Lumber drying kiln

A technology for wood drying kiln and kiln body, which is applied in the directions of drying solid materials, drying chamber/container, drying gas arrangement, etc., can solve the problems of uncontrolled temperature and relative humidity, large capital occupation, uneven drying, etc. Shortened cycle, safe energy consumption, and good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

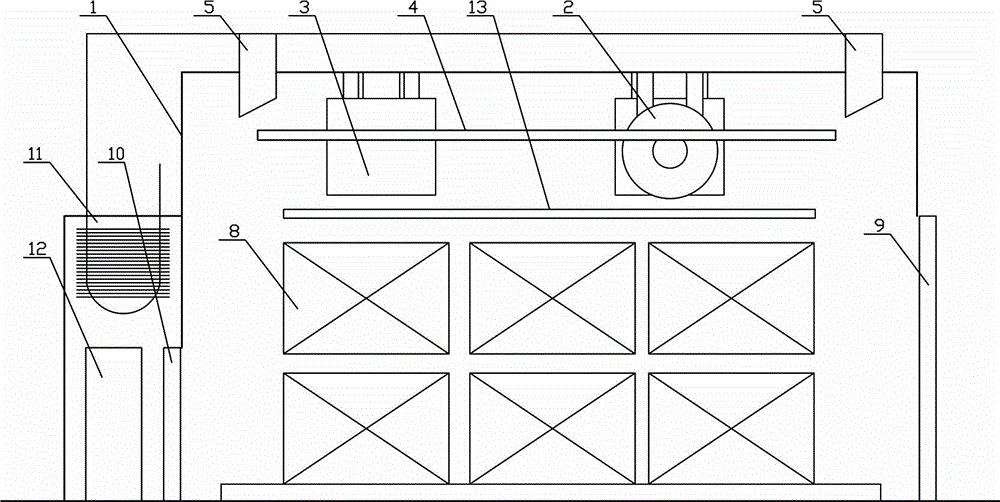

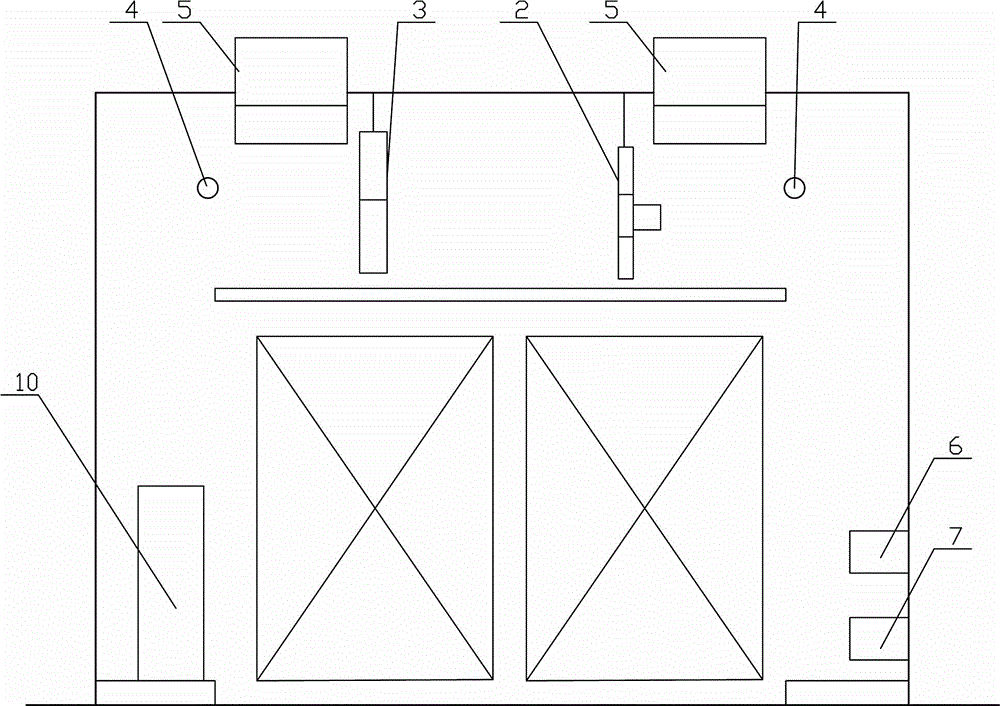

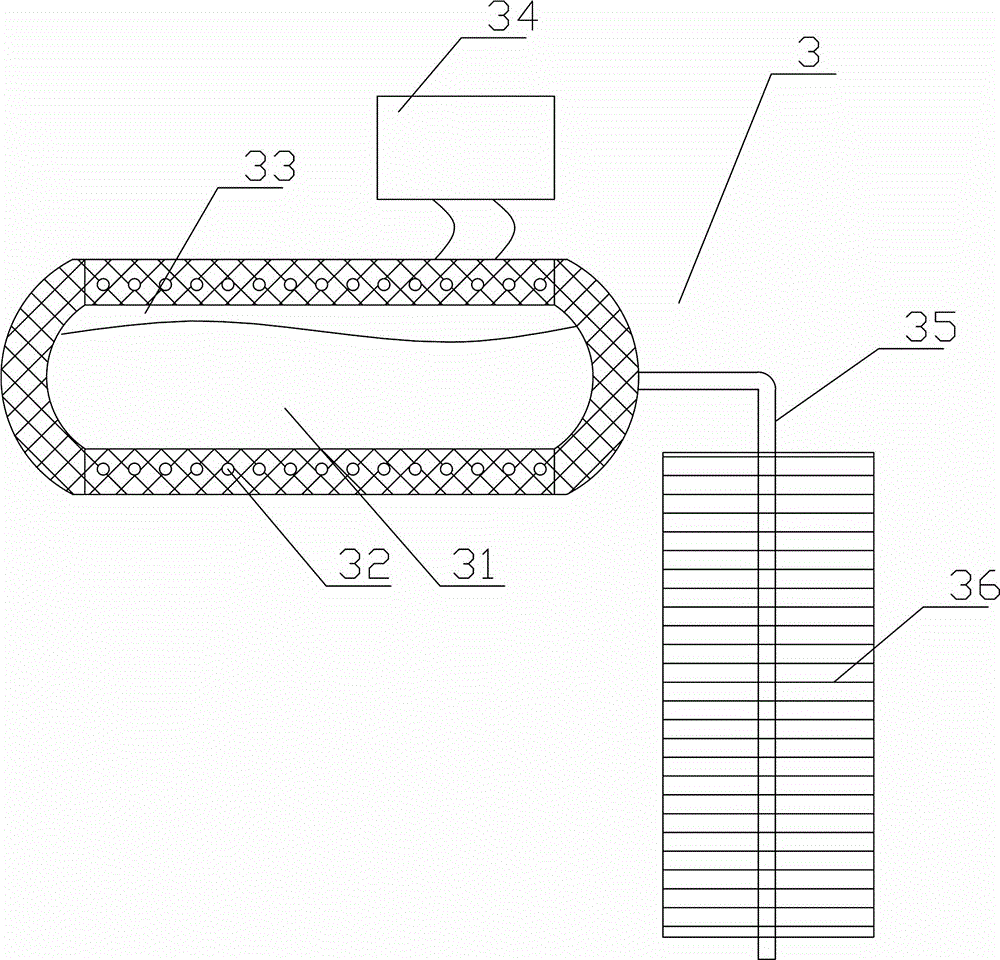

[0026] Such as figure 1 , 2 Among them, a wood drying kiln comprises a kiln body 1, a steam injection pipe 4 is arranged in the kiln body 1, and a main kiln door 9 is arranged on the kiln body 1. The kiln body 1 is provided with at least one set of air supply device 2 and heating device 3;

[0027] A plurality of exhaust devices 5 are arranged in the kiln body 1;

[0028] The kiln body 1 is provided with a temperature and humidity detection device 6 and a moisture content detection device 7 . The temperature and humidity detection device 6, the moisture content detection device 7, the air supply device 2, the heating device 3 and the control valves of the steam injection pipe 4 are all connected with the main control device. The main control device in this example uses PLC, thus realizing temperature. , Automatic control of humidity.

[0029] The maximum drying temperature of the wood drying kiln of the present invention is about 95°C. According to different moisture conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com