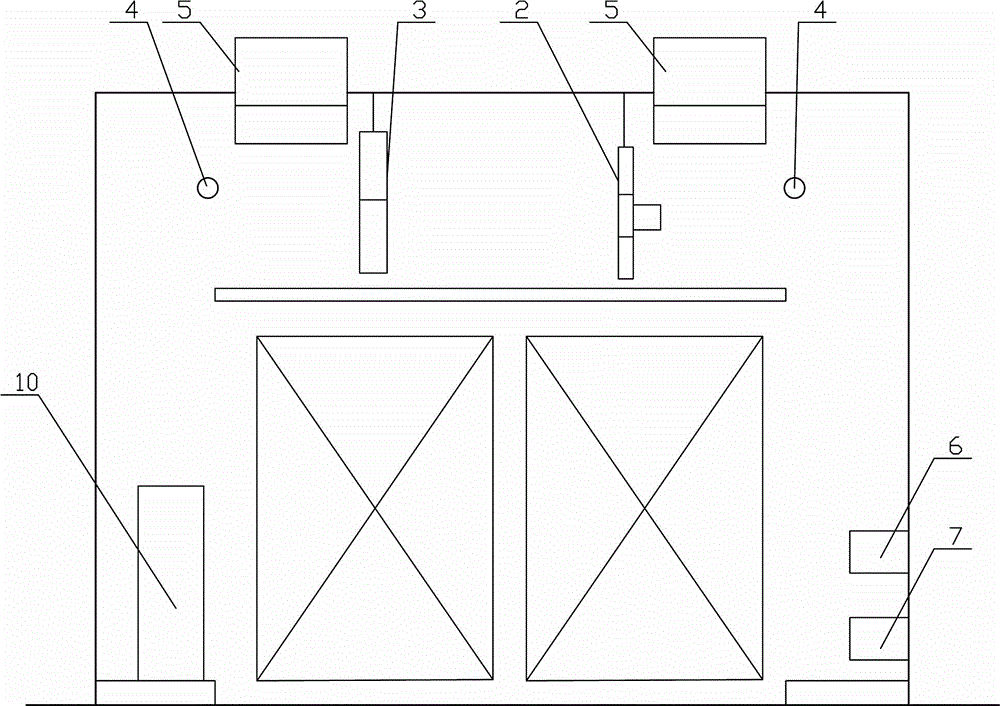

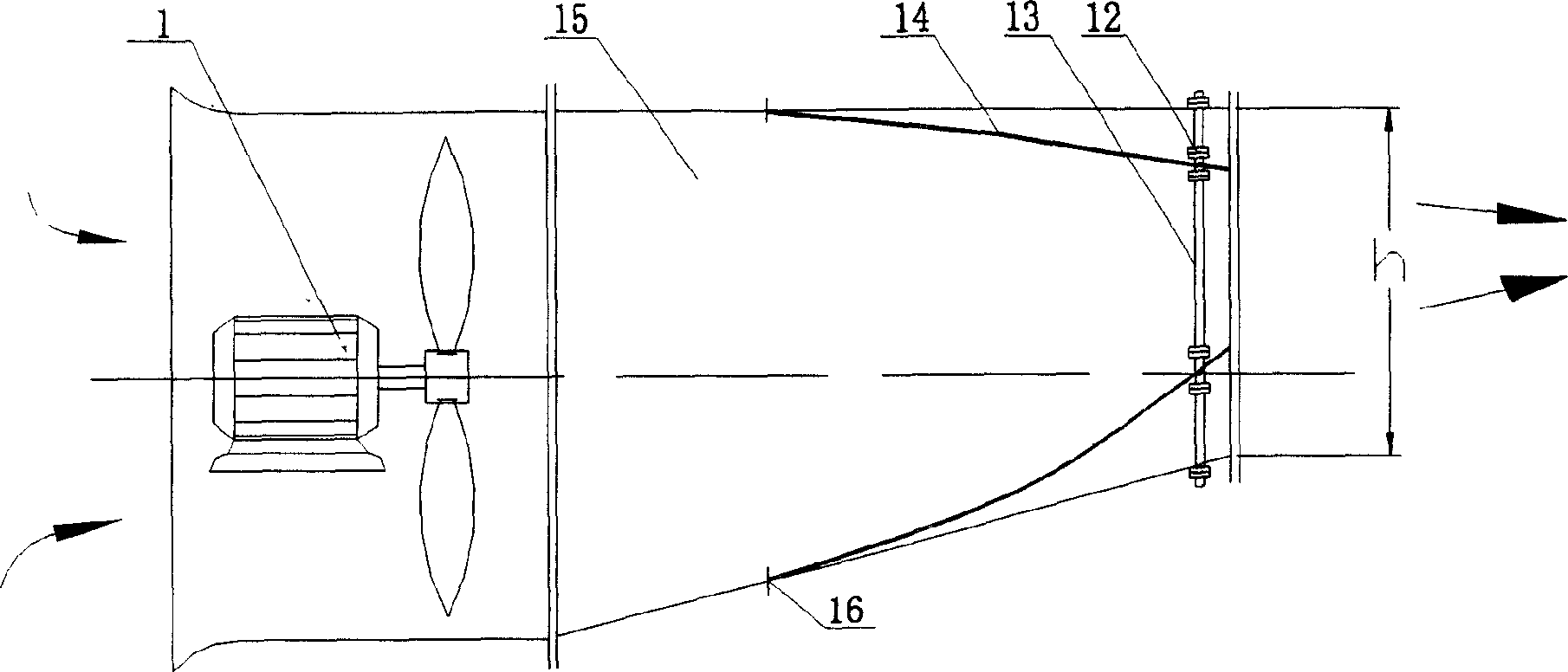

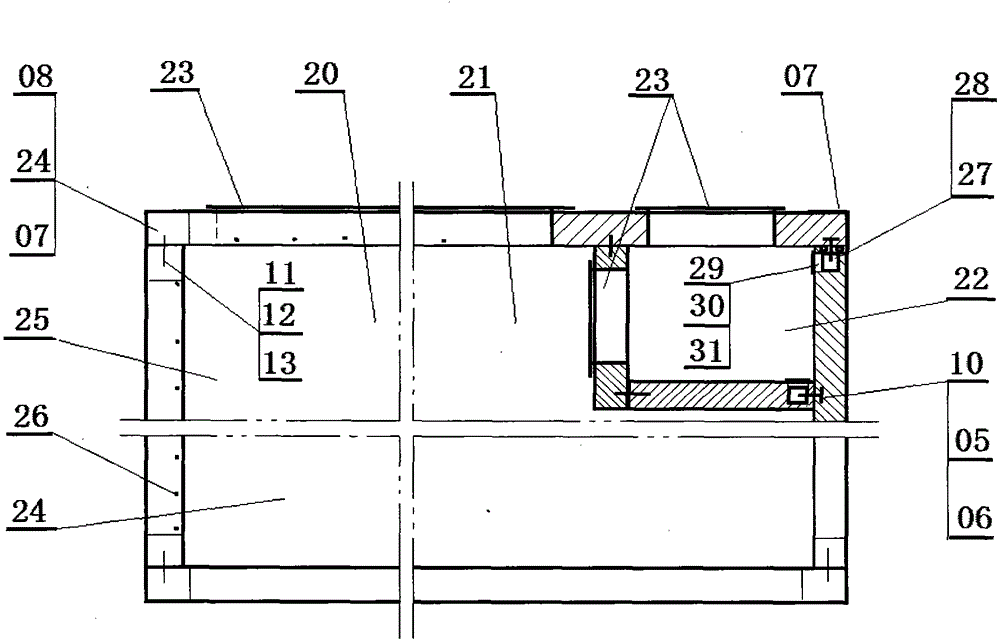

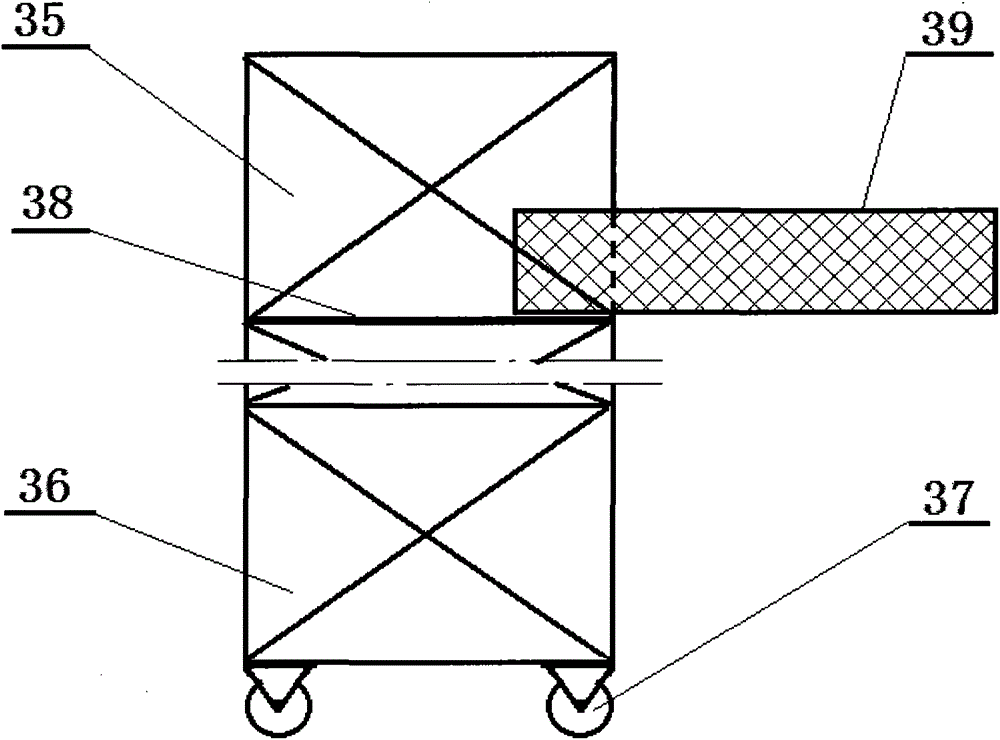

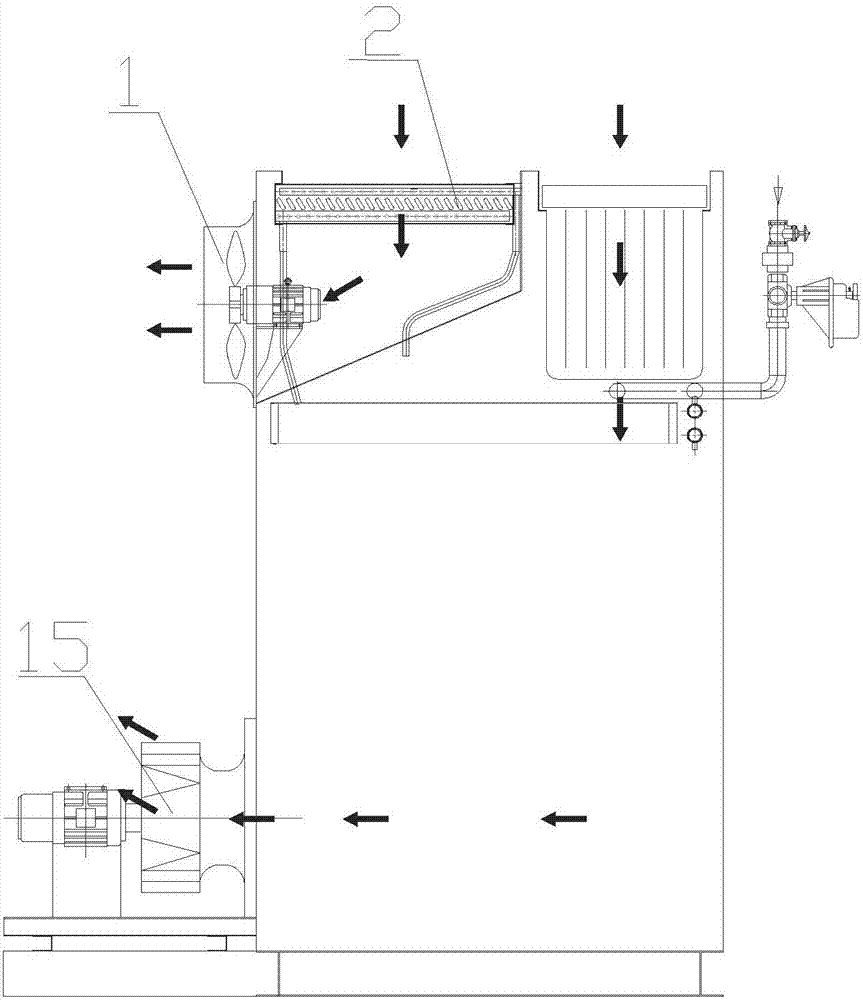

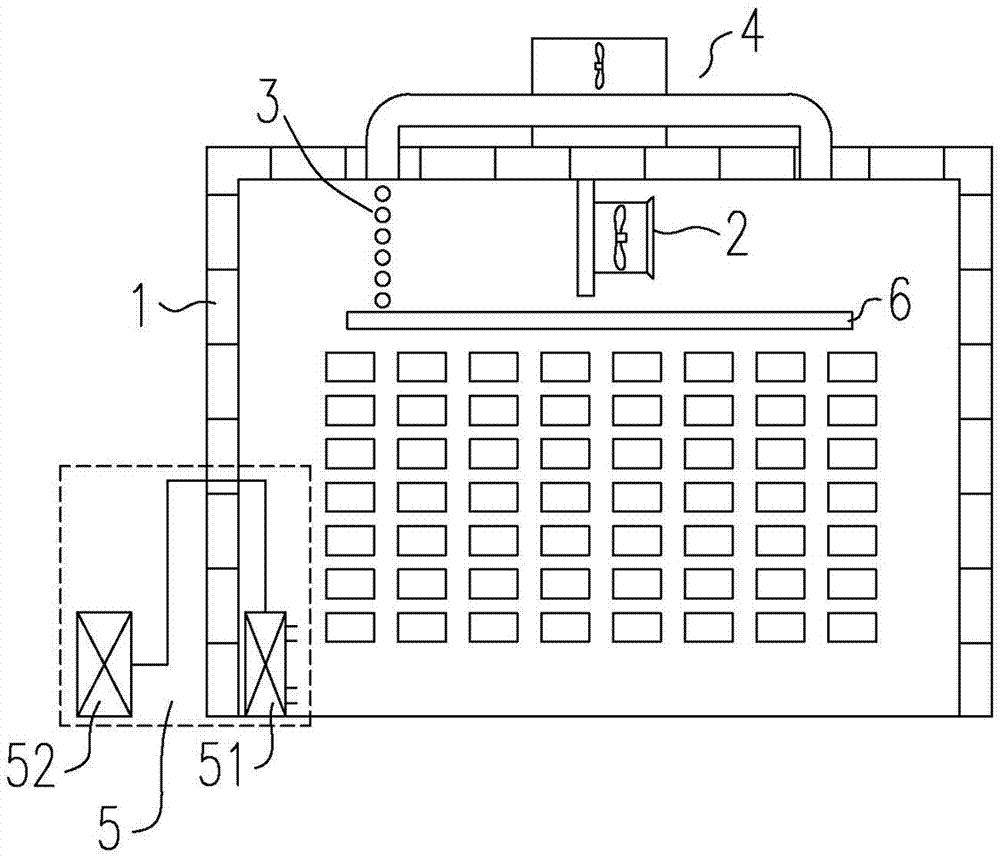

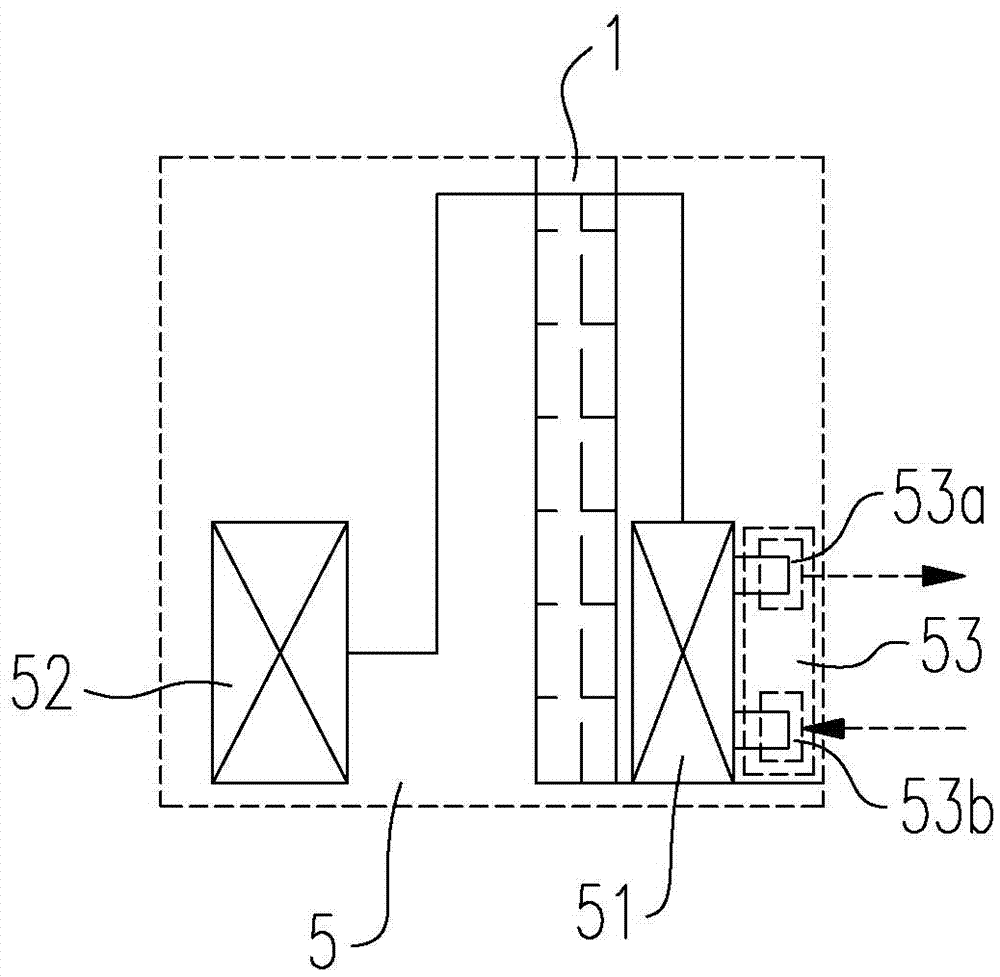

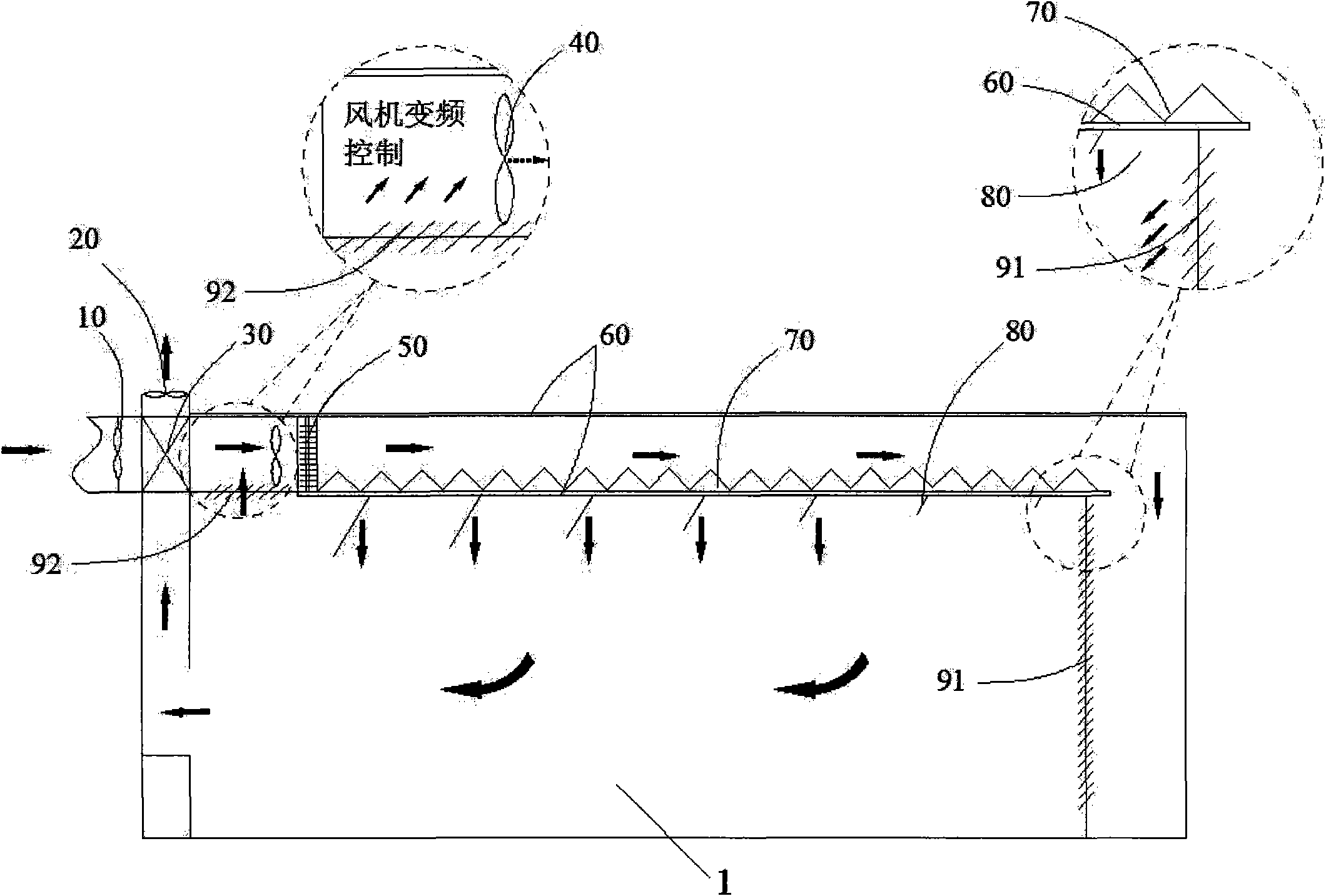

Heating and blowing device for large hot air drying room

InactiveCN103292590AStable forward and reverse air supplyThe same wind pressure and air volumeDrying gas arrangementsChemical productsEngineering

The invention relates to timbers, pharmaceuticals, foods and chemical products, in particular to a heating and blowing device for a large hot air drying room. A plurality of fans (1) are disposed in a rectangular fan support frame (12). Gaps among the fans (1) are blocked by air blocking plates (13). The fans are linked by a synchronization rotation linkage mechanism (2) for synchronous horizontal rotation. The fan support frame (12) is fixed on a rectangular movable frame (17). Rollers (19) embedded into guide rails (18) on two sides are disposed on two sides of the fan support frame (12). An air guide component (4) is disposed on a blowing side of each fan (1). A plurality of radiators (6) corresponding to the fans (1) are disposed at two ends of the guide rails. Three arc flow deflectors (11) are disposed at three inner included angles of the drying room. By the heating and blowing device, power consumption is lowered greatly, operation cost and drying cost are lowered, the drying room is enabled to be efficient, energy-saving and widely applicable, timbers of two or more different kinds or of different thicknesses can be evenly dried simultaneously, production efficiency is increased, and drying operations are highly flexible.

Owner:SHANGHAI UNIV OF ENG SCI

Novel quick drying device for edible mushrooms and quick tremella drying technology of novel quick drying device

InactiveCN102144802AReduce installed capacityReduce electricity consumptionFood treatmentEdible mushroomMoisture

The invention relates to a novel quick drying device for edible mushrooms and a quick tremella drying technology of the novel quick drying device. The novel quick drying device for the edible mushrooms comprises a drying box, which is characterized in that a plurality of layers of independent drying conveyor mesh belts are longitudinally arranged in the drying box, and a hot air pipe of which the upper side is provided with a blowing port and a microwave or far infrared heating device controlled by an intelligent controller are both mounted on the drying conveyer mesh belts; the length of the layers of drying conveyor mesh belts is 30-60 km, the conveying speed is 0.25-0.65m / min, and the drying time from feeding to discharging is 1.5-2 hours; tremella is dried to have the moisture content of 8%-12%, the drying process is controlled by a PLC (Programmable Logic Controller), the tremella on each layer is orderly and alternatively dried by the hot air, the microwave or the far infrared and the hot air, and the drying temperature for the tremella is strictly controlled to be 78-82 DEG C; and the temperature and the humidity are synchronously monitored, and moist steam is removed timely. The novel quick drying device for the edible mushrooms and the quick tremella drying technology can save large amount of electric energy consumption, reduce large amount of energy consumption and carbon emissions, improve automation degree, reduce labor charges and artificial loss and greatly improve the level of cleaner production.

Owner:FUJIAN AGRI & FORESTRY UNIV

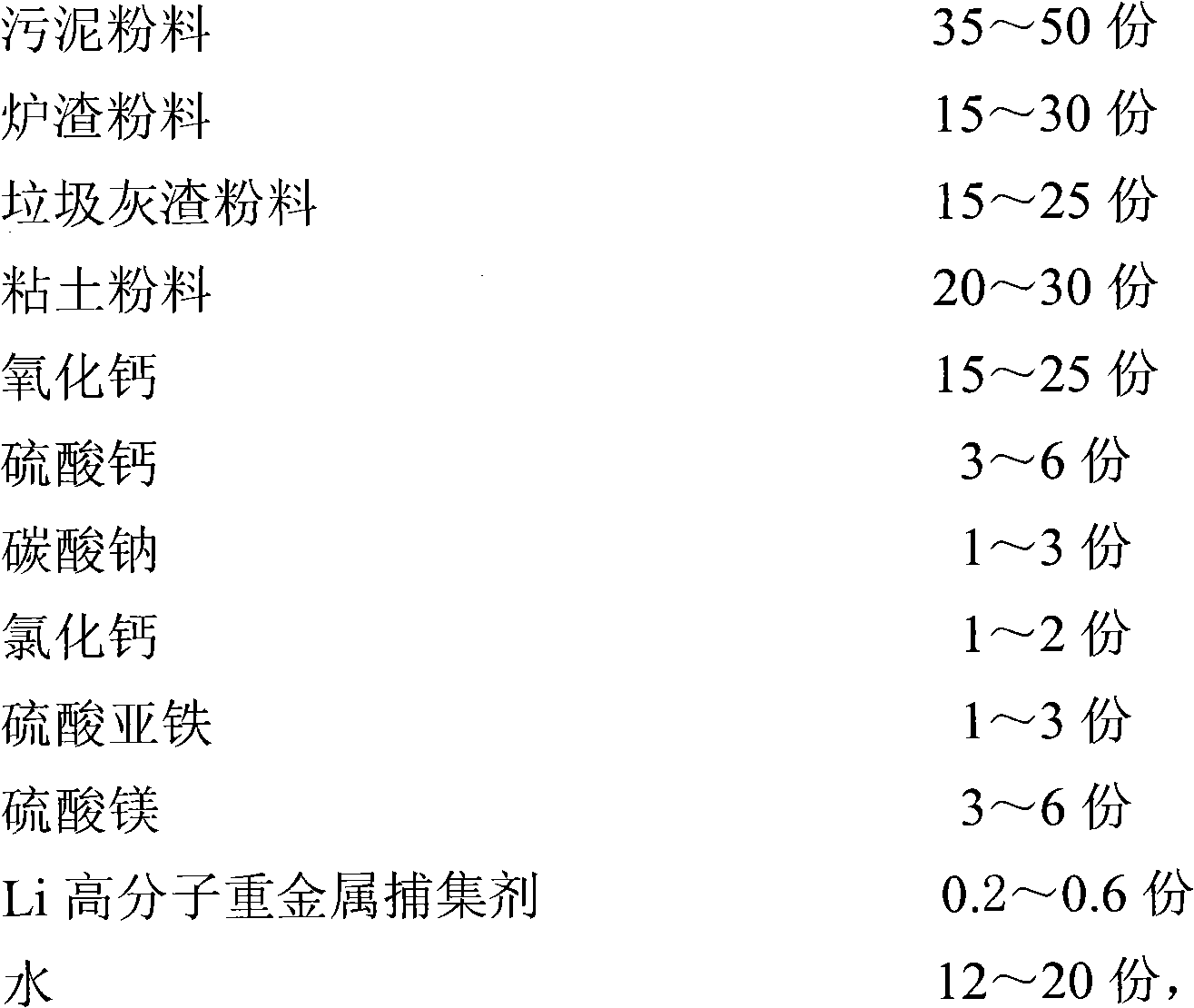

Sintered light-weight environment-friendly brick produced from electroplating sludge and manufacture method thereof

The invention relates to a sintered light-weight environment-friendly brick produced from electroplating sludge and a manufacture method thereof. The sintered light-weight environment-friendly brick is characterized by being prepared by adopting electroplating sludge, base waste sludge, furnace slag, refuse ash, calcium oxide, calcium sulfate, sodium carbonate, boric acid, ferrous sulfate, magnesium sulfate, Li macromolecular heavy metal trapping agent and water are adopted as raw materials; and the manufacture method comprises the following steps of: mixing and stirring the raw materials in a biaxial mixer to be in a moisture state; extruding into rectangular bars by a vacuum sludge extruder; cutting and forming by a blank cutter; manufacturing light-weight environment-friendly brick blanks of electroplating sludge under the pressure of 20-30 MPa; and conveying the formed and naturally dried light-weight environment-friendly brick blanks into a tunnel kiln to roast and manufacture light-weight environment-friendly brick products. Air laying bricks and pavement bricks in different specifications can also be manufactured by the raw materials of the invention, and the product has the advantages and the effects of light weight, great strength, zero pollution, low cost and good benefits.

Owner:清远绿由环保科技有限公司

Method for preparing compound Sihuang dysentery stopping preparation of traditional Chinese medicine for preventing intestinal diseases of animals

InactiveCN101590139AShorten drying cycleIncrease productivityAntibacterial agentsAerosol deliveryDiseaseCurative effect

The invention discloses a method for preparing a compound Sihuang dysentery stopping preparation of traditional Chinese medicine for preventing intestinal diseases of animals, which is characterized in that the method can be used for preparing compound Sihuang dysentery stopping oral liquid, compound Sihuang dysentery stopping extractums, compound Sihuang dysentery stopping granules and compound Sihuang dysentery stopping tablets. The preparation can be prepared into dosage forms of oral liquid, extractums, granules, tablets, and the like, has high content of effective constituents so as to improve the curative effect, has no residues, no generation of drug resistance and reasonable dosage forms, can be taken by drinking water and has convenient transport and use.

Owner:TIANJIN SHENGJI GRP CO LTD

High-strength aluminum oxide light-weight heat insulation brick and preparation method thereof

ActiveCN103044045AReduce consumptionTo achieve the purpose of energy savingHeat conservationUltimate tensile strength

The invention relates to a high-strength aluminum oxide light-weight heat insulation brick and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: premixing 25-40 wt% of alpha-Al2O3 fine powder with the particle size of 0.074-0.147mm, 25-40 wt% of alpha-Al2O3 fine powder with the particle size of 0.043-0.074mm, 10-15 wt% of alpha-Al2O3 fine powder with the particle size of less than 0.043mm, 10-15 wt% of alpha-Al2O3 micropowder, 3-10 wt% of rho-Al2O3 micropowder and 2-10 wt% of three-stone used as raw materials with combustion improver (accounting for 0.1-1 wt% of the raw materials), water (accounting for 20-35wt% of the raw materials) and water reducing agent (accounting for 0.1-0.7 wt% of the raw materials) for 5-10 minutes to obtain a premix; and adding foam into the premix, evenly mixing, carrying out casting molding and microwave drying, and keeping the temperature of 1450-1750 DEG C for 3-6 hours to obtain the high-strength aluminum oxide light-weight heat insulation brick. The invention has the characteristics of simple technique and energy conservation. The product has the characteristics of high strength, small linear variation rate, low volume density, low heat conductivity coefficient and short drying cycle.

Owner:WUHAN UNIV OF SCI & TECH

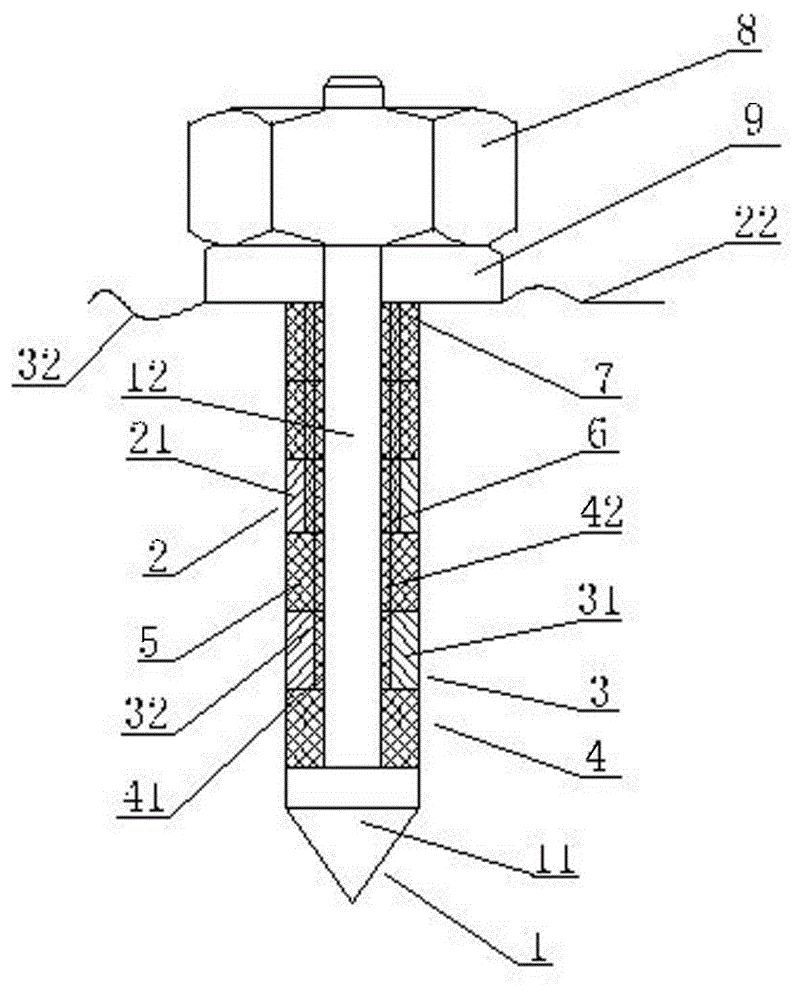

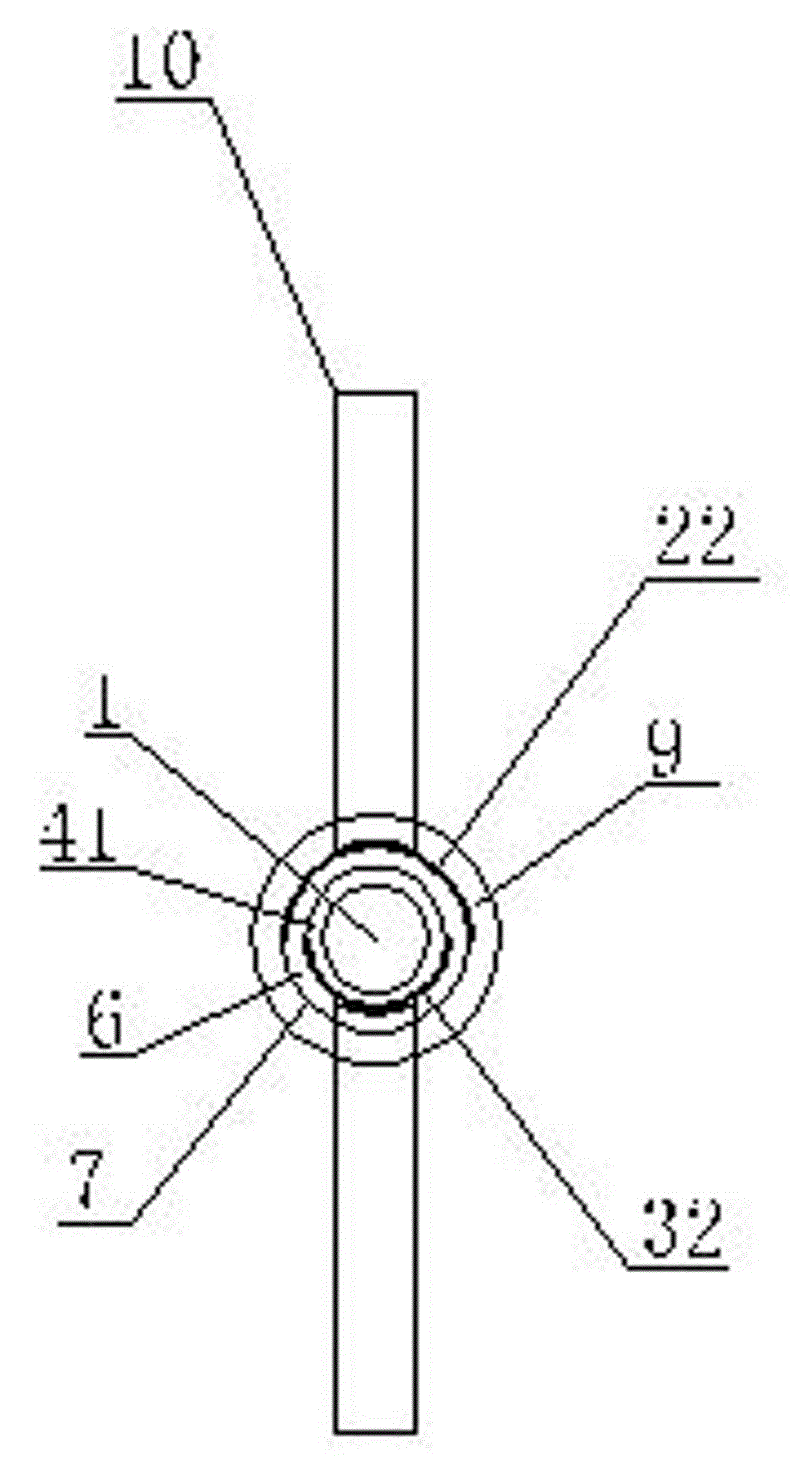

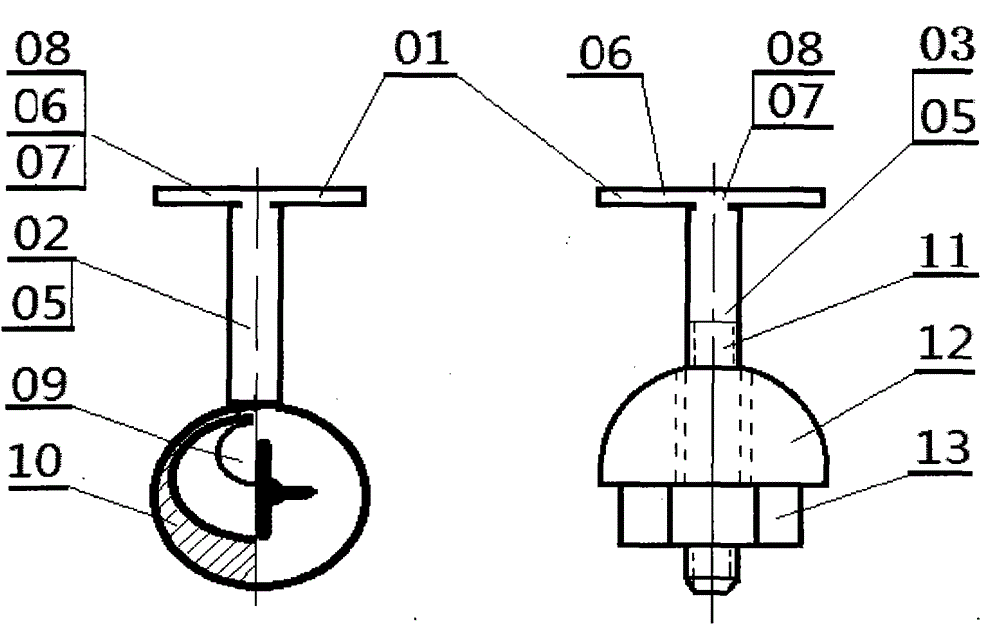

Method for measuring moisture content gradient in drying process of woods and measuring sensor used for the method

InactiveCN102621189AMeet drying quality requirementsLess dry massMaterial resistanceHardnessSafe operation

The invention relates to a method for measuring moisture content gradient in a drying process of woods and a measuring sensor used for the method. The method for measuring moisture content gradient in the drying process of woods includes: in the drying process of the woods, inserting a measuring sensor into the woods for measuring resistance within a certain distance in the width direction of two different-thickness layers of the woods on line, calculating the moisture content rate of the different-thickness layers of the woods according to the resistance and then calculating the moisture content gradient of the woods according to the moisture content ratio and the distance between the different-thickness layers. Due to the method, in the drying process of the woods, operating staff can calculate the moisture content gradient and moisture content deviation on the thickness by measuring the moisture content ratio of the two-layer or multiple-layer woods on line on the basis of easy and safe operation, softness or hardness of drying standard can be judged according to the moisture content gradient, temperature and humidity of the drying medium can be adjusted timely, and accordingly the aim for improving drying quality and shortening drying cycle can be achieved.

Owner:GUANGDONG YIHUA TIMBER IND

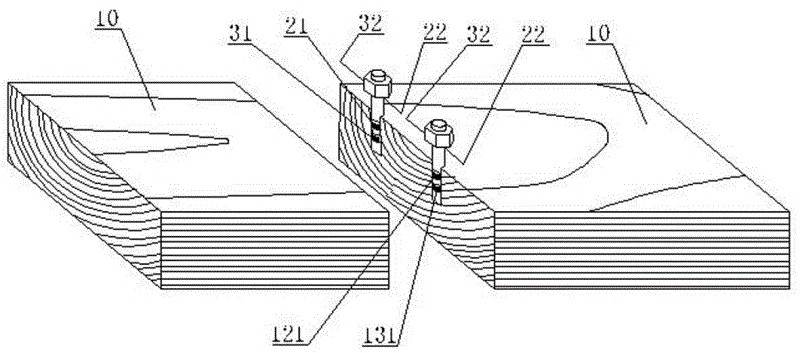

Sintered light environmental-friendly brick produced by using municipal sludge and manufacture method thereof

The invention relates to a sintered light environmental-friendly brick produced by using municipal sludge and a manufacture method thereof. The manufacture method is characterized by comprising the steps of: adding sludge, slag, rubbish ash, clay, calcium oxide, calcium sulfate, sodium carbonate, calcium chloride, ferrous sulfate, magnesium sulfate, an Li macromolecule heavy metal trapping agent and water as raw materials; mixing and stirring to be in a wet state and then extruding through an airing extruder, cutting and forming through a blanking machine; preparing a sludge light environmental-friendly brick blank under the pressure of 25-30MPa; and forming the naturally dried light environmental-friendly brick blank in an annular kiln for roasting and then preparing the light environmental-friendly brick. According to the invention, different specifications of building-blocks and sidewalk bricks can be manufactured by using the raw materials. The sintered light environmental-friendly brick has the advantages and effects of light weight, high strength, no pollution, low cost and good benefit.

Owner:清远绿由环保科技有限公司

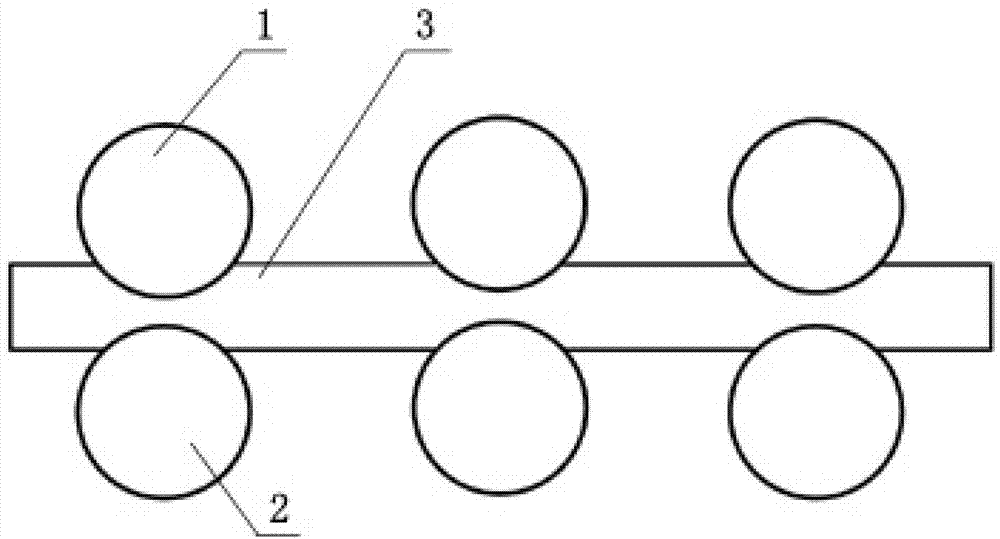

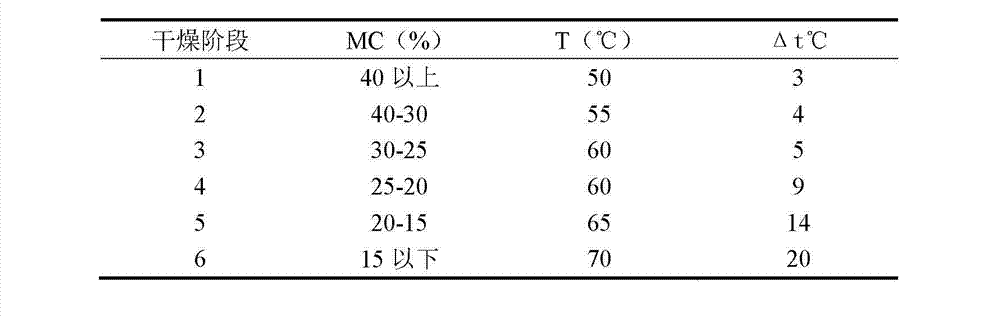

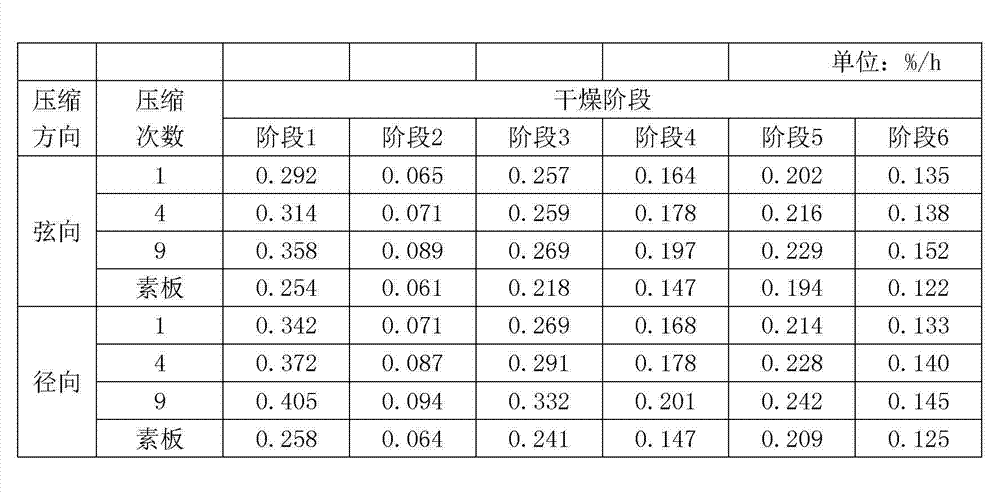

Preprocessing method for shortening wood drying time

ActiveCN102873730AShort processing timeImprove efficiencyWood compressionWood treatment detailsWood dryingPre treatment

A preprocessing method for shortening wood drying time includes the following steps: 1 selecting a wood plate to be dried; 2 adjusting a device: the device is a group of or multiple groups of roller presses which are sequentially ranked, the distance between upper press rollers and lower press rollers of each group of roller presses and press roller speed are adjusted according to set process parameters so as to lead the press rollers to have a set compression amount to the wood plate; 3 preprocessing the wood plate: the roller presses are started up, the wood plate is flatly arranged between an upper press roller and a lower press roller, the wood plate is led to pass one group of roller pressing or multiple groups of continuous roller pressing for one time or repeated many times from the input end of the roller presses to the output end of the roller presses by aid of friction of the surfaces of the press rollers or external force effect; and 4 drying the roller pressed wood plate. The preprocessing method is used for preprocessing of woods before drying, can shorten wood drying time of solid wood plates containing certain moisture, saves energy resources, is simple in structure and convenient to operate in devices, is safe to use and can reduce production cost.

Owner:BEIHUA UNIV

Regenerated brick prepared from papermaking sludge and preparation method thereof

InactiveCN103130492AHigh densityIncrease profitCeramic materials productionClaywaresBreaking strengthBrick

The invention relates to a regenerated brick prepared from papermaking sludge and a preparation method thereof. the invention solves the problem of restricted utilization ratio of bricks prepared from papermaking sludge, and overcomes the defects of low compression resistance, low breaking strength, poor air permeability and the like in the bricks prepared from papermaking sludge. The preparation method comprises the following steps: mixing and stirring 35-40 parts by weight of papermaking sludge with the water content of 45-55%, 20-25 parts by weight of power plant sintering ash, 40-45 parts by weight of clay, 2.5-4 parts by weight of flame-retardant permeable fiber monofilament, 3-5 parts by weight of blind coal, 3-5 parts by weight of water-soluble resin and 4-7 parts by weight of water to obtain a wet material; and extruding with an extruding machine to obtain a blank strip, cutting into green bricks, naturally drying in air, and sintering in a kiln.

Owner:FUJIAN YIYUAN WASTE UTILIZATION

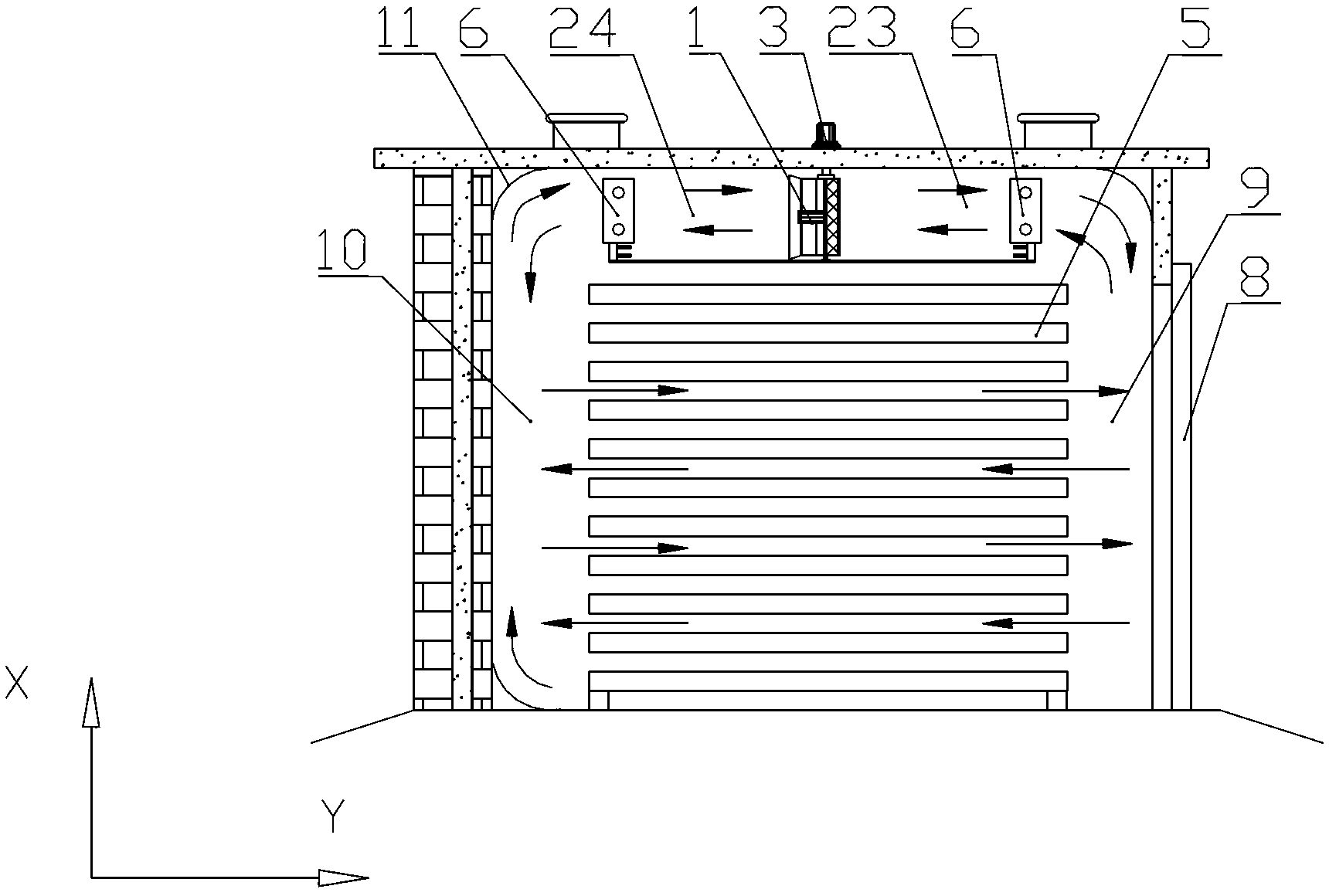

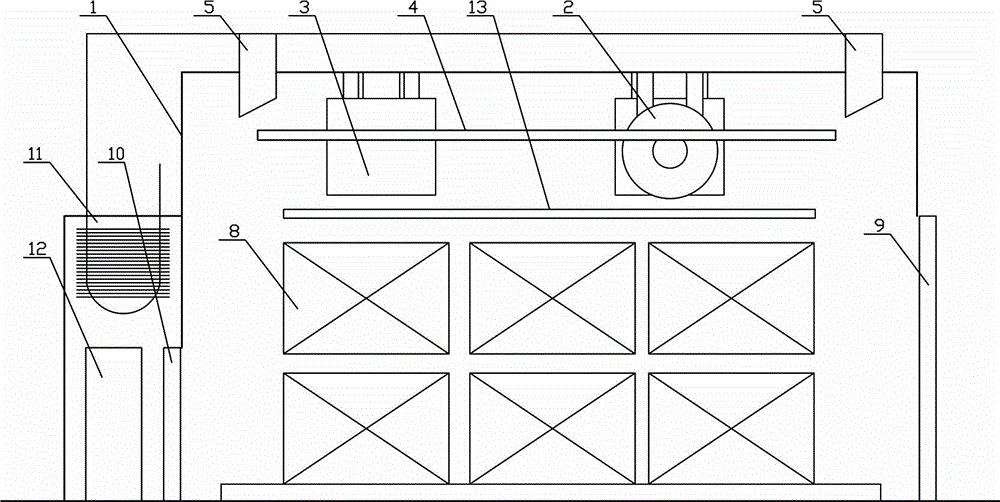

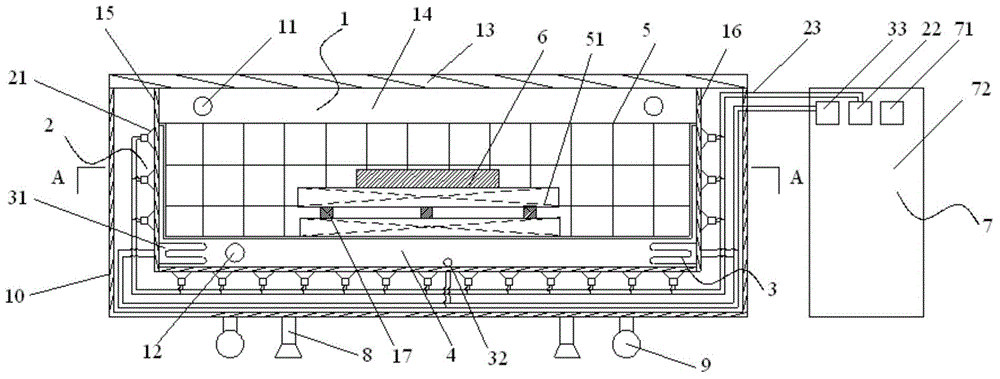

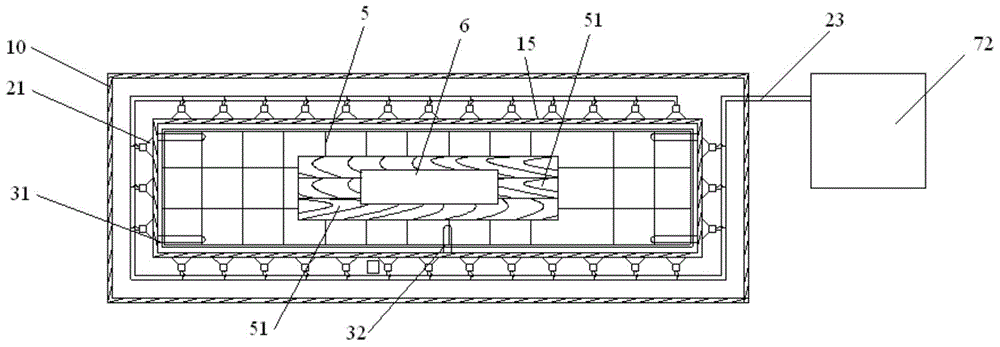

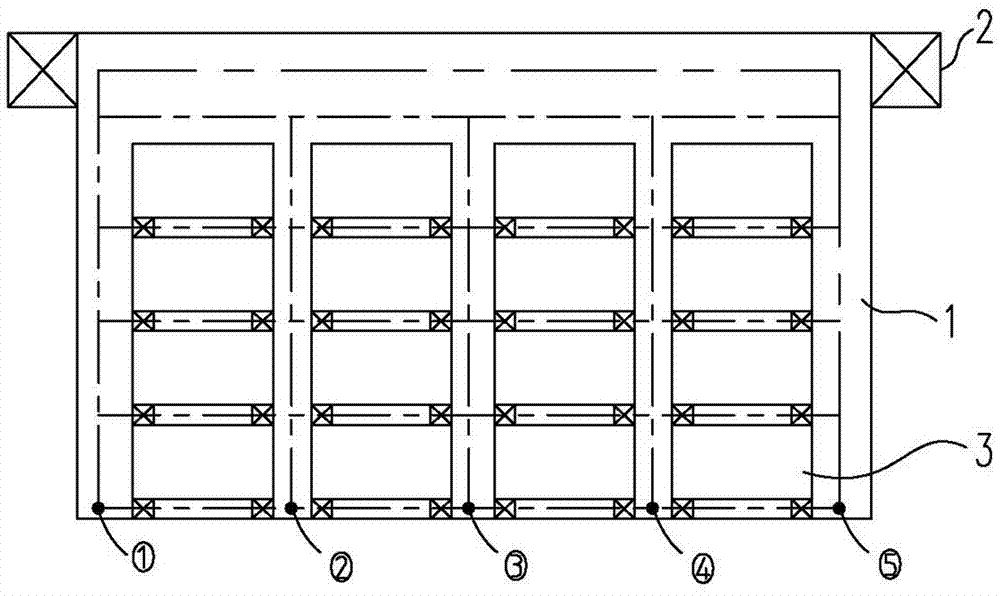

Lumber drying kiln

ActiveCN104964527AUniform temperatureReduce energy consumptionDrying gas arrangementsDrying chambers/containersEngineeringProcess engineering

A lumber drying kiln comprises a kiln body which is provided with a main kiln door. The kiln body is internally provided with at least one set of air feeding device and heating device. A plurality of exhausting devices are arranged in the kiln body. A temperature and humidity detecting device and a moisture content detecting device are arranged in the kiln body. According to the lumber drying kiln, the temperature in the kiln is even by means of the air feeding and heating mode, a steam spraying pipe is matched, the temperature and humidity in the kiln are easy to adjust and control, the energy utilization rate is high, and the energy conservation effect is good; an air speed field, a temperature field and a humidity field are uniform in distribution, and the drying uniformity is good; the drying efficiency is high, and the comprehensive technological economic performance is good. After the lumber drying kiln is adopted, the drying cycle is shortened by 33%, color changing, decaying and worm damage are zero, internal cracking is zero, end cracking and surface cracking is 0.6%, deformation is also greatly relieved, and the internal stress is fully eliminated.

Owner:宜昌金宝乐器制造有限公司

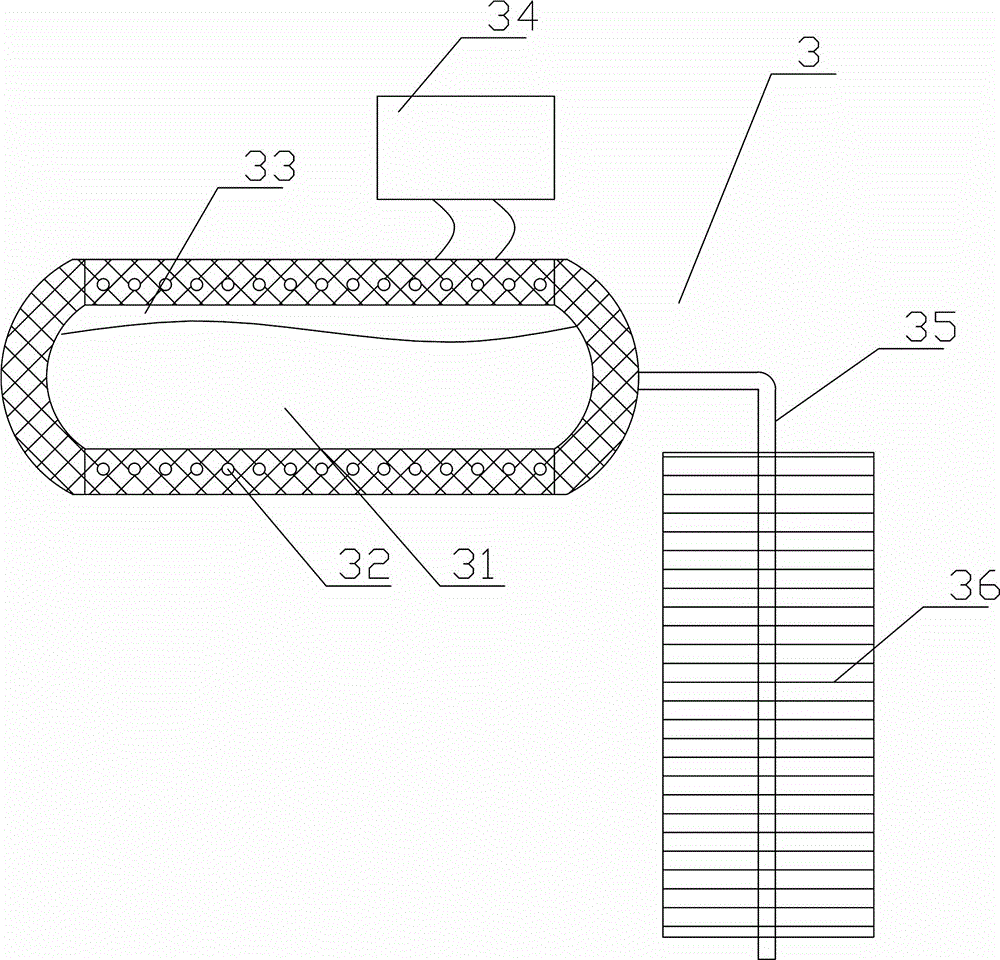

Treatment device for increasing drying rate of timber and method for drying timber by utilizing processing device

ActiveCN104422248AImprove breathabilityInternal moisture moves fastPreliminary solid treatment for dryingWater channelControl system

The invention discloses a pretreatment device and a treatment method for increasing a drying rate of timber. The device comprises a timber treatment chamber having a cavity, an ultrasonic treatment system and a temperature system. The method is characterized in that timber to be dried is pretreated ultrasonically, so that extracts inside the timber can be separated through a solution, a pit membrane and partial thin-wall tissues inside the timber are broken, the permeability of the timber is improved, water channels inside the timber are gotten through, the drying quality of the timber is improved, the drying defect in the drying process is reduced, and the drying period is shortened; moreover, the pretreatment device is simple and convenient to operate, the treatment process condition (ultrasonic power, frequency and time) is controllable, and the pretreatment device and the treatment method are suitable for treating various kinds of timber.

Owner:BEIJING FORESTRY UNIVERSITY

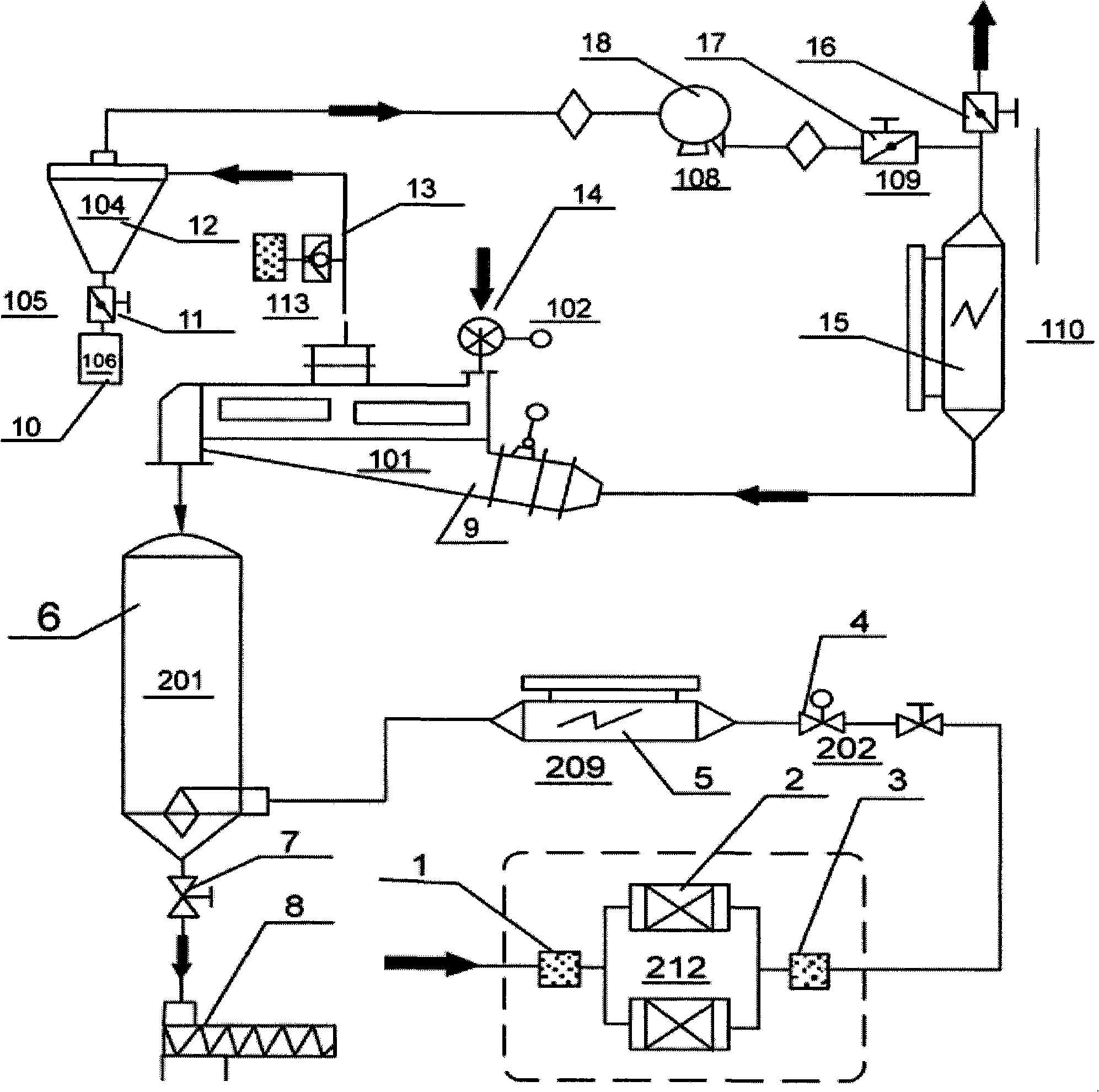

Continuous drier suitable for low-melting point chip and use method thereof

InactiveCN101270956ANo slice dwell time differenceNo blocking phenomenonDrying solid materials with heatDrying gas arrangementsMolecular sieveAir filter

The invention discloses a continuous dryer applicable for low melting point slices and the usage of the dryer. The dryer is characterized in that the dryer consists of a compressed air dryer, a molecular sieve drying device, a reducing valve, a dry heater, an inverse column stream mode drying tower, a gate valve, a screw extruder, a pulsed-bed crystallizer (pre-crystallizer), a dust trolley, a butterfly valve, a dust separator, an air filter, a rotary valve, a crystallization heater, a crystallization fan subsidiary pipeline systems. The usage of the continuous dryer has the characteristics that the drying capacity of the system is controlled between 50 to 1800KG / H; the water ratio of the wet slices is controlled equal to or less than 0.5 percent; the water ratio of the dry slices is controlled equal to or less than 0.002 percent (i.e., 20ppm); the duration of the feeding and discharging the slice materials (i.e., the drying duration) is controlled within 2 hours. The invention is especially applicable to low melting point PET slices.

Owner:张家港保税区万盛机械工业有限公司

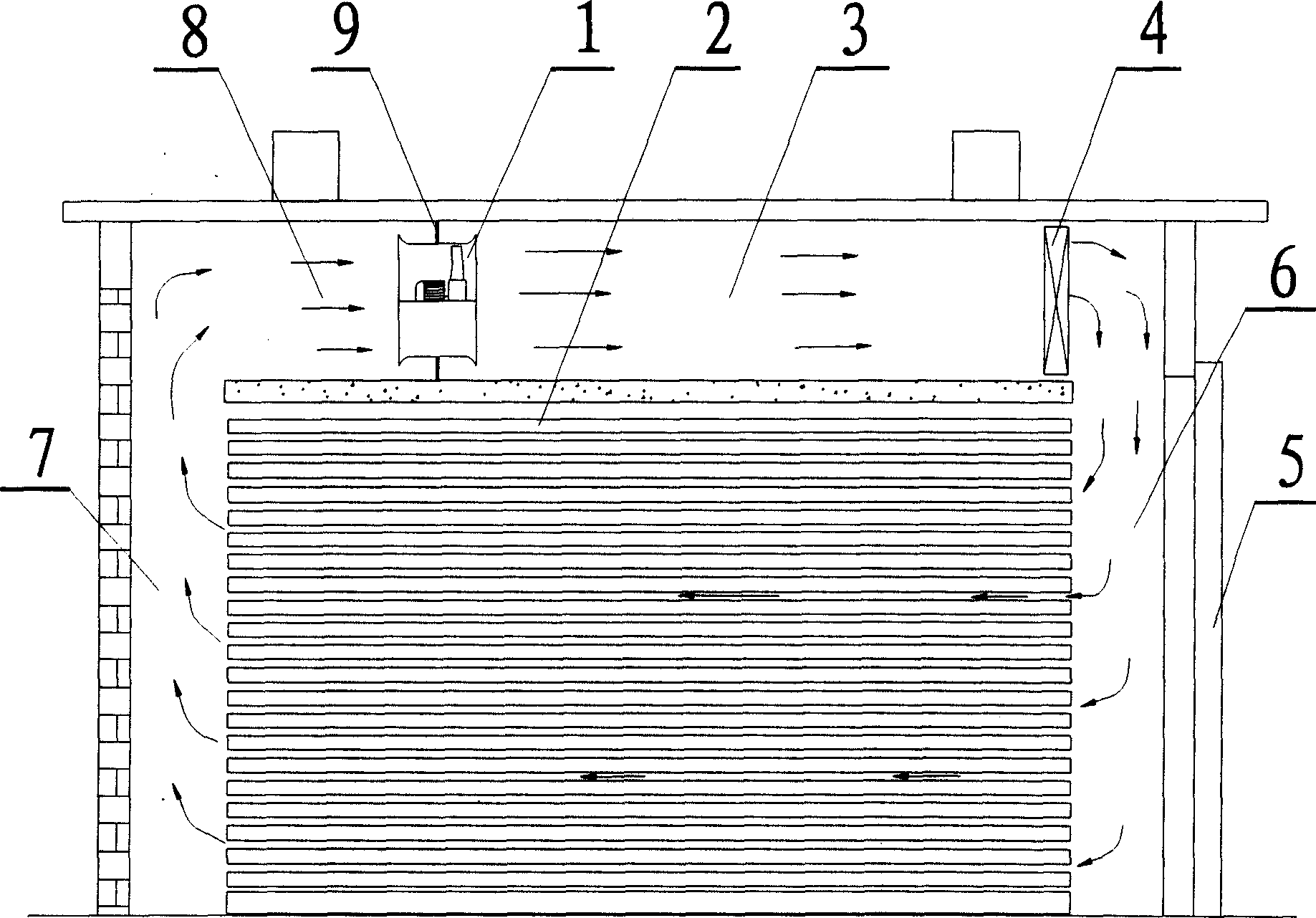

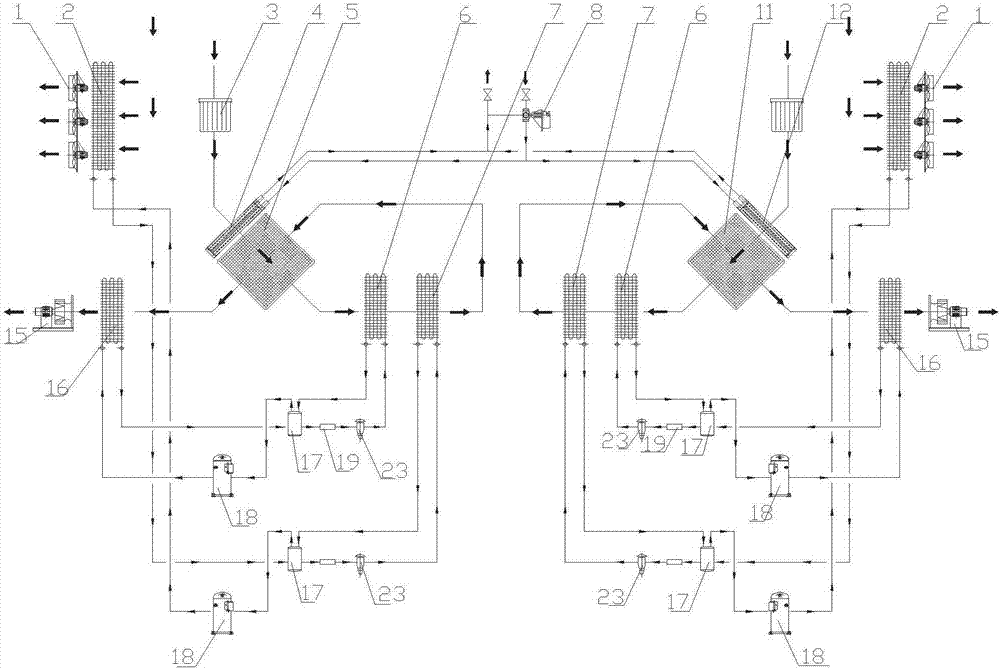

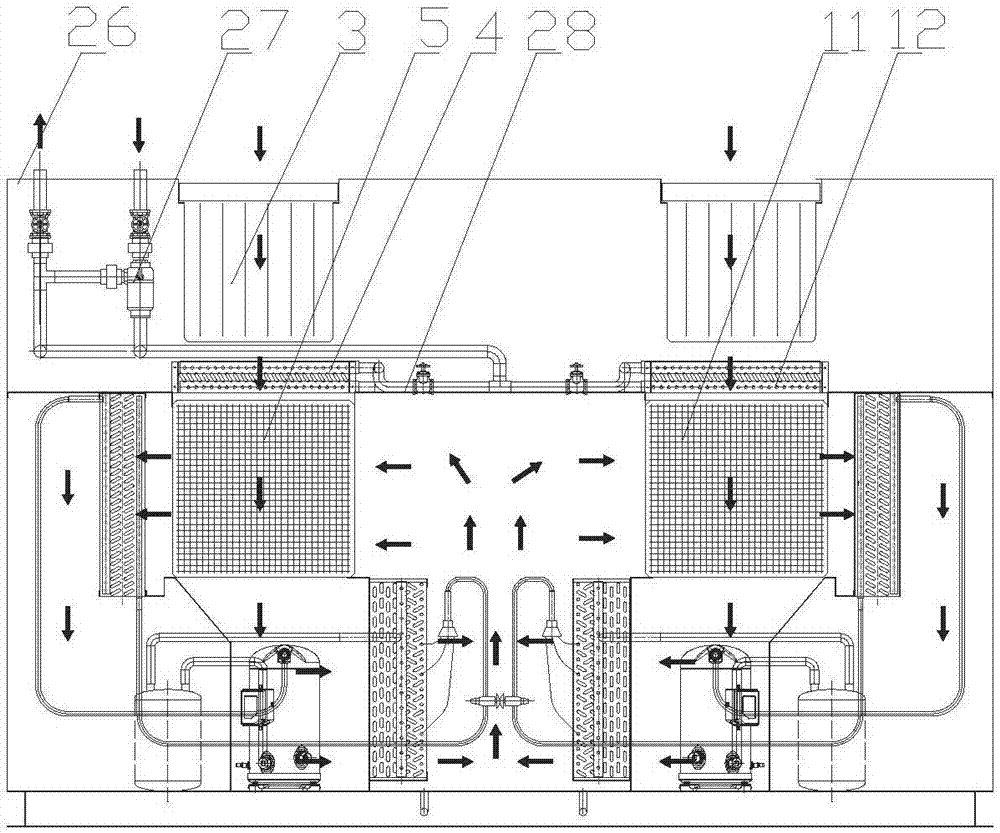

Controllable guided air supply system for drying houses

InactiveCN1670456AMeet the requirements of drying processLower the altitudeDrying gas arrangementsElectricityPulp and paper industry

This invention discloses an adjustable guide air supply system of drying chamber. Its feature is that guider air supplier is fixed at uptake of fan, specific change size shell of circle to rectangle is on the supplier, and adjustable diversion hyoplastron is fixed in it. Diversion bent plate is set lateral wall nook of drying chamber top part, smooth and fluent controlled additional air current is formed by it coordinated with guide sir supplier. The utility effect is that the adjustable diversion hyoplastron can adjust velocity, direction and flux of the drying air current to make it accordance with request of drying technique, so drying quality is improved. Smooth and fluent controlled additional air current is formed by diversion bent plate coordinated with guide sir supplier to reduce air supply resistance, improve air supply quality, shorten drying period and improve efficiency. Air supply suspended ceiling, air return suspended ceiling and aluminum separator between fans in existing drying chamber can be removed, so it can decrease the chamber height, saving initial cost. High efficiency environmental protection type fan is used in this invention, so noise pollution can be reduced, electricity consumption can be reduced, and dry cost also can be reduced.

Owner:SHANGHAI UNIV OF ENG SCI

Safe and energy-saving microwave vacuum continuous automatic drier

InactiveCN1908561AImprove efficiencySlow heatingDrying solid materials with heatHearth type furnacesMetallic materialsToughness

The present invention mainly relates to a microwave drier, especially a microwave vacuum drier. A safe and energy-saving microwave vacuum continuous automatic drier includes a tank (A), a hoisting system (8), a vacuum system (9), a microwave heating system (1) on the tank (A), characterized by including a delivery device (6) inside the tank (A), a discharging device (5) below the delivery device (6), the materials in the tank (A) are non-metallic materials. On the basis of ensuring the strength and the toughness, the striking a light and discharging are avoided in the vacuum state when metal is heated in the microwave. The invention adopts the way of microwave radiation heating, utilizing the characters of microwave high efficiency, easy to control, antisepsis, sterilization, fast heating, even heating, fast dehydration, preserving to reduce the power waster and advance the efficiency.

Owner:TIANSHUI HUAYUAN PHARMA EQUIP TECH

Drying method for teflon dispersed resin

ActiveCN101000208ASolve the problem of long drying cycleLow costDrying using combination processesDrying solid materials with heatPulp and paper industryDrying time

The invention relates to polytetrafluoroethylene dispersion resin drying method. Its features are that it adopts new type vacuum drier, introduce negative pressure induced draught fan to switch with the vacuum drier to change the negative pressure state in the drying system, takes out dried hot blast at the same time. This method can effectively control the drying time in 12-18 hours for the resin. Thus the production efficiency can be greatly improved. It has the advantages of short drying cycle, non expendable byproduct, saving cost, environmental protection.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for processing marinated fruits and vegetables

ActiveCN103637134AImprove penetration efficiencyReduce salinityFood dryingFood ultrasonic treatmentBiotechnologyBiology

The invention discloses a method for processing marinated fruits and vegetables. The method comprises the following steps: selecting, cleaning, drying and cutting marinating raw materials, adding edible salt and pure water, and marinating the raw materials by virtue of three-frequency ultrasonic assistance to obtain marinated fruits and vegetables, wherein the three-frequency ultrasonic assistance is specifically as follows: the upper marinating layer is 20-30KHz, the middle marinating layer is 90-100KHz, and the lower marinating layer is 50-60KHz, namely the upper layer is 10-30cm deep, the middle layer is 30-80cm deep, and the lower layer is 80-100cm deep; taking out marinated fruit and vegetable embryos and centrifugally removing water; putting the marinated fruit and vegetable embryos into a cylinder to implement natural fermentation so as to obtain fermented marinated fruit and vegetable products; performing seasoning preparation, microwave drying and packaging. According to the method disclosed by the invention, the marinated fruits and vegetables are processed by a three-frequency ultrasonic assistance marinating technology and a microwave drying technology; compared with the prior art, the method has the advantages that the salinity of a product is reduced, the production efficiency is improved, the production period is shortened, and the product quality is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

Agricultural and sideline product drying room and assembling method thereof

InactiveCN104675157APrevent leakageImprove installation accuracyAgricultural buildingsDrying solid materialsElectricityFiber

The invention discloses an agricultural and sideline product drying room and an assembling method thereof. The room is characterized by comprising a room body, a multi-layer goods shelf, a dehumidification curtain device and a heat supply and temperature adjustment device; the room body is hexahedral in appearance and comprises a plurality of assembled movable heat insulation wall boards; the dehumidification curtain device is in a hung curtain state, is made of dehumidification fibers and is hung on the inner sides of the heat insulation wall boards; the heat supply and temperature adjustment device is free of power consumption and adopts a solar water heater adopting water as heat conducting medium or a straw burning boiler as the heat source and comprises a heat radiator and a water pipe in an assembled manner. The room is of agricultural and sideline product intensive-processing drying equipment applied to countries lack of power, the address selection is flexible, assembling is facilitated, transportation capacity is saved, freshness can be reserved, dehumidification is performed scientifically, power is saved efficiently, and cost is lowered.

Owner:广东热带林环保木业科技有限公司

Temperature-adjustable four-effect drying system

ActiveCN107014198AShorten drying cycleAvoid it happening againSludge treatment by de-watering/drying/thickeningHeat recovery systemsSludgePulp and paper industry

The invention discloses a temperature-adjustable four-effect drying system. The temperature-adjustable four-effect drying system of an automatic temperature constant dehumidifying device comprises at least two dehumidifying heat pump assemblies and an auxiliary heat exchange assembly. Each dehumidifying heat pump assembly comprises at least one refrigerant module and an air module. The auxiliary heat exchange assembly is formed by connecting two heat exchangers in series through a circular pipeline. A refrigerant inlet and a refrigerant outlet are formed in the circular pipeline. The system has the following advantages that the dehumidifying amount can be increased by 10% or above, the closed drying process can be achieved, no peculiar smell is emitted in the sludge drying process, a deodorization device does not need to be mounted, the circular air amount and the dehumidifying air amount are designed separately, the sludge drying cycle can be shortened, dust caused by sludge drying is prevented, the structure design requirement of a sludge drying model can be met, meanwhile, the structure size of dehumidifying heat pump main bodies can be reduced, and the system is compact in structure and small in occupied area and maintaining space.

Owner:石曾矿

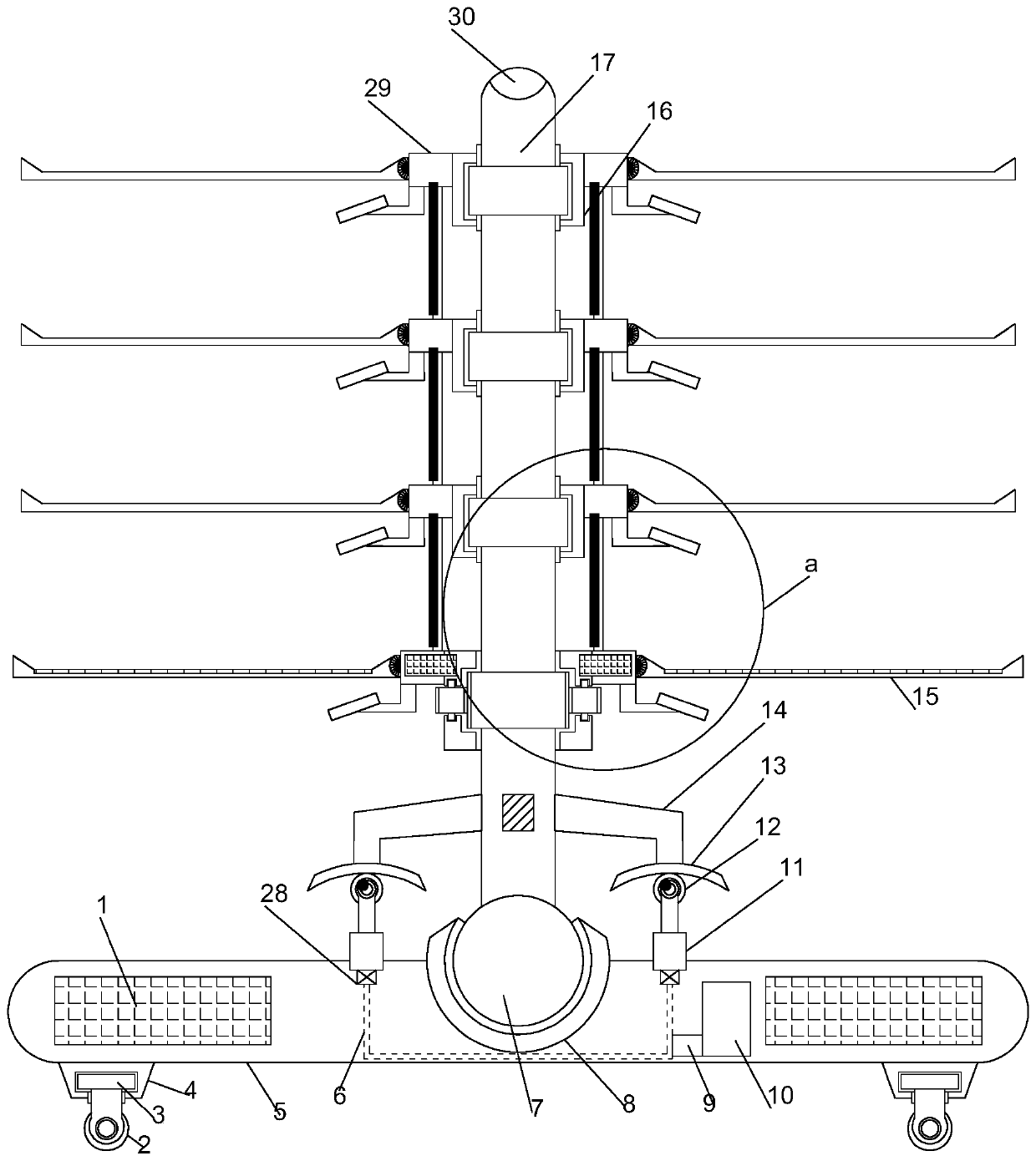

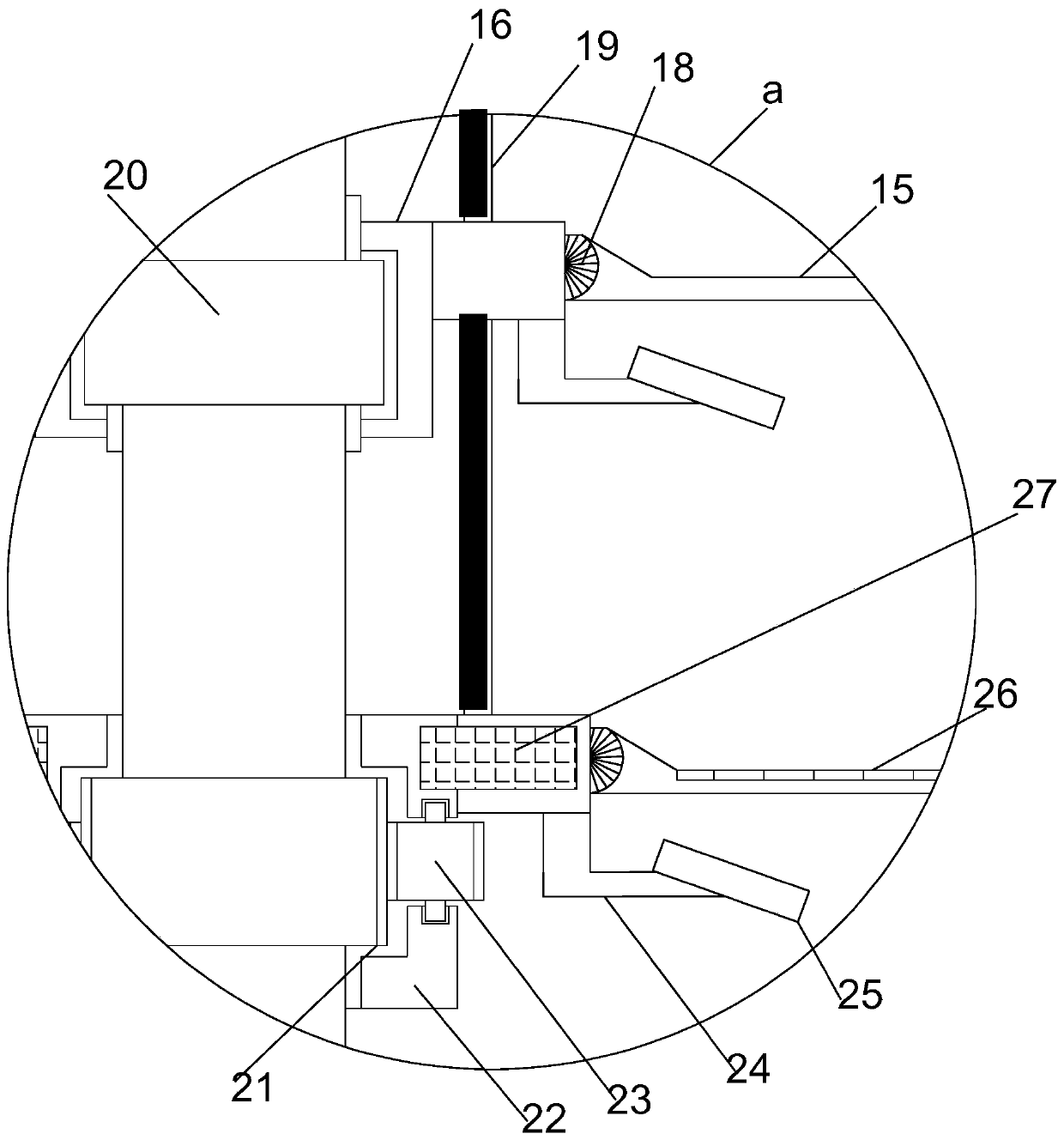

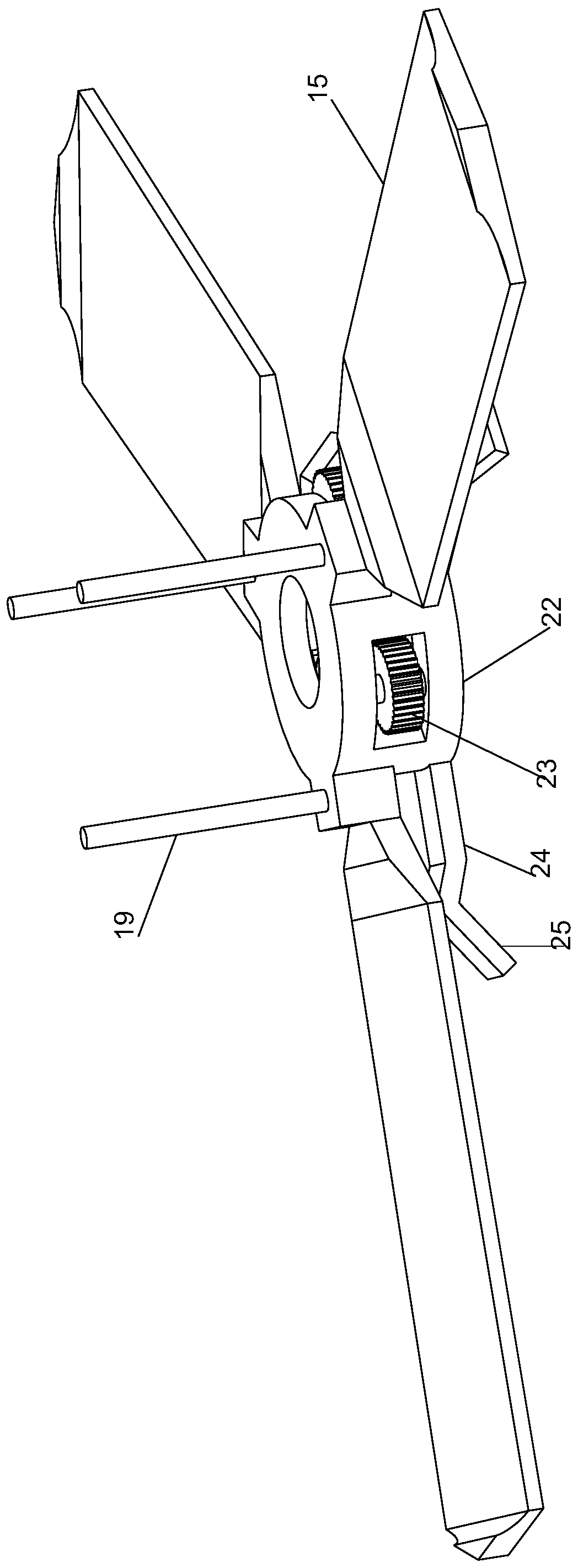

Airing device for medicinal material planting

ActiveCN110089279AImprove dehydration efficiencyImprove space utilizationAgriculture tools and machinesHarvested fruit hanging devicesPulp and paper industrySolar cell

The invention relates to the field of traditional Chinese medicine planting, in particular to an airing device for medicinal material planting. The airing device for medicinal material planting comprises a horizontally-arranged movable installing plate, multiple supporting installing cylinders are arranged at the lower end of the movable installing plate at equal angle, steering installing columnsare arranged on the supporting installing cylinders downwards, movable guiding wheels are arranged at the lower ends of the steering installing columns through rotating shafts, a swinging installingcolumn is vertically arranged over the movable installing plate, and a swinging ball shaft is arranged at the lower end of the swinging installing column. Energy is absorbed through solar cell panelsduring leisure and converted into electrical energy for storage, and in cooperation with an air structure which is rotatable and staggered, the space using rate is high, an illumination effect is good, swinging adjustment is actively conducted, and the illumination effect is further improved; in order to increase the air speed, the device is rotated, the flowing speed of air on the surfaces of medicinal materials is increased, the dehydration efficiency of the medicinal materials is remarkably improved, and the airing period is shortened.

Owner:安徽尚绿精谷网络科技有限公司

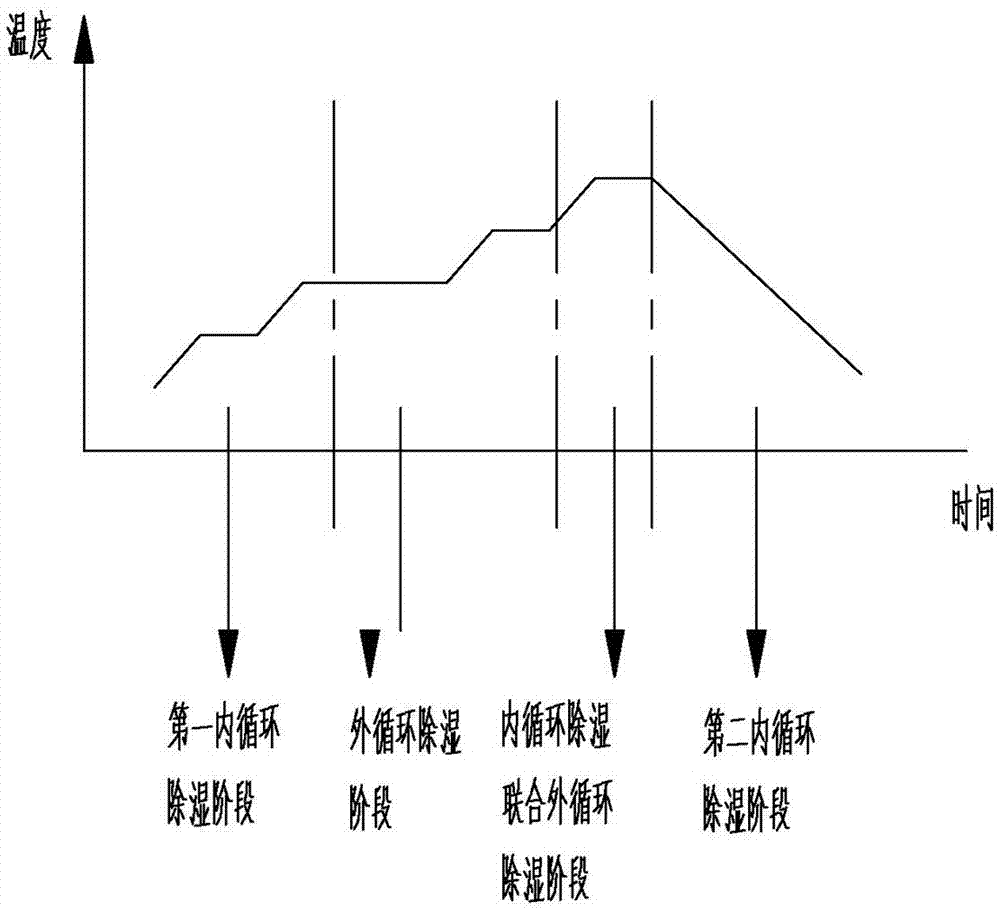

Active wood drying method

ActiveCN106871593AEfficient dryingOvercoming drynessDrying gas arrangementsDrying machines with local agitationPulp and paper industryWood drying

The application discloses an active wood drying method. The dehumidification method includes an internal circulation dehumidification method. A dehumidification point is arranged along an airflow internal circulation path. Wet media are received on the above dehumidification point, and dry media are discharged. The shrinking, crack and deformation of the dried wood are reduced obviously, and the wood maintains the original color. The active wood drying method is especially applied to drying of poplar wood, eucalyptus wood and impregnating modified wood. The active wood drying method has the advantages of high drying efficiency, low energy consumption and high drying quality. The technical problems that the eucalyptus wood and the poplar wood are easy to shrink, deform or crack in drying are solved.

Owner:杭州临安宇凯木制品有限公司

Nutritive fruit granule lotus root starch and preparation method thereof

InactiveCN107048268AShorten drying cycleReduce energy consumptionFood shapingFood dryingFlavorDried fruit

The invention relates to nutritive fruit granule lotus root starch and a preparation method thereof, and belongs to the technical field of food processing. The nutritive fruit granule lotus root starch comprises the following raw materials in parts by mass: 80-100 parts of lotus root starch, 15-30 parts of five-cereal powder, 25-35 parts of dried fruits and vegetables, 20-30 parts of nuts and 9-12 parts of white granulated sugar. A main preparation method of the nutritive fruit granule lotus root starch mainly comprises the following steps of preparing lotus root starch, performing low-temperature baking on the five-cereal powder, performing microwave vacuum drying on the nuts, performing temperature-change pressure difference puffing so as to prepare puffed fruits and vegetables, uniformly mixing fruit and vegetable granules and the nuts with the lotus root starch, the five-cereal submicron powder and the white granulated sugar in a certain proportion, performing packaging and performing sterilization so as to prepare the fruit granule lotus root starch. The fruit granule lotus root starch made by the preparation method disclosed by the invention reserves original flavor and nutrient substances of the raw materials, is comprehensive in nutrient components, is free from any additives, and more meets requirements of healthy foods, and the mouth feel of the nutritive fruit granule lotus root starch is better than that of conventional lotus root starch.

Owner:HANGZHOU EFUTON TEA

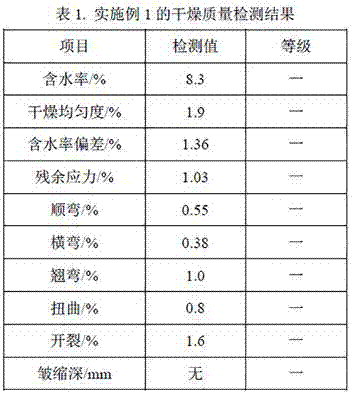

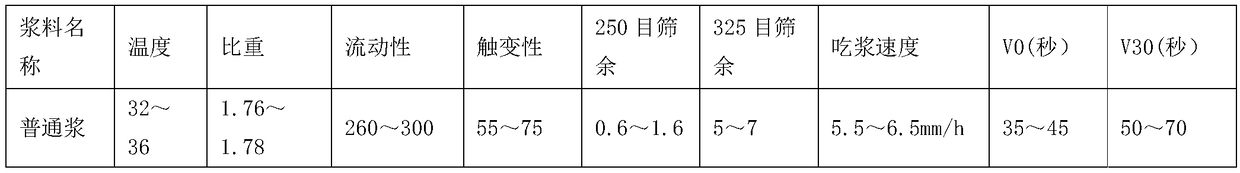

Rapid sanitary appliance production method

ActiveCN108892474AShorten drying cycleIncrease productivityCeramic shaping apparatusCeramic materials productionMicrowaveSlurry

The invention discloses a rapid sanitary appliance production method which includes the steps: grouting and forming: pouring slurry into a mold, demolding to form a sanitary appliance mud blank; microwave drying: conveying the sanitary appliance mud blank into a microwave drying oven to dry the mud blank for 3-6 hours. Microwave drying stages sequentially include a slow drying stage, an accelerated drying stage, a rapid drying stage and a cooling stage. The sanitary appliance mud blank is dried by the aid of a microwave drying mode, a drying period is controlled within the range from 3 hours to 6 hours and reduced to a large extent, and the production efficiency is improved. The method adopts four microwave drying stages, so that the sanitary appliance mud blank is slowly dried, dried in an accelerated manner, rapidly dried and cooled, and the drying qualification rate of sanitary appliances is effectively increased and reaches 97%.

Owner:FOSHAN DONGPENG SANITARY WARE +2

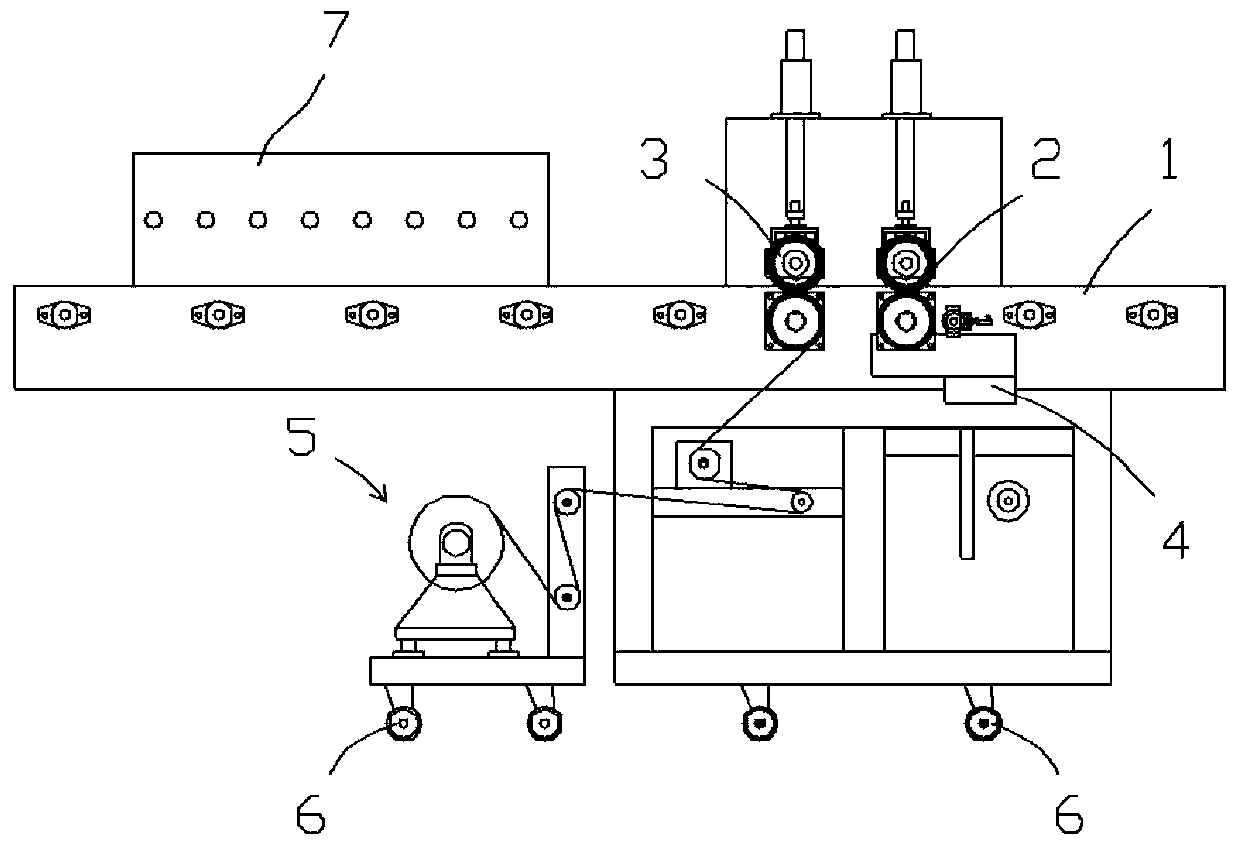

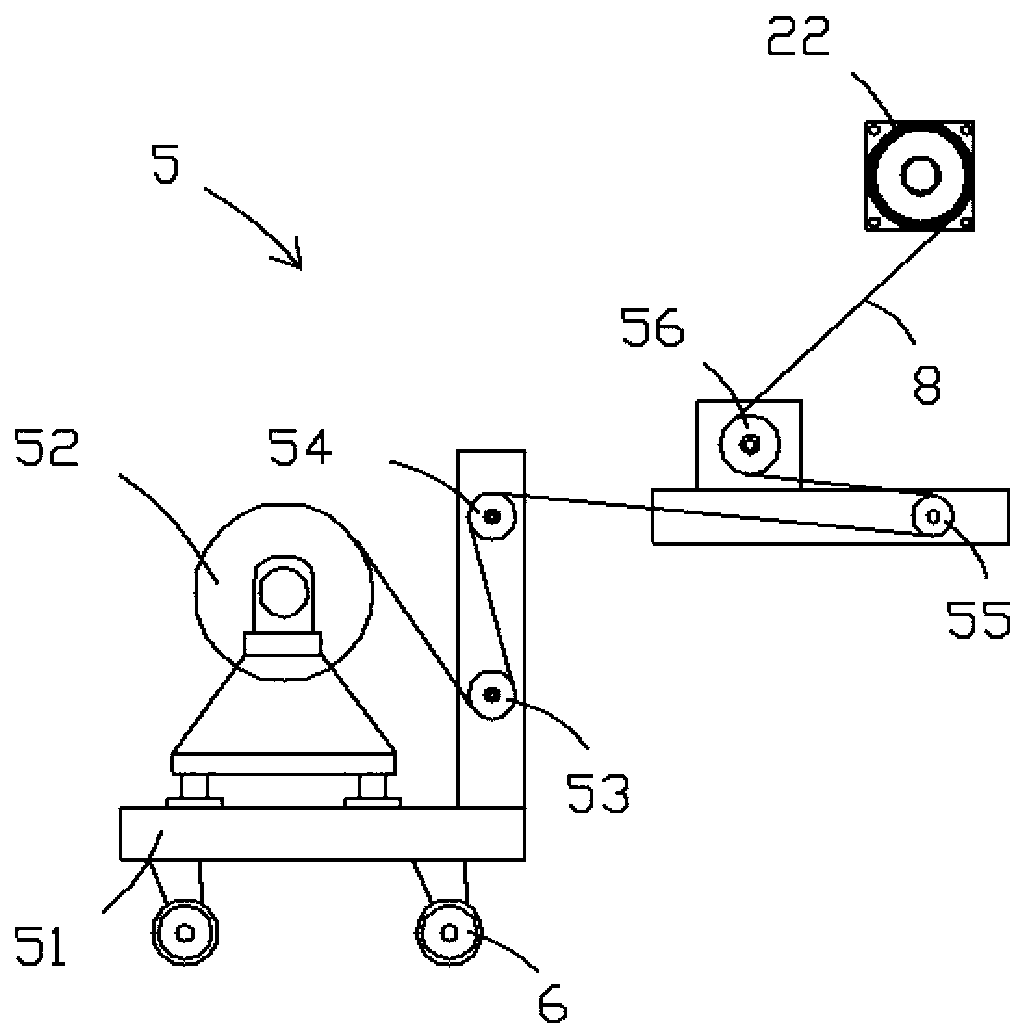

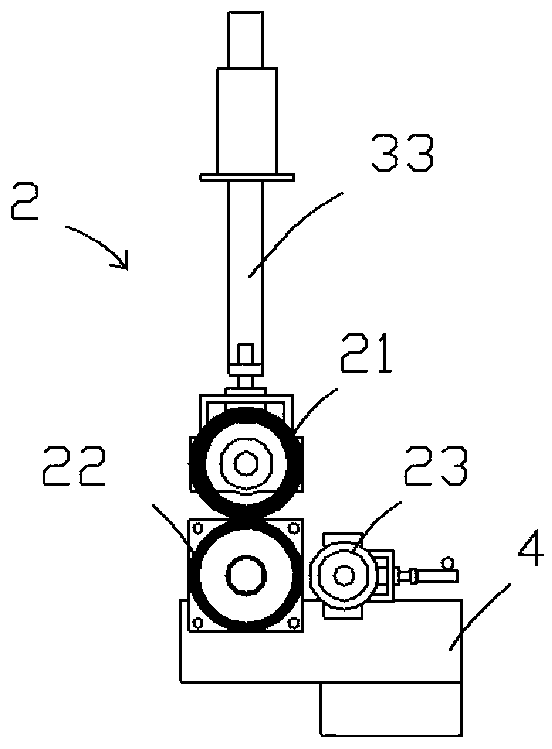

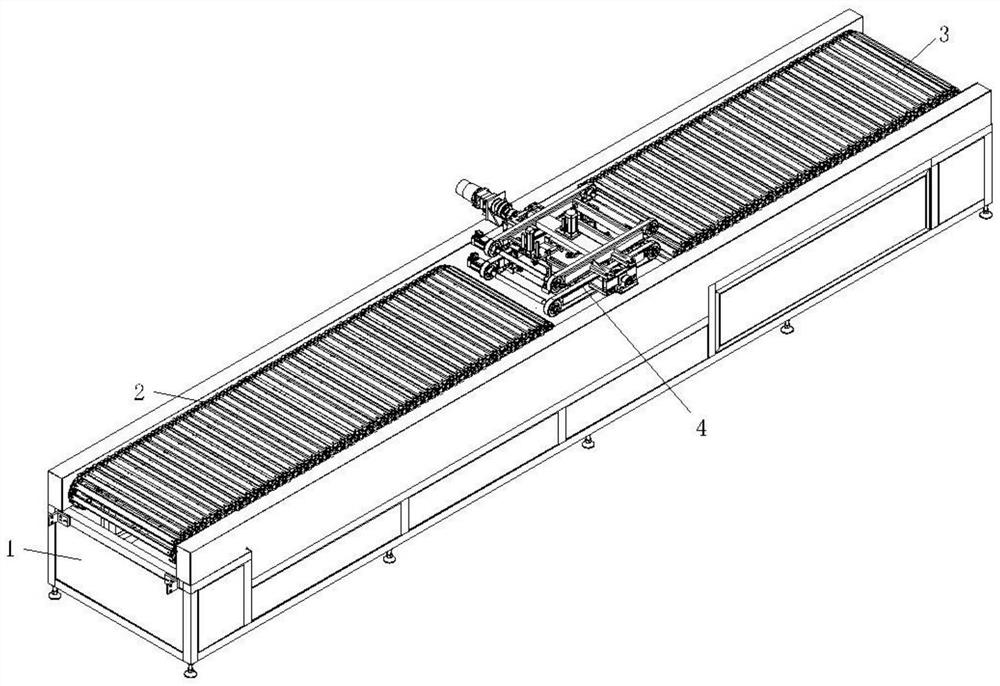

Film-covering liquid-coating extrusion integrated lining machine

InactiveCN103273723AHigh strengthImprove antiknock performanceLamination ancillary operationsLaminationElectric machineryEngineering

The invention discloses a film-covering liquid-coating extrusion integrated lining machine. The film-covering liquid-coating extrusion integrated lining machine comprises a frame (1), the frame (1) is provided with a rotary roller for conveying a work-piece, the rotary roller is driven by a motor, the frame (1) is provided with a pair of winding rollers (3) and a pair of liquid-coating rollers (2), the position on the frame (1) on the work-piece output end is provided with a UV photosensitive drying channel (7), the frame (1) below the liquid-coating roller (2) is provided with a liquid-coating box (4), the lower part of the liquid-masking roller (2) is positioned in the liquid-masking box (4). The application of the lining machine is wide and people can use the lining machine during short break in working time.

Owner:苏州威仕薄膜科技有限公司

Hot-pressing drying method of cryptomeria fortunei wood

InactiveCN108344257AReduce inner fissureInternal fissure realizationWood treatment detailsDrying solid materialsPulp and paper industryMechanical property

The invention relates to the field of wood processing, in particular to a hot-pressing drying method of cryptomeria fortunei wood. The hot-pressing drying method comprises the specific steps that thewater content of the cryptomeria fortunei wood is adjusted, and the processes of hot plate closed heating, hot plate opening, aftertreatment and the like are carried out. According to the hot-pressingdrying method, the wood can be dried to the required water content within short time, meanwhile, the cryptomeria fortunei wood can be compressed to a certain degree, the mechanical property of the cryptomeria fortunei wood is effectively improved, a processing technology is simple and feasible, the processing period is short, and operation is convenient; drying and enhancing of the cryptomeria fortunei wood are achieved at the same time, the problems of the low mechanical strength, drying and the like about the cryptomeria fortunei wood are solved, and the application of the cryptomeria fortunei wood is widened; and the cryptomeria fortunei wood can be used for the fields of furniture manufacturing, interior decoration and the like.

Owner:SICHUAN AGRI UNIV

Processing method of low-sugar candied blueberries

InactiveCN107410629AIncrease osmotic sugarImprove drying efficiencyConfectionerySweetmeatsSugar candyCarbon dioxide

The invention discloses a processing method of low-sugar candied blueberries. The processing method comprises the steps of performing cleaning, performing treatment with carbon dioxide, performing color protection, performing pulsed vacuum sugar permeability, performing drying and performing packaging. According to the processing method disclosed by the invention, a carbon dioxide treatment technique and a pulsed vacuum sugar permeability technique are adopted, so that the sugar permeability and drying cycle of blueberries can be significantly shortened, and effective components of anthocyan and the like in the blueberries can be well reserved; and the obtained blueberries are full in shape, fresh bright in color and pure in mouth feel, and requirements of consumers for diversified, novel and healthy candied blueberries can be met.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

PCB tunnel drying device

InactiveCN112595080ARealize automatic flipSave time in transitDrying machines with progressive movementsDrying solid materialsClassical mechanicsEngineering

The invention discloses a PCB tunnel drying device. The PCB tunnel drying device comprises a base, a first electric conveying belt, a second electric conveying belt, a turnover mechanism, a feeding mechanism, a tunnel drying box, a first electric gate, an infrared grating, a cooling device and a second electric gate plate. The first electric conveying belt is arranged on the front side of the topend of the inner side of the base in the front-back direction. The second electric conveying belt is arranged on the rear side of the top end of the inner side of the base in the front-back direction.The turnover mechanism is arranged in an inner cavity of the base and located on the inner side of the first electric conveying belt and the inner side of the second electric conveying belt. The feeding mechanism is arranged on the front side of the base. According to the PCB tunnel drying device, integrated operation of feeding, drying and cooling of PCBs can be achieved, manual operation itemsof workers and transfer time between different devices are reduced, automatic overturning of the circuit boards during tunnel drying can be achieved, the workers do not need to manually turn over thecircuit boards for secondary drying, the drying period is shortened, and the machining efficiency is improved.

Owner:董立喜

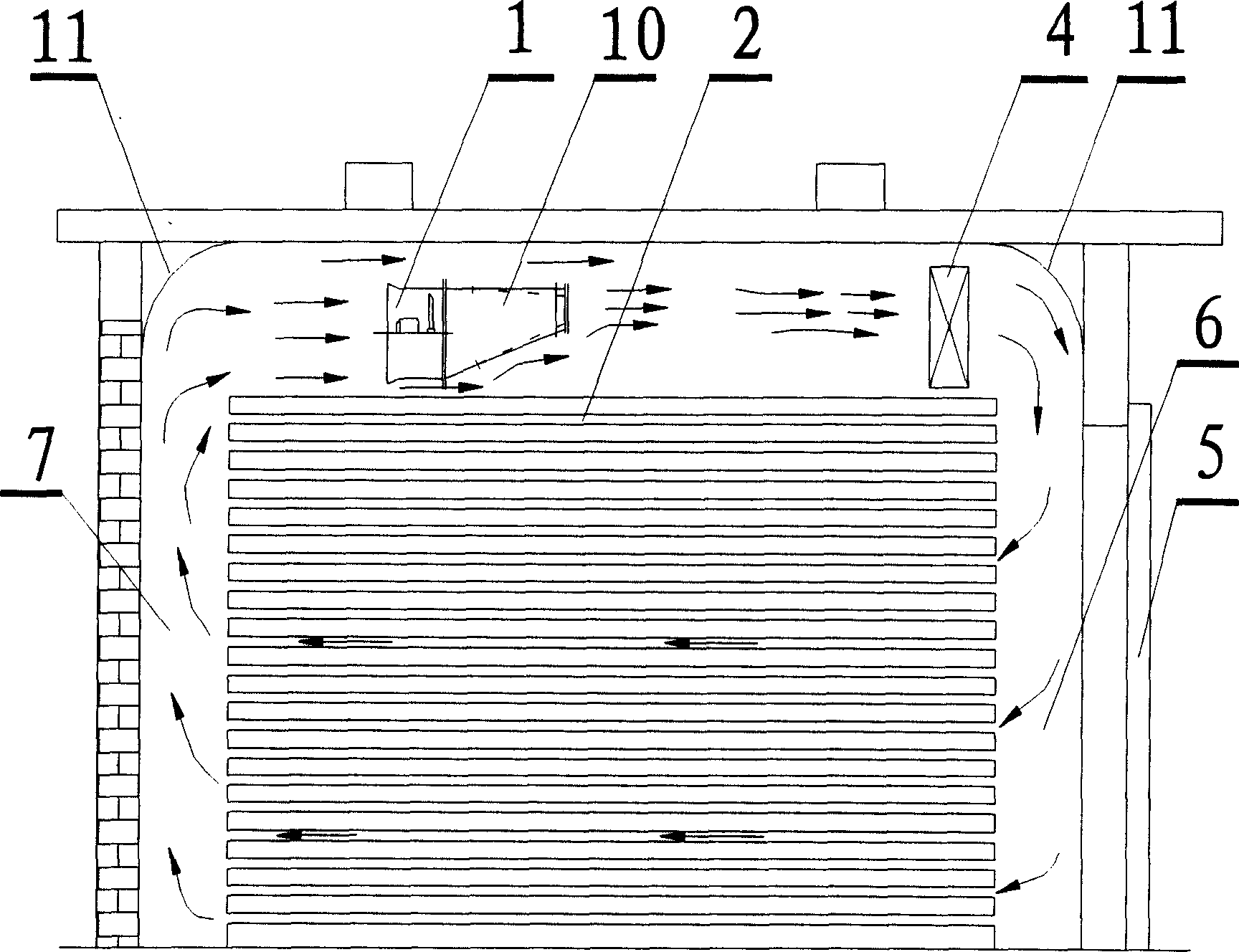

Active wood drying device

PendingCN106871594AImprove drying efficiencyShorten drying cycleDrying gas arrangementsDrying machines with local agitationProcess engineeringKiln

The application discloses an active wood drying device comprising a kiln body, a fan and a heating device, wherein the top of the kiln body is provided with a passive dehumidification device; the active wood drying device also comprises an active dehumidification device which at least comprises an active dehumidification part arranged in the kiln body. The drying efficiency can be improved greatly, the drying cycle is shortened, and the drying energy consumption is reduced.

Owner:清远市慧邦木业科技有限公司

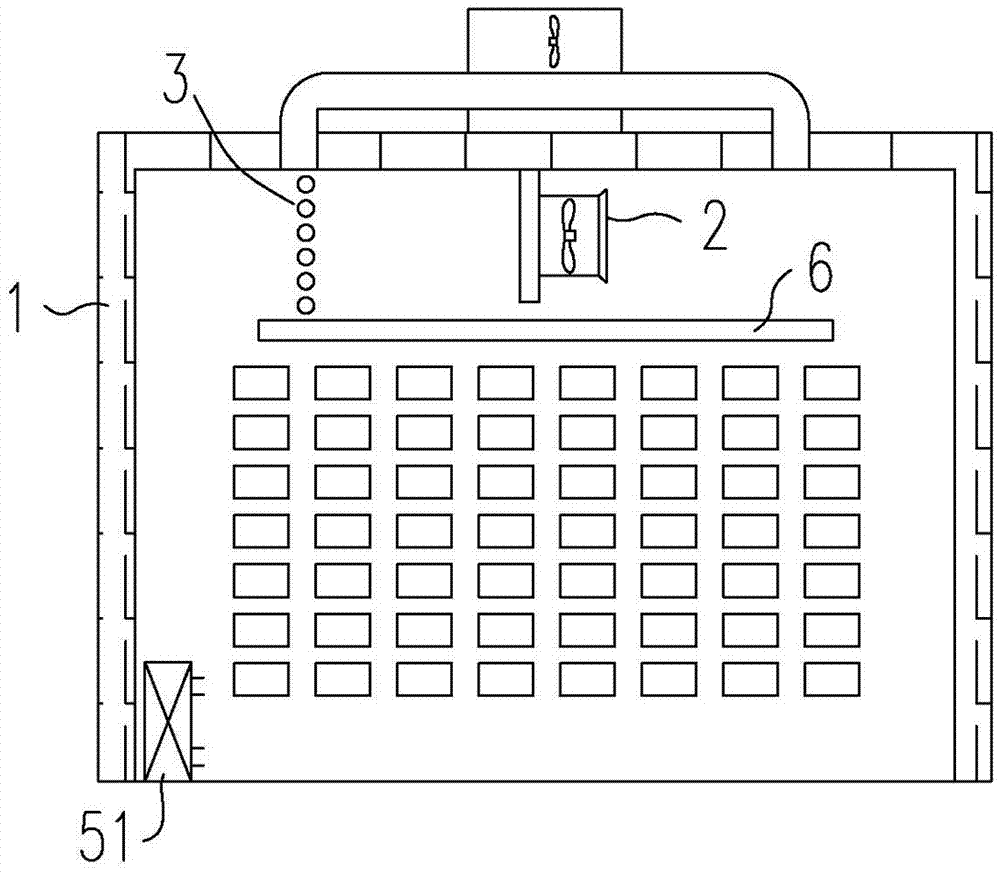

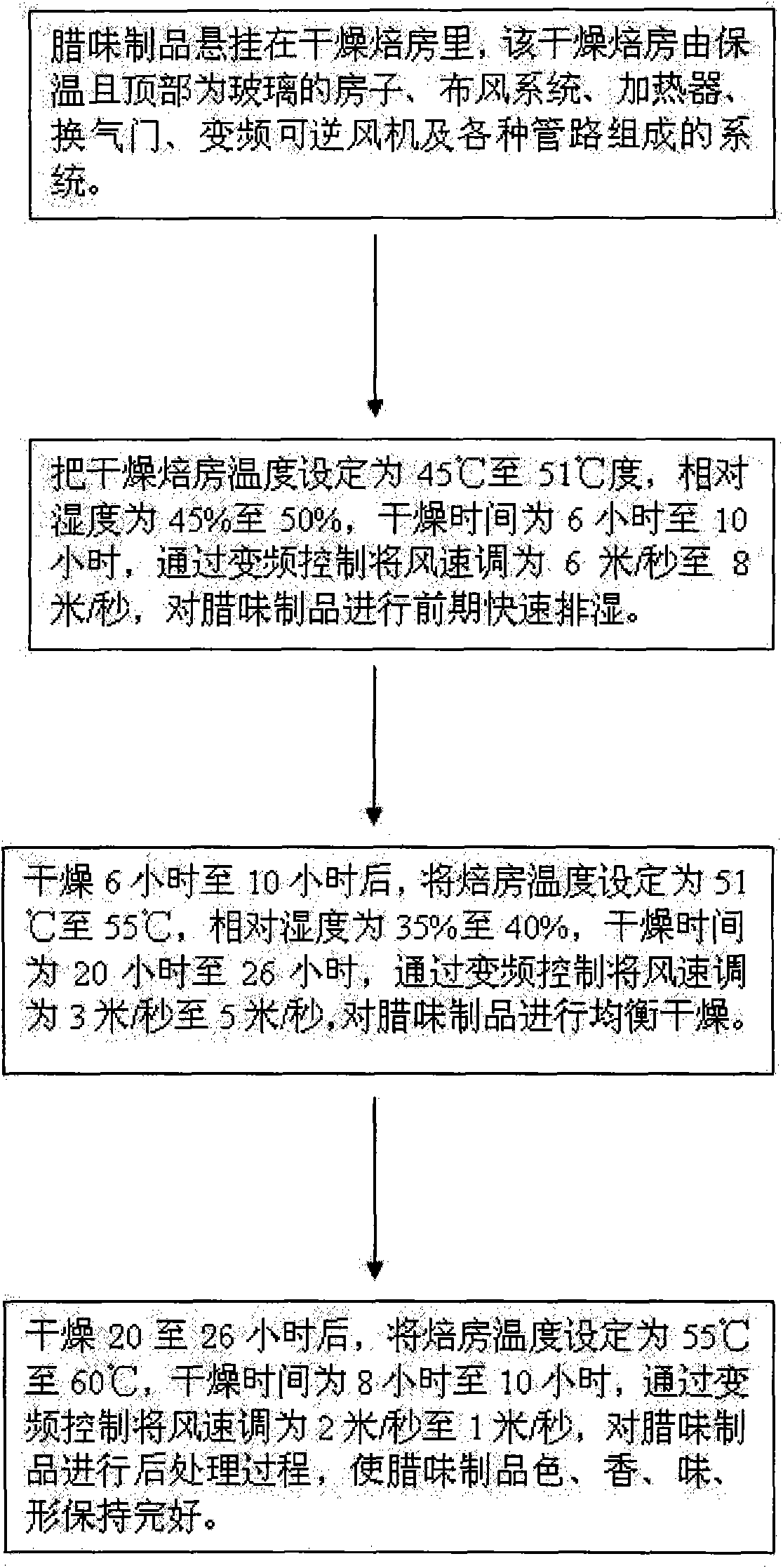

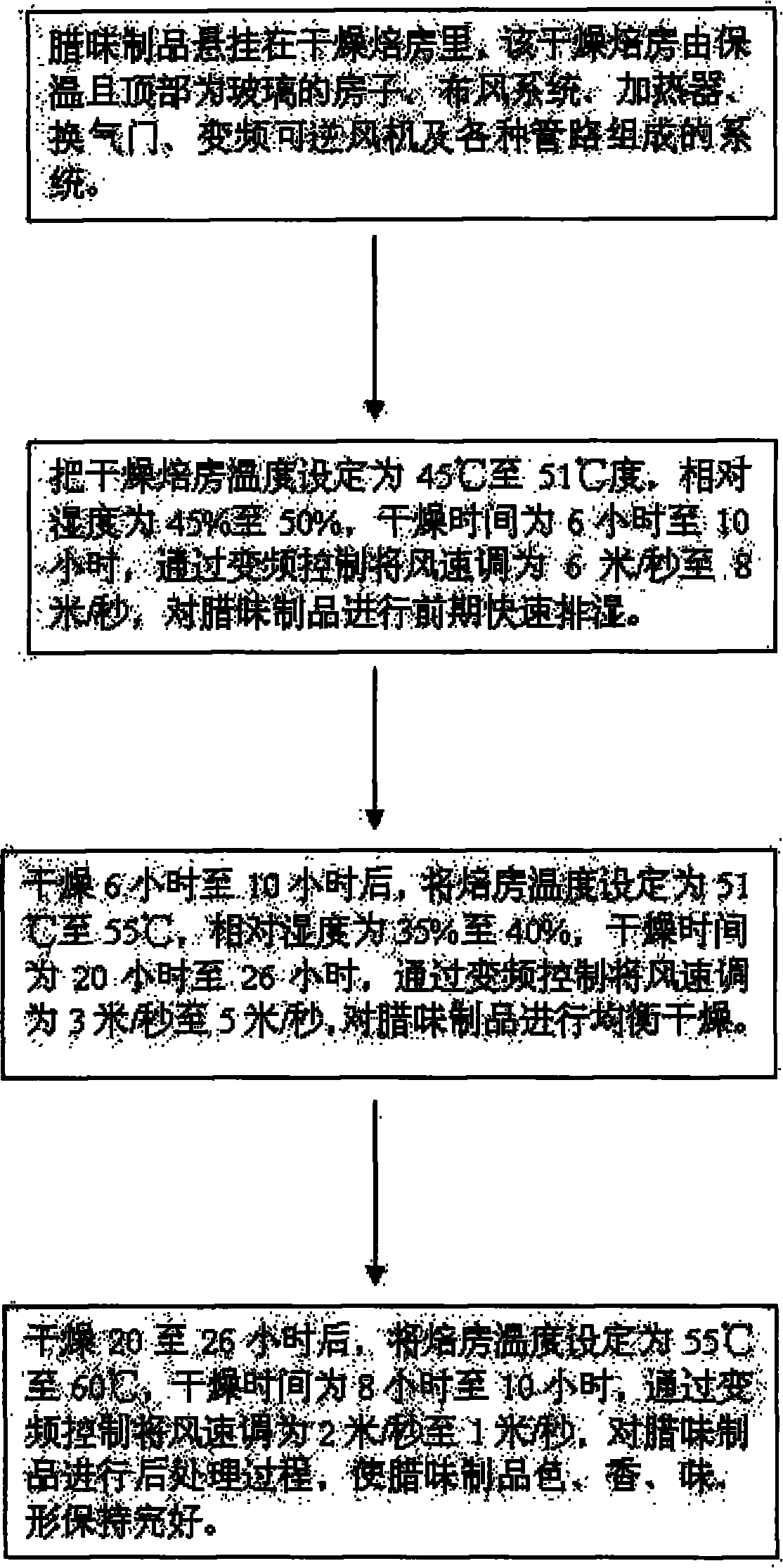

Energy-saving drying method for cured meat product

InactiveCN101878804ASolve consumptionTo overcome the large consumption,Food processingMeat/fish preservation by dryingAir volumeAgricultural engineering

The invention discloses an energy-saving drying method for cured meat products, which comprises a drying and baking main body. The drying method comprises the following steps that: (1) cured meat products required to be dried are hung in the drying and baking room with first preset air flow and first preset temperature, a ventilation door is opened, and the cured meat products exchange heat with hot air in the drying and baking room through convection to rapidly drain moisture out of the drying and baking room along with air; (2) after the moisture is rapidly drained in first preset drying time, the temperature of the drying and baking room is adjusted to second preset temperature, and the drying air flow in the baking room is adjusted to second preset air flow according to the change of humidity in the baking room to keep the drying rate of the cured meat products at certain gradient; and (3) after the balanced drying of the cured meat products in the second preset drying time, the ventilation door is opened, the temperature of the drying and baking room is reduced to third preset temperature, and hot air with third preset air flow is kept to flow in third preset drying time to enable the cured meat product to be well shrunk.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Drying device for the production of honeycomb ceramic body SCR denitration catalyst

InactiveCN106568302AEliminate dead endsPrevent burstDrying gas arrangementsDrying chambers/containersFresh airEnergy consumption

The invention discloses a drying device for the production of honeycomb ceramic body SCR denitration catalyst. An external casing is formed by a steel structure skeleton and a sealed heat insulation housing; at one side of the external body is provided with a sealed roller-blind door and an access door; the external casing is provided with a three-dimensional dynamic air supply system; two sides of the three-dimensional dynamic air supply system are provided with drying trolleys; the top of the external casing is provided with a waste discharging pipe, a mixed air pipe, a return air pipe and a fresh air pipe; the mixed air pipe is installed at the rear of the waste discharge pipe; the return air pipe is connected with the fresh air pipe; the mixed air pipe is connected with the return air pipe. By means of the device of the invention, drying period is shortened; the output in unit time is increased and energy consumption is greatly reduced; by means of the three-dimension dynamic air supply mode, the product qualified rate is greatly increased which reaches 95% and above.

Owner:咸阳陶瓷研究设计院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com