Sprouted auxiliary means for improving microwave desiccation homogeneity of granular garden stuff

A microwave drying and granular technology, which is applied to the preservation of fruits and vegetables, preservation of fruits/vegetables by dehydration, food science, etc., can solve the problems of slowing down the rehydration speed of freeze-dried fruits and vegetables, and achieves the improvement of microwave drying uniformity and uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

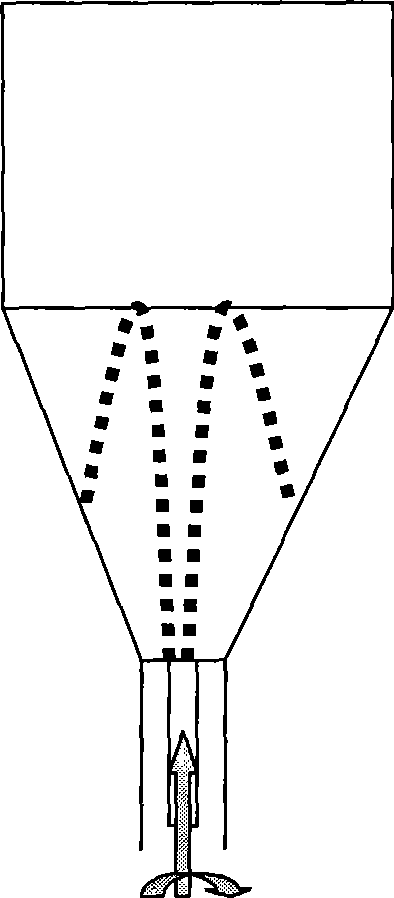

[0035] Example 1: Center spray assisted drying of carrot granules

[0036] Clean the carrots, cut them into regular particles, weigh a certain amount of carrots and put them into a microwave spouted bed. Adjust the spraying auxiliary air inlet direction to be consistent with the vertical line in the center of the drying bed to form a central spraying flow field. The initial value of the inlet air pressure is controlled at 900-1000Pa, and the material is violently continuously blown along the center column in the spouted bed. Spraying, with the evaporation of dried fruits and vegetables, after drying for 10 minutes, adjust the pressure of the spraying auxiliary air inlet to 550Pa, and at the same time, adjust the microwave input power to about 60% of the initial value (about 1.2g / w) to continue drying. The drying time is 12 to 14 minutes, which is the drying end point. The moisture content of the dehydrated carrot granules after drying is below 6%, the difference between the L ...

Embodiment 2

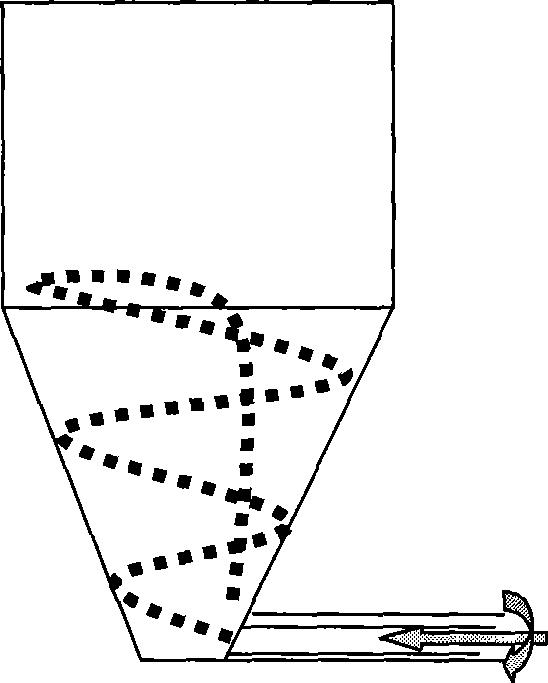

[0037] Example 2: Circumferential jet assisted drying of carrot granules

[0038] Clean the carrots, cut them into regular particles, weigh a certain amount of carrots and put them into a microwave spouted bed. Adjust the direction of the spray auxiliary air inlet to be consistent with the direction of the tangent line at the bottom of the drying bed to form a circular spherical spray flow field. At the same time, the upward adjustment angle of the air inlet guide valve in the vertical direction is about 20-30°, and the pressure of the air inlet The initial value is controlled at 1000-1100Pa. The material spirals upwards to a certain position in the circumferential direction of the spouted bed and then returns to the bottom from the central area of the drying bed. With the evaporation of moisture in the dried fruits and vegetables, after drying for 10 minutes, the sprayed The auxiliary air inlet pressure is adjusted to 600-700Pa. At the same time, the microwave input power i...

Embodiment 3

[0039] Embodiment 3: the central jet assisted drying of strawberry grain

[0040] Clean the strawberries, cut them into regular particles, weigh a certain amount of strawberries and put them into the microwave spouted bed. Adjust the spraying auxiliary air inlet direction to be consistent with the vertical line in the center of the drying bed to form a central spraying flow field. The initial value of the inlet air pressure is controlled at 800-900Pa, and the material is violently continuously blown along the center column in the spouted bed. Spraying, with the evaporation of dried fruits and vegetables, after drying for 10 minutes, adjust the auxiliary air inlet pressure of spraying to 500-600Pa, and at the same time, adjust the microwave input power to about 60% of the initial value (about 1.2g / w) to continue Drying, the drying time is 14-15 minutes is the drying end point, the moisture content of the dehydrated strawberry grains after drying is below 6%, the difference betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com