Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1308results about "Preliminary solid treatment for drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

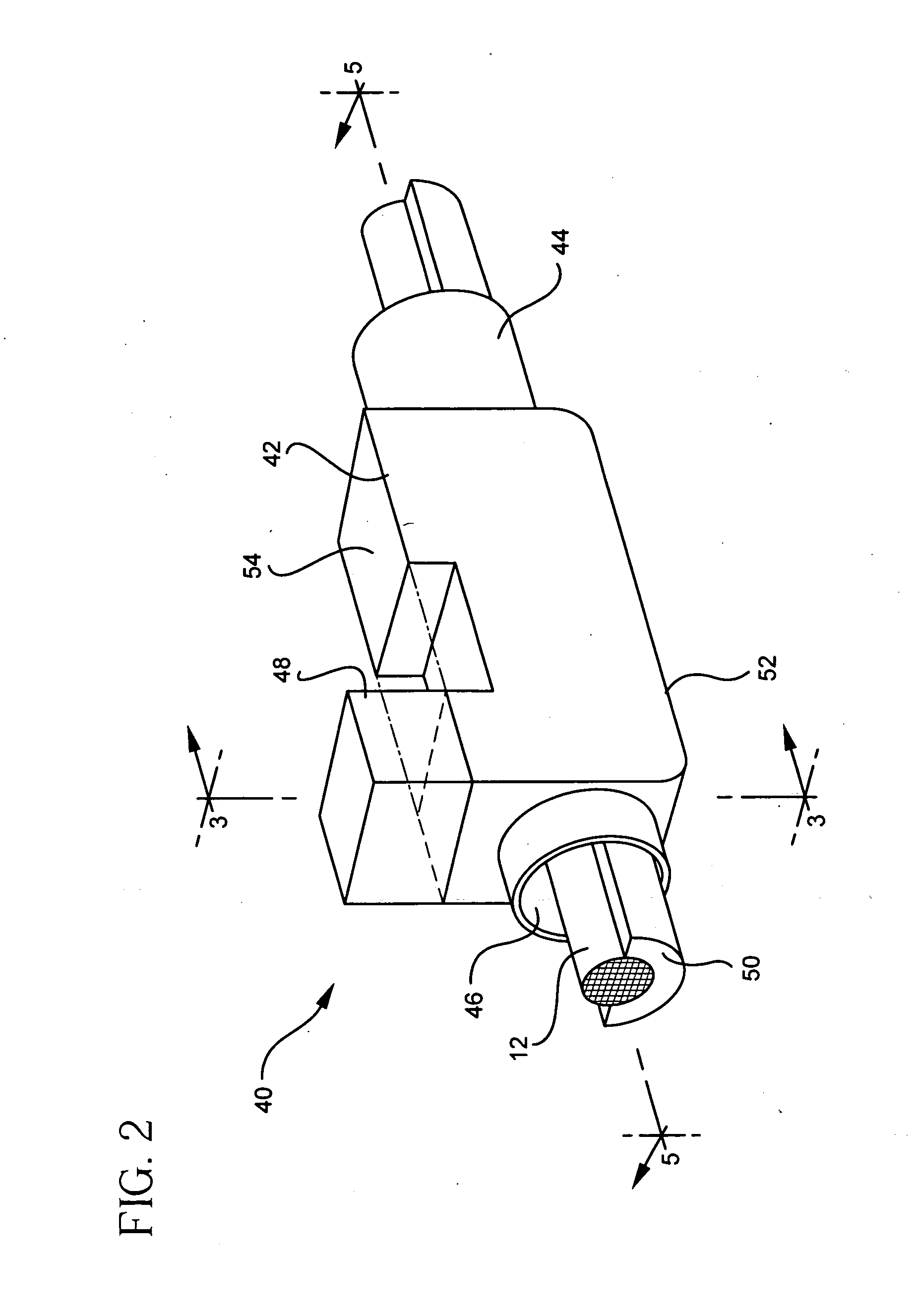

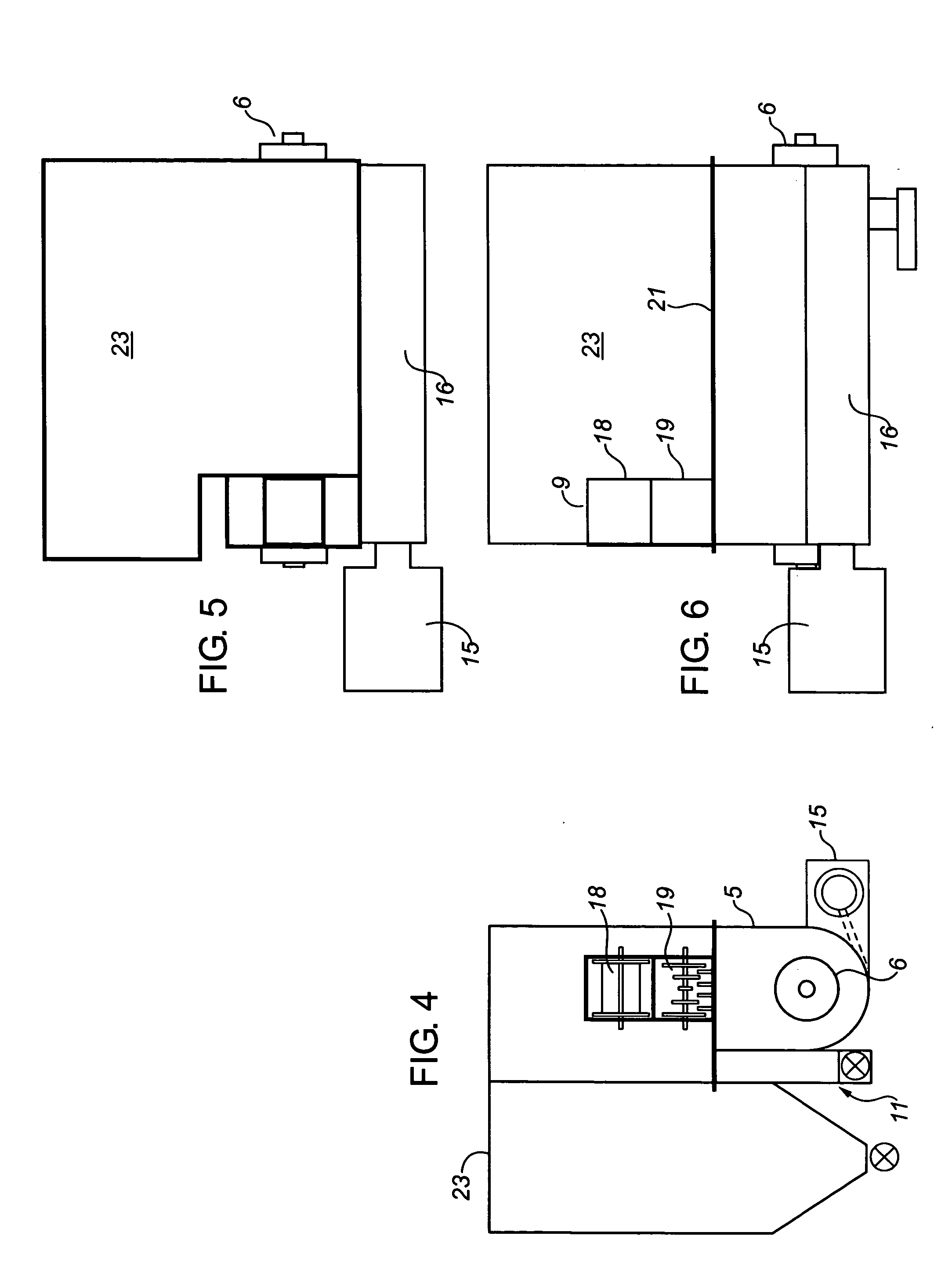

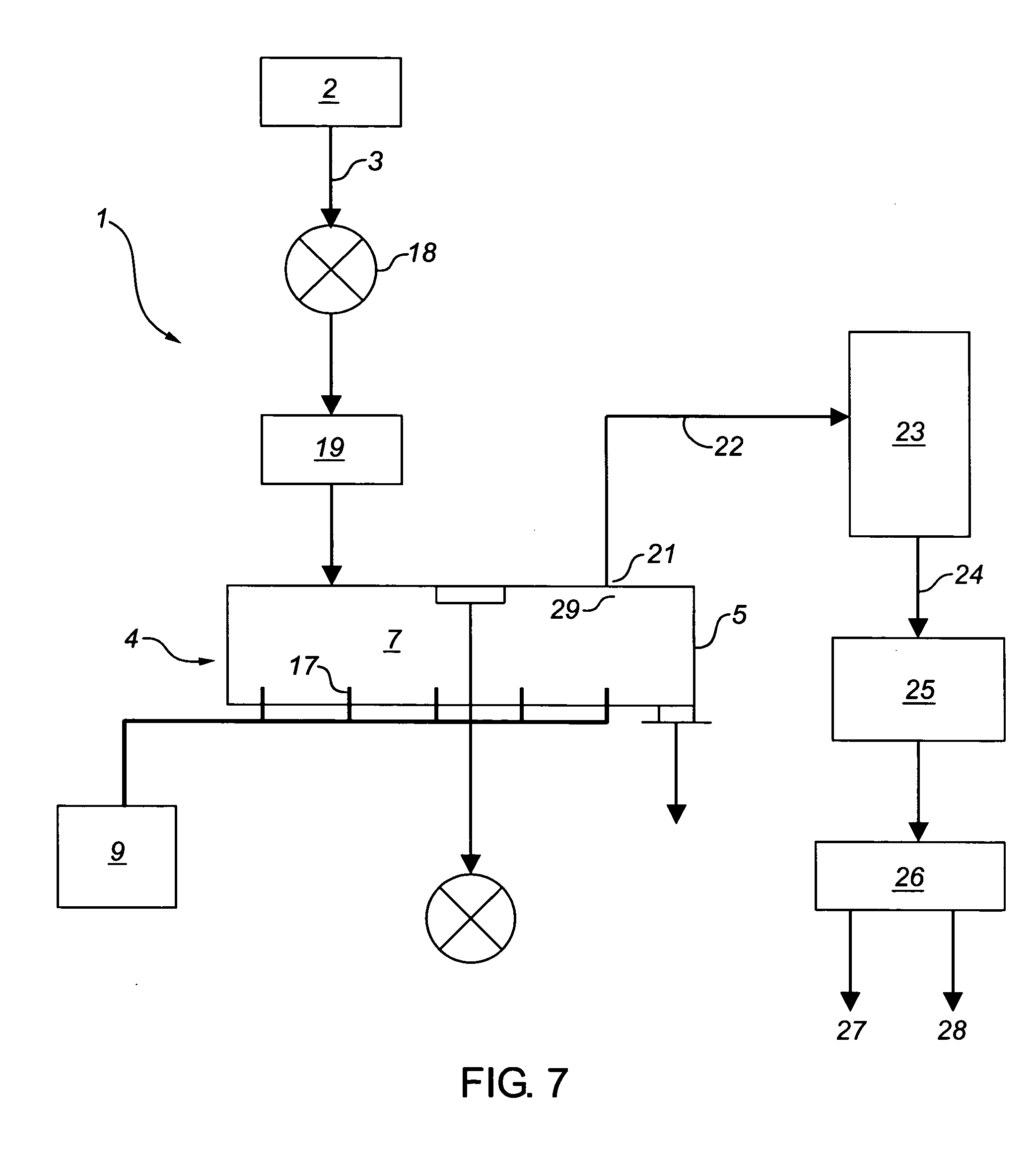

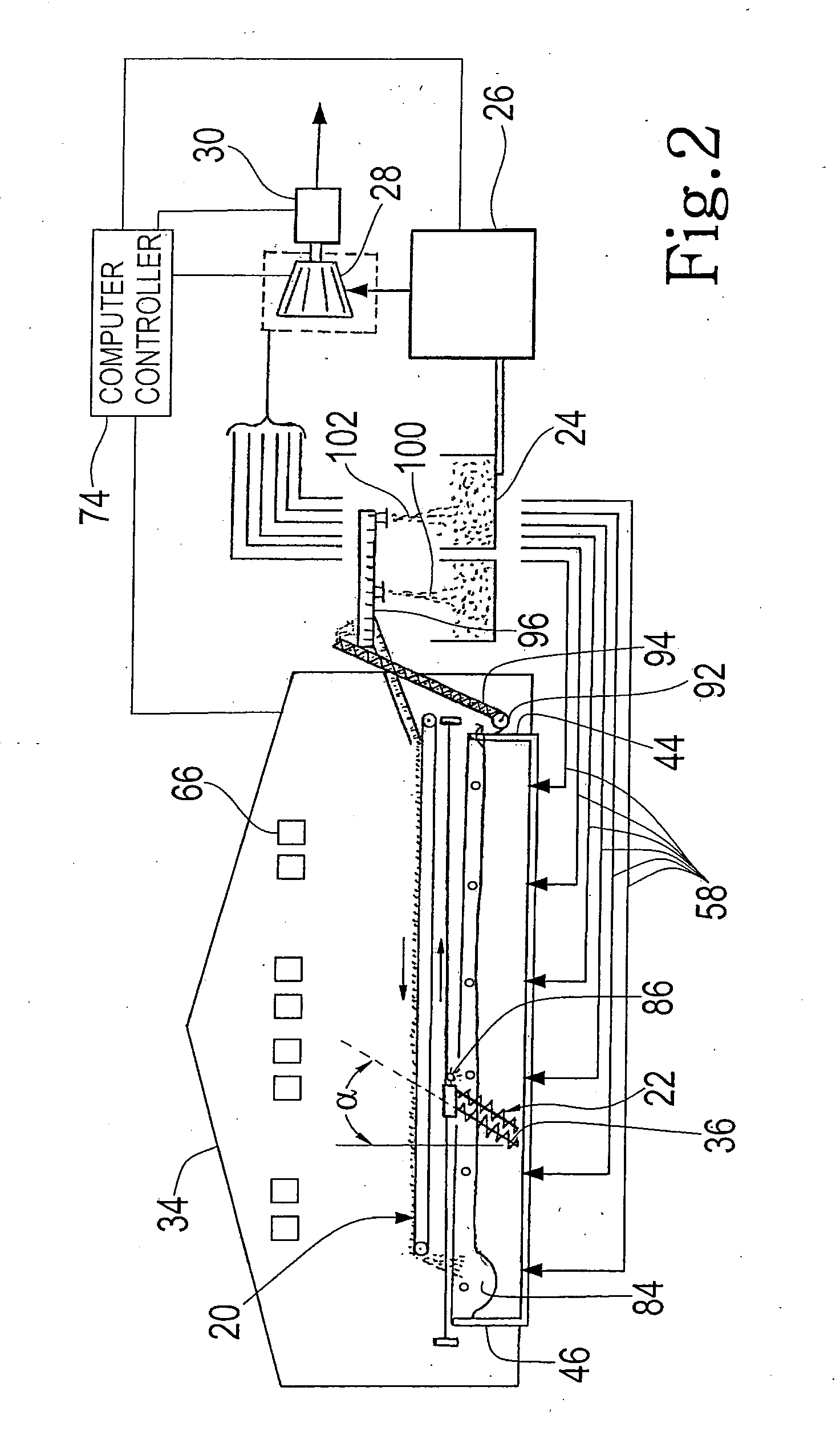

Microwave stiffening system for ceramic extrudates

InactiveUS20050093209A1Prevent saggingPreventing handling deformationDielectric heatingDrying solid materials with heatMicrowaveMetallurgy

An apparatus and method for stiffening an wet extruded ceramic body for improved handling prior to drying and firing. The ceramic body is formed from a plastically deformable material including inorganic raw materials, and organics, such as a binder having a thermal gel point. As the ceramic body log exits the extruder die it is passed through a microwave energy field to be heated to above the gelling point of the organic binder. The ceramic body then stiffens and can be easily handled without deformation.

Owner:CORNING INC

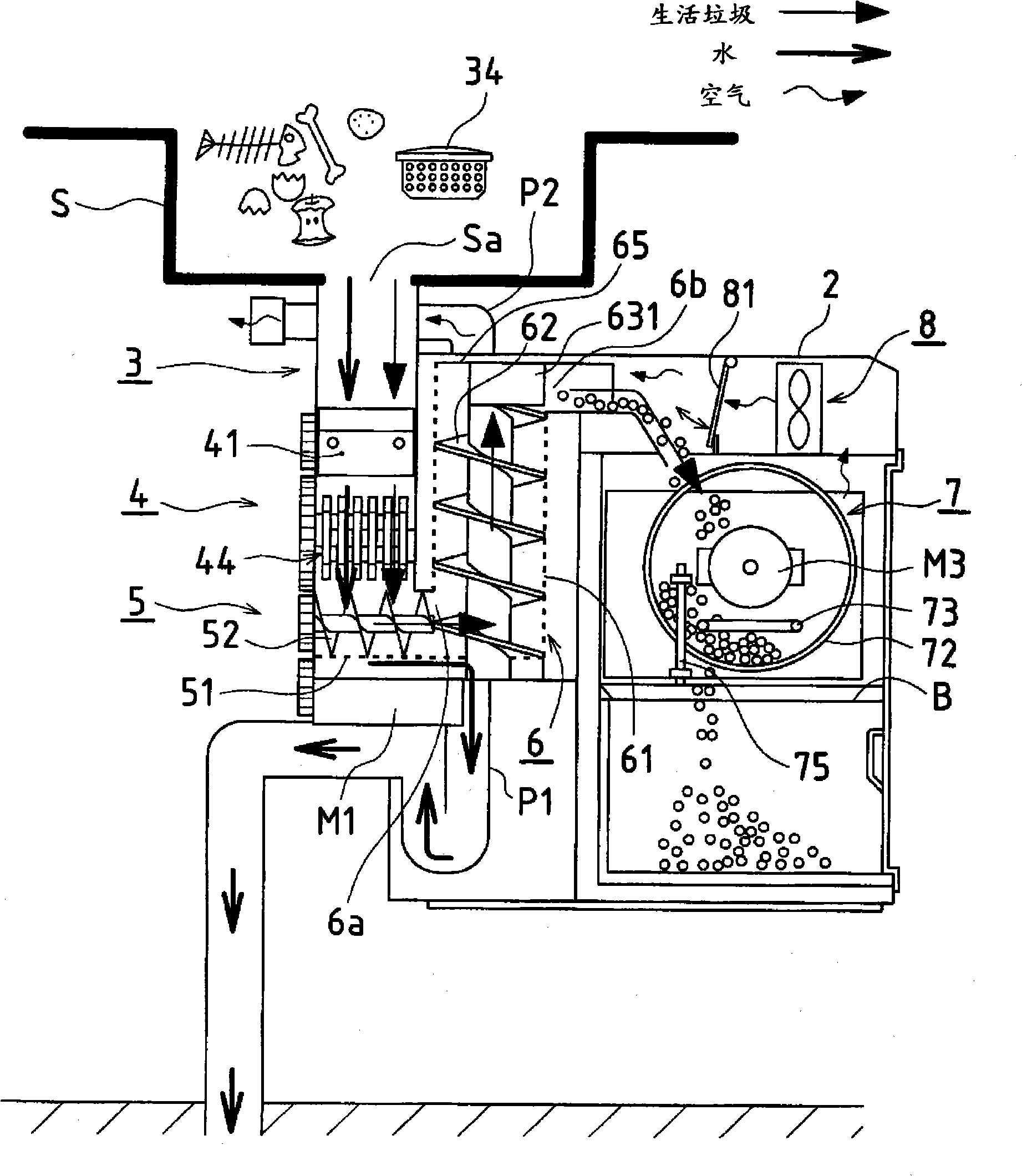

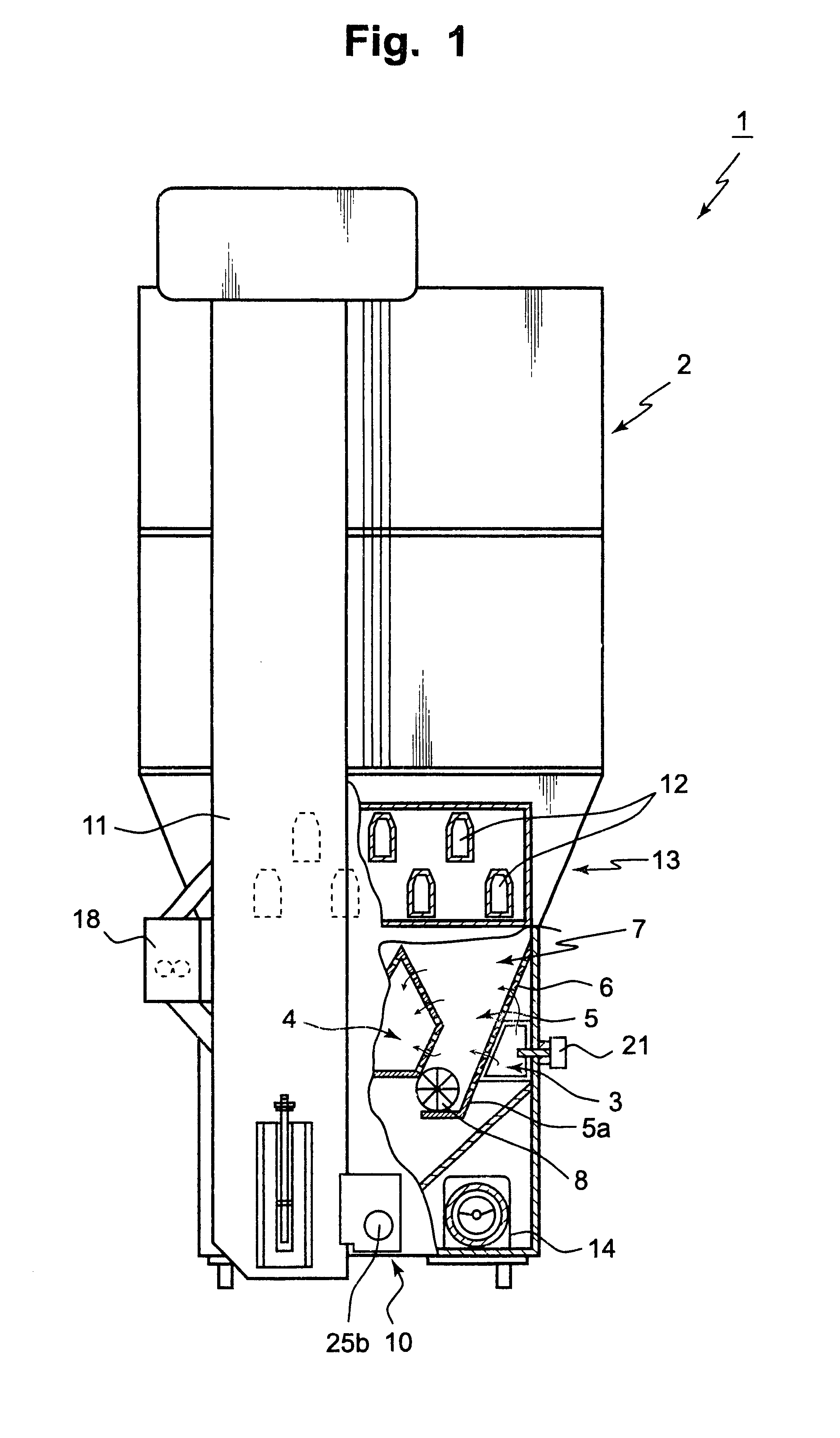

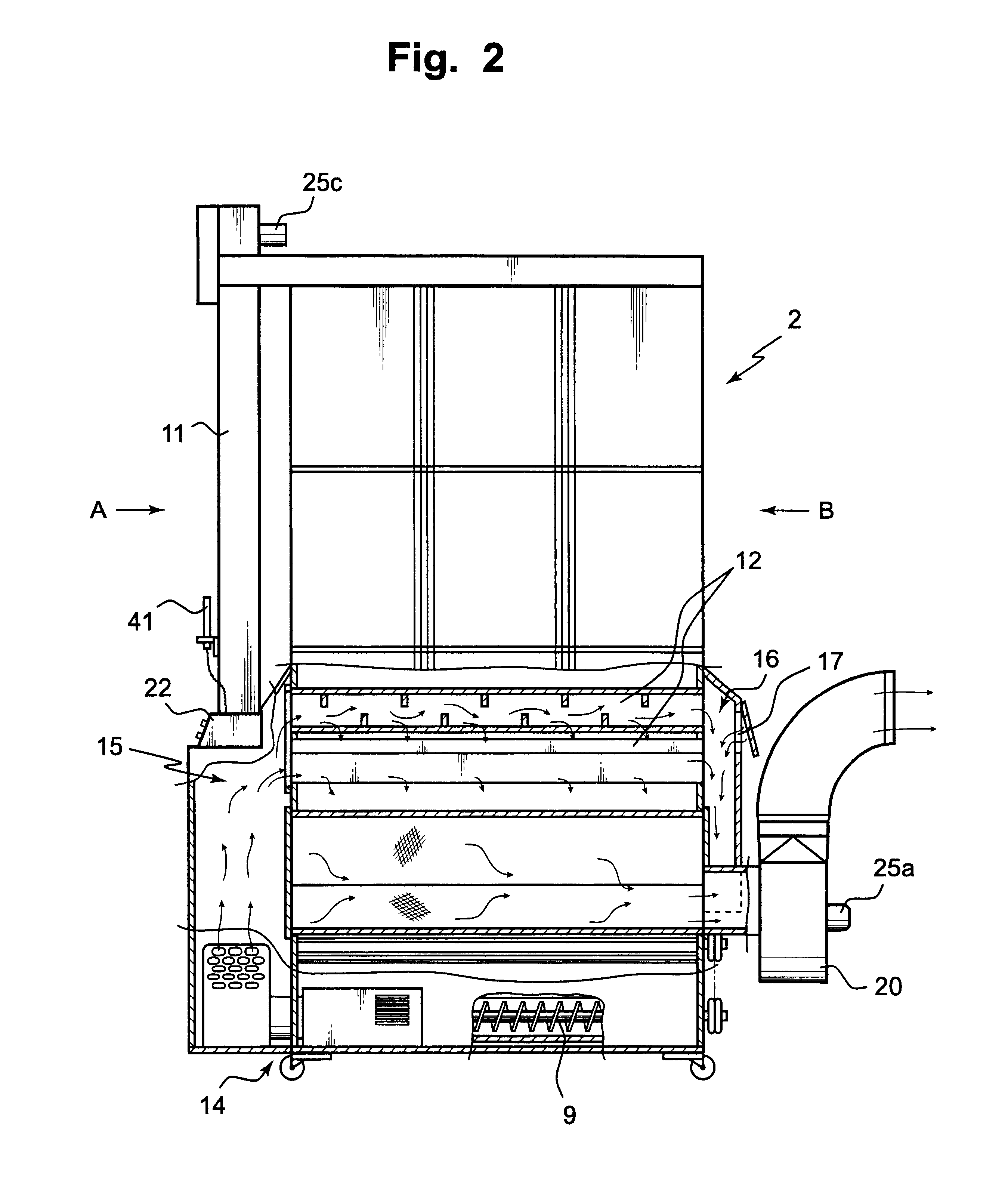

Garbage disposer

A garbage disposer (1), in one embodiment, is composed of a crushing means (4) which crushes garbage supplied through a plughole (Sa) and connection member (3) of a sink (S), a transverse conveyance means (5) which transversely conveys the garbage crushed by the crushing means (4), a dewatering means(6) which internally introduces the crushed garbage conveyed via the transverse conveyance means (5) and dewaters the crushed garbage while conveyed upward, a drying means (7) which internally supplies via a shute (9) the crushed garbage discharged via the dewatering means(6) and dries the crushedgarbage while rotated, and a garbage container (B) which is drawably disposed under the drying means (7). The crushed garbage dried to be reduced in volume by the drying means (7) is dropped therefrom down into the garbage container.

Owner:新矢 浩一

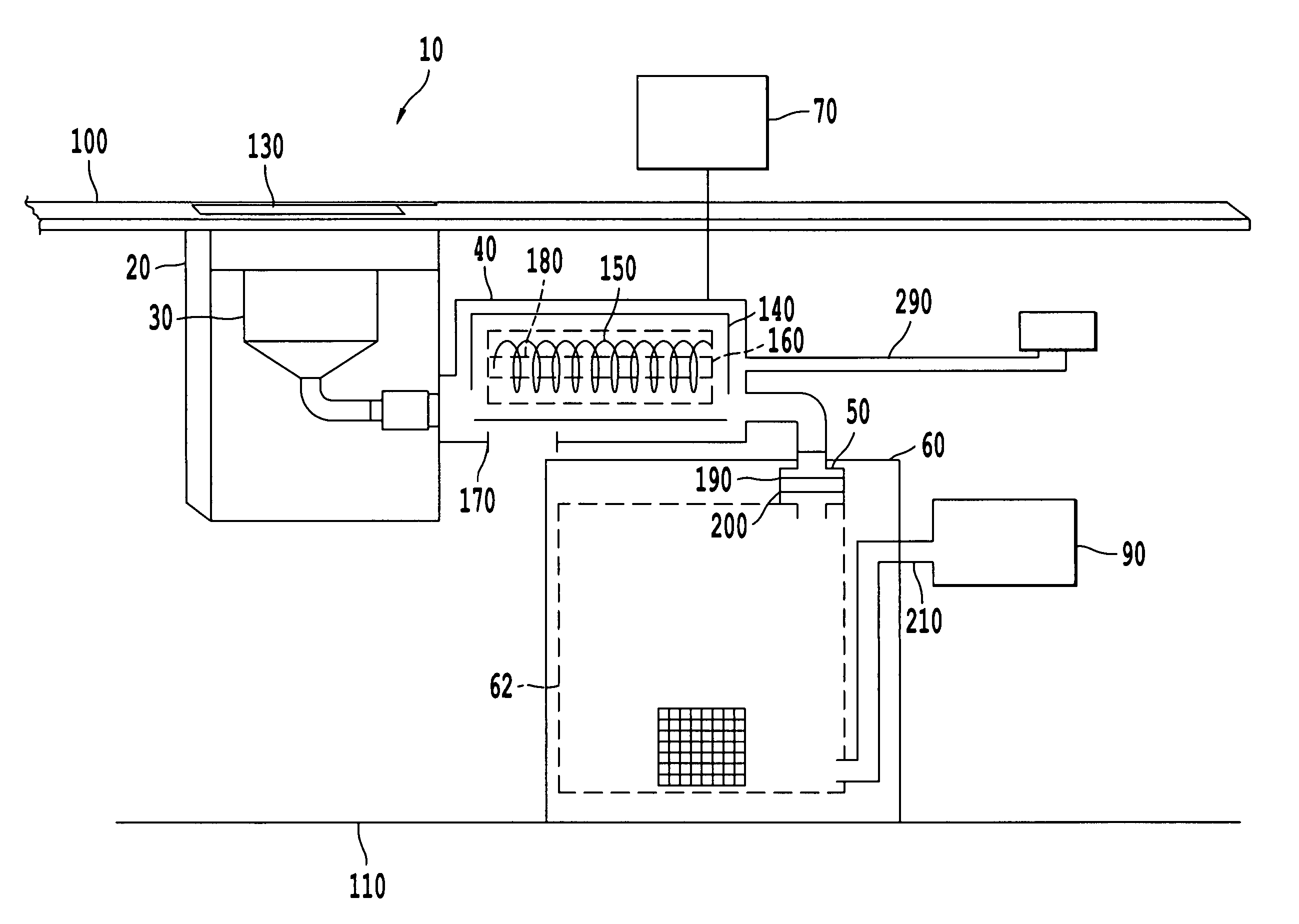

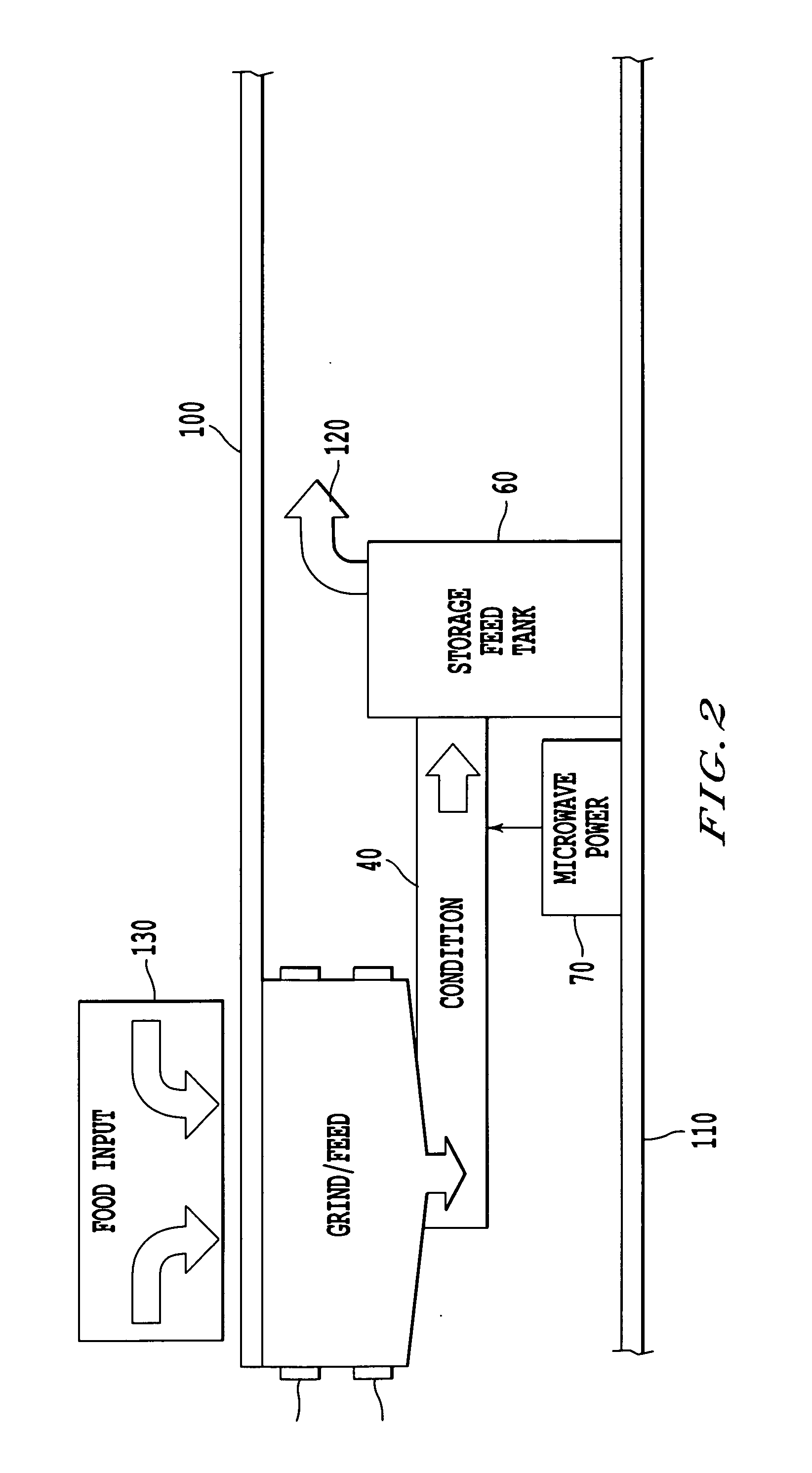

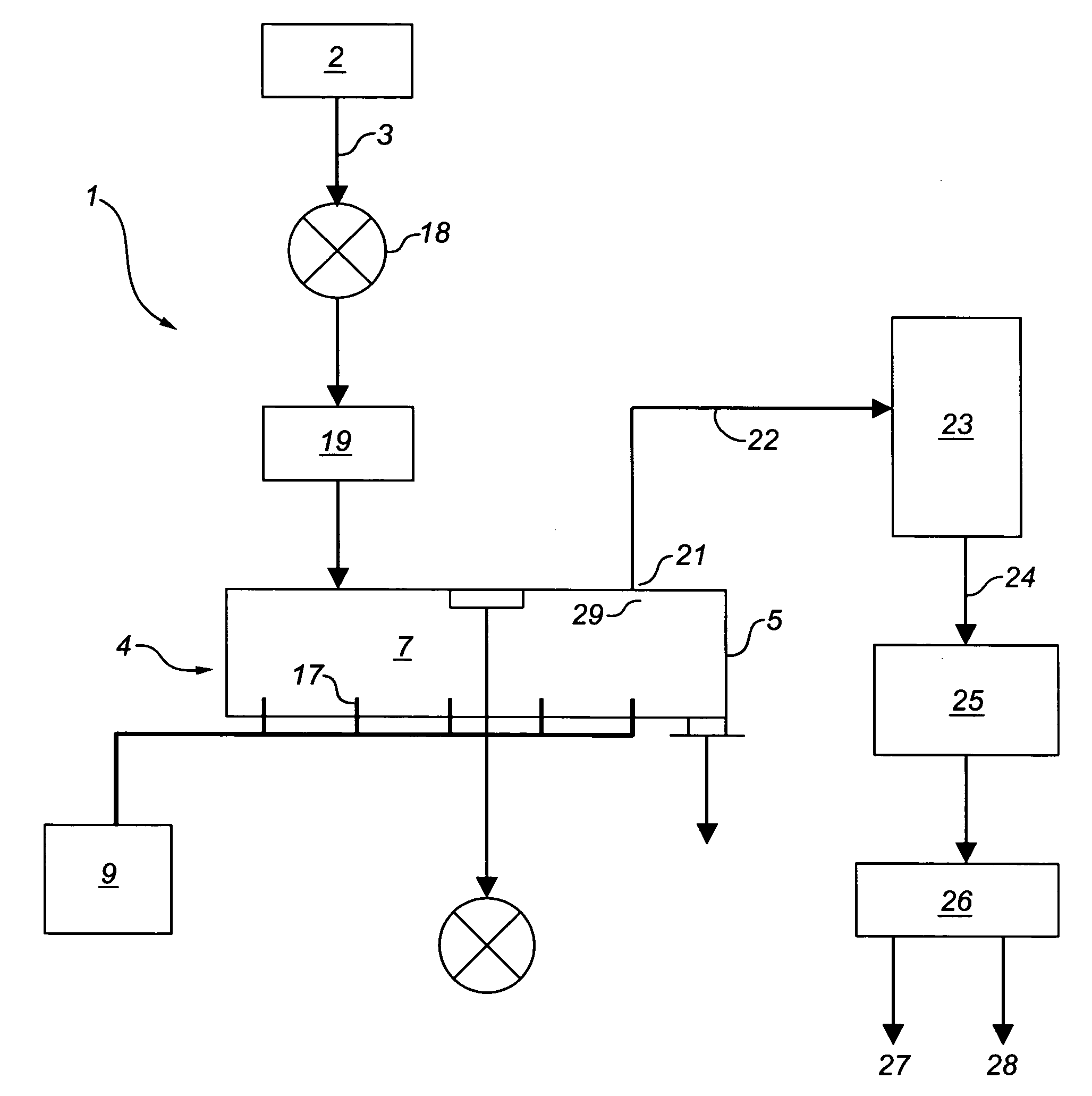

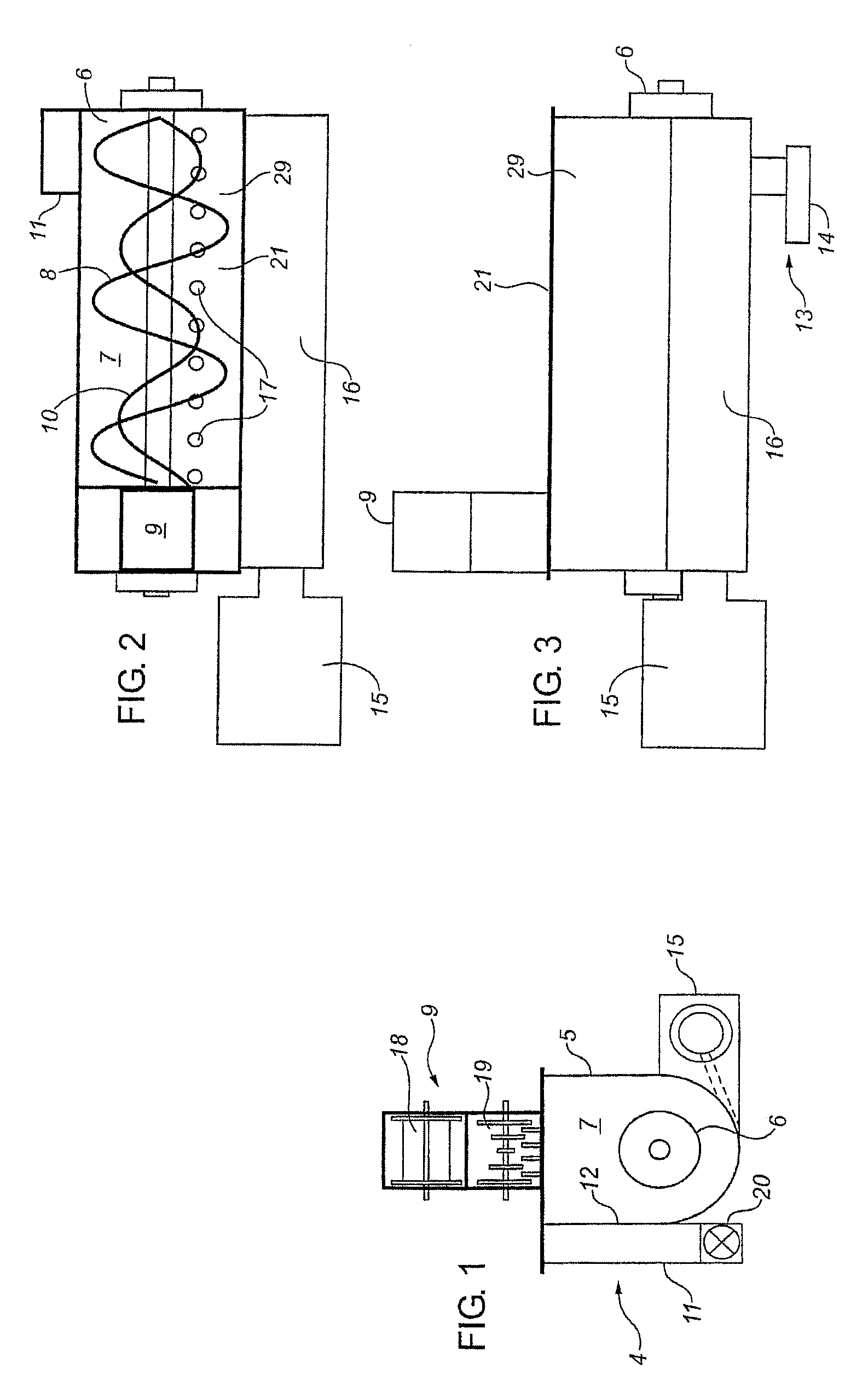

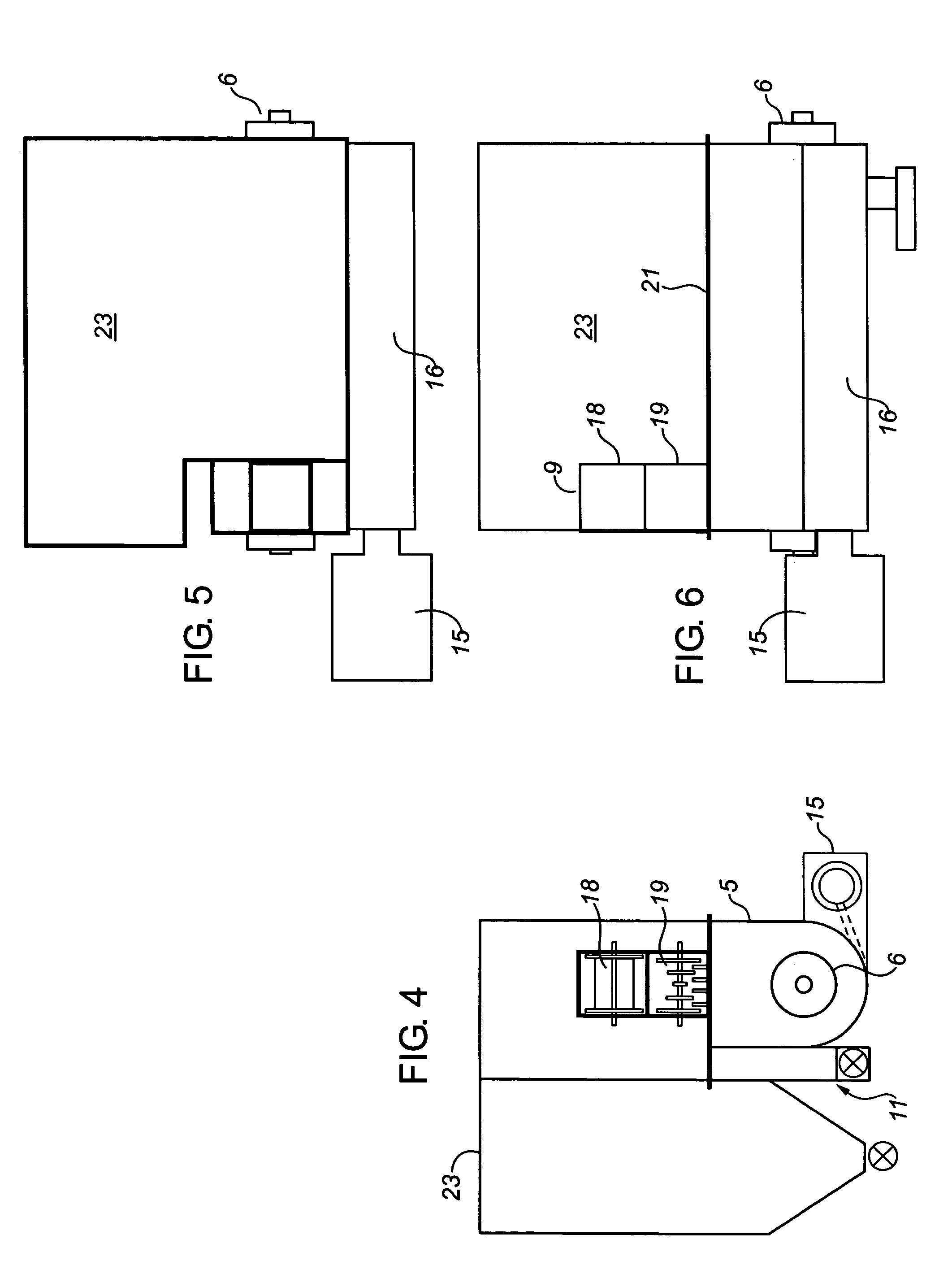

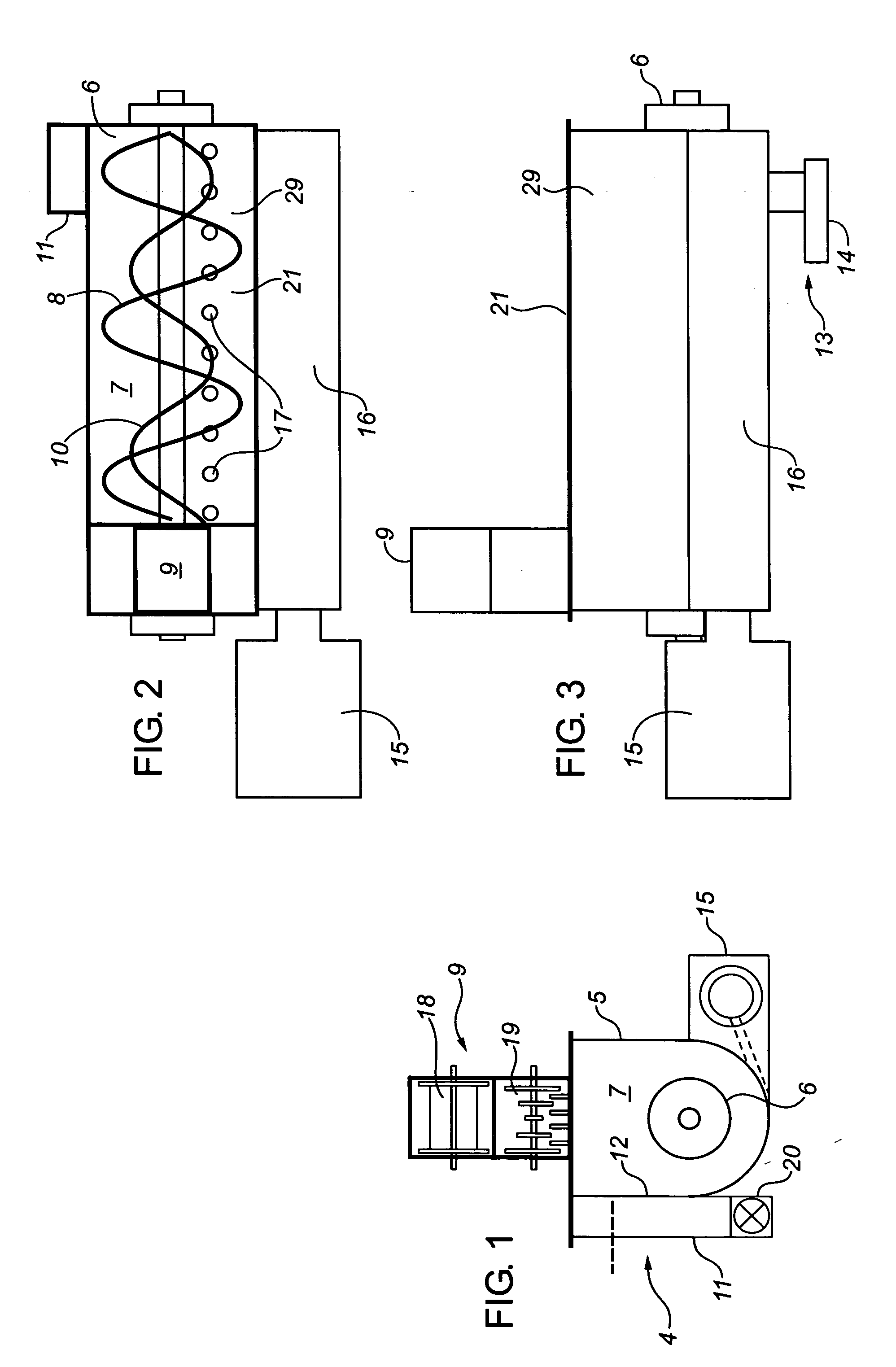

Waste handling system

InactiveUS20050274035A1Reduce moistureReduce volumeDrying solid materials with heatDrying machines with non-progressive movementsLitterEngineering

A waste conditioning or processing arrangement is provided which can effectively handle waste at its point of generation. In a preferred arrangement, the waste is conditioned by drying the waste and forming the waste into pellets or granules, with the waste also preferably sterilized during the conditioning. The resulting pelletized or granularized waste is remarkably smaller than the input waste, and can conveniently be stored for subsequent disposal or use. The arrangement can be used in a variety of contexts, and is particularly advantageous for food or organic wastes. The system can be used in restaurants or marine vessels for handling kitchen or galley waste. The system can also be advantageously used for certain agricultural waste.

Owner:GUY D MARCHESSEAULT

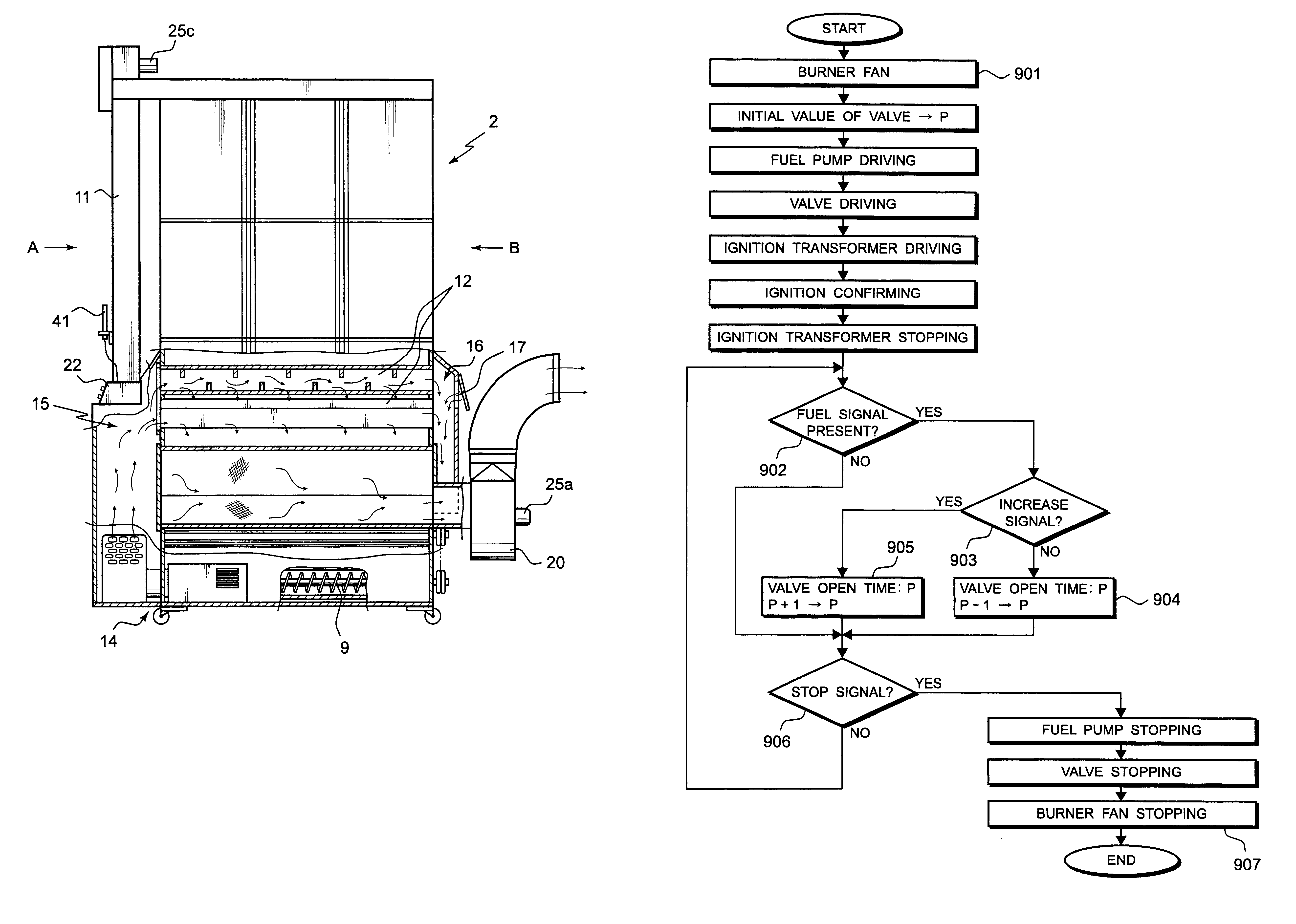

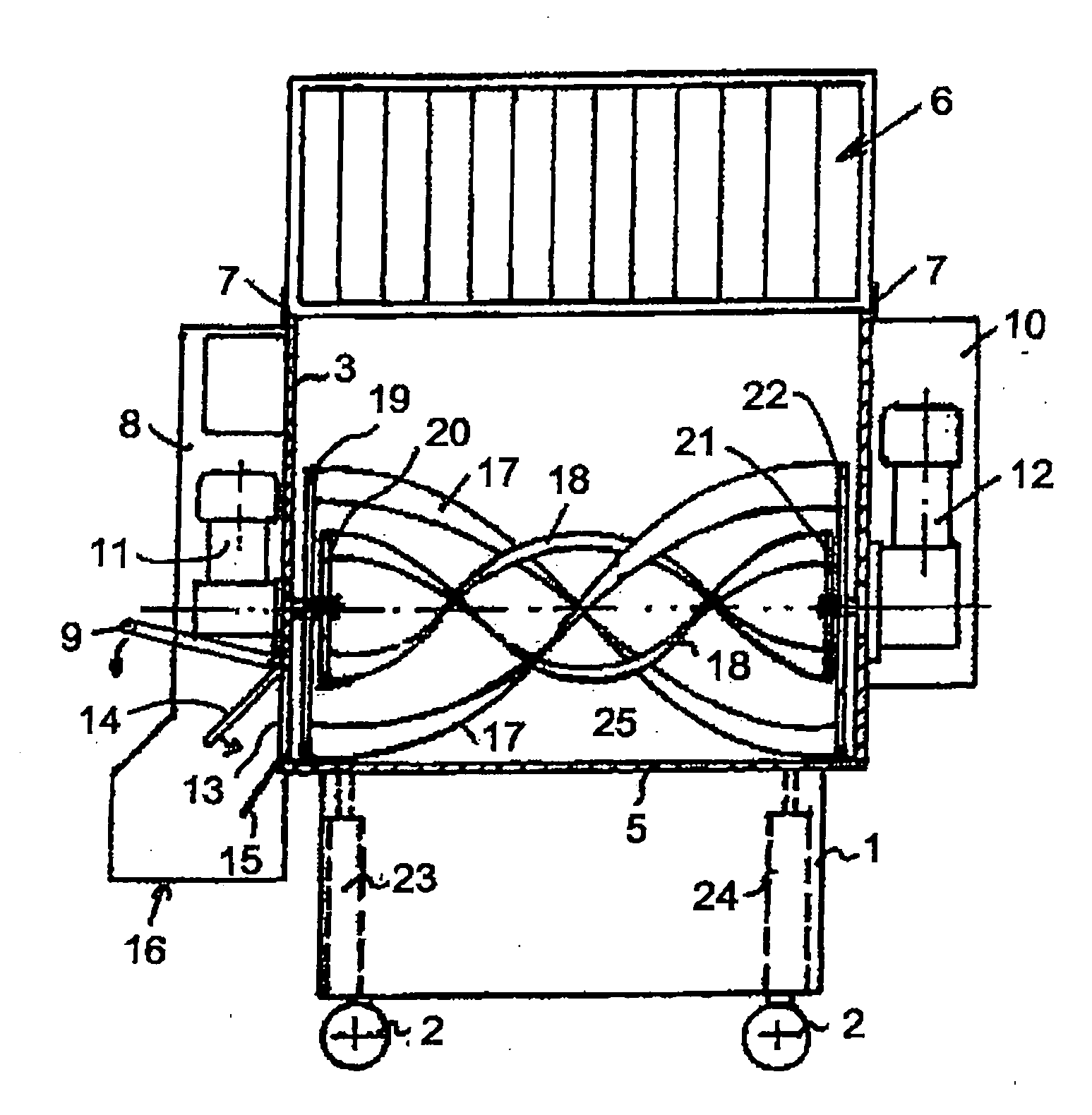

Dryer/Grinder

A grinder / dryer having a plurality of beater blades carried on a rotating shaft in a cylindrical housing, including one or a plurality of grinding members on the cylindrical side wall. The grinding members are adjustably positioned at different locations within the cylinder. The grinding members may be provided in a variety of different combination of elevated ridges and / or valleys used to dry and classify materials.

Owner:SCOTT EQUIP

Apparatus and process for removing liquids from drill cuttings

InactiveUS7337860B2Reduce cakingReduce resultSolid waste disposalHollow article cleaningCombustionProduct gas

Owner:CLEANCUT TECH LTD

Apparatus and process for removing liquids from drill cuttings

InactiveUS20050153844A1Reduce cakingReduce resultSolid waste disposalHollow article cleaningCombustionEngineering

Drill cuttings associated with drilling fluid are thermally cleaned. The wet cuttings are fed into a vessel chamber having mechanical mixers, such as ribbon blenders, extending lengthwise of the chamber. Direct heating is applied to the chamber contents by introducing hot combustion gas from a heater. A combination of direct heating and mechanical back mixing of wet colder cuttings with drier hotter cuttings results in conditioning and conduction heating of the wet cuttings. The drilling fluid is evaporated and removed as gas. Dried cuttings are separately recovered. Caking and agglomeration of the solids is reduced.

Owner:CLEANCUT TECH LTD

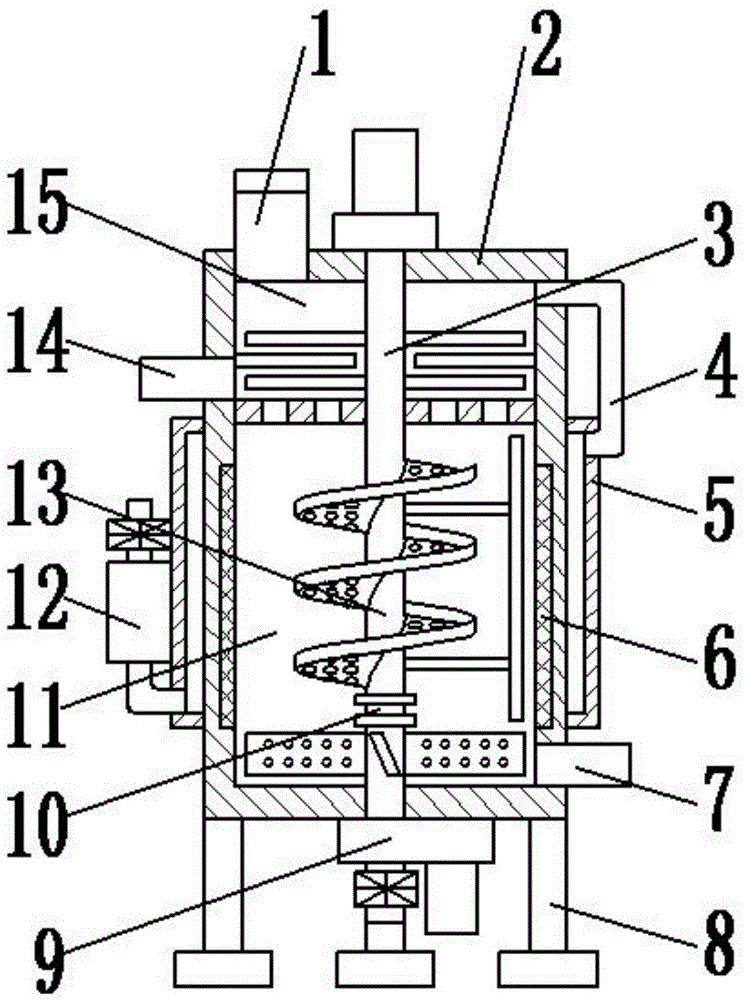

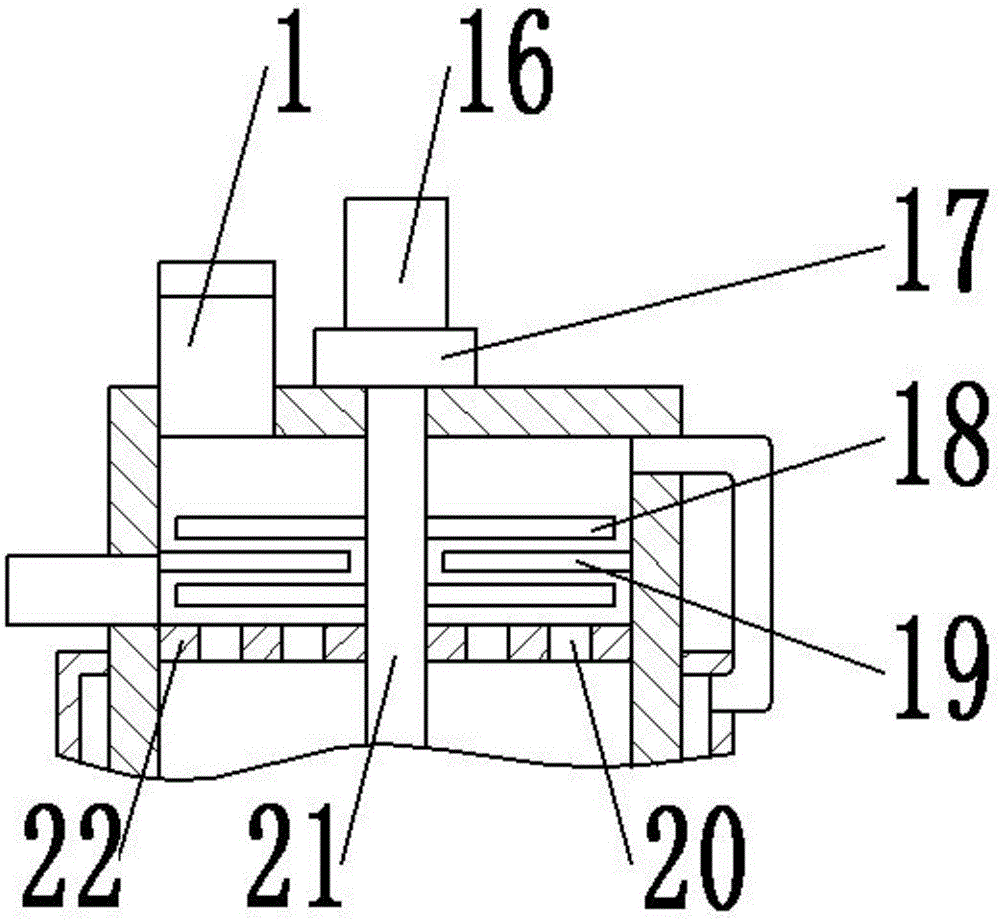

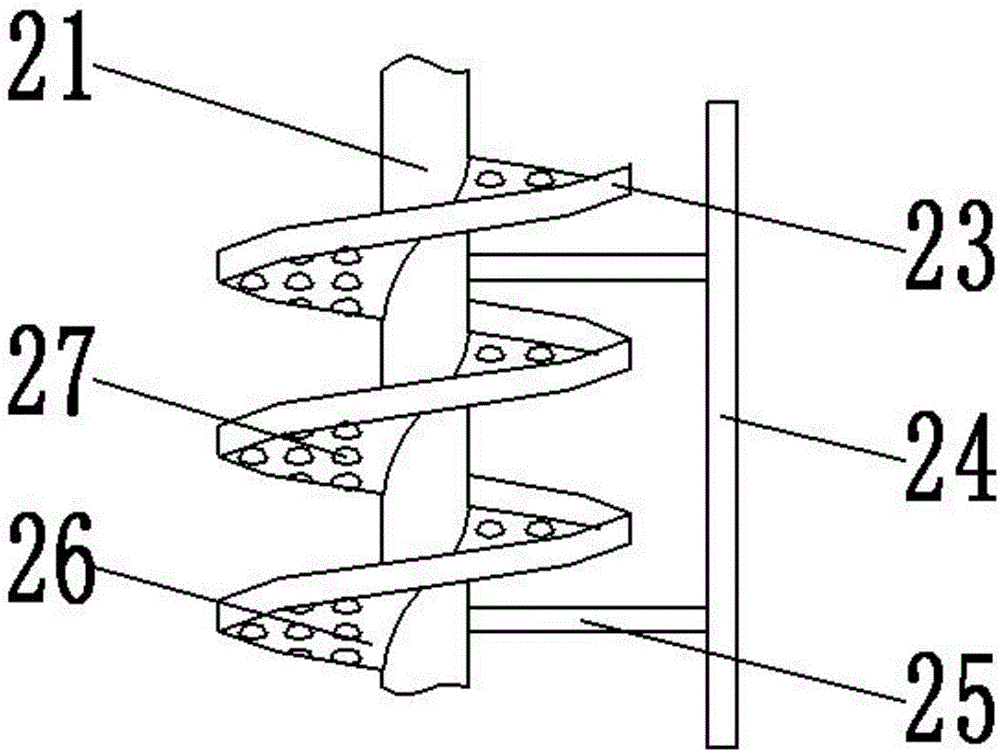

Quick sludge drying equipment with crushing device

ActiveCN106391234AKeep dryIncrease drynessSludge treatment by de-watering/drying/thickeningDrying solid materials without heatSludgeImpurity

The invention provides quick sludge drying equipment with a crushing device. The quick sludge drying equipment comprises a tank; the internal of the tank is divided into a crushing cavity and a drying cavity through a separation plate; the crushing device is arranged in the crushing cavity; an impurity removing pipe is arranged on the side wall of the bottom of the crushing cavity; a spiral stirrer and an air blowing drying device are arranged in the drying cavity; the spiral stirrer consists of a spiral stirring blade, a stop edge and a scraping plate; the air blowing drying device consists of a transmission box, a second motor, an intake pipe, a second rotating shaft and an air spraying plate; an electric heater is embedded in the side wall of the drying cavity; a discharge pipe is arranged on the side wall of the bottom of the tank; a jacket is arranged on the outer surface of the tank; and a dehumidifying device is arranged on the side wall of the bottom of the jacket. The quick sludge drying equipment crushes caked sludge through the crushing device, achieves the purpose of circularly stirring the sludge through the spiral stirrer, facilitates uniform contact between hot air and the sludge through the air blowing drying device, and facilitates uniform drying of the sludge.

Owner:深圳市海创环境治理科技有限公司

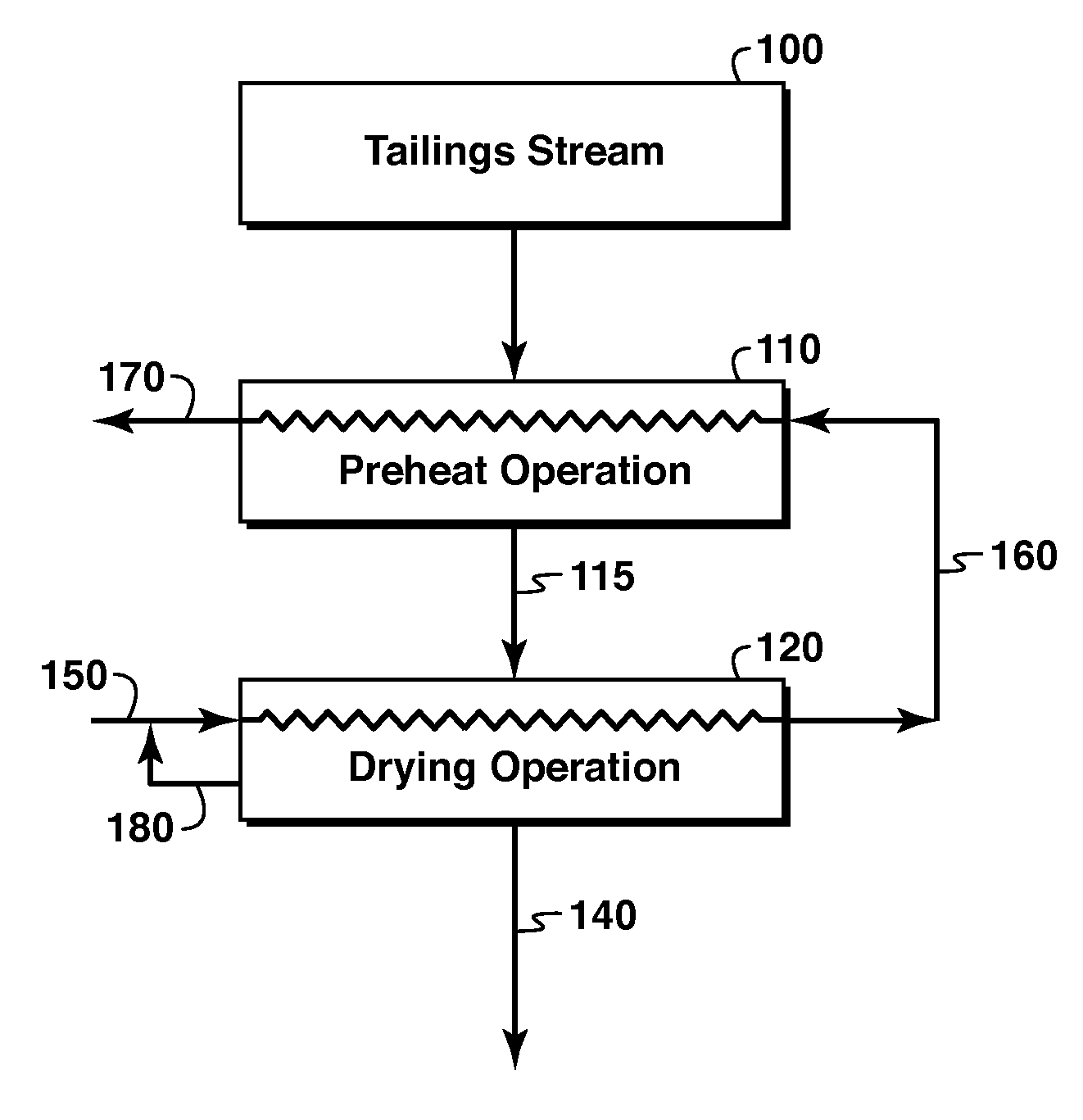

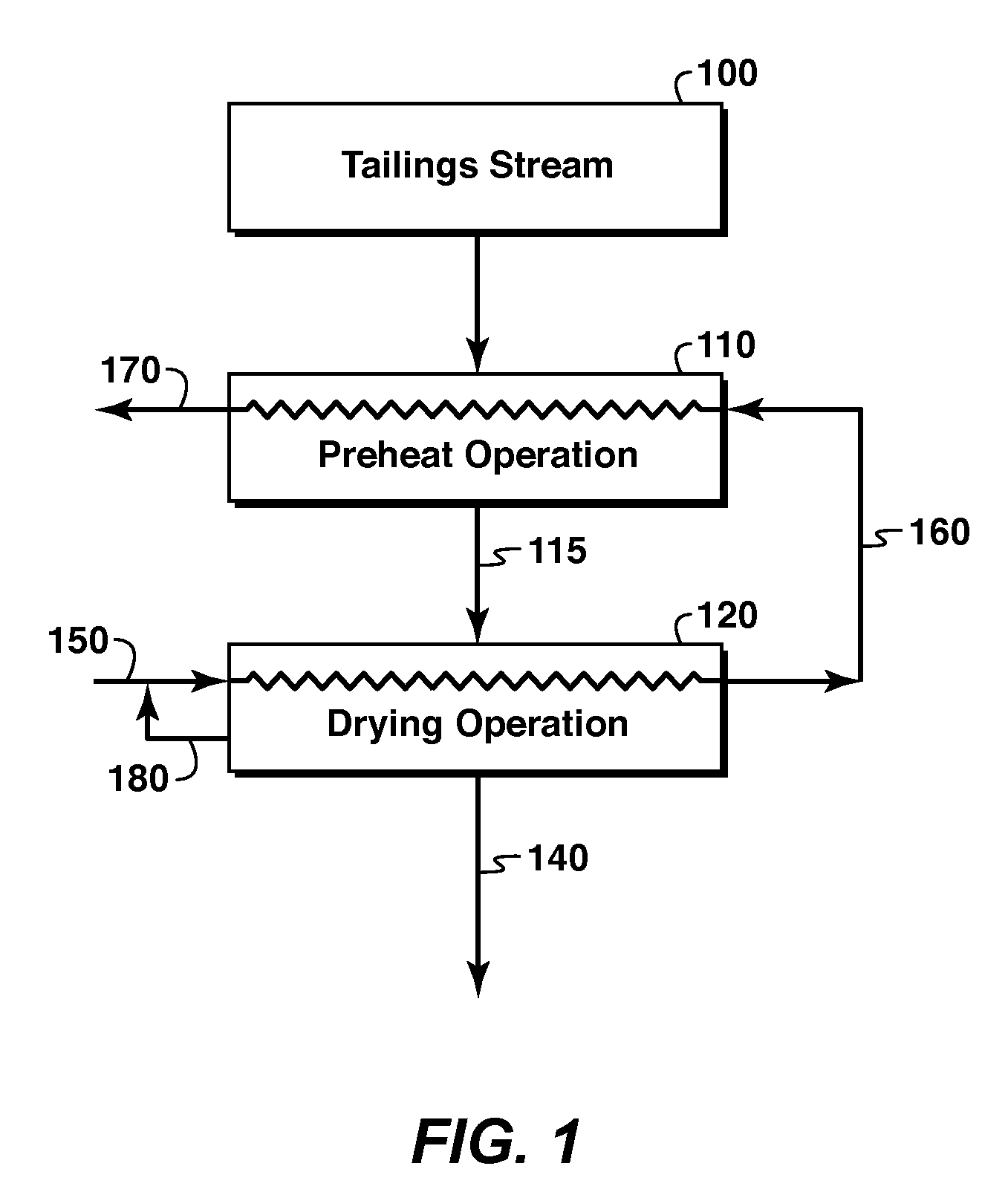

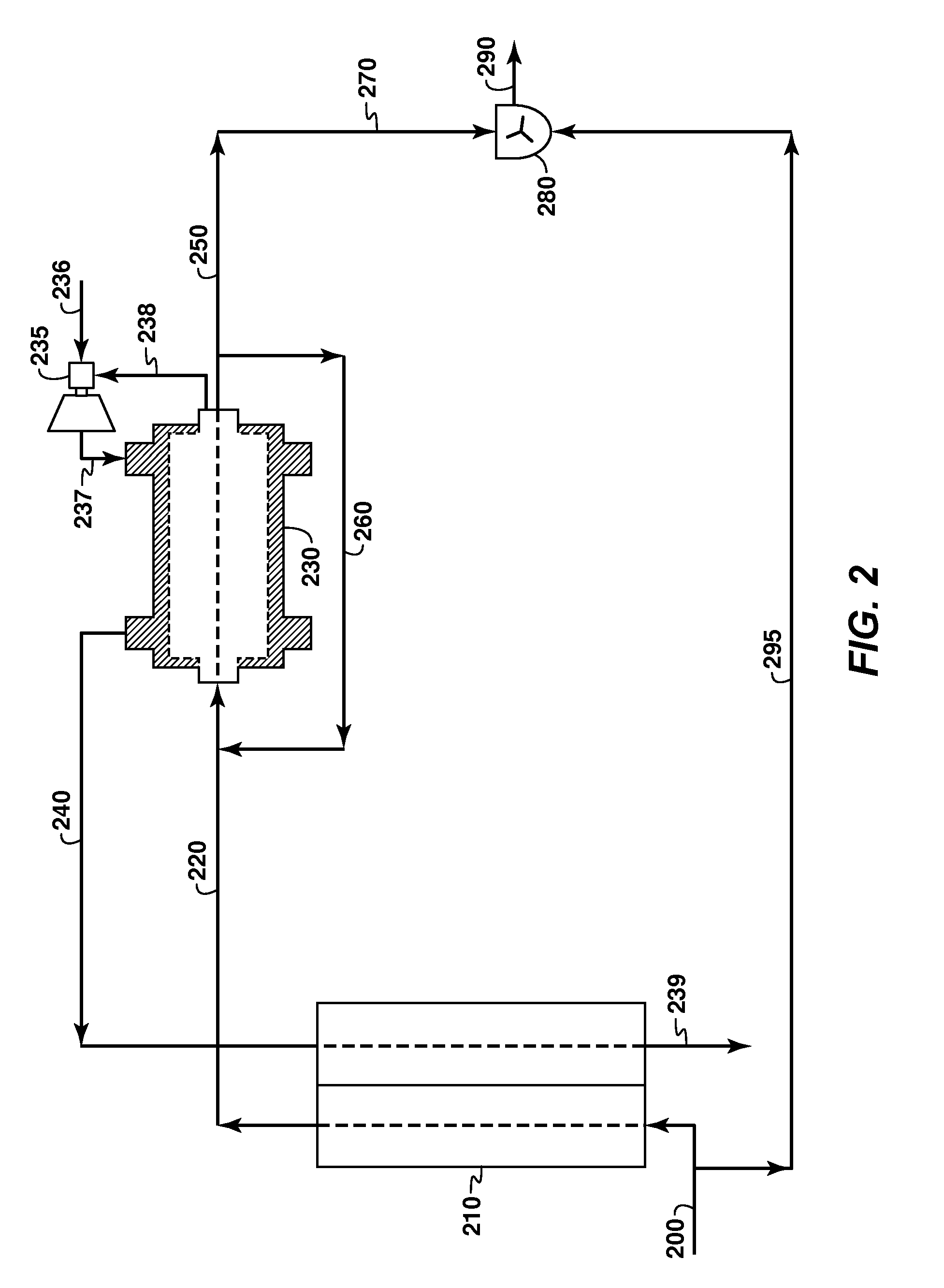

Heat and Water Recovery From Oil Sands Waste Streams

InactiveUS20110061610A1Lower energy requirementsReduce heatSand dryingLiquid hydrocarbon mixture productionWaste streamProcess engineering

Methods and systems for recovering heat and water from waste streams produced during oil sands extraction to form dry, stackable tailings. A tailings stream is preheated in a heat exchanger, thereby reducing the energy required to dry the tailings. The preheated tailings are then dried, thereby reducing the tailings to dry stackable tailings or thickened tailings suitable for mine backfill. Heat and high-quality water are recovered from the drying operation and re-used in the preheat operation, or in other steps of oil sands extraction or treatment processes, thereby reducing the overall heat and water requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

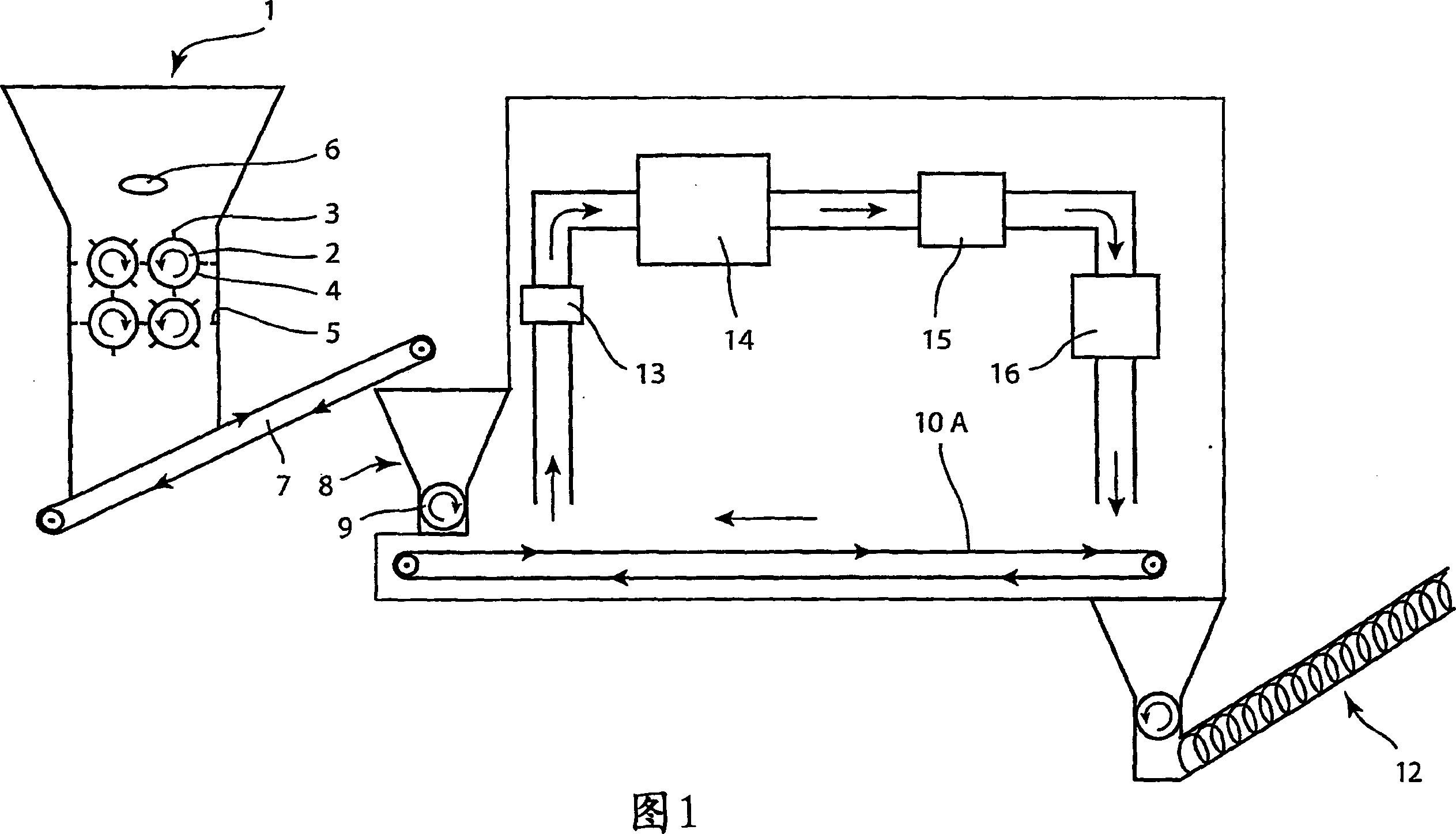

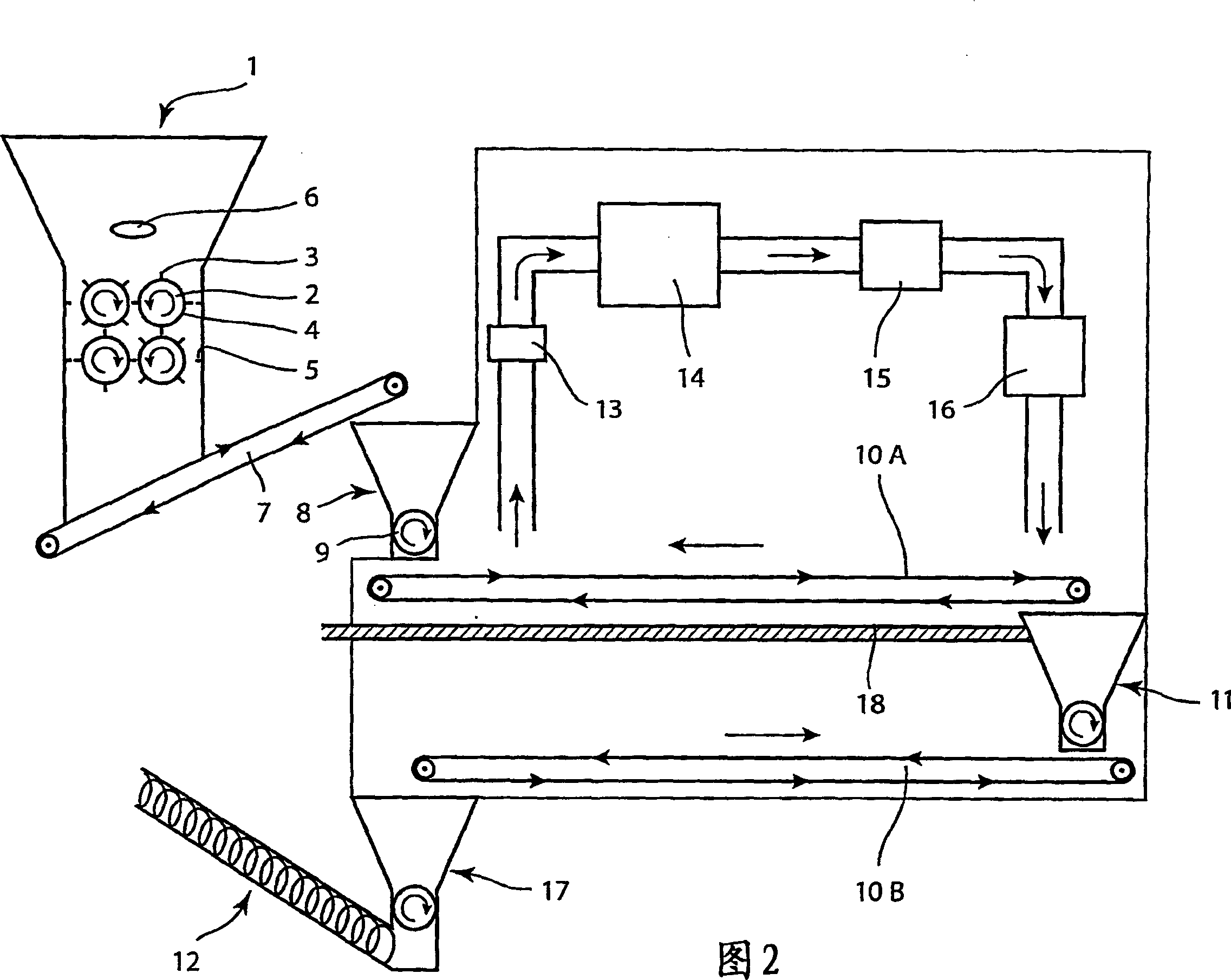

Biomass converters and processes

InactiveUS20080134540A1Reduce decreaseQuick limitBio-organic fraction processingExcrement fertilisersProcess engineeringDefining length

This invention pertains to a bio-mass processing system, and method of processing waste bio-mass, wherein one or more mixers mixes a bed of bio-mass material such as manure at substantially any and all locations in a defined length and width portion of the bed, in a dryer. Heated air percolates upwardly through the bed. Separation apparatus separates a relatively dryer fraction of the bio-mass material from the dryer. The separated finished product from the dryer is optionally fed to a boiler where the dried bio-mass material is burned. Heat of combustion from the boiler is used as dryer heat for drying the bio-mass feed material in the dryer. Excess heat is optionally used to produce steam, which powers a turbine, which powers an electrical generator. Residual ash from the combustion process comprises about 2% by weight of the solids content of e.g. a feed stream coming into the dryer.

Owner:ECOCOMBUSTION ENERGY SYST CORP

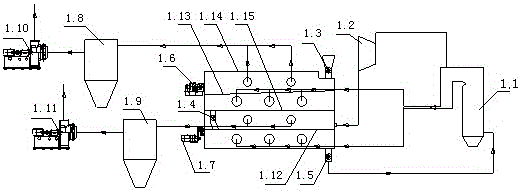

Brown coal drying method and device utilizing waste heat of smoke and steam of power plant

ActiveCN106382790AImprove economyImprove operational efficiencyDrying solid materials with heatDrying gas arrangementsBrown coalProcess engineering

The invention discloses a brown coal drying method and device utilizing waste heat of smoke and steam of a power plant. The drying method comprises two-time drying treatment, wherein the two-time drying treatment comprises the steps that firstly, the high-temperature smoke directly discharged by a power plant coal fired boiler is utilized for conducting first-time drying treatment on damp materials, the high-temperature smoke directly makes uniform contact with the damp materials, and intermediate materials are obtained; and secondly, the high-temperature smoke and the high-temperature steam directly discharged by the power plant coal fired boiler are utilized for conducting second-time drying treatment on the intermediate materials at the same time, the high-temperature smoke directly makes uniform contact with the intermediate materials, meanwhile, the intermediate materials make uniform contact with a heat exchange pipe inflated with the steam for heat exchange, dried materials are obtained, and second-time drying treatment is achieved. The brown coal drying method and device have the beneficial effects that the power plant waste heat serves as a heat source for brown coal drying, the running economical efficiency of a power plant generator set is improved, a system for drying the brown coal and a brown coal power generation system are integrated, efficient utilization of power plant energy and optimization of a technology system are achieved, and the brown coal drying method and device belong to the poly-generation technology of the power plant.

Owner:邹平双飞成套设备有限公司

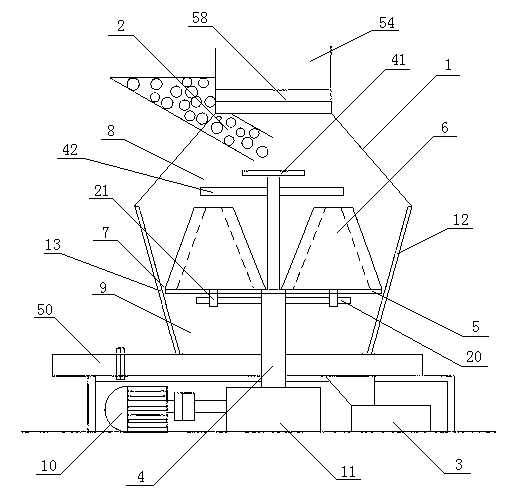

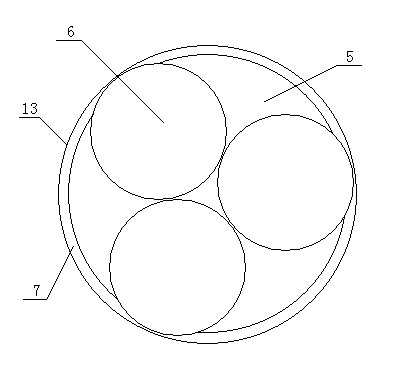

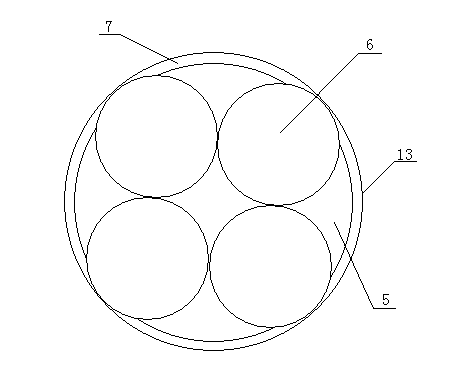

Drying and sorting integrated crusher and process

InactiveCN102698835ASimple production processLess investmentDrying gas arrangementsGrain treatmentsEngineeringHardness

The invention discloses a drying and sorting integrated crusher and a process thereof. The crusher comprises a crushing device, an air blast device, a sorting device and a drying preheating device. Ores are preheated by the drying preheating device and are crushed by the crushing device, and dust formed after the ores are crushed by the crushing device is raised by air which is blown by the air blast device into the sorting device; and a finished product is obtained by the settlement of the dust in the sorting device. According to the drying and sorting integrated crusher, the crushing device comprises a spindle, a crushing disc and 3 to 8 grinding rollers; the spindle is vertical; the crushing disc is horizontal; the grinding rollers are erected on the crushing disc and are meshed with the inner wall of a crushing cavity; and the adjacent grinding rollers are meshed with each other. When the crushing device runs, the grinding rollers revolve on the own axis while rotating around the spindle. The crushing device has a high-efficiency crushing effect on low-hardness ores, and is particularly suitable for crushing asbestos ores. When the drying and sorting integrated crusher is applied to the asbestos ores, the process can be simplified, investment of equipment and capital construction can be reduced, energy consumption and cost can be reduced, and the production efficiency can be improved greatly.

Owner:NANJING EFFUL

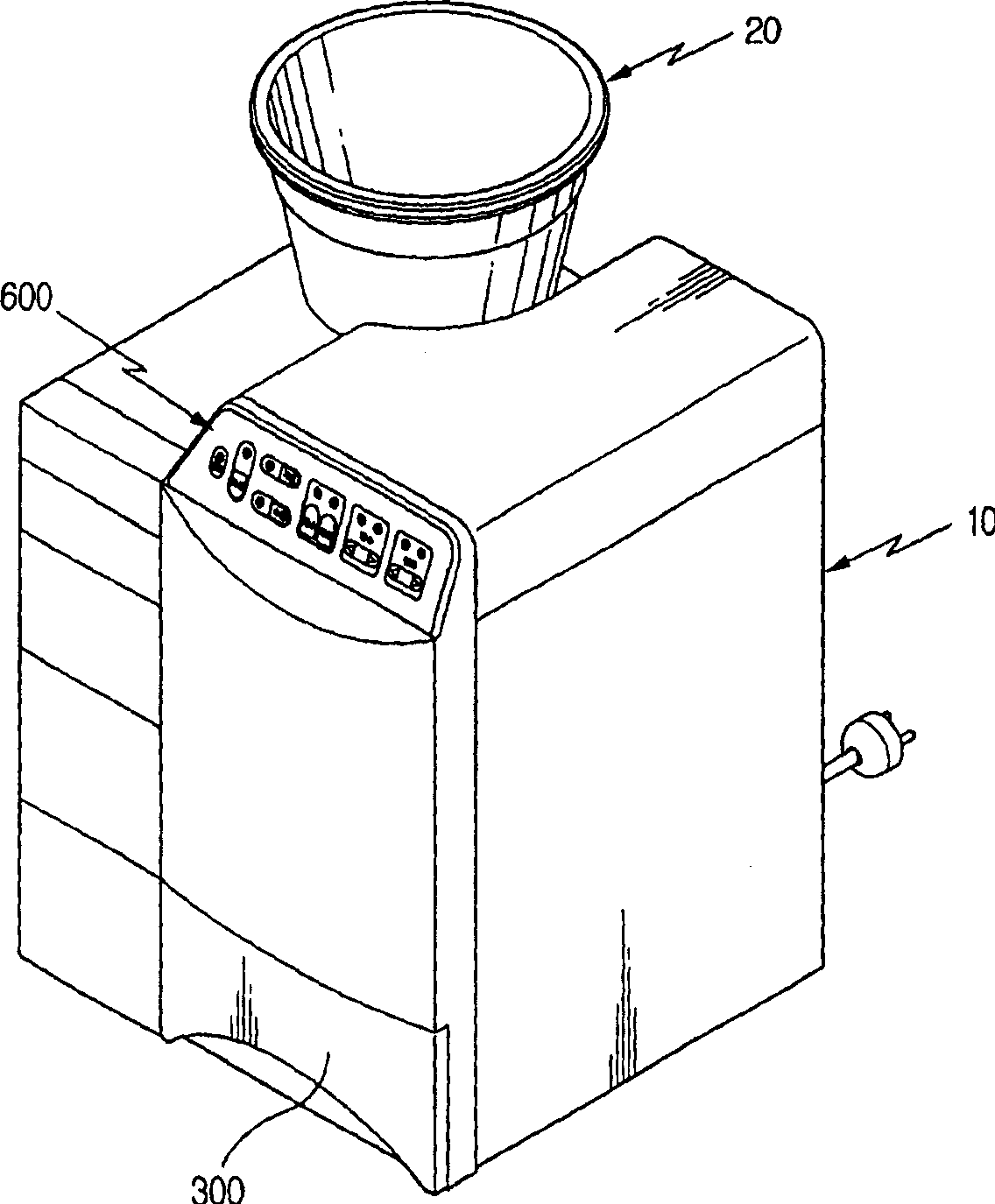

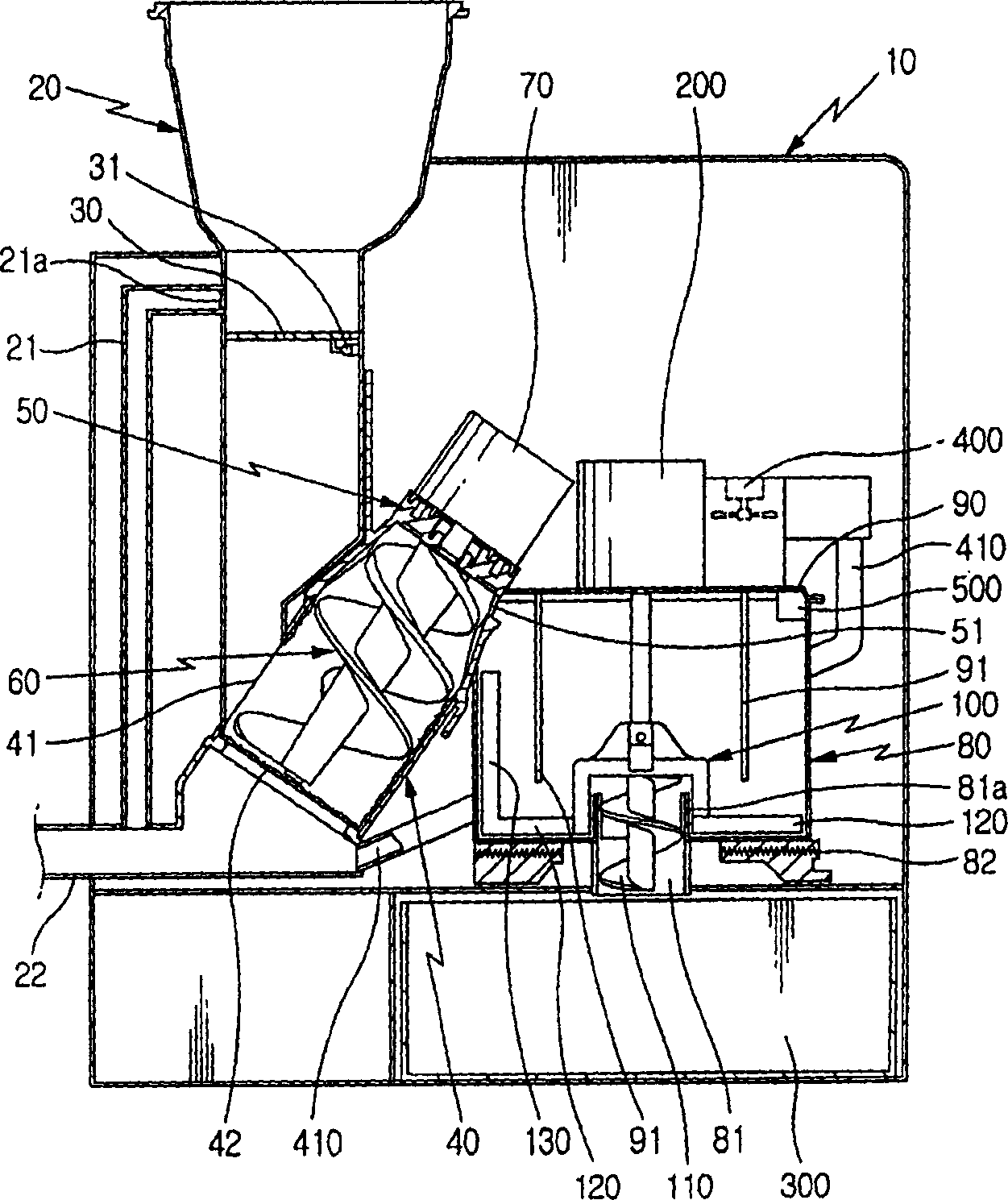

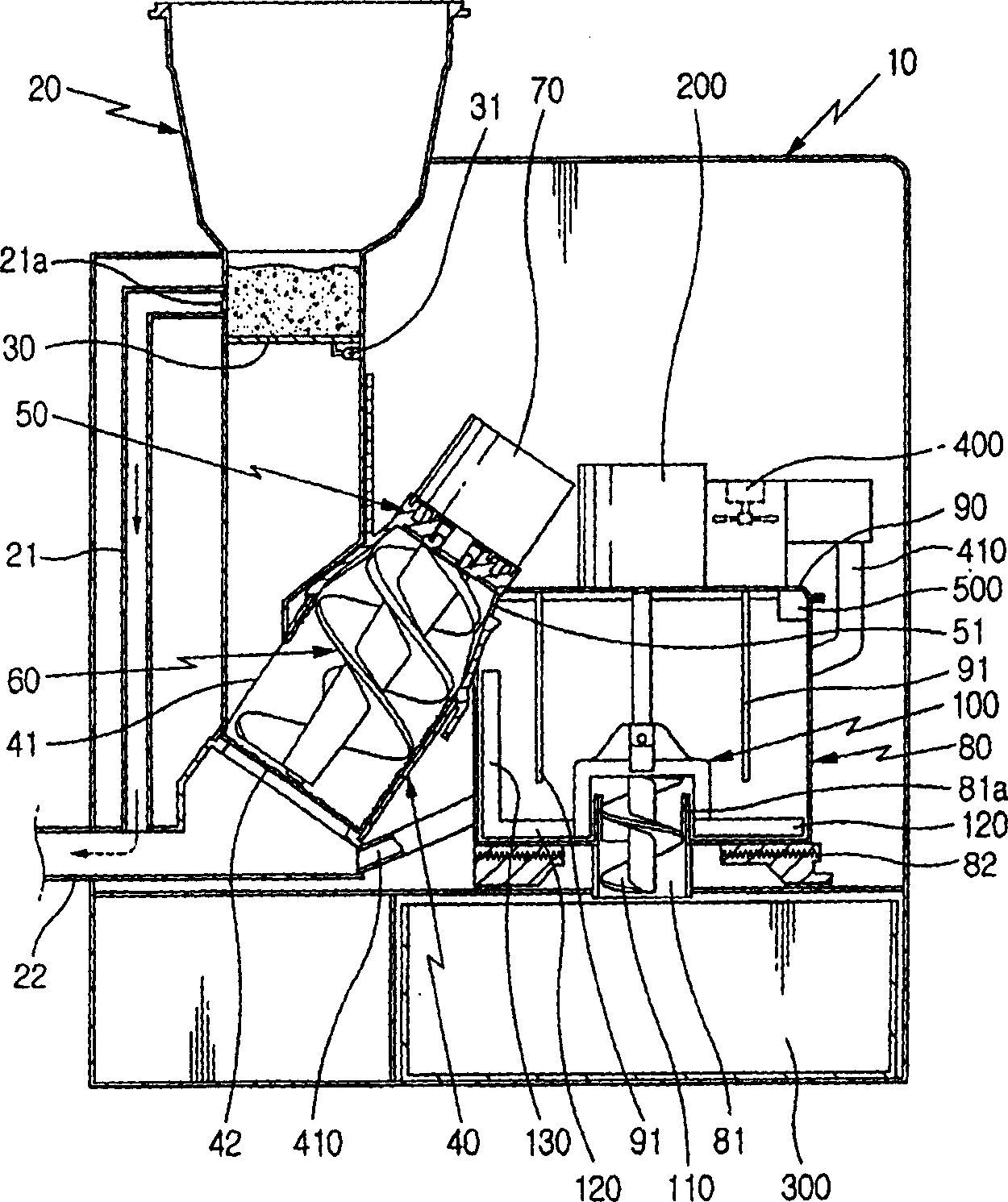

Food-trash processing unit for kitchen

InactiveCN1741865AEasy to useDrying using combination processesSludge treatment by de-watering/drying/thickeningVerminEngineering

The invention relates to a food-trash processing unit for kitchen, which is installed in the under space of a tableware washing stand to separate automatically the food-trash. This food-trash processing unit comprises an inlet duct (20) provided in the body (10) so as to be connected to a drain of a tableware washing stand; a dewatering drum (40) connected to the inlet duct (20); a cap (50) mounted on the dewatering drum (40) and having a discharge opening (51); a transferring screw (60) supported on the cap (50); a drying container (80) disposed under the cap (50) and connected to the discharge opening (51), said drying container being provided with a discharge opening (81) and a heater (82); a stirring member (100) inserted inside the drying container (80); a storing receiver (300) disposed withdrawably under the drying container (80); a ventilating fan (400) and a vermin exterminator (500), each disposed in the drying container (80); and a controller (600) for automatically controlling the above-described components.

Owner:SOFTBIOTECH CORP

Sludge Dewatering and Drying

InactiveUS20100170854A1Reduce disposal costsFacilitates environmental complianceAuxillariesDrying solid materials without heatFiltrationDewatered sludge

Methods, apparatus and systems for dewatering and drying the dewatered sludge. Sludge pumped into the sludge dewatering apparatus is mixed in-line with a pre-measured quantity of polymers to agglomerate solids entrained in the sludge. The agglomerated sludge is routed to a filtration station comprising filtration chambers. The filtration chambers are fitted with industry standard filter bag. The agglomerated sludge is subjected to dewatering in the filter bags and the dewatered sludge is subsequently compacted, dried and discarded.

Owner:SEVERN TRENT DE NORA LLC

Apparatus for drying granular objects involving pre-heating process

InactiveUS6223451B1Reduce harmMoreDrying solid materials with heatDrying gas arrangementsProcess engineeringBucket elevator

An apparatus for drying granular objects comprises, from the top of the apparatus, a holding section; a heating section for heating the granular objects flowing down from the holding section, the heating section being provided beneath the holding section and having a plurality of air ducts to which heated air is introduced; a drying air producing section connected to the air ducts, in which the heated air from the air ducts is mixed with air taken-in from the outside of the apparatus to produce a drying air; and a drying section for drying the granular objects by directly exposing the granular objects to the drying air. The dried granular objects are taken out from a taking-out section and returned to the holding section through a bucket elevator. The apparatus further comprises a detector for detecting the temperature of the drying air. Based on the detected temperature, a control device controls the temperature of the heated air so as to keep the temperature of the drying air to a predetermined temperature. The temperature of the drying air can be set to a desirable temperature while the heated air for the heating is kept at a high temperature. The drying operation is performed speedily and safely.

Owner:SATAKE CORP

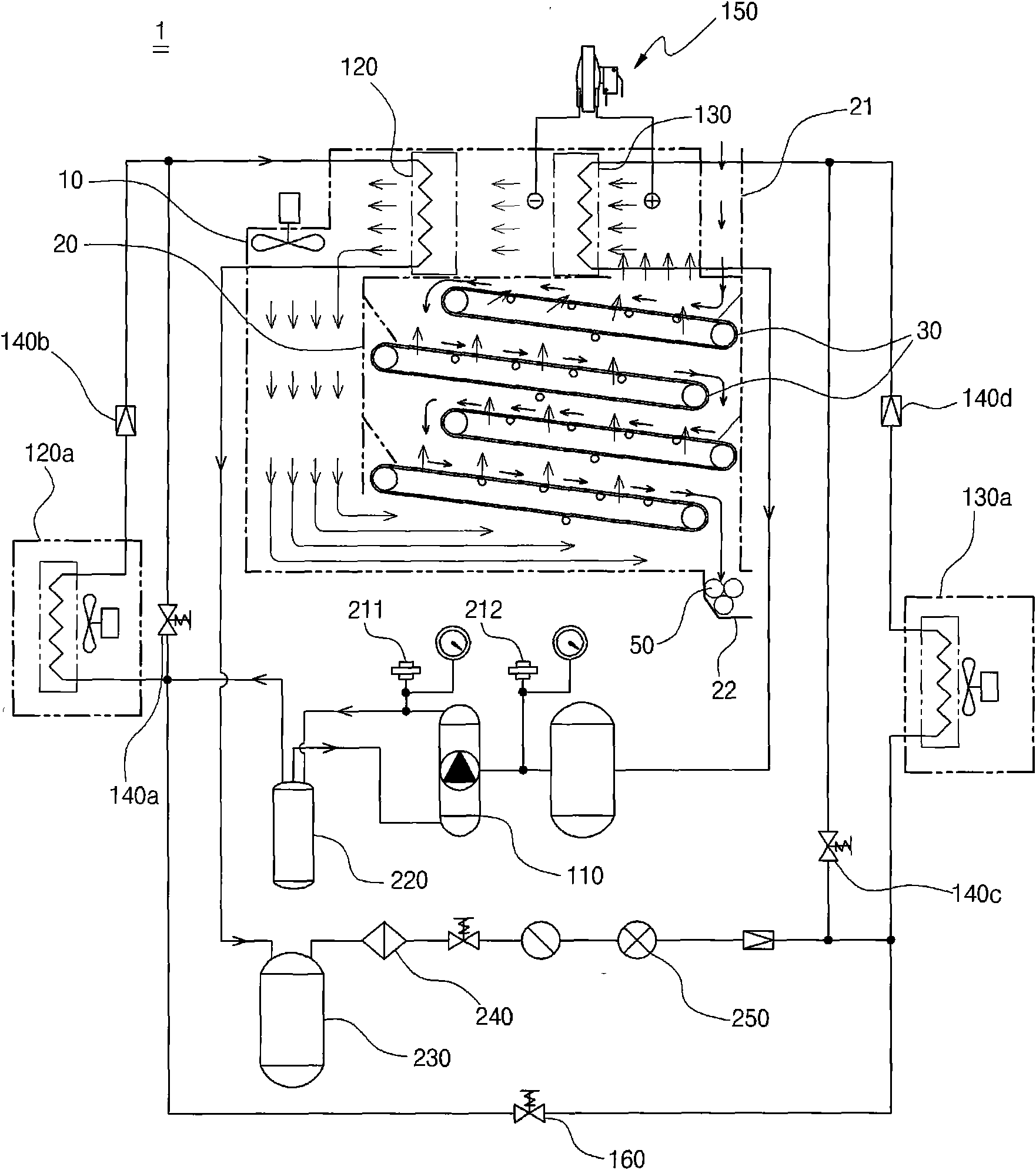

Multipurpose drying apparatus using heat pump system

InactiveCN101782315AIncrease temperatureDry properlyHeat pumpsDrying solid materials with heatProcess engineeringRefrigerant

The invention provides a multipurpose drying apparatus using heat pump system. According to one side of the invention, the multipurpose drying apparatus is characterized in that the drying is performed through a heat pump system, the heat pump system circulates the refrigerant by means of a compressor, a main condenser and a main evaporator, the multipurpose drying apparatus using heat pump system includes a drying apparatus body, wherein a main condenser and a main evaporator are provided to perform heat exchange; and a drying chamber formed inside the drying apparatus, to perform drying to drying objects. The heat pump system includes an auxiliary condenser, provided at the external of the drying apparatus body, and is configured to selectively link between the compressor and the main condenser, so as to reduce the temperature inside the drying apparatus body.

Owner:成 明济 +2

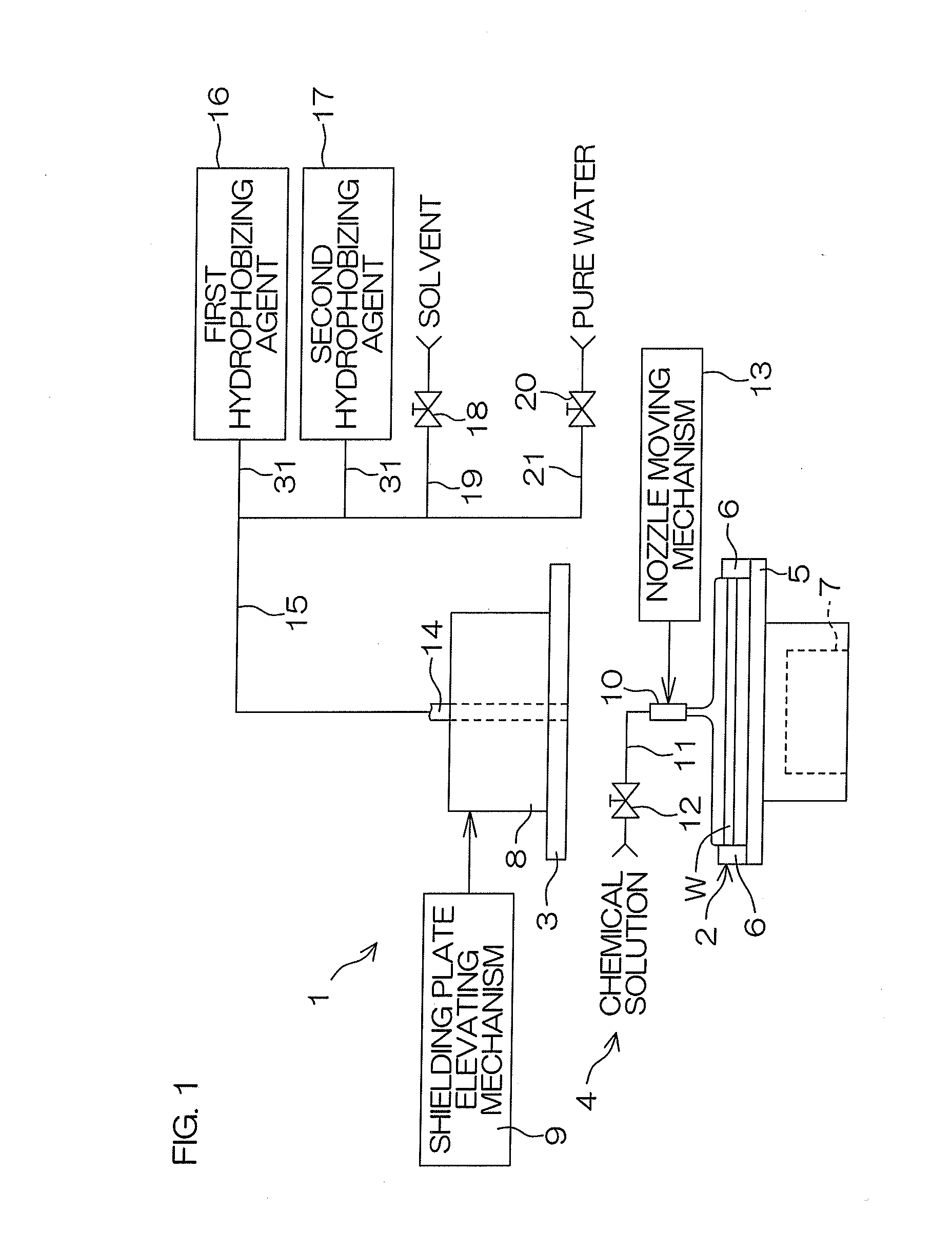

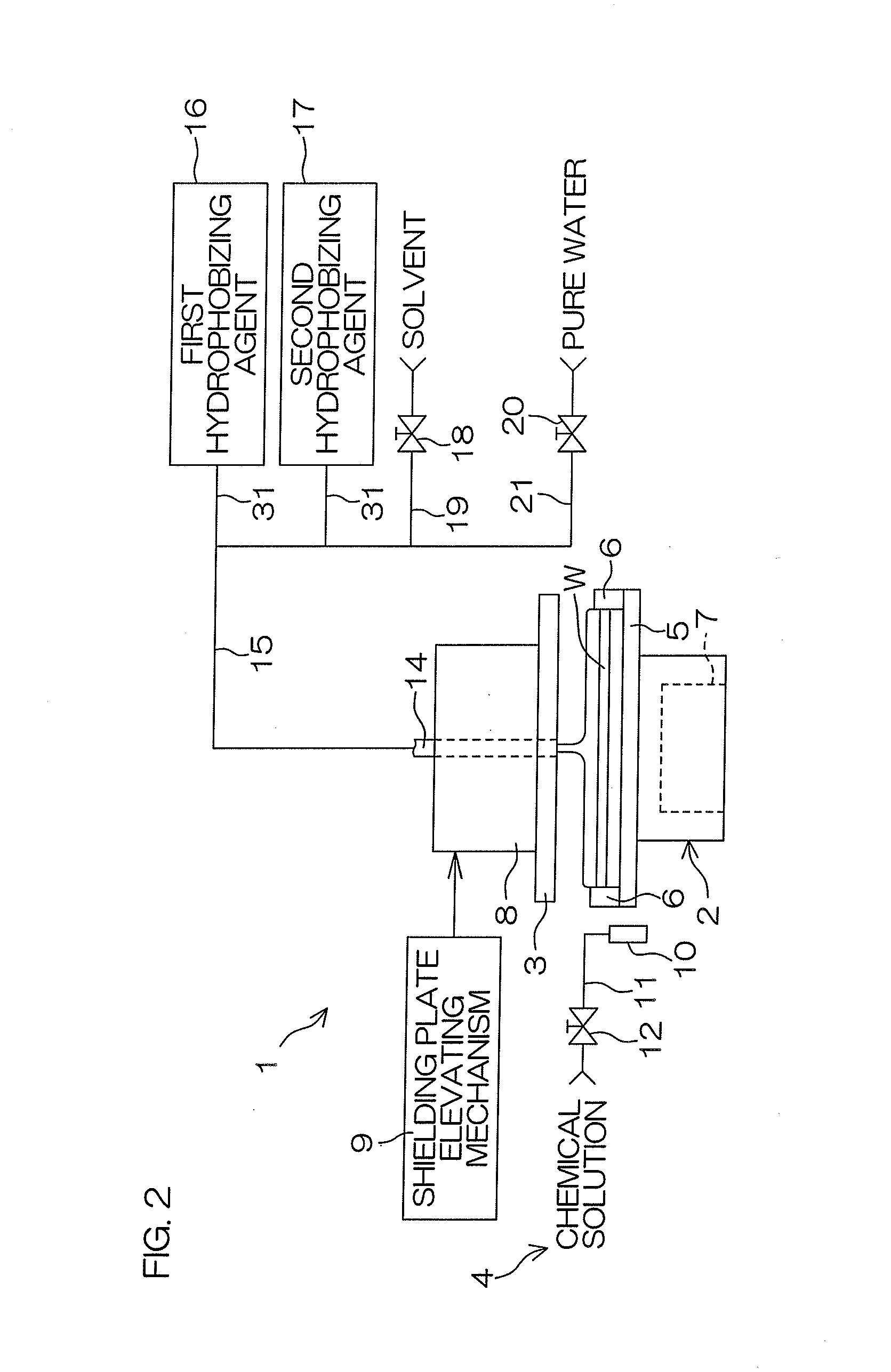

Substrate processing method and substrate processing apparatus

ActiveUS20120045581A1Shorten substrate processing timeShort timeOther chemical processesPhotomechanical apparatusEngineeringSubstrate surface

A hydrophobizing agent is supplied to a substrate and a surface of the substrate is hydrophobized. Thereafter, the substrate is dried. The substrate to be processed is maintained in a state of not contacting water until it is dried after being hydrophobized. Collapse of a pattern formed on the substrate surface is thereby suppressed or prevented.

Owner:DAINIPPON SCREEN MTG CO LTD

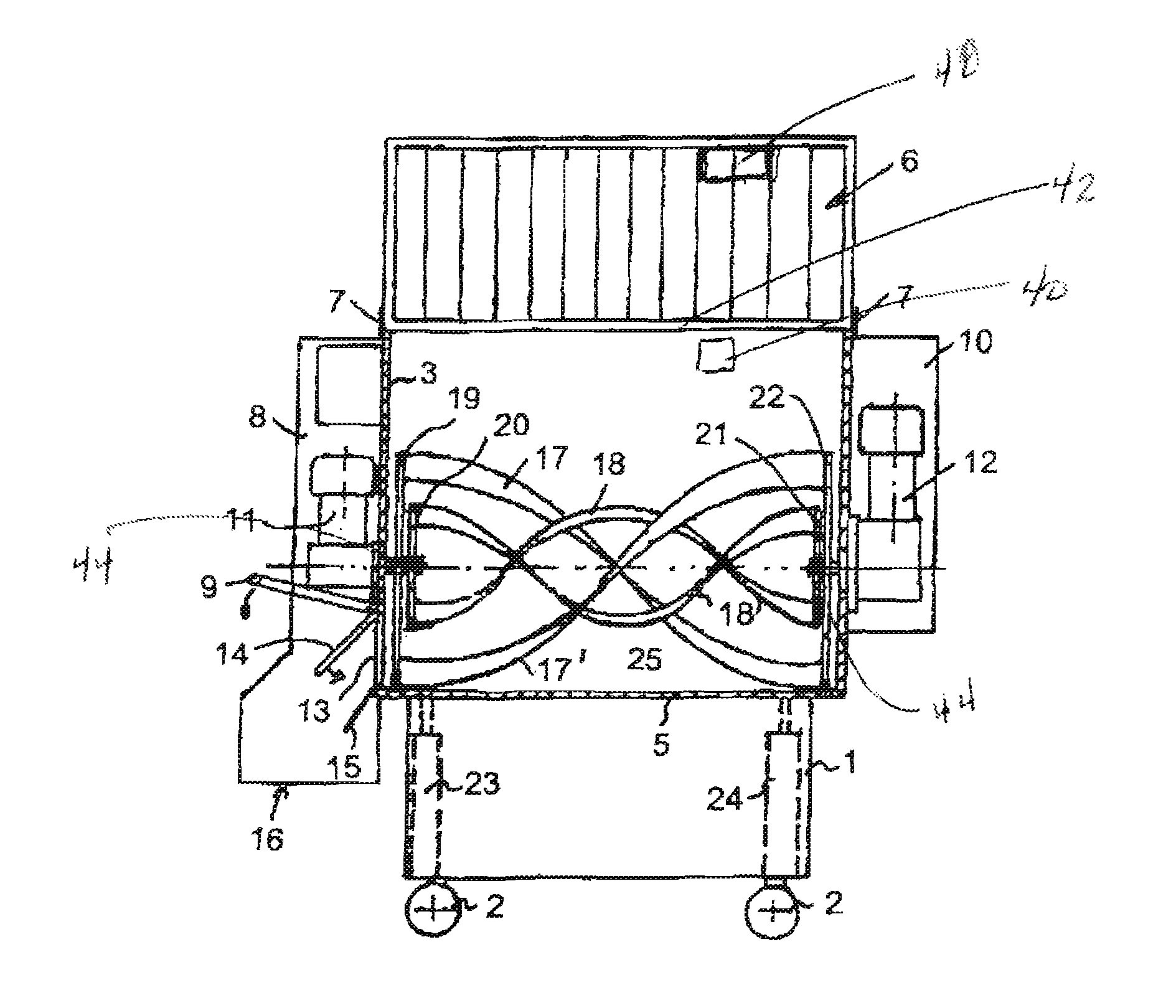

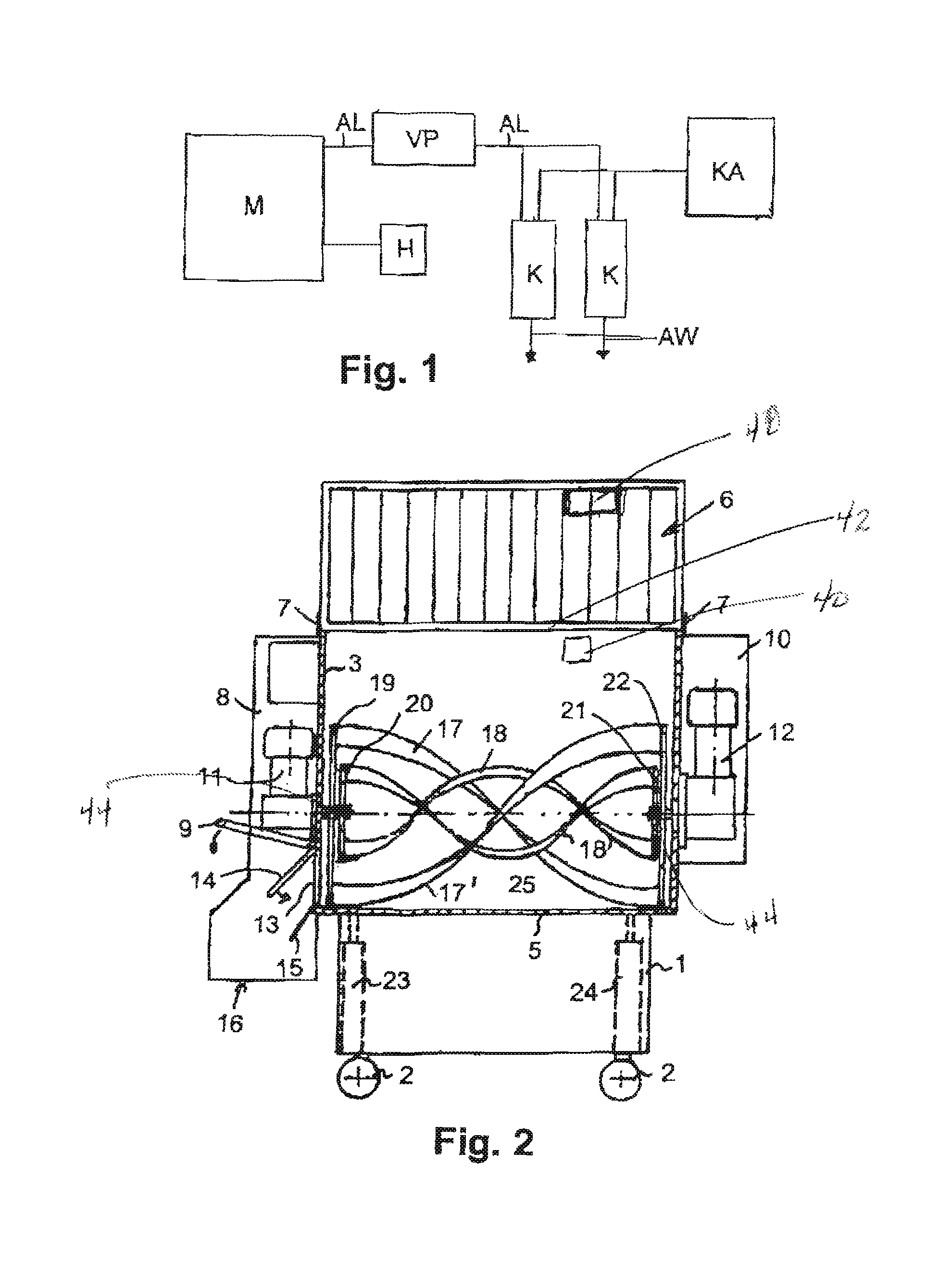

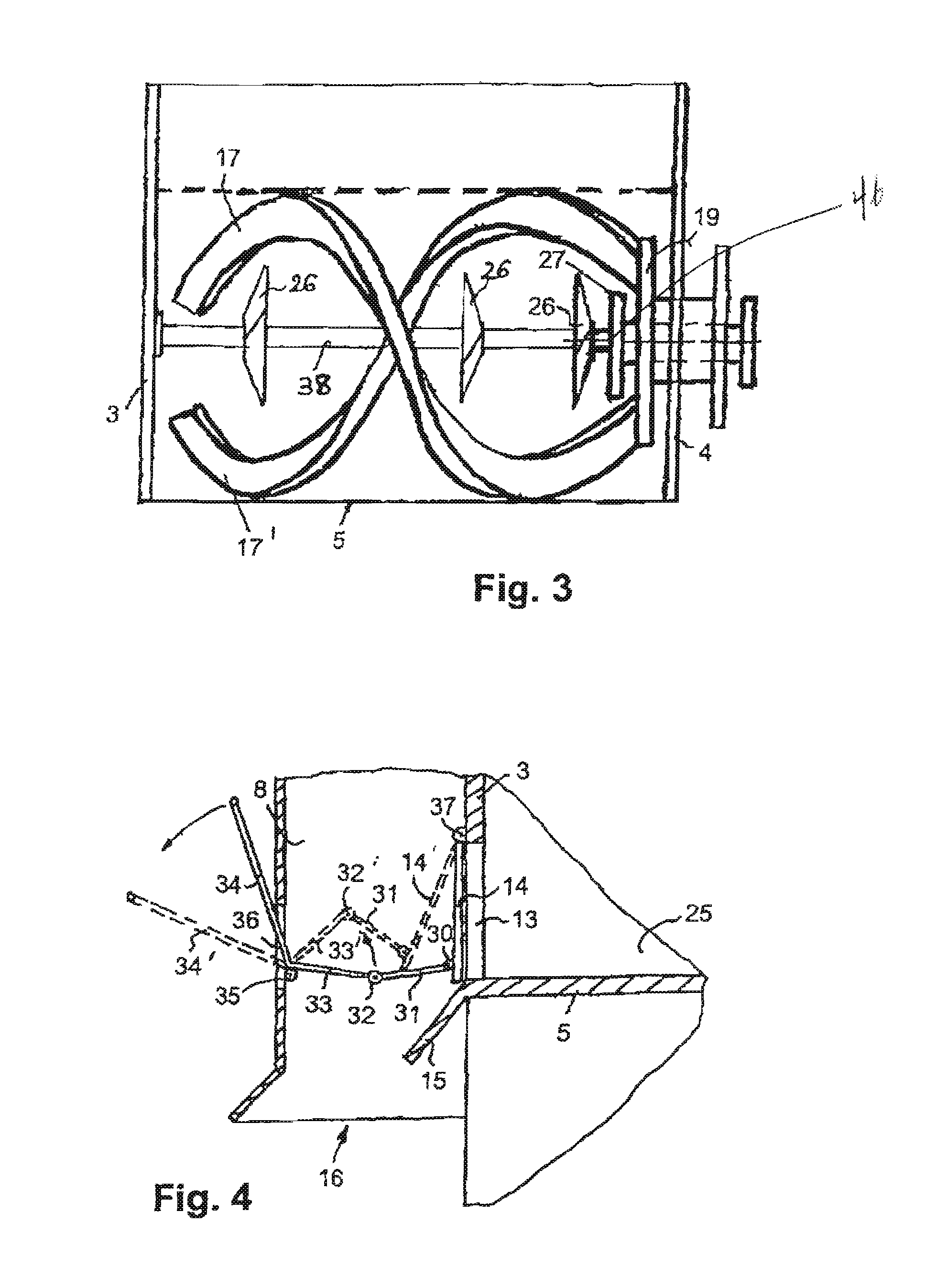

Installation for drying organic matter

ActiveUS8561314B2Efficient heatingFast heatingDrying solid materials with heatDrying solid materials without heatLitterEngineering

An installation for drying organic matter, especially kitchen and food wastes or other biological matter, including matter that contains packaging residues, napkins, straws or the like. The installation comprises the following components: (a) a vacuum mixer (M) having a closable charging opening for introducing the organic matter and a closable discharge opening, disposed at the bottom or laterally towards the bottom, for the dried matter, (b) at least one vacuum pump (VP) for evacuating the air in the mixer to generate the vacuum, the pump being connected to at least one evacuation tube mounted above the maximum filling level in the housing of the mixer (M), (c) a heater (H) for heating the organic matter, (d) at least one condenser (K), connected to the air evacuation duct (AL) of the vacuum pump (VP) and having a cooling unit (KA) connected thereto to condense the evacuated air, and (e) a discharge duct (AW) for the condensate obtained from the evacuated air by cooling in the condenser (K).

Owner:INOTEC MASCHENENTWICKLUNG & VERTRIEB

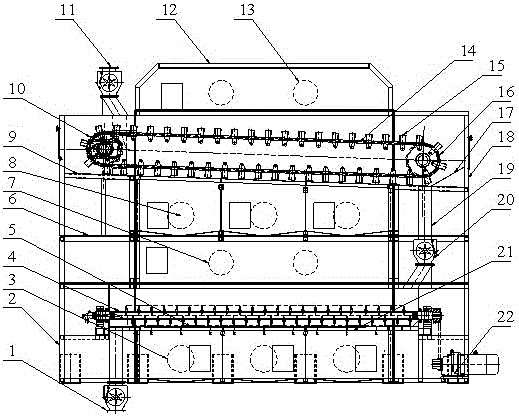

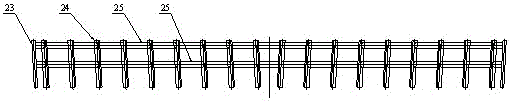

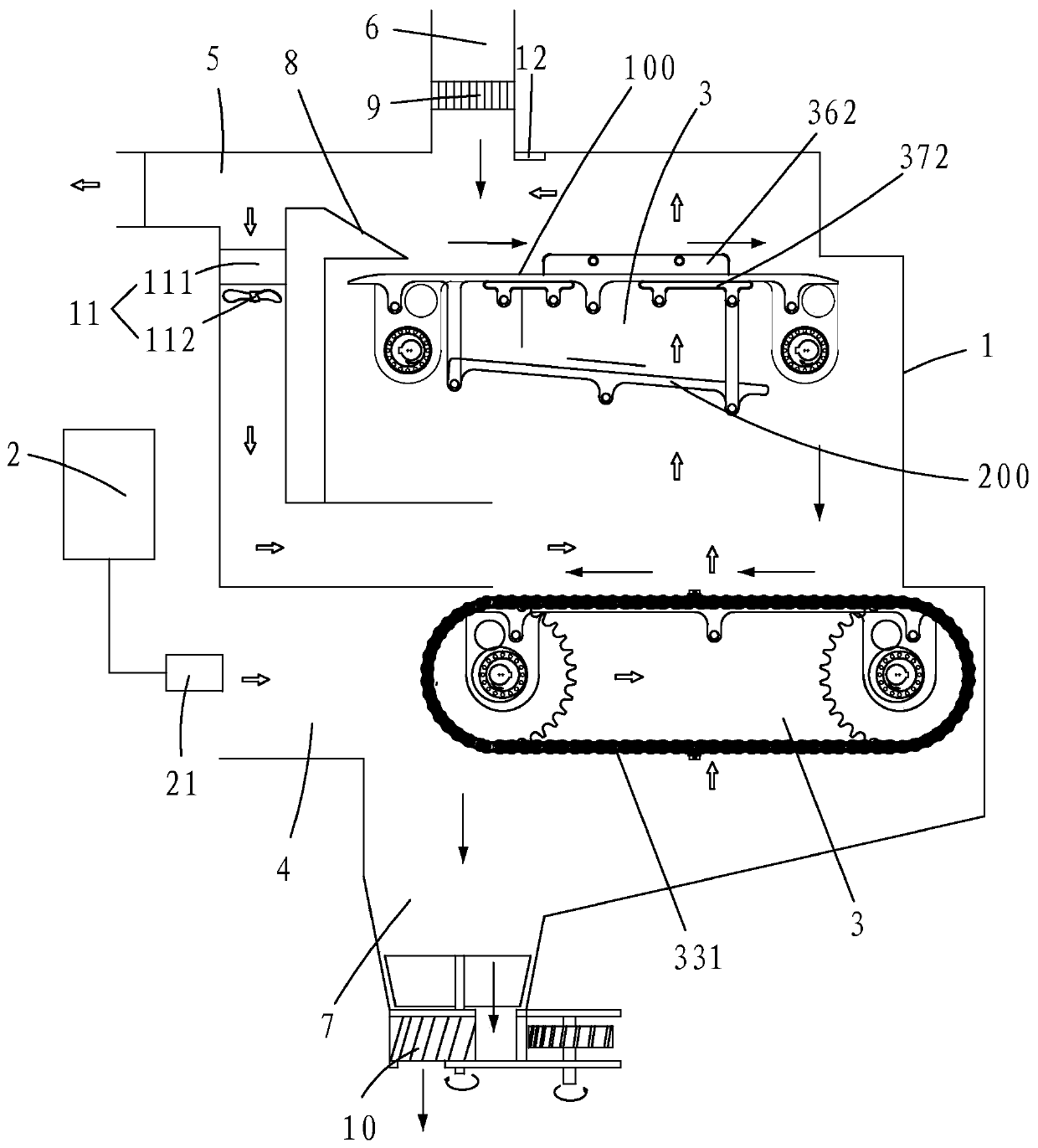

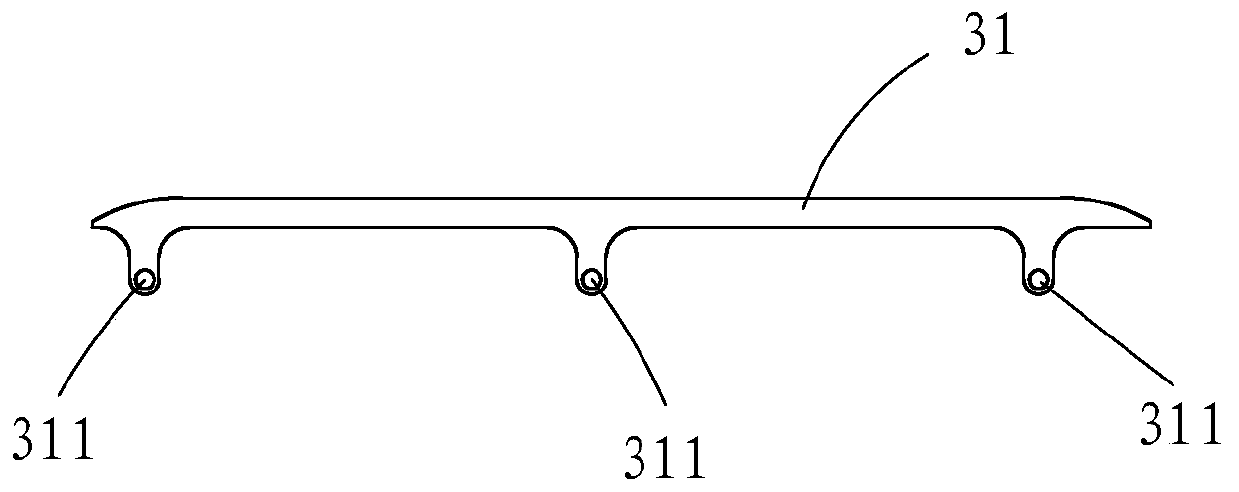

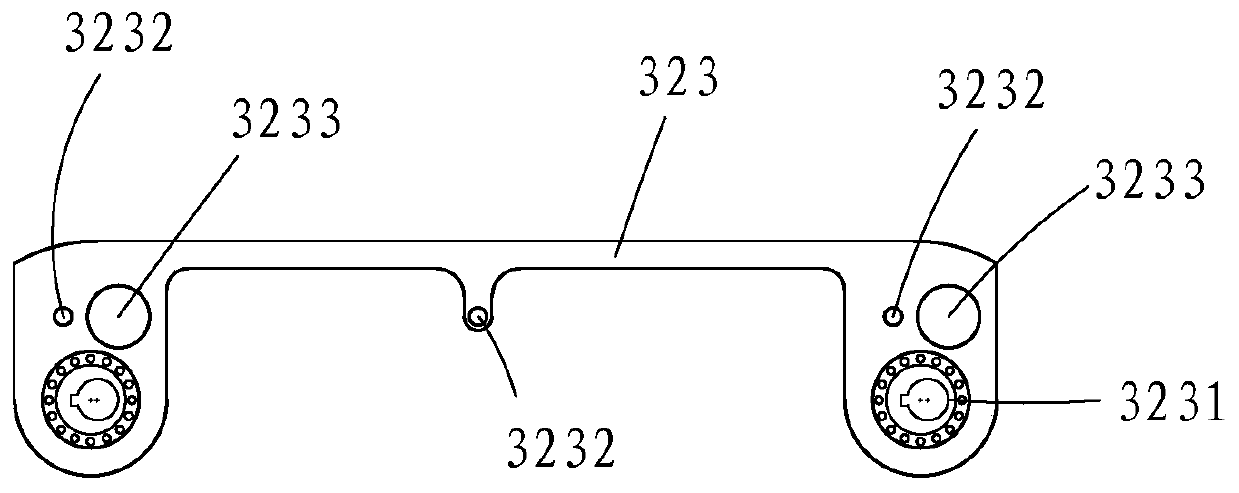

Peristaltic propulsion type drying equipment

PendingCN110487026AEasy to dryEfficient dryingSludge treatment by de-watering/drying/thickeningDrying gas arrangementsProcess engineeringHeat supply

The invention discloses peristaltic propulsion type drying equipment. The peristaltic propulsion type drying equipment comprises a heat supply module, a drying chamber and a material conveying devicearranged in the drying chamber, wherein the drying chamber is provided with a heat source inlet, a heat source outlet, a material inlet and a material outlet; a heat source of the heat supply module is arranged at the position of the heat source inlet and used for providing a heat source for the drying chamber; the material conveying device is used for providing a platform for horizontally pavingmaterials and pushing materials, and comprises two or more groups of grid strips which are laminated at intervals to form a laminated propelling type material conveying platform; a gap is formed between every two adjacent grid strips; and when the materials are conveyed forwards, the ventilation gaps are kept smooth, and the advancing materials are repeatedly overturned. According to the peristaltic propulsion type drying equipment, in the material conveying process, the interactive grid strips generate the transparent gaps, so that the mobility of air is improved, and the materials are advantageously dried.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

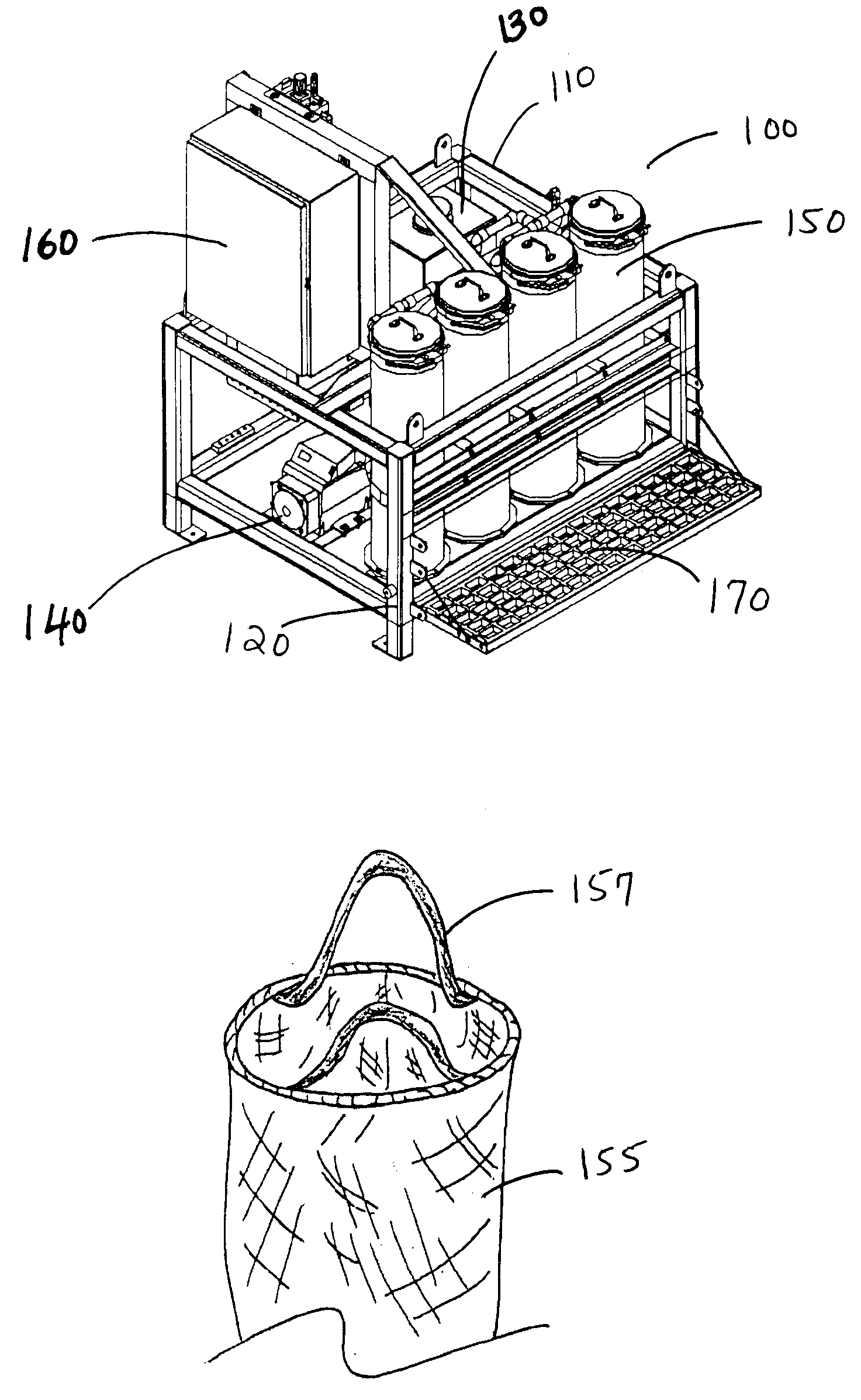

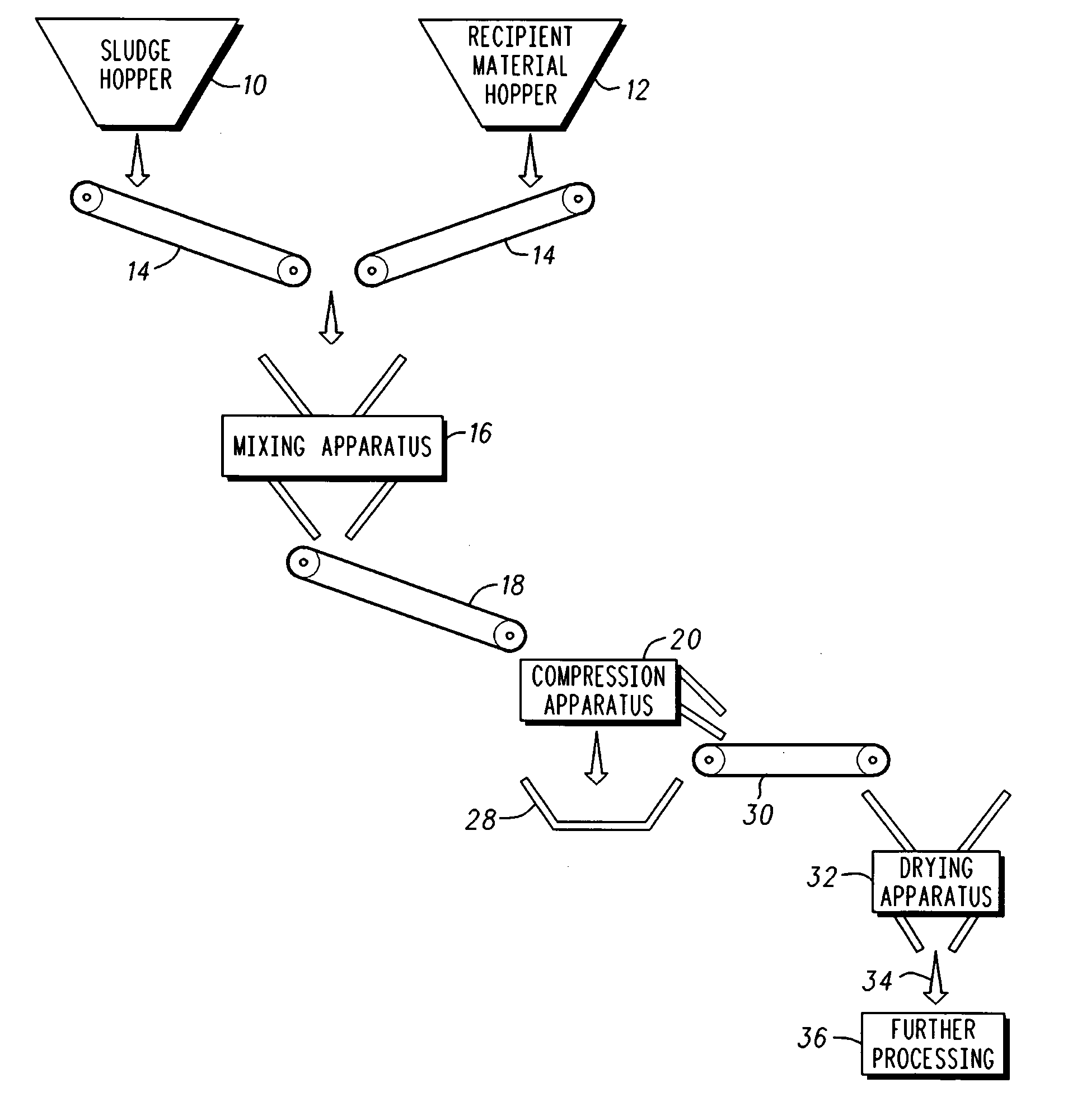

Waste treatment system

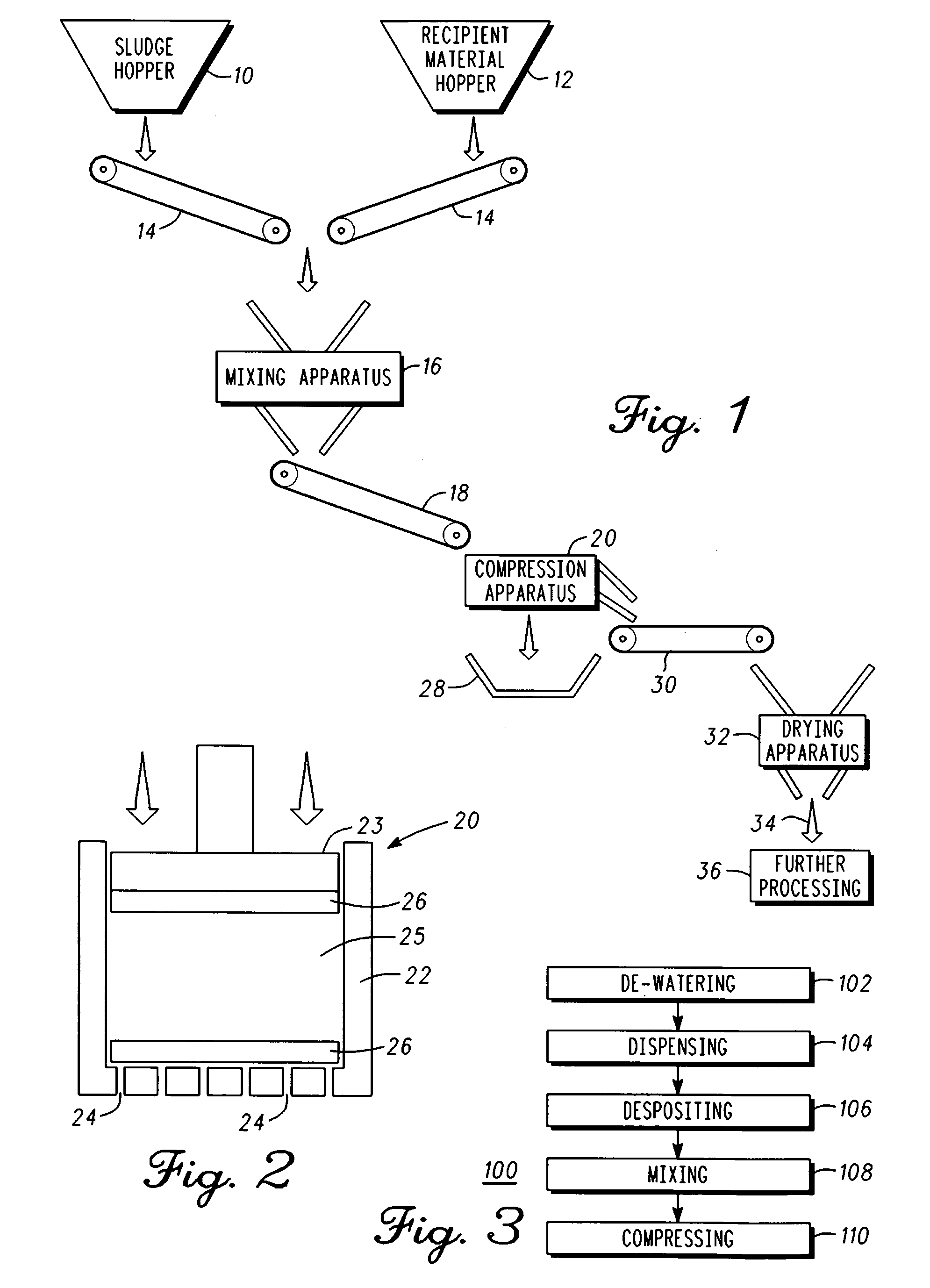

InactiveUS20100096336A1Drying using combination processesDrying solid materials without heatSludge cakeWater treatment system

A system for removing water from sludge is disclosed. The system (100) includes: de-watering (102) sludge comprising an output from a wastewater treatment system to form a semi-solid sludge cake; dispensing (104) the sludge in a sludge hopper and dispensing a blending material in a recipient blending material hopper; depositing (106) the sludge and the blending material in a mixing device; mixing (108) the sludge and the blending material having a porous structure in a weight ratio of the sludge to the blending material of about from 2:1 to about 10:1; and compressing (110) the sludge and the blending material to release moisture. The system (100) provides an improved method of de-watering sludge, for more efficient processing, transporting and recycling, depending on the application.

Owner:HYDROPRESS HLDG

High-temperature and high-humidity rapid drying process method for wood

ActiveCN103017485AHigh yieldEvenly heatedDrying solid materials with heatDrying gas arrangementsHigh humidityEngineering

The invention relates to a wood drying process technology, in particular to a high-temperature and high-humidity rapid drying process method for wood, belonging to the field of wood processing. The high-temperature and high-humidity rapid drying process method comprise the following steps of: (1) humidifying and heating; (2) heating and humidifying pretreatment; and (3) high-temperature and high-humidity drying. According to the invention, the drying process problems that the traditional drying process cannot be used for drying hardwood, difficultly-dried hardwood and fast growing wood easily undergoing shrinkage and collapse after drying are solved, the dried wood is uniform in the distribution of moisture content and low in moisture content gradient in a thickness direction, and the defect that the fast growing wood is shrunk and collapsed after being dried is overcome. Meanwhile, the process flow of the traditional drying technology is simplified, and the most common drying process method with broadest applicable range is formed, is suitable for any varieties of tree wood with the thickness below 100mm and is easier to master by a technician.

Owner:贵州保城新材料有限公司

Installation for drying organic matter

ActiveUS20100132210A1Reduce working at heightsSimple configurationDrying solid materials with heatDrying solid materials without heatLitterOrganic matter

An installation for drying organic matter, especially kitchen and food wastes or other biological matter, including matter that contains packaging residues, napkins, straws or the like. The installation comprises the following components: (a) a vacuum mixer (M) having a closable charging opening for introducing the organic matter and a closable discharge opening, disposed at the bottom or laterally towards the bottom, for the dried matter, (b) at least one vacuum pump (VP) for evacuating the air in the mixer to generate the vacuum, the pump being connected to at least one evacuation tube mounted above the maximum filling level in the housing of the mixer (M), (c) a heater (H) for heating the organic matter, (d) at least one condenser (K), connected to the air evacuation duct (AL) of the vacuum pump (VP) and having a cooling unit (KA) connected thereto to condense the evacuated air, and (e) a discharge duct (AW) for the condensate obtained from the evacuated air by cooling in the condenser (K).

Owner:INOTEC MASCHENENTWICKLUNG & VERTRIEB

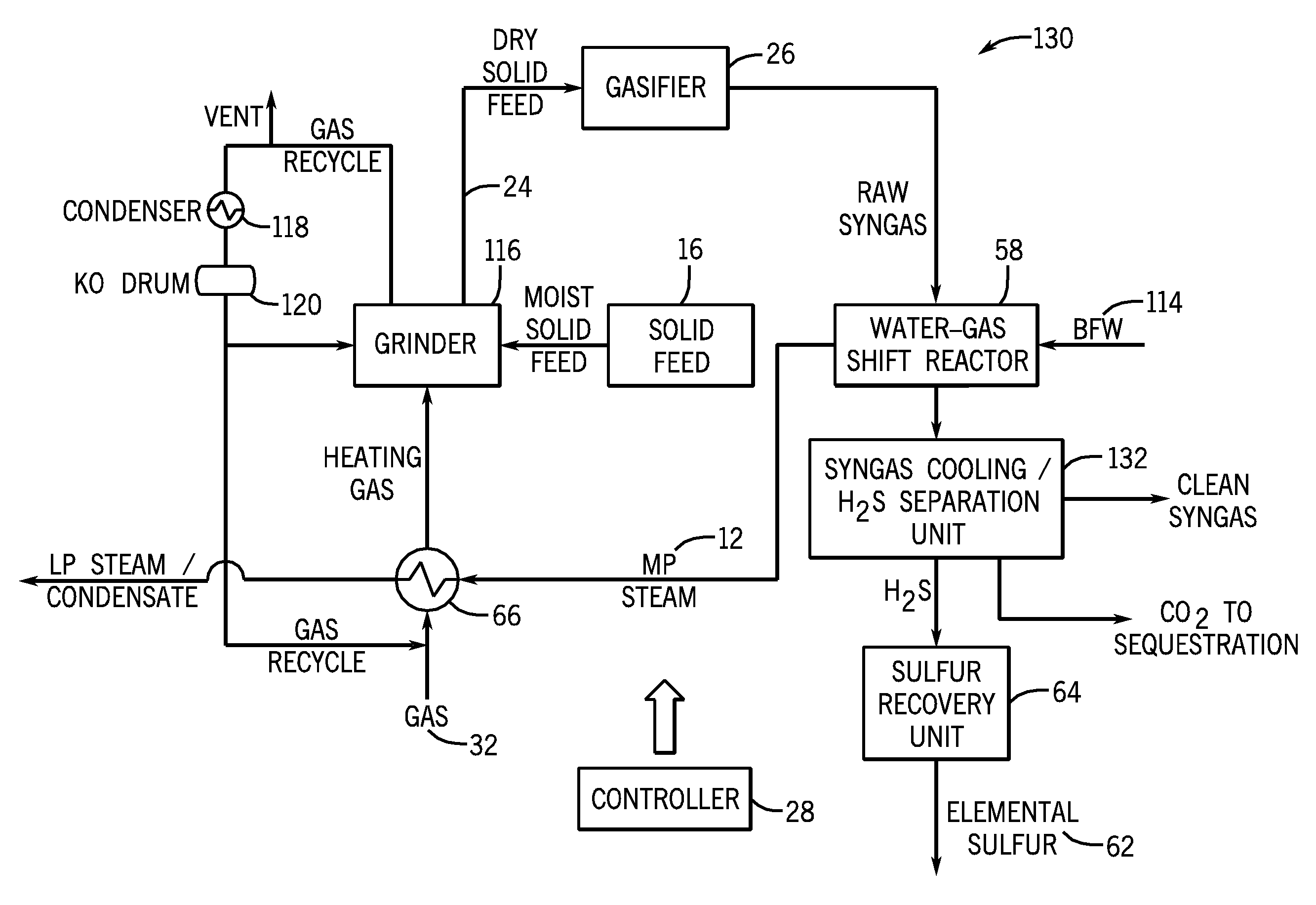

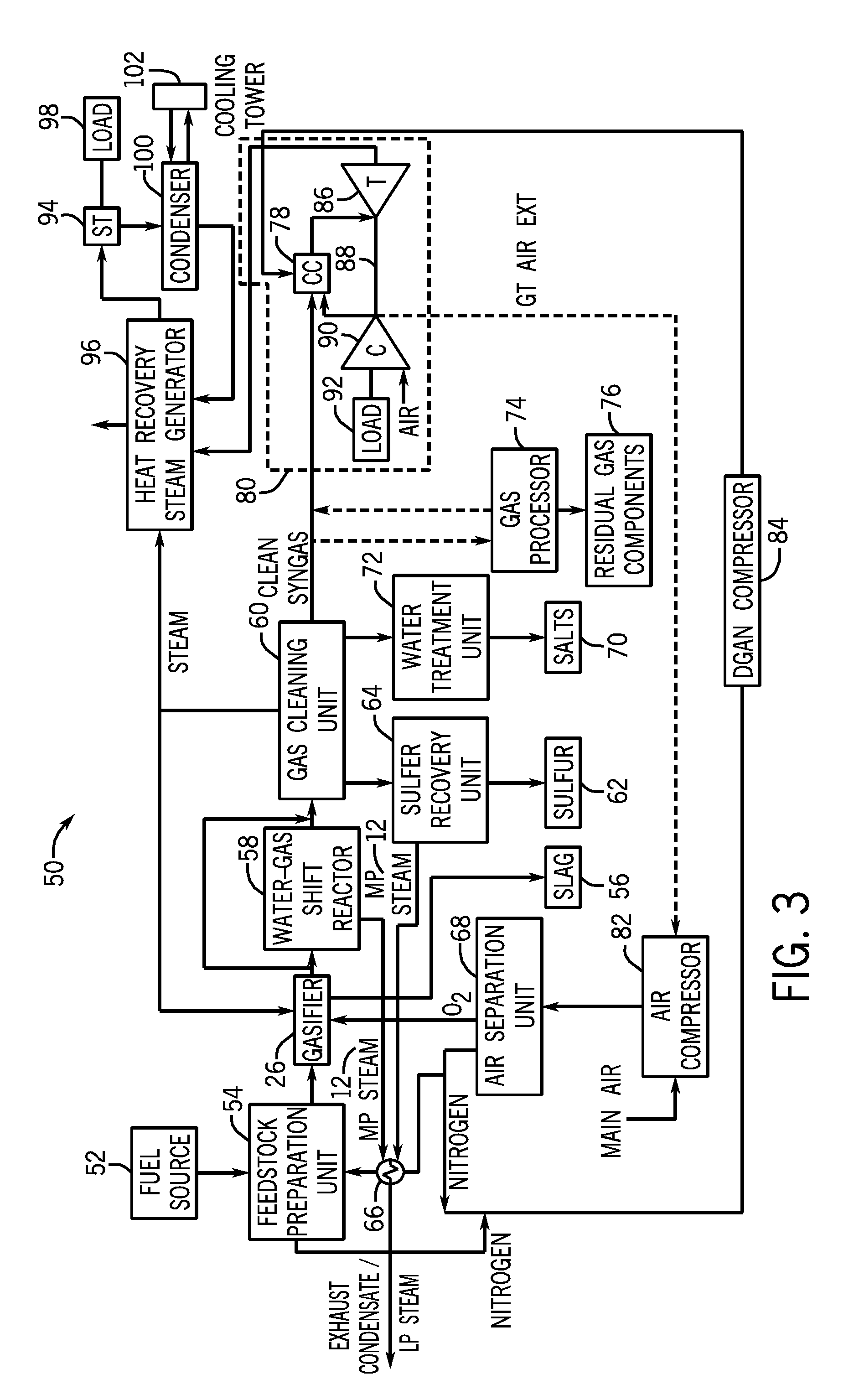

Method and apparatus for drying solid feedstock using steam

ActiveUS20110061298A1Solid fuel pretreatmentDrying gas arrangementsSteam pressureProcess engineering

Steam may be used to dry feedstock prior to delivery to a gasifier. A steam supply may be delivered to embodiments such as a feedstock dryer. Heat from the steam may then be transferred into the feedstock and used in drying the feedstock. Steam pressures may include pressures from 75 pounds per square inch up to and including 900 pounds per square inch.

Owner:AIR PROD & CHEM INC

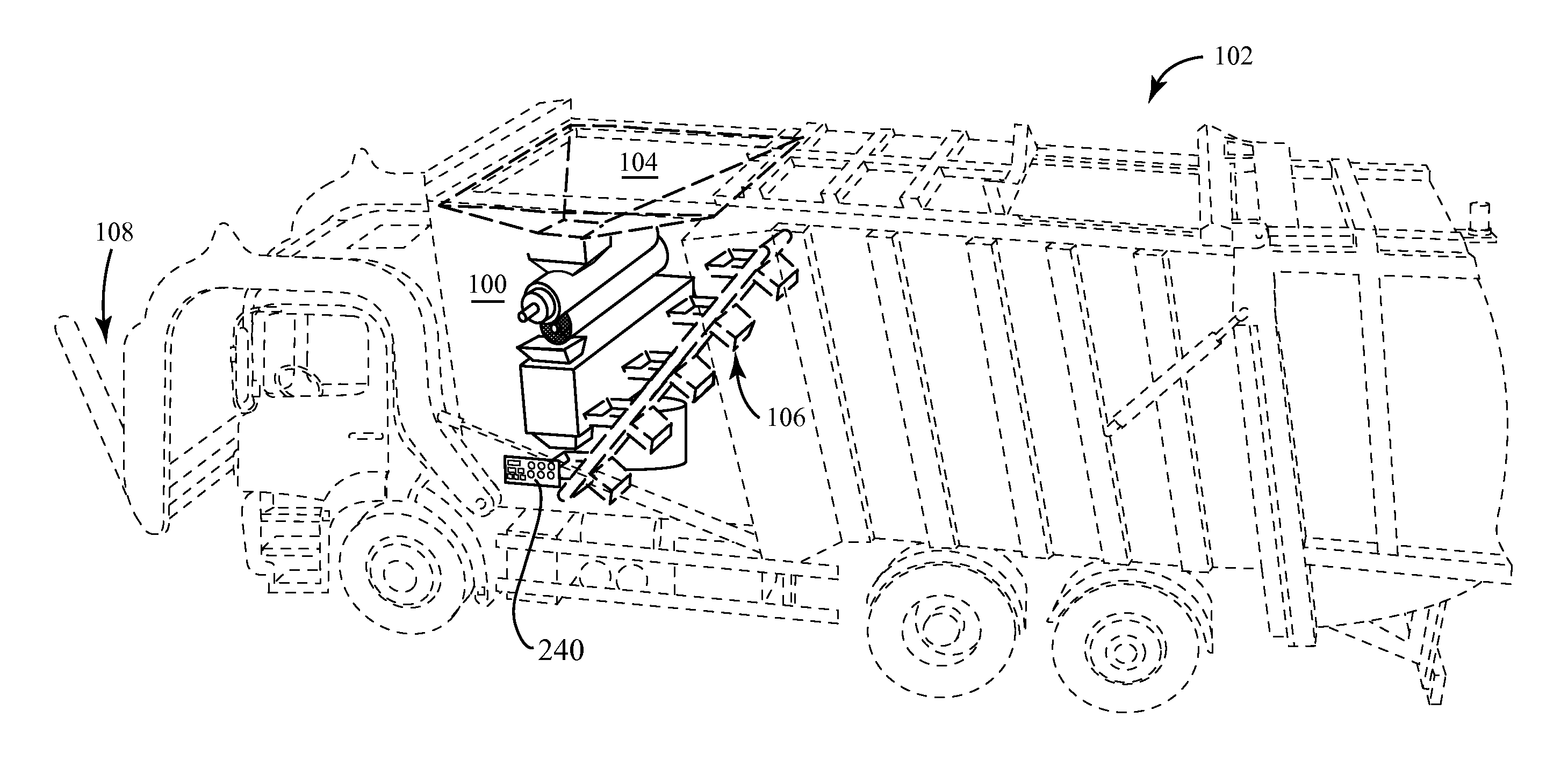

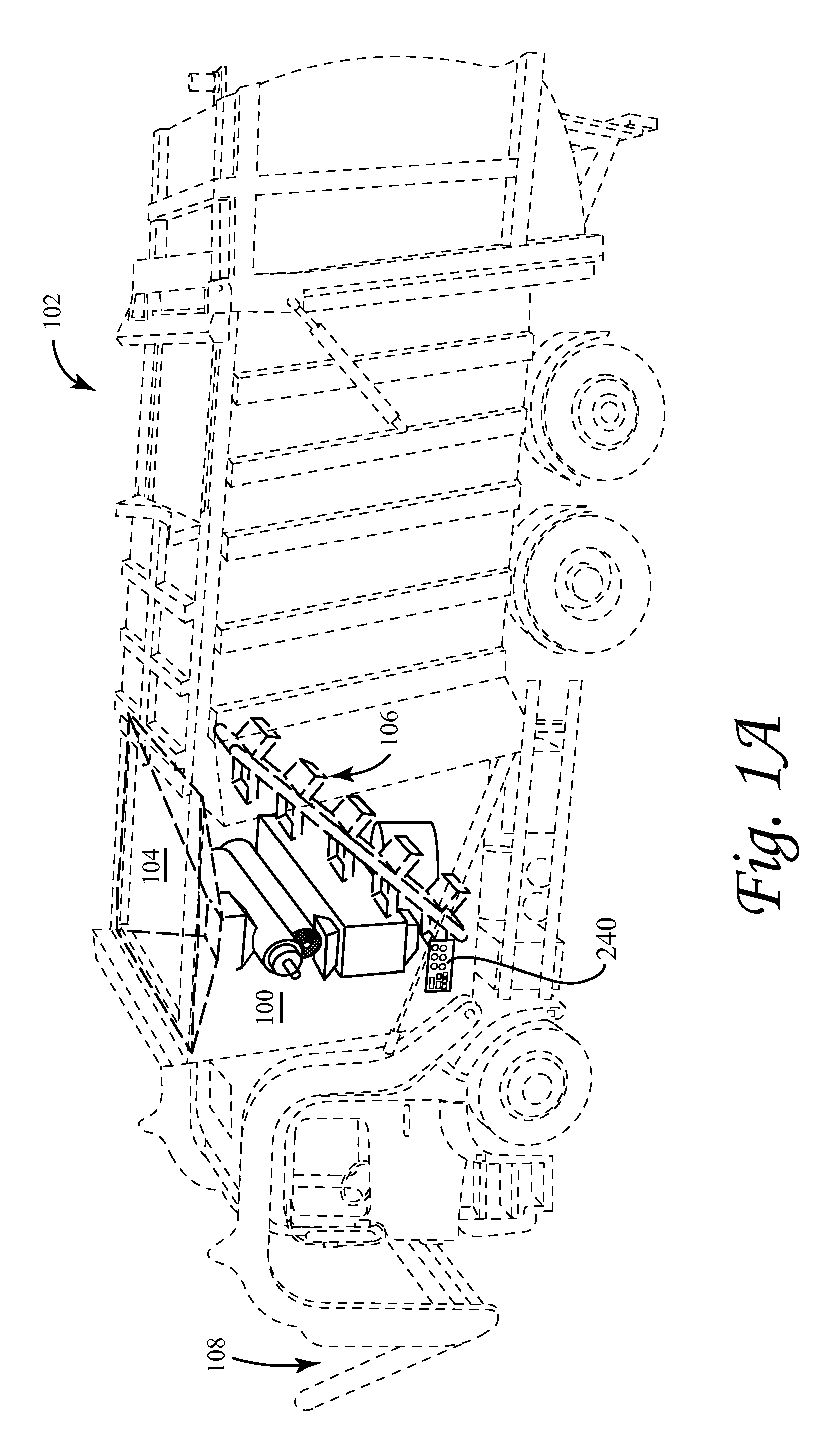

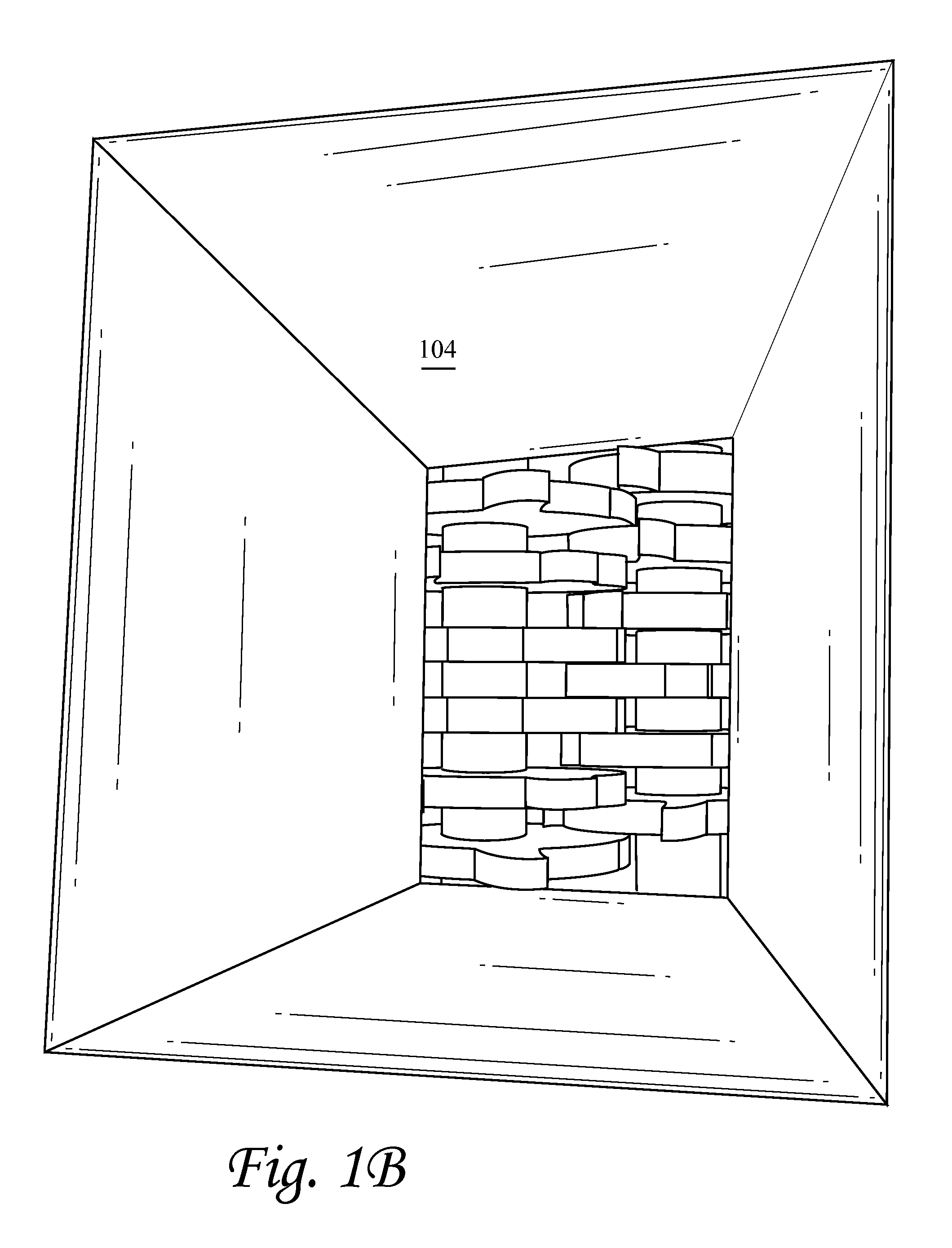

Device for conversion of waste to sources of energy or fertilizer and a method thereof

ActiveUS20130205613A1Efficient conversationEasy to handleDrying using combination processesDrying solid materials with heatEnvironmental engineeringWaste treatment

The present invention provides a compact device (that may be installed onto a mobile or stationary platform) for conversion of waste to sources of energy or fertilizer. The device includes multiple stages for efficient conversation and processing of waste into energy or fertilizer, including a first stage for reducing a size of received waste, a second stage for compressing the reduced sized waste into partially dehydrated waste, a third stage for grinding and further compression of received waste from second stage to pulverize the constituent parts into highly dense substantially dehydrated pellets or fertilizers, with a fourth stage for further drying of the received pellets or fertilizers and a final fifth stage for cooling the received pellets or fertilizers into highly dense pellets. The device of the present invention further includes a controller for controlling each operational stage.

Owner:REGREEN TECH INC

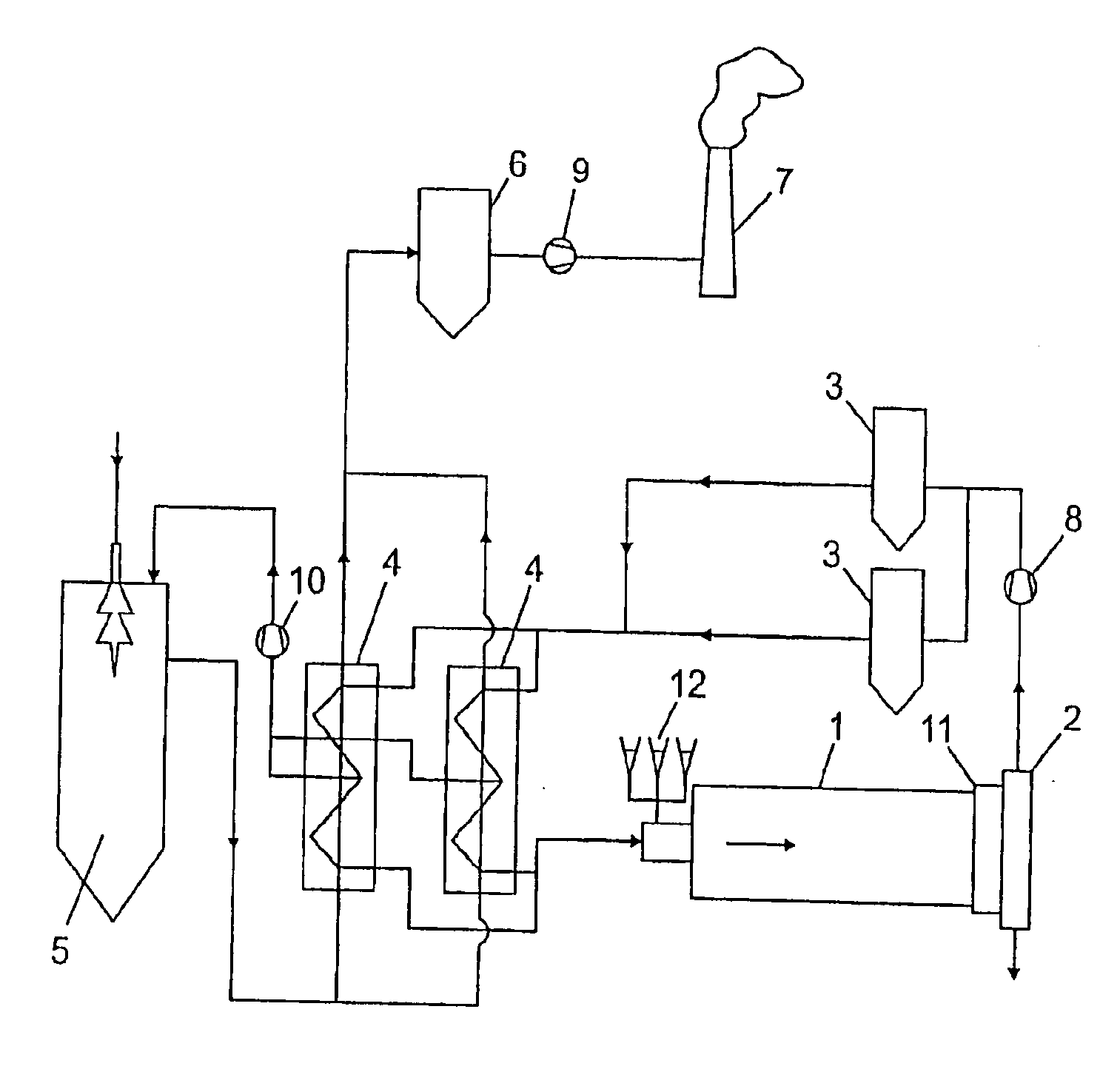

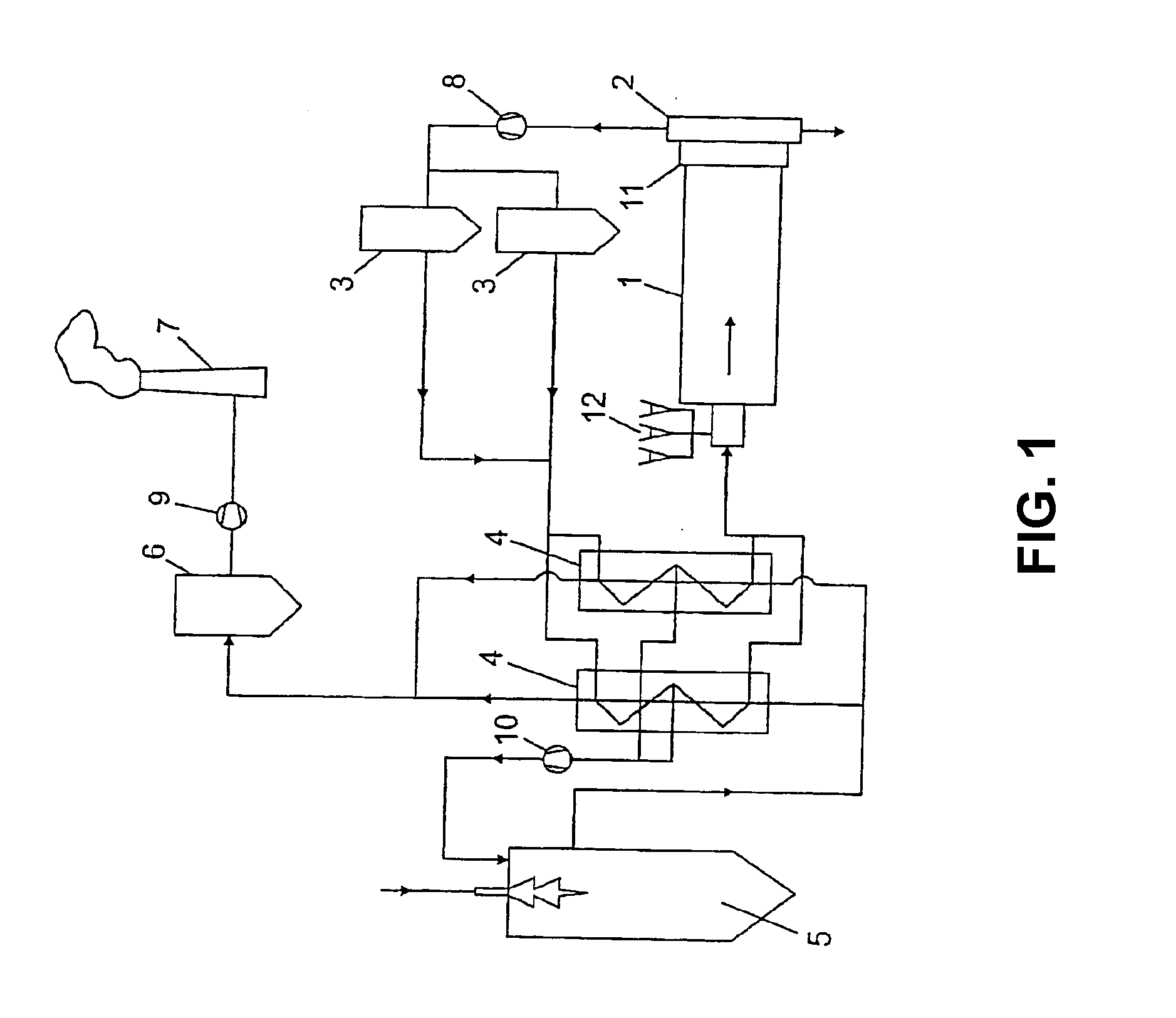

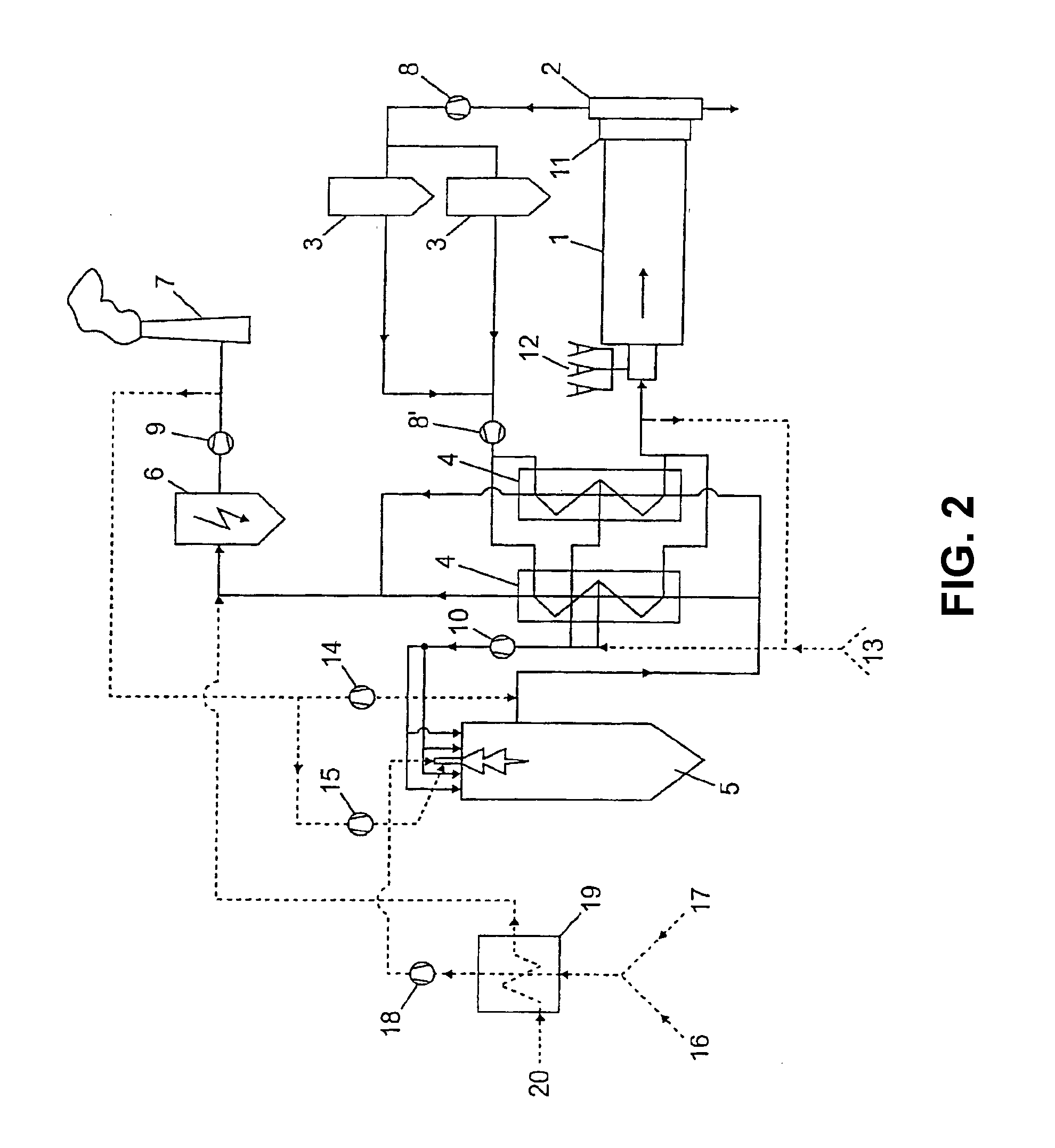

Method for continuously drying bulk goods, in particular wood fibers and/or wood chips

ActiveUS20170051972A1Emit energyPositive to qualityDrying gas arrangementsDrying machines with non-progressive movementsWood fibreProcess engineering

A method for drying bulk goods, in particular wood fibers and / or wood chips, wherein the bulk goods is continuously dried in a dryer (1), in particular a drum dryer. The vapor-gas mixture flows through the drum dryer (1) in a dryer circuit and is indirectly heated via at least one heat exchanger (4) by a burner waste gas that is heated in at least one burner (5). The drying vapors are supplied to the at least one heat exchanger (4). Upstream, downstream and / or within the at least one heat exchanger (4), at least a partial flow of the drying vapors are branched off to be conducted into the burner (5). The remaining partial flow is conducted to the dryer (1) again. The partial flow of drying vapors to the burner (5) is driven by at least one regulable partial vapor fan (10).

Owner:KRONOPLUS LTD

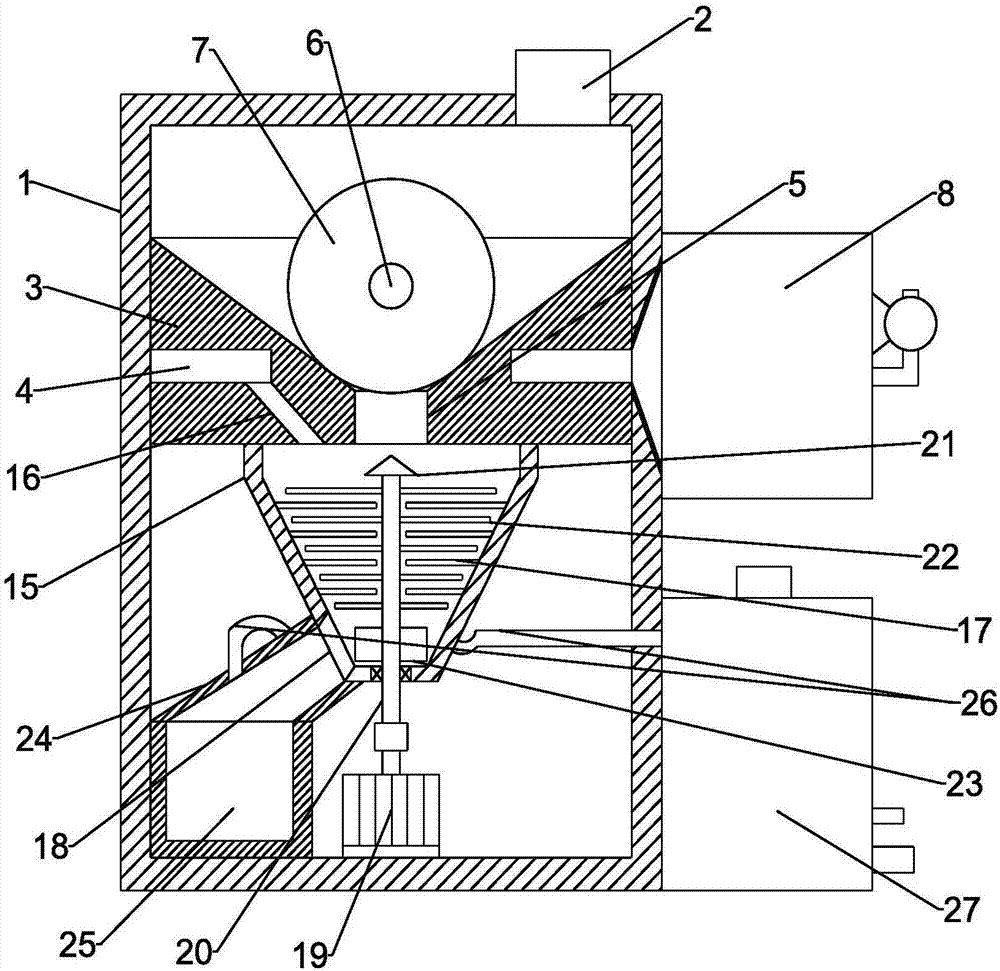

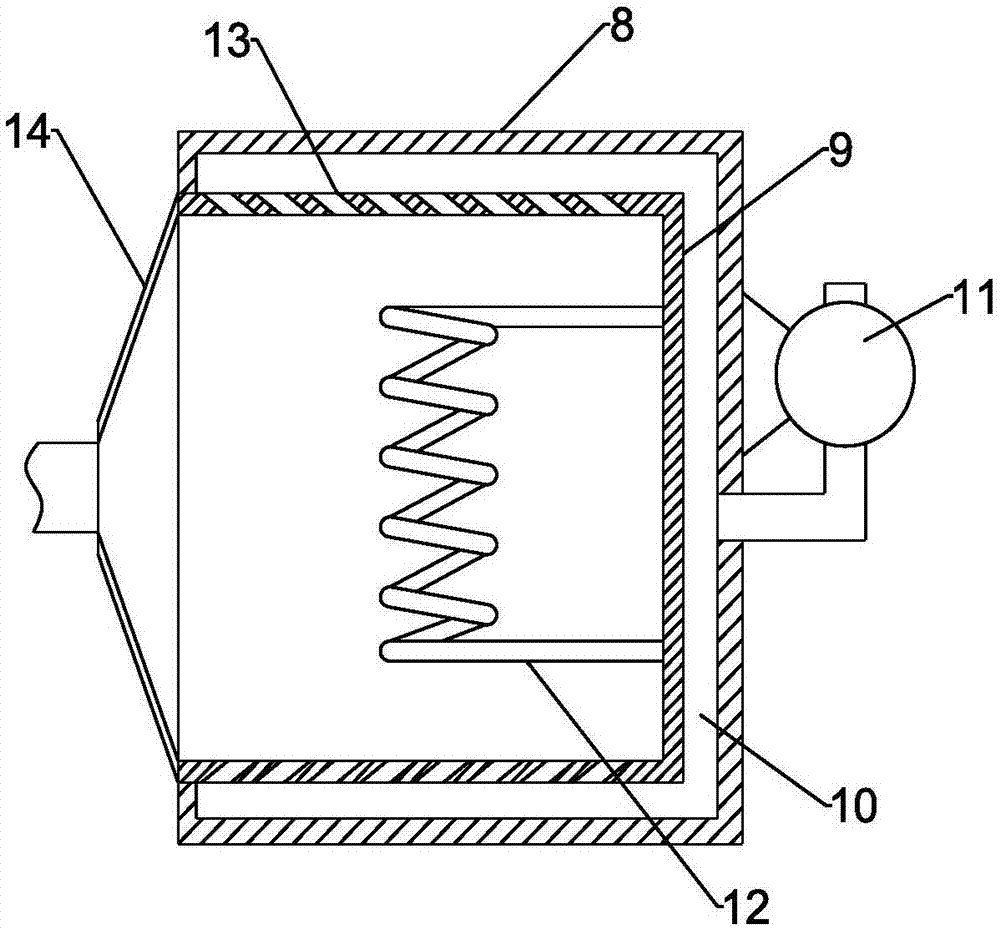

Dry smashing device used for food safety inspection

InactiveCN108007129AGuarantee the uniformity of crushingImprove drying efficiencyPreparing sample for investigationDrying gas arrangementsFood safetyEngineering

The invention discloses a dry smashing device used for food safety inspection. The dry smashing device comprises a shell, a heating cavity and a heat exchange cavity, a grinding base is arranged at the upper portion of the interior of the shell, an annular cavity is formed in the grinding base, a rotating shaft and a grinding shaft are arranged between front and back side walls of the shell, a heating cavity is arranged on the right side of the shell, the heating cavity is internally provided with an inner shell, a heat preservation cavity, an air blower, a heating pipe, an air inlet hole andan air outlet hopper, a smashing cavity is arranged at the lower end of the grinding base, a fixed blade and a discharging opening are arranged in the smashing cavity, the shell is internally providedwith a motor, a stirring rotating shaft, a rotating blade and an arc-shaped discharging blade, the right wall of the shell is provided with a heat exchange cavity, and a spiral pipe is arranged in the heat exchange cavity. By means of the dry smashing device, the sample drying efficiency is improved through drying of the heating cavity, the machining efficiency is improved through grinding and cutting smashing repeated machining, meanwhile, through the design of the heating cavity and the heat exchange cavity, the energy resource using rate is improved, and energy conservation and environmental protection are achieved while the machining efficiency is stably improved.

Owner:BEOSON JIANGSU FOOD SAFETY TECH CO LTD

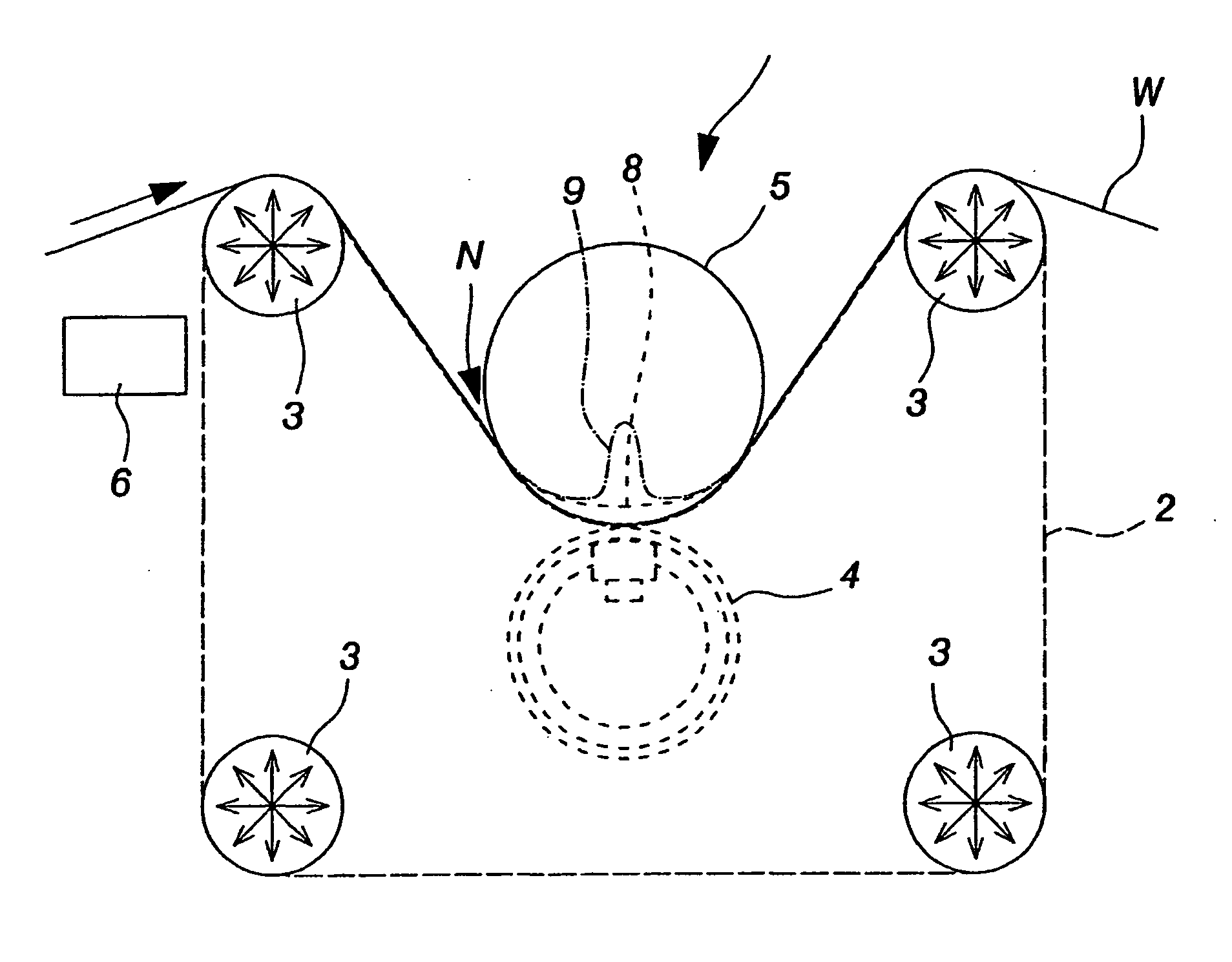

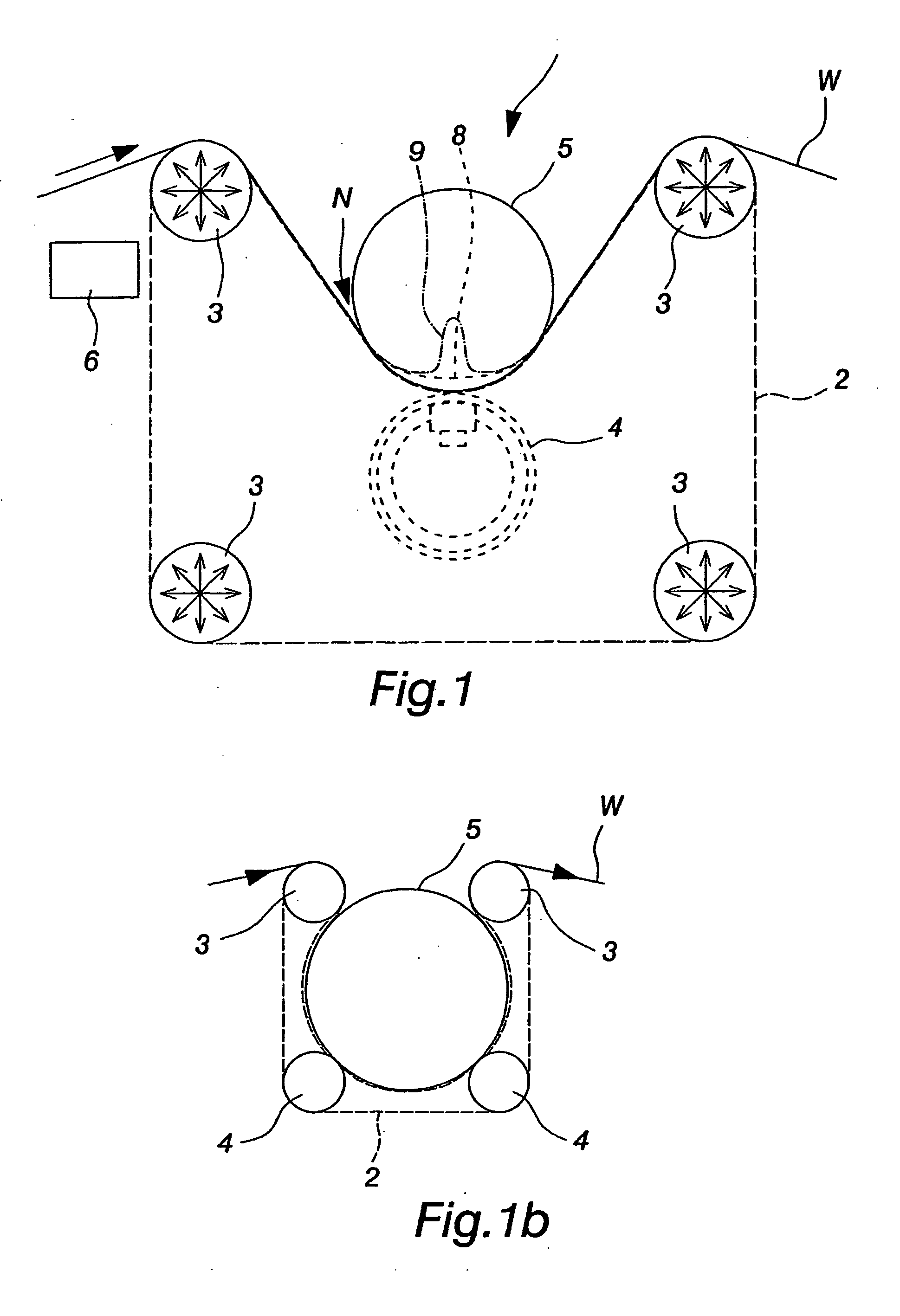

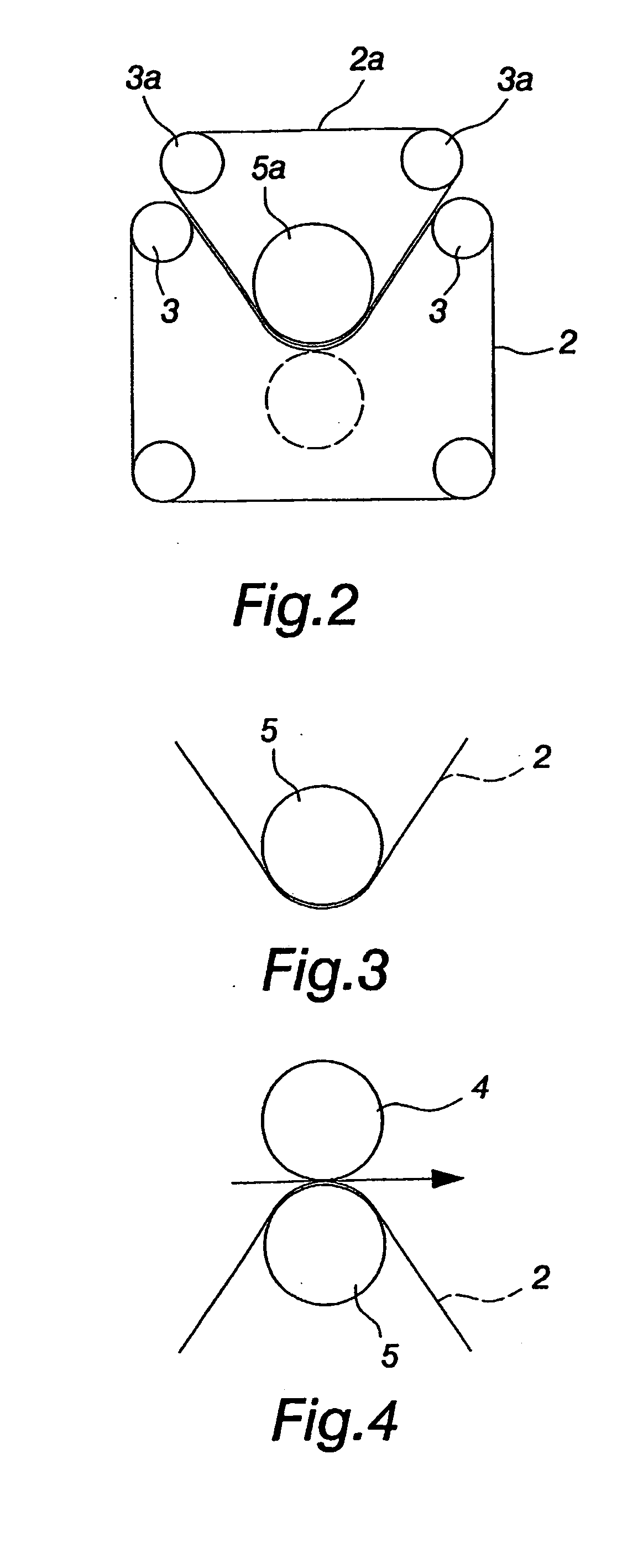

Processing device and method of operating the device for processing a coated or uncoated fibrous web

ActiveUS20050251977A1Reduce heat lossMinimizing convective heat lossNon-fibrous pulp additionLiquid surface applicatorsFiberContact pressure

A processing device and method applying the same for processing a coated or uncoated fibrous web is provided. The device comprises a belt configured to extend around a guiding element, at least one counter-element being disposed outside said belt to provide a contact area with the belt, such that the belt and the counter-element establish therebetween a web processing zone for passing a web to be processed therethrough. The processing zone length is defined by the disposition of the belt's guiding element and / or by the configuration of the counter-elements. The contact pressure applied to a web in the processing zone is within the range of between about 0.01 MPa and about 200 MPa.

Owner:VALMET TECH INC

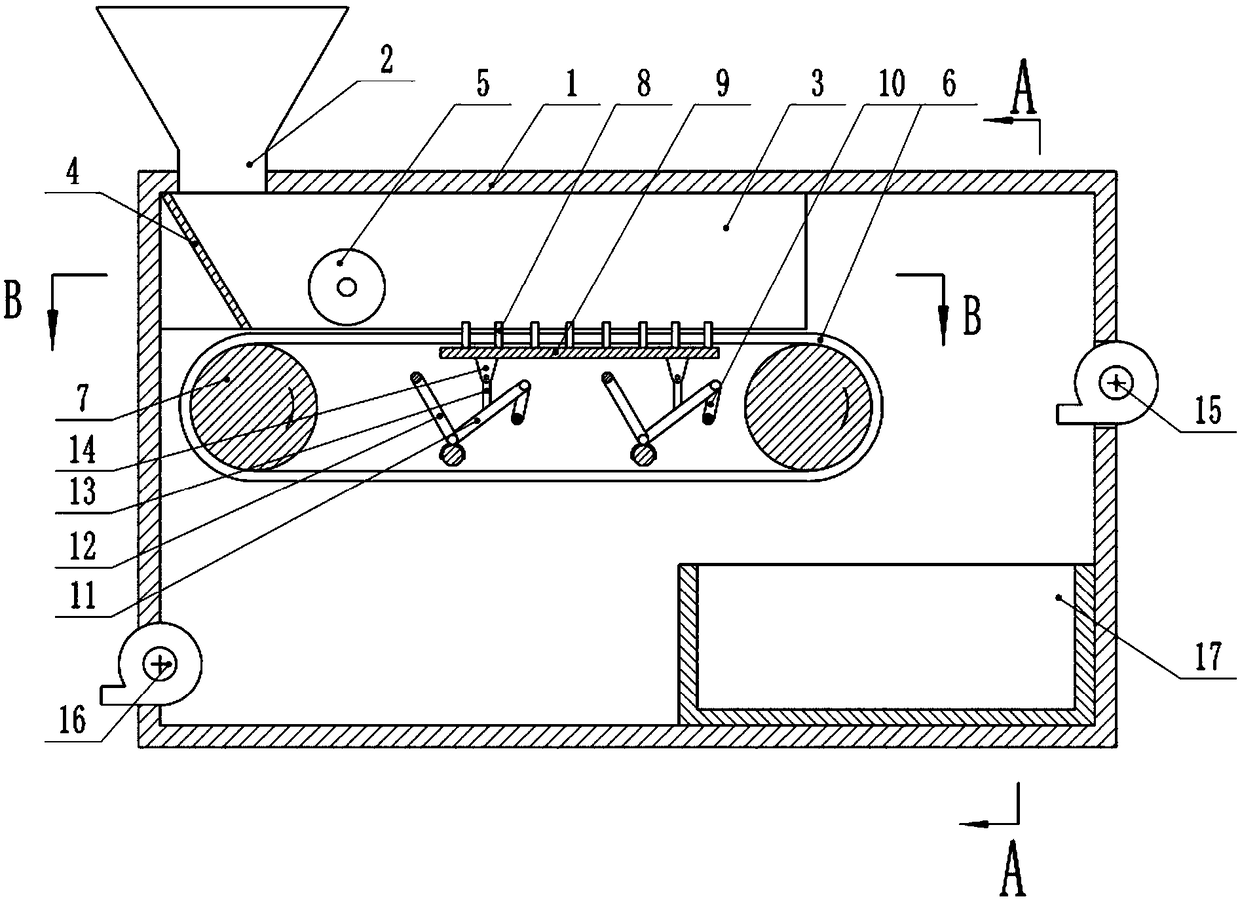

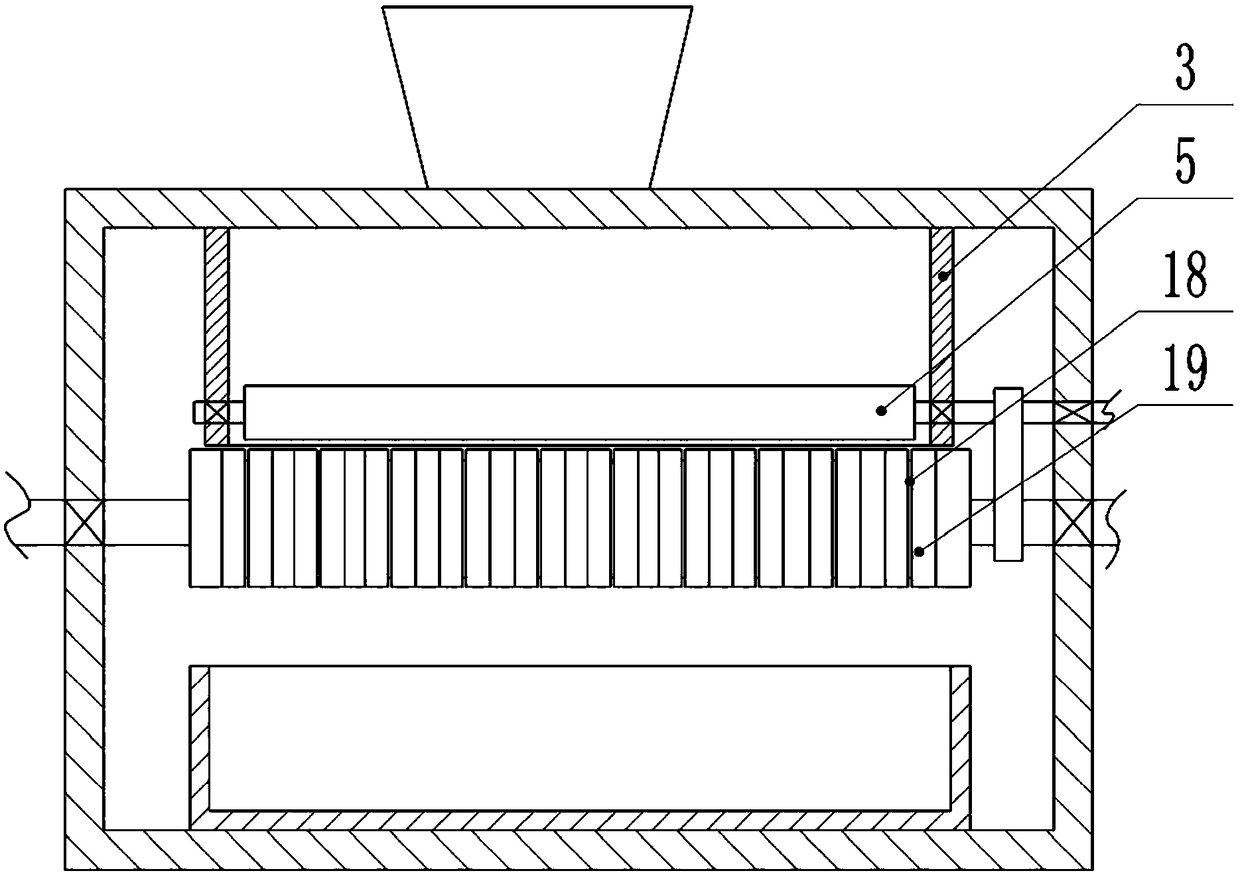

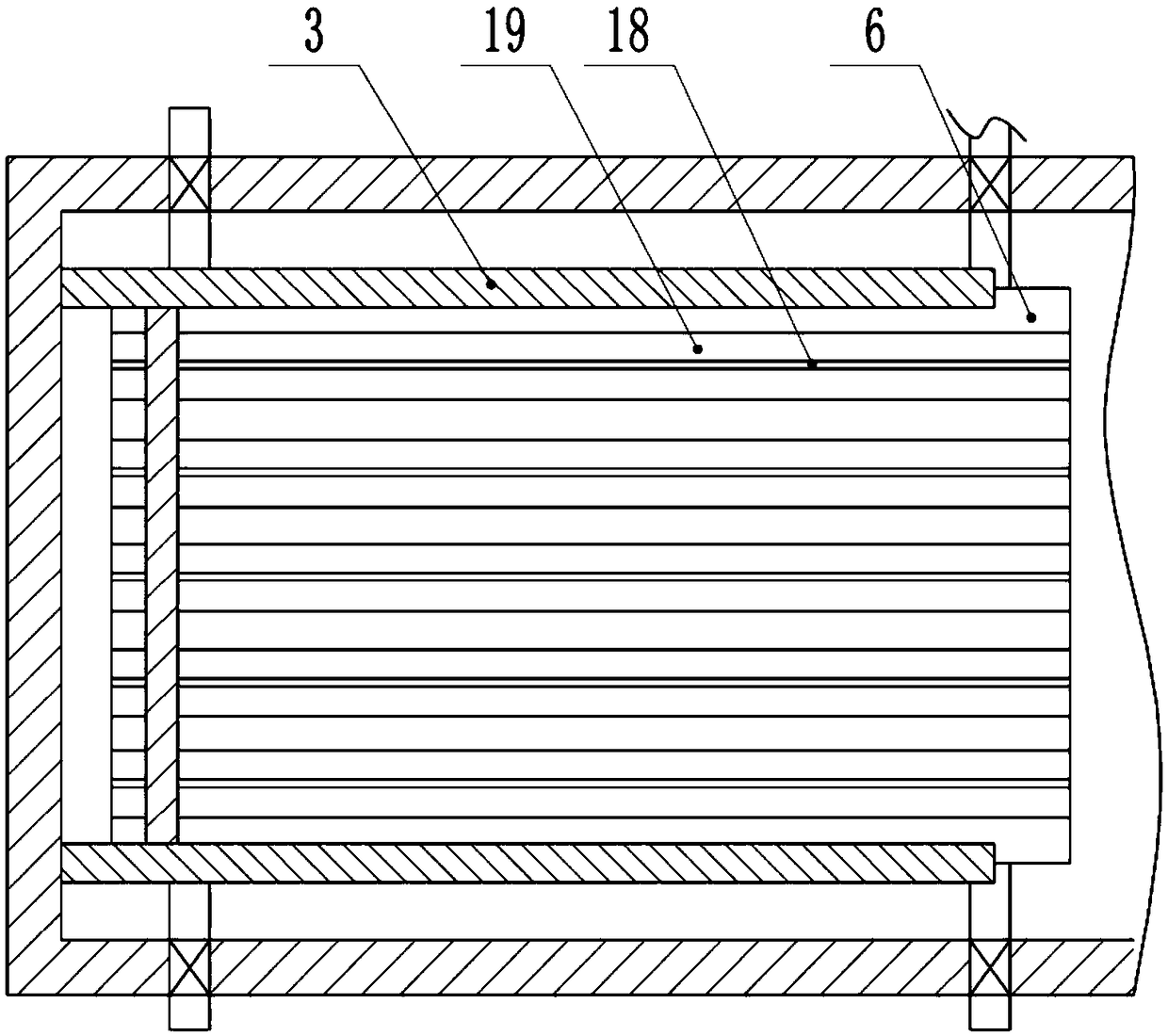

Solid chemical fertilizer drying device

ActiveCN108775772AAvoid cloggingAvoid scatterDrying gas arrangementsPreliminary solid treatment for dryingEngineeringMechanical engineering

The invention belongs to the technical field of chemical fertilizer preparing, and particularly discloses a solid chemical fertilizer drying device. The solid chemical fertilizer drying device comprises a drying box internally provided with a hot air structure and a conveying mechanism. The conveying mechanism comprises two conveying rollers and a power source, and a conveying belt is connected between the two conveying rollers and provided with a plurality of V-shaped grooves. The sides, close to the conveying rollers, of the V-shaped grooves are provided with openings. An overturning mechanism is arranged between the two conveying rollers and comprises two rotation shafts. Bent axles are arranged at the middle portions of the rotation shafts, connecting rods are hinged to the bent axles,oscillating bars are hinged to the inner wall of the drying box, the ends, away from the bent axles, of the connecting rods are hinged to the lower ends of the oscillating bars, and support rods arefixedly connected to the middle portions of the connecting rods. Supports are hinged to the upper ends of the support rods. A horizontal movable plate is fixed between the upper ends of the two supports and provided with a plurality of rows of overturning rods. The overturning rods are located under the openings. The lower ends of the oscillating bars are rotationally connected with vibration rollers. A material collecting box is arranged in the drying box. According to the scheme, chemical fertilizer overturning is achieved in the chemical fertilizer conveying process, and the drying effect is good.

Owner:遵义大兴复肥有限责任公司

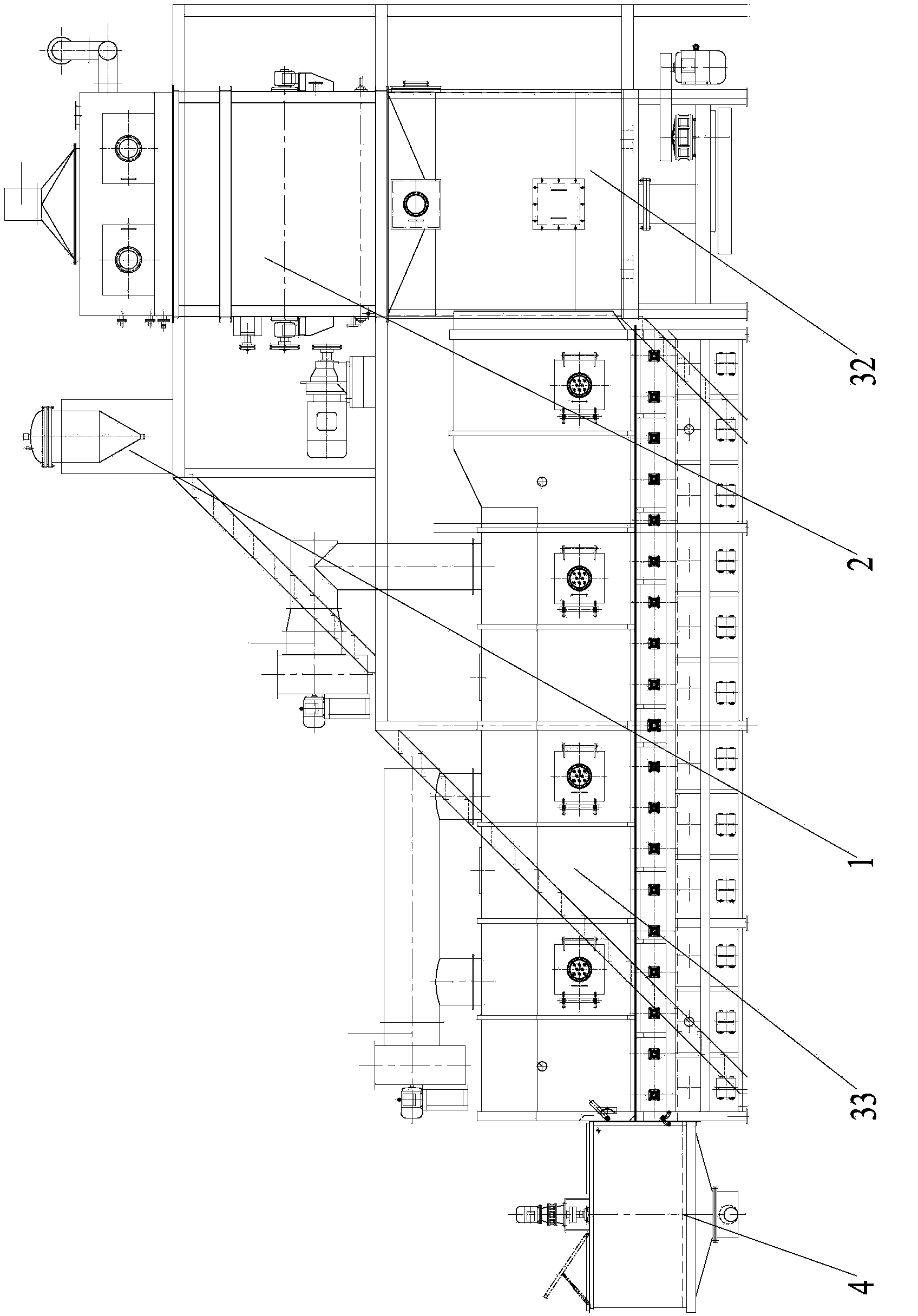

Mixing and drying all-in-one machine and mixing and drying process

ActiveCN104279839AMixed dryingQuick mixDrying machine combinationsMixersAutomatic controlHybrid system

The invention provides a mixing and drying all-in-one machine. The mixing and drying all-in-one machine comprises a burdening system, a mixing system, a drying system, a smashing and screening system and an automatic control system, wherein material transport pipelines are arranged among the burdening system, the mixing system, the drying system and the smashing and screening system; the burdening system can be used for burdening materials of a preset weight; the mixing system can be used for mixing the materials; the drying system can be used for drying the materials; the smashing and screening system can be used for smashing and screening the materials; screen underflow left after screening can be transported to a storage cabin or used later; the automatic control system is used for controlling the work of the burdening system, the mixing system, the drying system and the smashing and screening system. The invention further provides a mixing and drying process. By adopting the mixing and drying all-in-one machine provided by the invention, the materials can be mixed uniformly and dried effectively, hermetic production is performed, safety and reliability are realized, environmental pollution is prevented, the equipment integration level is high, the occupied floor area is small, the problems of long halt time and high cleaning workload caused by bonding of the materials are solved, and the production efficiency is increased.

Owner:ASIA CUANON TECH SHANGHAI

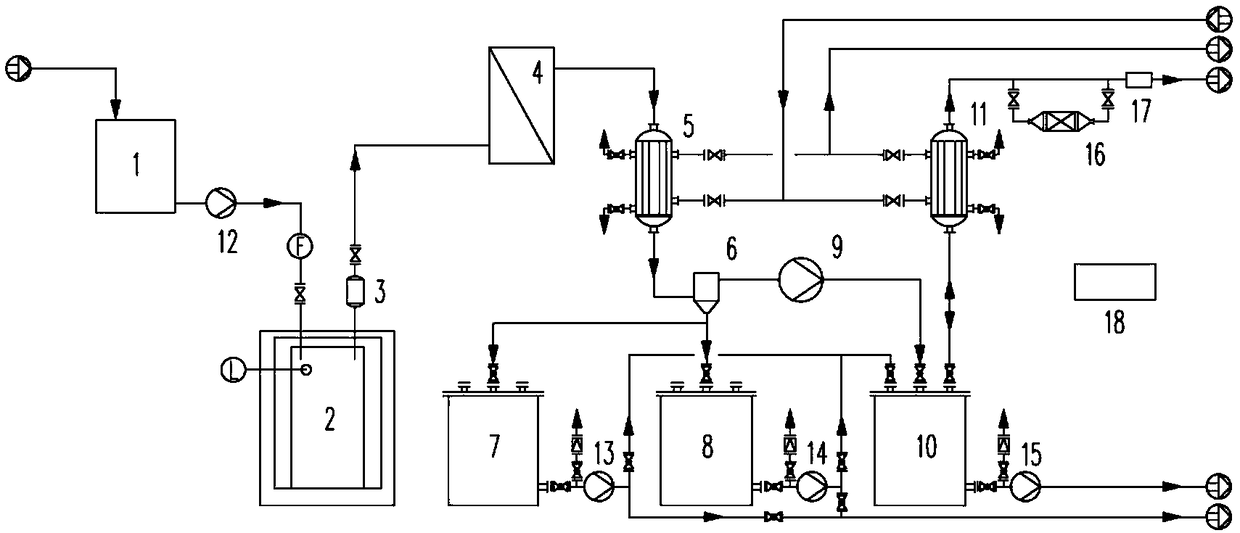

In-barrel vacuum microwave drying system and method for radioactive wet wastes

InactiveCN108630335ADry fastMeet staging criteriaDrying solid materials without heatSludge dryingMicrowaveAtmospheric air

The invention belongs to the technical field of radioactive waste treatment and relates to an in-barrel vacuum microwave drying system and method for radioactive wet wastes. The drying system comprises a drying barrel, a demister, a filter, a condenser, a steam-water separator, a vacuum pump, a tail gas continuous monitoring device and connecting pipelines; the drying barrel is used for drying thewastes by microwave heating; the demister, the filter, the condenser, the steam-water separator and the vacuum pump which are connected in sequence are respectively used for realizing demisting, filtration, condensation, steam-water separation and vacuumizing treatment of evaporated tail gases generated by drying; and the tail gas continuous monitoring device is connected with the condenser and is used for monitoring noncondensable gases in the evaporated tail gases and discharging qualified noncondensable gases into the air by the connecting pipeline connected with an outlet of the tail gascontinuous monitoring device. By using the drying system and method disclosed by the invention, the rapid drying of various radioactive wastes can be realized, new substances are not introduced in a drying process, and the tail gases discharged after being dried almost have no any harmful effects on the environment.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Device for drying material

InactiveCN1942728AHas a mild scentWon't escapeProductsSludge treatment by de-watering/drying/thickeningAir cyclePulp and paper industry

An apparatus for drying materials such as fertilizers, mud, etc., comprising a grinding section and a drying section comprising at least one conveyor belt (10) and an air heater (16). A closed air circulation system is provided above the conveyor belt, which directs air countercurrently to the material on the conveyor belt. The temperature of the air heated in the heater (16) and the time for drying the material are adjusted so that the dried material does not contain bacteria and weeds.

Owner:阿斯比约恩·哈默

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com