Quick sludge drying equipment with crushing device

A crushing device and rapid drying technology, applied in the directions of sludge drying, drying solid materials, drying gas arrangement, etc., can solve the problems of uneven bearing force of stirring blades, affecting sludge drying efficiency, and uneven sludge drying, etc. The effect of facilitating heat transfer, facilitating heat transfer and accelerating drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

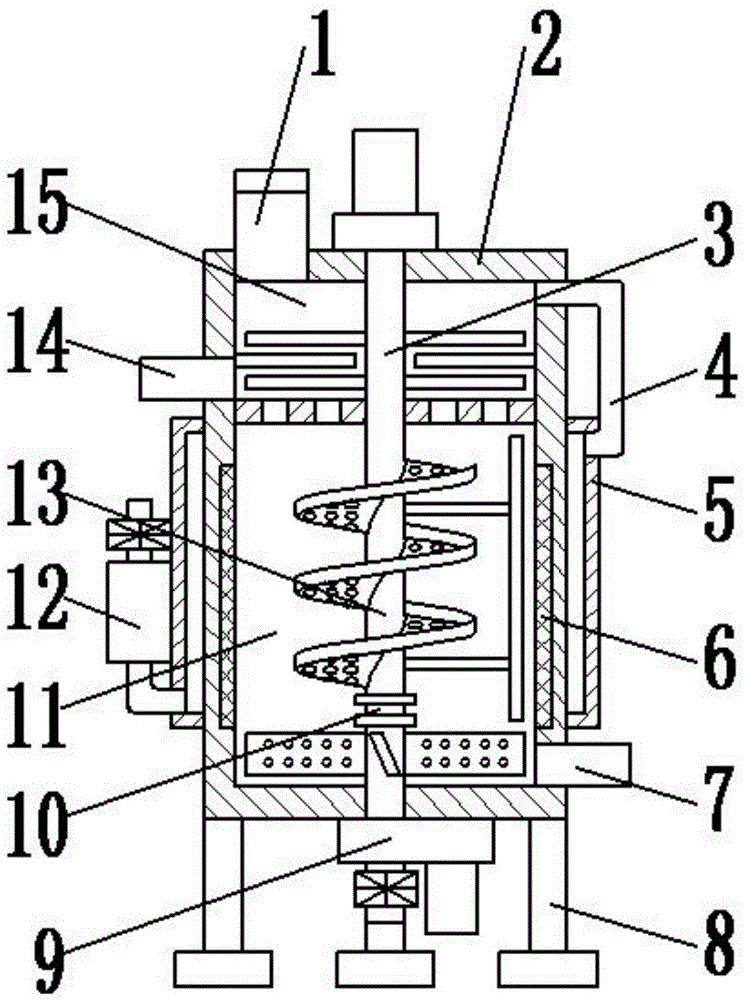

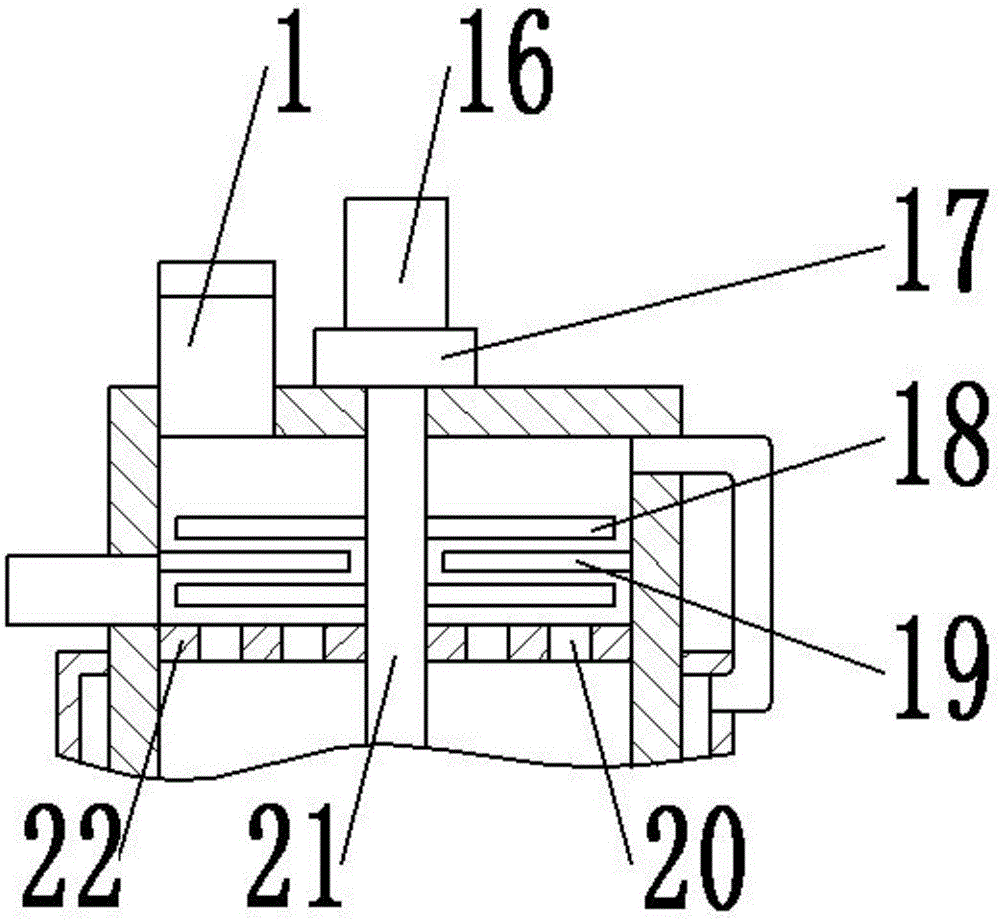

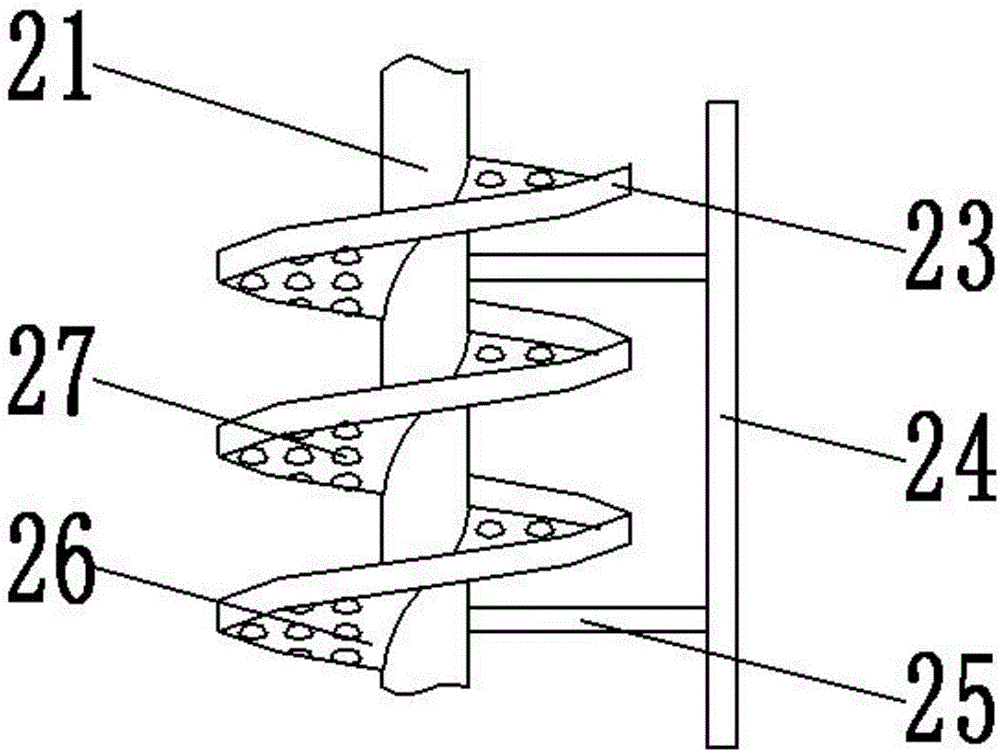

[0018] see Figure 1-5 , a sludge rapid drying equipment with a crushing device, including a tank body 2; the tank body 2 is set as a hollow cylinder made of stainless steel, and the interior is divided into a crushing chamber 15 and a drying chamber 11 by a partition 22; A number of blanking holes 20 are evenly distributed on the partition 22; a feeding pipe 1 is arranged on the top surface of the tank body 2; a sealing cover is arranged at the opening of the feeding pipe 1; a crushing device is arranged in the crushing chamber 15 3; the crushing device 3 is composed of a first motor 16, a first rotating shaft 21, a fixed blade 19 and a rotating blade 18; the first motor 16 is connected to the first rotating shaft 21 through a reducer 17, and the first motor 16 and reducer 17 are fixed on the top surface of the tank body 2; the first rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com