Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

329results about "Sludge drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

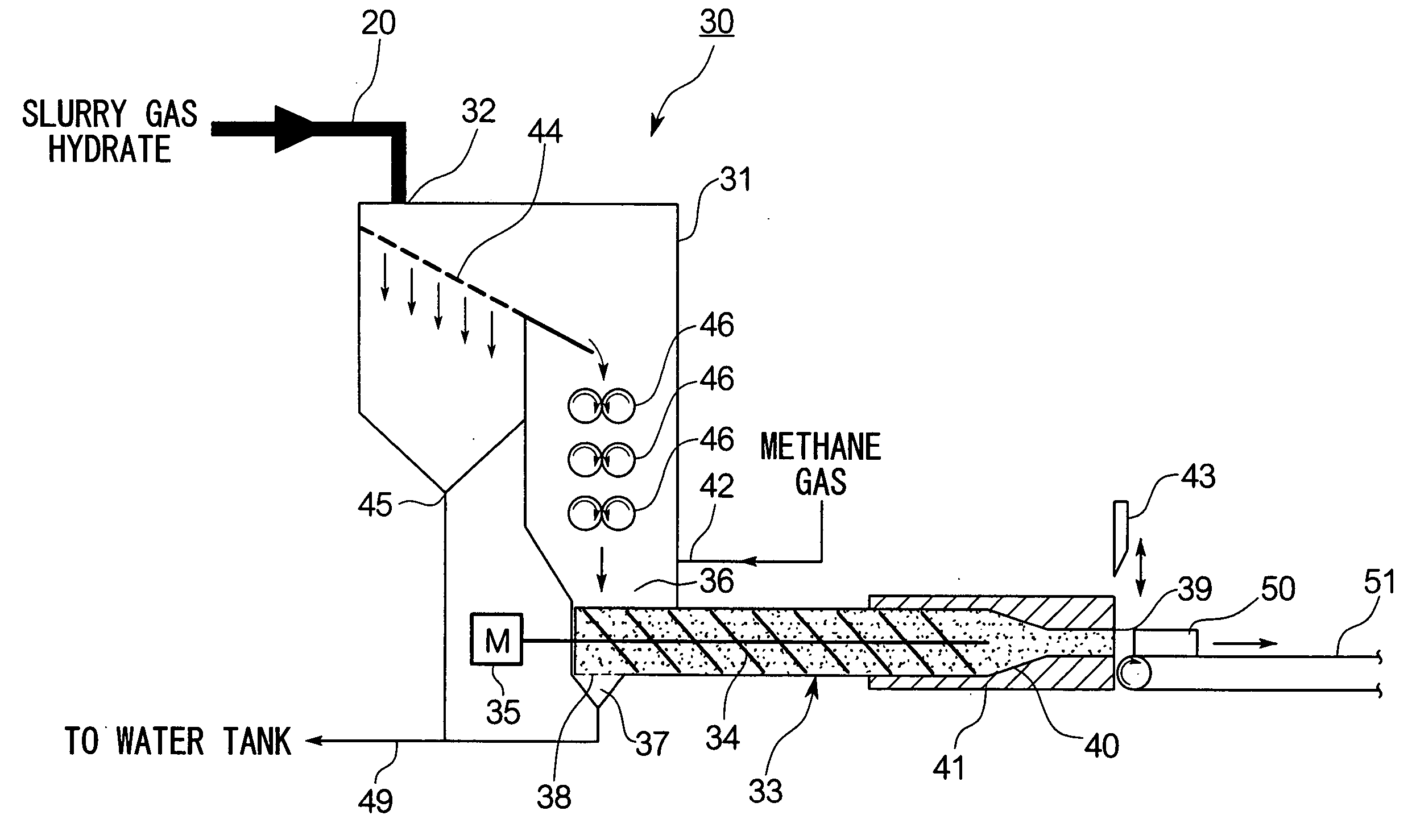

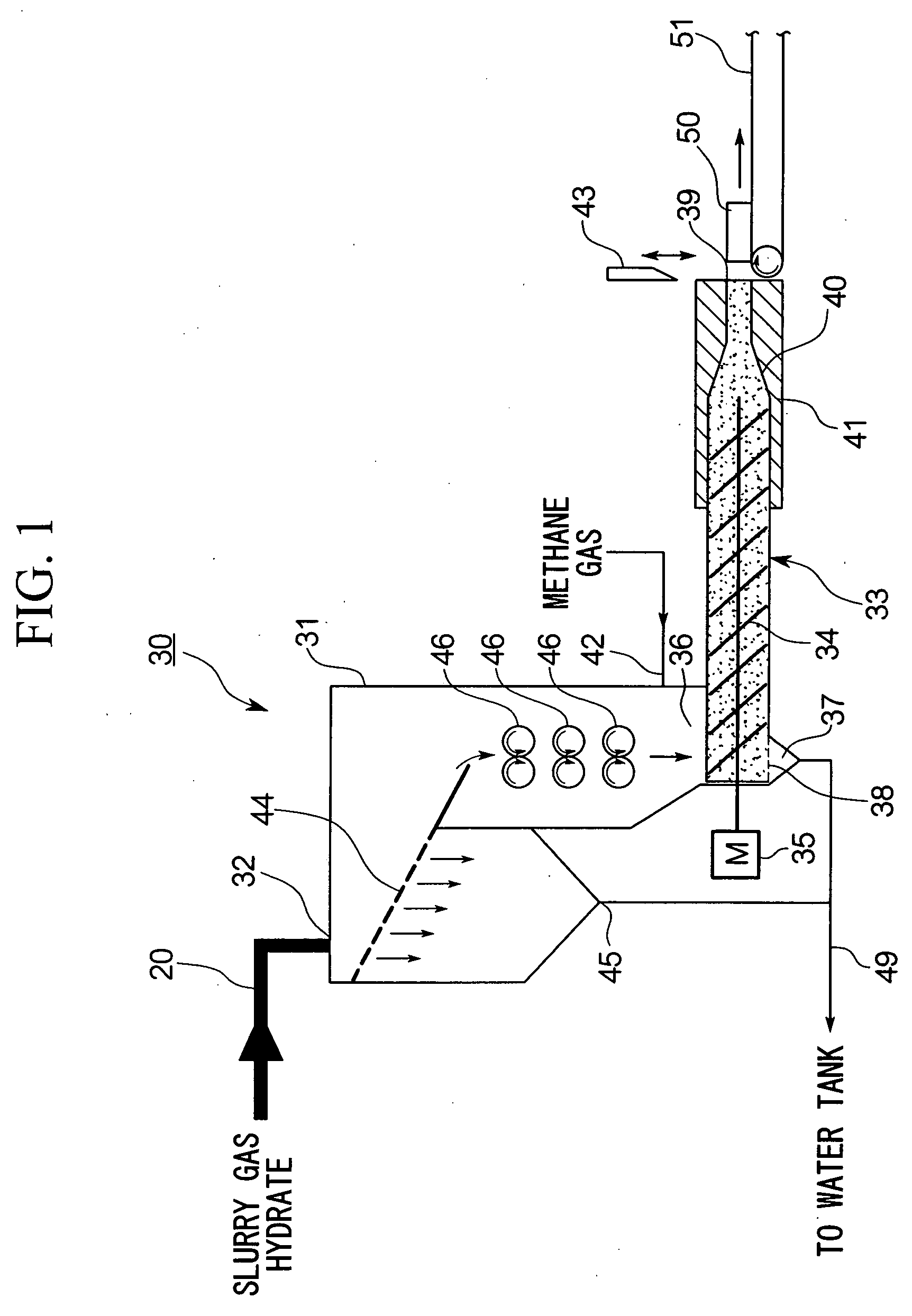

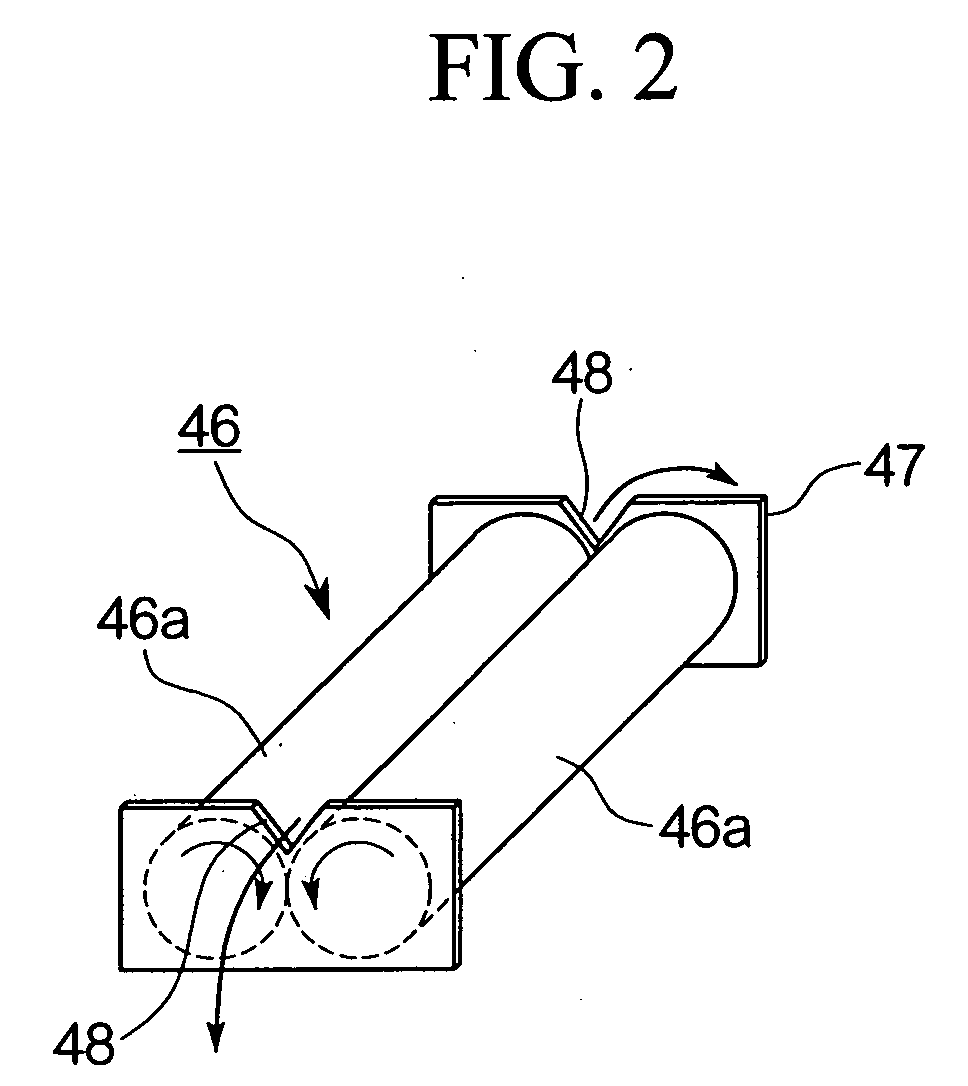

Gas hydrate production device and gas hydrate dehydrating device

InactiveUS20050107648A1Easy to implementSmall sizeOrganic chemistryDrying solid materials without heatAmbient pressureSlurry

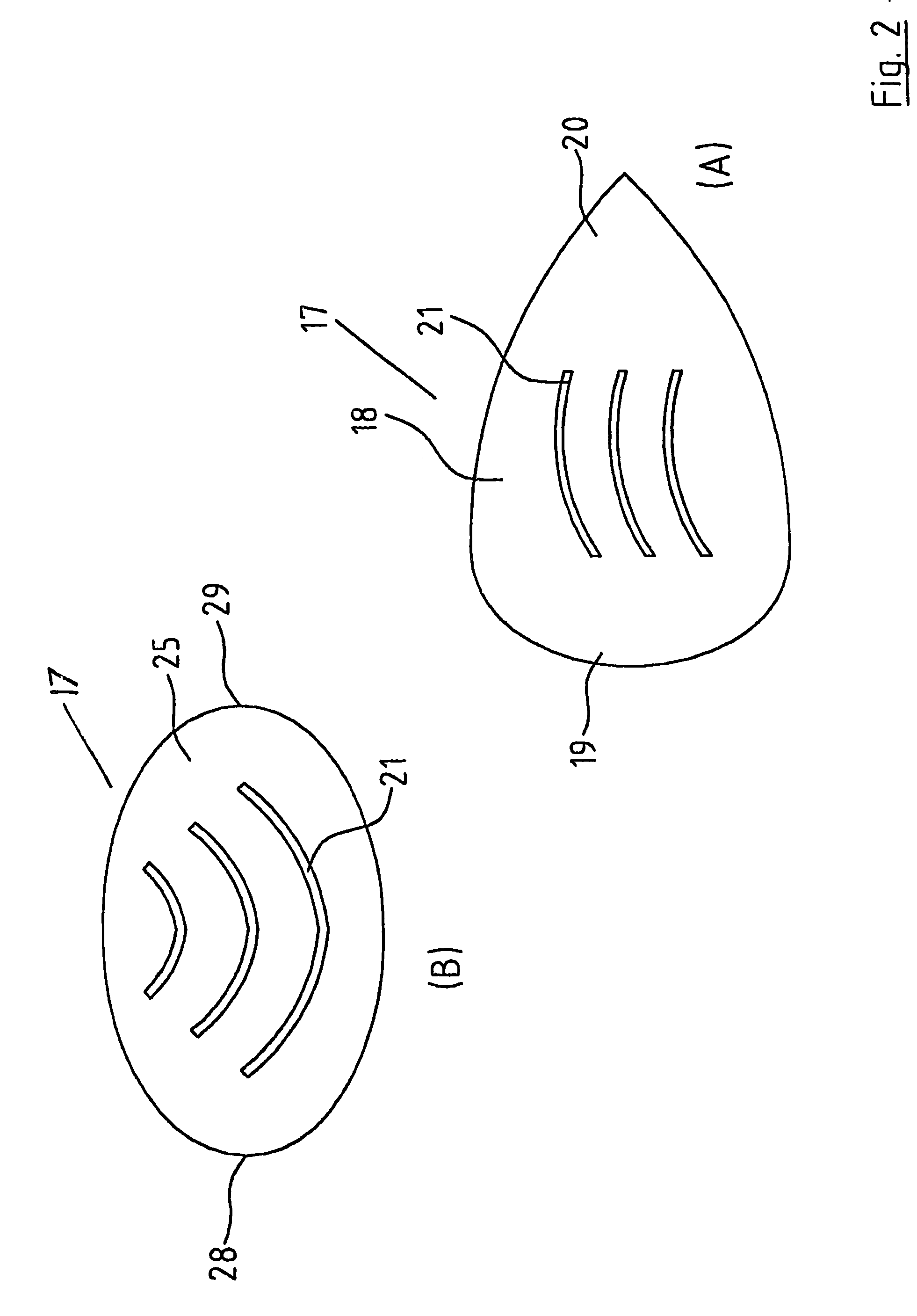

The invention relates to a gas hydrate dewatering cooling and outputting apparatus which dewaters and solidifies gas hydrate slurry and takes out the solidified gas hydrate under ambient pressure. The apparatus comprises an output apparatus body 31 having a supply port 32 for the gas hydrate slurry on an upper part of a pressure vessel, a screw extruder 33 provided at a lower part inside the output apparatus body 31 and having a drain 37 and an outlet sealing device, and a cooling device 41 which cools the vicinity of the outlet 39 of the screw extruder 33. According to such a construction, slurry gas hydrate can be efficiently and continuously dewatered, cooled and solidified, and gas hydrate powder can be consolidated into blocks and taken out to the atmosphere.

Owner:MITSUBISHI HEAVY IND LTD

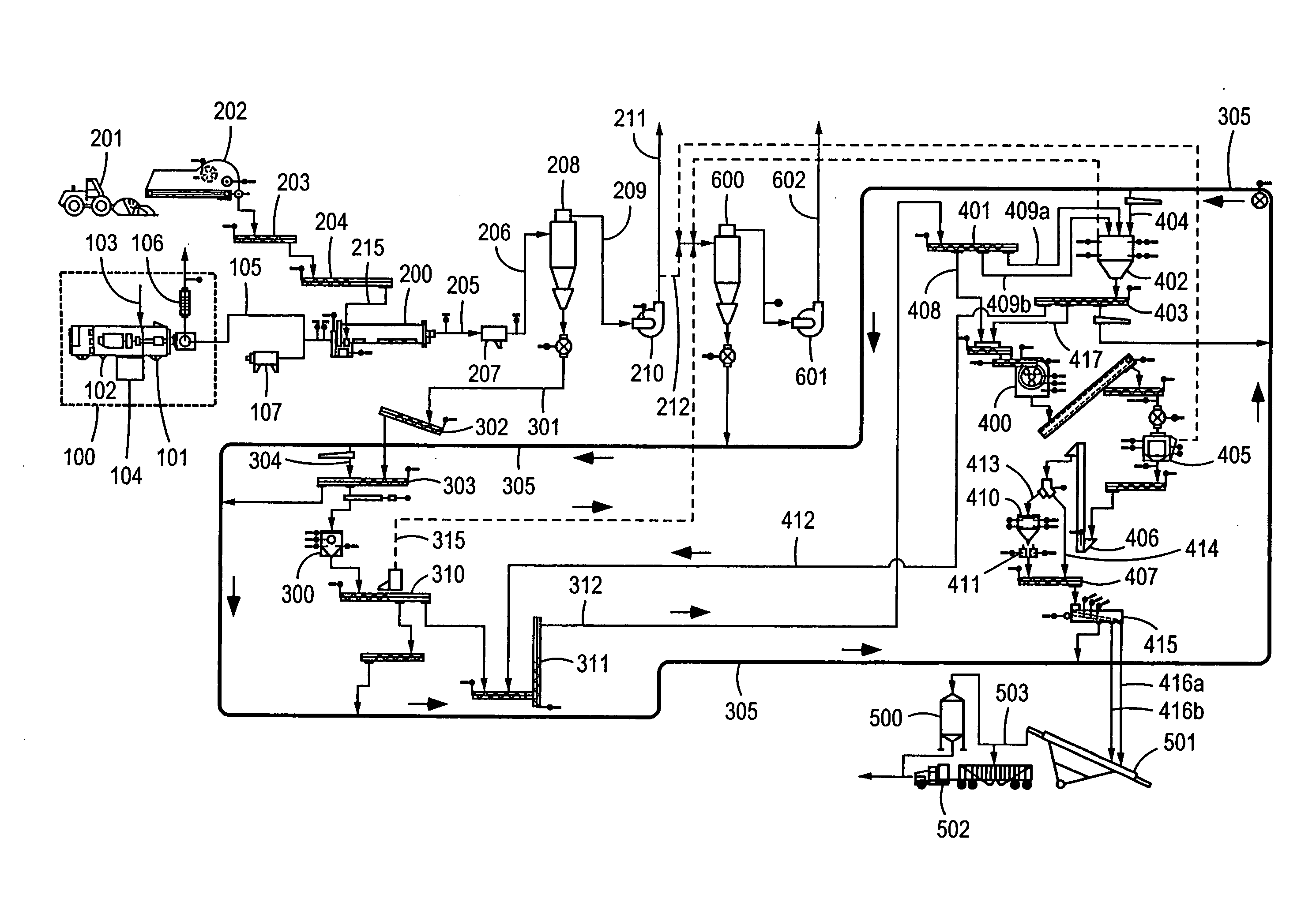

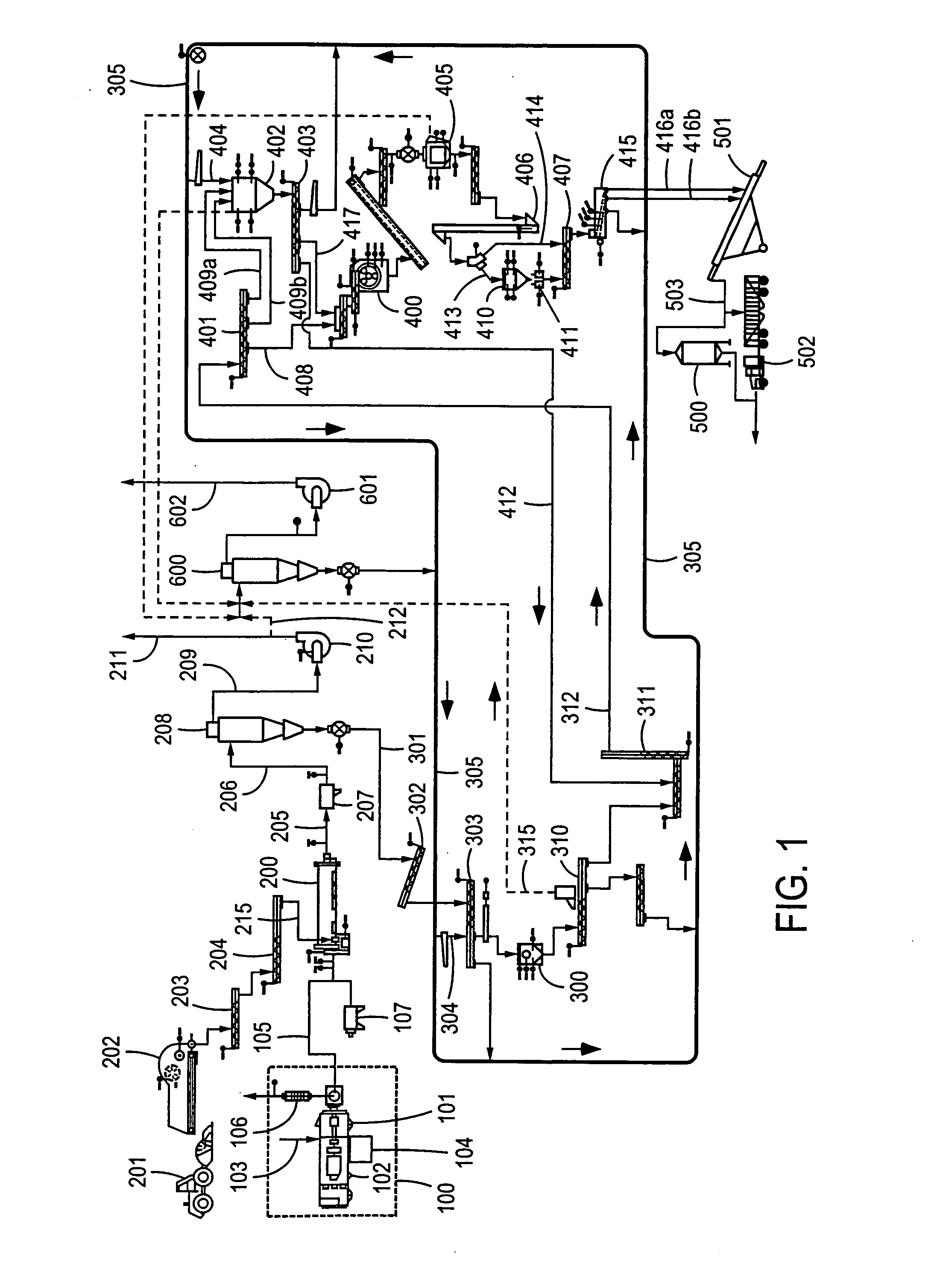

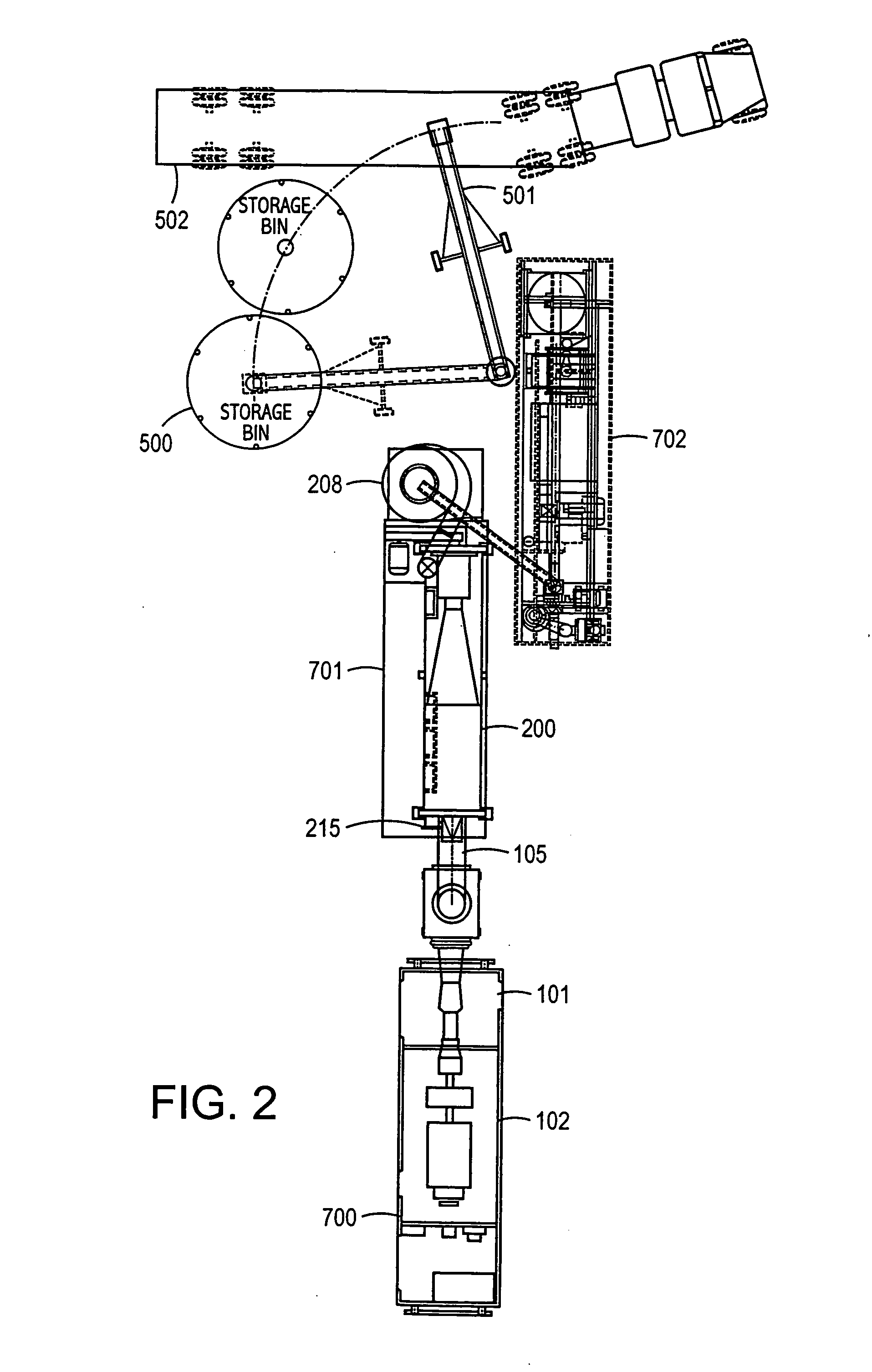

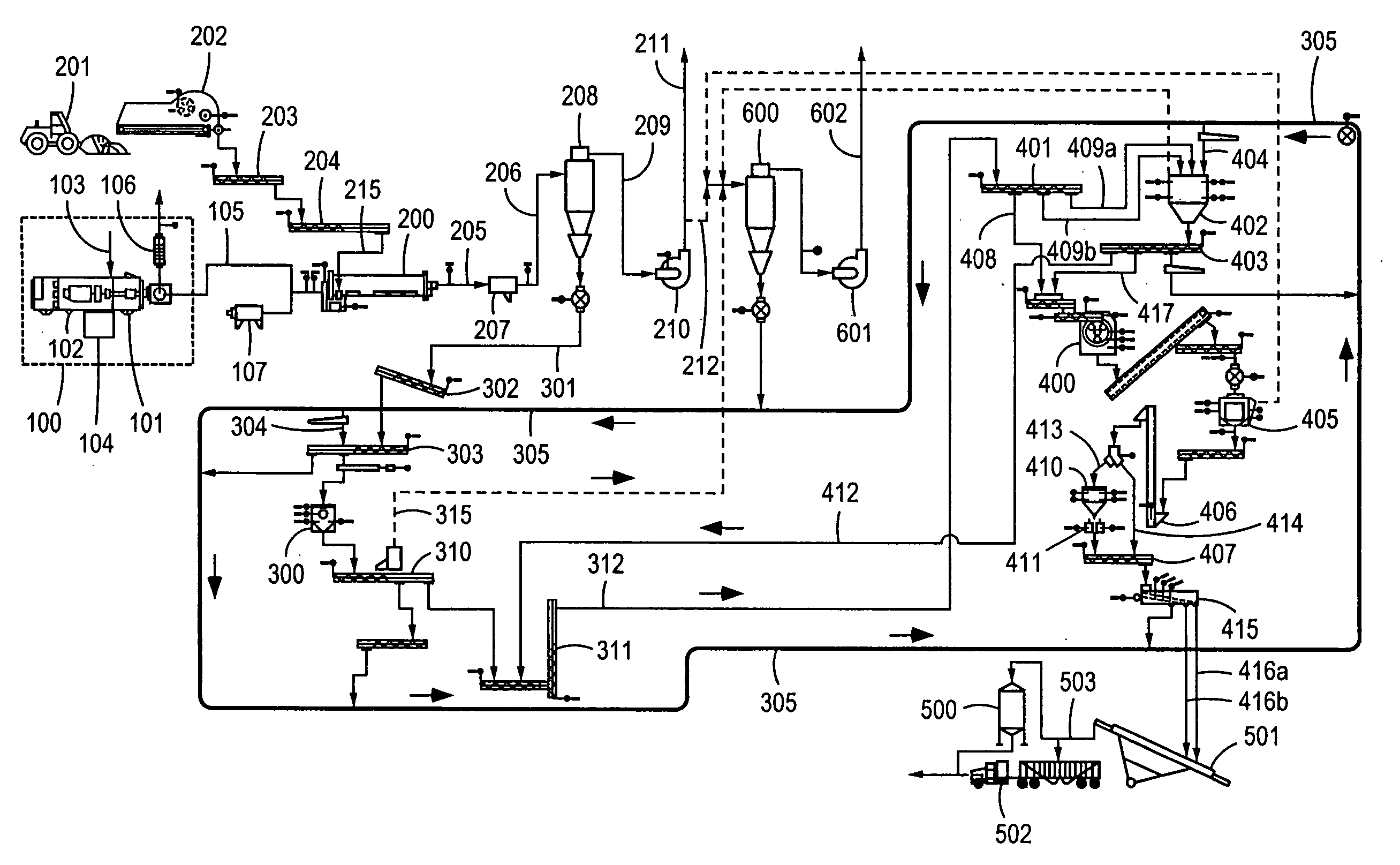

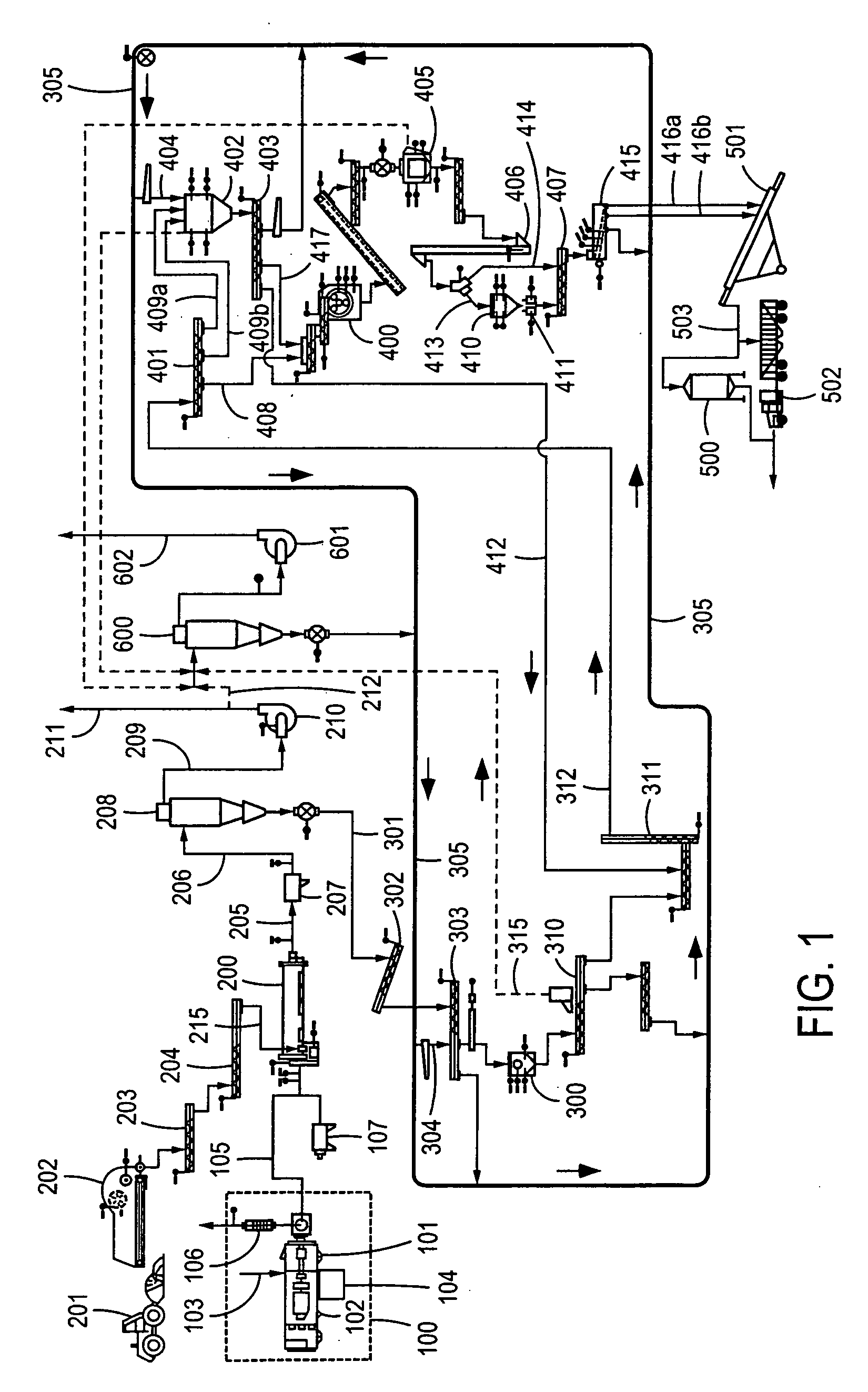

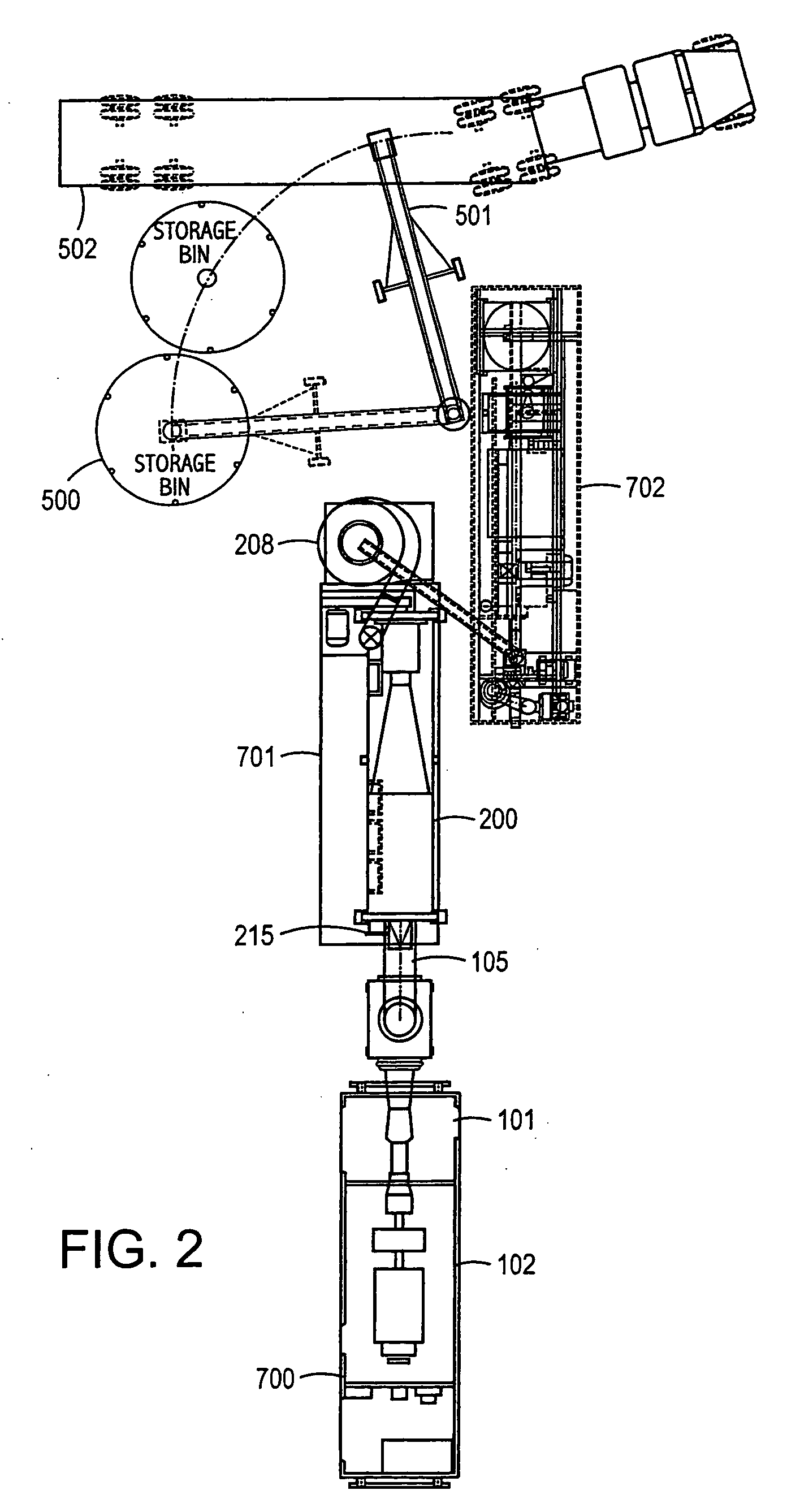

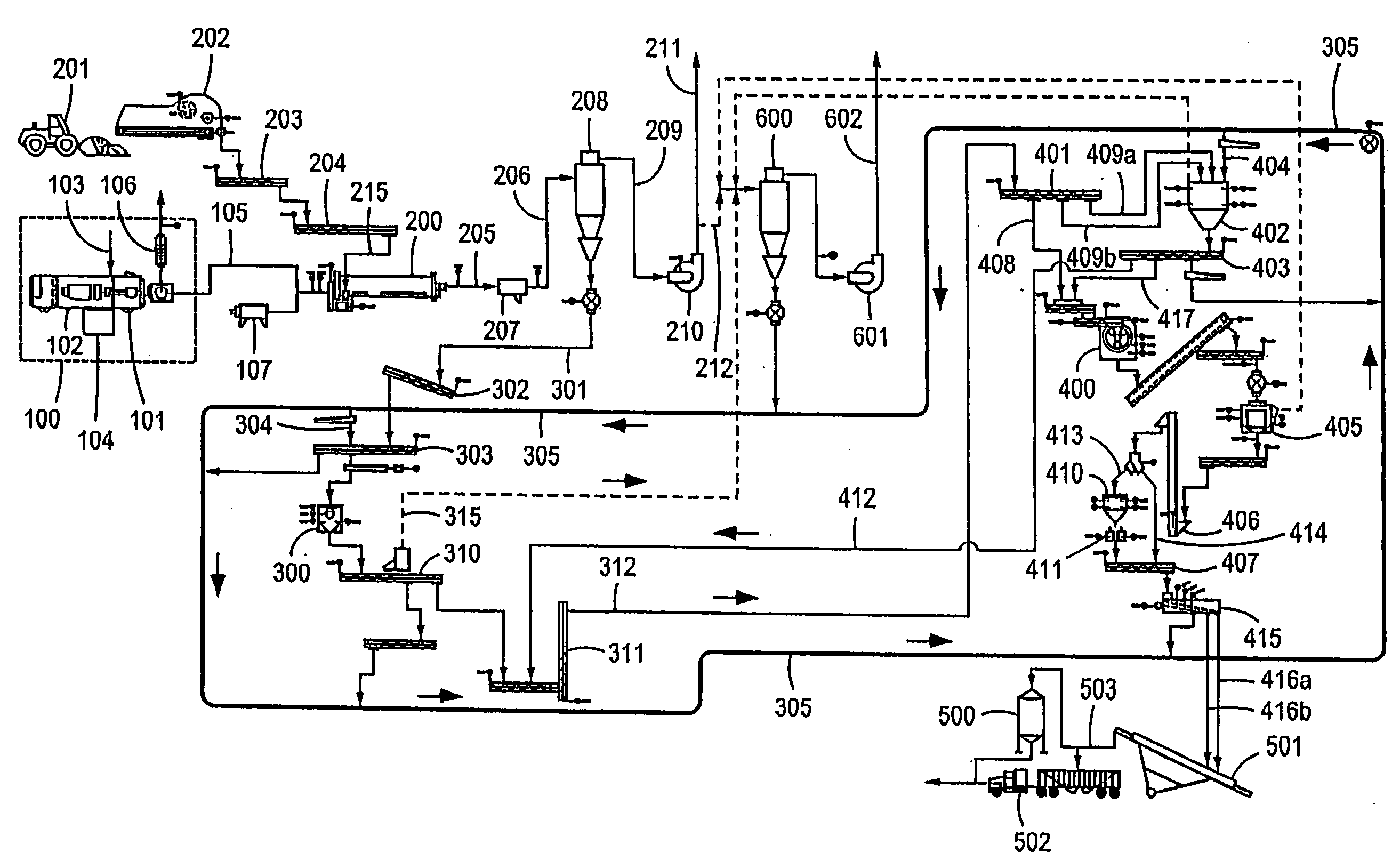

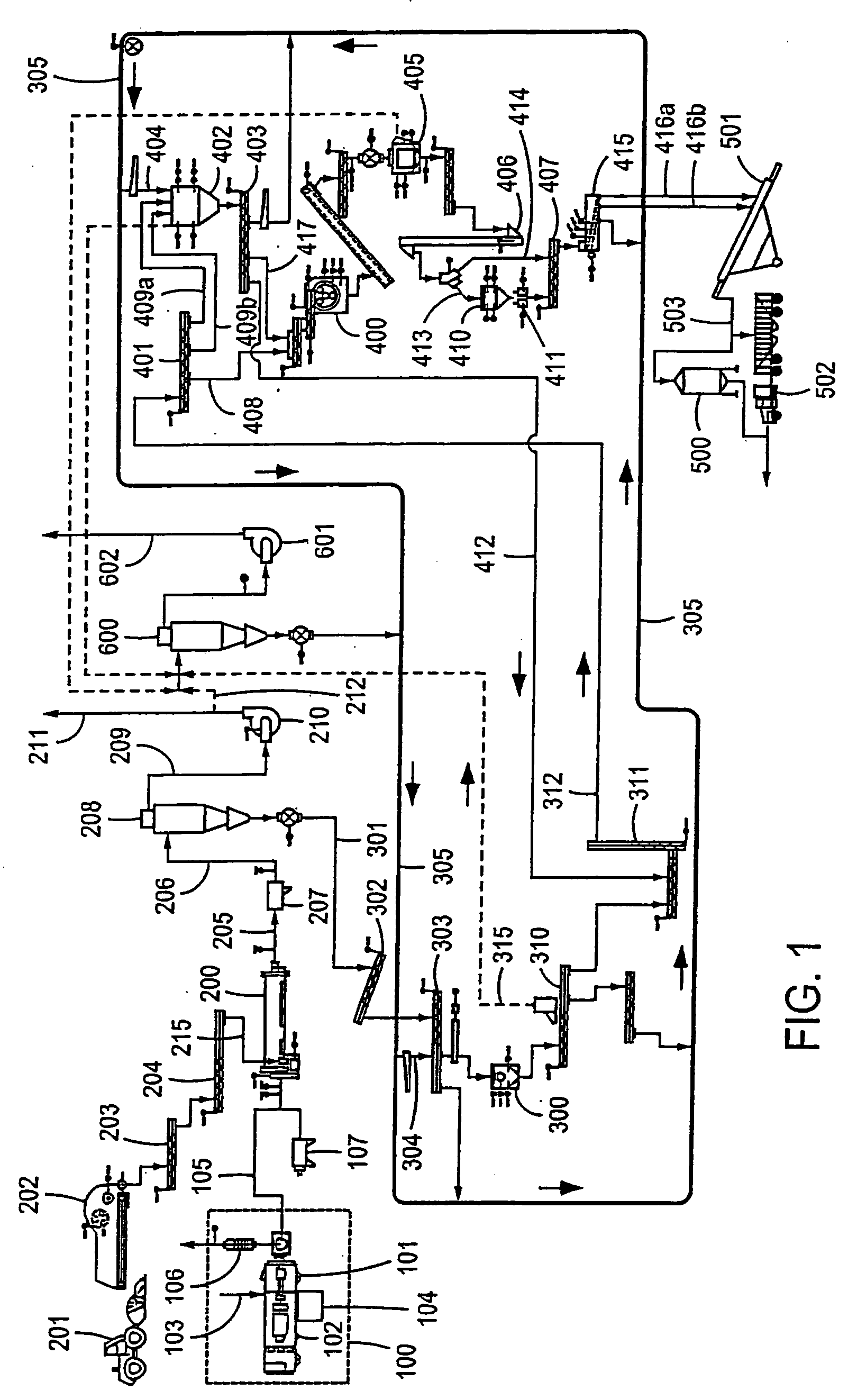

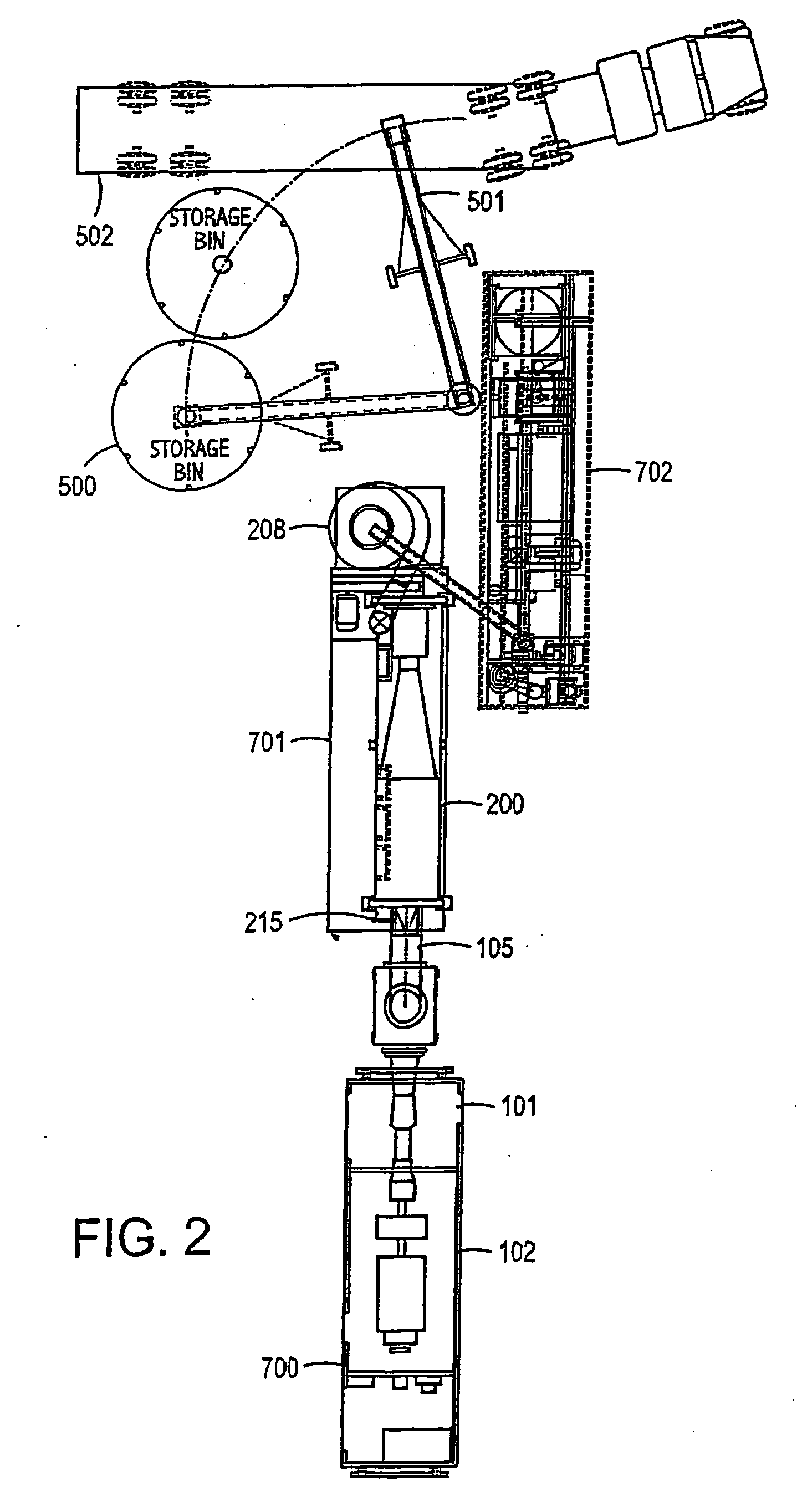

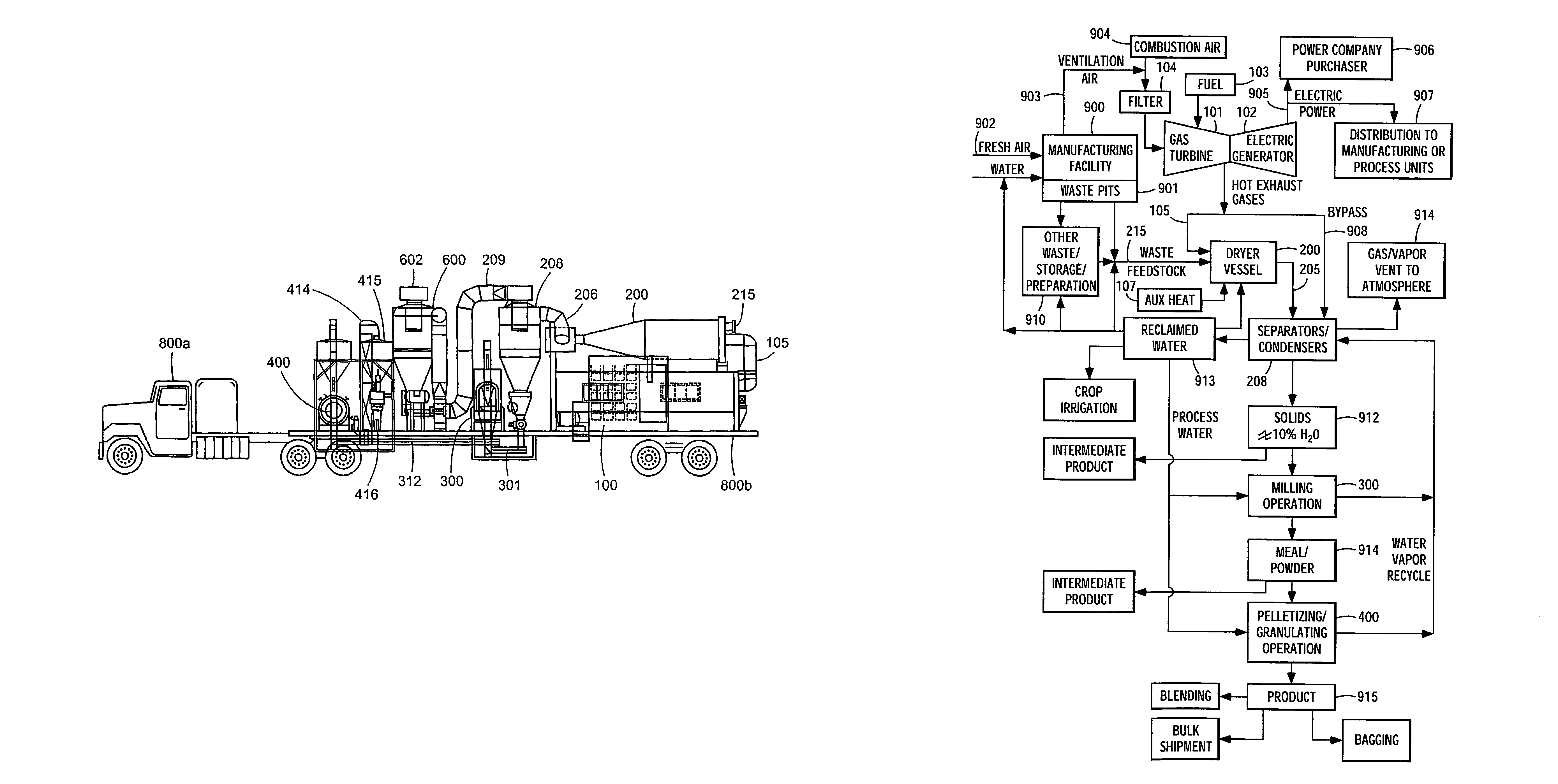

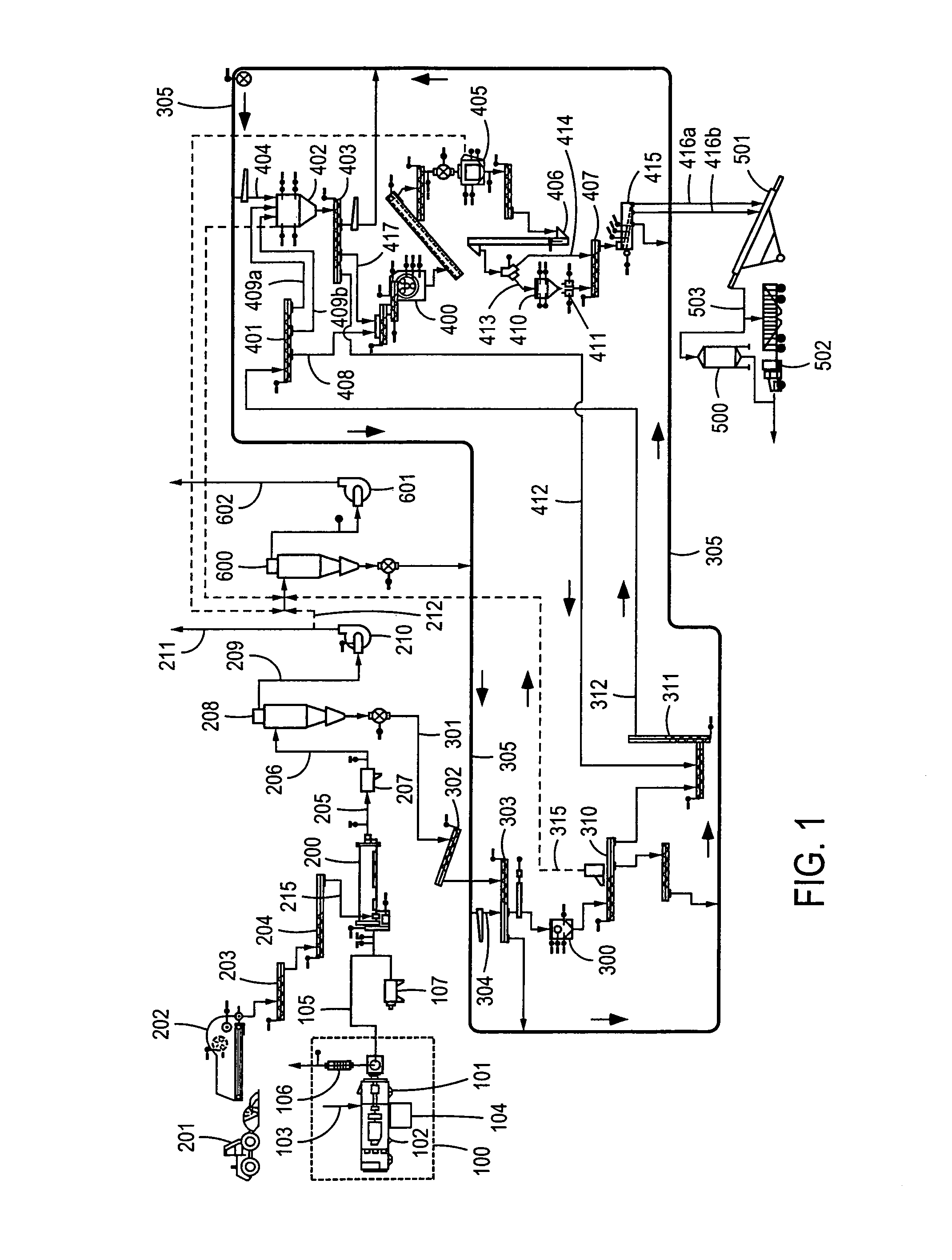

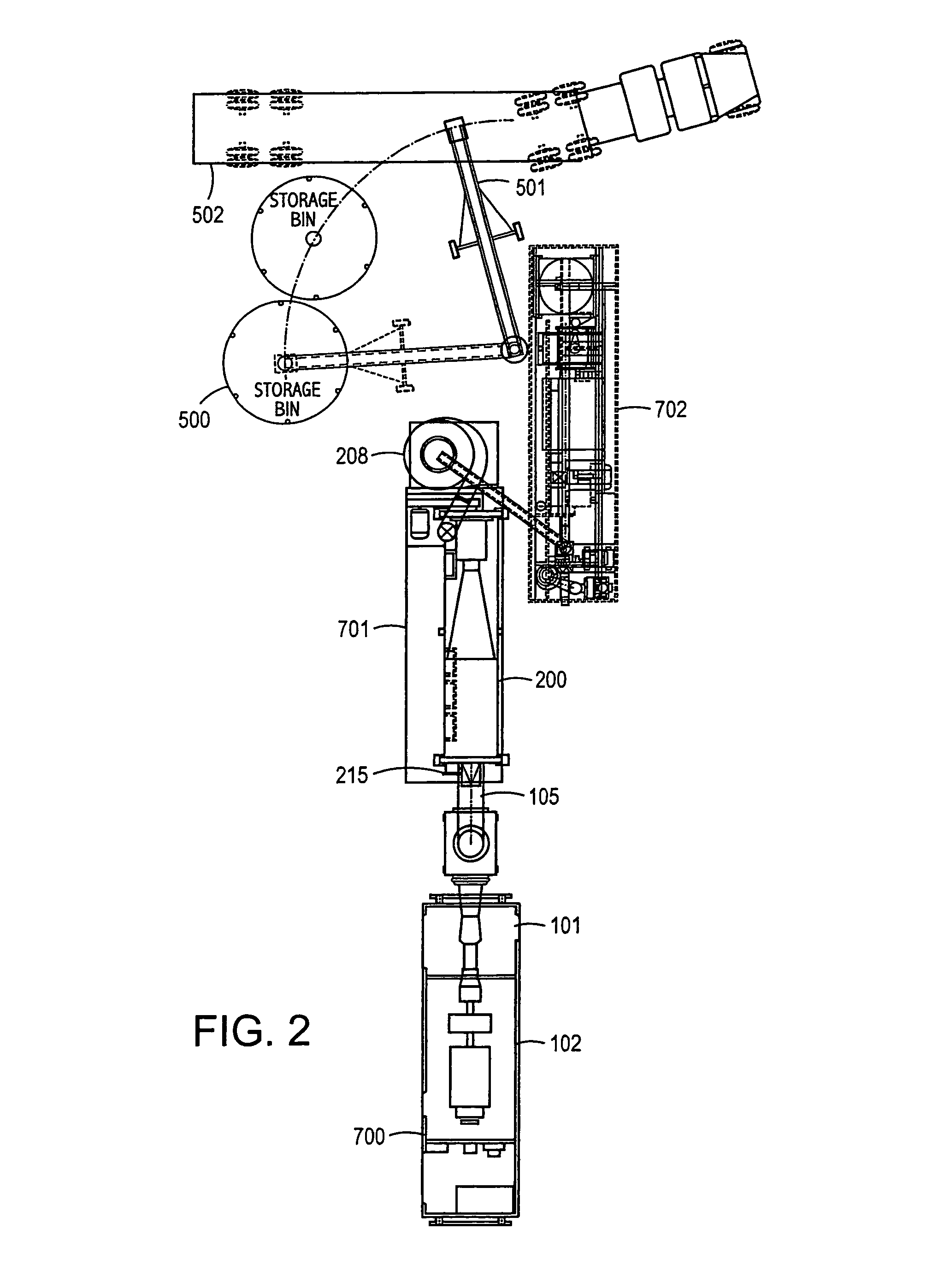

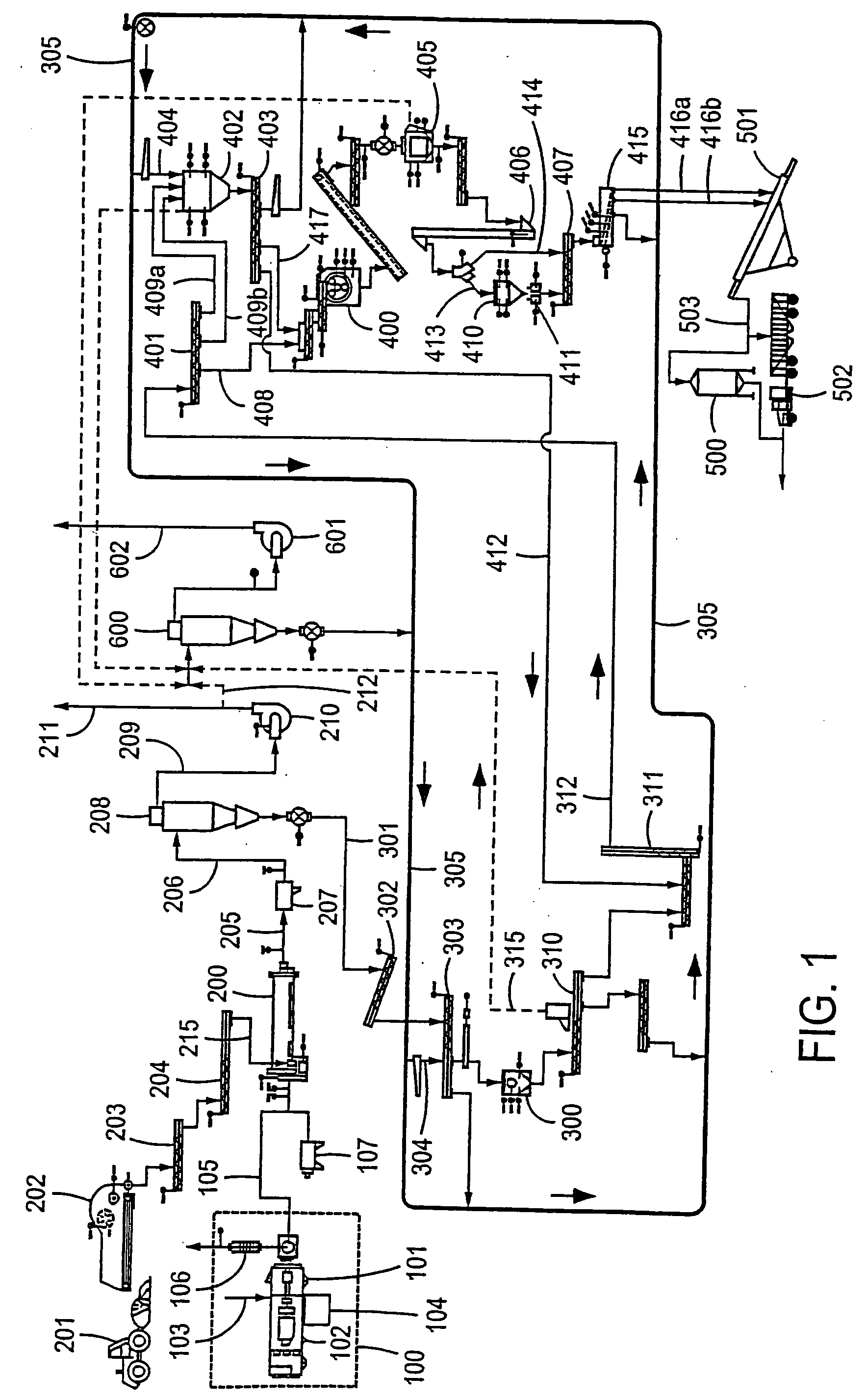

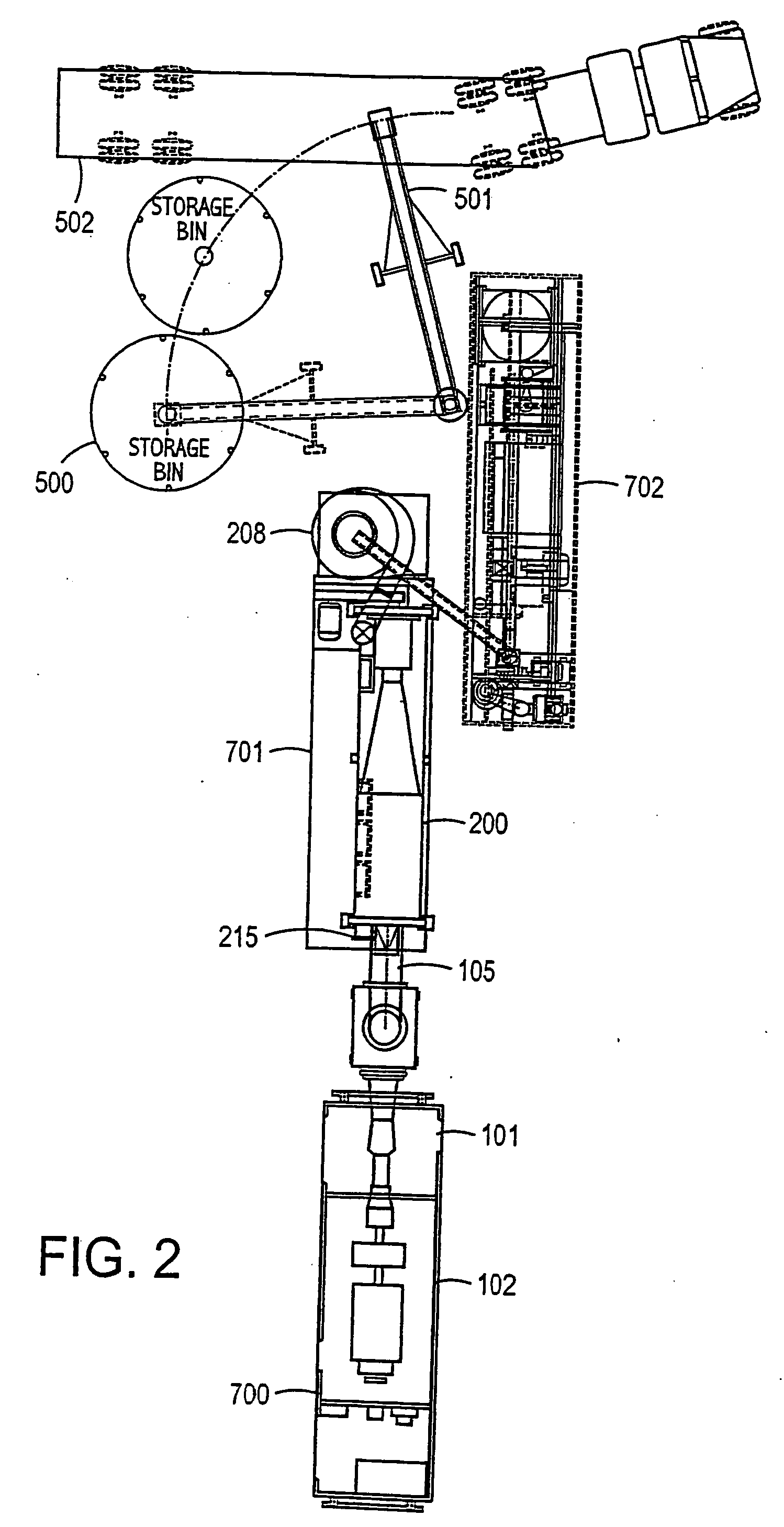

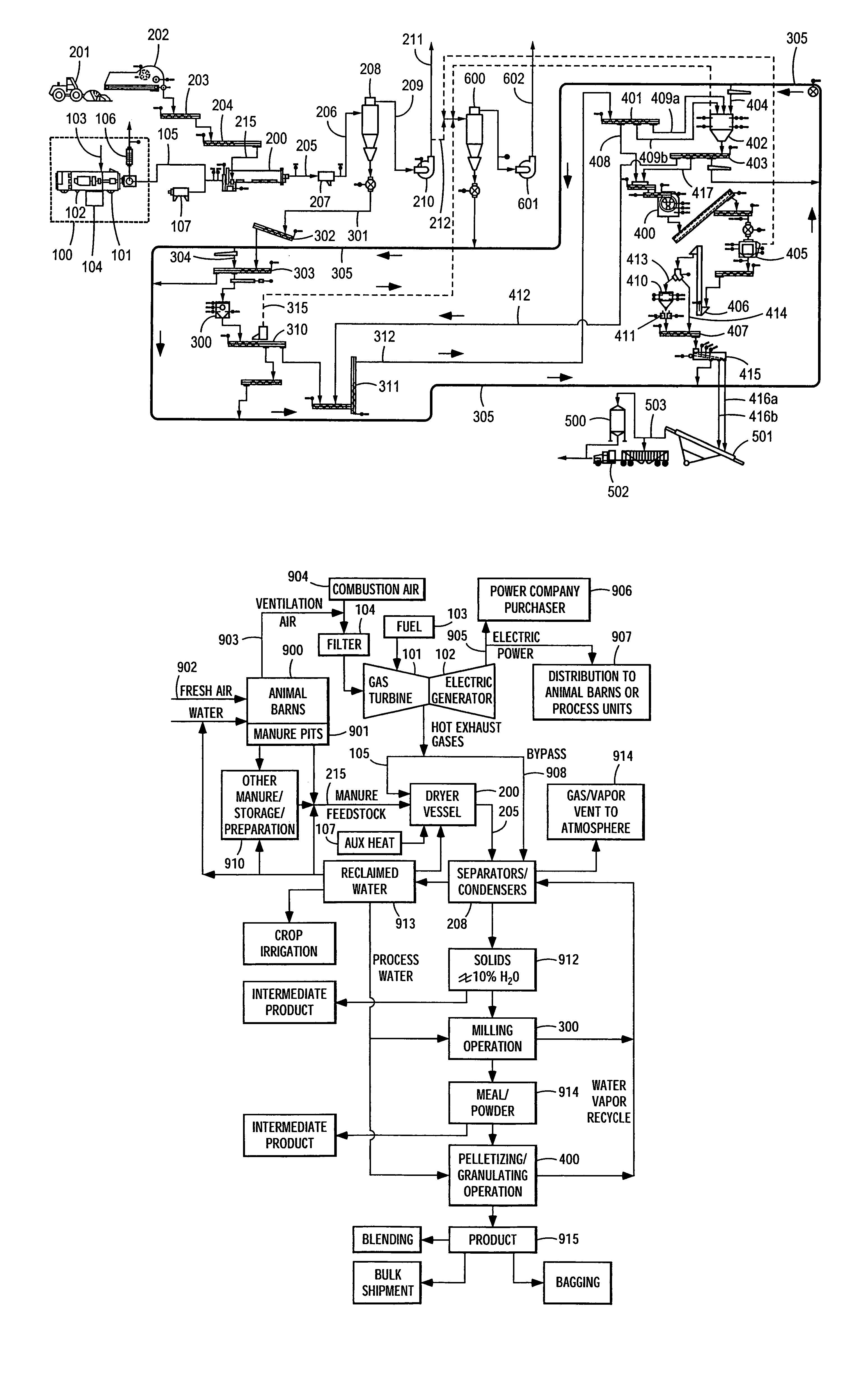

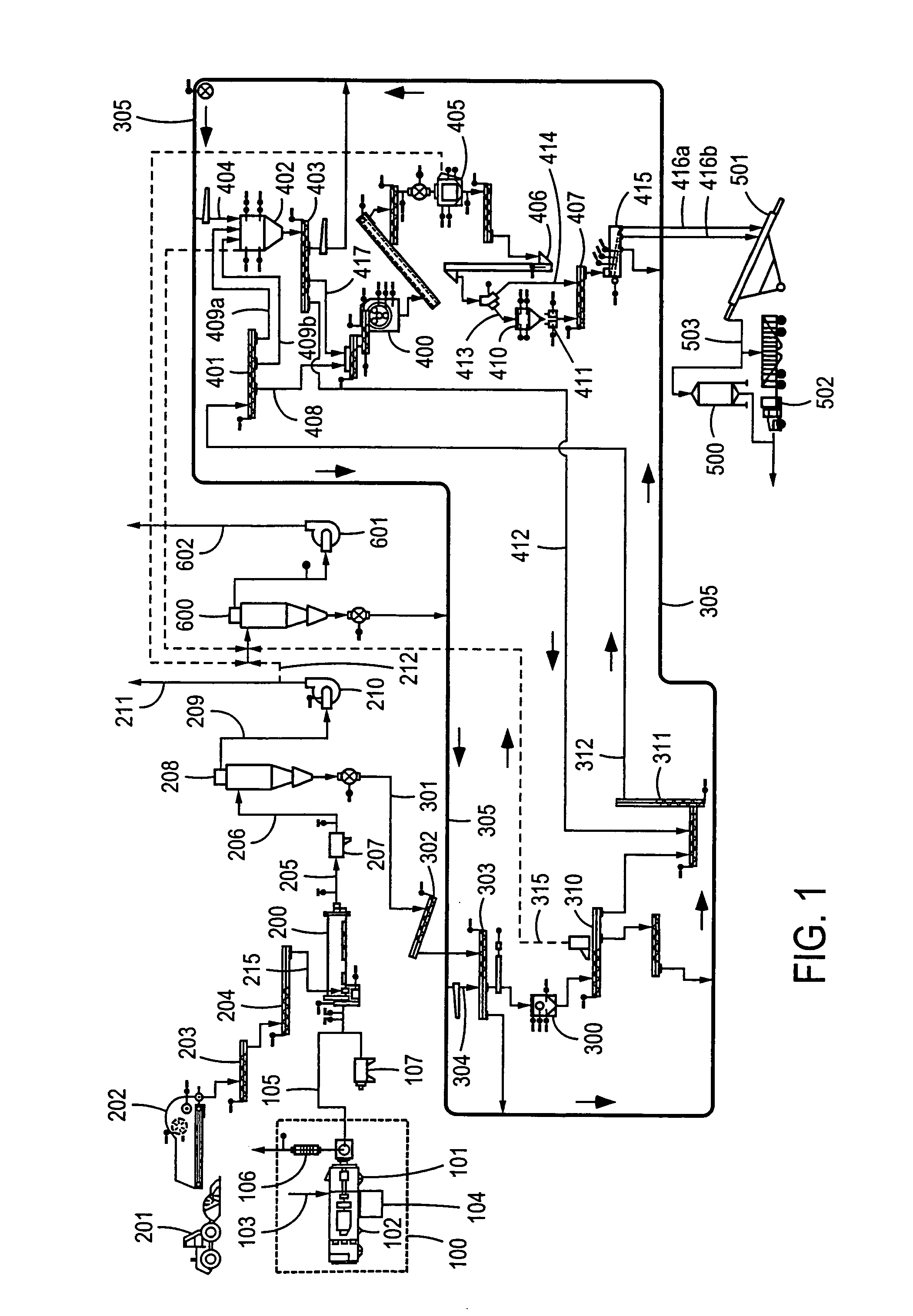

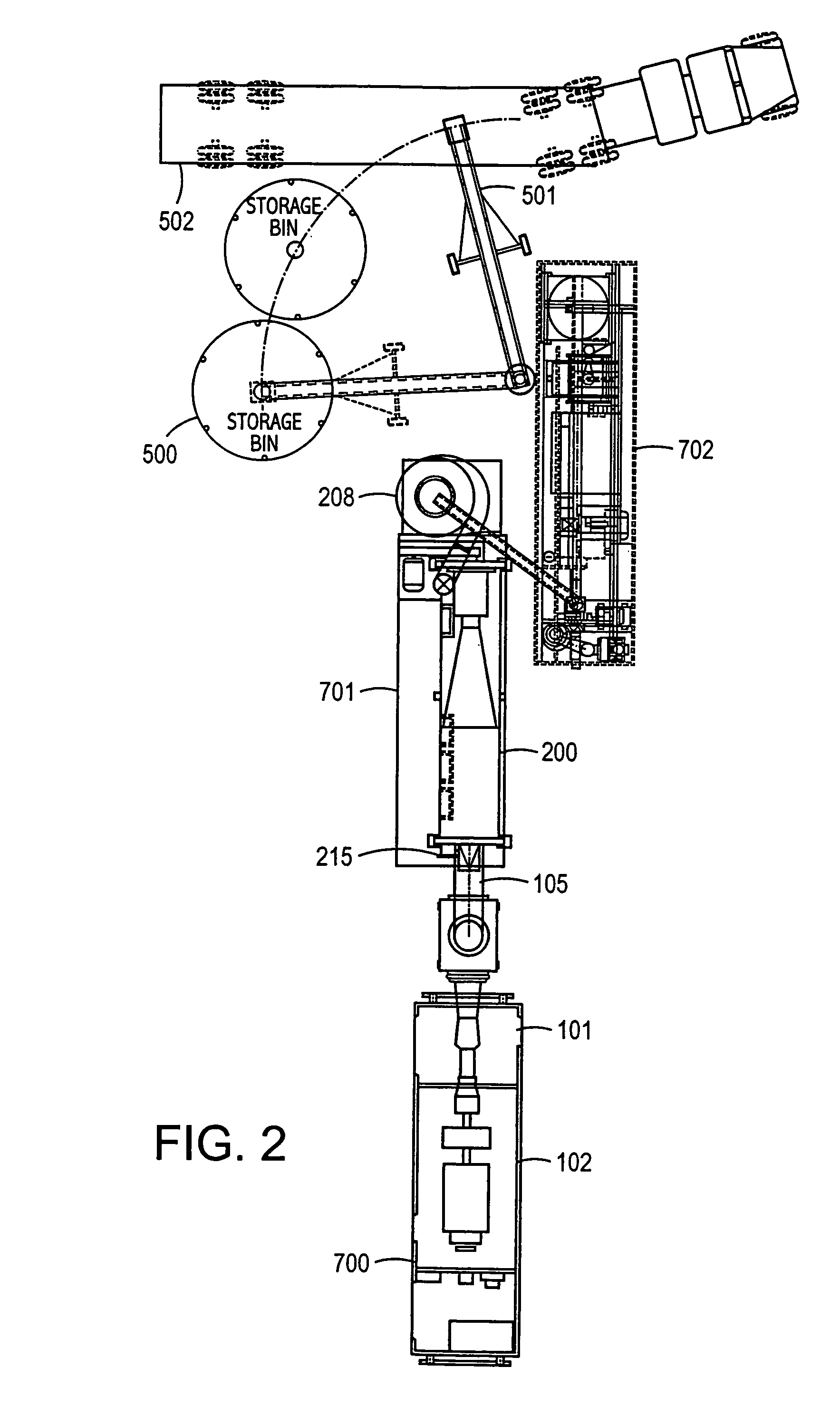

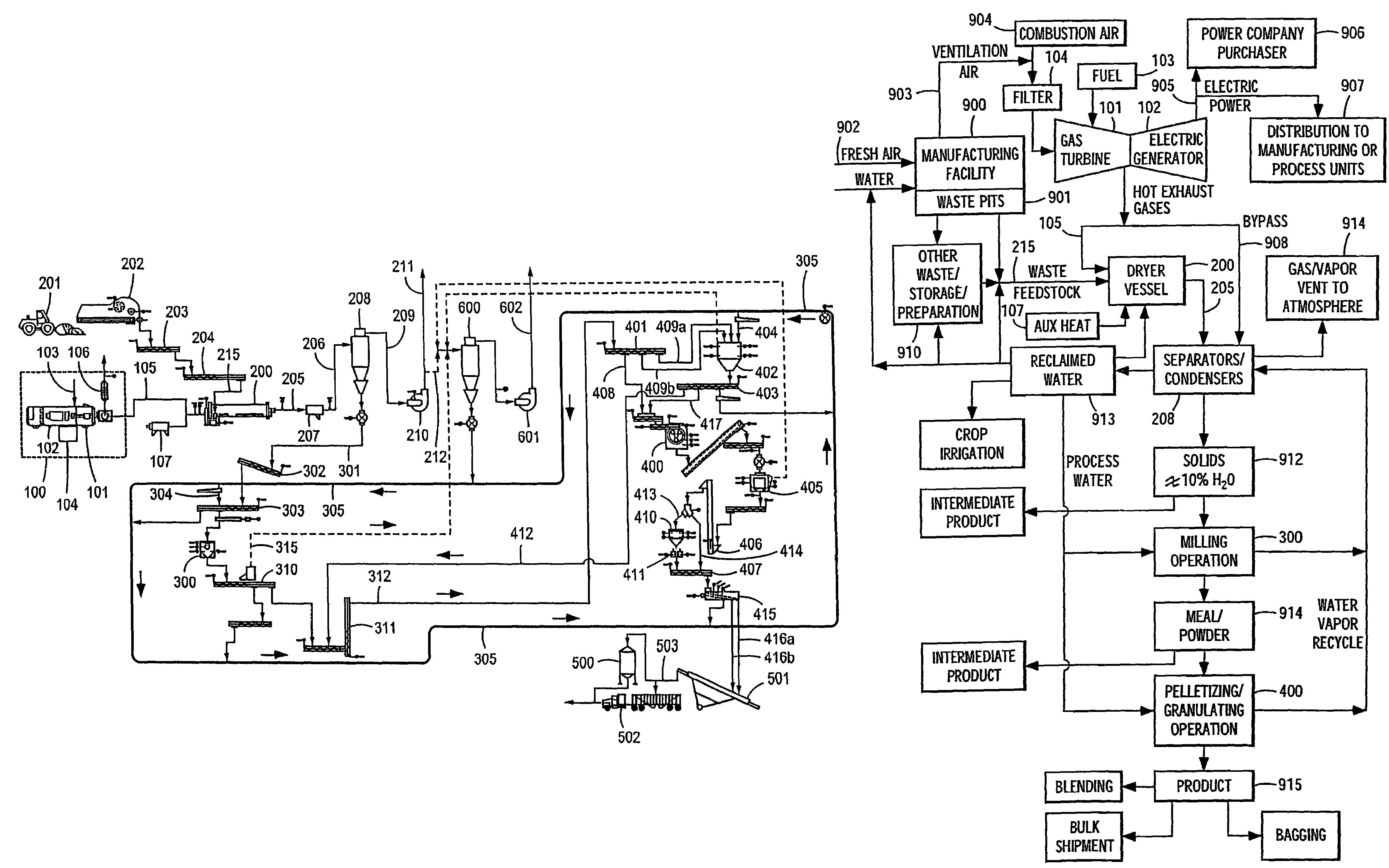

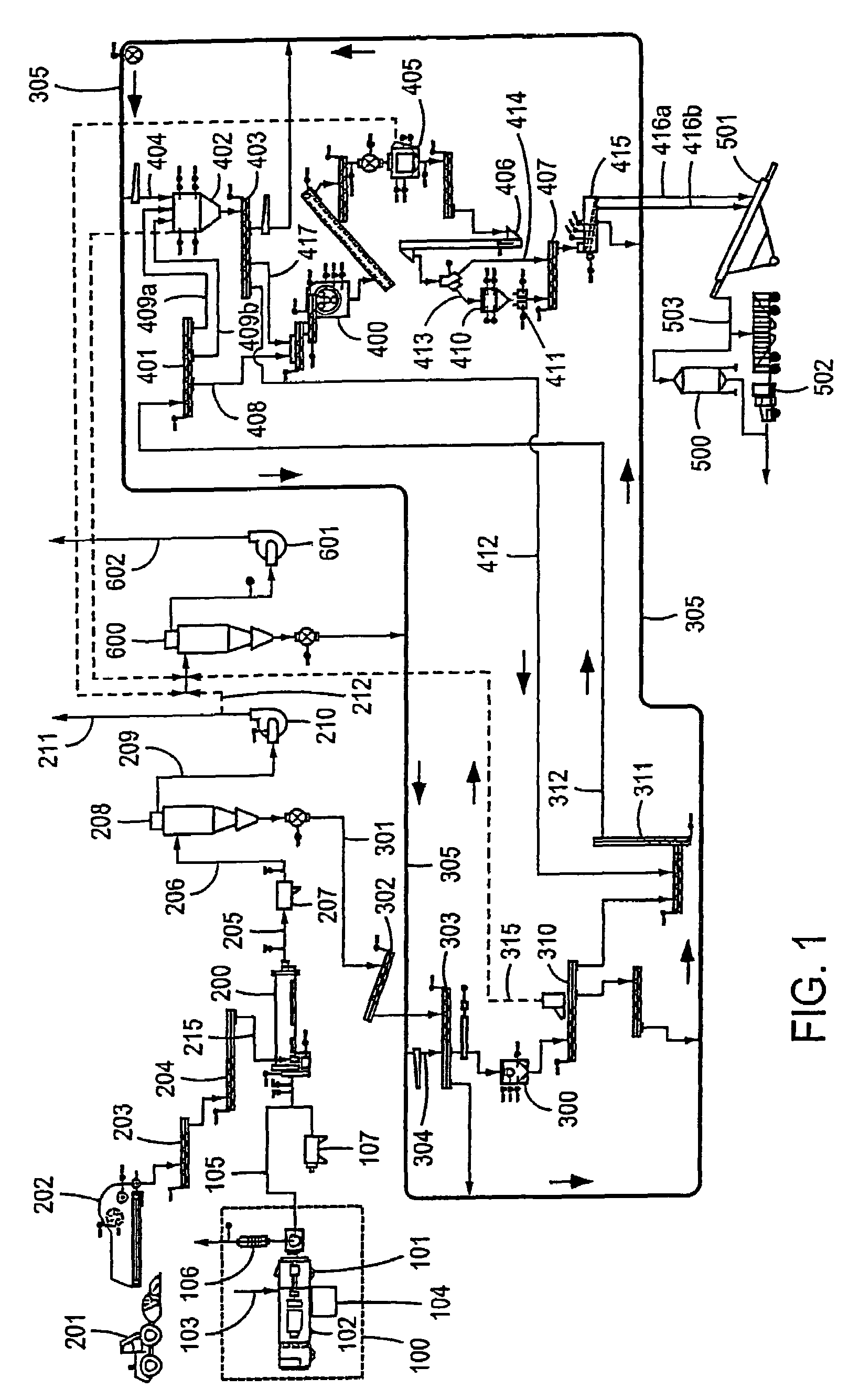

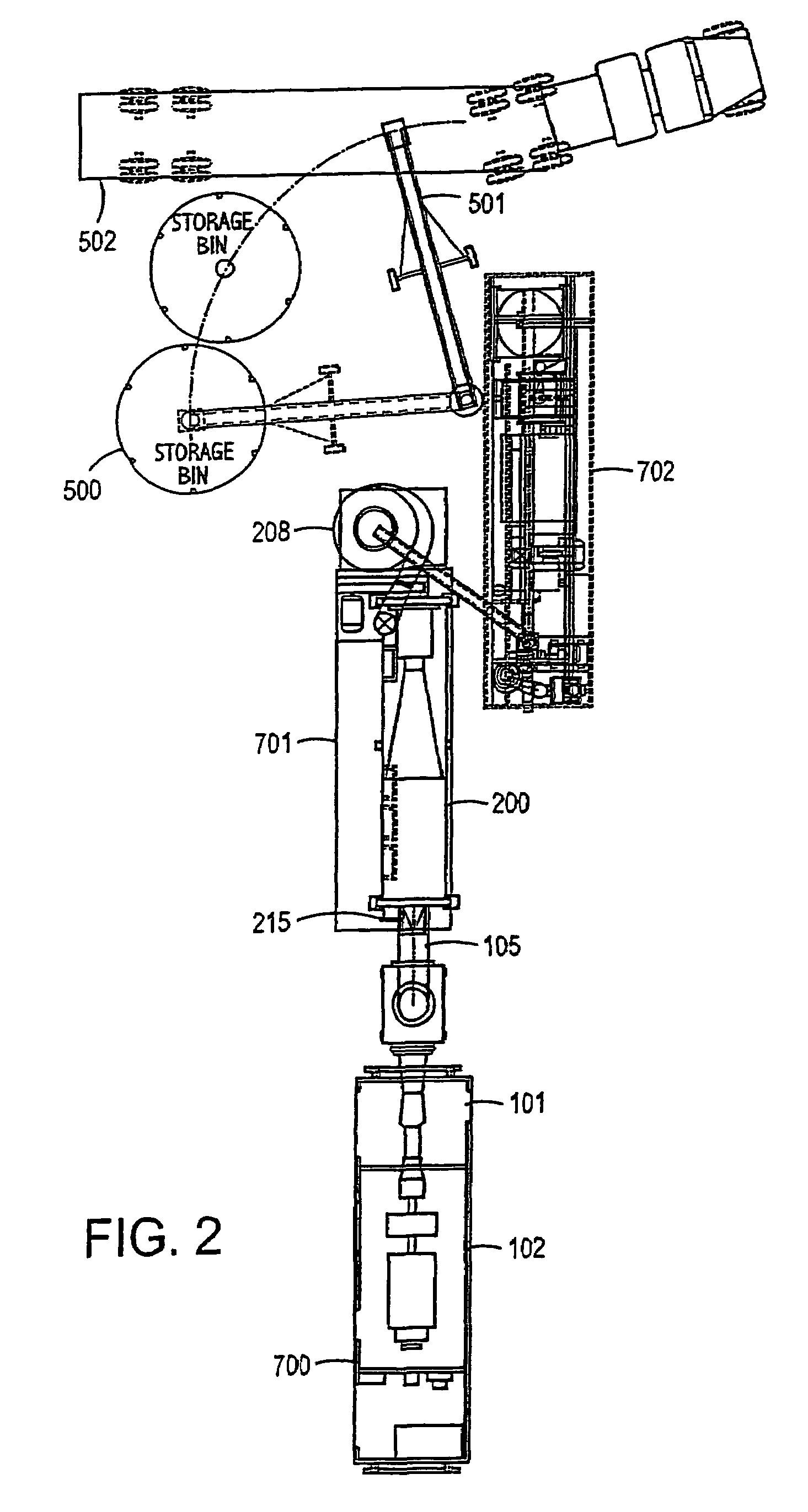

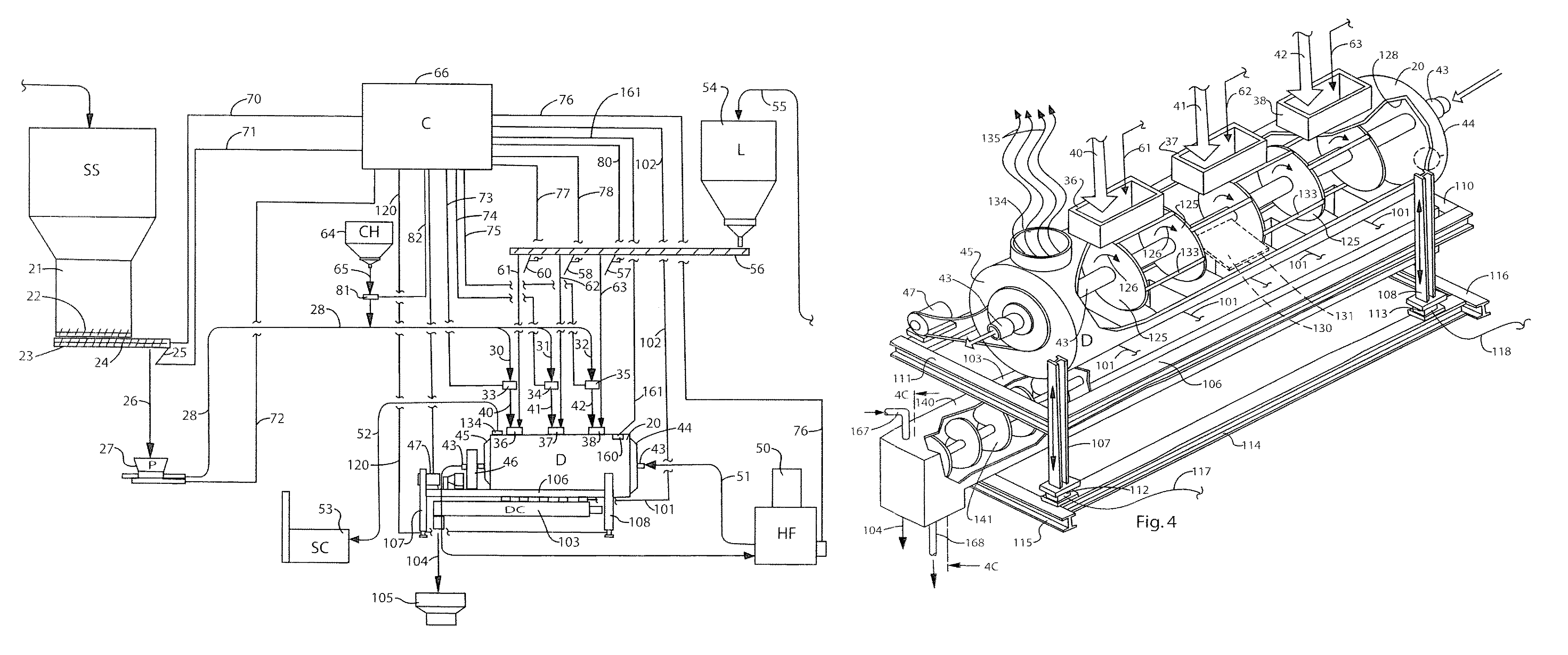

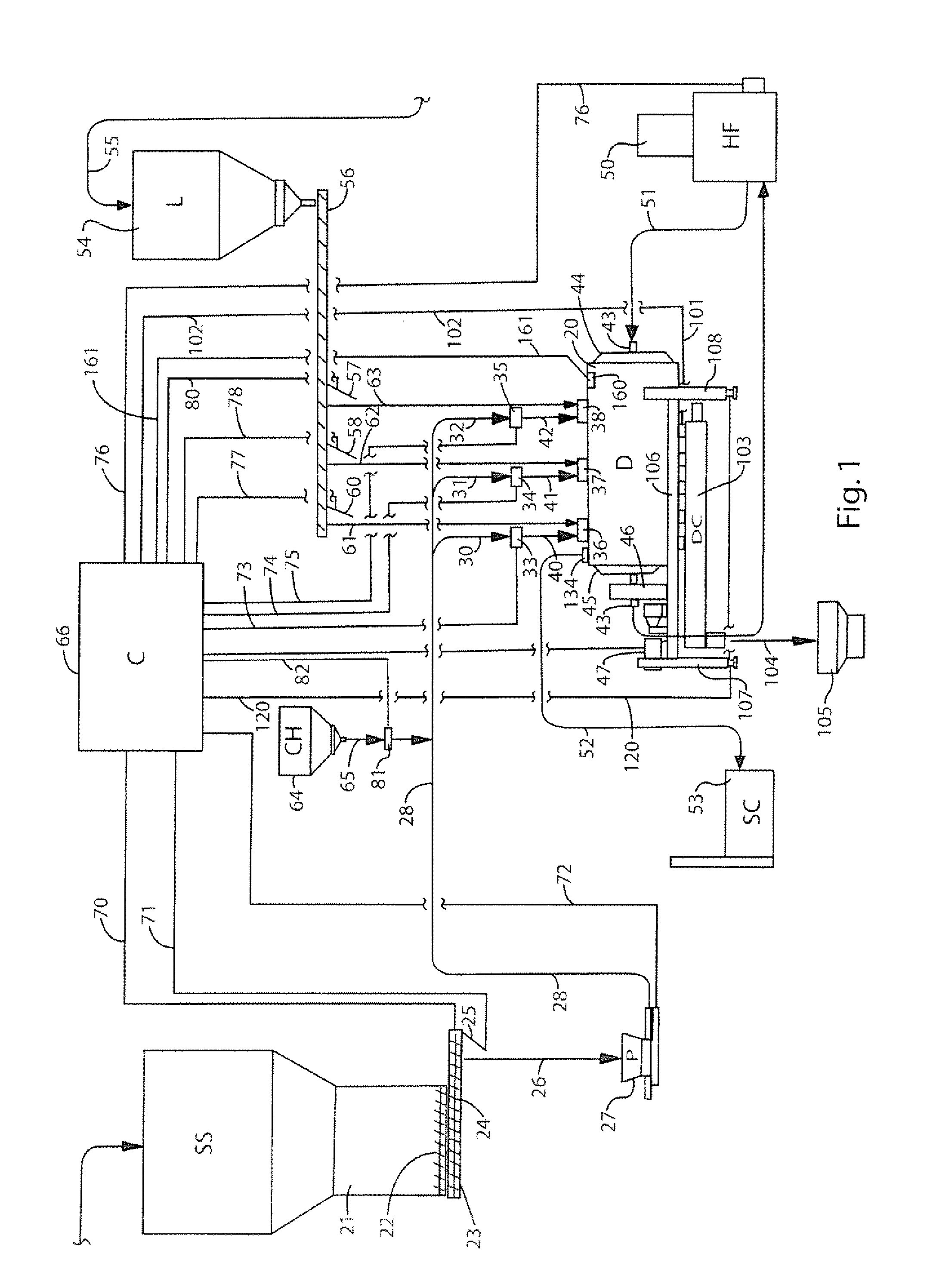

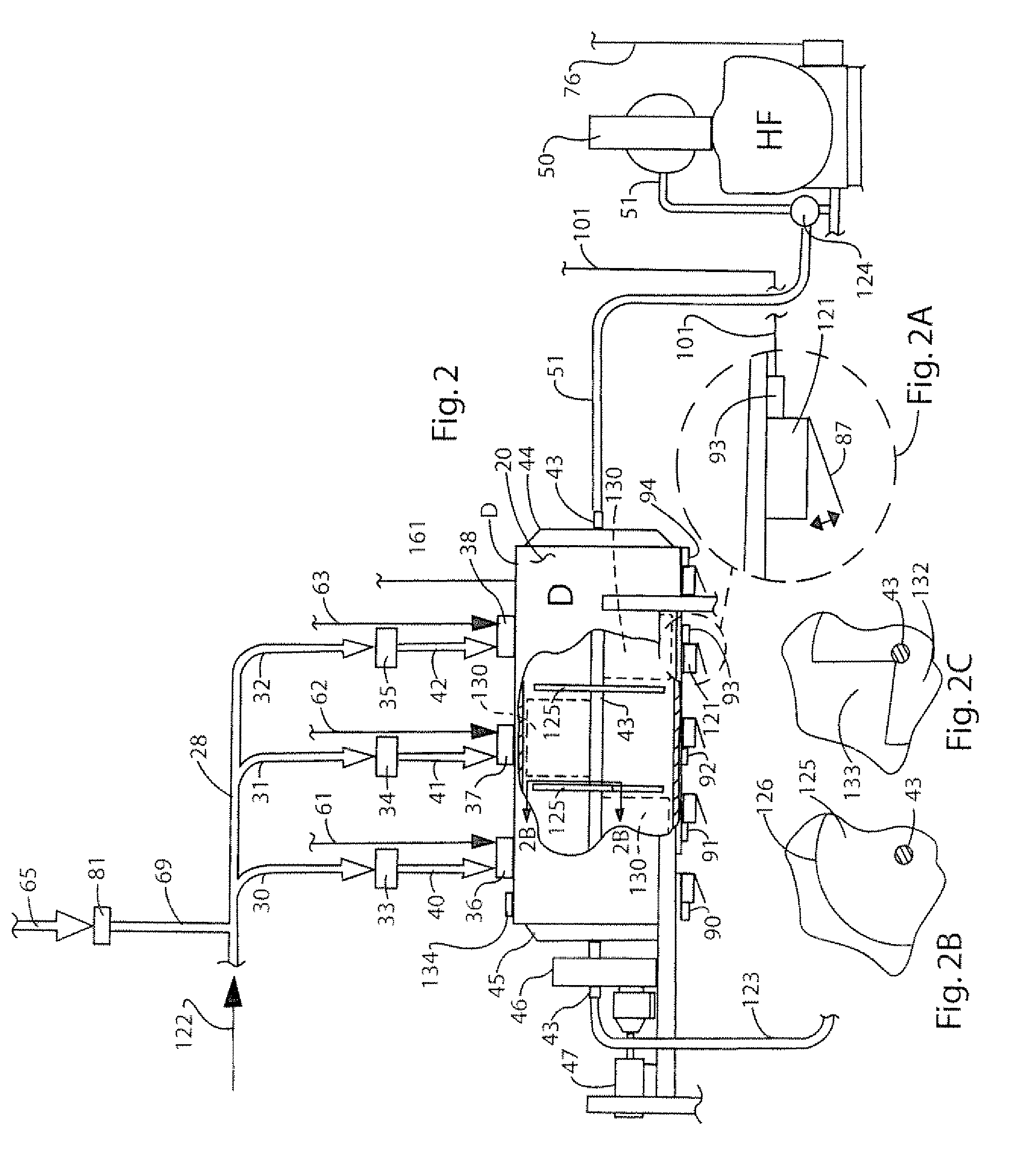

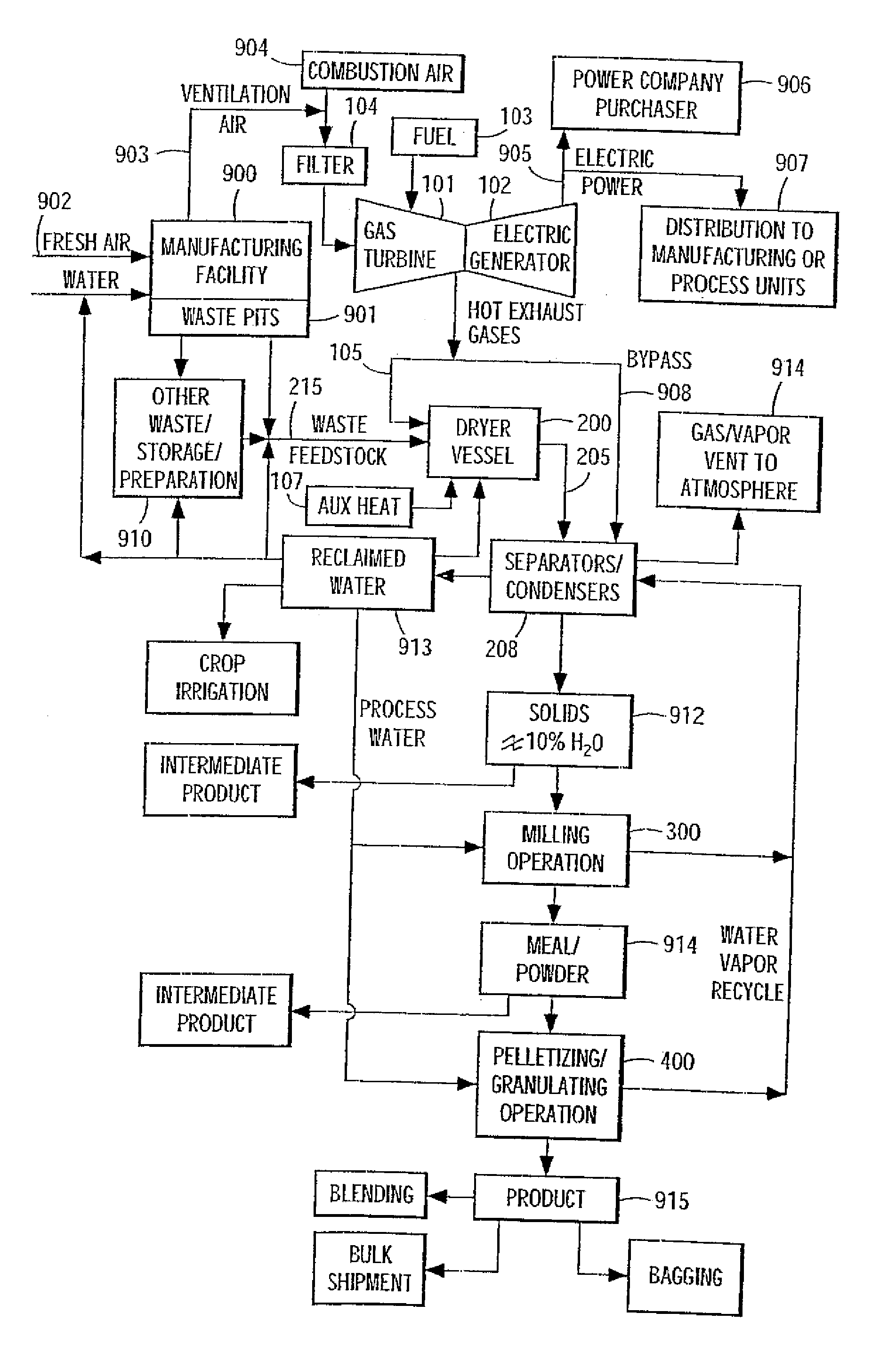

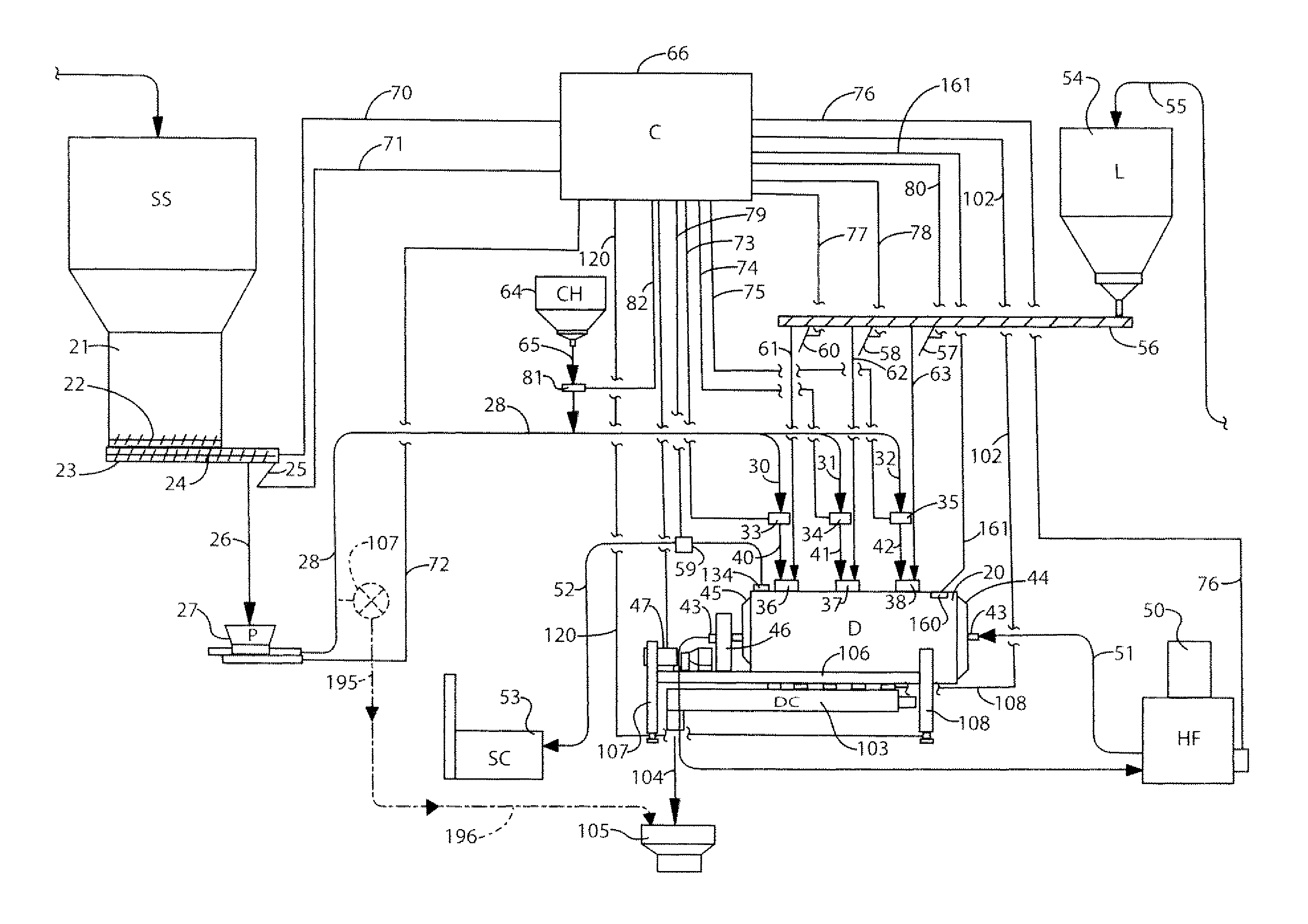

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS20060010712A1Drying using combination processesBio-organic fraction processingOrganic farmingSewage

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

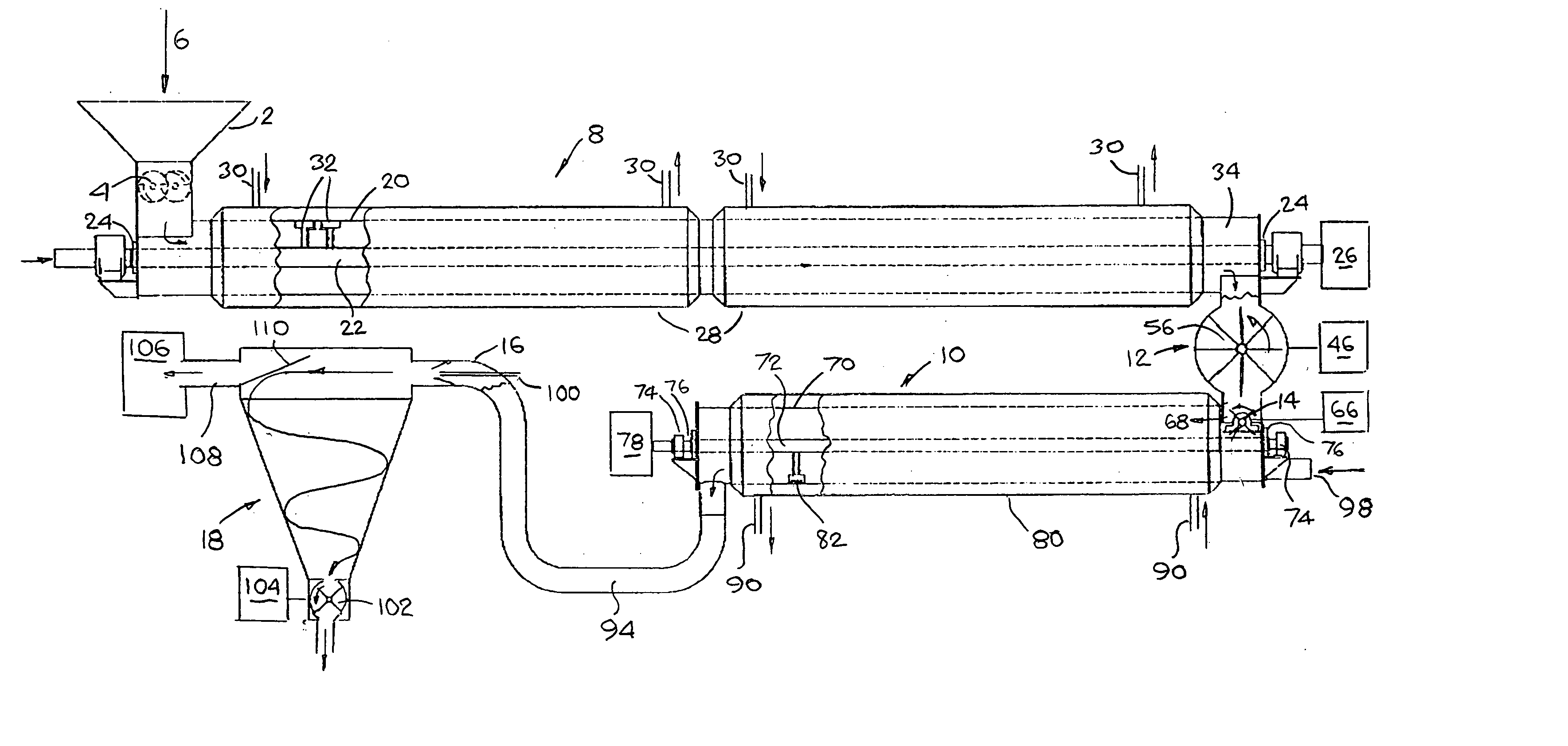

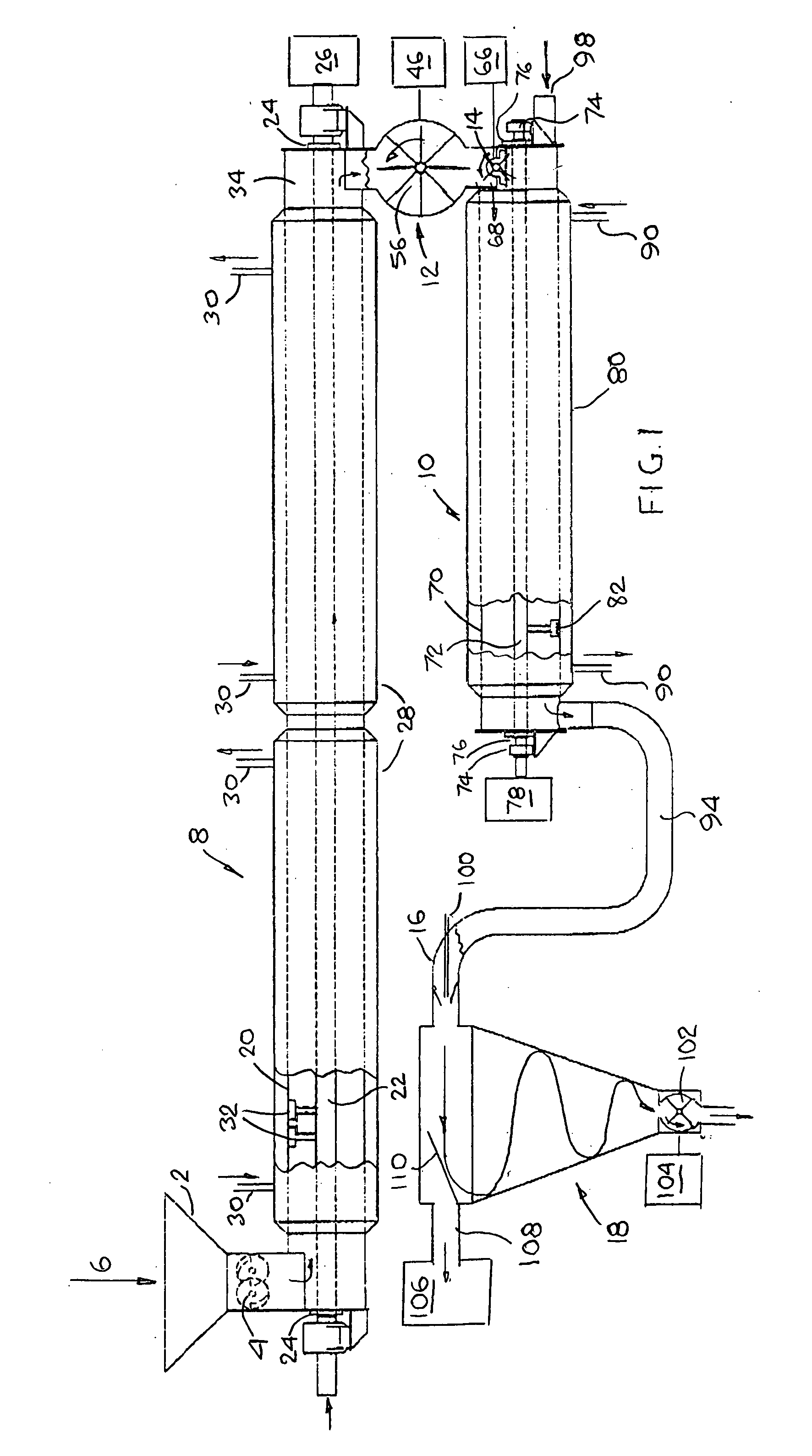

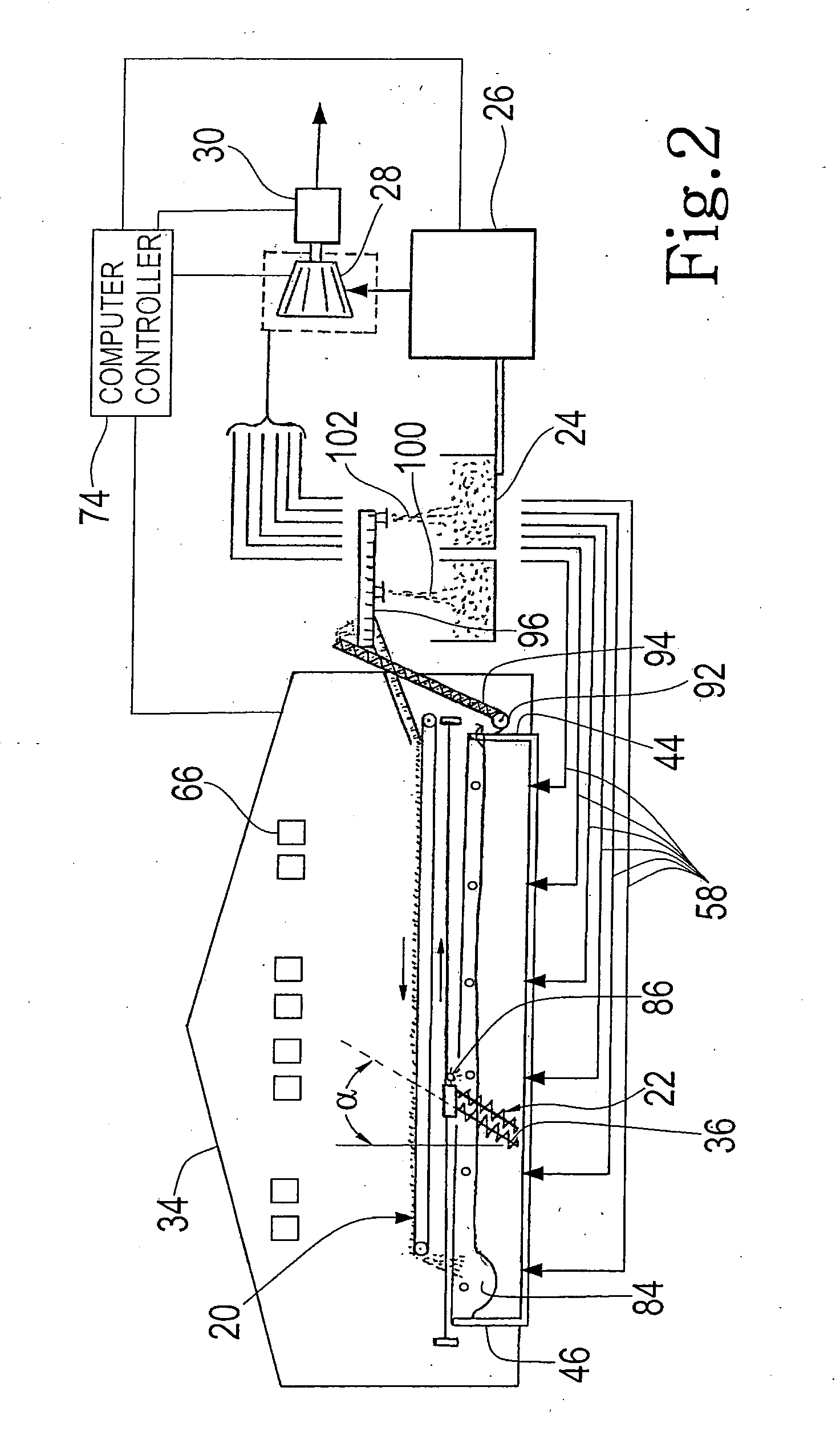

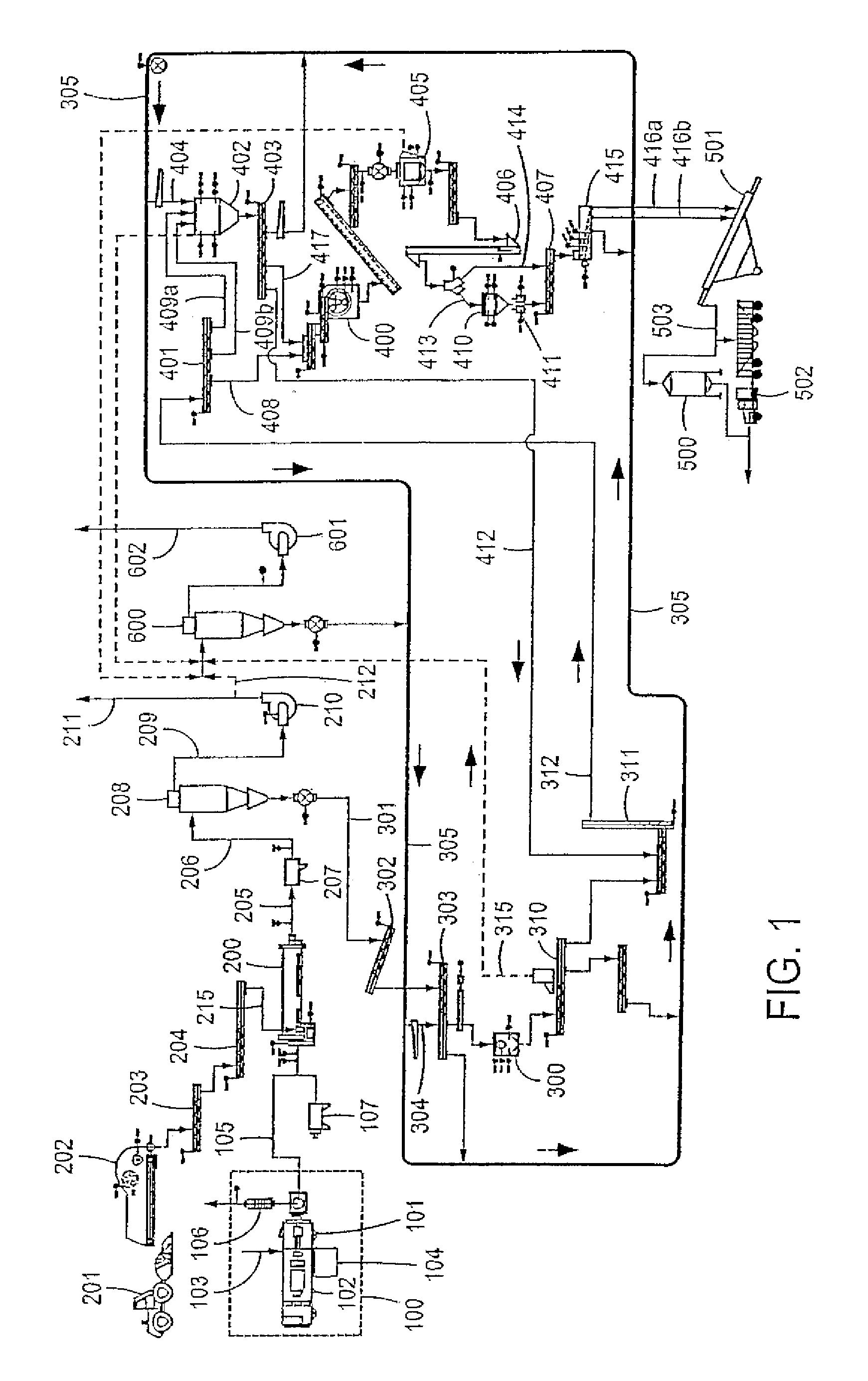

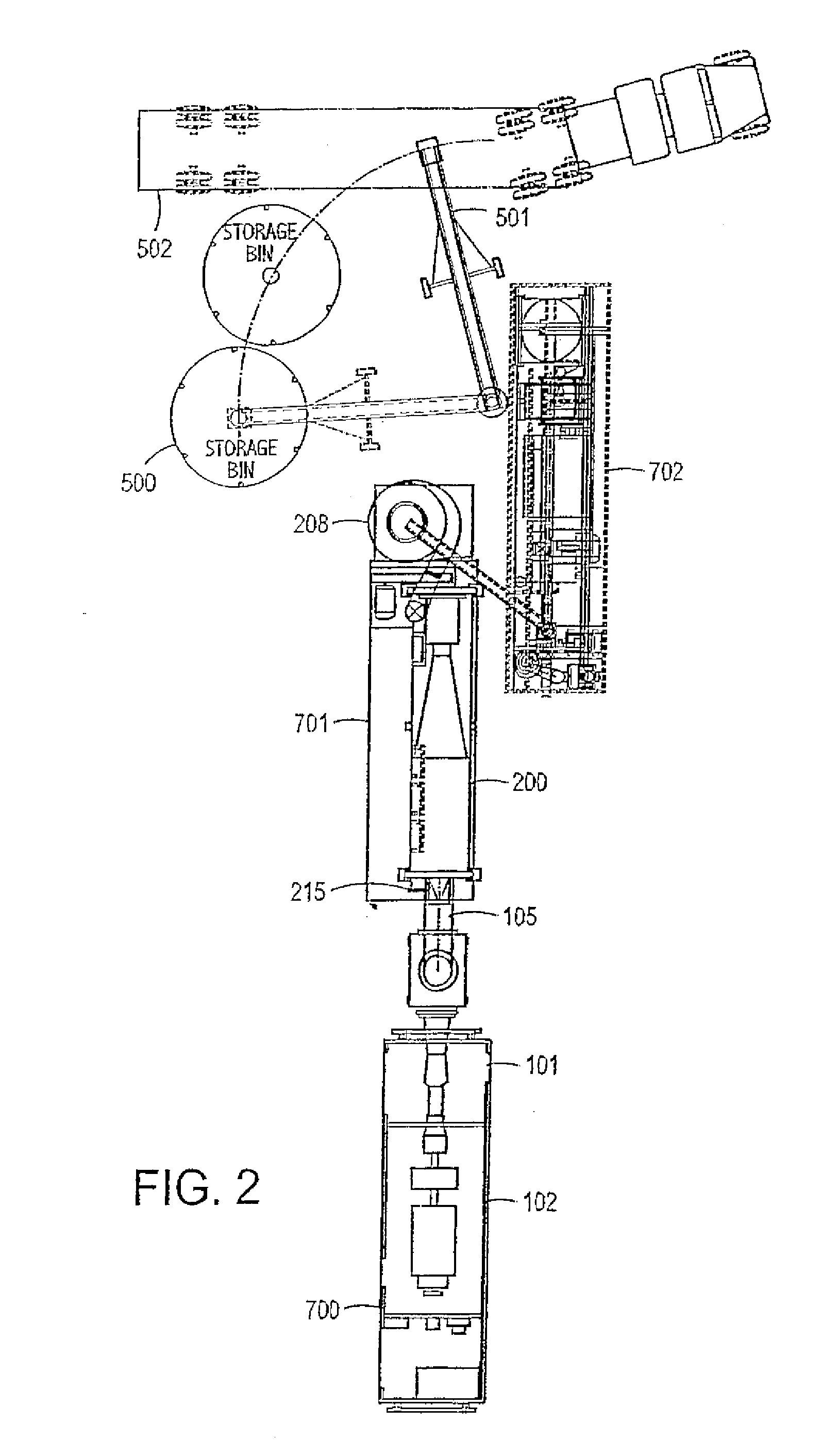

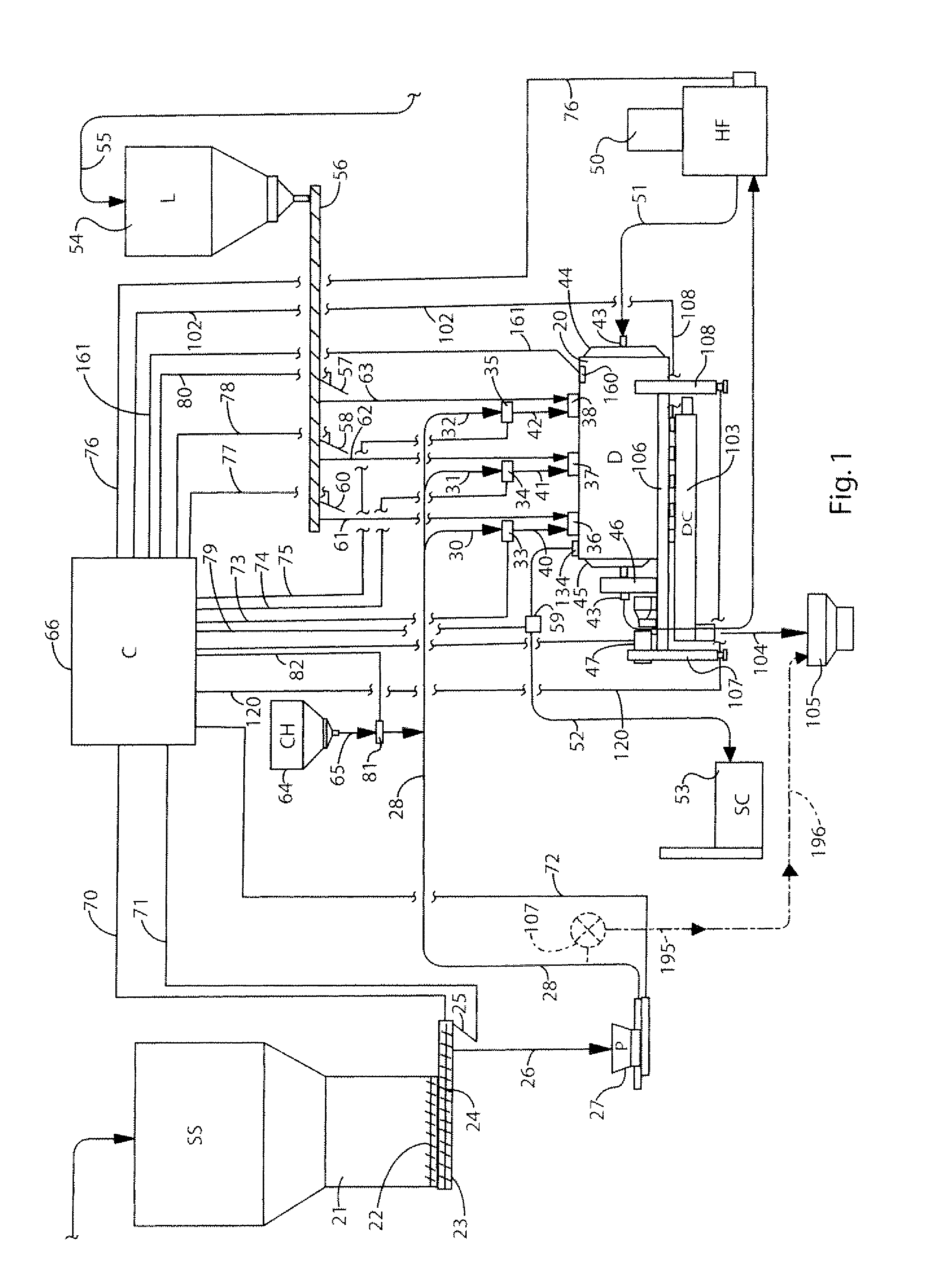

Process and system for drying and heat treating materials

InactiveUS20060010714A1Drying solid materials with heatExcrement fertilisersEngineeringProcess engineering

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

Process and system for drying and heat treating materials

InactiveUS20060101665A1Water/sewage treatment by centrifugal separationReversed direction vortexProcess engineeringMoisture

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

Process and system for drying and heat treating materials

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

Process and apparatus for manufacture of fertilizer products from manure and sewage

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

Process and apparatus for manufacture of fertilizer products from manure and sewage

InactiveUS7024796B2Drying using combination processesBio-organic fraction processingAgricultural scienceOrganic farming

This invention discloses systems and methods for conversion of manure to novel fertilizer and / or soil builder products useful as input for organic farming operations. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel. The dryer vessel receives the manure for contact with the turbine exhaust gases to convert the manure to a dry material, which is passed to the processing unit where it is formed into granules, pellets or other desired form for the final dry fertilizer product. The method comprises drying, heating and converting the manure to form novel self binding fertilizer and soil builder type products for organic farming and other uses.

Owner:EARTHRENEW INC

Sludge dryer

InactiveUS20050000108A1Avoid lostPrevent partial lossDrying solid materials without heatRotary drum furnacesSludgeEvaporation

Owner:RAGNARSSON ANDERS T

Process and system for drying and heat treating materials

InactiveUS7685737B2Water/sewage treatment by centrifugal separationReversed direction vortexProcess engineeringMoisture

Owner:EARTHRENEW INC

Methods of enhancing fine particle dewatering

InactiveUS6855260B1Increase tonnageGood removal effectWaste water treatment from quariesDrying solid materials with heatFine particulateSlurry

A new method of improving the process of dewatering fine particulate materials is disclosed. In this method, an aqueous slurry of fine particles is treated with appropriate hydrophobizing reagents so that the particulate material becomes moderately hydrophobic with its water contact angle considerably below 90°. A low hydrophile-lipophile balance (HLB) number surfactant is then added to the slurry, so that the surfactant molecules adsorb on the moderately hydrophobic surface primarily by hydrophobic attraction and, thereby, increase its contact angle close to or above 90°. By virtue of the greatly enhanced hydrophobicity, the water molecules adhering to the surface are destabilized and removed more readily by a mechanical dewatering process. Any nonionic surfactant with its HLB number below about 15 may be used for the hydrophobicity enhancement. The surfactants may be used in conjunction with appropriate solvents such as light hydrocarbon oils and short-chain alcohols. The moisture reduction can be further improved by using appropriate electrolytes in conjunction with the low HLB surfactants, spraying surface tension lowering reagents onto the filter cake, subjecting the cake to a suitable vibratory means, and by using combinations thereof.

Owner:YOON ROE HOAN

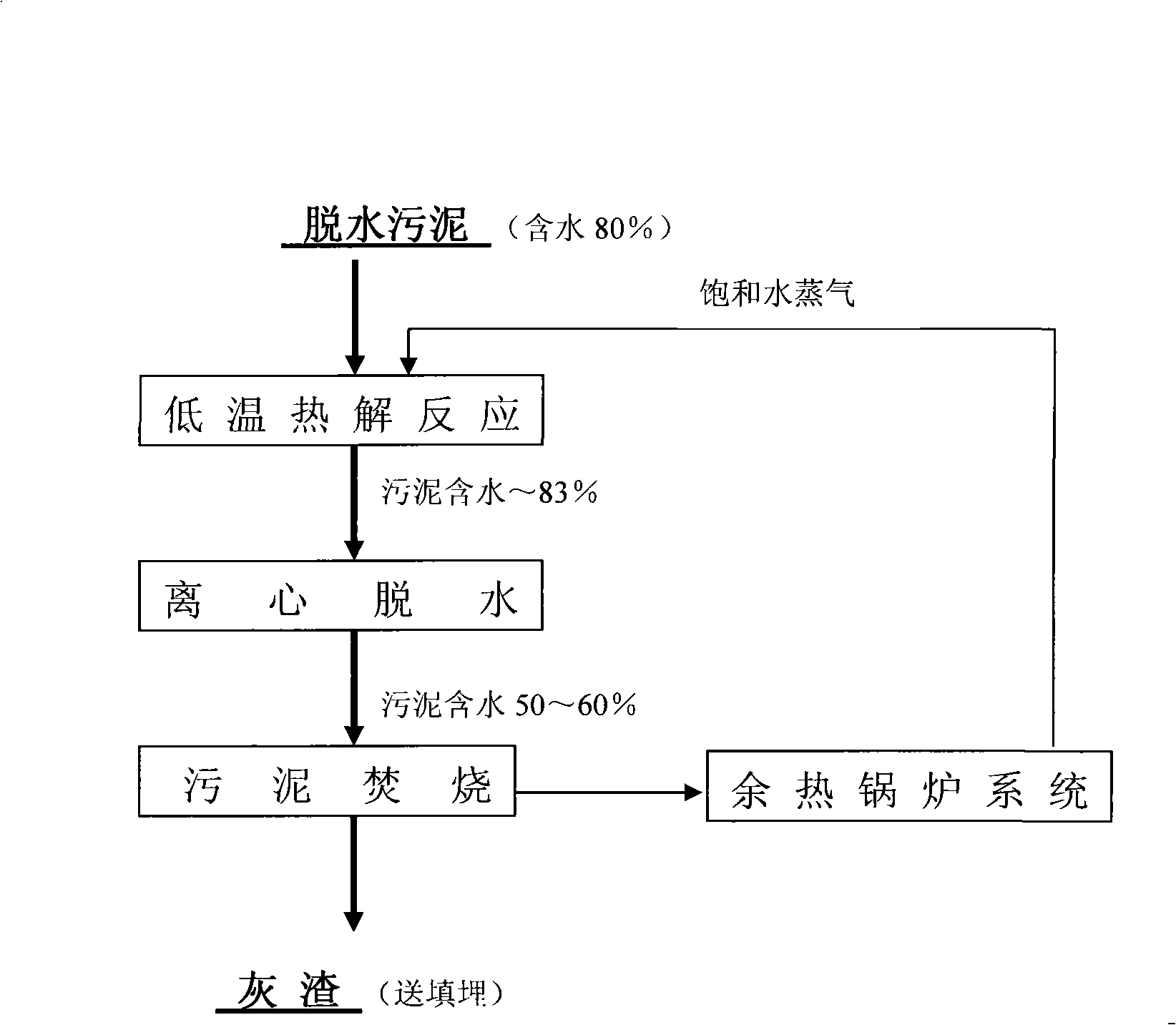

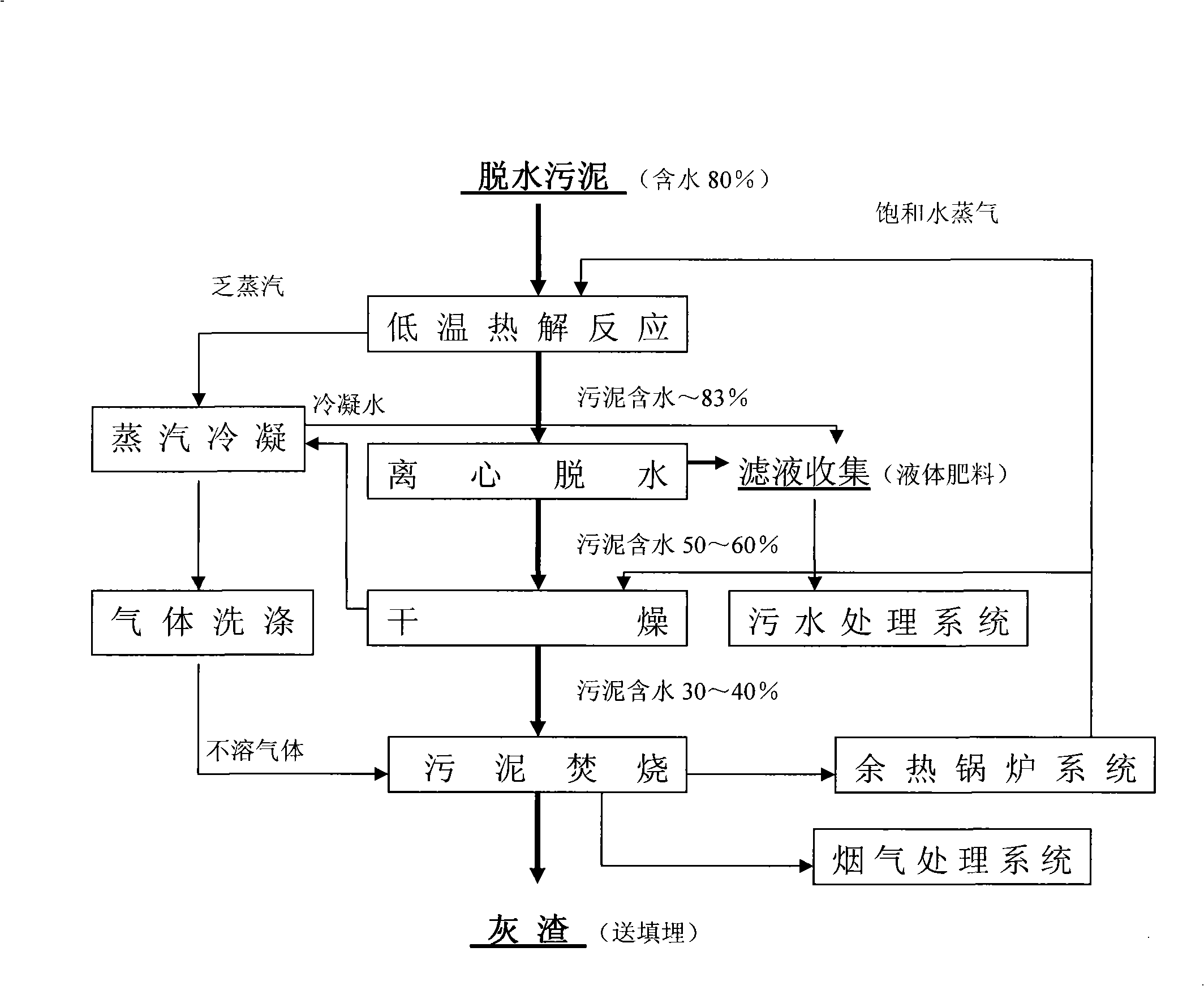

Wet sludge anhydration burning processing system and process

ActiveCN101290121AThoroughly deodorizedHarmlessDrying using combination processesSludge treatment by oxidationSteam condensationResource utilization

The invention relates to a wet sludge drying and incineration processing system. The system comprises a low-temperature pyrolytic reaction device, a centrifuging filtering device, a steam condensation device, a filtrate recovery device and a sludge incineration device; the low-temperature pyrolytic reaction device is used for carrying out low-temperature pyrolytic reaction between wet sludge and saturated steam in order to convert macromolecular organics in the wet sludge into low-molecular organics and destroy a sludge water-holding structure; the centrifuging device is used for carrying out centrifuging filtering to the wet sludge after pyrogenation; the steam condensation device is used for condensing and collecting bled steam converted from saturated steam in the low-temperature pyrolytic reaction device; the filtrate recovery device is used for collecting filtrate produced in the centrifuging device and for collecting condensed fluid from the steam condensation device; the sludge incineration device is used for incinerating semidry sludge after being dehydrated in the centrifuging device and insoluble gas remained in the steam condensation device as fuel. The system also relates to a process for carrying out the processing of wet sludge drying and incineration by adopting the processing system. The system and the process can solve the problem of sludge resource regeneration in a mode of environmental protection, energy conservation, high resource utilization rate and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

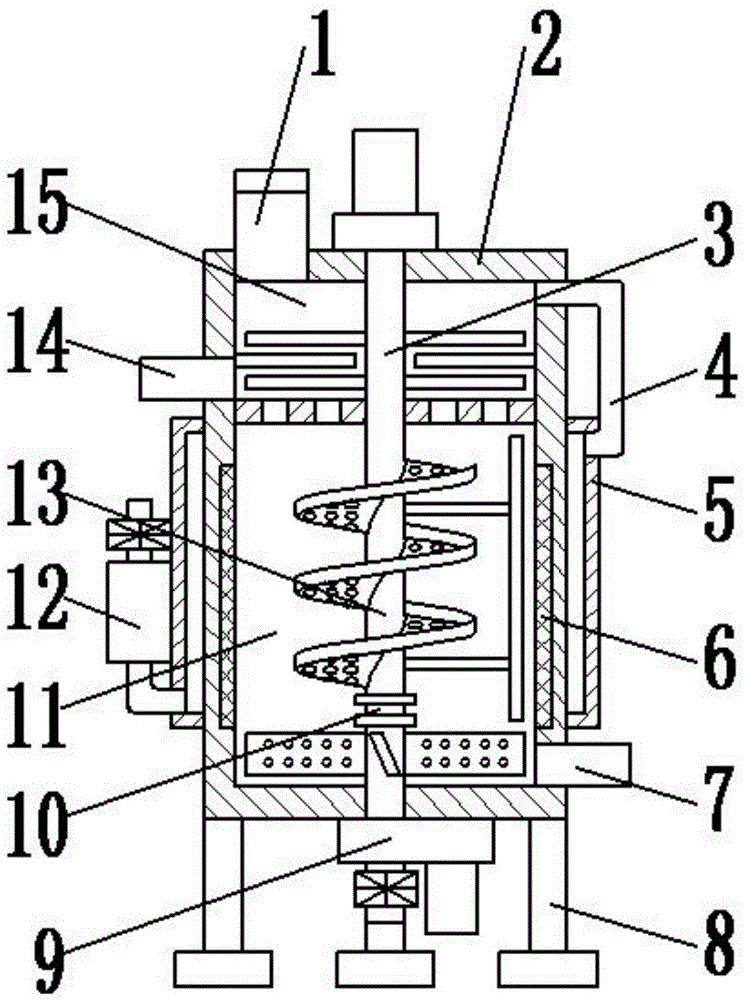

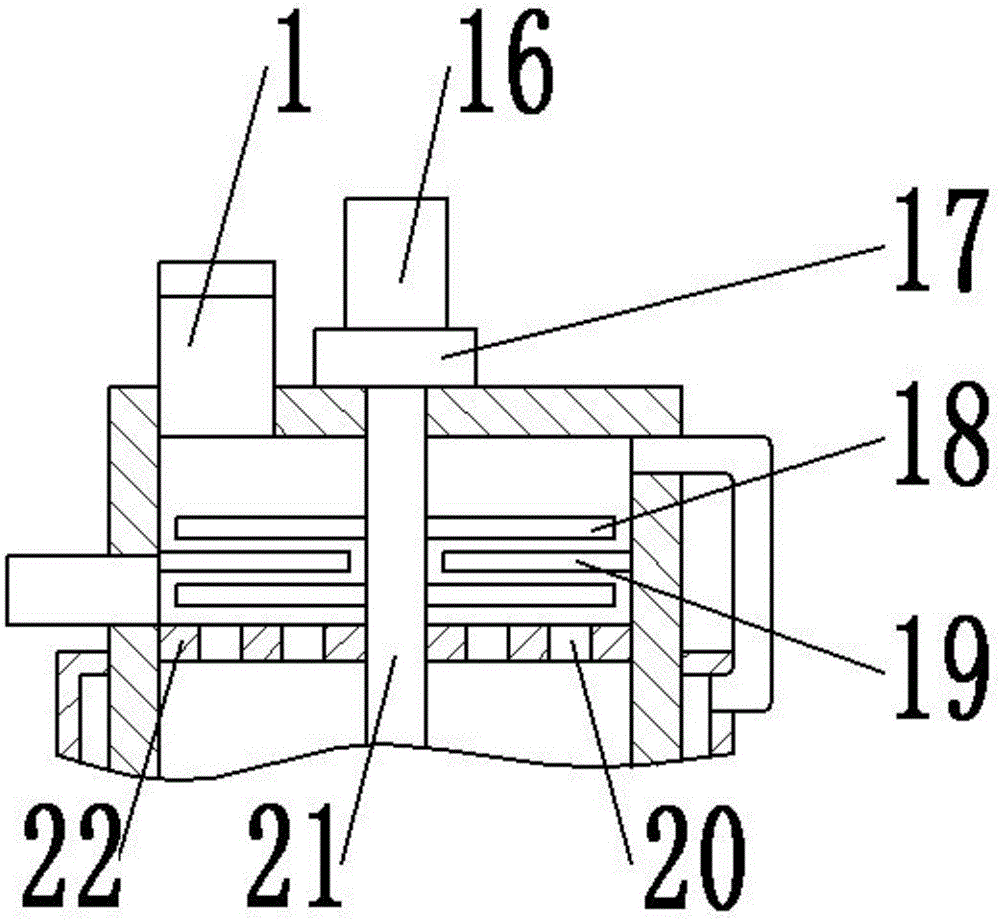

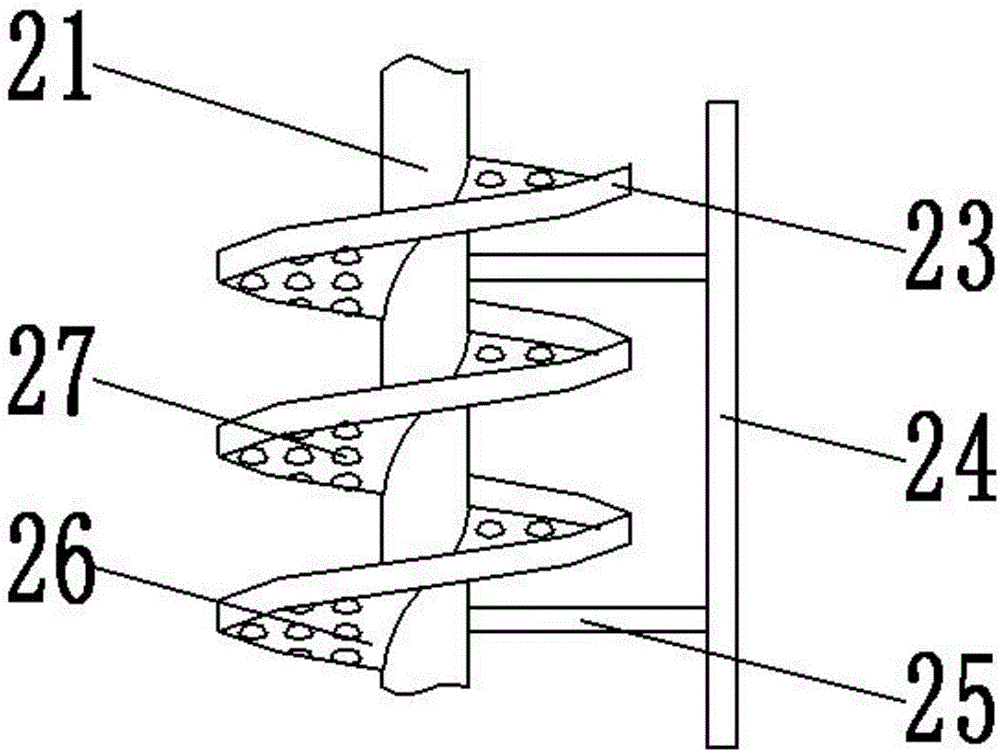

Quick sludge drying equipment with crushing device

ActiveCN106391234AKeep dryIncrease drynessSludge treatment by de-watering/drying/thickeningDrying solid materials without heatSludgeImpurity

The invention provides quick sludge drying equipment with a crushing device. The quick sludge drying equipment comprises a tank; the internal of the tank is divided into a crushing cavity and a drying cavity through a separation plate; the crushing device is arranged in the crushing cavity; an impurity removing pipe is arranged on the side wall of the bottom of the crushing cavity; a spiral stirrer and an air blowing drying device are arranged in the drying cavity; the spiral stirrer consists of a spiral stirring blade, a stop edge and a scraping plate; the air blowing drying device consists of a transmission box, a second motor, an intake pipe, a second rotating shaft and an air spraying plate; an electric heater is embedded in the side wall of the drying cavity; a discharge pipe is arranged on the side wall of the bottom of the tank; a jacket is arranged on the outer surface of the tank; and a dehumidifying device is arranged on the side wall of the bottom of the jacket. The quick sludge drying equipment crushes caked sludge through the crushing device, achieves the purpose of circularly stirring the sludge through the spiral stirrer, facilitates uniform contact between hot air and the sludge through the air blowing drying device, and facilitates uniform drying of the sludge.

Owner:深圳市海创环境治理科技有限公司

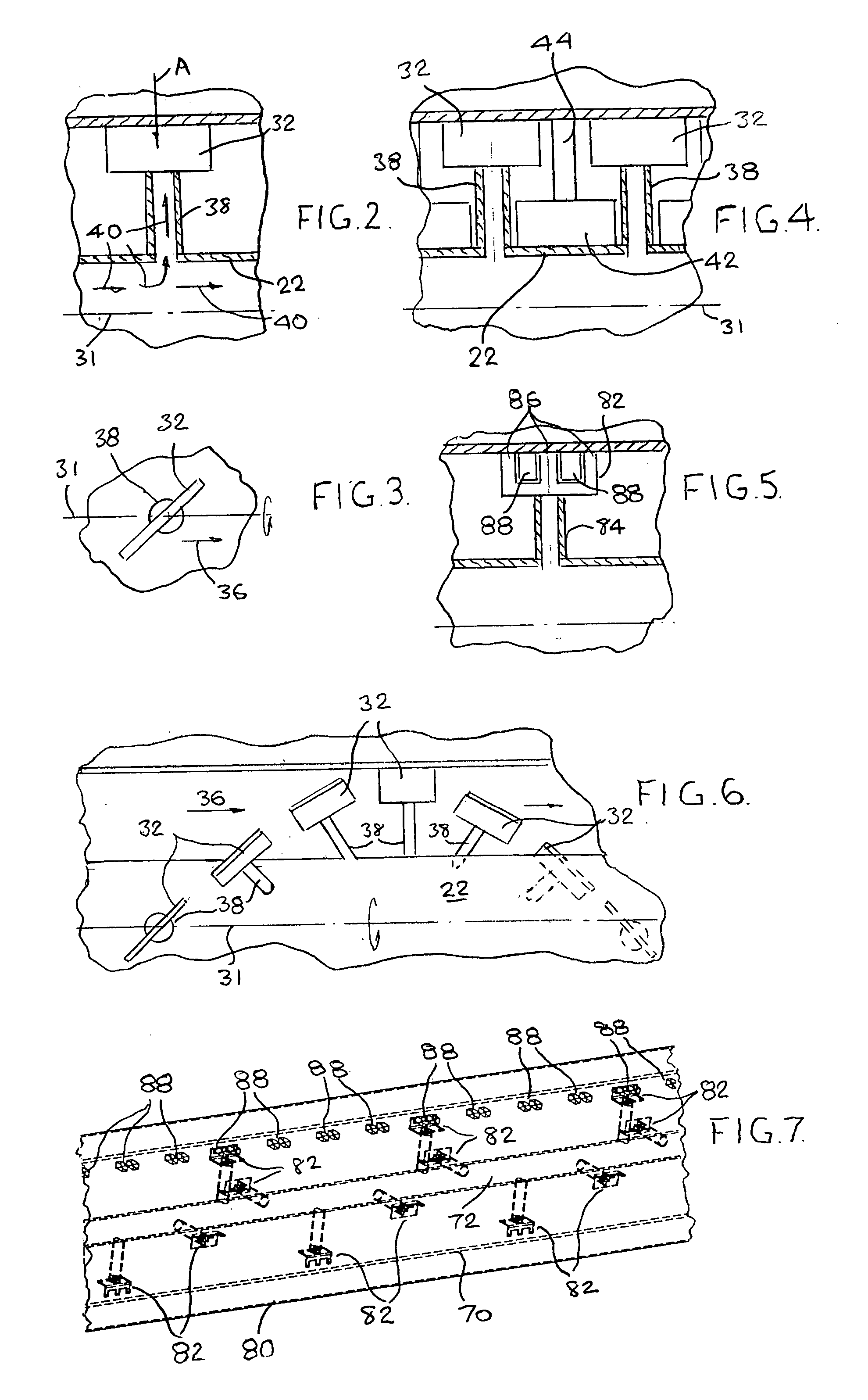

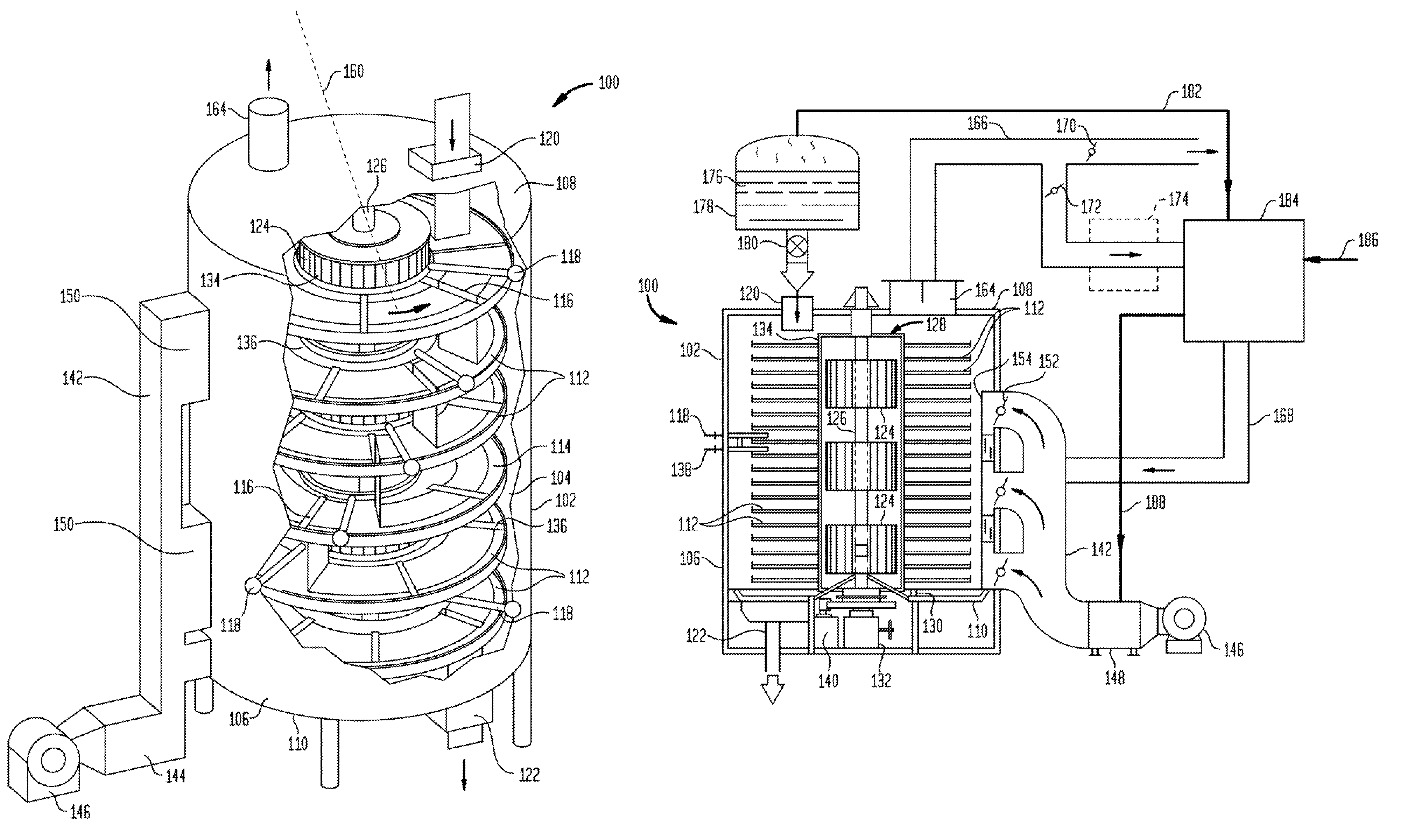

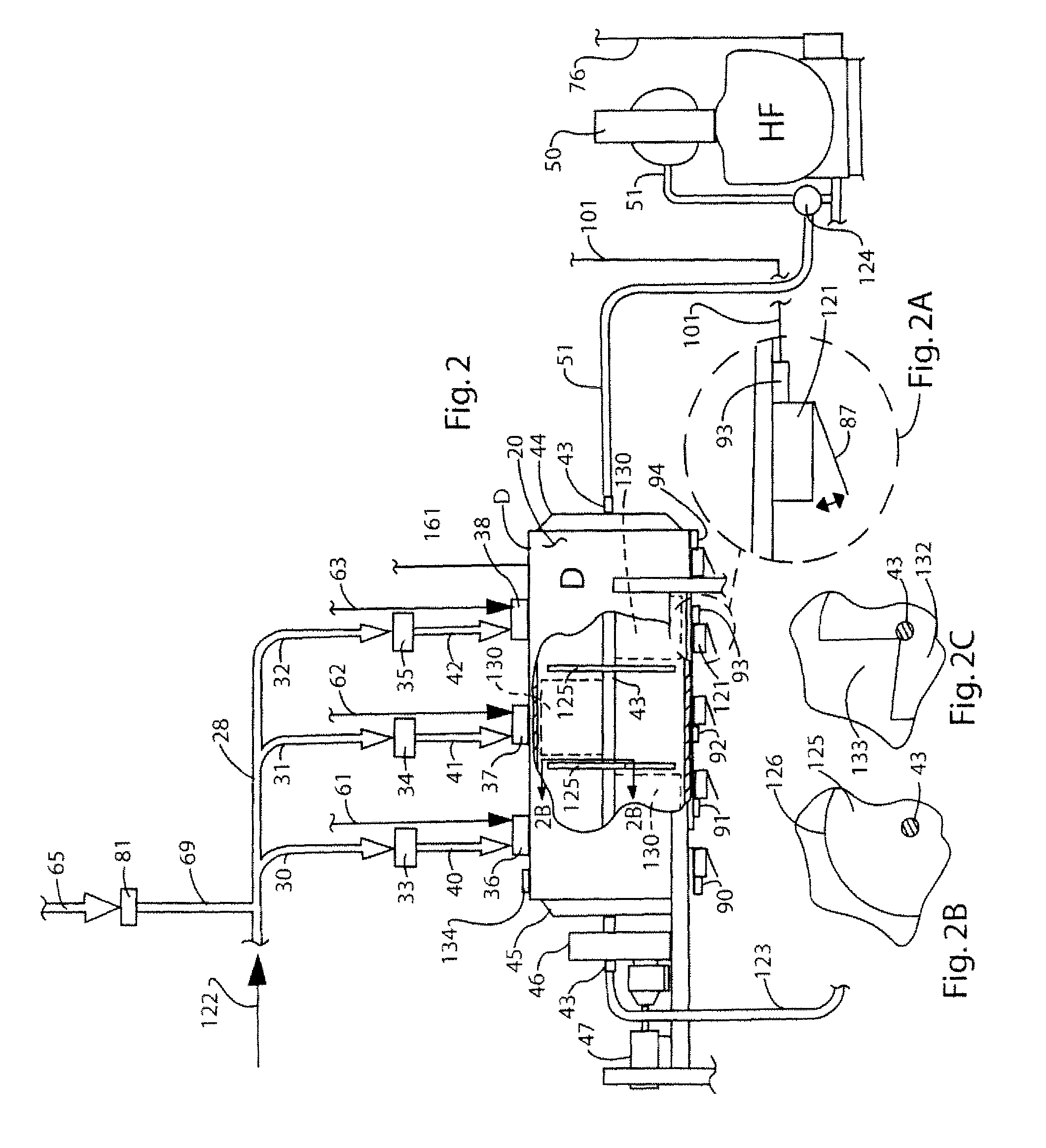

Biomass converters and processes

InactiveUS20080134540A1Reduce decreaseQuick limitBio-organic fraction processingExcrement fertilisersProcess engineeringDefining length

This invention pertains to a bio-mass processing system, and method of processing waste bio-mass, wherein one or more mixers mixes a bed of bio-mass material such as manure at substantially any and all locations in a defined length and width portion of the bed, in a dryer. Heated air percolates upwardly through the bed. Separation apparatus separates a relatively dryer fraction of the bio-mass material from the dryer. The separated finished product from the dryer is optionally fed to a boiler where the dried bio-mass material is burned. Heat of combustion from the boiler is used as dryer heat for drying the bio-mass feed material in the dryer. Excess heat is optionally used to produce steam, which powers a turbine, which powers an electrical generator. Residual ash from the combustion process comprises about 2% by weight of the solids content of e.g. a feed stream coming into the dryer.

Owner:ECOCOMBUSTION ENERGY SYST CORP

Apparatus, method and system for treating sewage sludge

ActiveUS7669348B2Drying using combination processesDrying solid materials with heatAfter treatmentSludge

An apparatus, method and system is provided for treating sewage sludge by heating the same in a container to drive off pathogens and / or pasteurize the sewage sludge while the material is tumbled in the container and with moisture gases being evaporated therefrom and drawn off from the container. After treatment the treated sludge is discharged from the container. There is provided at least one weight-responsive member on which the container is mounted, and a control is provided connected to the one or more weight-responsive member whereby the solids content of the treated material can be determined by measuring the difference in weight of material in the container, before and after moisture is drawn off from the material and prior to its discharge from the drum. The control is preferably effected by means of a computer.

Owner:RDP TECH

Sludge Dewatering and Drying

InactiveUS20100170854A1Reduce disposal costsFacilitates environmental complianceAuxillariesDrying solid materials without heatFiltrationDewatered sludge

Methods, apparatus and systems for dewatering and drying the dewatered sludge. Sludge pumped into the sludge dewatering apparatus is mixed in-line with a pre-measured quantity of polymers to agglomerate solids entrained in the sludge. The agglomerated sludge is routed to a filtration station comprising filtration chambers. The filtration chambers are fitted with industry standard filter bag. The agglomerated sludge is subjected to dewatering in the filter bags and the dewatered sludge is subsequently compacted, dried and discarded.

Owner:SEVERN TRENT DE NORA LLC

Process and system for drying and heat treating materials

ActiveUS20080110043A1Water/sewage treatment by centrifugal separationDrying solid materials with heatProcess engineeringMoisture

Owner:EARTHRENEW INC +1

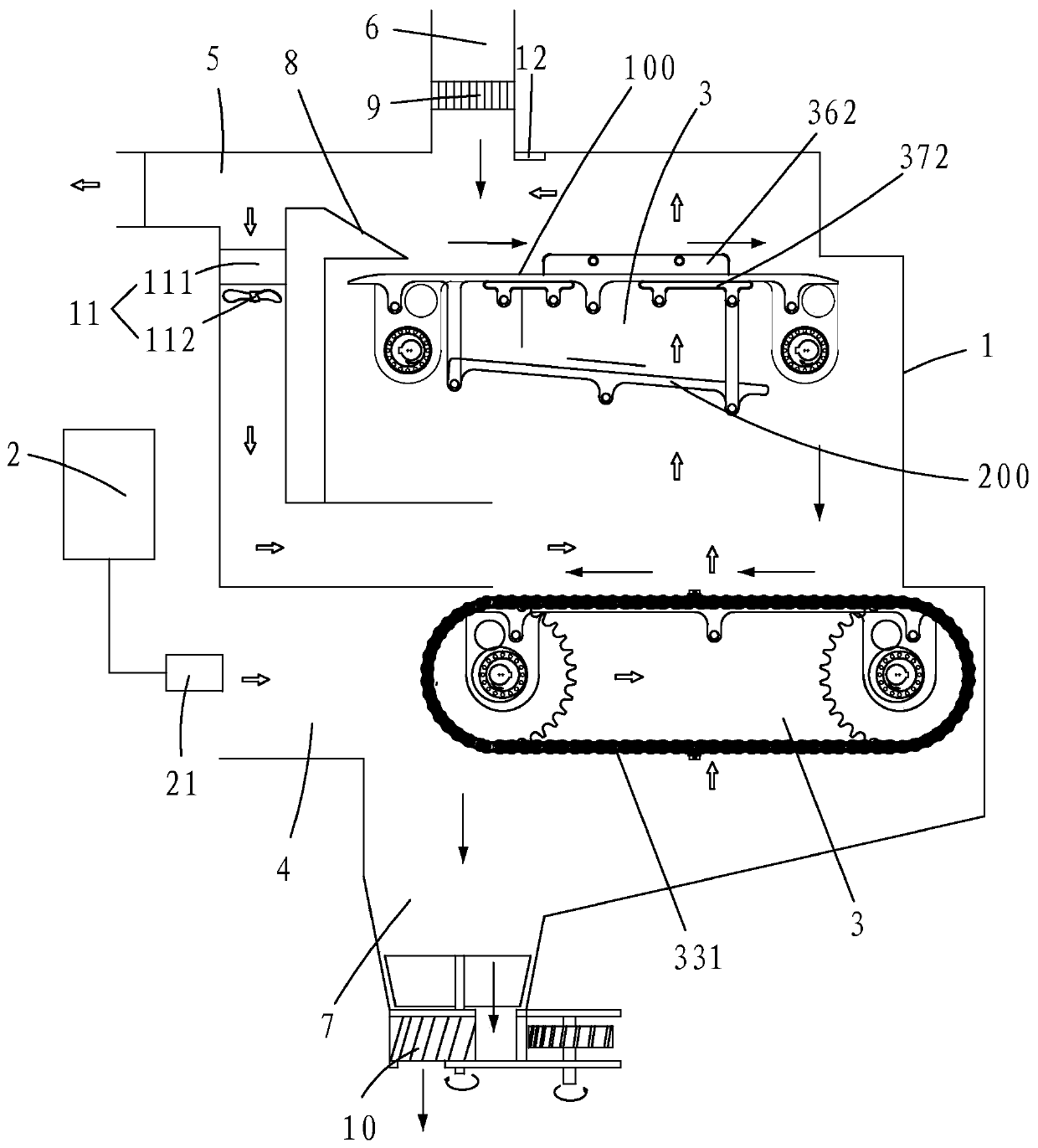

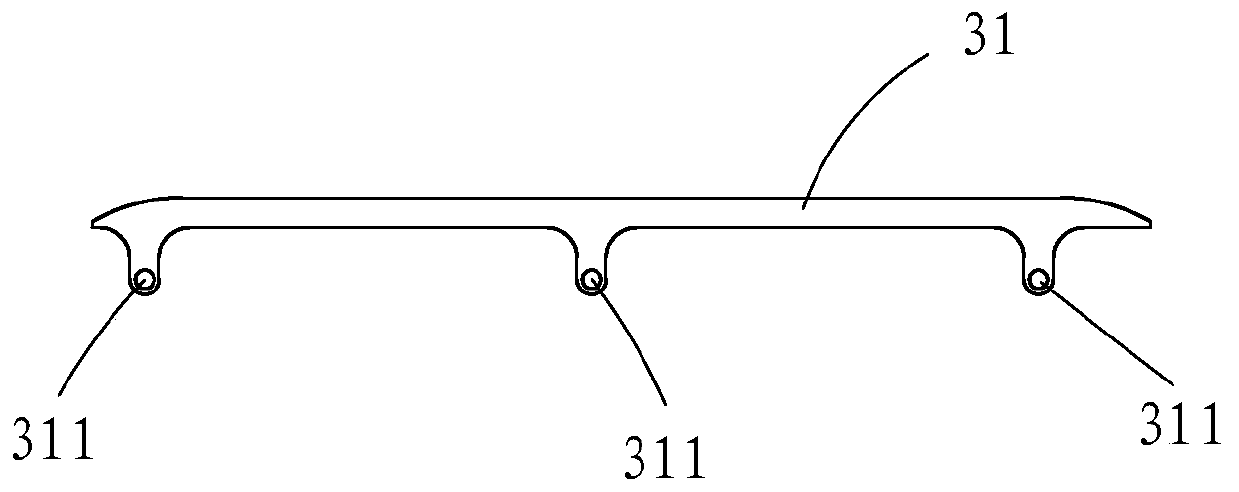

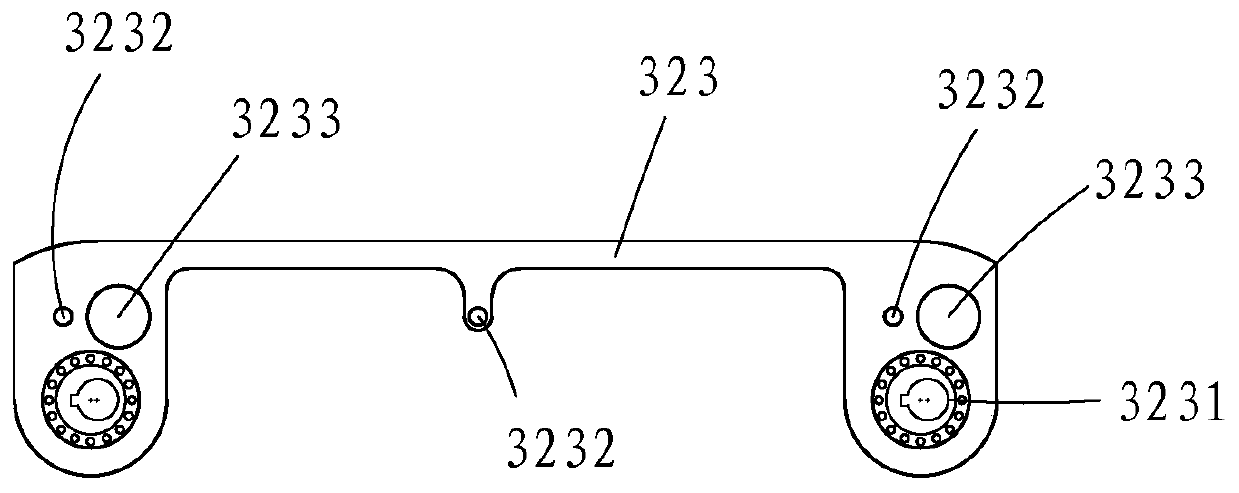

Peristaltic propulsion type drying equipment

PendingCN110487026AEasy to dryEfficient dryingSludge treatment by de-watering/drying/thickeningDrying gas arrangementsProcess engineeringHeat supply

The invention discloses peristaltic propulsion type drying equipment. The peristaltic propulsion type drying equipment comprises a heat supply module, a drying chamber and a material conveying devicearranged in the drying chamber, wherein the drying chamber is provided with a heat source inlet, a heat source outlet, a material inlet and a material outlet; a heat source of the heat supply module is arranged at the position of the heat source inlet and used for providing a heat source for the drying chamber; the material conveying device is used for providing a platform for horizontally pavingmaterials and pushing materials, and comprises two or more groups of grid strips which are laminated at intervals to form a laminated propelling type material conveying platform; a gap is formed between every two adjacent grid strips; and when the materials are conveyed forwards, the ventilation gaps are kept smooth, and the advancing materials are repeatedly overturned. According to the peristaltic propulsion type drying equipment, in the material conveying process, the interactive grid strips generate the transparent gaps, so that the mobility of air is improved, and the materials are advantageously dried.

Owner:AMCON FUJIAN ENVIRONMENT PROTECTION EQUIP CO LTD

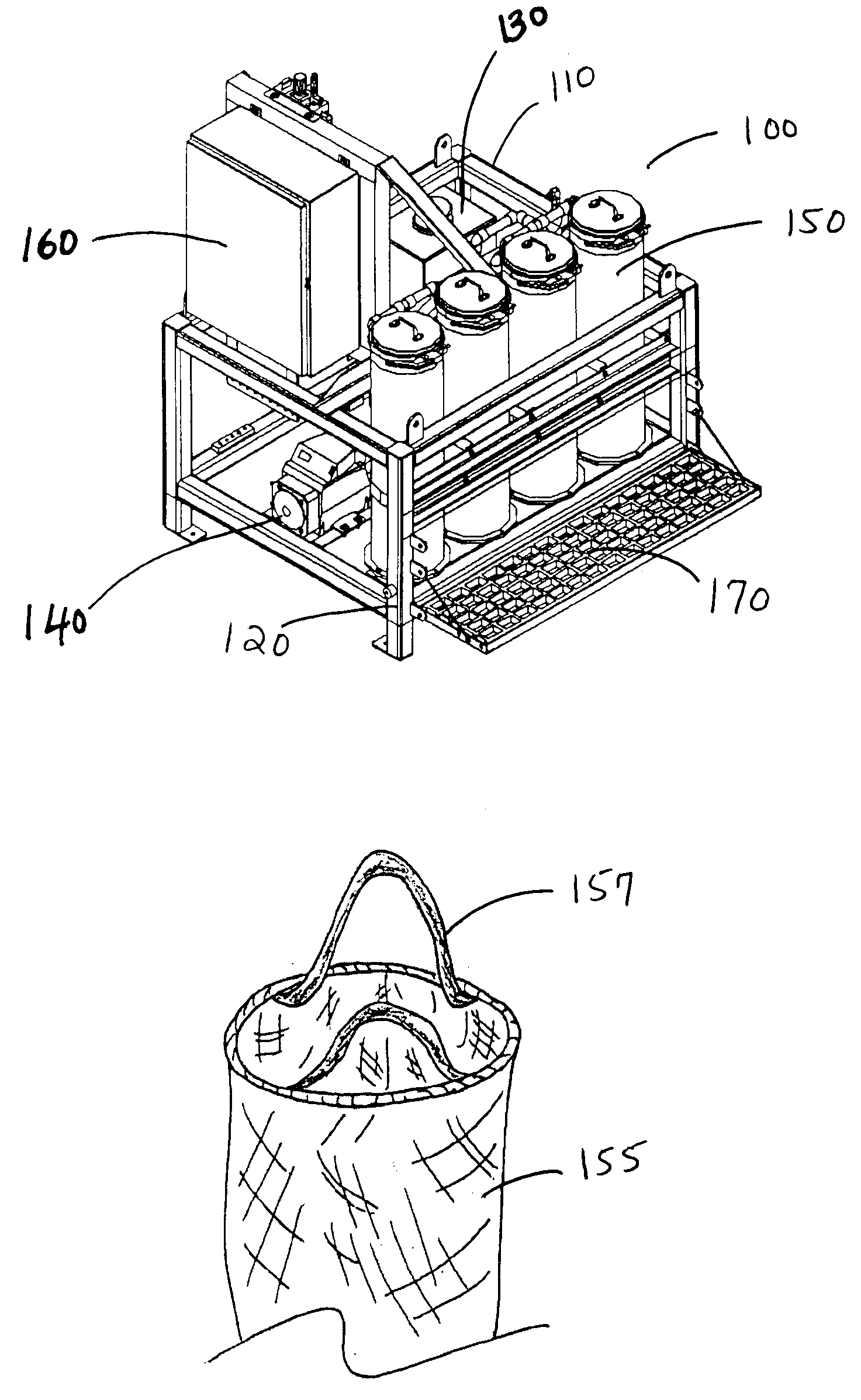

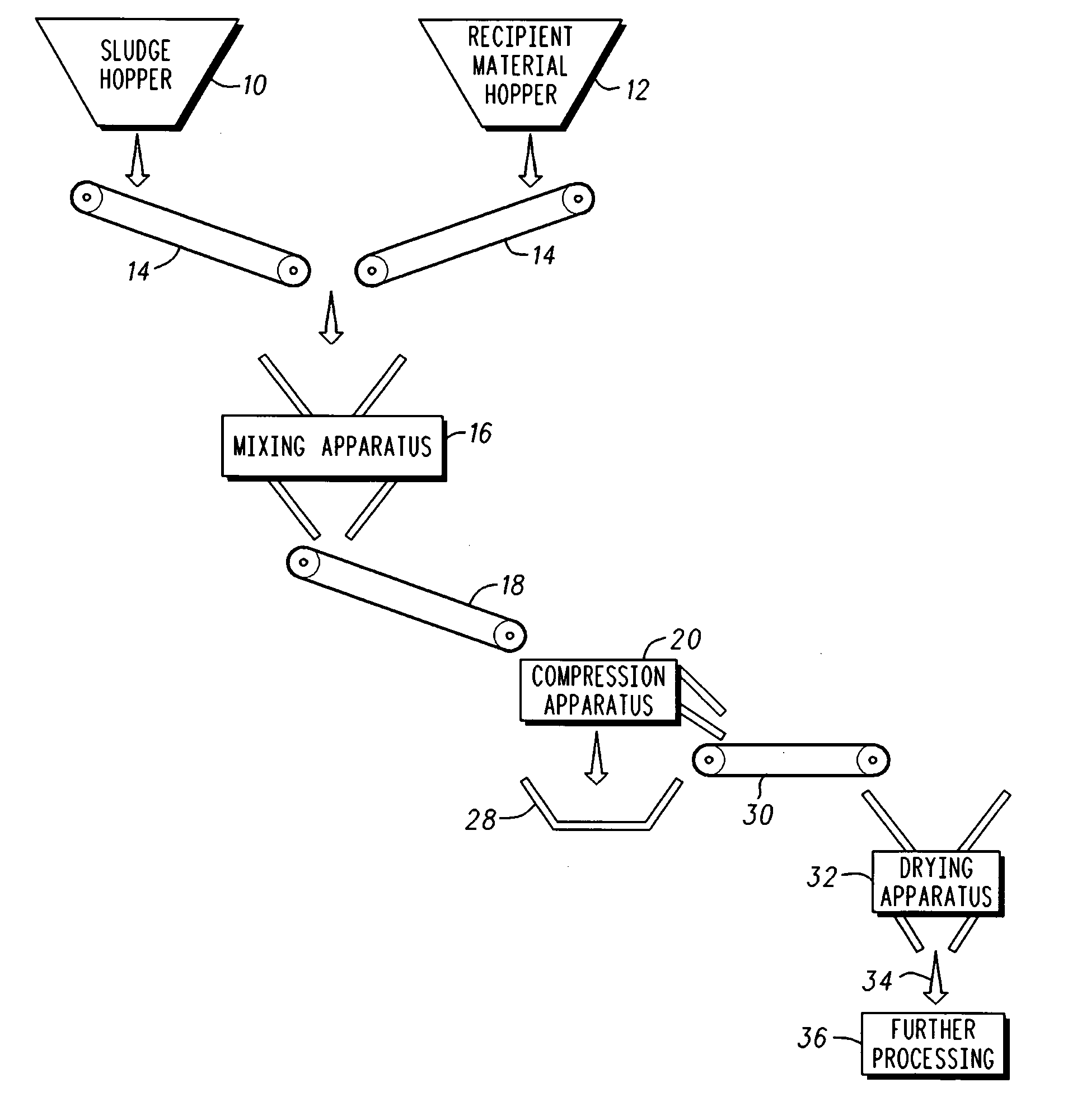

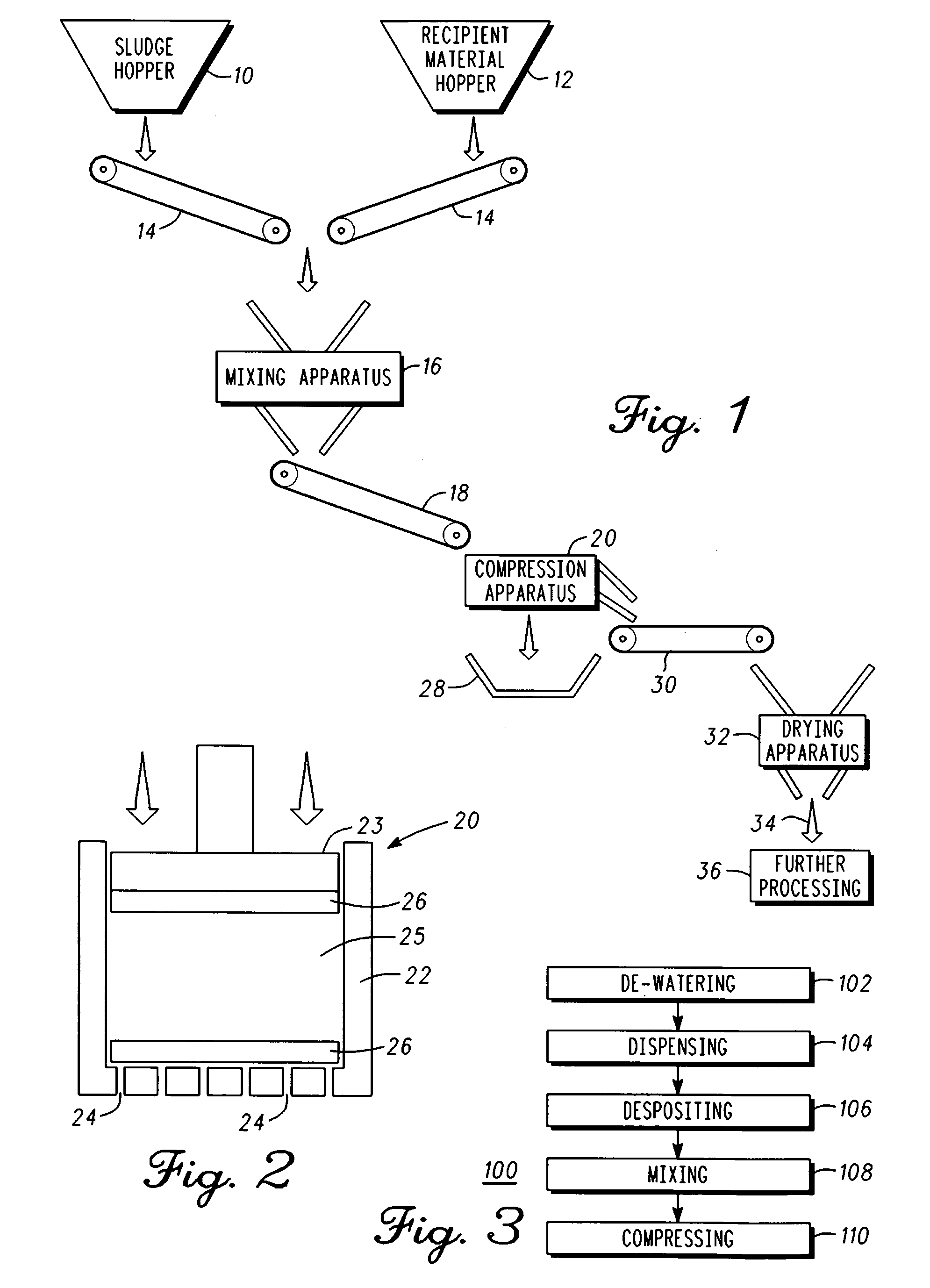

Waste treatment system

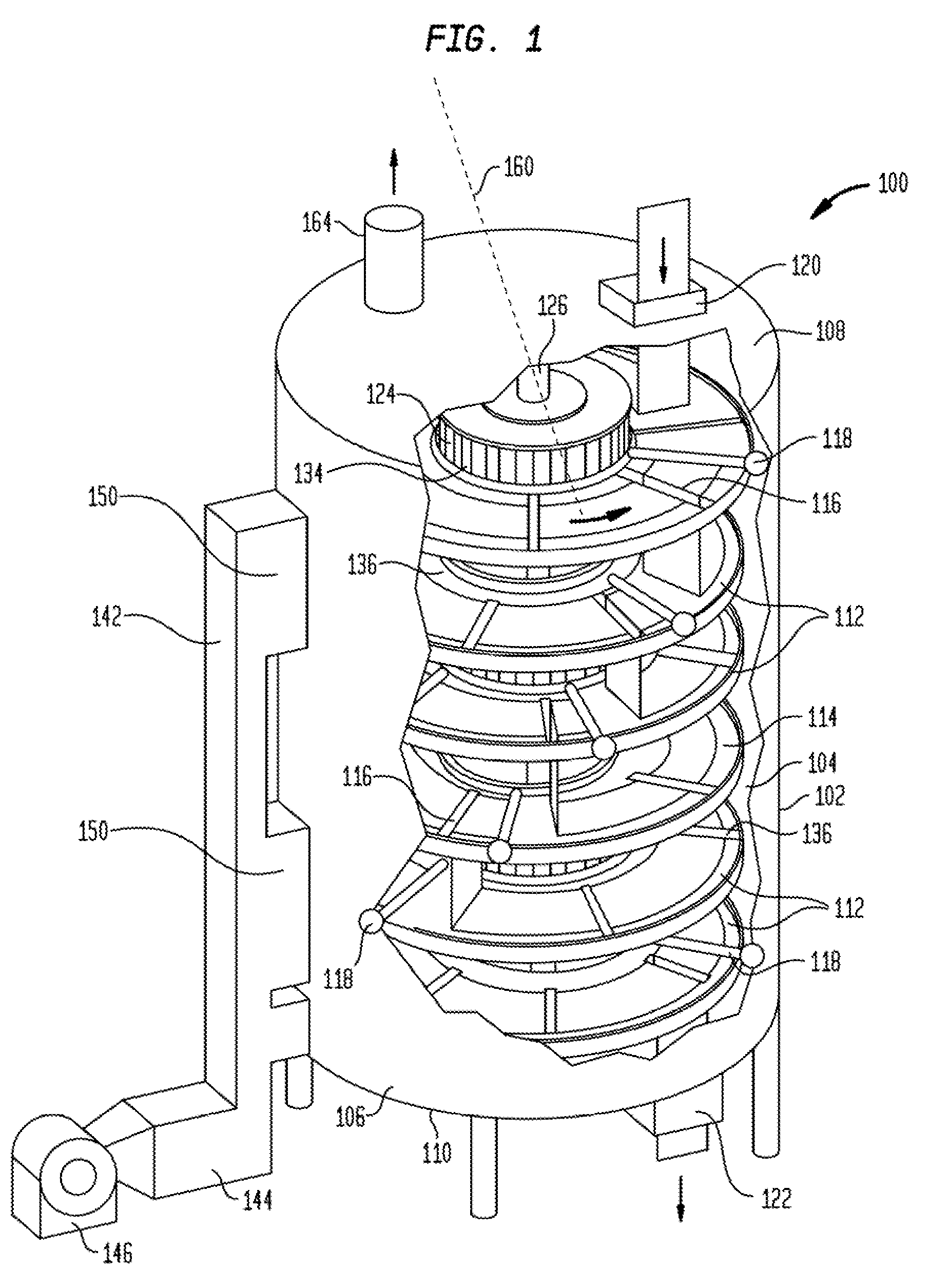

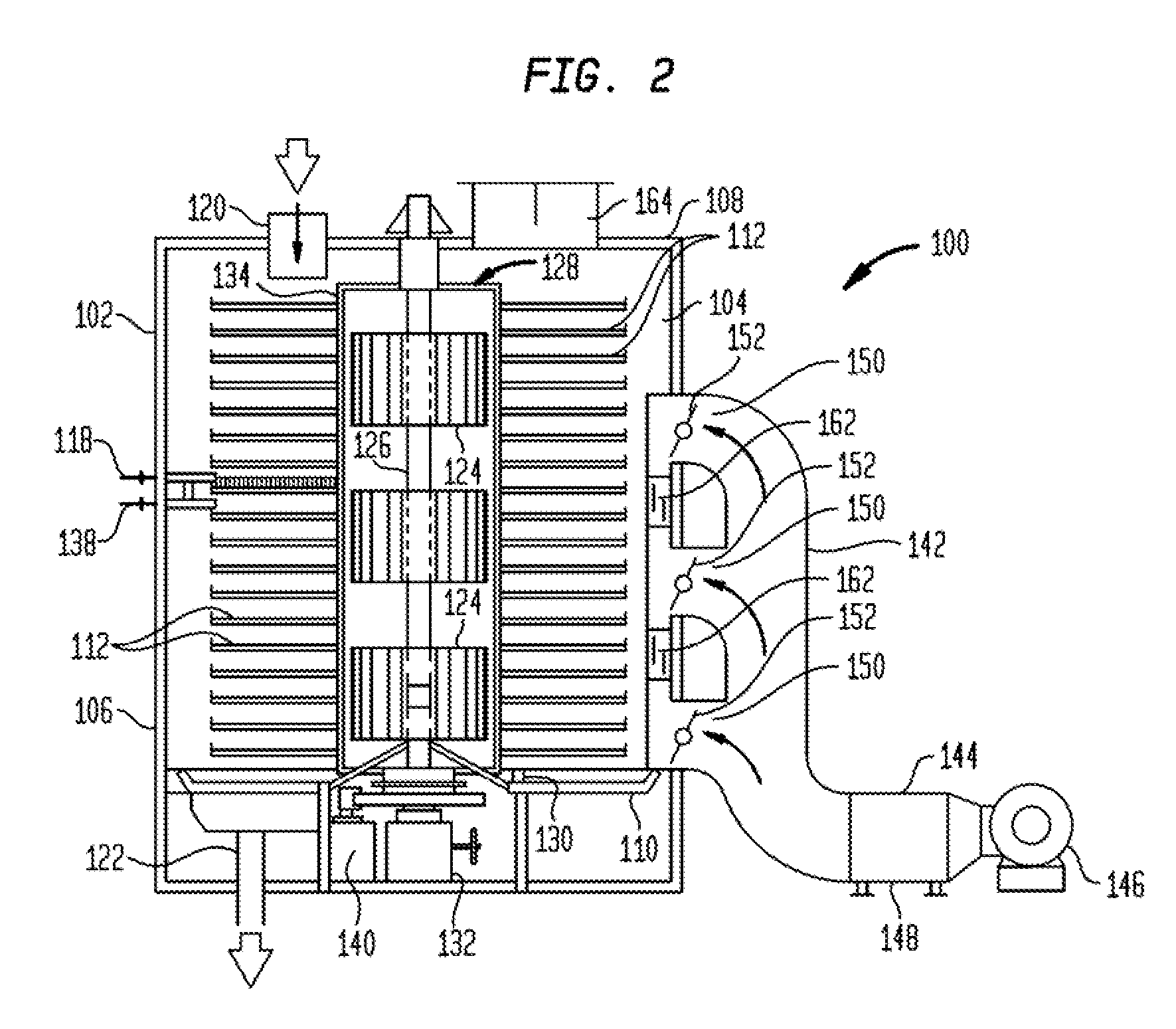

InactiveUS20100096336A1Drying using combination processesDrying solid materials without heatSludge cakeWater treatment system

A system for removing water from sludge is disclosed. The system (100) includes: de-watering (102) sludge comprising an output from a wastewater treatment system to form a semi-solid sludge cake; dispensing (104) the sludge in a sludge hopper and dispensing a blending material in a recipient blending material hopper; depositing (106) the sludge and the blending material in a mixing device; mixing (108) the sludge and the blending material having a porous structure in a weight ratio of the sludge to the blending material of about from 2:1 to about 10:1; and compressing (110) the sludge and the blending material to release moisture. The system (100) provides an improved method of de-watering sludge, for more efficient processing, transporting and recycling, depending on the application.

Owner:HYDROPRESS HLDG

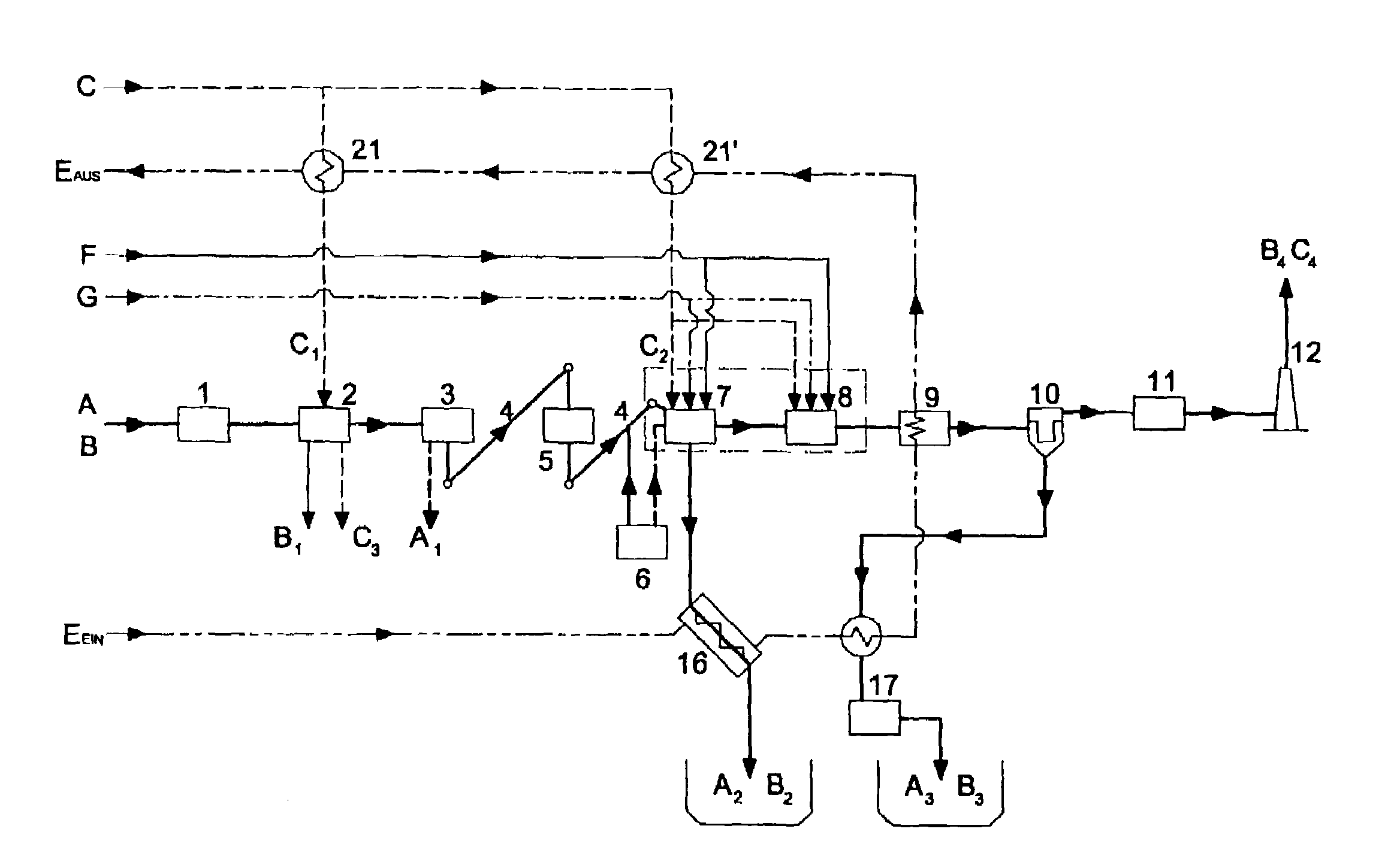

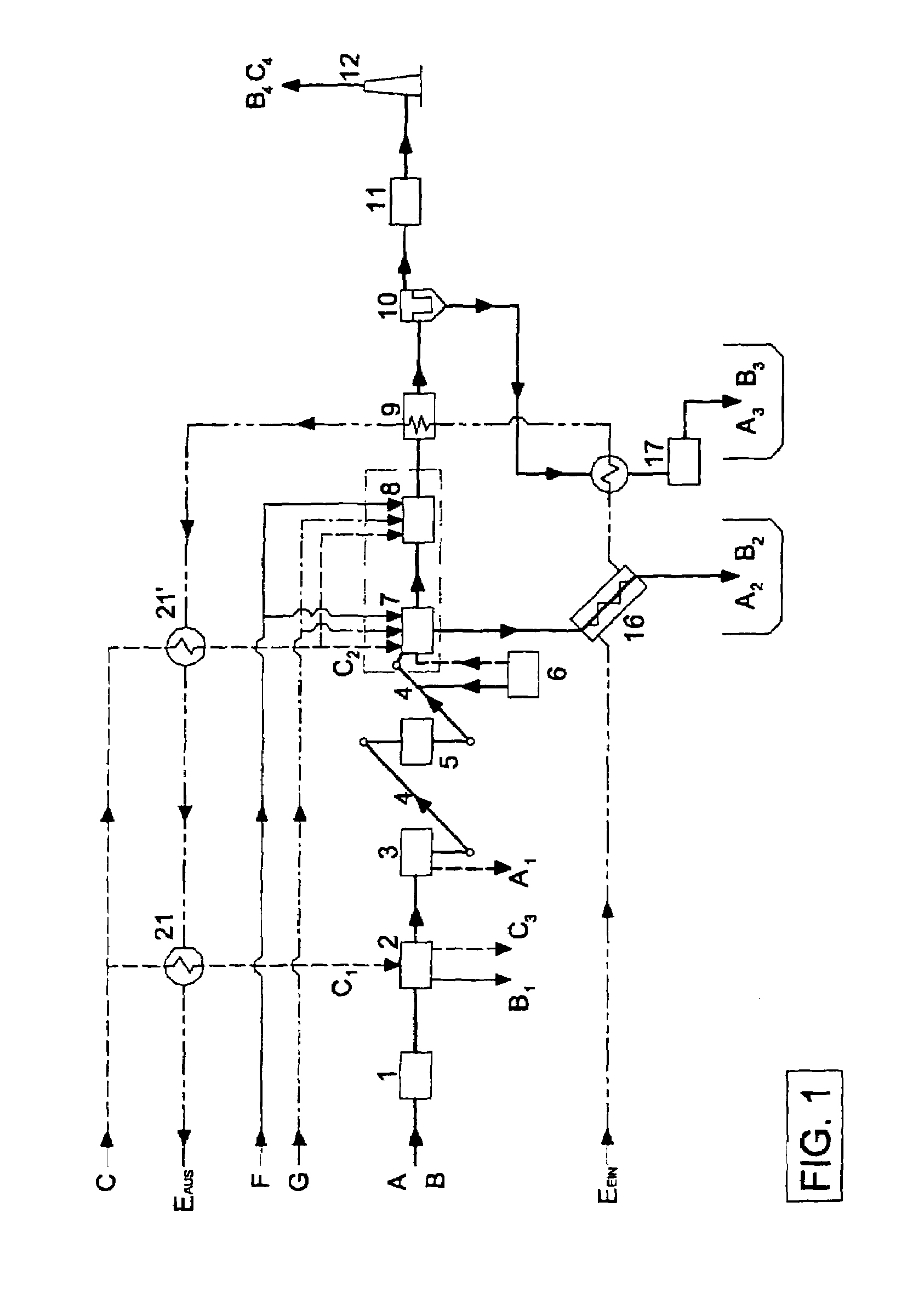

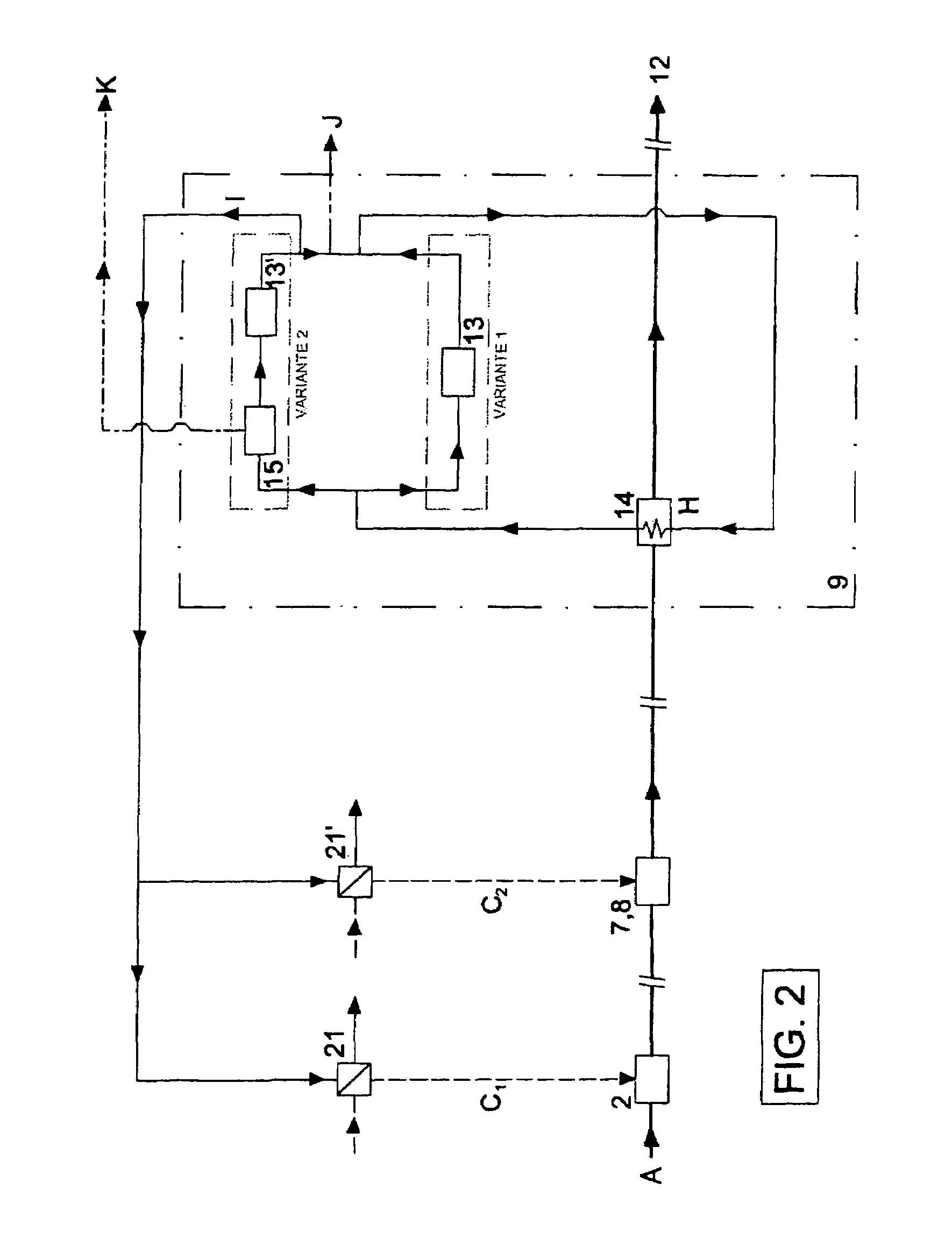

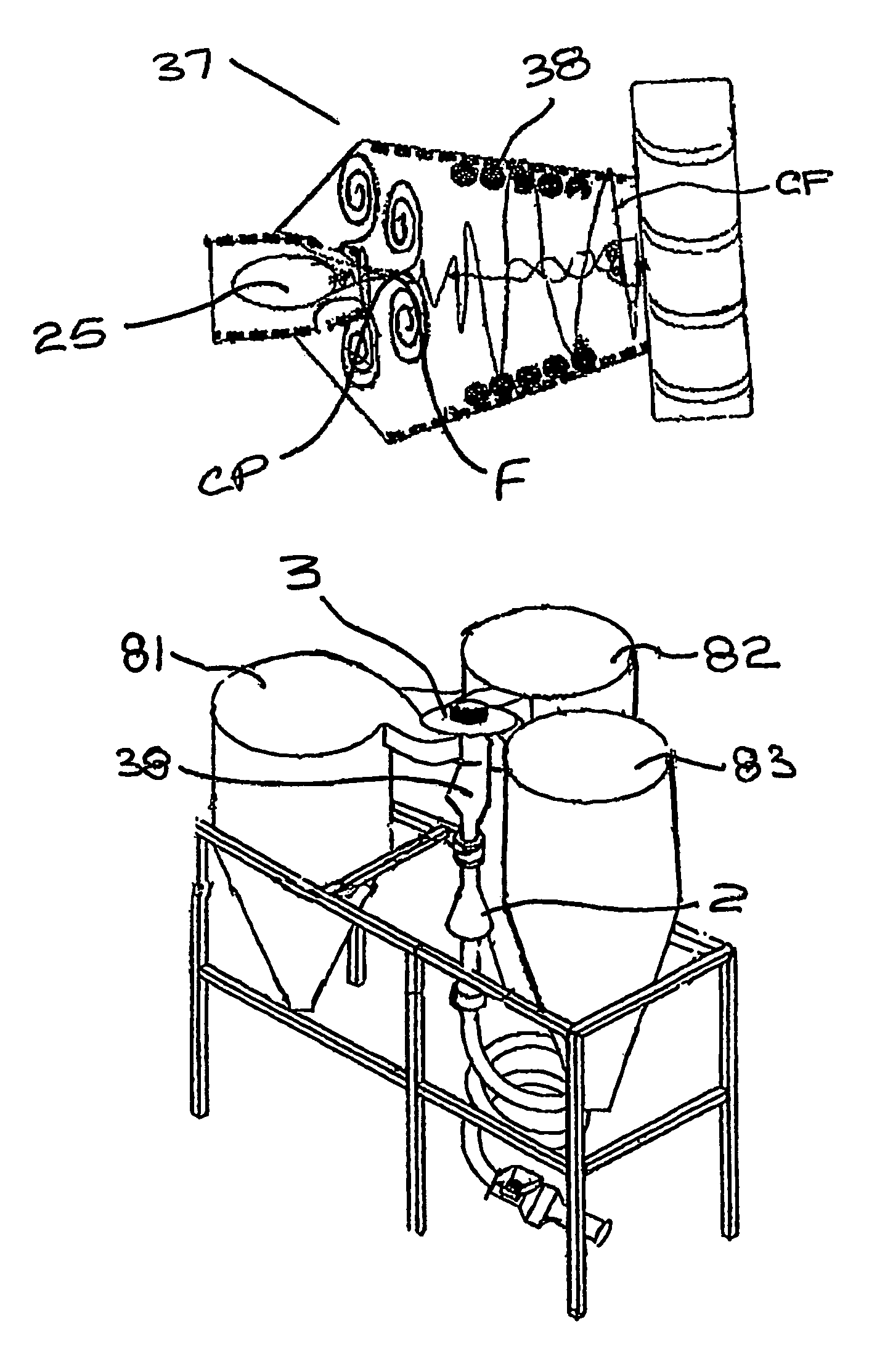

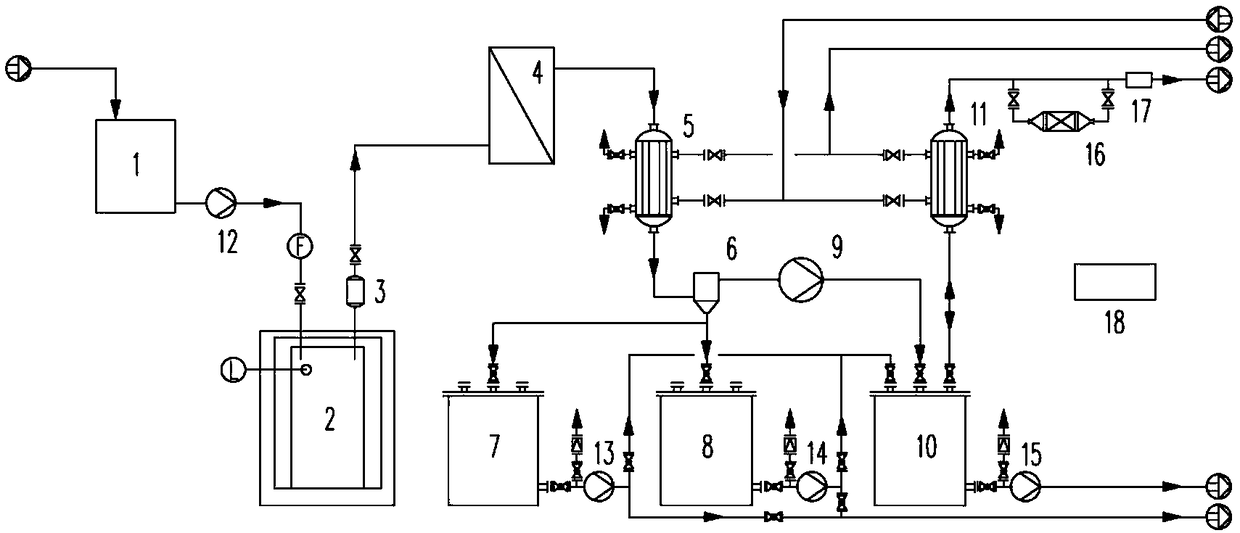

Process and apparatus for treating biogenic residues, particularly sludges

The invention relates to a process and apparatus for treating biogenic residues, particularly sludges, preferably in the area of a clarification plant. Biogenic residues with a variable dry substance are subjected to aerobic drying until an energy-independent thermal treatment can be carried out. During the drying process, evaporated water is discharged in an odor-free condition without releasing freely volatile components, the dried sludge is intermediately stored a number of times and then utilized in preferably a number of successive thermal treatment steps. The two-stage cleaning of the stream of waste gas includes a dust collection unit and an adsorption unit. The waste heat is recycled through a heat exchanger to generate heat and electricity. The apparatus for carrying out the process includes a wet sludge storage container (1), a low temperature drying system (2), storage containers (3, 5) for intermediate storage of the dried biogenic residues, and a thermal treatment system with one or more thermal treatment steps (7, 8). Cleaning of the flue gas takes place preferably by means of a primary cleaning step (10) and a secondary cleaning step (11) for adsorption, for example, with clarified water. Energy recovery (9) from the hot waste gas is ideally carried out before the flue gas cleaning.

Owner:KALOGEO ANLAGENBAU

Apparatus and method for the treatment of biosolids

ActiveUS8464437B1Reduce moistureReduce the amount requiredDrying using combination processesDrying solid materials with heatSufficient timeSewage

Biosolids in the nature of sewage sludge is processed in a controlled environment to produce a dried sludge product of relatively high dry solid content with the elimination of or reduced levels of pathogens. The water containing sewage sludge is dried while cascading within a processing chamber using heated air at a temperature below the ignition or smoldering temperature of the sewage sludge to prevent the formation of embers. The sewage sludge before discharge is retained within the processing chamber for a sufficient time and temperature as mandated by the Environment Protection Agency rules and guidelines.

Owner:KOMLINE SANDERSON CORP

Methods of enhancing fine particle dewatering

InactiveUS20050139551A1Increase tonnageGood removal effectWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningFine particulateSlurry

A new method of improving the process of dewatering fine particulate materials is disclosed. In this method, an aqueous slurry of fine particles is treated with appropriate hydrophobizing reagents so that the particulate material becomes moderately hydrophobic with its water contact angle considerably below 90°. A low hydrophile-lipophile balance (HLB) number surfactant is then added to the slurry, so that the surfactant molecules adsorb on the moderately hydrophobic surface primarily by hydrophobic attraction and, thereby, increase its contact angle close to or above 90°. By virtue of the greatly enhanced hydrophobicity, the water molecules adhering to the surface are destabilized and removed more readily by a mechanical dewatering process. Any nonionic surfactant with its HLB number below about 15 may be used for the hydrophobicity enhancement. The surfactants may be used in conjunction with appropriate solvents such as light hydrocarbon oils and short-chain alcohols. The moisture reduction can be further improved by using appropriate electrolytes in conjunction with the low HLB surfactants, spraying surface tension lowering reagents onto the filter cake, subjecting the cake to a suitable vibratory means, and by using combinations thereof.

Owner:YOON ROE HOAN

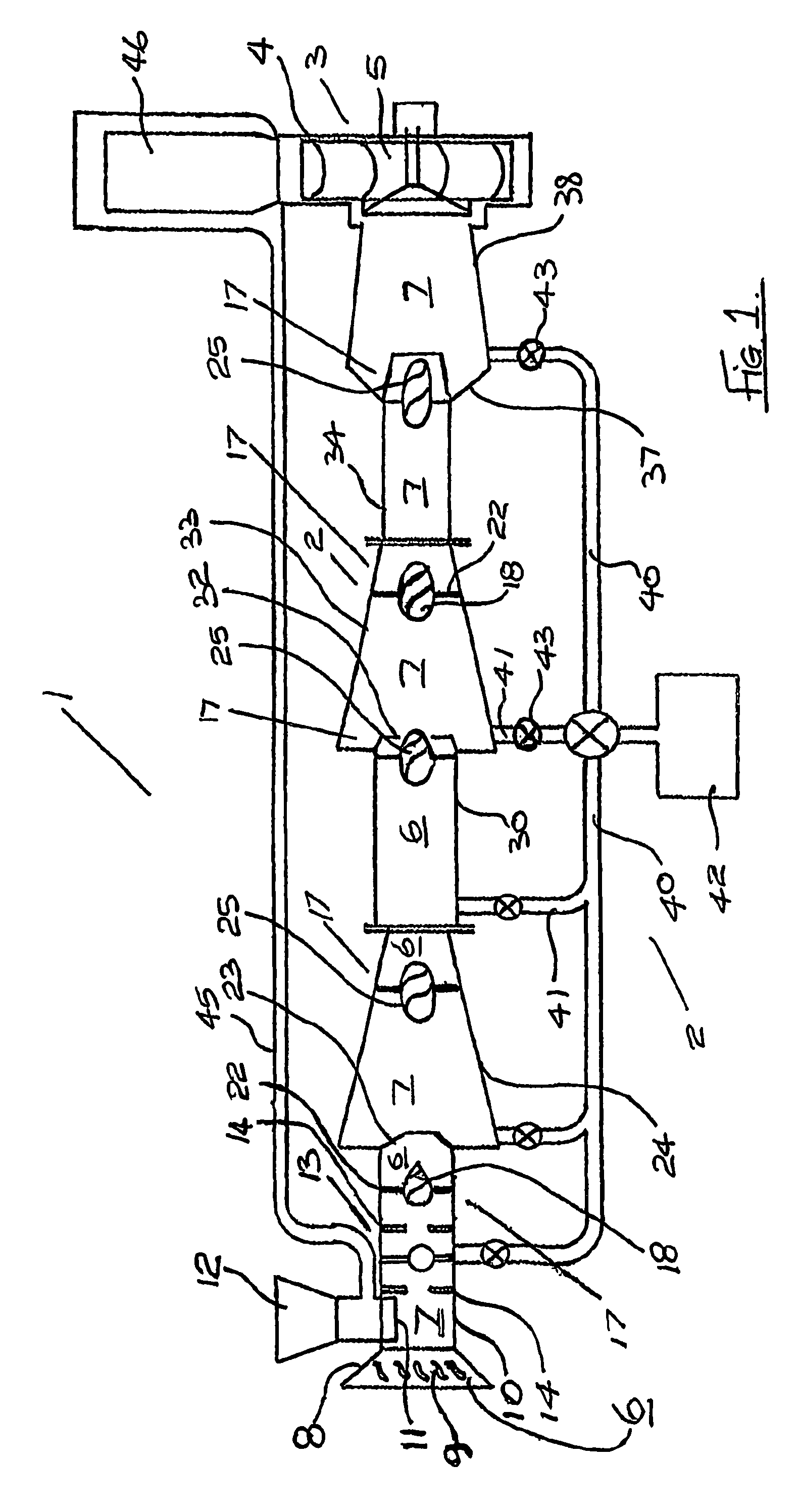

Material dewatering apparatus

InactiveUS7380348B2Efficient implementationCombination devicesDrying using combination processesWaste managementSump

The invention provides a pneumatic dewatering apparatus (1) for wet product. The apparatus (1) comprises essentially a cyclone chamber (2) connected to a centrifugal fan (3). Various vortex flow forming stations (6), each followed by a vortex shedding station (7), are mounted within the cyclone chamber (2). Tight centripetal vortices are formed and are then shed such that water is delivered out the cyclone chamber (2) into a sump (42).

Owner:SOLID SOLUTIONS

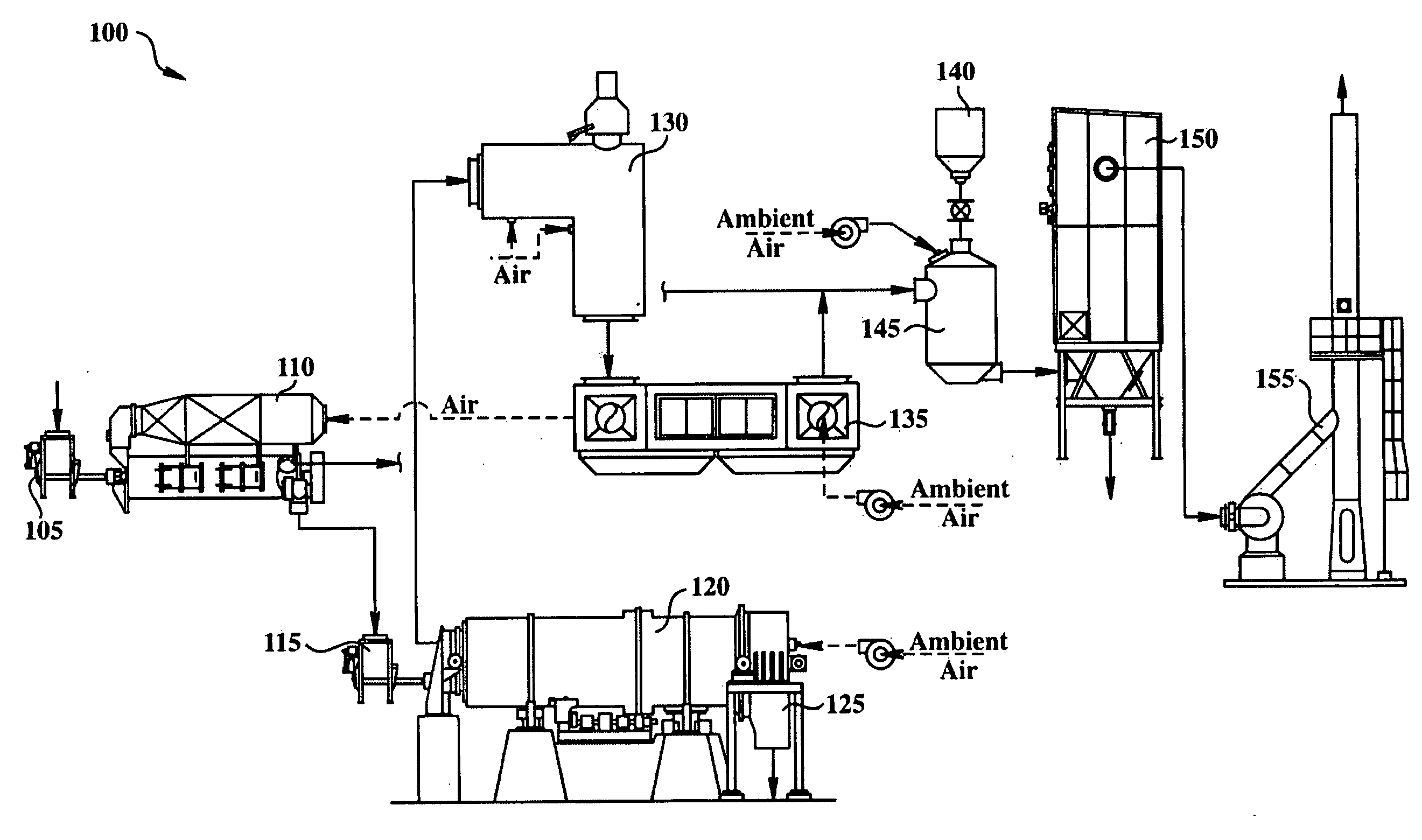

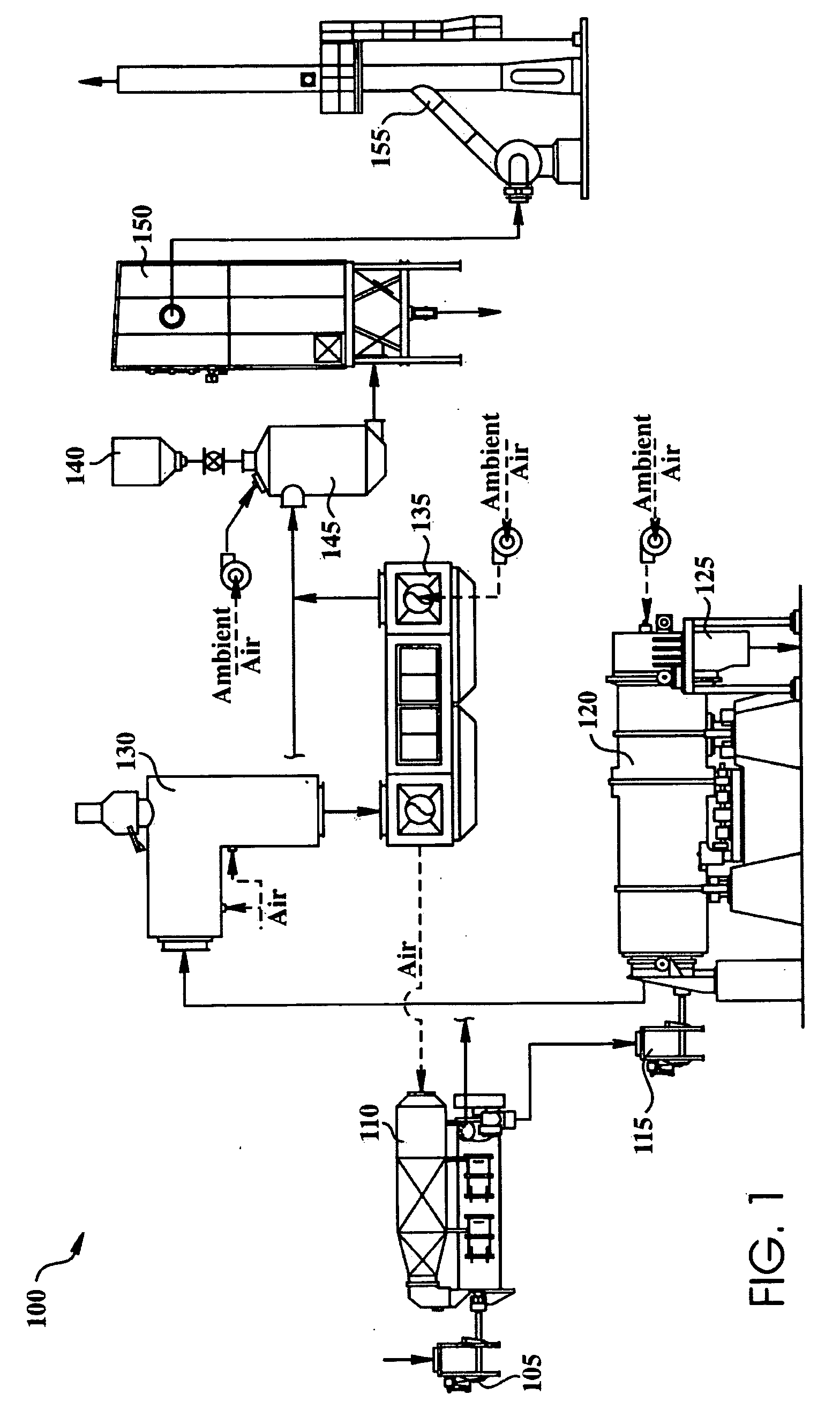

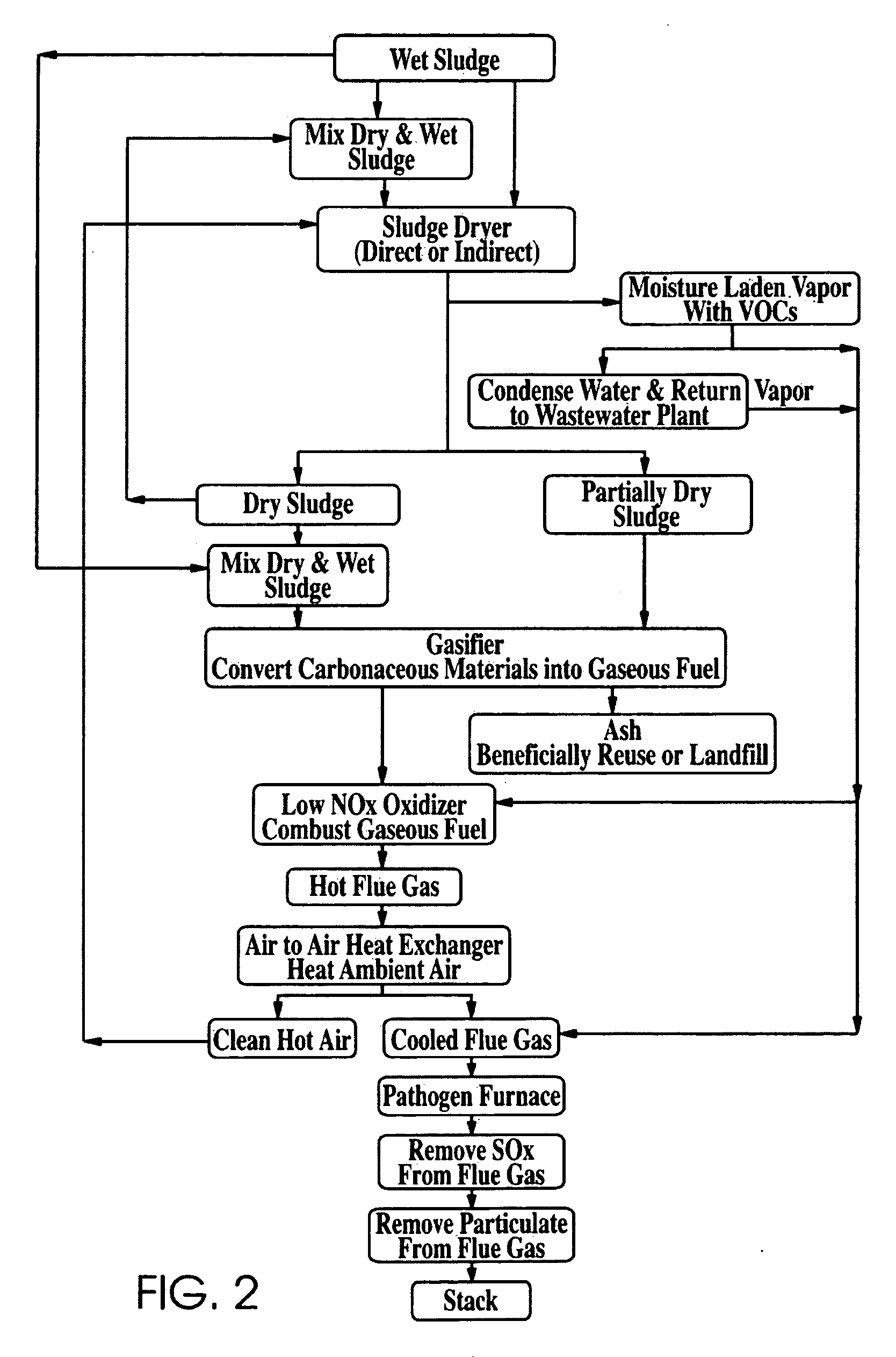

Systems and Methods for Processing Municipal Wastewater Treatment Sewage Sludge

InactiveUS20090249641A1Low cost of treatmentSimple methodDrying using combination processesDrying machine combinationsWastewaterMunicipal sewage

The present invention relates generally to systems and methods for drying and gasifying substances using the calorific value contained in the substances, and it more specifically relates to apparatus and methods for processing wet, pasty, sticky substances, such as municipal wastewater treatment sewage sludge, into a workable, powdered product.

Owner:JOHNSON BRUCE +1

Apparatus, method and system for treating sewage sludge

ActiveUS8065815B2Drying using combination processesDrying solid materials with heatAfter treatmentSludge

An apparatus, method and system is provided for treating sewage sludge by heating the same in a container to drive off pathogens and / or pasteurize the sewage sludge while the material is tumbled in the container, and with moisture gases being evaporated therefrom and drawn off from the container. After treatment the treated sludge is discharged from the container. There is provided at least one weight-responsive member on which the container is mounted, and a control is provided connected to the one or more weight-responsive member whereby the solids content of the treated material can be determined by measuring the difference in weight of material in the container, before and after moisture is drawn off from the material and prior to its discharge from the drum. The control is preferably effected by means of a computer.

Owner:RDP TECH

In-barrel vacuum microwave drying system and method for radioactive wet wastes

InactiveCN108630335ADry fastMeet staging criteriaDrying solid materials without heatSludge dryingMicrowaveAtmospheric air

The invention belongs to the technical field of radioactive waste treatment and relates to an in-barrel vacuum microwave drying system and method for radioactive wet wastes. The drying system comprises a drying barrel, a demister, a filter, a condenser, a steam-water separator, a vacuum pump, a tail gas continuous monitoring device and connecting pipelines; the drying barrel is used for drying thewastes by microwave heating; the demister, the filter, the condenser, the steam-water separator and the vacuum pump which are connected in sequence are respectively used for realizing demisting, filtration, condensation, steam-water separation and vacuumizing treatment of evaporated tail gases generated by drying; and the tail gas continuous monitoring device is connected with the condenser and is used for monitoring noncondensable gases in the evaporated tail gases and discharging qualified noncondensable gases into the air by the connecting pipeline connected with an outlet of the tail gascontinuous monitoring device. By using the drying system and method disclosed by the invention, the rapid drying of various radioactive wastes can be realized, new substances are not introduced in a drying process, and the tail gases discharged after being dried almost have no any harmful effects on the environment.

Owner:CHINA NUCLEAR POWER ENG CO LTD

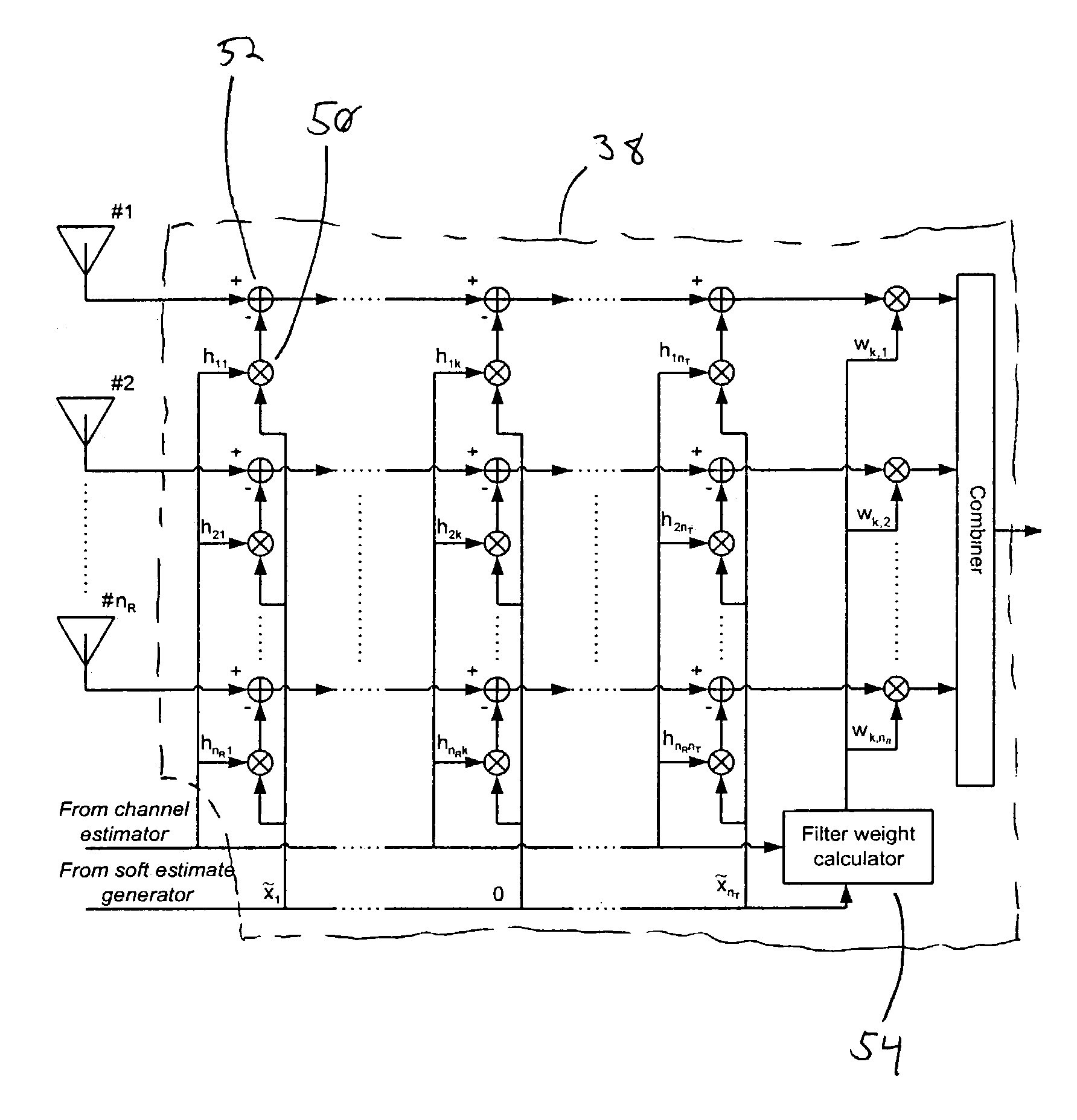

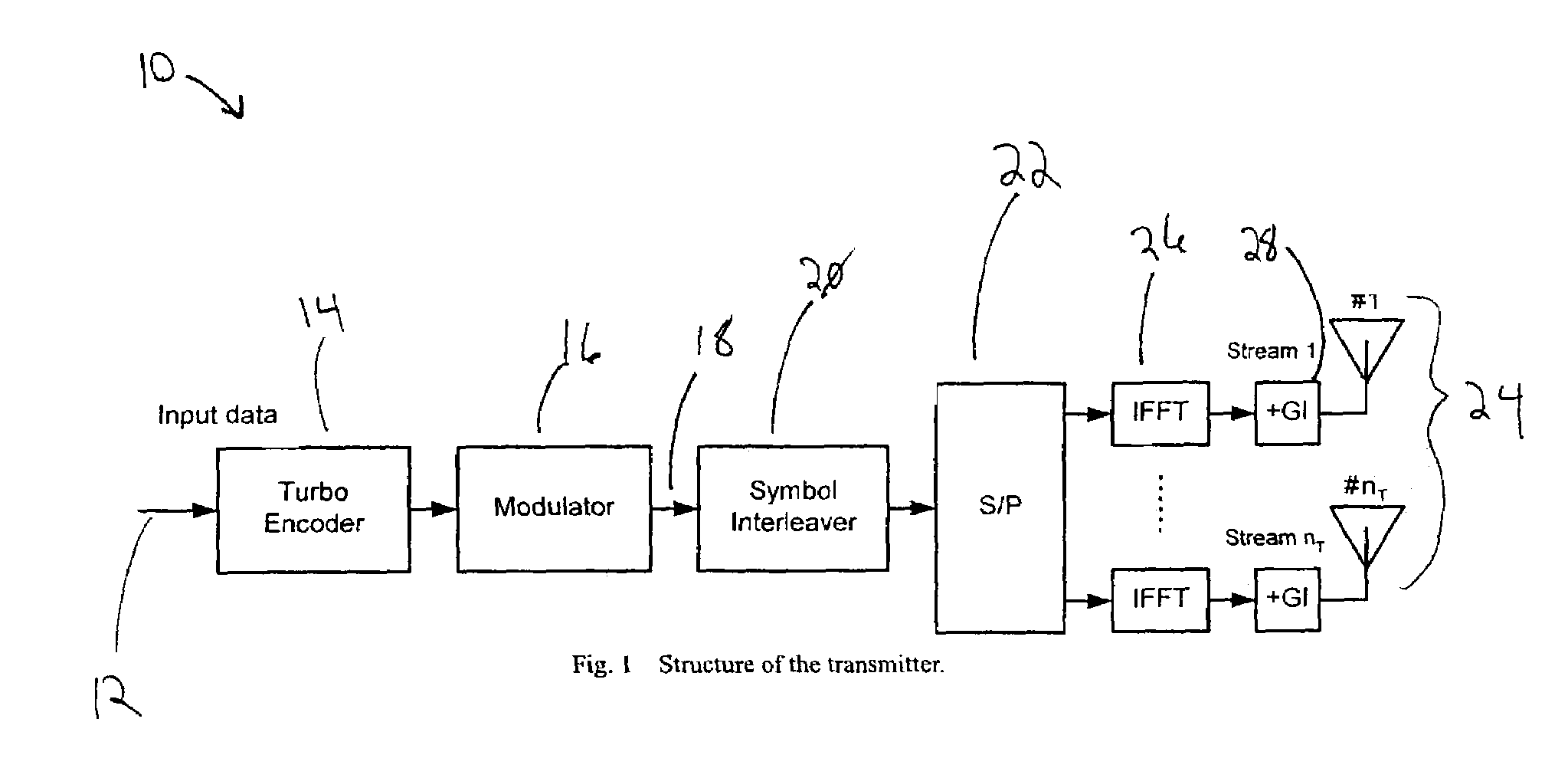

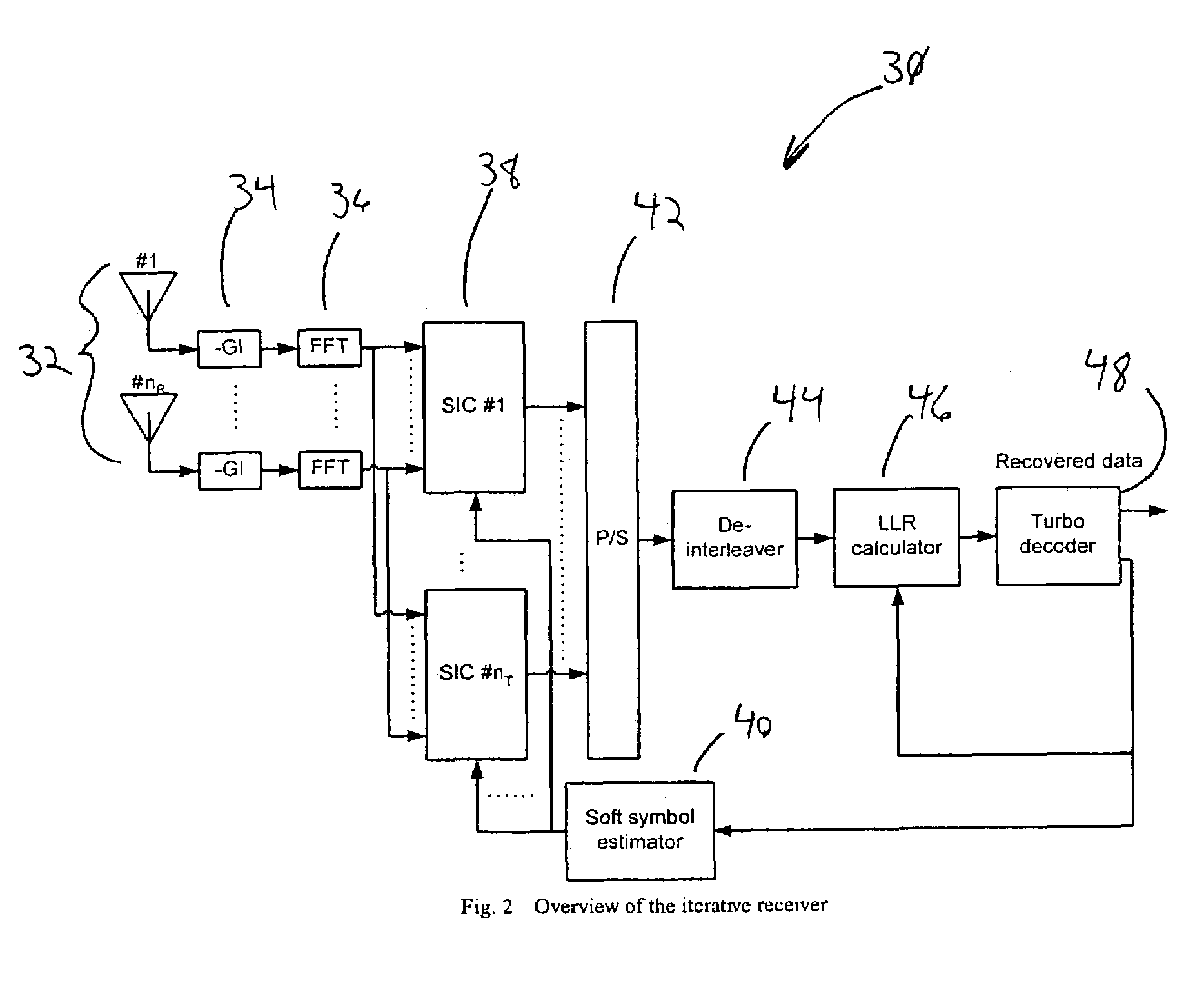

Iterative soft interference cancellation and filtering for spectrally efficient high-speed transmission in MIMO systems

ActiveUS7386057B2Guaranteed normal transmissionSpatial transmit diversityPolarisation/directional diversityMulti inputFrequency spectrum

Canceling interference in a multi-input multi-output (MIMO) system is accomplished with a plurality of interference cancellers. Each interference canceller outputs an interference-cancelled received version of its corresponding transmitted signal. An estimate of the transmitted signals from all transmitting antennae is used in each interference canceller. Each estimate is multiplied by a channel coefficient matrix, which can be derived from the communication of known pilot symbols, and the resulting products of each estimate and the channel coefficient matrix are subtracted from the received signals, resulting in a corresponding difference. Each corresponding difference may be multiplied by a filter weight vector. The received signal is decoded based upon the resulting products If a predetermined interrupt criteria is not met, then the decoded signal is used in the preparation of the estimate for a subsequent interference cancellation iteration. The method can be iteratively performed until the predetermined interrupt criteria is met.

Owner:NEC CORP

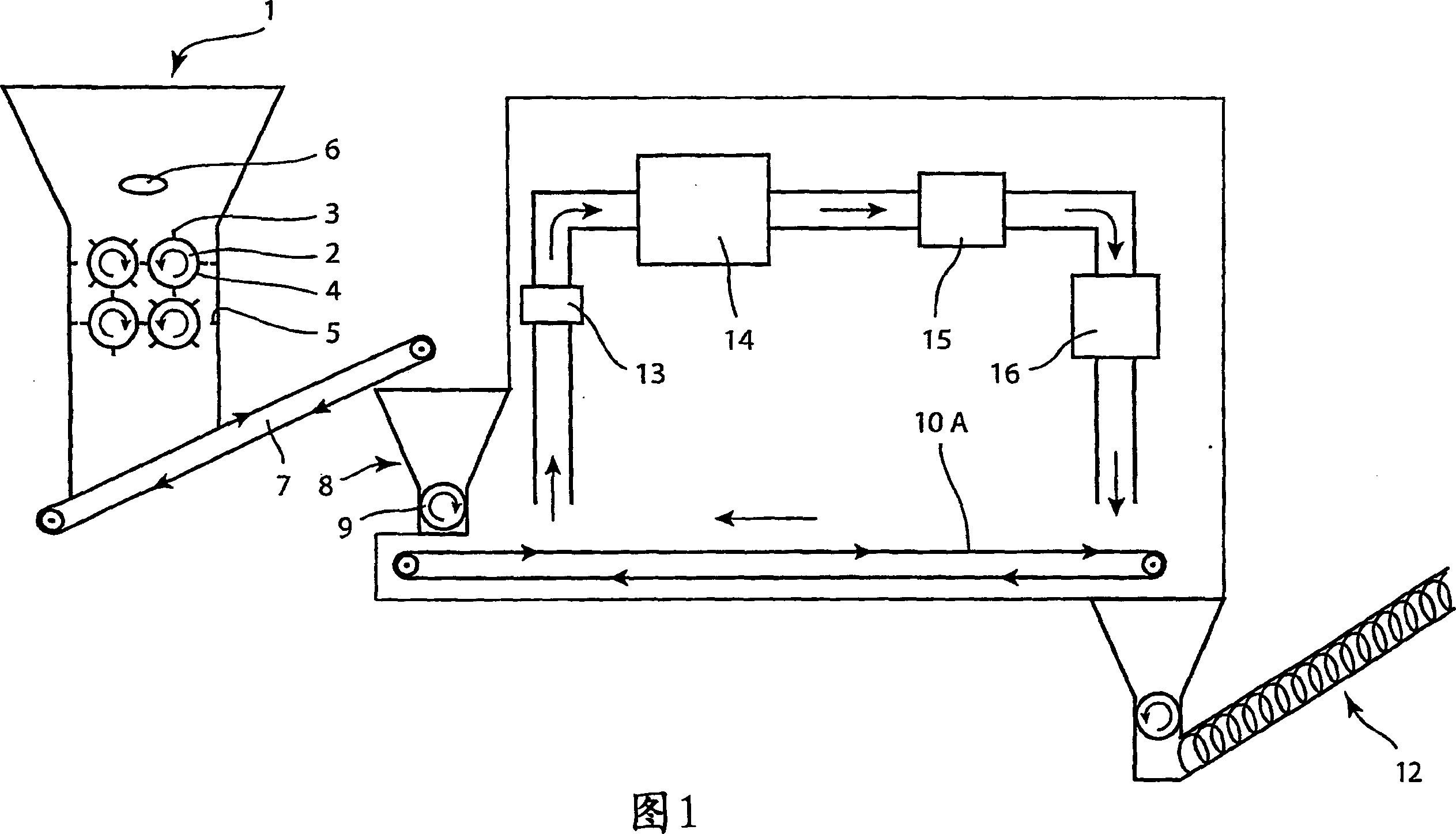

Device for drying material

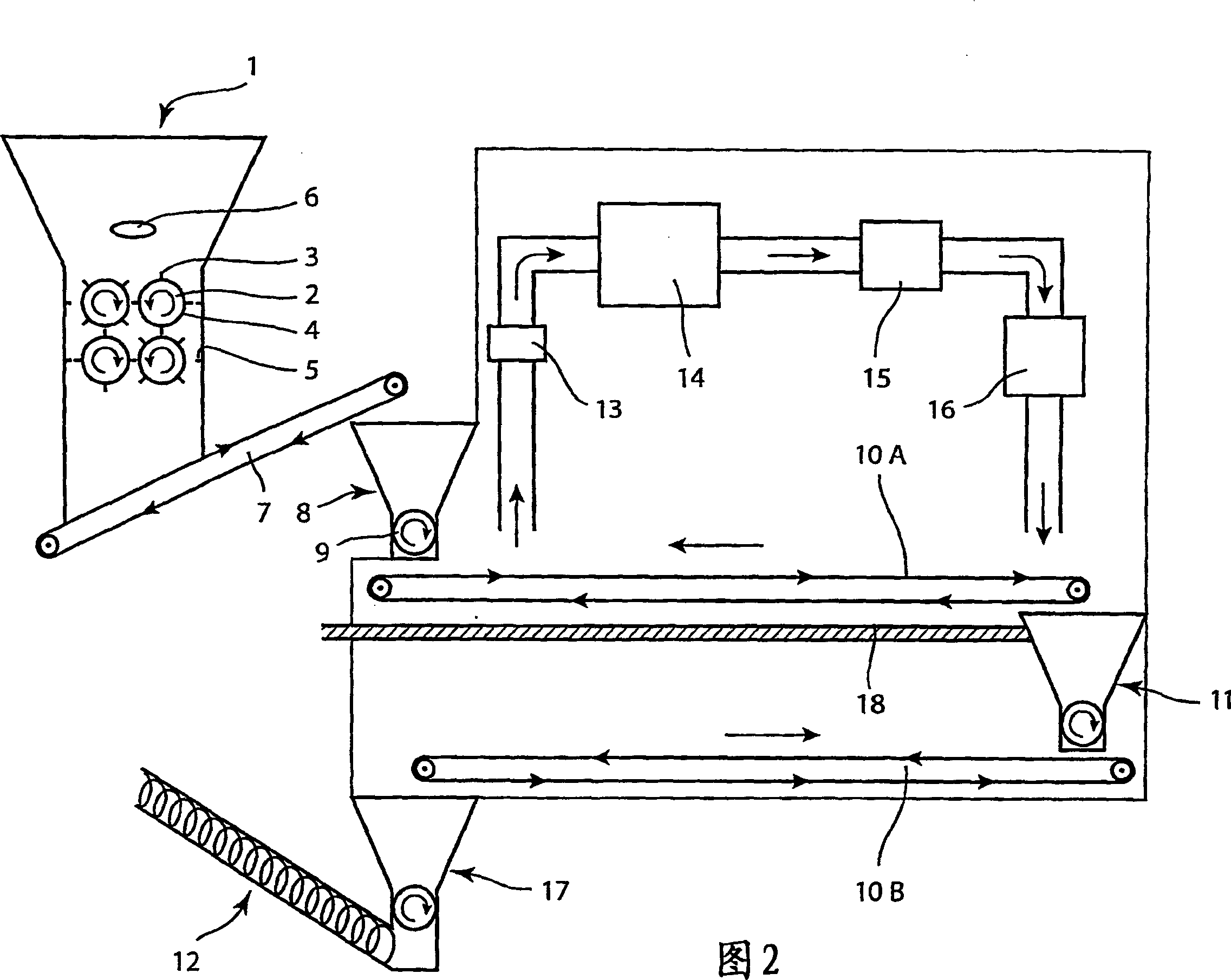

InactiveCN1942728AHas a mild scentWon't escapeProductsSludge treatment by de-watering/drying/thickeningAir cyclePulp and paper industry

An apparatus for drying materials such as fertilizers, mud, etc., comprising a grinding section and a drying section comprising at least one conveyor belt (10) and an air heater (16). A closed air circulation system is provided above the conveyor belt, which directs air countercurrently to the material on the conveyor belt. The temperature of the air heated in the heater (16) and the time for drying the material are adjusted so that the dried material does not contain bacteria and weeds.

Owner:阿斯比约恩·哈默

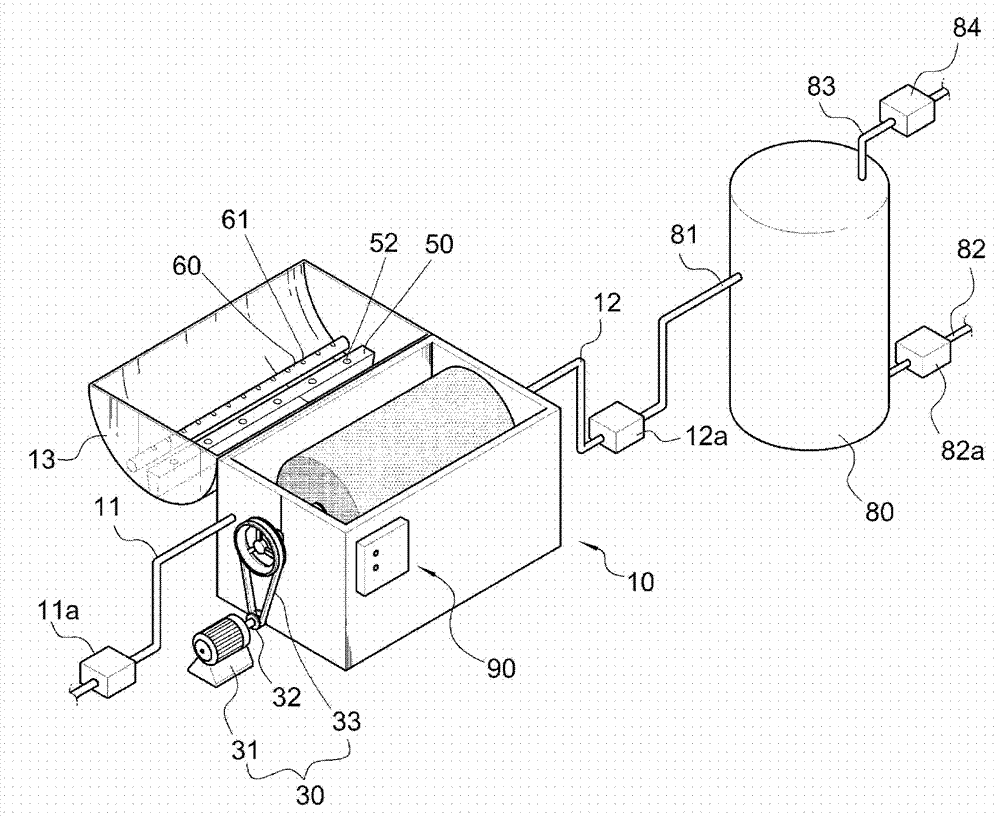

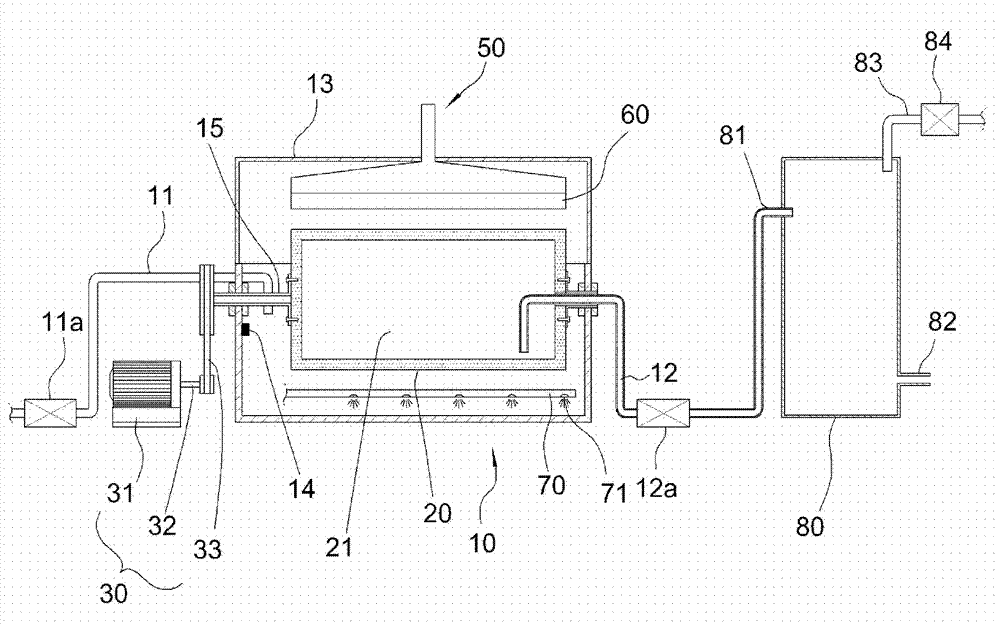

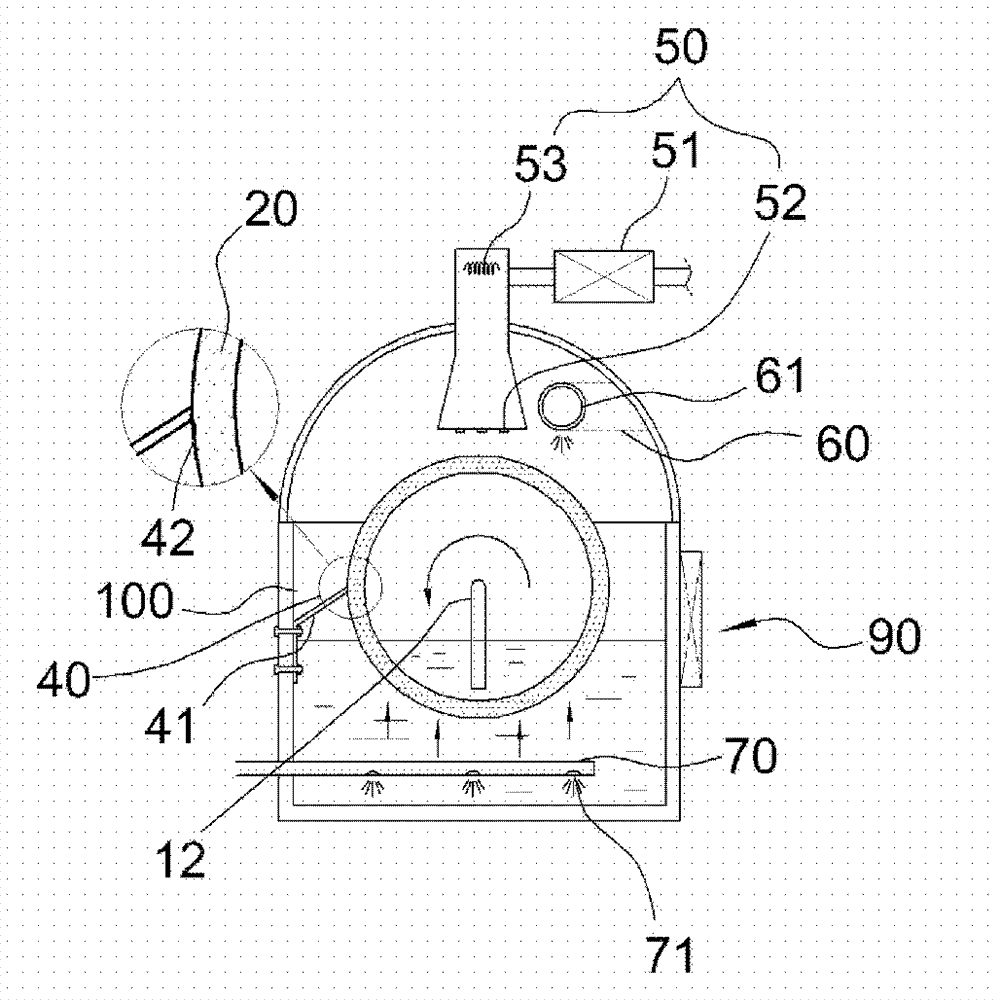

Filtering and drying apparatus for wastes recycling

InactiveCN102728139ASimple Reuse DisposalEasy to peelDrying using combination processesDrying solid materials with heatFiltrationSludge

The present invention relates to a filtering and drying apparatus for slurry and resource recycling. A sludge and resource recycling filtration-drying apparatus is provided to prevent the contamination of the region around the apparatus by the falling of sludge using a cover. A sludge and resource recycling filtration-drying apparatus comprises the following: a treatment tank(10) including a supplying pipe(11), a discharging pipe(12), a detecting sensor, and a rotary shaft; a rotating drum including a treated water containing space; a driving device(30) rotating the rotary shaft; a scraper separating foreign materials from the surface of the rotating drum; a hot air drier(50) supplying hot air to the surface of the rotating drum; a drum washer(60) supplying washing water to the surface of the rotating drum; an aerator supplying air to the bottom of the treatment tank; and a microfiltration device(80) including a treated water outlet(82) and a vacuum pump(84).

Owner:尹相镇

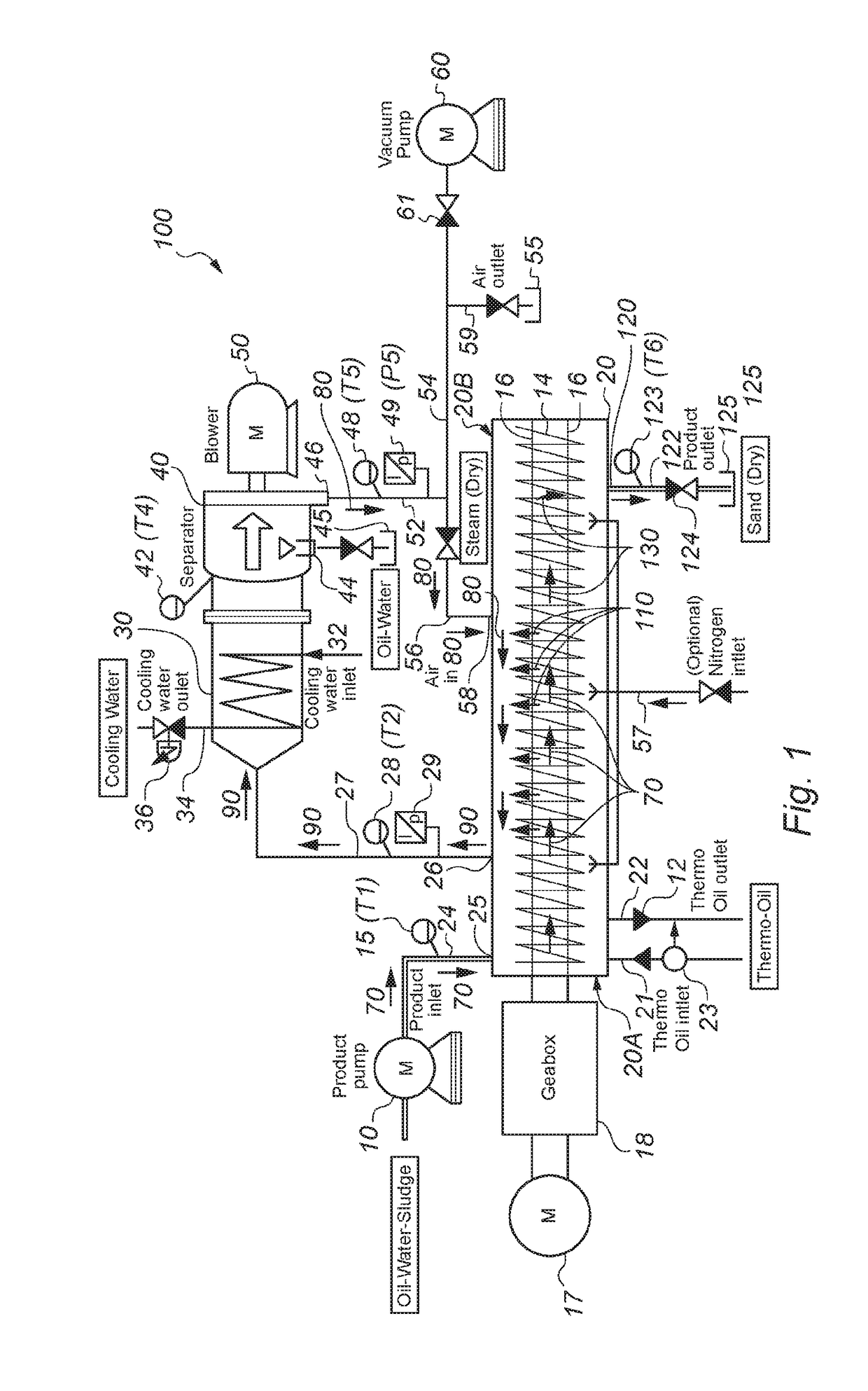

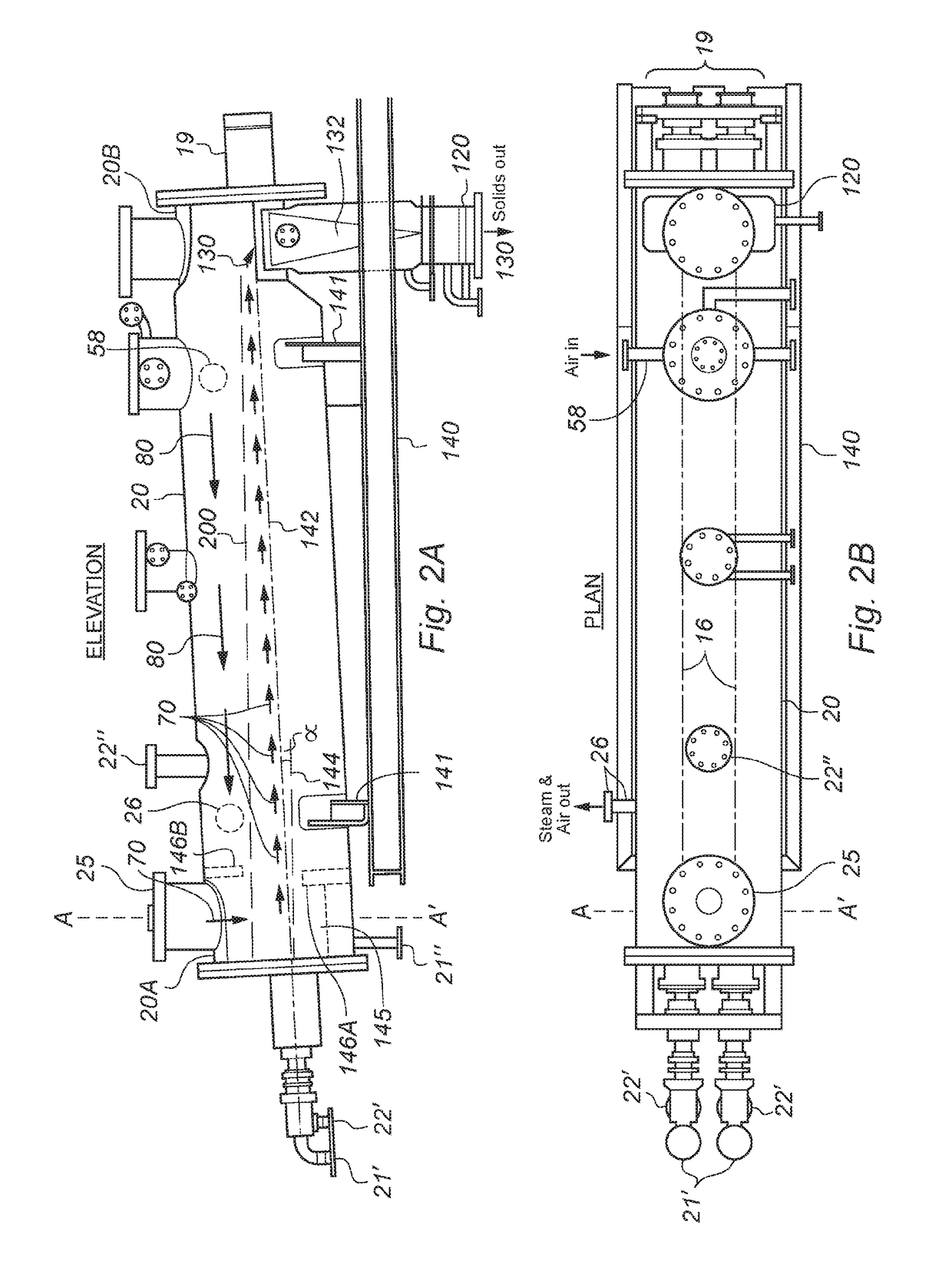

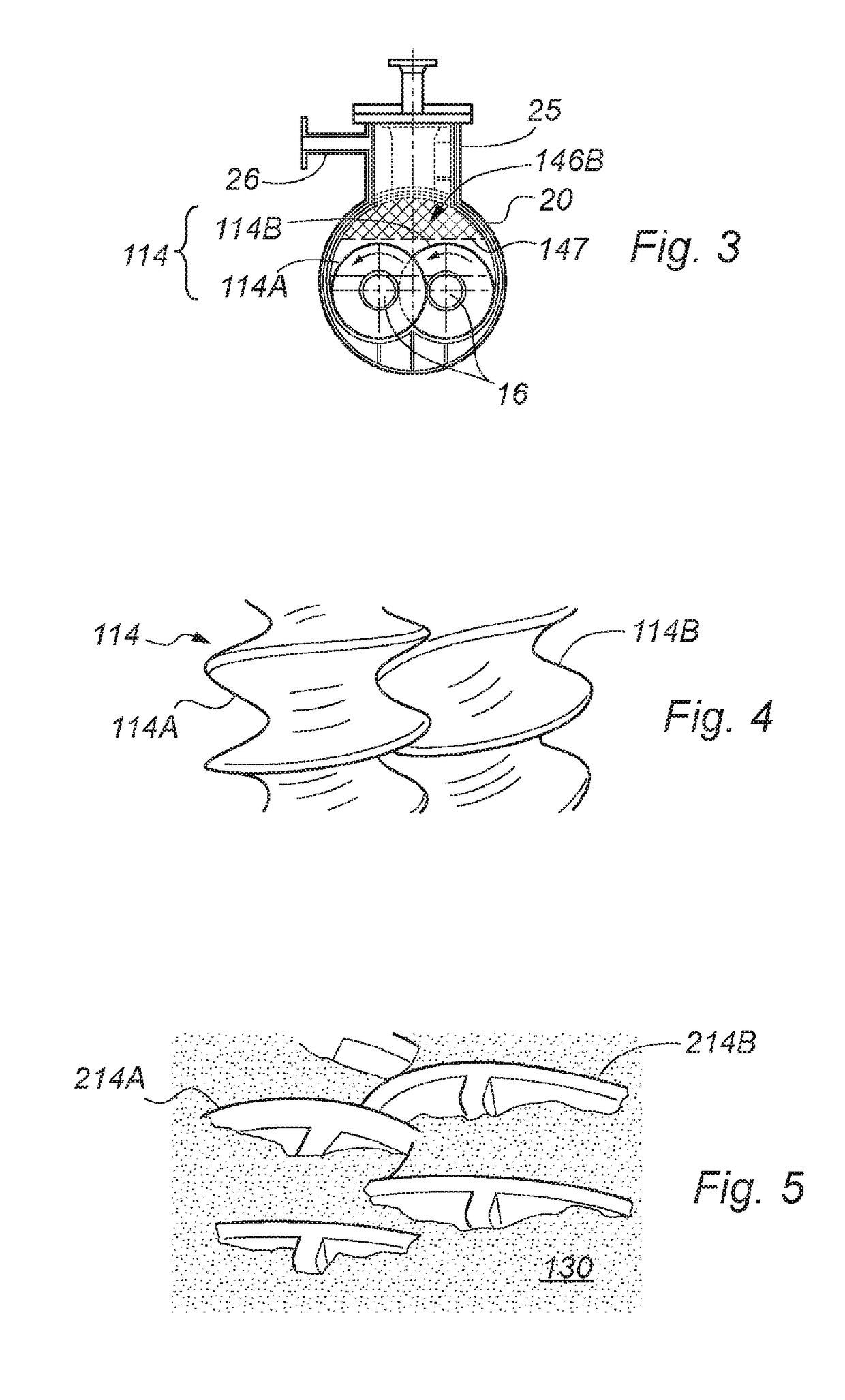

Method(s) and Apparatus For Treating Waste

InactiveUS20190071340A1Sludge treatment by de-watering/drying/thickeningDrying solid materials with heatWaste productSlurry

The present invention relates to method(s), apparatus and use(s) of apparatus for treating materials such as waste products and by-products of industrial processes e.g. slurries comprising solids and liquids, or, more particularly, slurries comprising solids, oil(s), and water. The invention further relates to method(s), apparatus and use(s) for treating slurry, the apparatus comprising a treatment chamber having a first end configured to receive slurry to be treated and a second end configured to allow egress of solids; at least one heated material conveyor configured to draw material comprising slurry and / or solids through the chamber in a direction from the first end towards the second end; the at least one heated material conveyor being further configured to heat and mix material comprising slurry and / or solids as these are drawn along; a condenser configured to receive vapours from the chamber and condense the vapours into liquid form.

Owner:ENERGY RECOVERY SYST

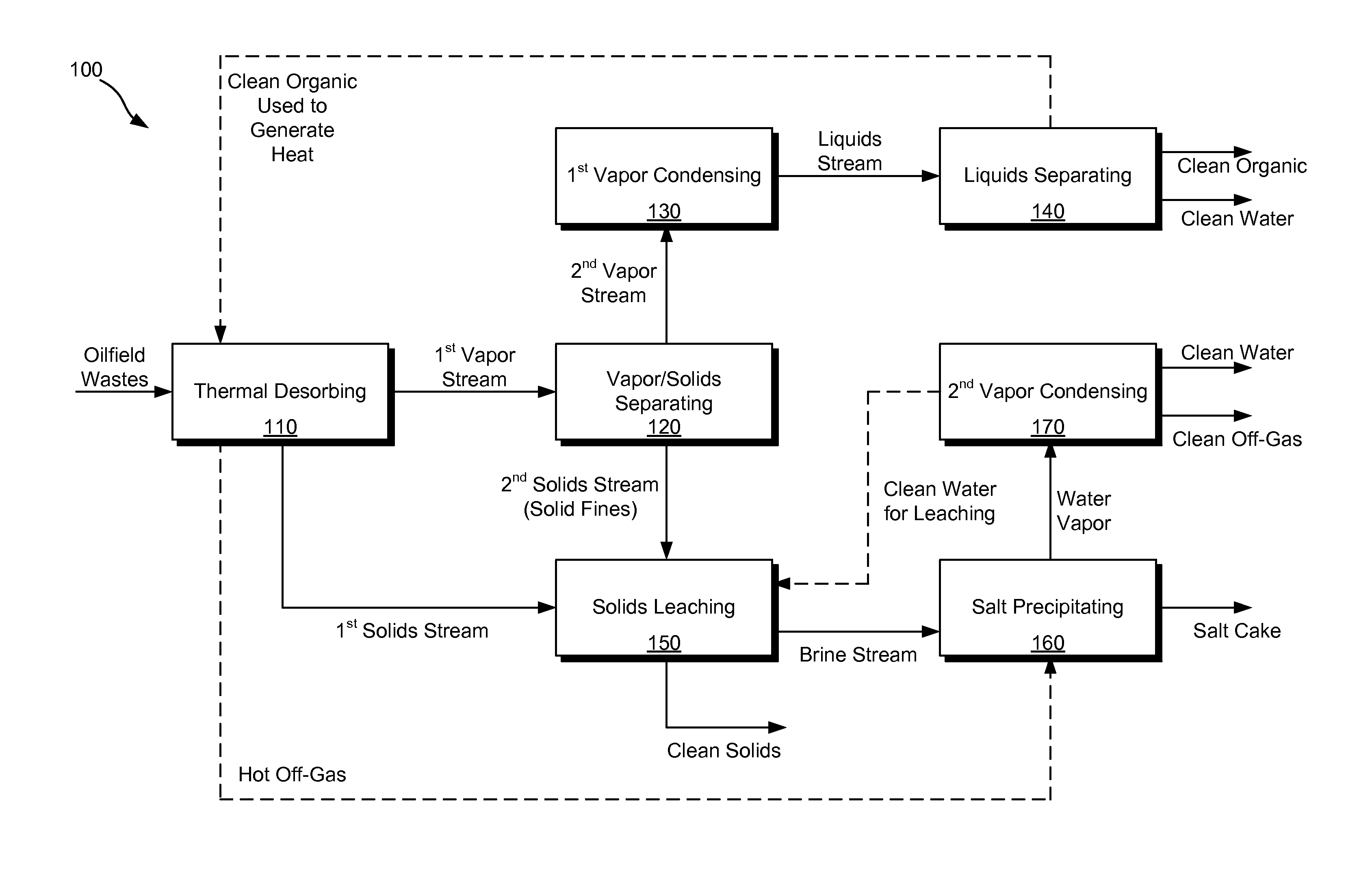

Process for separation and recovery of cuttings, emulsion and slurry components

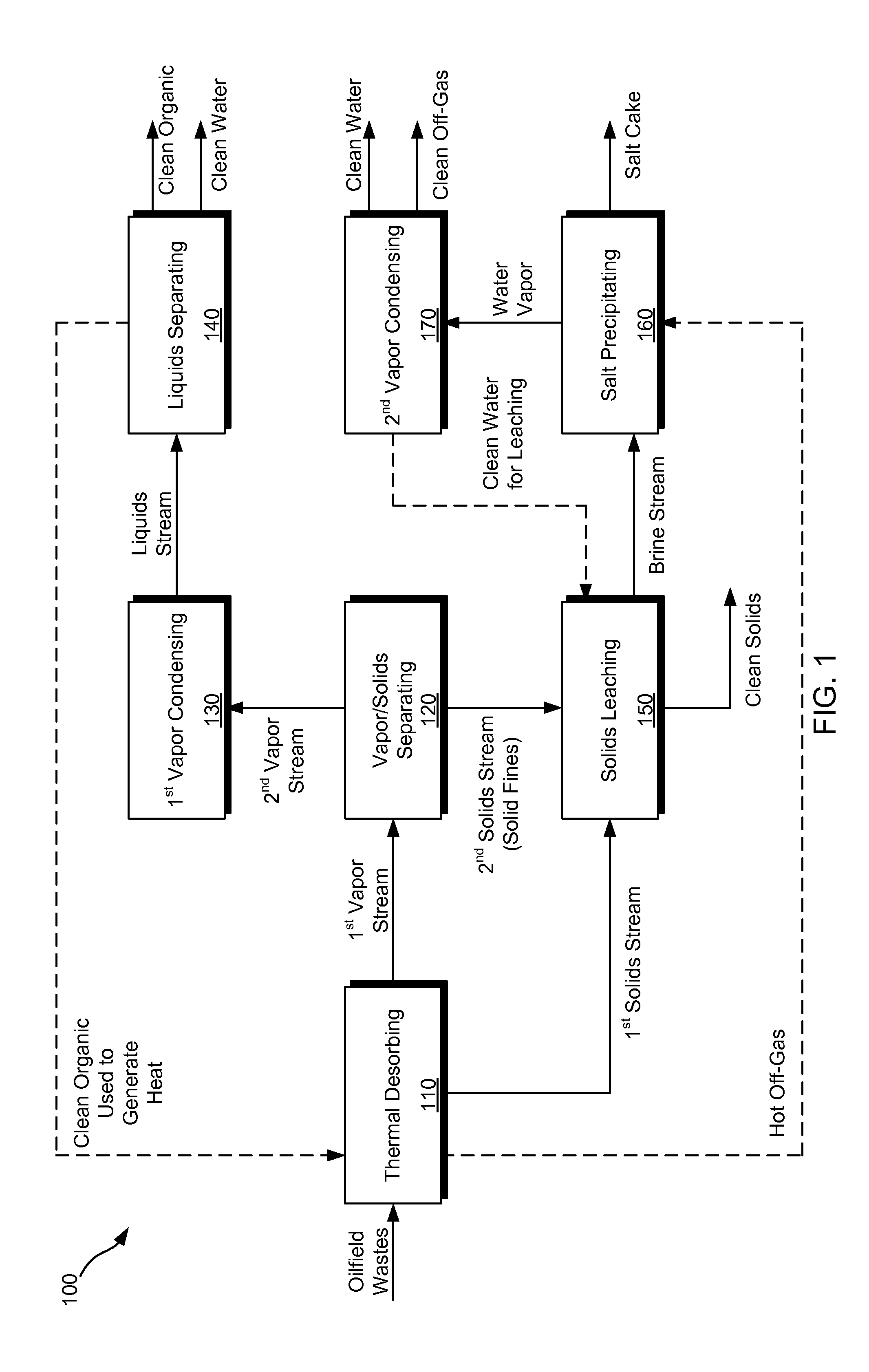

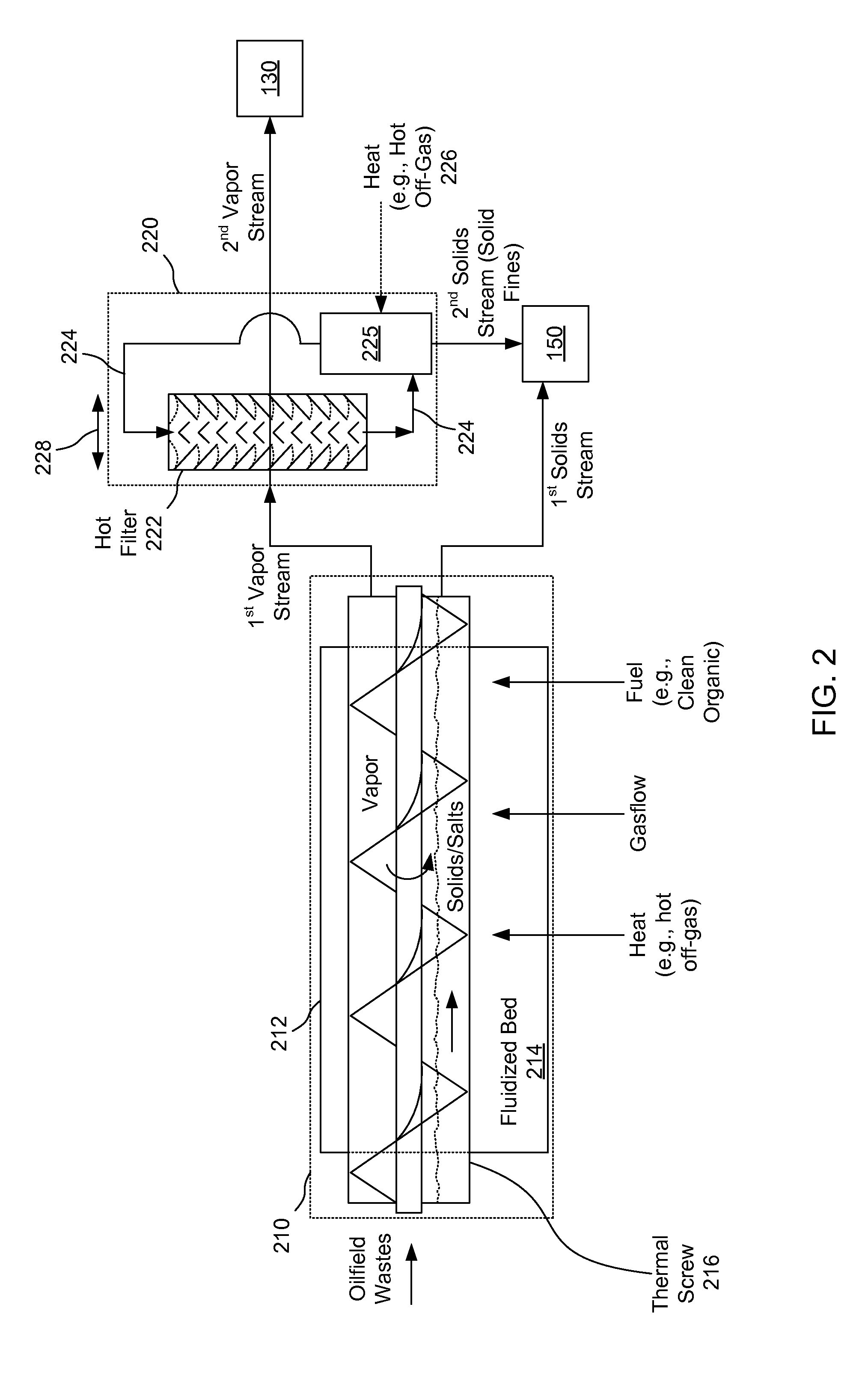

InactiveUS20130331632A1Drying solid materials with heatHydrocarbon purification/separationEmulsionCombustion

This disclosure describes systems, methods, and apparatus for separating and purifying components from mixtures and emulsions containing hydrocarbons, water, salt, and mineral solids. Key unit operations are thermal desorbing, hot filtering, direct contact condensing, solids leaching, evaporating, and salt precipitating. Preferred embodiments of the process and system use process-generated fuel, leach water, and hot combustion gas to conduct thermal desorption, solids leaching, and salt precipitating. Use of process generated streams for key unit operations greatly reduces the need for purchased utilities and contributes both to process efficiency and economy.

Owner:C&E RECLAMATION

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com