Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

344results about How to "Improve drying uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

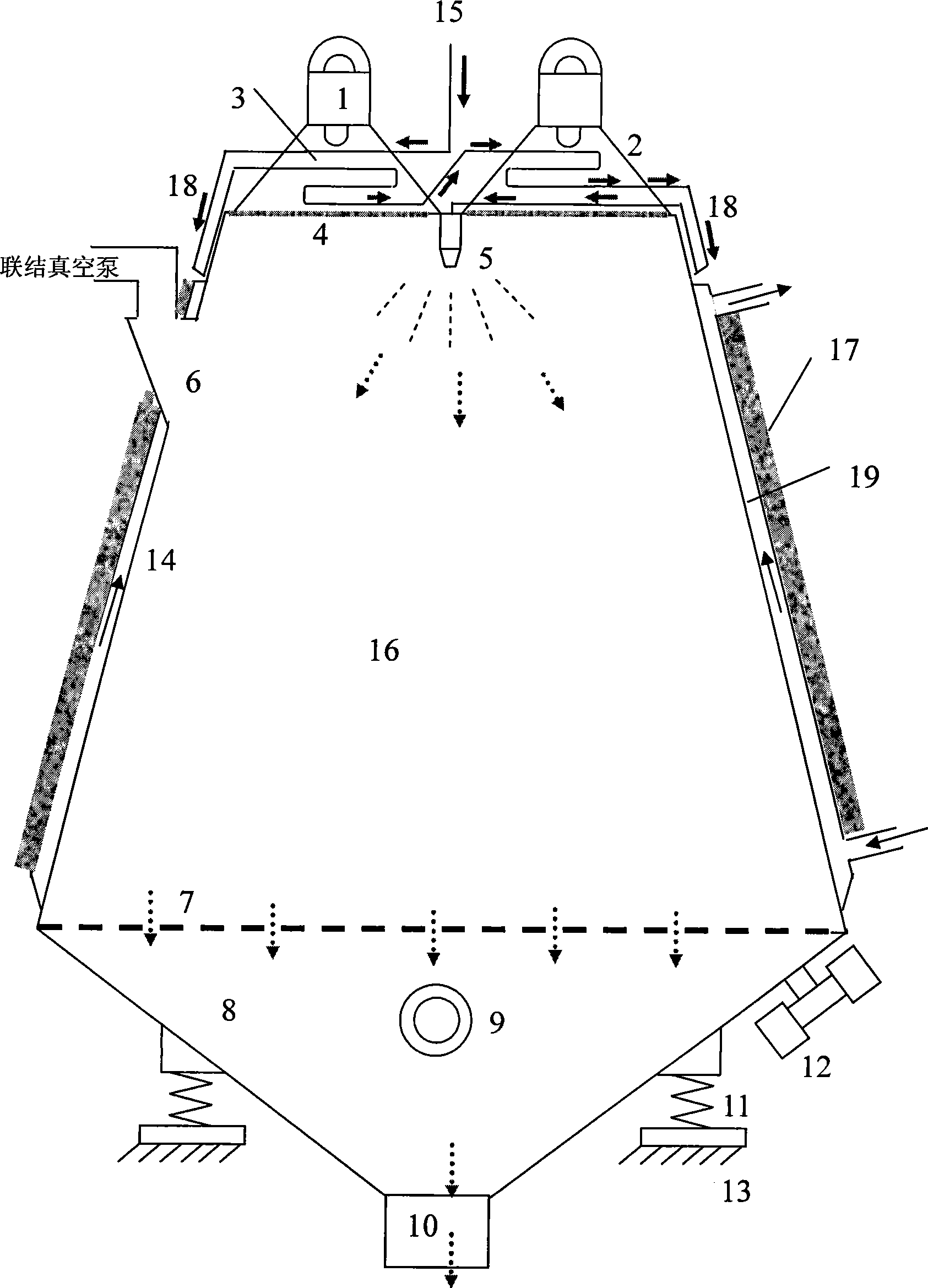

Sprouted auxiliary means for improving microwave desiccation homogeneity of granular garden stuff

InactiveCN101433233ASpray evenlyImprove uniformityFruits/vegetable preservation by dehydrationFood treatmentAir volumeAgricultural engineering

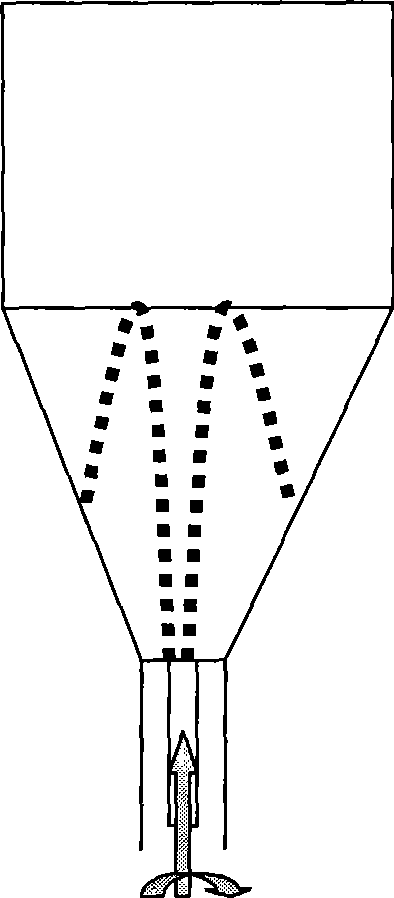

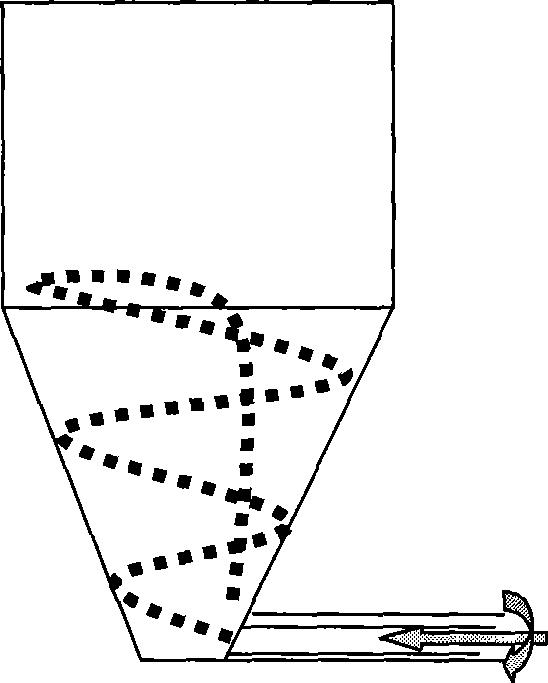

The invention discloses an auxiliary spouting method for improving the uniformity of microwave drying of granular fruits and vegetables, which belongs to the technical field of the processing of fruit and vegetable food. Pretreated fruits and vegetables are placed into a microwave spouting drying bed, the microwave power and the air intake heating temperature are preset, then the central air intake volume and the air intake angle of the spouting bed are adjusted to ensure that a dried material spouts in the spouting bed in different forms, the air intake pressure and the air intake angle are adjusted according to different drying stages of the material at the same time, and the microwave energy received by the material is more uniform than that of the prior fixation or fluidization mode; and the microwave adopts internal heating, so the moisture of the dried fruits and vegetables is effectively and quickly evaporated to achieve the aim of uniform drying. Through the auxiliary spouting method, the material is uniformly heated in a microwave field, the moisture is evaporated quickly, the drying time is greatly shortened, the prior color and luster, shape and nutrient substances of the dried fruits and vegetables can be furthest retained, and the dried fruits and vegetables have porous structures and good rehydration property, thereby obtaining a high-quality dehydrated fruit and vegetable product.

Owner:JIANGNAN UNIV +1

Low-temperature making process of flavored dried fish with low salt

InactiveCN102246978AThe production process is simpleReduce manufacturing costFood preparationUnsaturated fatty acidChemistry

The invention relates to the technical field of freshwater fish processing, aiming to provide a low-temperature making process of a flavored dried fish with low salt. The low-temperature making process of the flavored dried fish with low salt, provided by the invention, comprises the steps of pretreatment, low-temperature salting, desalting and low-temperature drying. According to the invention, the food safety problem of the fish product is solved through low-salt and low-temperature salting, low-temperature drying and no addition of any pigment, essence and preservative; and the produced dried fish has the advantages of good mouthfeel, low salt and high content of highly unsaturated fatty acid.

Owner:HANGZHOU QIANDAO LAKE YONGCHENG GREEN FOOD

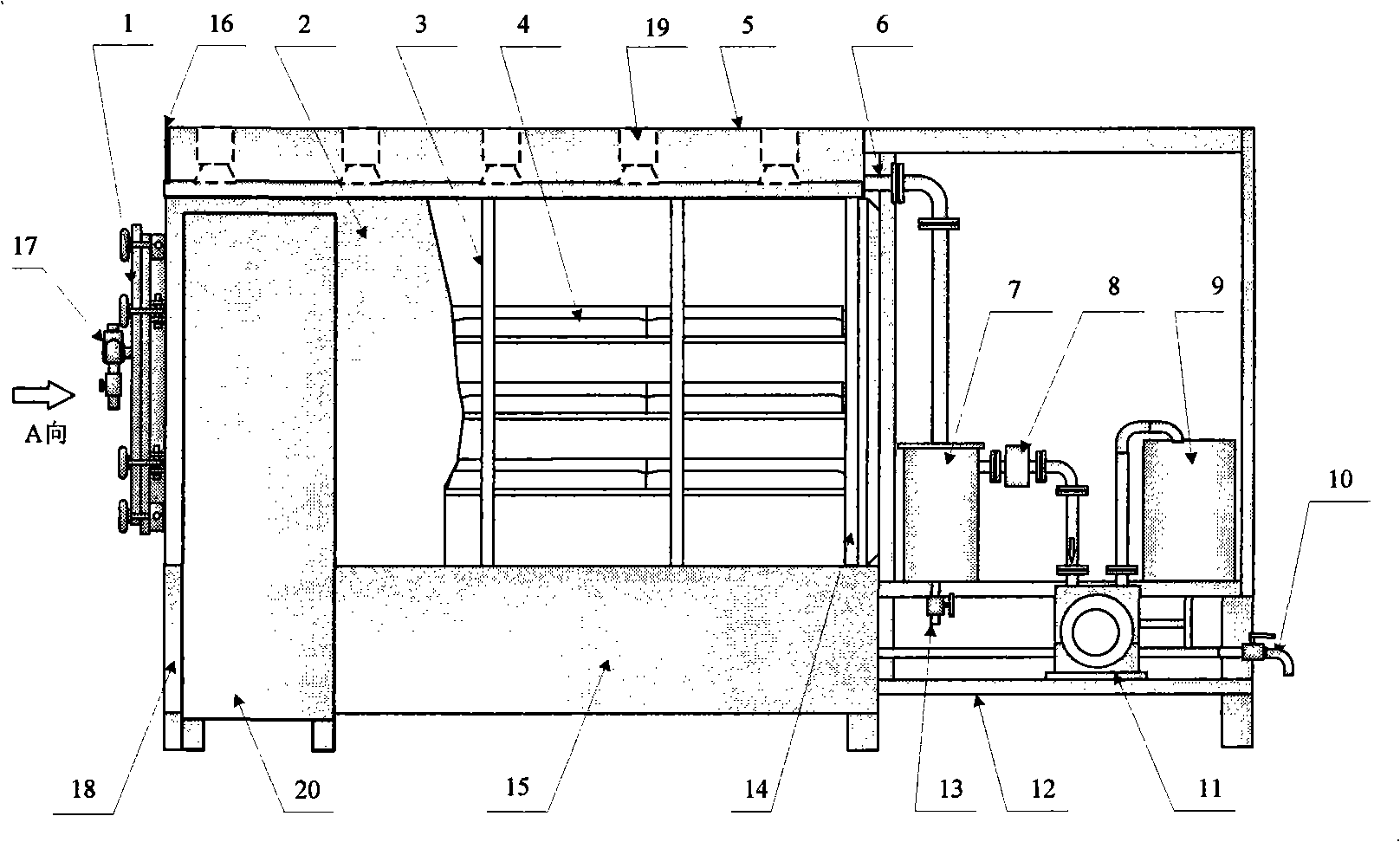

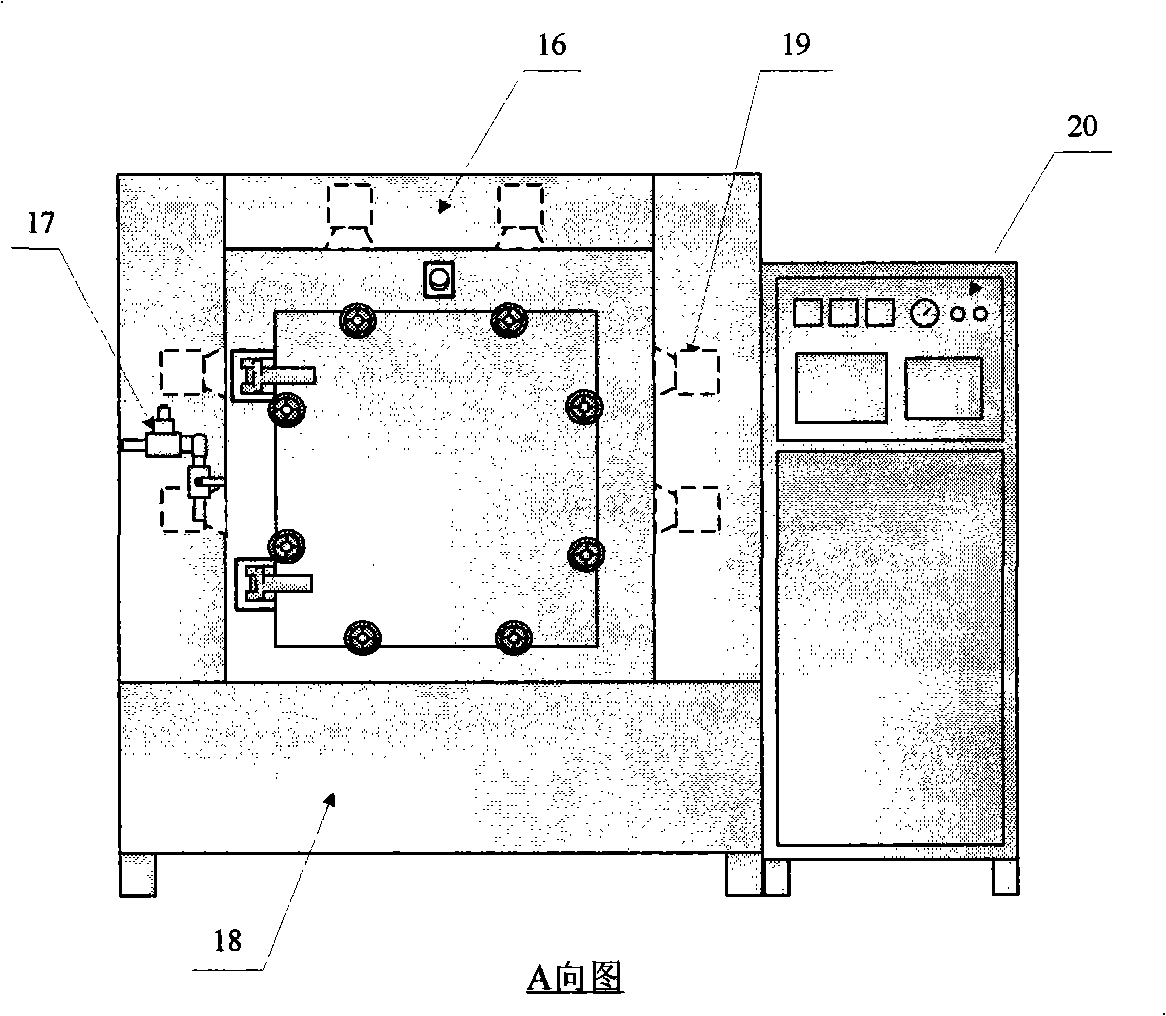

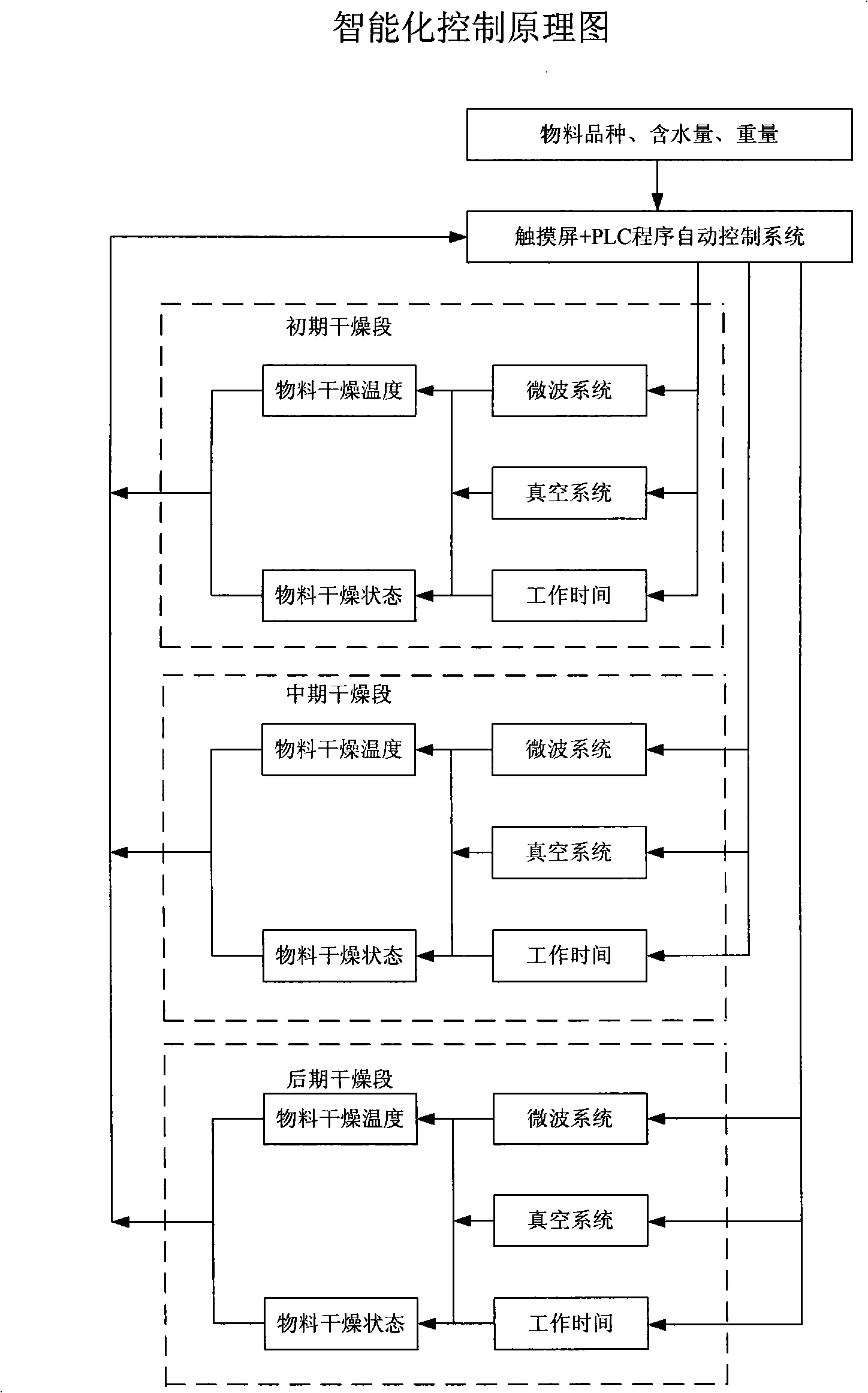

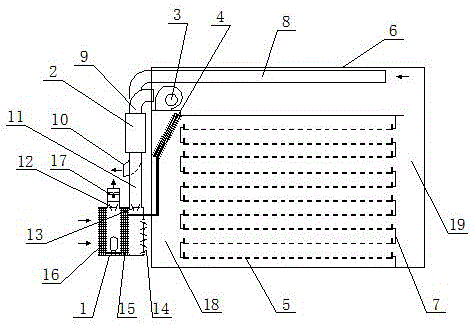

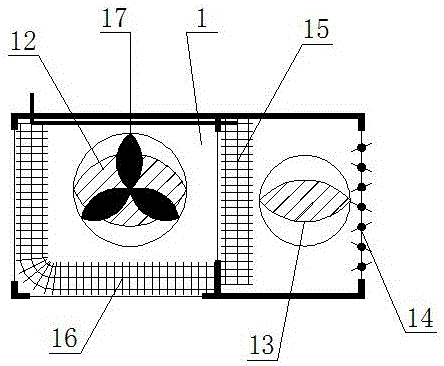

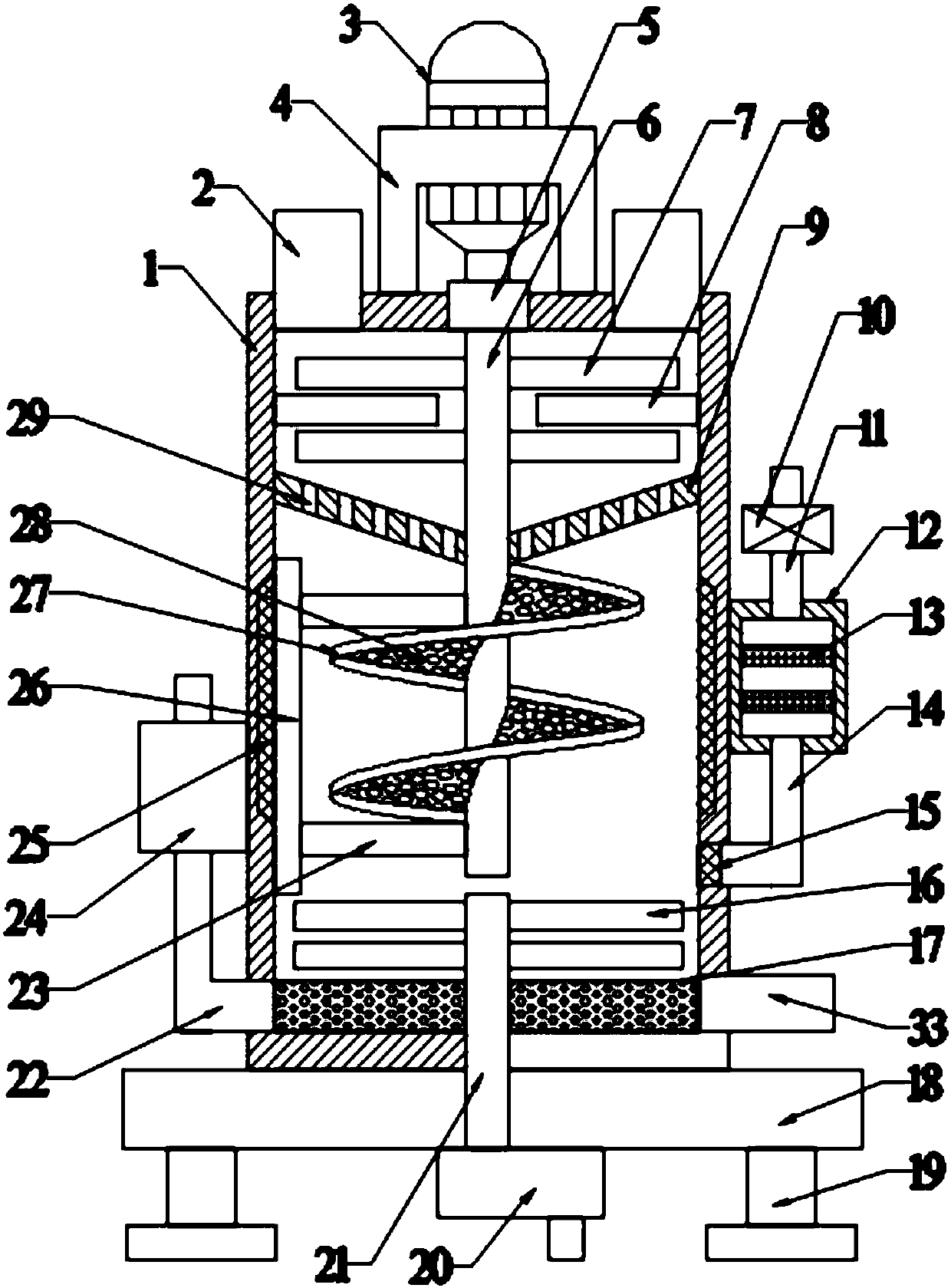

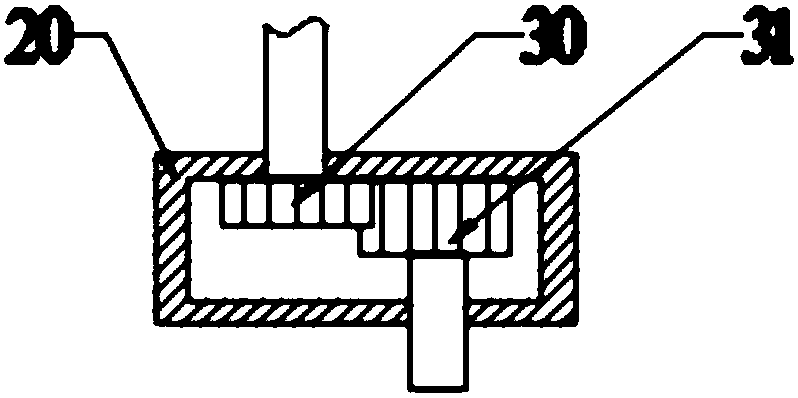

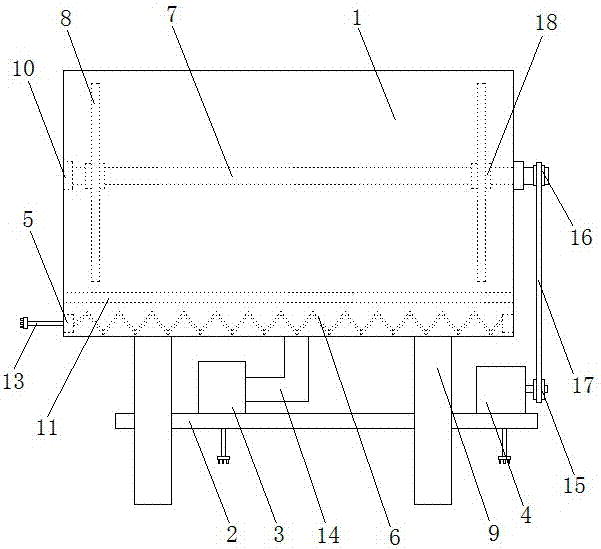

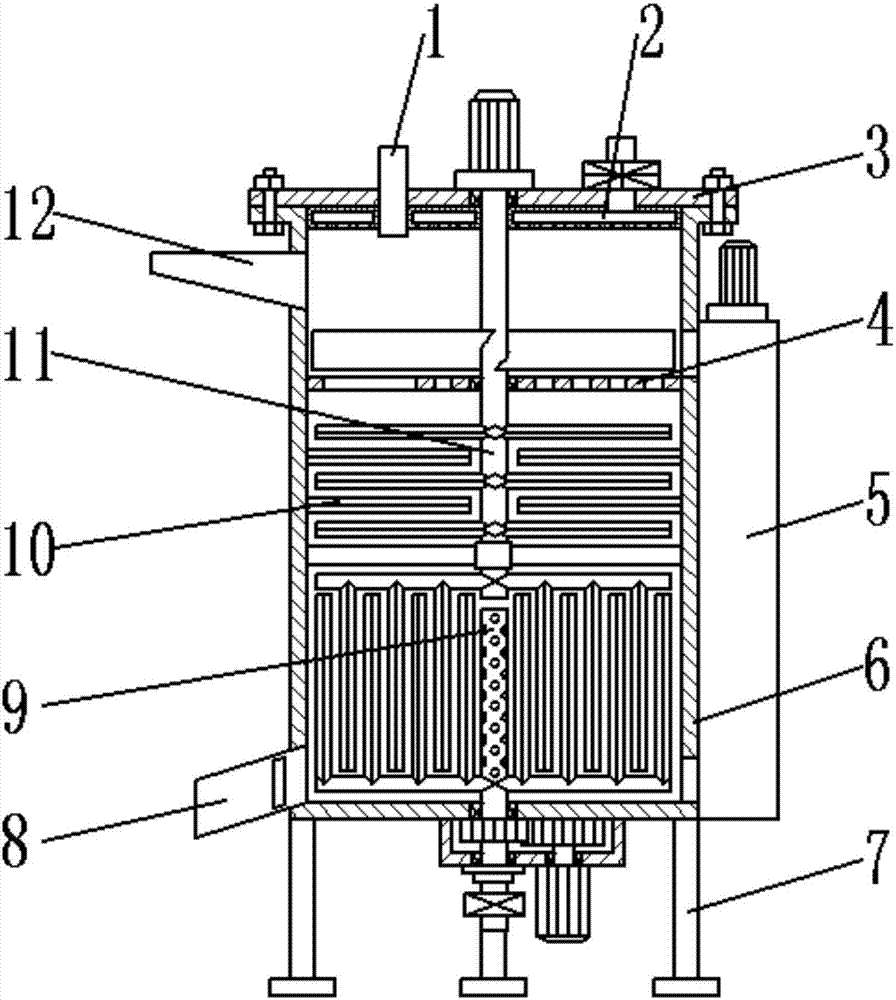

Intelligentized static microwave vacuum drying machine

InactiveCN101338968AReduce energy consumptionQuality improvementDrying using combination processesDrying solid materials with heatMicrowaveHigh energy

The invention provides an intelligent static microwave vacuum drier which is used for quickly drying plant extracts, foodstuff, subsidiary agricultural products, chemical products and so on under low temperature to get high quality dry products. In order to solve the defects of the prior art, namely, low dry quality, high energy dissipation, low output, long cycle, large investment, high cost, unstable operation of equipment and so on, the intelligent static microwave vacuum drier can dry materials quickly and uniformly at low temperature in static state. During the drying process, the power, the temperature and the time are intelligently and automatically controlled according to the varieties and the dryness of materials, thus getting high-quality dry materials with the moisture error less than positive or negative 2 percent. The equipment runs stably and dries uniformly; little energy is consumed; little money is invested on equipment without environmental pollution. By comparing the intelligent static microwave vacuum drier with the traditional electrothermal vacuum drying and electrothermal cabinet drying, the energy is saved by more than 90 percent; by comparing the intelligent static microwave vacuum drier with the spray drying, the energy is saved by more than 80 percent; by comparing the intelligent static microwave vacuum drier with the basket microwave vacuum drier, the energy is saved by more than 10 percent. The dry quality is better than the quality of other dry modes.

Owner:吴琦 +1

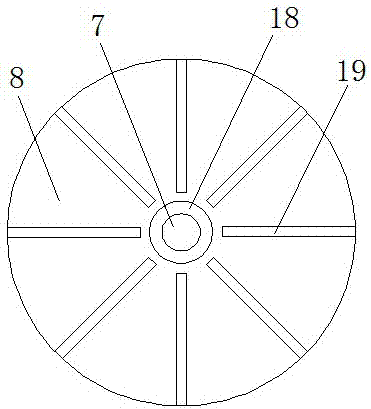

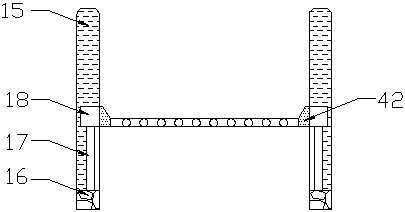

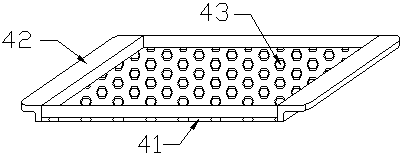

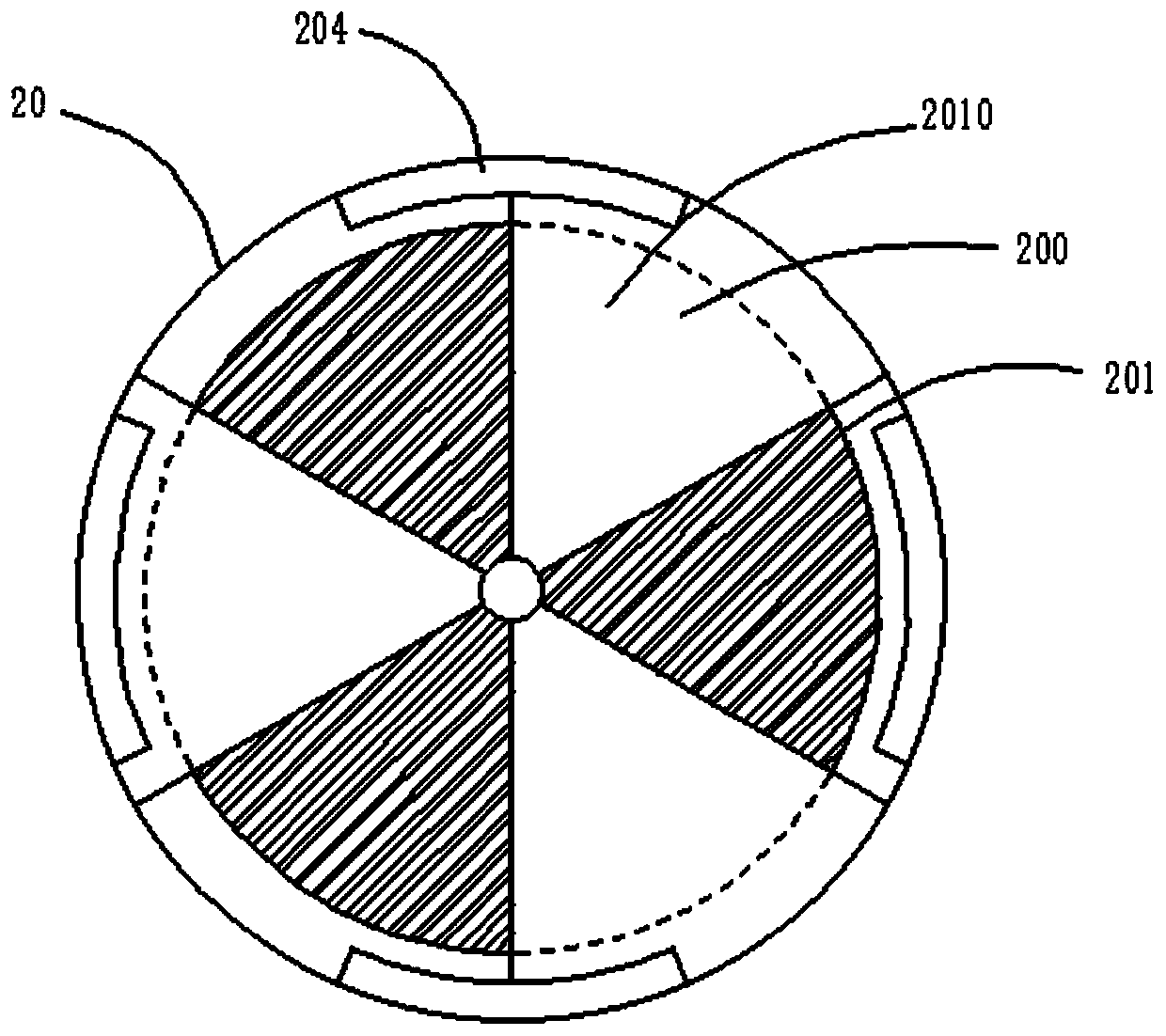

Air energy heat pump agricultural product drying device

ActiveCN106369959AImprove drying uniformityReduce drying energy consumptionHeat pumpsDrying gas arrangementsProcess engineeringRefrigeration

The invention relates to an air energy heat pump agricultural product drying device. The air energy heat pump agricultural product drying device is formed by an air energy heat pump outdoor main engine, a total heat exchanger, a first draught fan, a condenser, a material disc, a drying box shell, barge boards, an air exhaust pipe, an air supply pipe, an air supply static pressure chamber and an air return static pressure chamber. The air energy heat pump outdoor main engine comprises three air quantity adjusting valves and two evaporators, the two evaporators are connected in parallel, and are connected with the condenser in series through a refrigeration agent pipe to form a part of refrigerating cycle; outdoor fresh air treated through the air energy heat pump outdoor main engine exchanges heat with exhausted air in the total heat exchanger to be supplied into the drying box shell; the first draught fan provides power for circular flow of air in the drying box shell; and the barge boards are installed at appropriate positions of the front and the back of the material disc, and needled airflow paths in the material disc are obtained. By means of the air energy heat pump agricultural product drying device, three drying working conditions including single heating, low temperature dehumidification and dehumidification while heating of agricultural products can be achieved, the uniform air supply speed of the material disc can be achieved, and the energy using efficiency and the agricultural product drying uniformity can be improved.

Owner:福建古田康亿达生物科技有限公司

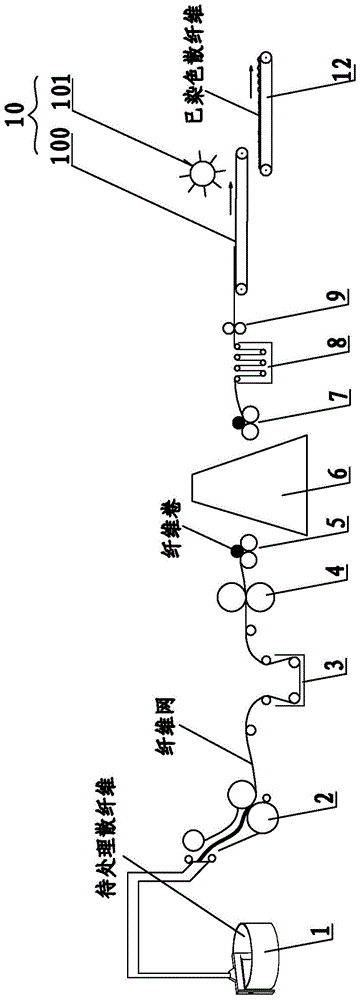

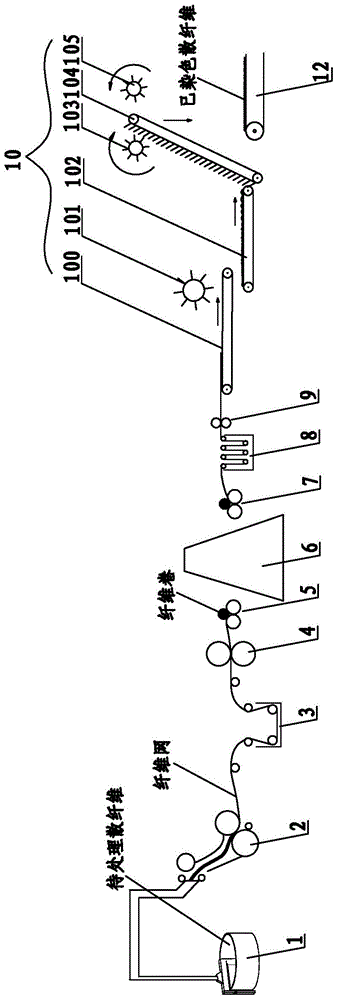

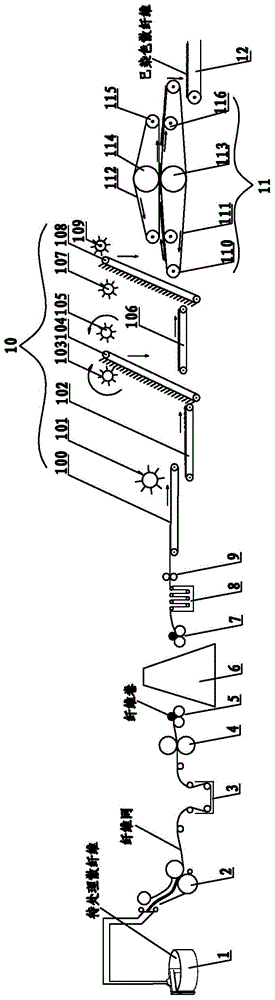

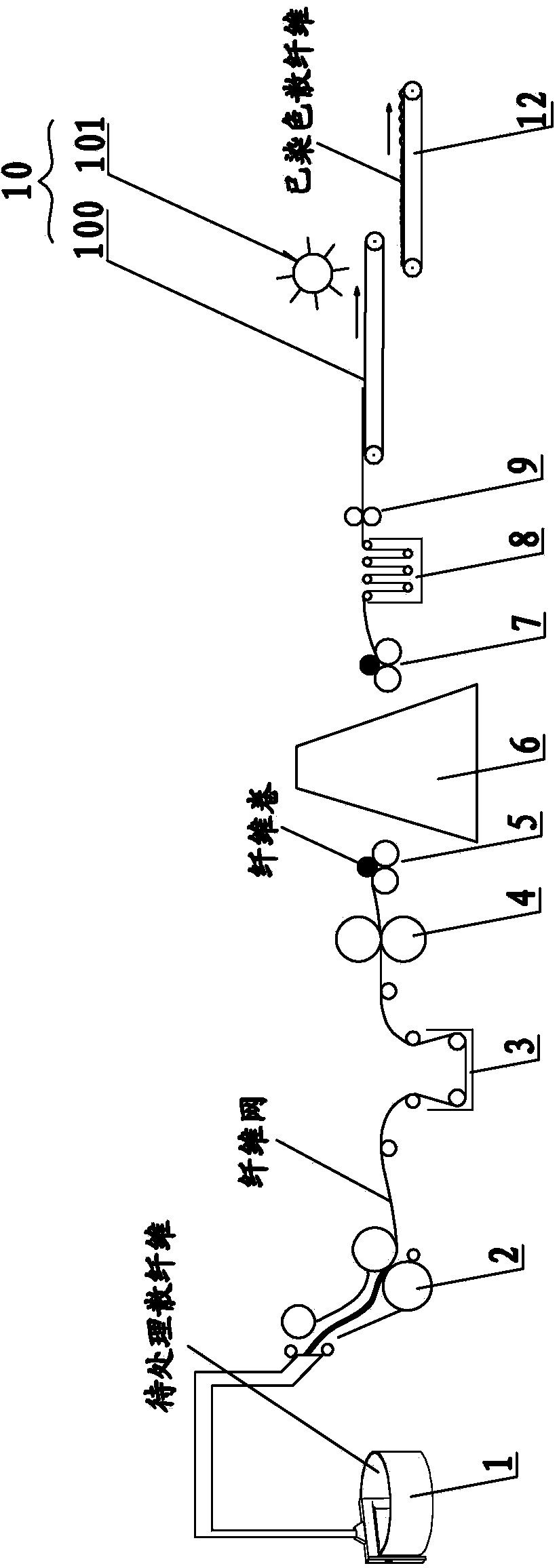

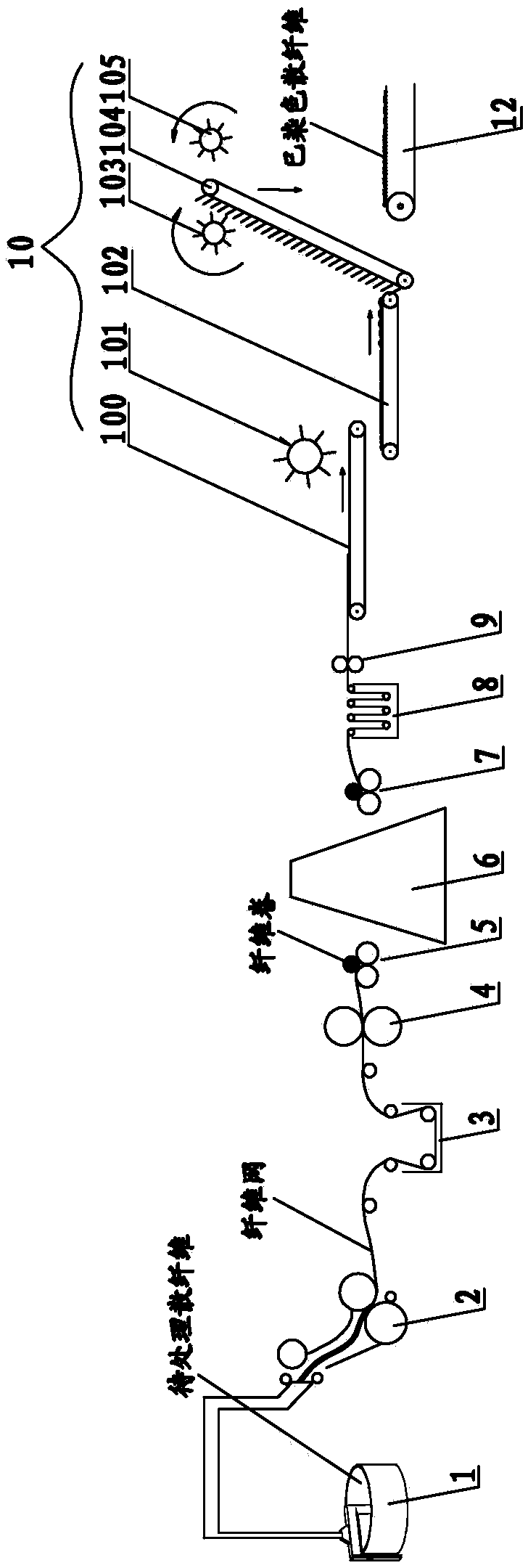

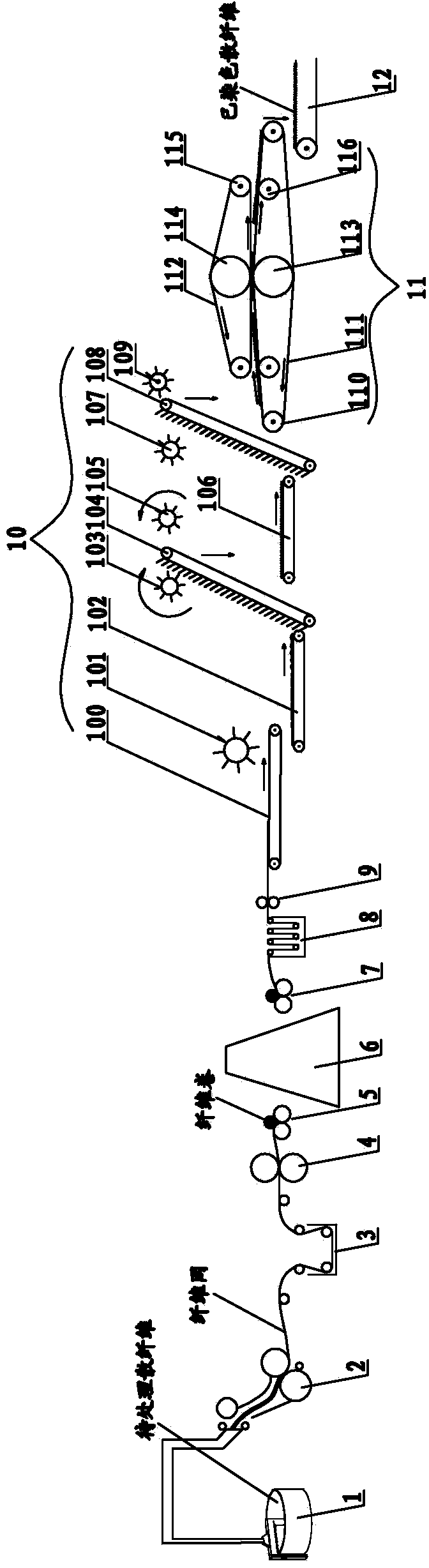

Loose fiber dyeing process

ActiveCN103911782AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberPolymer science

The invention relates to a loose fiber dyeing process and belongs to technical field of fiber dyeing. The process sequentially includes: grabbing cotton, forming nets, soaking, mangling, forming rolls, cold piling, unrolling, washing, squeezing, splitting, spreading and drying. Squeezed loose fibers are fed to the spreading procedure after splitting, the loose fibers are squeezed at the squeezing force of 3-15kg / cm<2> under the premise of not damaging the fibers, the squeezed dyed fibers are directly fed through a lower conveying belt to an eight-cage dryer or a loose fiber high-frequency dryer for drying. By the process, the defects that continuous production cannot be performed and machining efficiency is low in conventional technologies are overcome, the defects that of uneven dyeing, low drying efficiency, large energy consumption and the like when the loose fibers are dried in a net structure are overcome, fiber damage is low during processing, and the quality of the finished fibers is guaranteed.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

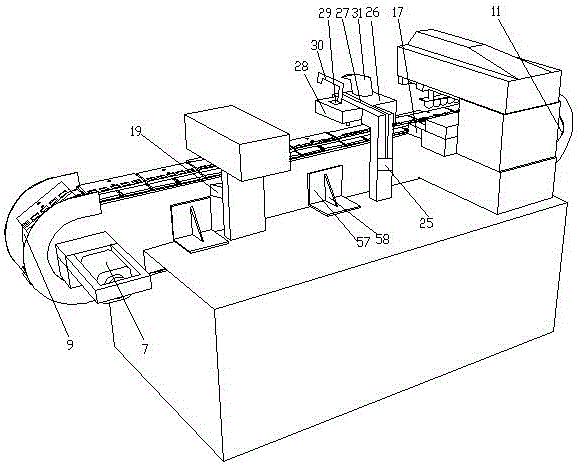

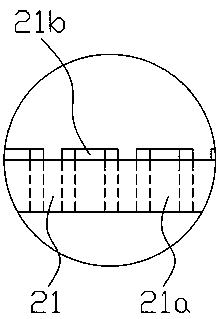

Loose stock dyeing device

ActiveCN103882637AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberProcess efficiency

The invention relates to a loose stock dyeing device and belongs to the technical field of stock dyeing devices. The loose stock dyeing device comprises a cotton grabbing device, a net forming device, a steeping device, a mangle device, a coiling device, a cold-batch fixation device, a uncoiling device, a washing device, a squeezing device, a splitting device and a drying device, wherein the cotton grabbing device, the net forming device, the steeping device, the mangle device, the coiling device, the cold-batch fixation device, the uncoiling device, the washing device, the squeezing device, the splitting device and the drying device are sequentially arranged. A loose stock net after squeezing is sent to the splitting device to be split and sent to the drying device to be dried. According to the technical scheme, the defects that continuous production cannot be performed and processing efficiency is low in the prior art are overcome, and the defects that dyeing is uneven, drying efficiency is low and energy consumption is large in drying loose stock with a net-shaped structure are overcome. In the processing process, stock damage is little, and the quality of finished stock products is ensured.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

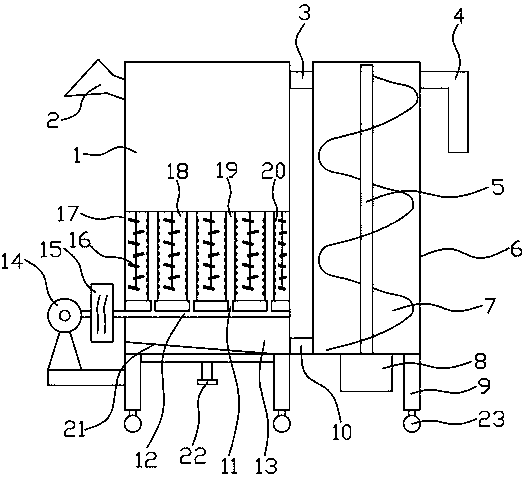

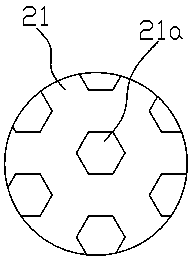

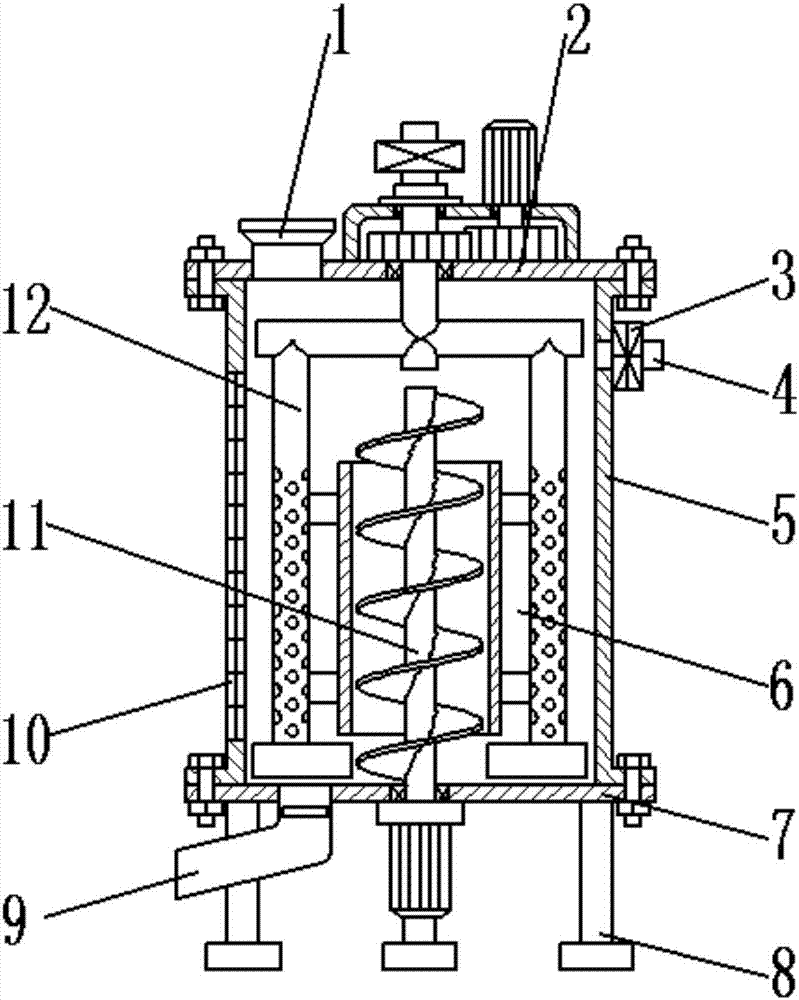

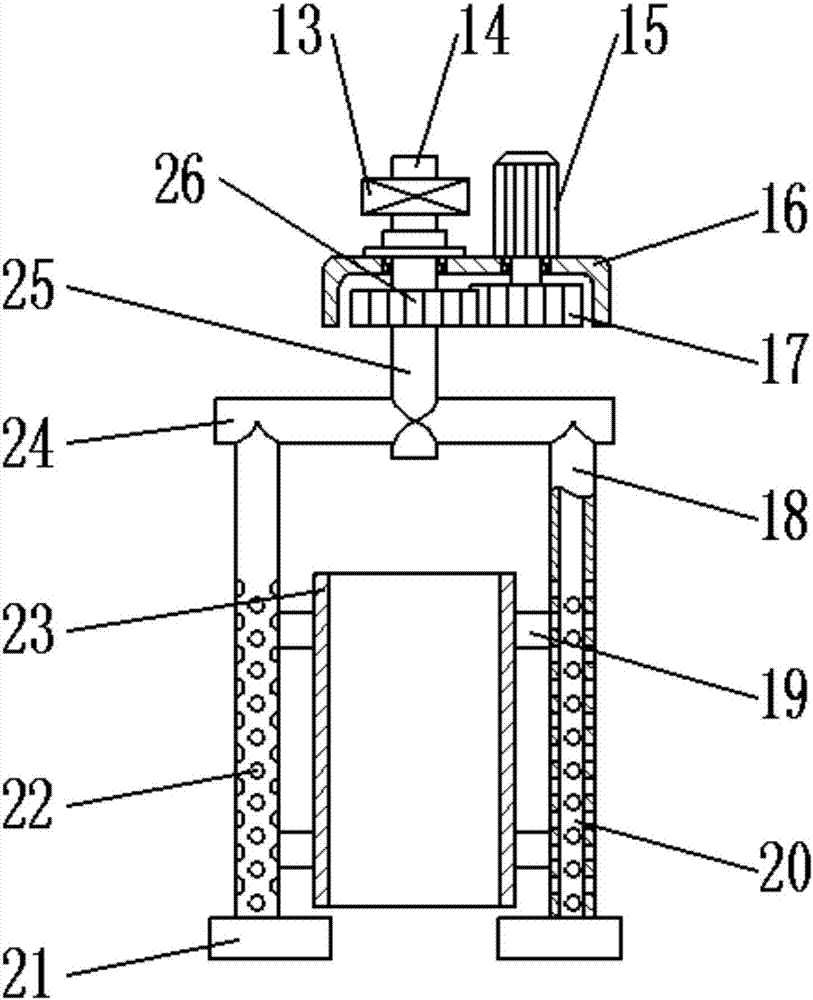

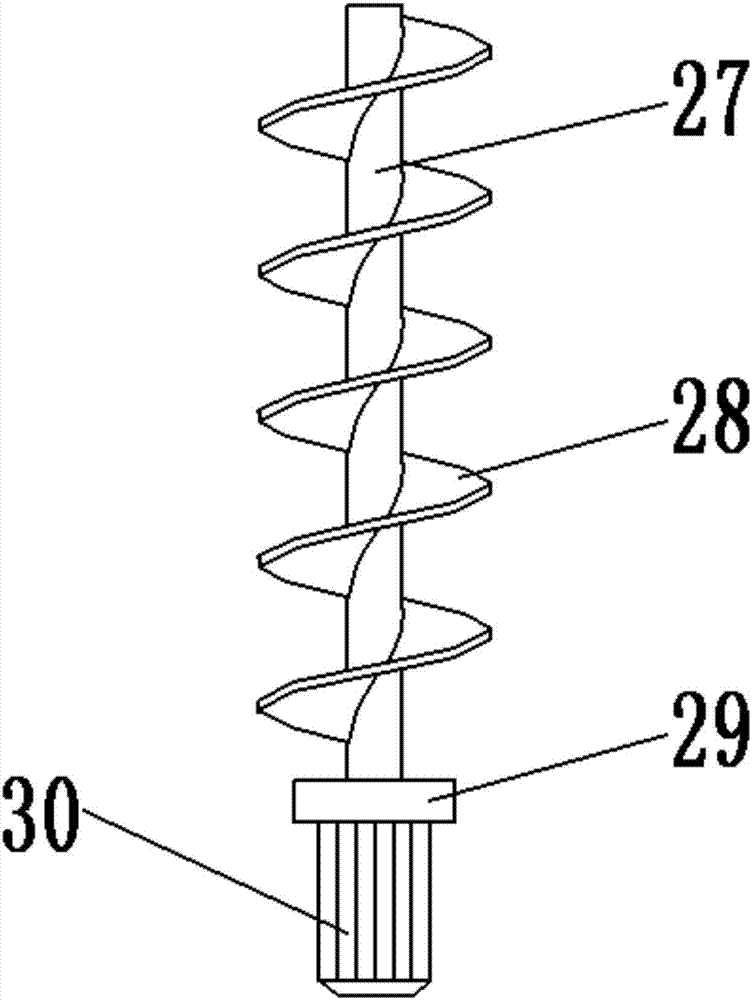

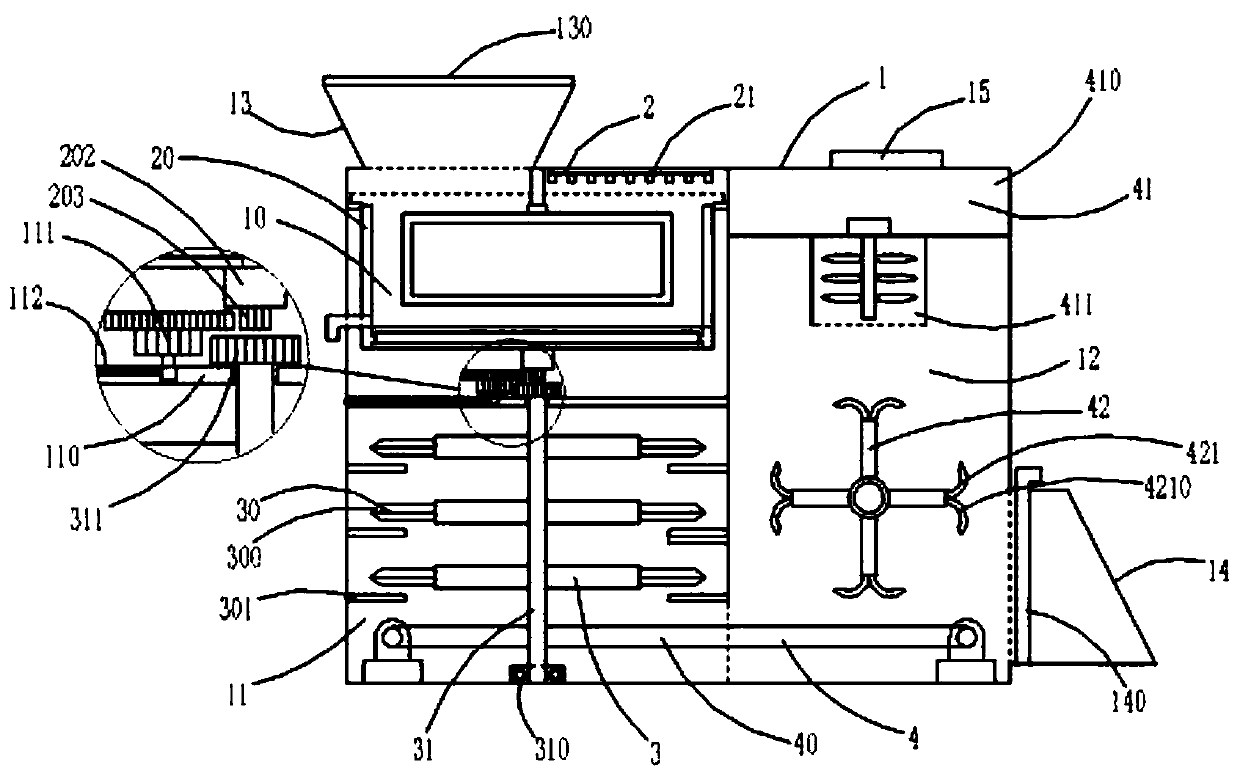

Plastic waste crushing and drying device

InactiveCN107906891AImprove drying degree and drying speedImprove drying uniformityPlastic recyclingDrying gas arrangementsScrapEngineering

The invention provides a plastic waste crushing and drying device, and belongs to the technical field of plastic recovery processing. The plastic waste crushing and drying device comprises a box body,a rotating motor, a motor frame, a filtering device, a base, supporting legs and a hot air blower; feeding hoppers arranged on the left side and the right side of the box body, and the feeding hoppers penetrate through the upper wall of the box body; and the rotating motor is arranged right above the box body. According to the device, a rotating shaft is driven by the rotating motor to rotate, the rotating shaft drives rotating crushing blades and a fixed blade to rotate relative to each other to carry out the crushing treatment on the plastic waste, so that the drying degree and the drying speed of the plastic can be improved; the plastic waste falling to the bottom of the box body is lifted upwards through the arrangement of a spiral stirring blade, and meanwhile, an electric heater isused for drying the plastic so that the drying uniformity of the plastic waste can be improved; and the plastic waste adhered to the inner wall of the box body is scraped off through the arrangement of a scraper so that the heat transfer of the electric heater can be facilitated, and rapid drying of the plastic waste can be facilitated.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

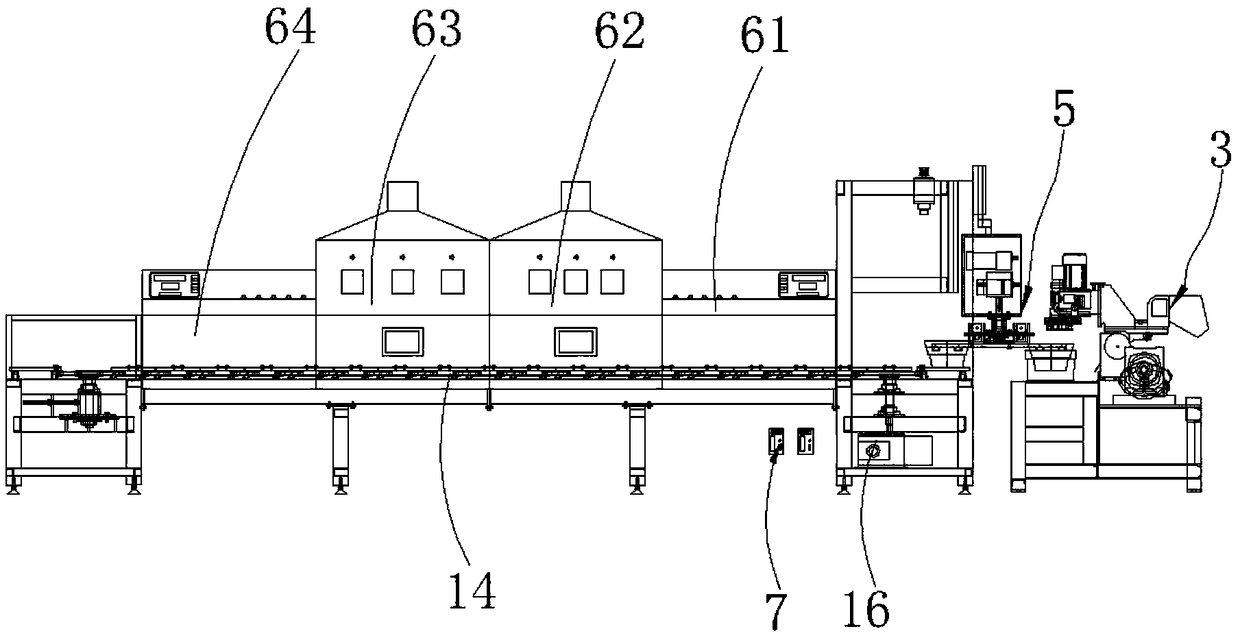

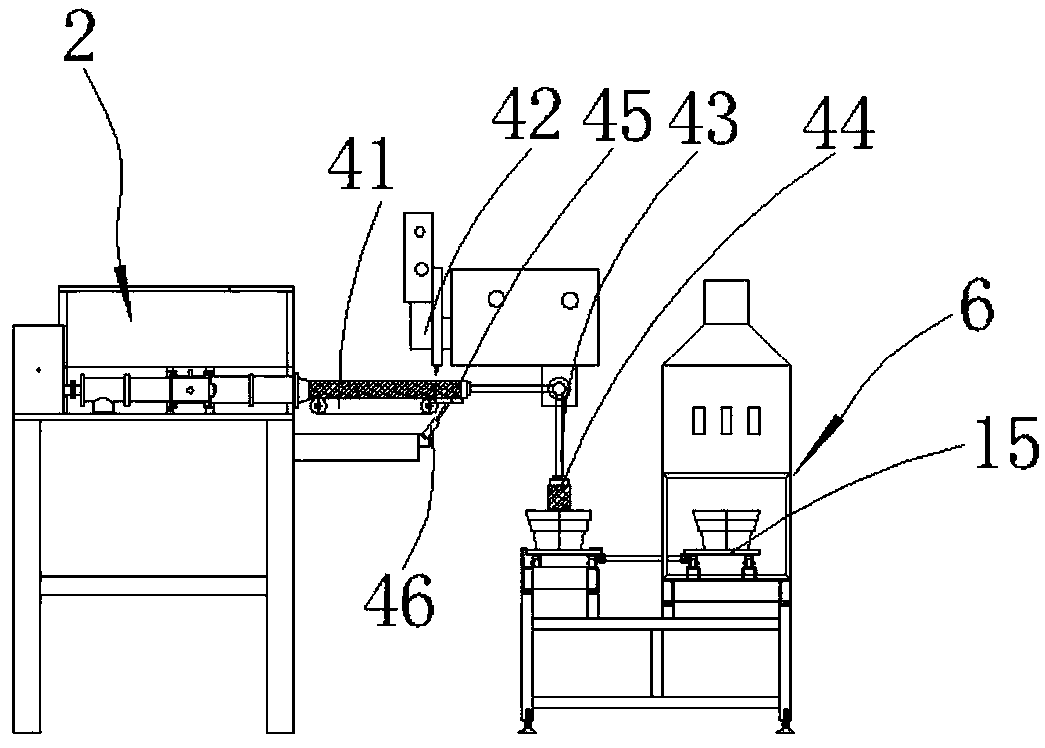

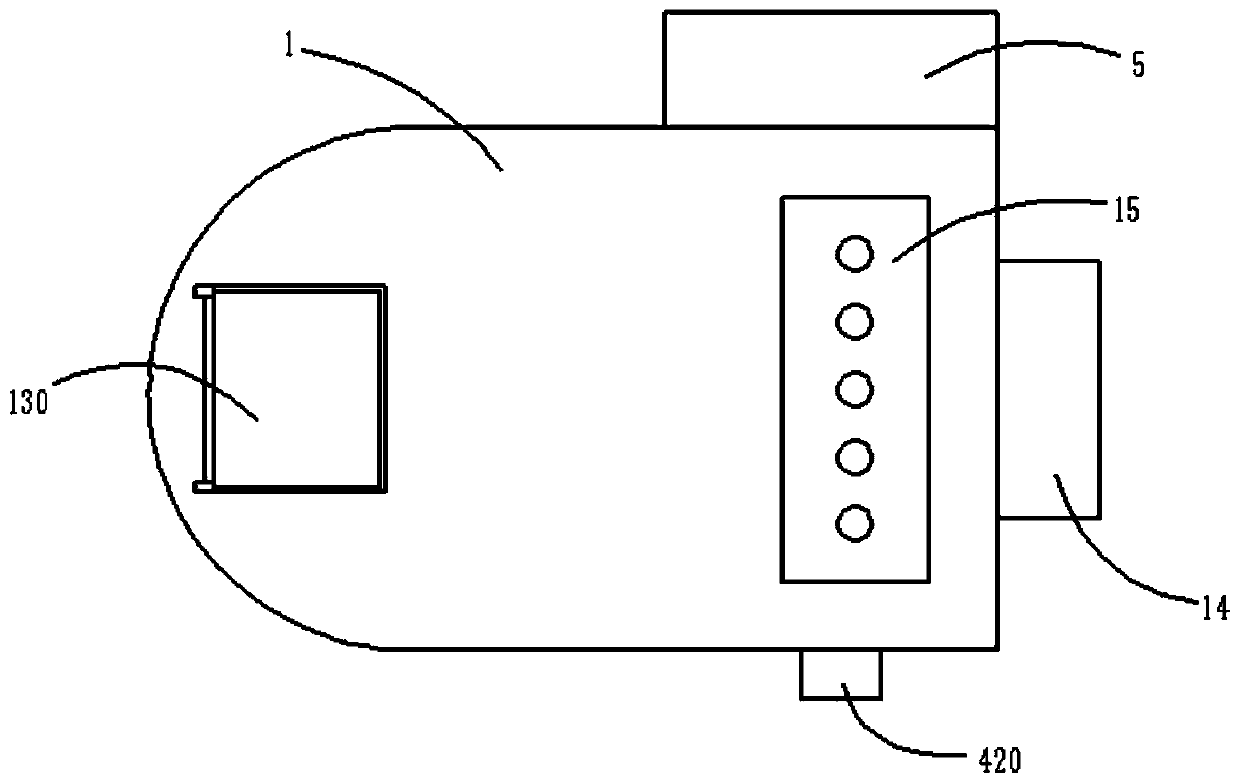

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

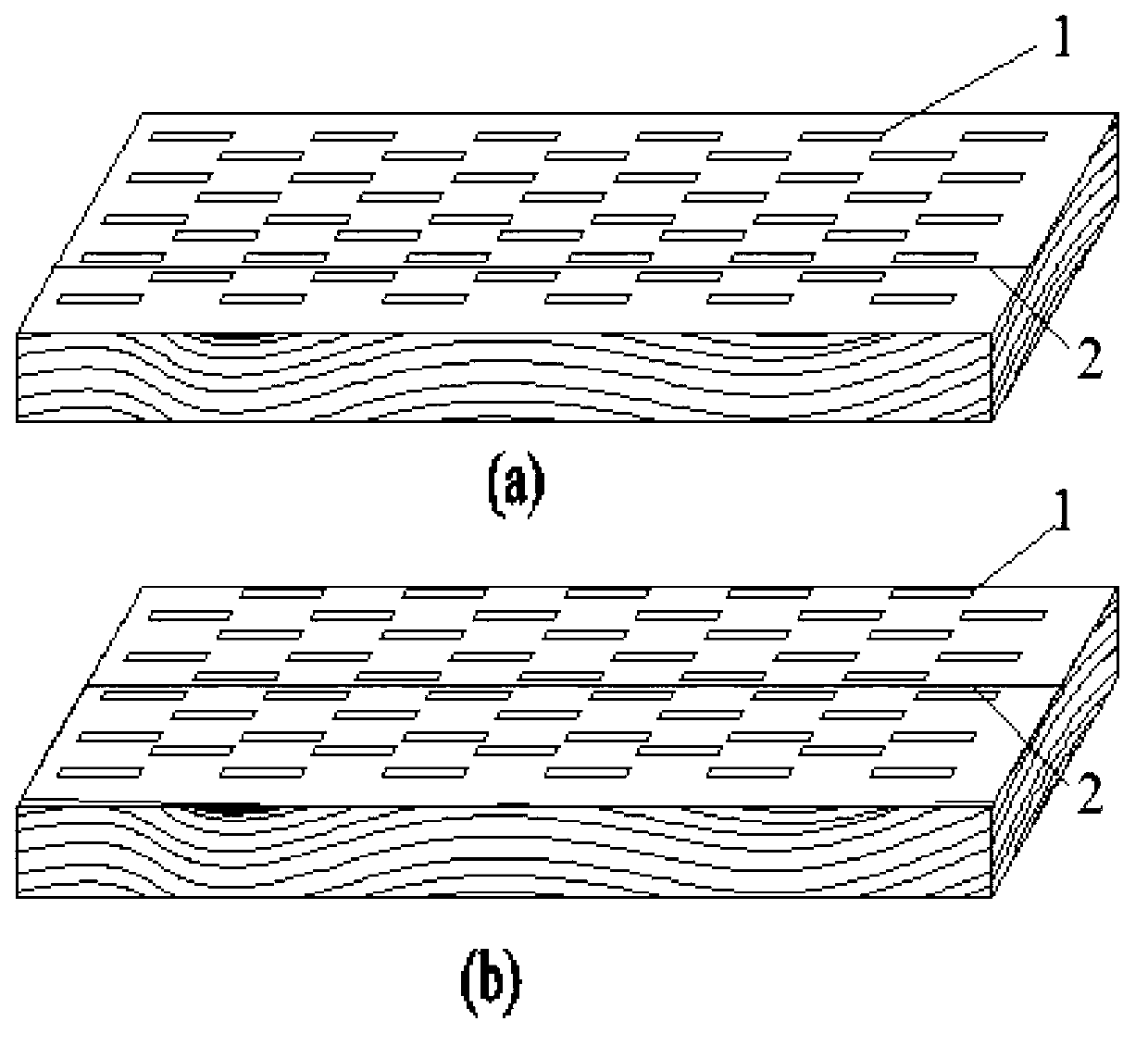

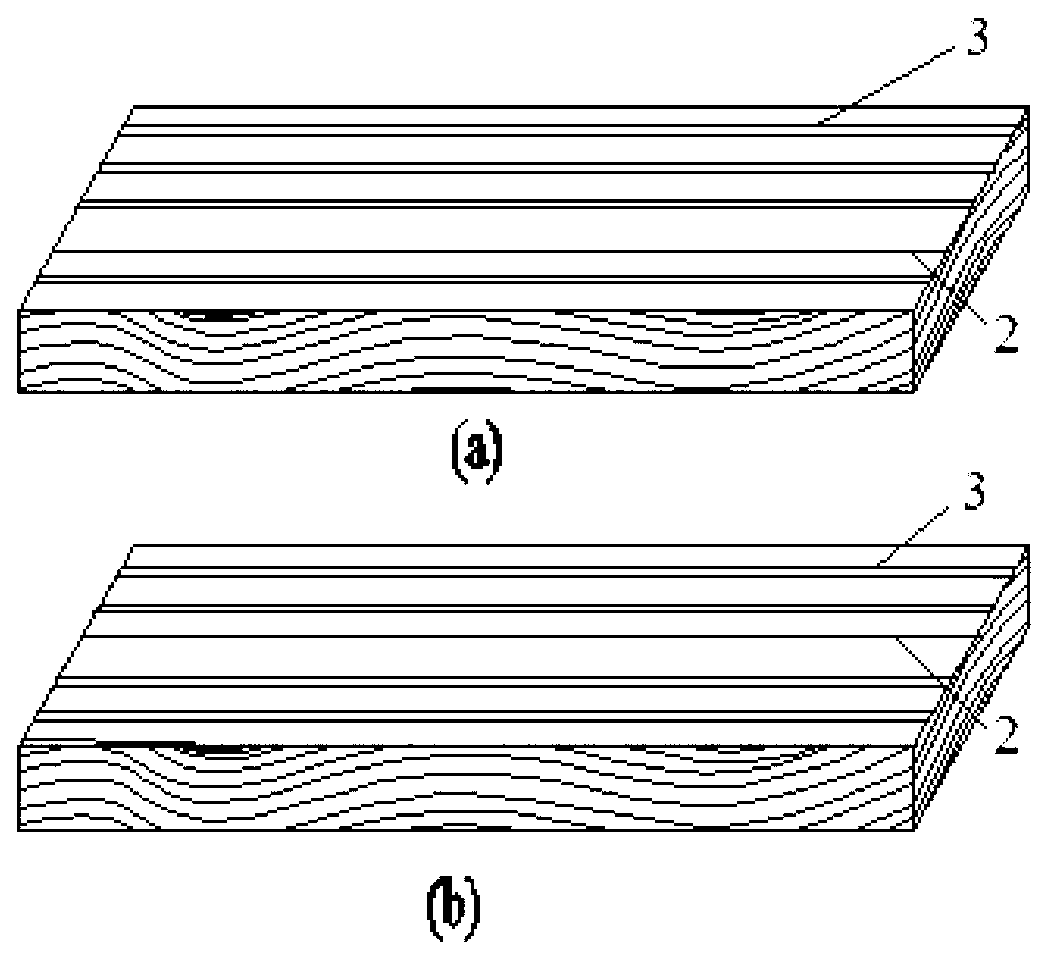

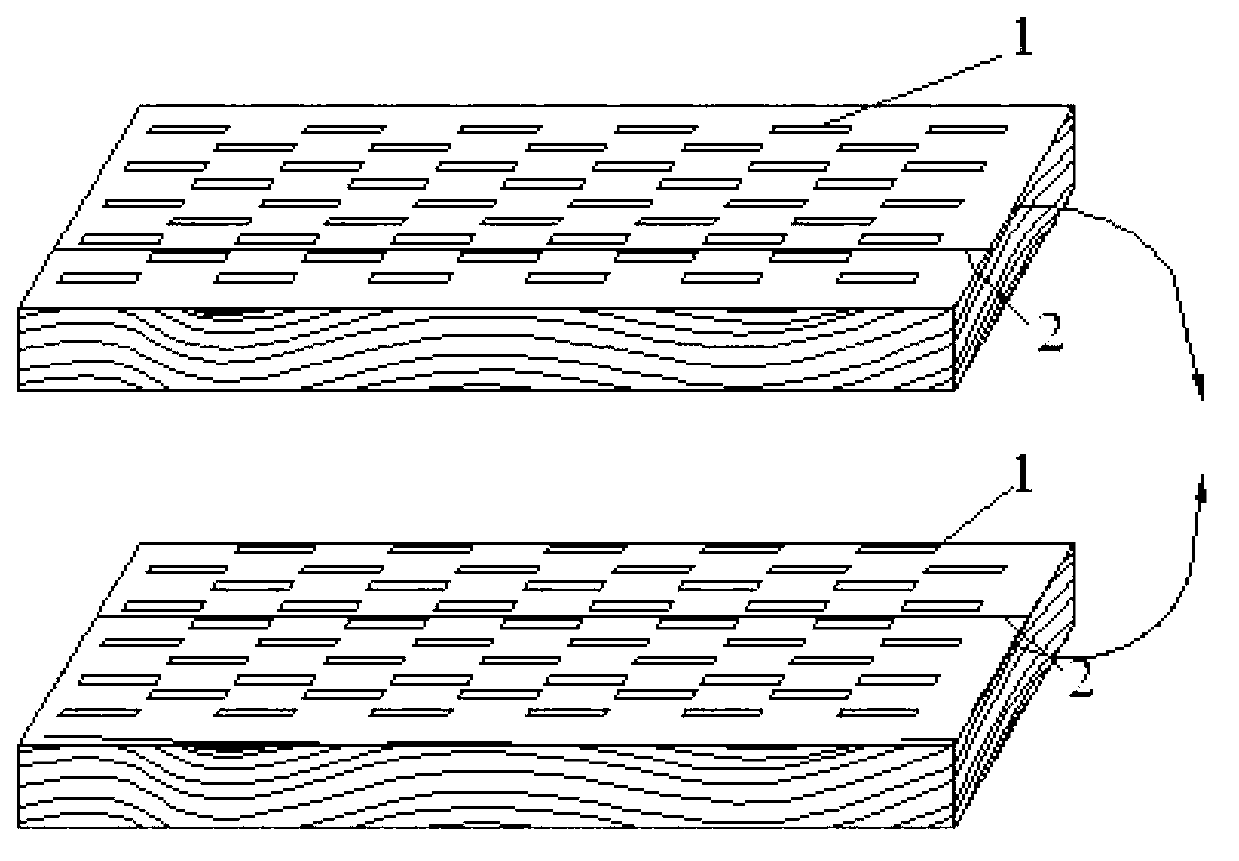

Glue laminated wood member with controllable dimensional stability and preparation method thereof

InactiveCN102990730AReduce crackingReduce laminate delaminationLaminationLamination apparatusSolid woodAdhesive cement

The invention discloses a glue laminated wood member with controllable dimensional stability and a preparation method thereof, belonging to the field of glue laminated wood preparation. The glue laminated wood member with controllable dimensional stability is composed of laminated sheets and adhesive layers through pressed superimposition, wherein each laminated sheet is an indentation laminated sheet which is processed by using solid-wood dimension stocks through transverse widening and longitudinal lengthening, the indentation laminated sheet is provided with continuous or discontinuous indentations along the texture direction, the adhesive layers adhered to the surfaces of the indentation laminated sheets are arranged between adjacent indentation laminated sheets, and adhesives are filled in the indentations. The glue laminated wood member with controllable dimensional stability is prepared through the steps of processing indentations, controlling the moisture content and the like, and the prepared glue laminated wood member with controllable dimensional stability solves the problems that the durability of common glue laminated wood members is poor caused by that middle-layer plates of the common glue laminated wood members are delaminated or subjected to shear failure or the stress between laminated sheets is concentrated due to environment temperature changes, or the quality of members prepared by using fast-growing wood is uncontrollable, the strength of the members is degraded caused by traditional wood removal through slotting, and the like.

Owner:NANJING UNIV OF TECH

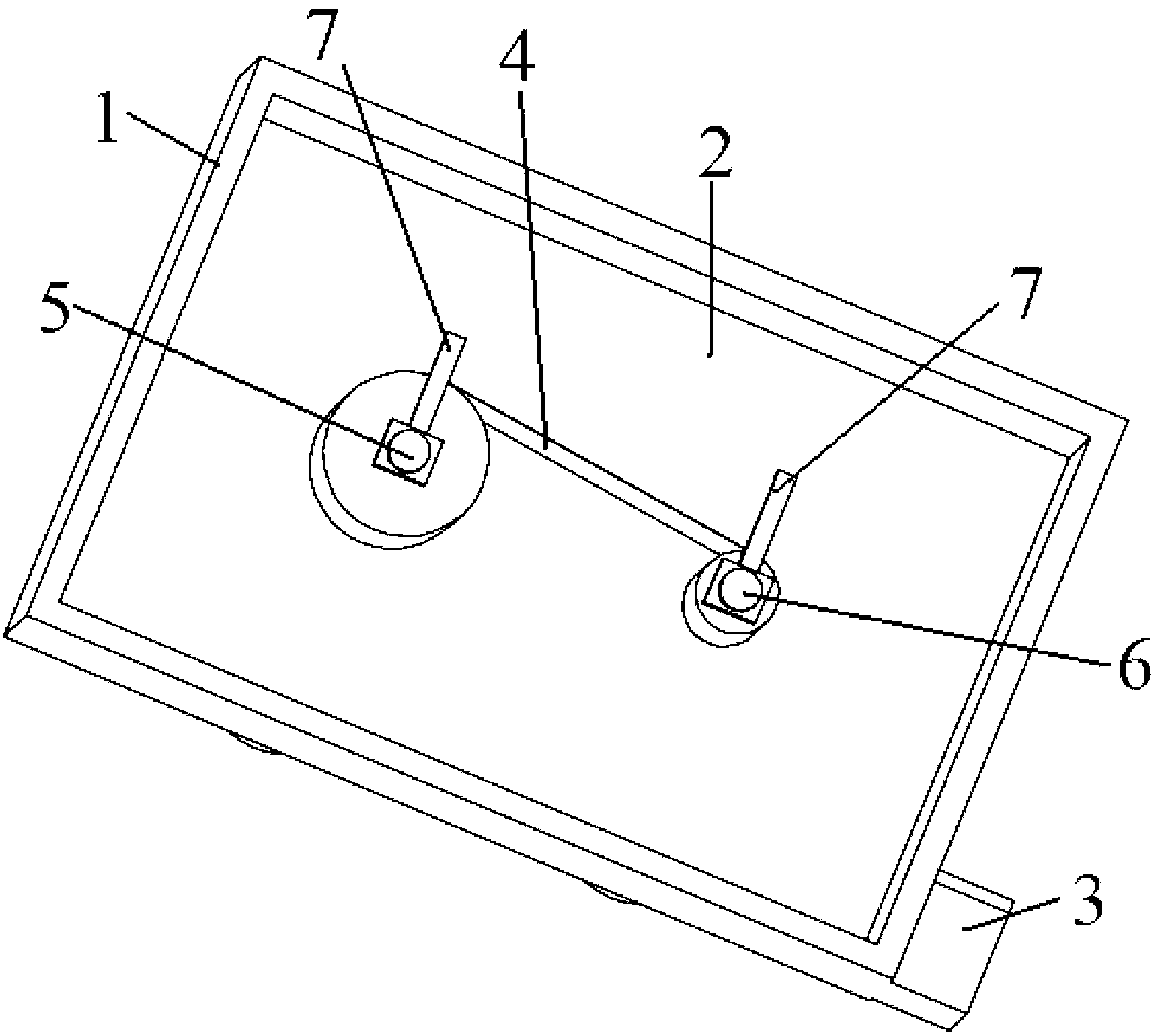

Drying device for wood boards for furniture

InactiveCN107401904AAchieve dryingImprove drying efficiencyDrying gas arrangementsDrying chambers/containersRotational axisDrive wheel

The invention discloses a drying device for wood boards for furniture. The drying device comprises a drying cylinder, a fixed plate, a blower, a motor, heating blocks, a heating wire, a rotary shaft and a bearing plate. The drying device is characterized in that the drying cylinder is arranged on brackets, the fixed plate is arranged between the brackets, the blower is arranged on the fixed plate, the motor is arranged on the fixed plate, a power line and a driving wheel are arranged on the motor, the heating blocks are arranged in the drying cylinder, power lines are arranged on the heating blocks, the heating wire is arranged between the heating blocks, one end of the rotary shaft is arranged in a bearing, the other end of the rotary shaft passes through the bearing, a driven wheel is arranged on the rotary shaft, and the bearing plate is arranged on the rotary shaft by virtue of an installation ring. According to the drying device, the heating wire is arranged between the heating blocks in the drying cylinder, and heat can be supplied to a drying chamber by virtue of the heating wire, so that the wood boards in the drying cylinder are dried.

Owner:李琪

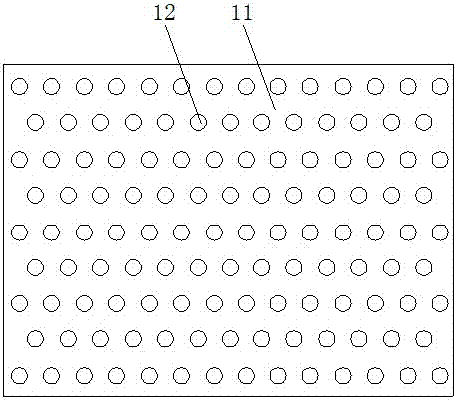

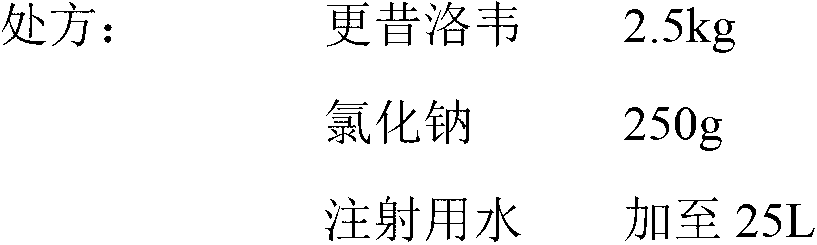

Ganciclovir for injection and preparation method thereof

ActiveCN103054819AAdvantages and Notable ImprovementsImprove yieldPowder deliveryInorganic non-active ingredientsMedicineFreeze-drying

The invention discloses ganciclovir for injection and a preparation method thereof. The preparation is formed by regulating the pH of a solution containing ganciclovir and sodium chloride to 10.0-11.5 by adopting a pH regulator, and freezing and drying repetitively. The freeze-dried powder injection of the ganciclovir for injection has the advantages of high yield, good re-dissolubility, more stable quality and the like; change of related substances during the period of accelerated test is not obvious; and the ganciclovir for injection is safer for clinical application.

Owner:BEIJING WANPENGLANGGE PHARMA TECH

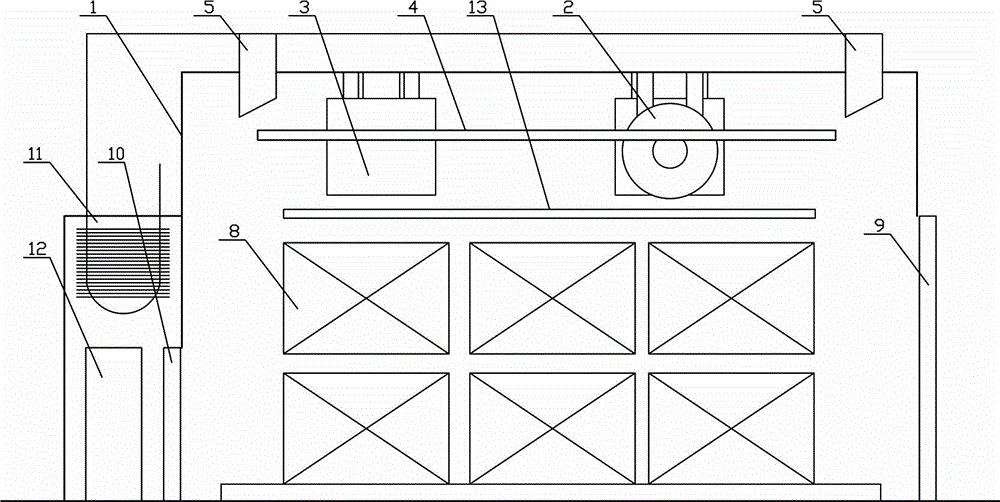

Hot air circulating oven for medicinal materials

InactiveCN106091607AImprove drying uniformityAvoid wastingDrying gas arrangementsDrying solid materialsEngineeringPulp and paper industry

The invention provides a hot air circulating oven for medicinal materials. The hot air circulating oven comprises an oven, wherein a placing platform is arranged in the oven and is arranged on the inner wall of the oven through sliding tracks at two sides; the oven is provided with an air heater; a movable track is arranged between the air heater and the inner wall of the oven; the air heater moves left and right through a moving device arranged on the movable track; and two sides of the upper end surface of the placing platform are provided with detecting devices through which the position of the air heater on the movable track is controlled. The medicinal materials are dried through the oven, the movable track and the moving device drive the air heater to move left and right, and furthermore, the medicinal materials are dried on a fixed point by virtue of hot air; the residual heat is recovered by using a heat recovery device, so that resource waste is avoided, and the drying uniformity of the medicinal materials is improved; and a dehumidifying device is arranged for dehumidifying the inside of the oven, so that the drying efficiency is increased.

Owner:WUHU YANGYAN PHARMA

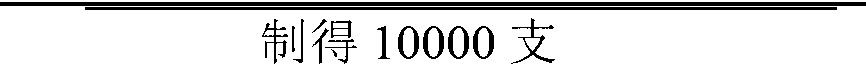

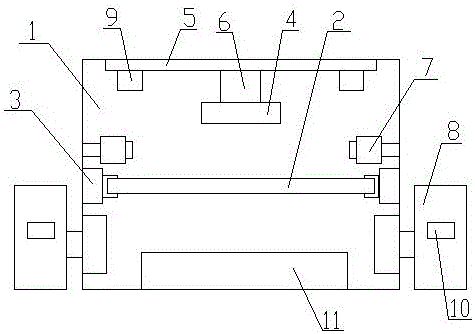

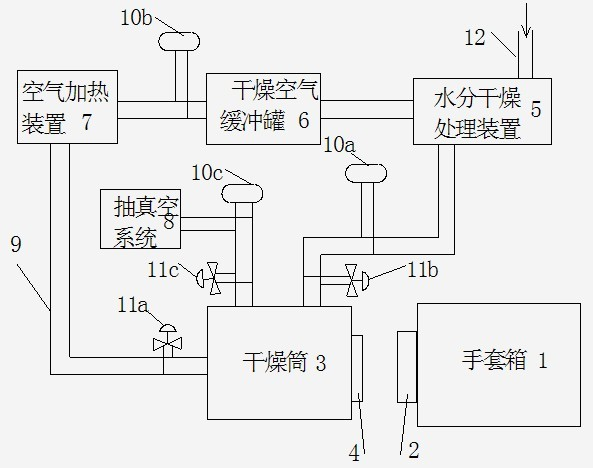

Drying system for lithium ion battery cores

InactiveCN102620543AKeep dryQuality improvementFinal product manufactureDrying gas arrangementsManufacturing cost reductionProcess engineering

Owner:惠州市博能新能源有限公司

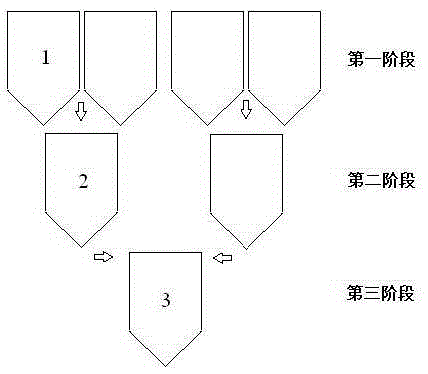

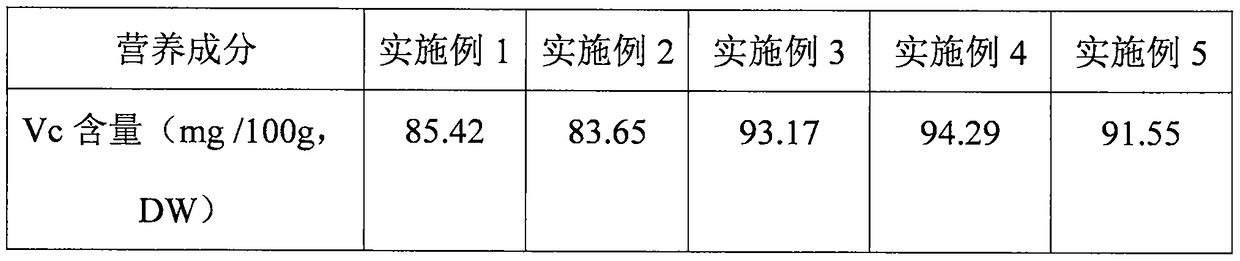

Method for rapid preparation of fruit and vegetable crisp grains by three-stage atmospheric pressure microwave spouting drying

The invention discloses a method for rapid preparation of fruit and vegetable crisp grains by three-stage atmospheric pressure microwave spouting drying, and belongs to the fruit and vegetable food treatment technical field. The method comprises the technological process for preparation of the fruit and vegetable crisp grains: carrying out fresh fruit and vegetable raw material pretreatment comprising selection, cleaning, grain-sized dicing, blanching and enzyme deactivation and color protection treatment, carrying out three-stage atmospheric pressure microwave spouting drying of the pretreated fruit and vegetable grains, and carrying out packaging storage. Compared with a single hot air drying, the adopted microwave drying technology has the energy saved by 50%-55% and the time shortened by 60%-65%; compared with a single-stage atmospheric pressure microwave spouting drying, the adopted technology has the energy saved by 20%-30% or more and the time shortened by 20%-30%. The pulse spouting is beneficial for improving the uniformity of material drying, and can improve the quality of the fruit and vegetable dried products; besides, the three-stage drying can effectively improve the material loading capacity and the utilization rate of energy consumption, and is beneficial for integrated application of the microwave drying technology and equipment in the fields of agricultural products and food processing.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

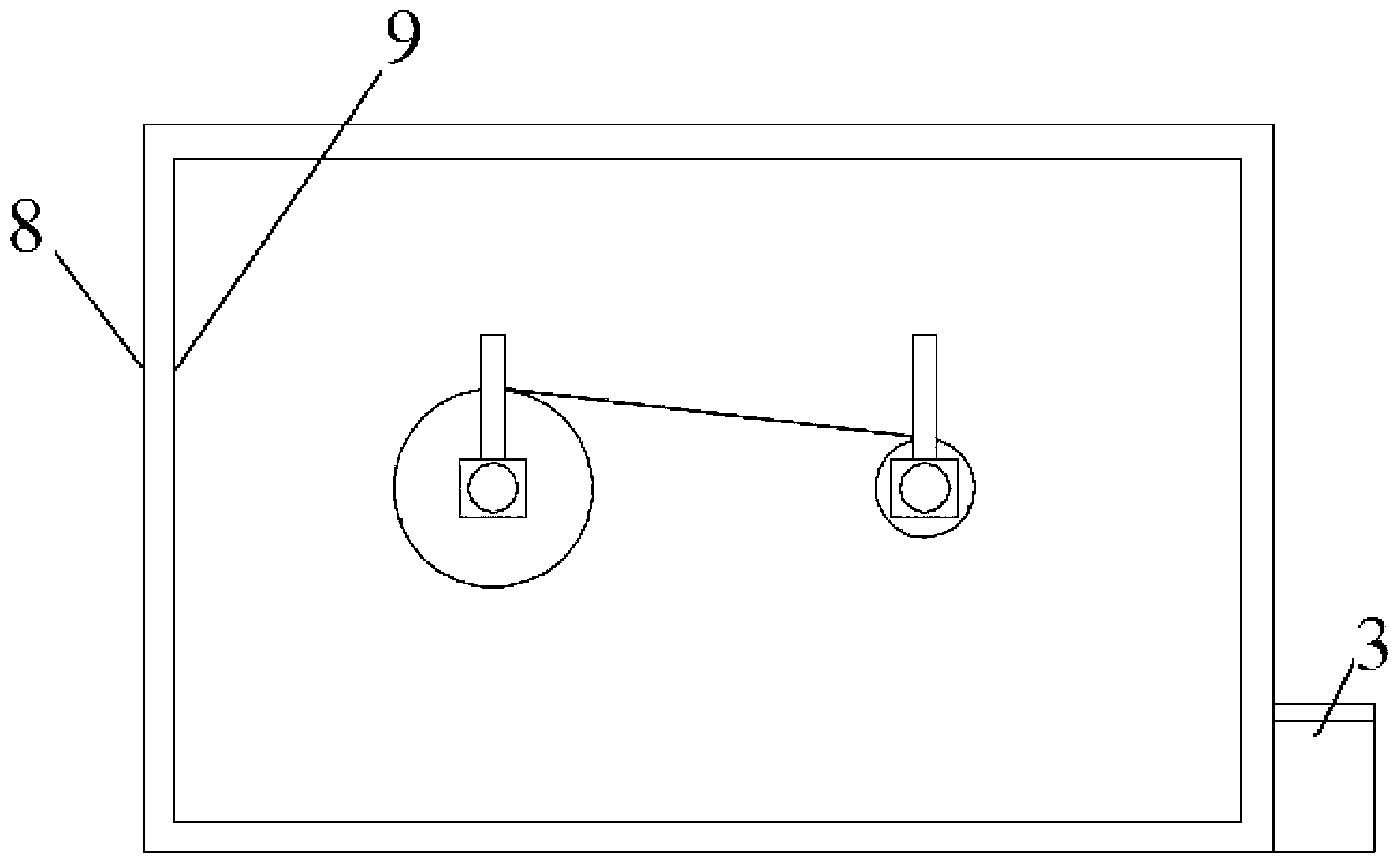

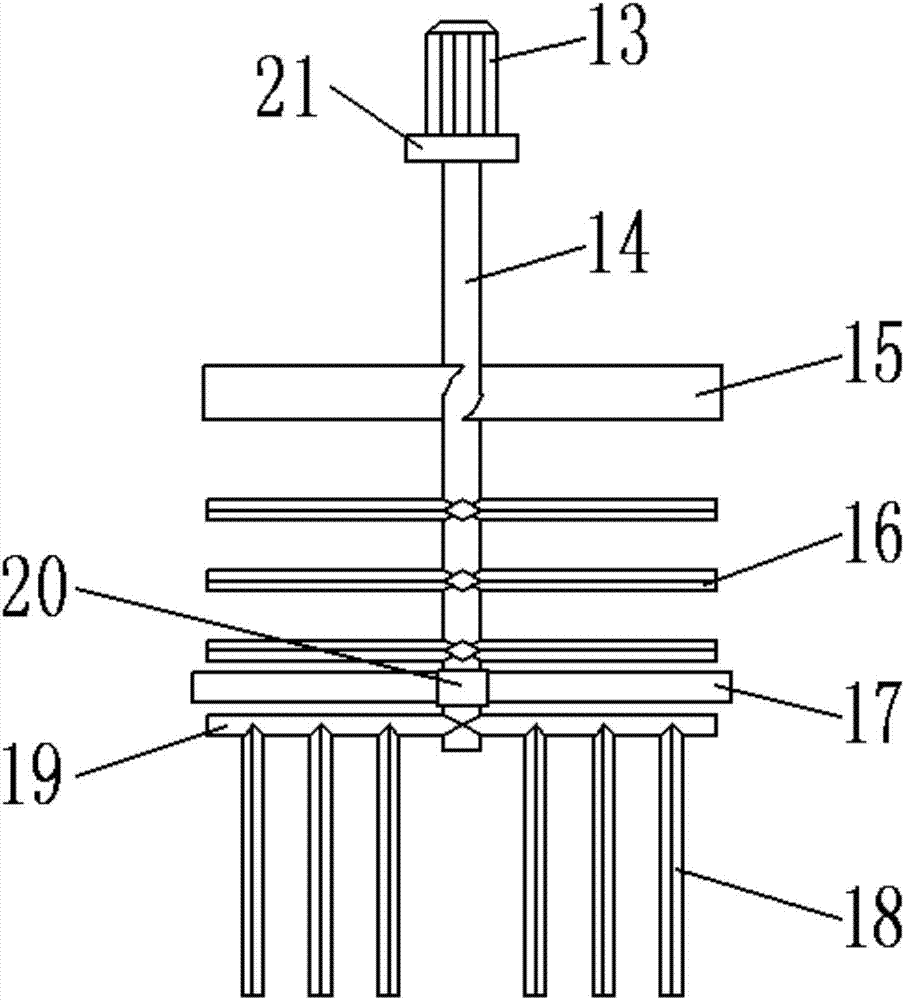

Vacuum oven and drying method of power lithium ion cell pole piece

ActiveCN103256792AEvenly bakedImprove drying uniformityDrying machines with progressive movementsHeating arrangementVacuum pumpingLithium

The invention discloses a vacuum oven and a drying method of a power lithium ion cell pole piece. The vacuum oven comprises an oven body, a heating device and a vacuum pumping device. A drying chamber is arranged in the oven body. Two parallel rotatable rotation shafts are arranged in the drying chamber. Two ends of a pole piece roll material are wound on the two rotation shafts respectively. Compared with the prior art, the two rotation shafts are arranged and rotate in two directions to drive the pole piece roll material to be wound back and forth. In the process of rolling the pole piece roll material, the heating device can dry the pole piece roll material at the same time. The pole piece roll material can be wound back and forth to ensure that pole pieces of all parts can be evenly dried. Thus, drying uniformity of the cell pole piece is improved.

Owner:奇瑞新能源汽车股份有限公司

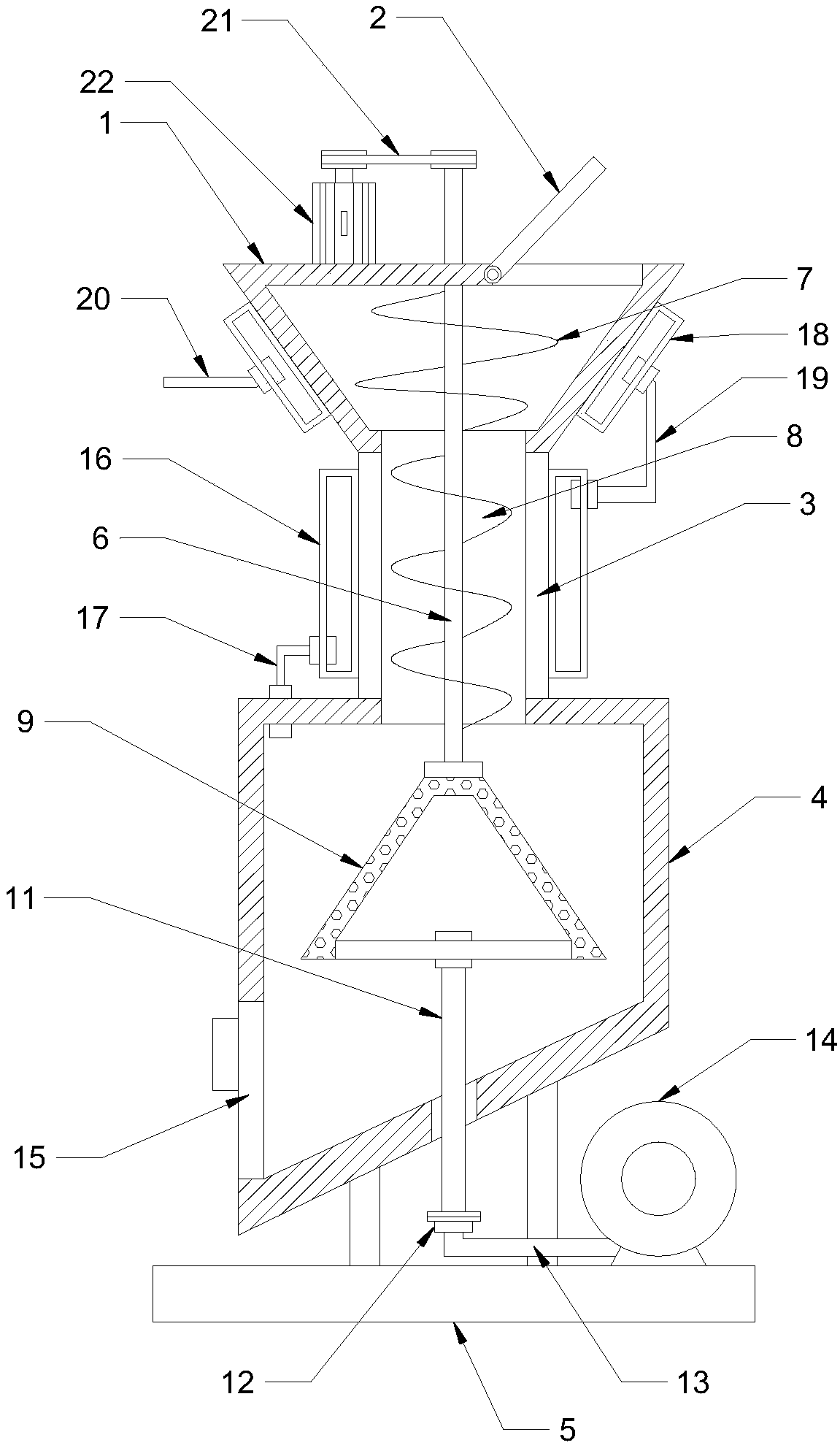

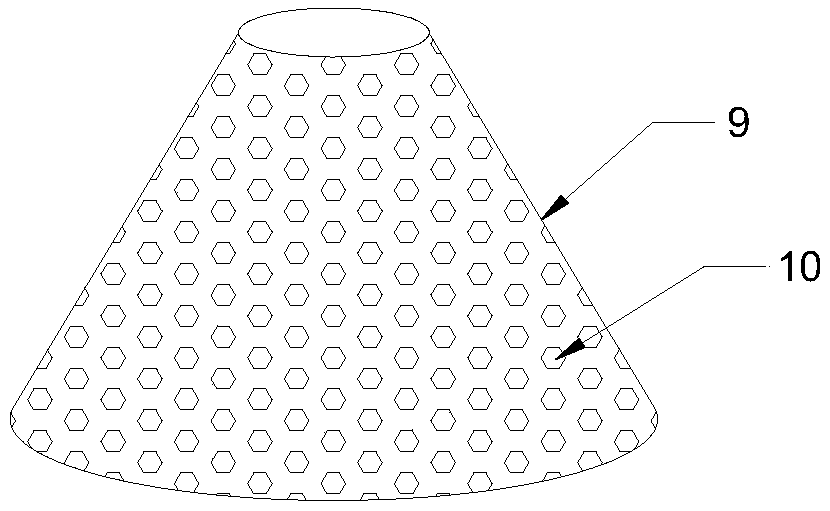

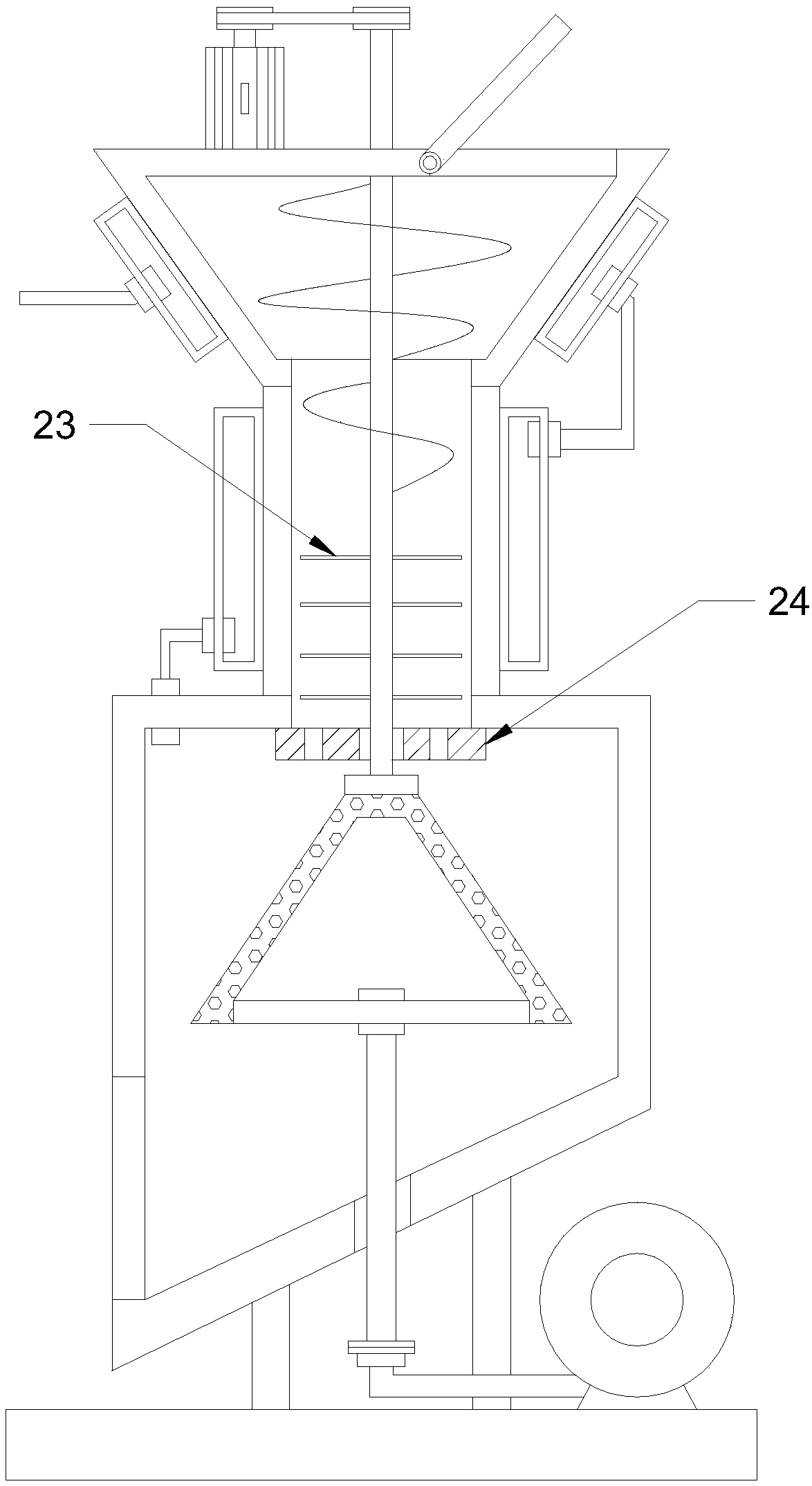

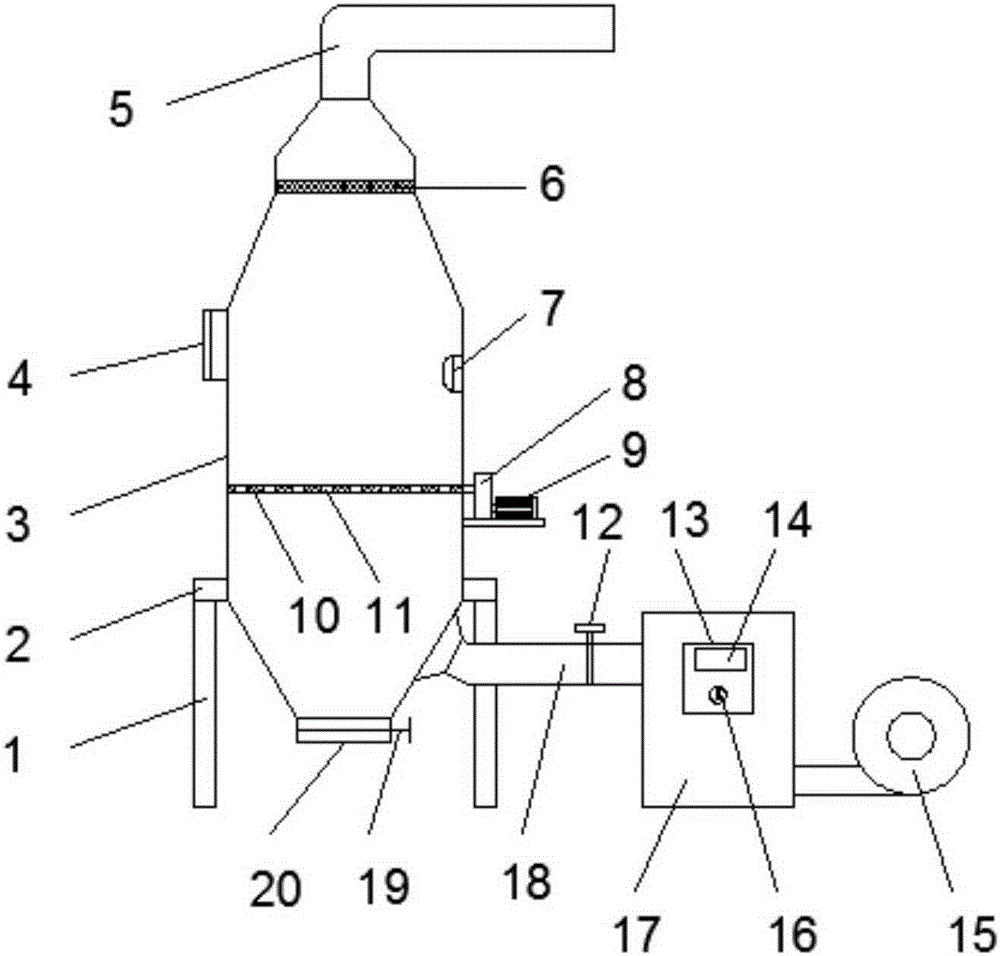

Energy-saving feed particle drying equipment

InactiveCN109631498ABlow evenlyEven and efficient dryingGranular material dryingDrying gas arrangementsEngineeringExhaust pipe

The invention discloses energy-saving feed particle drying equipment. The energy-saving feed particle drying equipment comprises a storage hopper, a feeding pipe and a drying box. The drying box communicates with the lower end of the storage hopper through the feeding pipe. A first preheating jacket sleeves the outer side of the feeding pipe, the first preheating jacket communicates with the innercavity of the drying box through a first communicating pipe. A second preheating jacket sleeves the outer side of the storage hopper, the second preheat jacket communicates with the first preheat jacket through a second communicating pipe, and the second preheating jacket communicates with an exhaust pipe. According to the energy-saving feed particle drying equipment, through a drying cylinder being a hollow cone, a drum, a rotating joint and an air heater, the uniform blowing of hot air from meshes of the drying cylinder is realized, feed particles spread and sliding down from the surface ofthe drying cylinder are evenly and efficiently dried, and the drying uniformity and the drying effect are improved; and the feed particles are preheated by arranging the first preheat jacket and thesecond preheat jacket, subsequent drying is facilitated, and meanwhile, heat is used fully.

Owner:柳良红

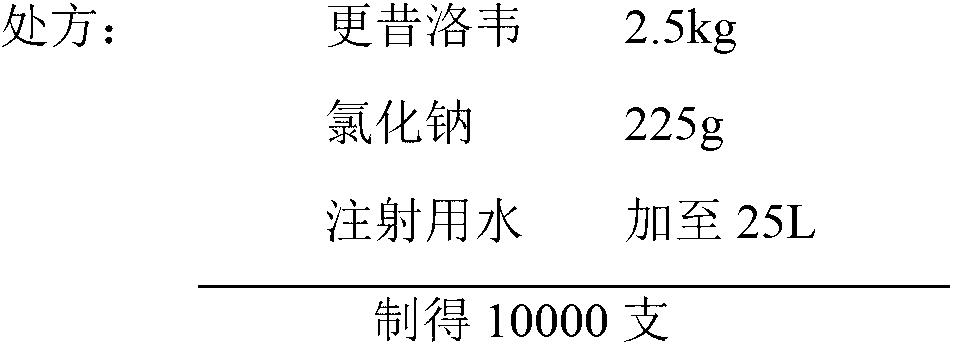

Integral cleaning type medicine drying box

ActiveCN104913607AReasonable structural designAvoid cross contaminationDrying gas arrangementsDrying machines with local agitationInsulation layerEngineering

The invention discloses an integral cleaning type medicine drying box. The integral cleaning type medicine drying box comprises a box body with a box door, and is characterized in that the box door is arranged on the front of the box body, a box container is arranged in the box body, a drying cavity is arranged in the box container, an air distribution adjusting sheet and a primary-efficiency filter screen are sequentially arranged on two sides of the drying cavity from inside to outside respectively, a circulating air return cavity is arranged on the left side of the box container, and a circulating air feed cavity is arranged on the right side of the box container. A heat insulation layer is arranged between the box container and the box body, a control box is arranged on the right side of the box body, the top of the right of the box body is provided with an air inlet, a circulating fan is arranged at an air inlet, ventilation and heat radiation pipes are arranged beside the circulating fan, the top of the left side of the box body is provided with a moisture discharge outlet, a dehumidifying fan is arranged at the moisture discharge outlet, a heat exchanger is arranged in the middle of the top of the box body, the air inlet end of the heat exchanger is provided with an intermediate-efficiency filter, and the air outlet end of the heat exchanger is provided with a high-efficiency filter. The integral cleaning type medicine drying box is reasonable in structure, convenient to clean, simple to operate, safe in use, energy saving, environment friendly and wide in using range.

Owner:SICHUAN GUOKANG PHARMA

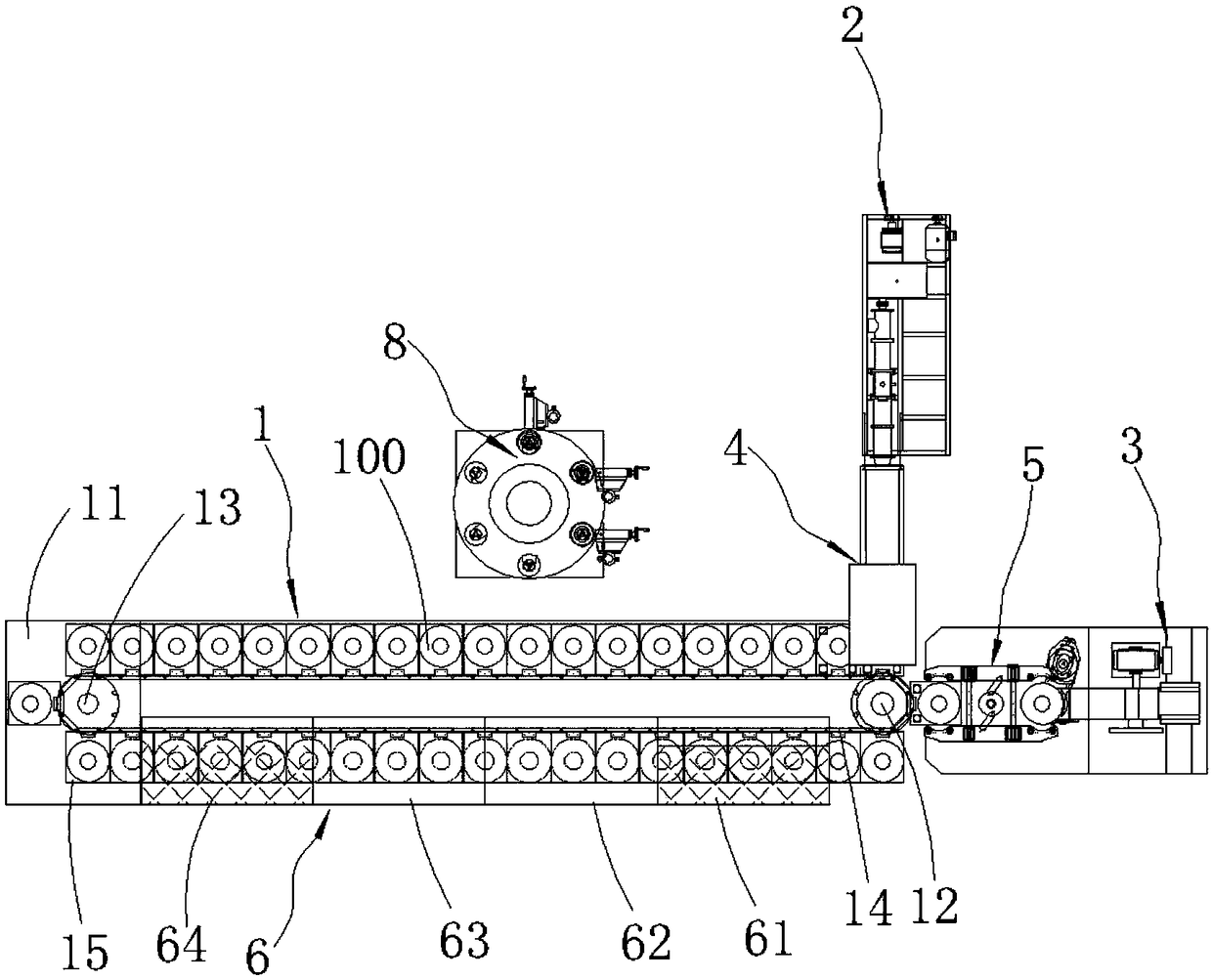

Ceramic microwave automatic forming line and ceramic forming method

InactiveCN108608567AAvoid crackingReduce labor costsCeramic shaping plantsFeeding arrangmentsProduction lineMicrowave

The invention relates to the field of ceramic microwave automatic forming lines and ceramic forming methods, in particular to a ceramic microwave automatic forming line and a ceramic forming method. The ceramic microwave automatic forming line and the ceramic forming method are characterized by comprising a circulated conveying line, an automatic pugging machine and an automatic forming machine, the circulated conveying line is sequentially provided with an automatic mud putting machine, an automatic mold clamping machine and a microwave drying box, the automatic pugging machine is connected with the circulated conveying line through the automatic mud putting machine, and the automatic forming machine is connected with the circulated conveying line through the automatic mold clamping machine. Manual transferring labor is not needed for joining parts between equipment of the ceramic microwave automatic forming line, the automatic degree is high, the production efficiency is high, and the space occupied by the equipment is small; by means of the ceramic forming method, the labor cost is saved, the operation accuracy is high, and the finished product rate is improved; and compared with a traditional drying manner, the microwave drying manner is good in drying uniformity, a blank body is not prone to cracking, the drying time is short, and the energy consumption is low.

Owner:福建省德化博龙陶瓷有限公司

Multifunctional paddy drying device

InactiveCN108458583AImprove automation performanceImprove storage effectDrying gas arrangementsDrying chambers/containersPulp and paper industryAutomation

The invention discloses a multifunctional paddy drying device, and belongs to the technical field of paddy drying equipment. The device comprises a barn, where a drying chamber is connected to the lower end of the barn; a hot air system is arranged in the drying chamber; a drying tank is connected to the lower end of the drying chamber; a returning tank is connected to one side of the drying tank;a bottom door is arranged on the bottom part of the drying tank; a filter plate is inclinedly connected to the upper end of the bottom door; filter holes with the hole diameters being smaller than paddy particles are formed in the surface of the filter plate; and sponge rings consistent to the specifications of the filter holes are connected to the upper surfaces of the filter holes. The multifunctional paddy drying device provided by the invention is high in automation degree, simple and convenient to operate, fast in drying speed, high in uniformity and high in reliability; and after drying, the head rice rate of paddy is high, the edible quality of the paddy can be improved, and a storage property is prolonged.

Owner:浦江县晶富农业科技有限公司

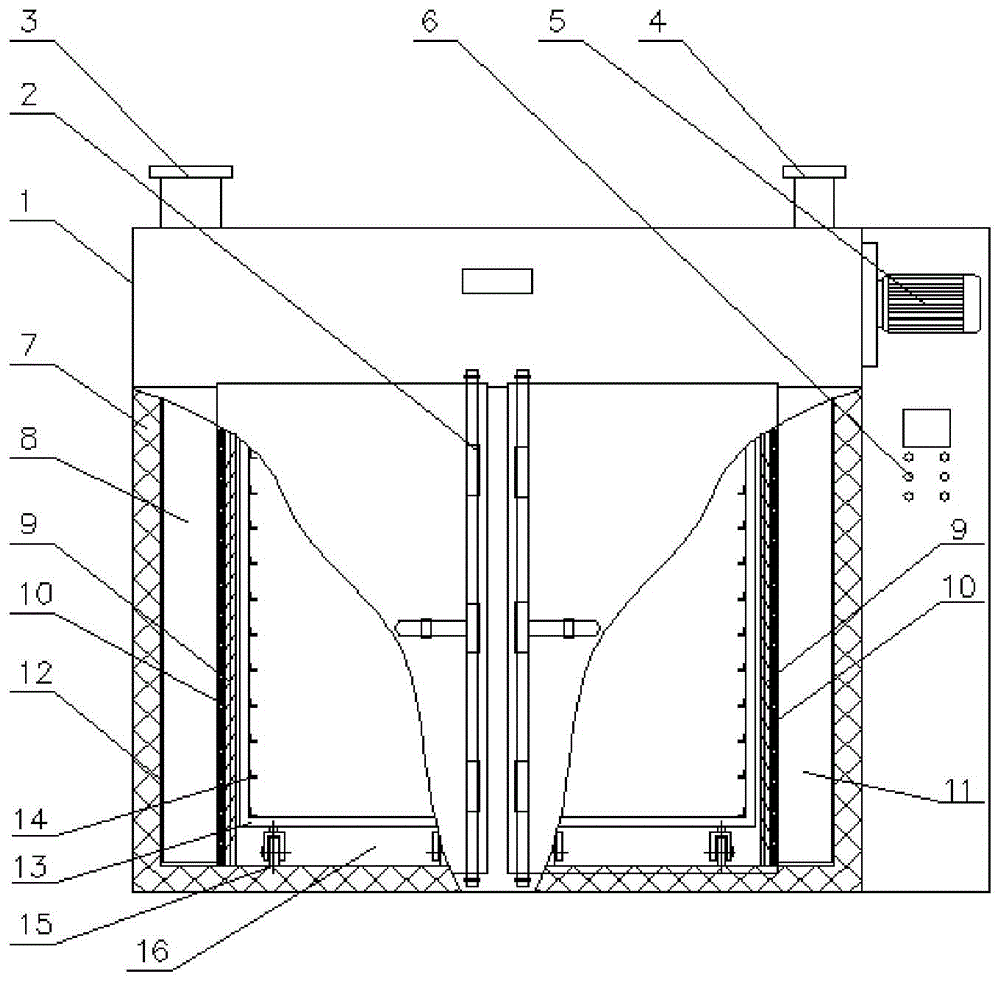

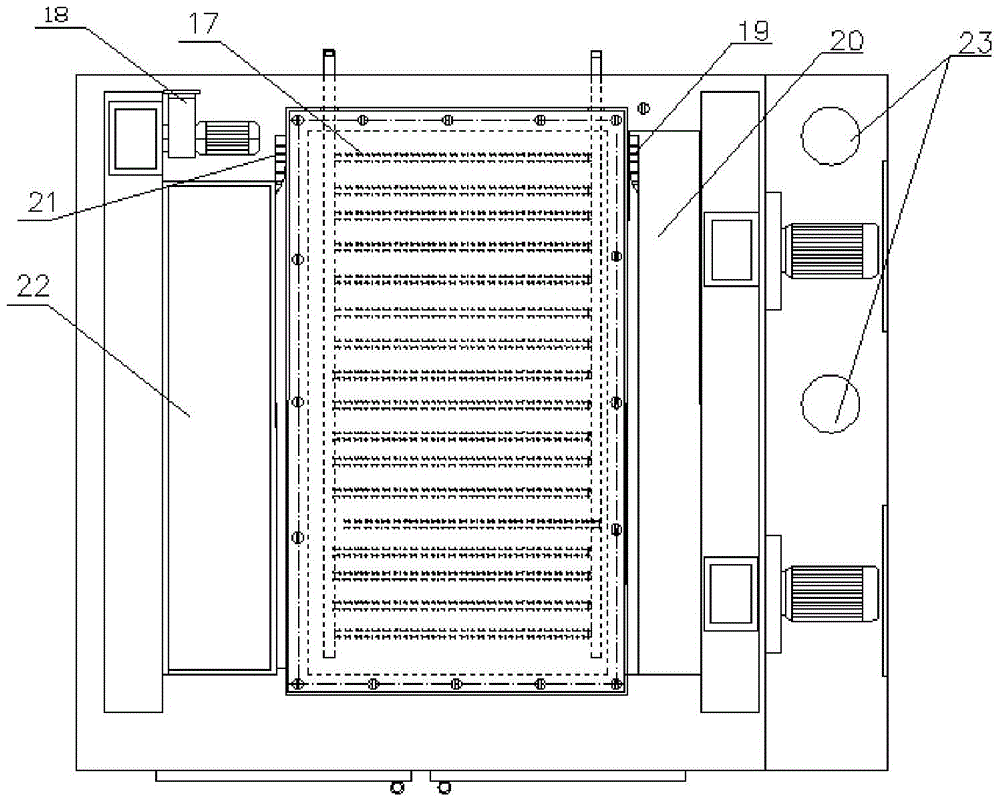

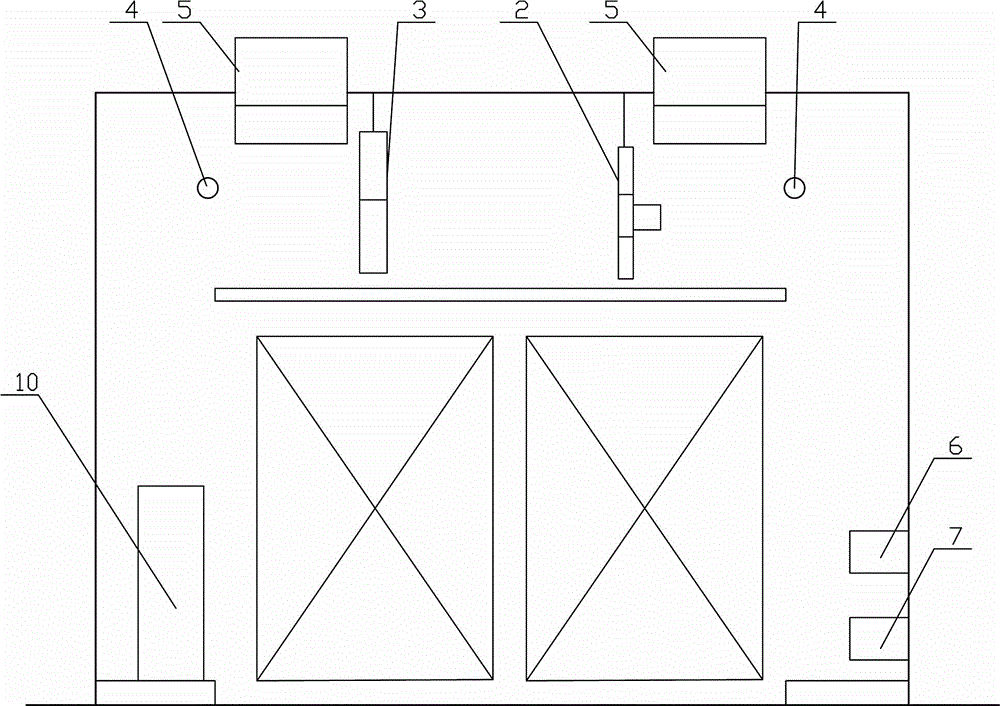

Lumber drying kiln

ActiveCN104964527AUniform temperatureReduce energy consumptionDrying gas arrangementsDrying chambers/containersEngineeringProcess engineering

A lumber drying kiln comprises a kiln body which is provided with a main kiln door. The kiln body is internally provided with at least one set of air feeding device and heating device. A plurality of exhausting devices are arranged in the kiln body. A temperature and humidity detecting device and a moisture content detecting device are arranged in the kiln body. According to the lumber drying kiln, the temperature in the kiln is even by means of the air feeding and heating mode, a steam spraying pipe is matched, the temperature and humidity in the kiln are easy to adjust and control, the energy utilization rate is high, and the energy conservation effect is good; an air speed field, a temperature field and a humidity field are uniform in distribution, and the drying uniformity is good; the drying efficiency is high, and the comprehensive technological economic performance is good. After the lumber drying kiln is adopted, the drying cycle is shortened by 33%, color changing, decaying and worm damage are zero, internal cracking is zero, end cracking and surface cracking is 0.6%, deformation is also greatly relieved, and the internal stress is fully eliminated.

Owner:宜昌金宝乐器制造有限公司

Quartz sand circulation drying equipment used in building construction

InactiveCN107270678AEasy to cycle dryImprove drying uniformitySand dryingDrying gas arrangementsHollow coreHollow cylinder

The invention provides a quartz sand circulation drying equipment used in building construction, which includes a tank body; There is a bottom cover; the feed pipe is welded and fixed on the left side of the upper cover; the exhaust pipe is welded and fixed on the top side wall of the tank; the exhaust fan is arranged on the exhaust pipe; the discharge is welded and fixed on the left side of the bottom cover tube, the bottom surface of the bottom cover is welded and fixed with a bracket; the interior of the tank is set as a drying chamber; the drying chamber is provided with a hot gas uniform distribution and stirring device and a material lifting device; the present invention utilizes a rotating The air distribution pipe evenly sprays the hot air blown by the hot air blower into the tank, and the quartz sand at the bottom of the tank is stirred and turned by the rotating stirring plate, and the quartz sand is realized by using the rotating lifting cylinder and the lifting device. Circular turning, the cyclic drying of the quartz sand is beneficial to improve the uniformity of drying.

Owner:合肥多智科技开发有限公司

Method for jointly drying cucumbers by vacuum pulse and negative-pressure pulse-spouted microwave

ActiveCN108936424AInhibit browning reactionReduce browning reactionFood dryingFood ingredient functionsUltrasonic assistedEngineering

The present invention relates to a method for jointly drying cucumbers by vacuum pulse and negative-pressure pulse-spouted microwave, and belongs to the technical field of fruit and vegetable processing. The processing method comprises the following operation steps: cucumber selection, cleaning and slicing, ultrasonic-assisted color protection with a color-fixing liquid, blanching enzyme-deactivation sterilization treatment with ultrasonic-assisted high-temperature and high-humidity superheated steam, vacuum pulse drying, two-stage negative-pressure pulse-spouted microwave drying, and vacuum packaging. The cucumber product processed by the method has the advantages of short drying time, high effective component retention rate, good quality, cleanness and sanitation.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Clay circulation smashing and drying integrated tank for building construction

InactiveCN107309040ACrushed fullyExpand the drop areaHollow article cleaningDrying gas arrangementsSurface cleaningLiter/feed

The invention provides an integrated clay circulation crushing and drying tank for building construction, comprising a tank body; a cover plate is arranged at the top opening of the tank body; an exhaust pipe is welded and fixed on the left side of the cover plate; The surface is equipped with a cleaning device; the feed pipe is welded and fixed on the top side wall of the tank body, and the discharge pipe is welded and fixed on the bottom side wall of the tank body; The middle part of the tank is equipped with a first crushing and distributing device and a second crushing and drying device; the outer wall of the tank is provided with a lifting device; the present invention uses the first crushing and distributing device to shear and pulverize clay in one direction , through the second crushing and drying device, the clay is sheared and crushed in another direction, and the distribution area of hot air is expanded to improve the drying uniformity of the clay; the cyclic crushing and drying of the clay is realized through the lifting device, which is convenient for improving the crushing efficiency. quality and dry quality.

Owner:合肥多智科技开发有限公司

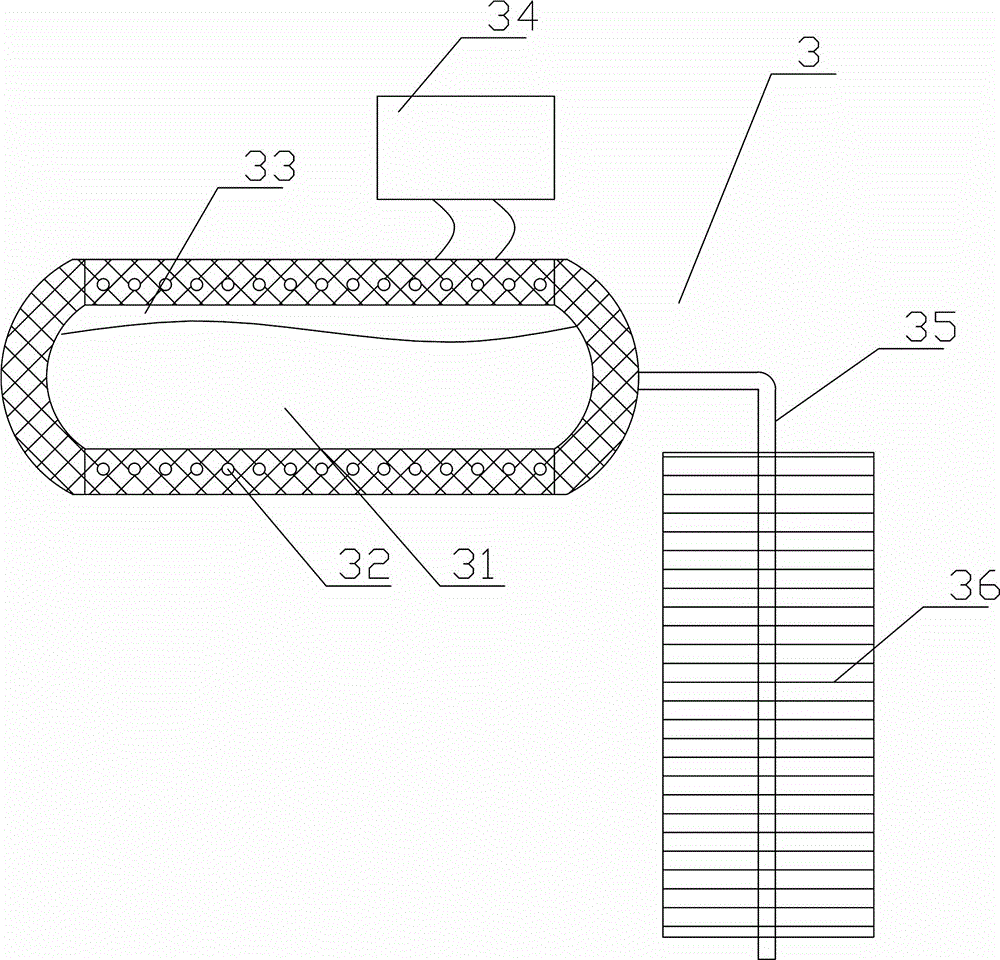

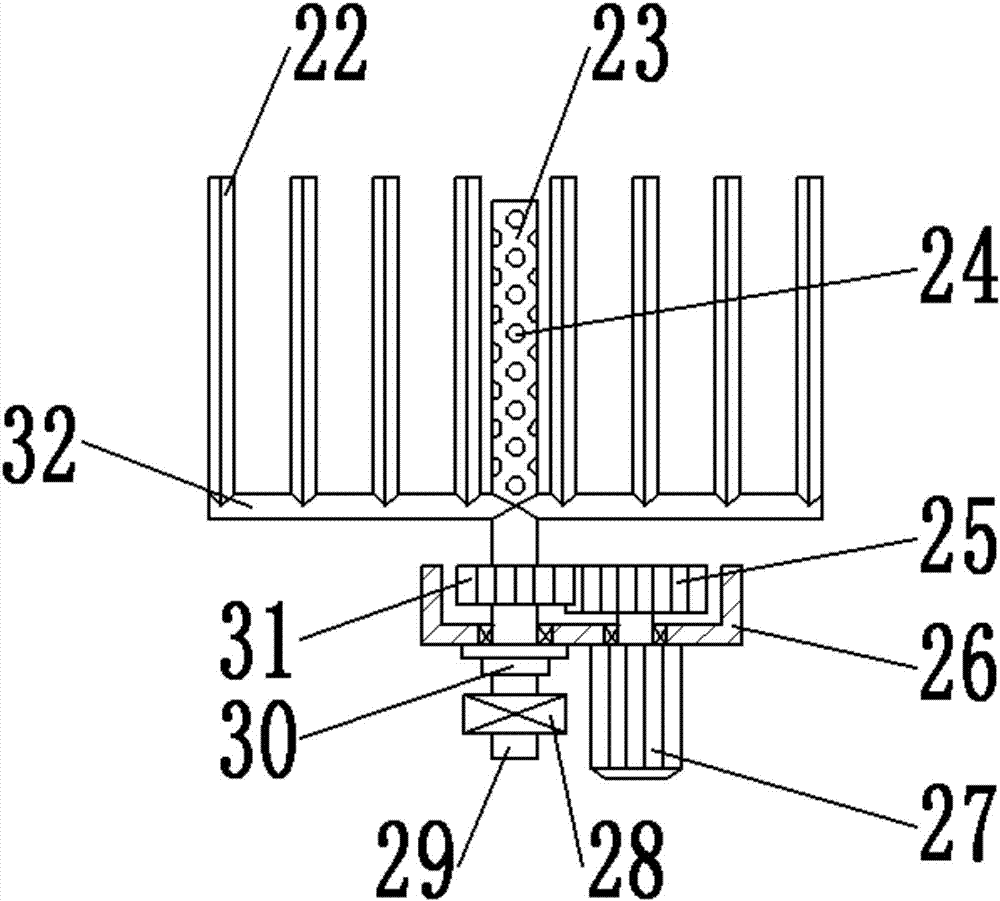

Microwave spraying vacuum drying machine

InactiveCN101458033AAvoid deposition overheating burnt problemAvoid overheating and burningDrying using combination processesDrying solid materials with heatMicrowaveChinese traditional

The invention relates to a microwave spraying vacuum drier for drying sticky materials, in particular for chemicals, Chinese traditional medicines and food, and the like, with strong thermal sensitivity as desiccant. The invention comprises a drying container, a feed inlet, a microwave feed-in device and a material atomization device arranged on the top part of the drying container, a container for drying finished products arranged on the lower part of the drying container, a metal screen arranged between the drying container and the container for drying finished products, a vacuum pump joint arranged on the lateral wall of the drying container, a material preheating components connected between the feed inlet and the material atomization device below the microwave feed-in port of the microwave feed-in device and a vibrating mechanism for delivering materials and preventing materials from being sticky to the wall surface. The vacuum drier of the invention has the advantages of simple production, wide application range, as well as comparatively high drying uniformity and efficiency.

Owner:HENAN UNIV OF SCI & TECH

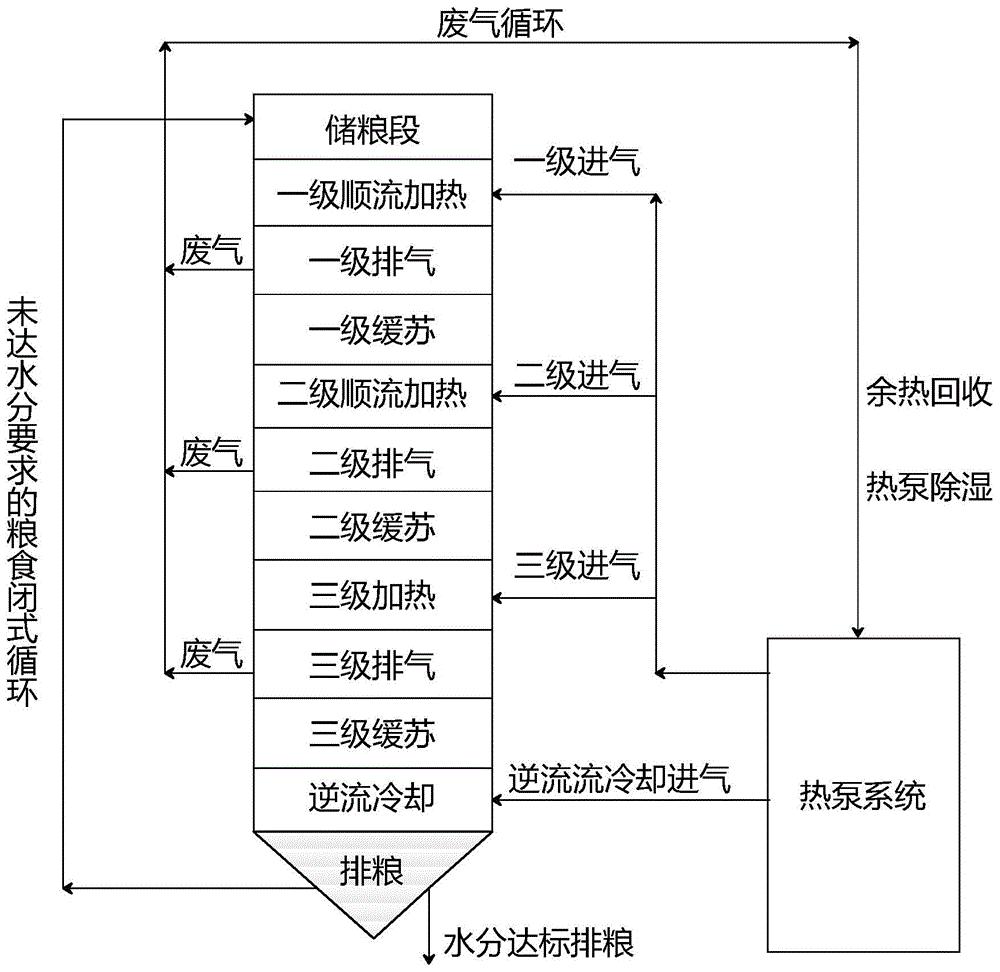

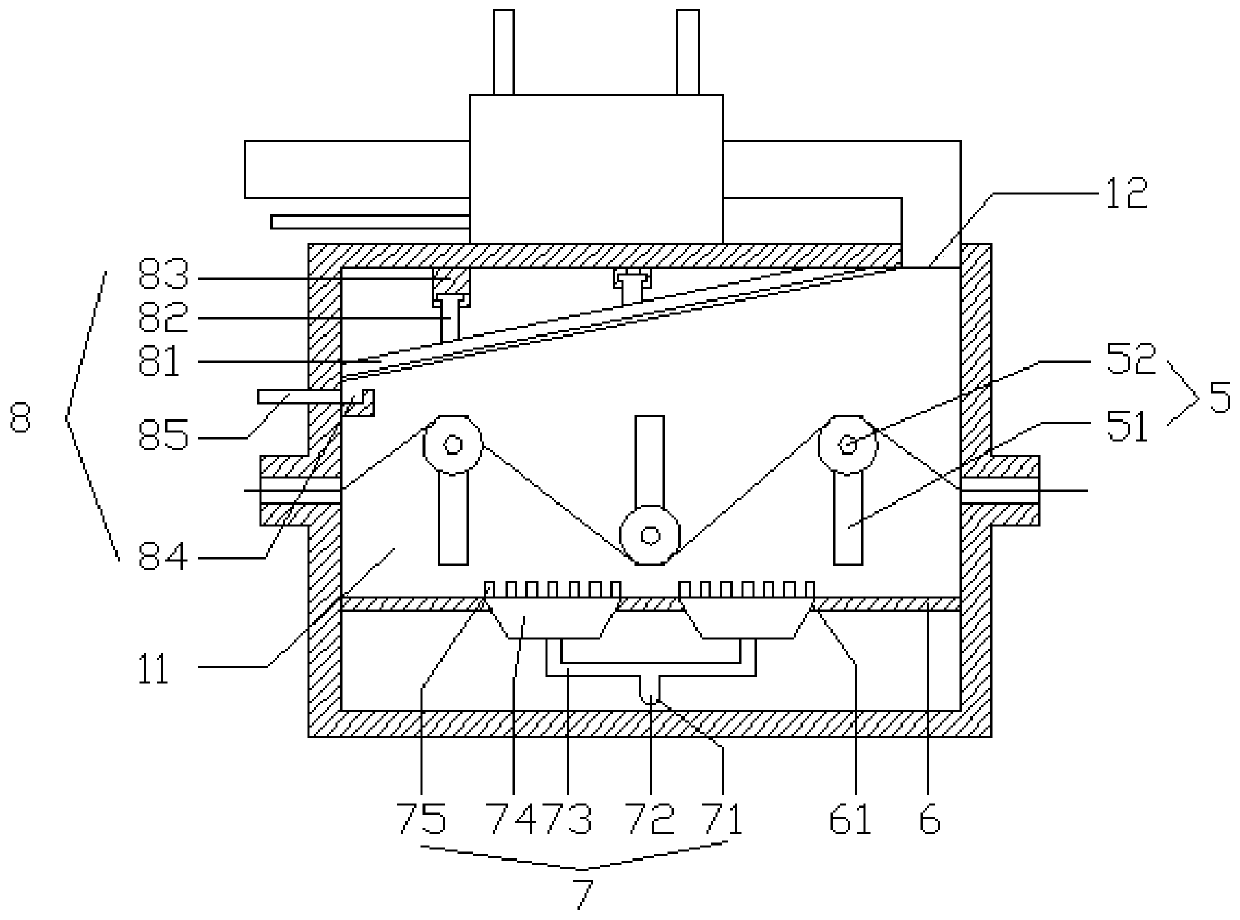

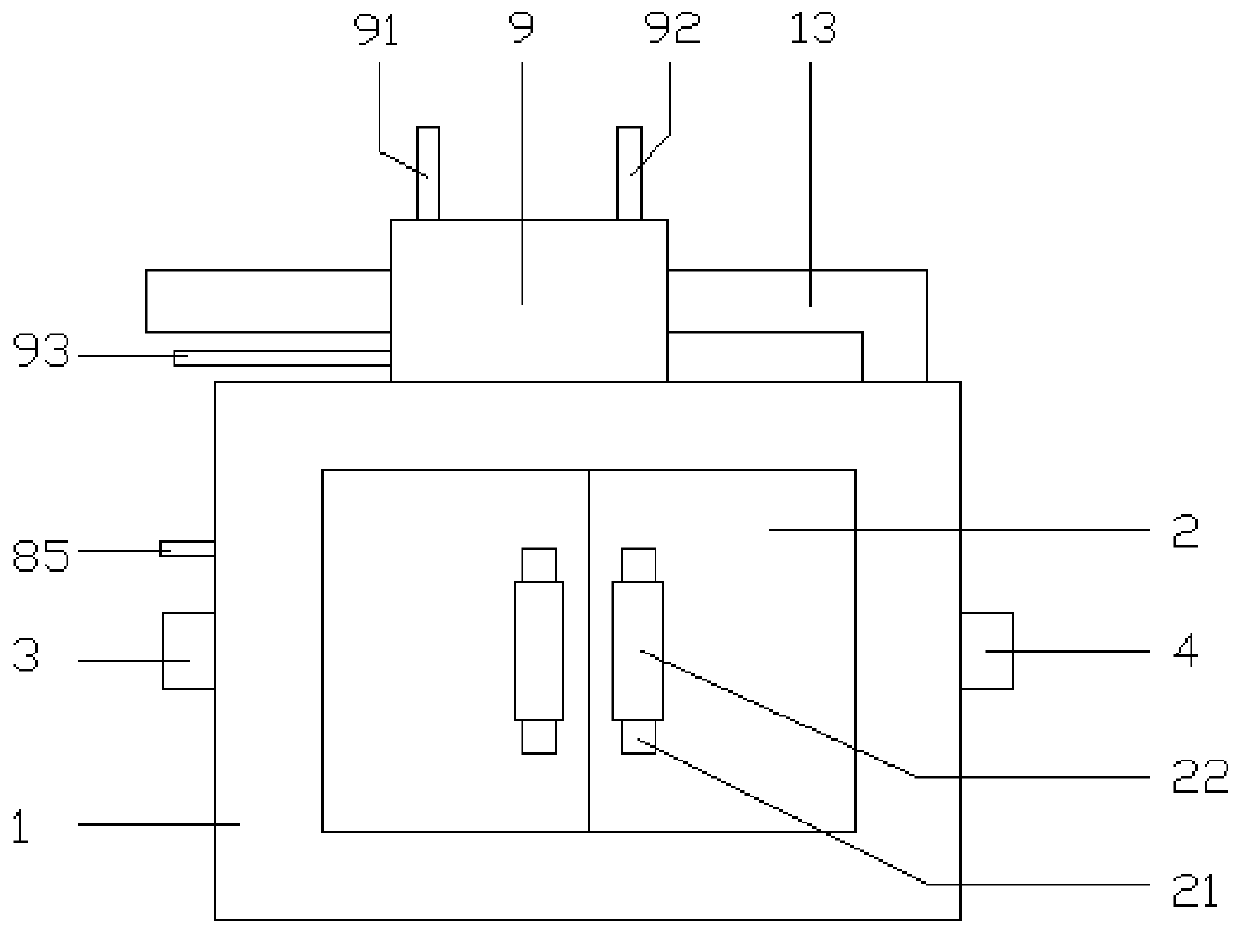

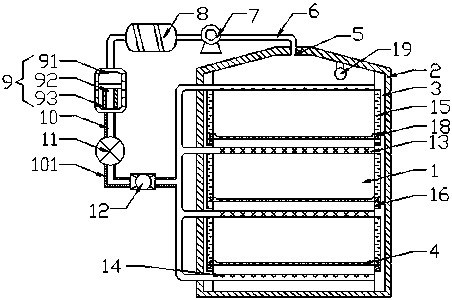

Multi-graded concurrent tempering heat pump dehumidification and closed type circulating coarse cereal drying process method

InactiveCN104663875AImprove general performanceImprove drying uniformityClimate change adaptationSeed preservation by dryingAutomatic controlAutomated control system

The invention provides a multi-graded concurrent tempering heat pump dehumidification and closed type circulating coarse cereal drying process method which takes a regenerative cycle heat pump system as heat supply source to dry and dehydrate coarse cereals. The drying process method comprises multi-graded concurrent tempering and countercurrent cooling circulating of the coarse cereals, and drying medium waste gas recycling, dehumidification and circulation. In a full-automatic intelligent drying process, upper computer touch screen software and a lower computer programmable logic controller (PCL) of an automatic control system are adopted, and process parameters including a drying medium temperature, a performance airspeed, tempering time and drying time in a drying process are accurately calculated according to the variety of the coarse cereals and the initial water content of the coarse cereals, so that an optimal drying process method is given. The drying process method is characterized in that when the initial water content of the coarse cereals is 17%-19% and the final water content is 14%, the process parameters are as follows: the drying temperature is 40-60 DEG C, the airspeed is 0.5m / s-2.5m / s, the drying time is 1-1.5 hours and the tempering time is 3.5-5.5 hours.

Owner:TIANJIN UNIV OF SCI & TECH

Drying device for building board with adjusting function

PendingCN109737706AGuaranteed linearityReasonable structural designDrying gas arrangementsDrying chambers/containersEngineeringLateral position

The invention discloses a drying device for building boards with an adjusting function, and belongs to the technical field of drying of building boards. Adjusting devices are arranged on the left sideand the right side of the top of a base respectively, and damping devices are arranged at the top of the adjusting devices, a cross beam is arranged at the top of the damping devices, a sliding railis arranged at the center of the bottom of the cross beam, a guide block is embedded in the slide rail, a drying box is fixedly connected to the bottom of the guide block, a heater is arranged on theside, far away from a opening, of an inner cavity of the drying box, reflecting plates are arranged on the left side and the right side of the heater respectively, a filtering plate is fixedly arranged below the heater, and a fan is arranged below the filter plate. According to the device, the height and the transverse position of the drying box can be adjusted, the drying area of the building boards can be improved, the drying effect can be improved, the drying efficiency is improved, and the drying uniformity is good.

Owner:王程

Drying device used for textile printing and dyeing

PendingCN110455061AReduce foldingImprove drying uniformityDrying gas arrangementsDrying machines with progressive movementsTextile printerTextile printing

The invention discloses a drying device used for textile printing and dyeing. The drying device comprises a device body, a movable bin door, a feed port, a discharge port, a material guide mechanism,a partition plate, a drying mechanism, a flow guide mechanism and a waste heat collection device. Compared with the prior art, the drying device is simple in structure and reasonable in design; textiles are tensioned through the arranged material guide mechanism; hot gas flow is guided into the waste heat collection device through the arranged flow guide mechanism and the arranged waste heat collection device; and waste heat in the hot gas flow is effectively utilized. Furthermore, condensed liquid drops can also be guided out through the flow guide mechanism, it is avoided that because the liquid drops drop to the textiles, the drying effect is influenced, and the drying device is worthy of popularization.

Owner:海盐鸳鸯丝绸印染股份有限公司

Drying equipment for processing honeysuckle of traditional Chinese medicine

InactiveCN107726816AImprove drying efficiencyImprove drying uniformityDrying gas arrangementsDrying chambers/containersTemperature controlHeat losses

The invention discloses drying equipment for processing honeysuckle of traditional Chinese medicine. The drying equipment comprises a drying cavity and a heat preservation shell, and the heat preservation shell is arranged on the outer side of the drying cavity; and the drying equipment further comprises side plates, drying trays, an exhaust port, an exhaust pipe, a circulating fan, a filter, a gas drying device, an air inlet pipe, drying pipes and air outlets. According to the drying equipment, the drying trays move between every two adjacent drying pipes, on one hand, air flowing inside thedrying cavity can be increased, so that the drying efficiency of the honeysuckle is effectively improved, and on the other hand, the drying pipes can be used for drying the honeysuckle at the bottom of the trays, the drying uniformity of the honeysuckle can be effectively improved, and crushing of the honeysuckle caused by stirring in the drying process can avoided; and the air in the drying cavity is recycled so that the heat loss can be reduced, the drying cost of the honeysuckle can be reduced, the temperature in the drying cavity can be conveniently controlled to be 45DEG C to 50 DEG C, and the drying quality of the honeysuckle is effectively improved through the drying equipment.

Owner:卓秋吟

Traditional Chinese herbal medicine drying equipment

InactiveCN105202869AGuaranteed qualityQuality improvementDrying solid materials with heatDrying gas arrangementsHerb medicineBiochemical engineering

The invention provides traditional Chinese herbal medicine drying equipment, which comprises a drying tube body, wherein a drying round plate is arranged at the middle part of the drying tube body; the size of the drying round plate is matched with the inner wall of the drying tube body; a plurality of ventilation holes are uniformly formed in the drying round plate; the two side ends of the drying round plate are provided with a rotating shaft; the rotating shaft is rotationally connected with the inner wall of the drying tube body; a temperature sensor is arranged on the inner wall of the drying tube body; a filtering net plate is arranged on the upper end of the drying tube body; a waste material cover covers the filtering net plate; the top end of the waste material cover is communicated with a waste material pipe; a fixing ring is supported on the outer wall of the drying tube body; the lower end, supporting the fixing ring, is fixedly provided with a support rod; a discharging opening is formed right under the drying tube body; a heating box is connected onto the side wall of the lower end of the drying tube body through the air inlet pipe; the air inlet end of the heating box is connected with a blast blower; a controller is arranged on the outer wall of the heating box. The traditional Chinese herbal medicine drying equipment has the advantages that the structure is simple; the design is reasonable; medical materials can be sufficiently and uniformly dried; the temperature inside the tube body is controlled; the finished product quality and the finished product obtaining efficiency of the medical materials are improved.

Owner:成都米戈科技有限公司

Forage cutting and processing device for black goat feeding

ActiveCN110115161AEasy to cutImprove drying efficiencyDrying gas arrangementsAnimal feeding stuffDrive shaftPulp and paper industry

The invention discloses a forage cutting and processing device for black goat feeding. The device comprises a box, a forage washing component, a cutting component and a stirring and drying component,the box comprises a washing cavity, a cutting cavity and a drying cavity, a fixing plate is arranged inside the cutting cavity, a linkage gear and a threaded adjusting rod are arranged on the fixing plate, the forage washing component comprises a washing net barrel and a washing nozzle, the washing net barrel is connected inside the washing cavity in a clamped manner, and the washing nozzle is arranged at the upper end of the inside of the washing cavity; the cutting component comprises a cutter and a transmission shaft arranged inside the cutting cavity, the stirring and drying component comprises a forage conveying component, a drying component and a stirring component, the conveying component is arranged inside the drying cavity, the drying component comprises a heater and an air blower, the heater is arranged inside the drying cavity, the air blower is connected with the heater, and a control panel is arranged at the upper end of the box and electrically connected with electrical equipment. Forage after being treated by the device is conducive to growth and development of black goat, and the device is suitable for large-scale popularization.

Owner:LINYI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com