Drying and sorting integrated crusher and process

A crusher and drying technology, used in drying solid materials, drying gas layout, dryers, etc., can solve problems such as low production efficiency, large investment, and large land occupation, so as to improve production efficiency, reduce investment, and increase value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

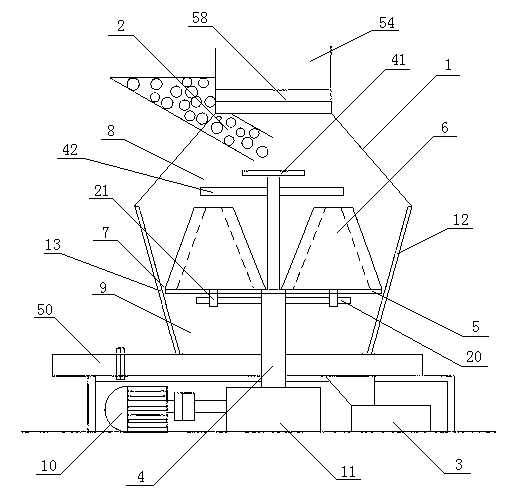

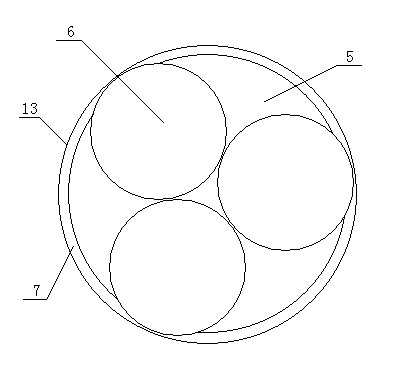

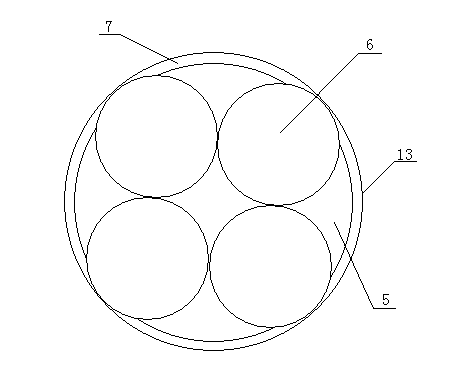

[0027] A crusher includes a crushing cavity, a crushing device, and a power device. Such as figure 1 As shown, the crushing cavity is a cavity enclosed by the casing 1, and the horizontal section is circular. The top of the crushing cavity includes an inlet 2 and the bottom includes an outlet 3. The crushing device includes a main shaft 4, a crushing disc 5 and a plurality of rollers 6. The crushing disc 5 is placed horizontally and has a circular shape, with a gap 7 between the edge and the inner wall 13 of the crushing cavity. The width of the gap 7 is 0.5-8 cm. The crushing disc 5 divides the crushing cavity into a crushing area 8 and an aggregate area 9 from top to bottom. The main shaft 4 is placed vertically, the upper end is connected to the center of the crushing disc, and the lower end is connected to the power device. The roller 6 is a columnar body which is engaged with the inner wall of the crushing cavity, and adjacent rollers are engaged with each other.

[002...

Embodiment 2

[0033] On the basis of Example 1, further, such as figure 1 As shown, the bottom of the crushing disc includes a transmission device 20, the roller 6 includes a roller shaft 21, and the transmission device 20 connects the main shaft 4 and the roller shaft 21. Such as Figure 8 As shown, the roller 6 has vertical grooves 30, and protrusions 31 are formed between the grooves. The rotation of the main shaft 4 drives the rotation of the roller shaft 21 via the belt transmission device 20, thereby driving the rotation of the roller 6. That is, when the crusher is working, in addition to following the crushing disc 5 to rotate around the main shaft, the roller 6 also rotates. In addition to being crushed between the inner wall of the crushing cavity and the cylindrical roller 6, the material is also crushed by the squeezing caused by the grooves and protrusions after the rollers 6 rotate mutually, thereby improving the working efficiency of the crusher. The speed of the roller is 30...

Embodiment 3

[0037] On the basis of embodiment 1, it further includes a spreading device. Such as figure 1 As shown, the spreading device includes a spreading disc 41, which is located at the top of the extension part of the main shaft 4, facing the feed inlet 2 directly. When the crusher is working, the main shaft 4 rotates to drive the sprinkler 41 to rotate, and the material entering the crushing cavity through the feed port is thrown on the sprinkler 41, and the material is dispersed around the crushing cavity by the centrifugal force of the rotating sprinkler 41. The spreading disc is a disc or an umbrella-shaped disc.

[0038] Further, such as figure 1 As shown, the spreading device also includes a buffer tray 42. The buffer tray 42 is connected to the extension part of the main shaft 4. When the crusher is working, the material that enters the crushing cavity through the feed port is dispersed by the material spreader 41 and further dispersed by the buffer disk 42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com