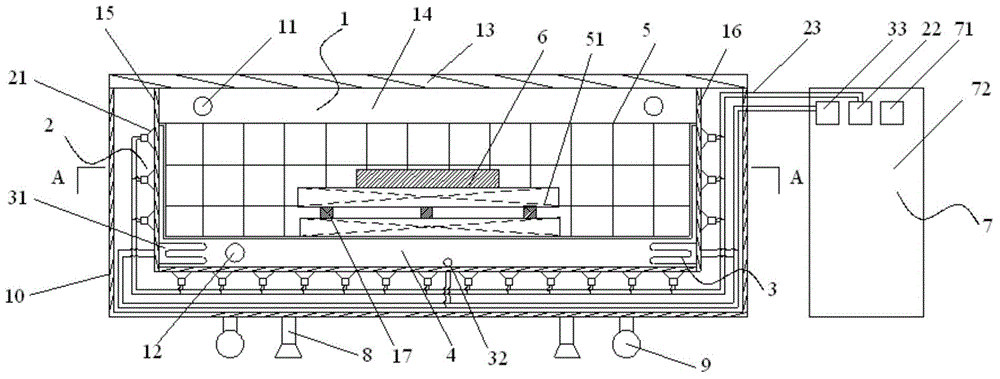

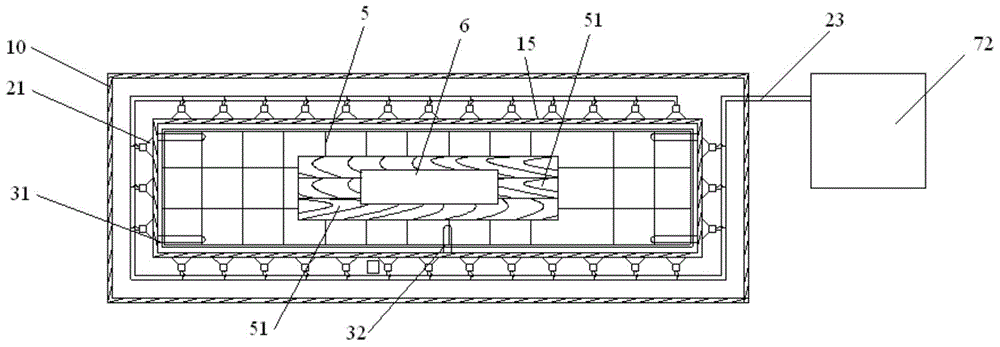

Treatment device for increasing drying rate of timber and method for drying timber by utilizing processing device

A wood treatment and wood drying technology, which is applied in the direction of promoting the drying of solid materials, such as preliminary treatment, drying of solid materials, and drying, can solve the problems of poor drying quality, large equipment investment, and low drying rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Take fir wood segments with dimensions of 1000mm (length) × 200mm (width) × 20mm (thickness) for ultrasonic pretreatment to open up the moisture channel inside the wood and shorten the drying time for subsequent wood drying treatment.

[0117] In the embodiment of the present invention, the thickness of the wood is 2 cm as an example, other woods with a thickness of 1-10 cm are also suitable for the present invention, and the thickness of the wood is preferably 2-5 cm.

[0118] 1. Open the liquid inlet 11, and the treatment liquid (i.e. water) 4 is poured into the cavity 14 inside the wood treatment chamber through the liquid inlet 11. The highest position of the ultrasonic transducer is flush with or slightly higher than the highest position of the ultrasonic transducer;

[0119] In addition to using water, the treatment liquid in the embodiment of the present invention can also use an alkaline solution, the mass percent concentration of the alkaline solution is 0.01-1...

Embodiment 2

[0128] Except that the ultrasonic pretreatment time is 1 h, the rest are the same as in Example 1.

Embodiment 3

[0130] Except that the ultrasonic pretreatment time is 1.5h, the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com