Active wood drying device

A kind of drying equipment and active technology, applied in the direction of wood drying, drying gas arrangement, local mixing dryer, etc., can solve the problems of high drying energy consumption, large energy consumption, increased raw material inventory burden and cash flow stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

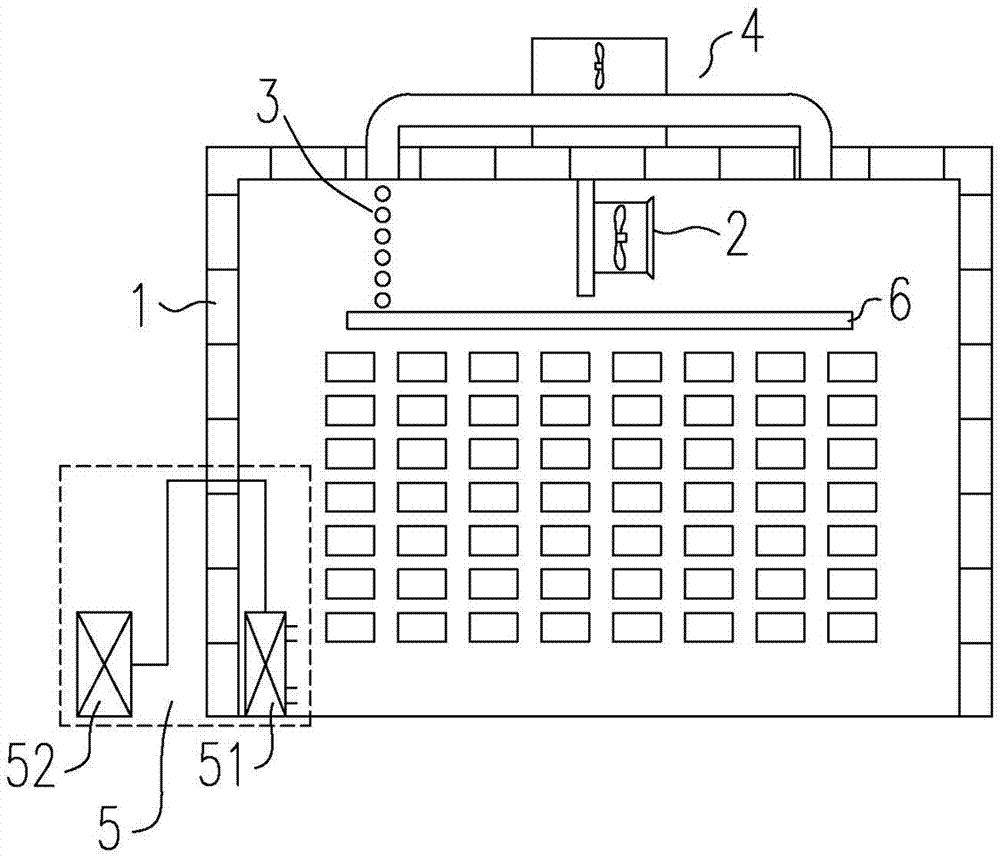

[0023] Embodiment 1: as figure 1 The shown active wood drying equipment includes a kiln body 1, a fan 2, a heating device 3 and a partition 6. The top of the kiln body 1 is provided with a passive dehumidification device 4, and the bottom of the kiln body 1 is provided with an active dehumidification device 5.

[0024] Kiln body 1

[0025] Because it is an improved structure of the existing drying kiln structure, the technical solution can be applied to various existing kiln body structures, such as brick kiln structure kiln body or aluminum alloy structure kiln body.

[0026] fan 2

[0027] The arrangement of fans includes top fan type, side fan type and end fan type. In this technical solution, considering its cooperation with passive dehumidification device 4 and active dehumidification device 5, the top fan type is the best choice, namely The fan 2 is located on the top of the kiln body 1 of the drying kiln.

[0028] Heating device 3

[0029] Those of ordinary skill in...

Embodiment 2

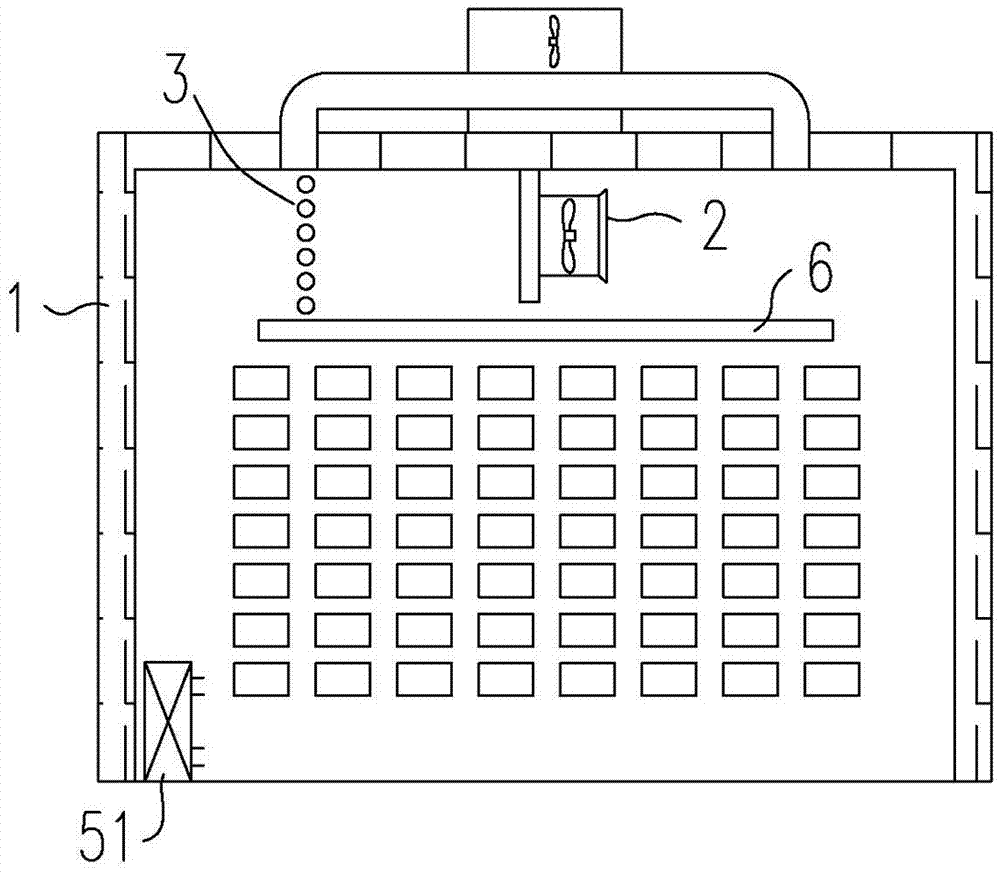

[0038] Embodiment 2: the difference between embodiment 2 and embodiment 1 is, as image 3 As shown, the active dehumidification device 5 is an integrated dehumidifier, which only forms an active dehumidification part 51 in the kiln body 1 . Optional dehumidifiers include compressor-type inverter dehumidifiers, with a daily dehumidification capacity of 25L / day and an applicable area of about 80㎡.

Embodiment 3

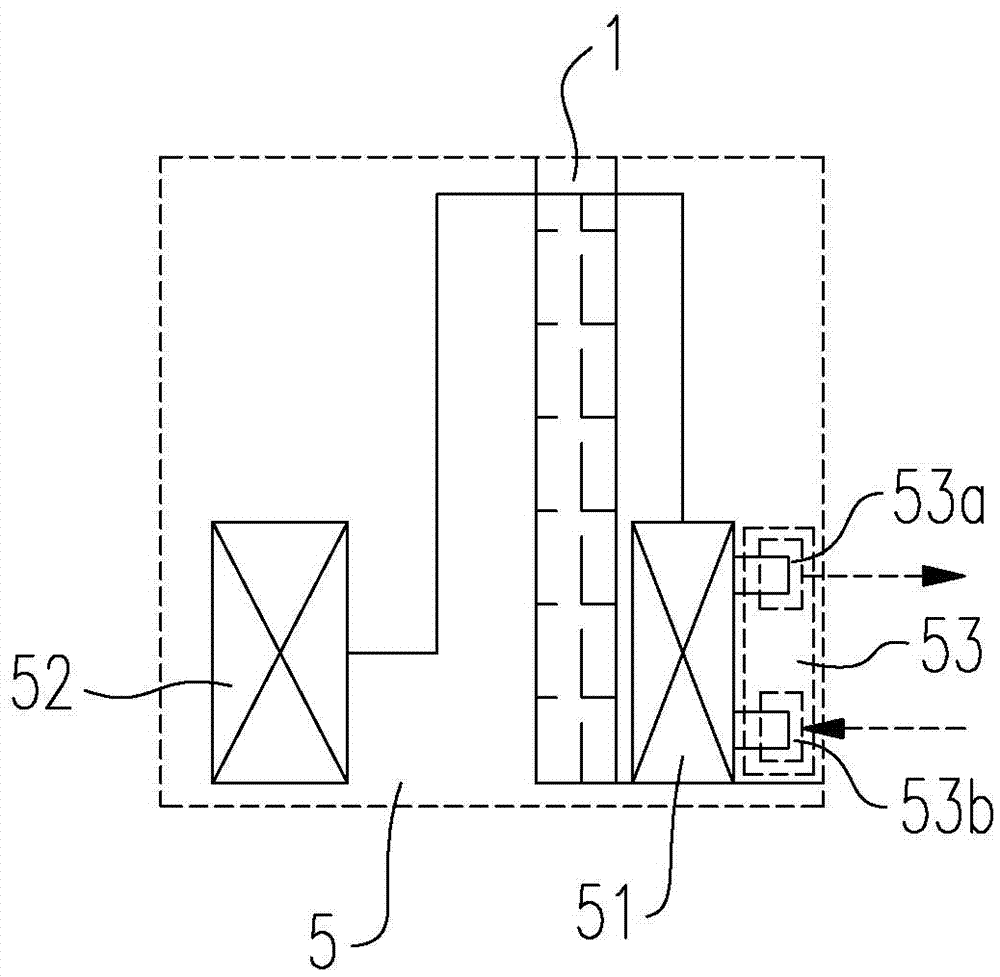

[0039] Embodiment 3: the difference between embodiment 3 and embodiment 1 is, as image 3 As shown, the active dehumidification unit 51 is located outside the kiln body 1 and processes the drying medium inside the kiln body 1 through the dehumidification pipeline 7 and the discharge pipeline 8 . The dehumidification pipeline 7 forms a dehumidification point 53a in the kiln body 1, which is used to pump the hot and humid drying medium into the active dehumidification part 51 and treat it; the discharge pipeline 8 forms a discharge point 53b in the kiln body 1, which is used to actively dehumidify the The dry and cold air treated by the section 51 is discharged back to the inside of the kiln body 1 . The advantage of placing it outside is that the dry medium sent back to the inside of the kiln body 1 is dry and cold medium, and its temperature is lower than that of the dry medium in the kiln body 1. This method is beneficial to the cooling process and drying in the cooling stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com