Prefabricated bamboo composite pipe gallery and manufacturing method thereof

A composite pipe, pipe gallery technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of poor anti-leakage and earthquake resistance of integrated pipe gallery, large amount of construction work, long construction period, etc., and achieve good earthquake resistance. and anti-geological subsidence ability, reduce engineering cycle, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

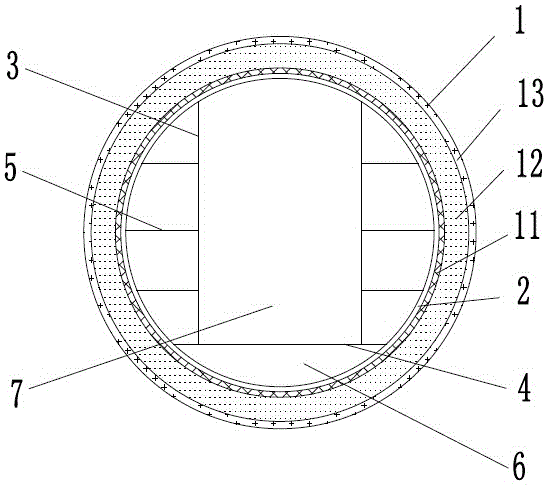

[0025] An example of the present invention is figure 1 as shown, figure 1It is a schematic cross-sectional structure diagram of a prefabricated bamboo composite pipe gallery. The section of the pipe gallery is circular and is formed by connecting several sections of prefabricated pipe joints. The pipe joint includes a pipe body 1 , a load-bearing member 2 , a vertical support beam 3 , a horizontal support beam 4 and a pipe support 5 . The radial direction of the pipe body 1 from inside to outside is an inner lining layer 11, a structural layer 12 and an outer protective layer 13. Both the inner lining layer 11 and the outer protective layer 13 are used to protect the structural layer 12, so that the pipe body 1 is waterproof and seepage-proof Leakage, corrosion resistance, prolong service life, the structural layer 12 is the main reinforcement structure of the pipe body 1. The inner liner 11 includes a flame-retardant resin and a flame-retardant fabric. The flame-retardant r...

Embodiment 2

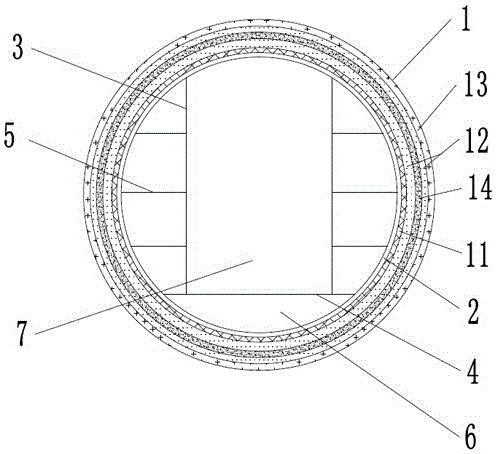

[0027] An example of the present invention is figure 2 as shown, figure 2 It is a schematic cross-sectional structure diagram of a prefabricated bamboo composite pipe gallery. In this embodiment, the structural layer 12 also includes a sand glue layer 14 mixed with mineral sand and resin, and the sand glue layer 14 is located between the bamboo strip layers. The sand glue layer 14 is sandwiched between the bamboo strip layers, which can increase the rigidity of the pipe body 1 . Others are the same as embodiment 1.

[0028] The prefabricated bamboo composite pipe gallery described in Examples 1-2 of the present invention is made of bamboo, which is green and environmentally friendly, with renewable resources and low material cost. The prepared pipe gallery has high strength, light weight, good leakage resistance, and shock resistance. Strong, high production efficiency, convenient construction.

Embodiment 3

[0030] A method for making a prefabricated bamboo composite pipe gallery. First, a pipe body 1 of a pipe joint is prepared. The preparation method of the pipe body 1 includes the following steps:

[0031] (1) Preparation of the inner lining layer 11: the flame-retardant fabric ( Such as non-woven fabrics, knitted felts, mesh cloth, etc.) are wound on the pipe mold with several layers, and the inner lining layer is formed after curing; the specific operation in this embodiment is as follows: take the flame-retardant epoxy resin and add it in proportion to curing agent, mix evenly, then take a flame-retardant glass fiber knitted mat and soak it with the prepared resin, wind it on the pipe mold, wrap it in two layers, and then solidify it to form the inner lining layer 11 after curing;

[0032] (2) Prepare the structural layer 12: make the bamboo strips into a continuous shape (for example, the bamboo strips can be closely arranged in parallel rows, arranged in multiple rows alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com