Biomass fuel forming method

A technology of biomass fuel and molding method, applied in the direction of biofuel, waste fuel, etc., can solve the problems of poor operating environment, low production efficiency, environmental pollution, etc., and achieve the effects of simple process, low cost, and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1. The weight ratio of main components of biomass briquettes: 20-95 parts of straw, 2-60 parts of starch.

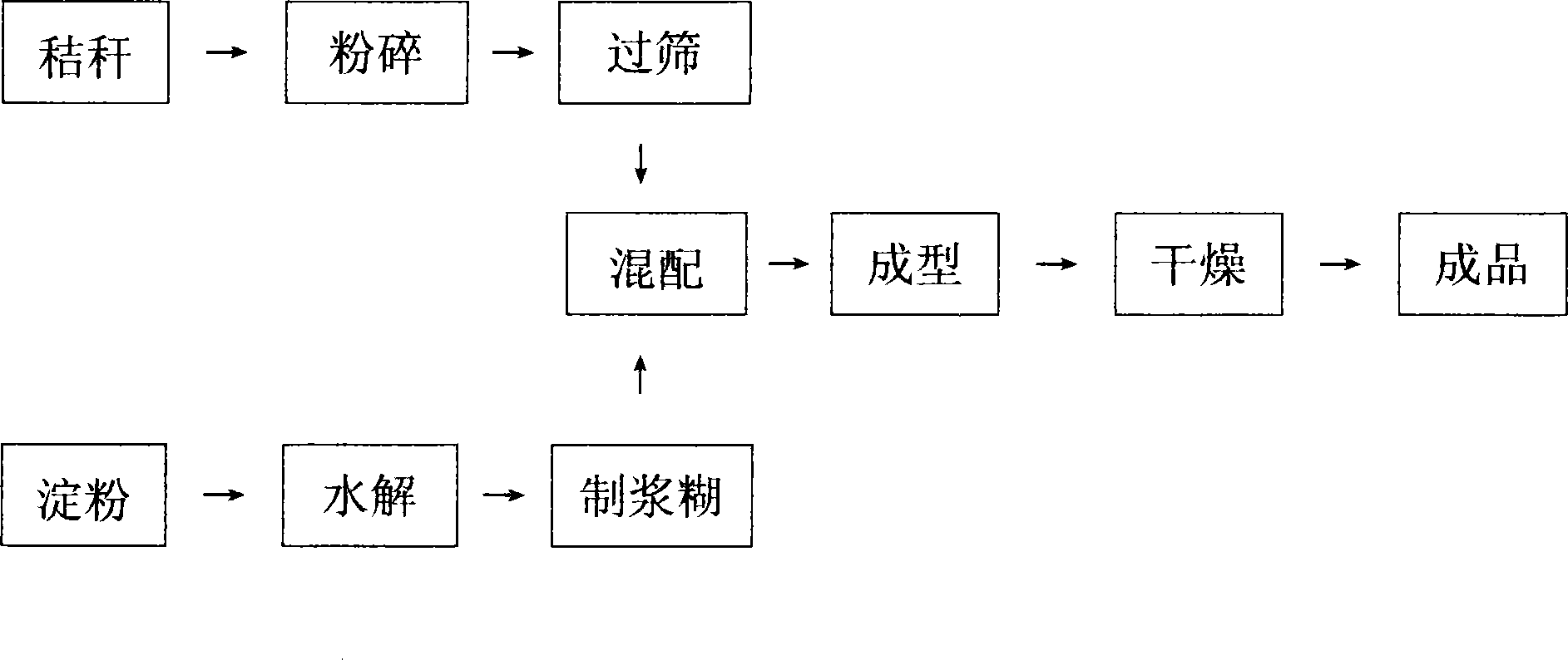

[0012] Its production process is shown in Figure 1, including straw, crushing, sieving, starch, hydrolysis, paste making, mixing, molding, and drying processes.

[0013] Process description

[0014] 1. Straw: Use corn, rice, wheat, cotton, various plant straws, rhizomes, furfural residue, sugar residue and organic waste, at least one of them.

[0015] 2. Crushing: use a pulverizer.

[0016] 3. Sieving: pass through a 10-120 mesh sieve, and take the granulated powder under the sieve.

[0017] 4. Starch: use at least one of corn, potato, sweet potato and various plant fruit starches and degenerated starches.

[0018] 5. Hydrolysis: add water according to the ratio of starch: water = 1:5-40, the amount of water added is related to the molding method and raw materials.

[0019] 6. Paste making: Put the hydrolyzed starch into a heater with stirring, heat...

Embodiment 2

[0023] Embodiment 2. The weight ratio of main components of biomass briquette: 60-80 parts of straw, 10-60 parts of starch, 0-10 parts of preservative, 0-10 parts of flame retardant, and 0-10 parts of waterproofing agent.

[0024] Its production process includes straw, crushing, sieving, starch, hydrolysis, paste making, additives, mixing, molding, and drying processes.

[0025] Process Description

[0026] Additives refer to preservatives, flame retardants and waterproofing agents, and the number of varieties added is related to raw materials and production seasons.

[0027] All the other procedures are the same as Example 1.

Embodiment 3

[0028] Embodiment 3, the weight ratio of the main components of biomass burning incense: 60-80 parts of straw, 3-9 parts of starch, 1-3 parts of waterproofing agent, 1-3 parts of flame retardant, and 0-2 parts of fragrance.

[0029] Its production process flow is the same as example 2, and the operation description is the same as example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com