Preprocessing method for shortening wood drying time

A technology for wood drying and drying treatment, applied in wood treatment, wood treatment details, wood compression and other directions, can solve the problems of microwave pretreatment method consuming large energy, rising cost, difficult to popularize, etc., and achieves convenient process and equipment arrangement, cost The effect of reducing and eliminating pressure-resistant processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is a pretreatment method implemented before the wood drying process, and the processing equipment used in the method is commissioned to manufacture according to the technical indicators and requirements proposed by the inventor. The structure of the equipment is simple, the production operation is convenient and safe, and it can directly preprocess solid wood panels with a wide range of moisture content.

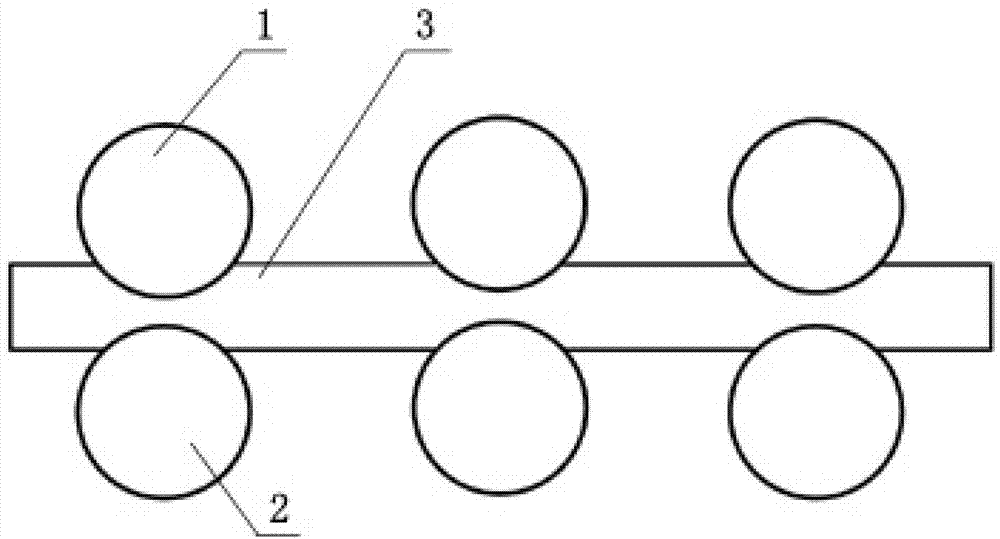

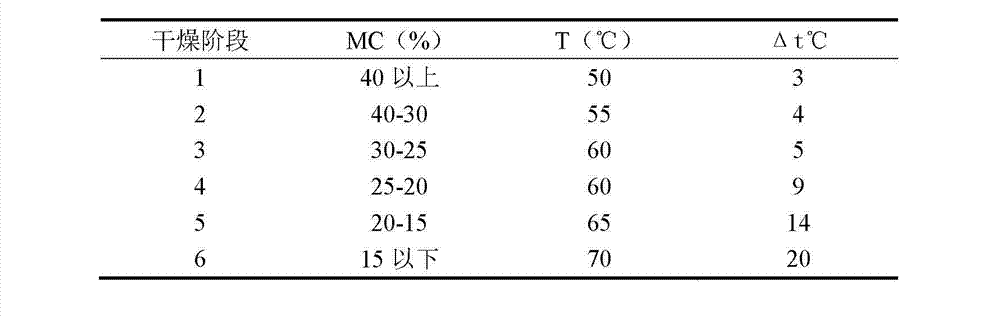

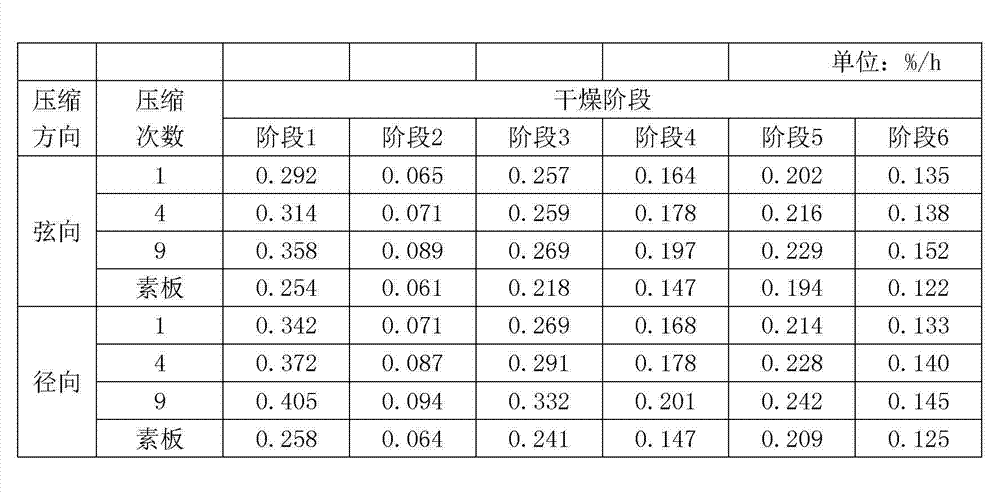

[0022] The present invention adopts the following steps to complete, (1) select wood boards: the materials used in the present invention are boards of solid wood, the species of trees are not limited, and if the external dimensions of the boards are selected within the design size range, the width of the boards needs to be greater than the thickness. The moisture content should be above the saturation point of wood fiber. (2) Adjust the process parameters of the equipment: the equipment is a group or multiple groups of roller presses arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com