Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

226 results about "Polymer concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

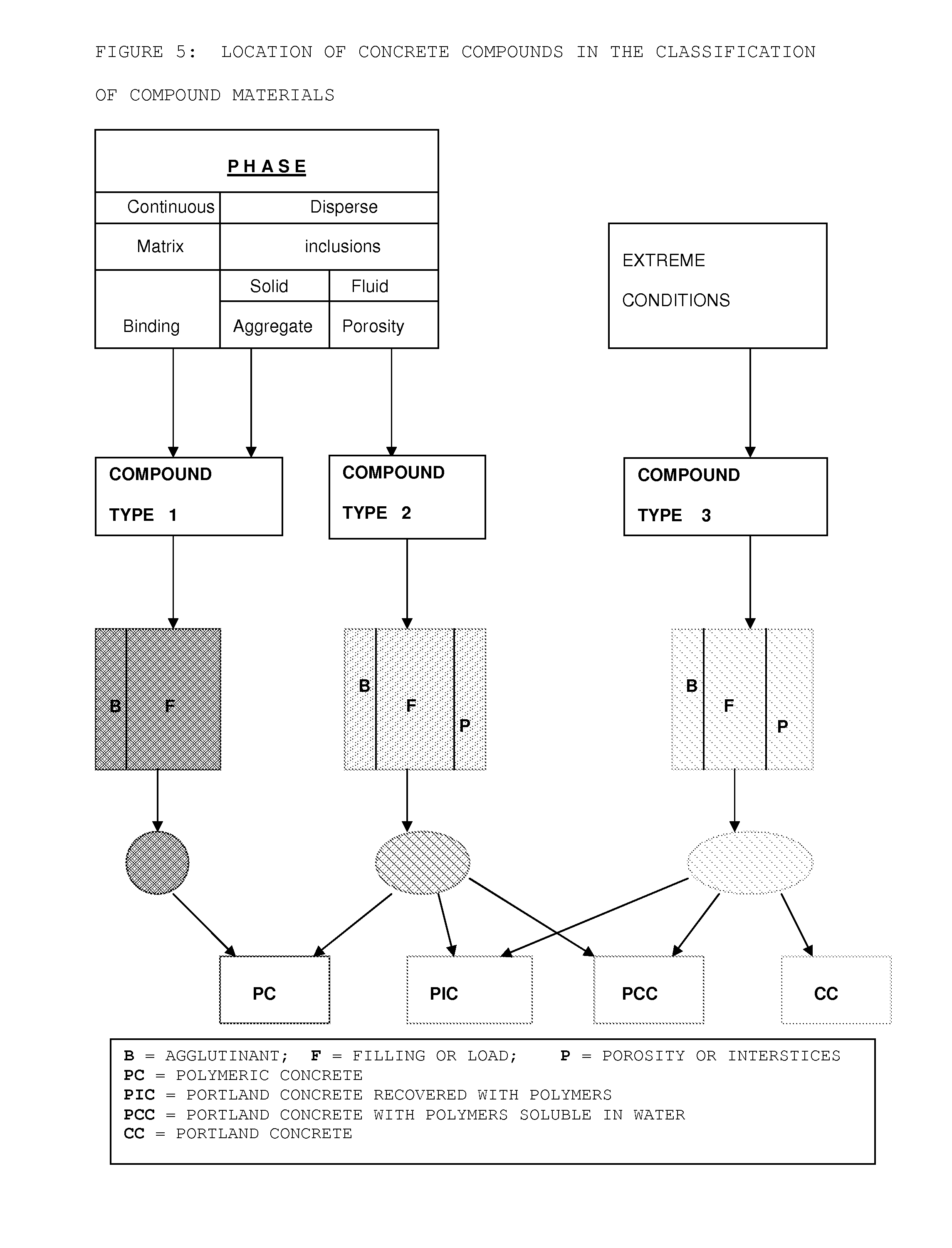

Polymer concretes are a type of concrete that use polymers to replace lime-type cements as a binder. In some cases the polymer is used in addition to portland cement to form Polymer Cement Concrete (PCC) or Polymer Modified Concrete (PMC). Polymers in concrete have been overseen by Committee 548 of the American Concrete Institute since 1971.

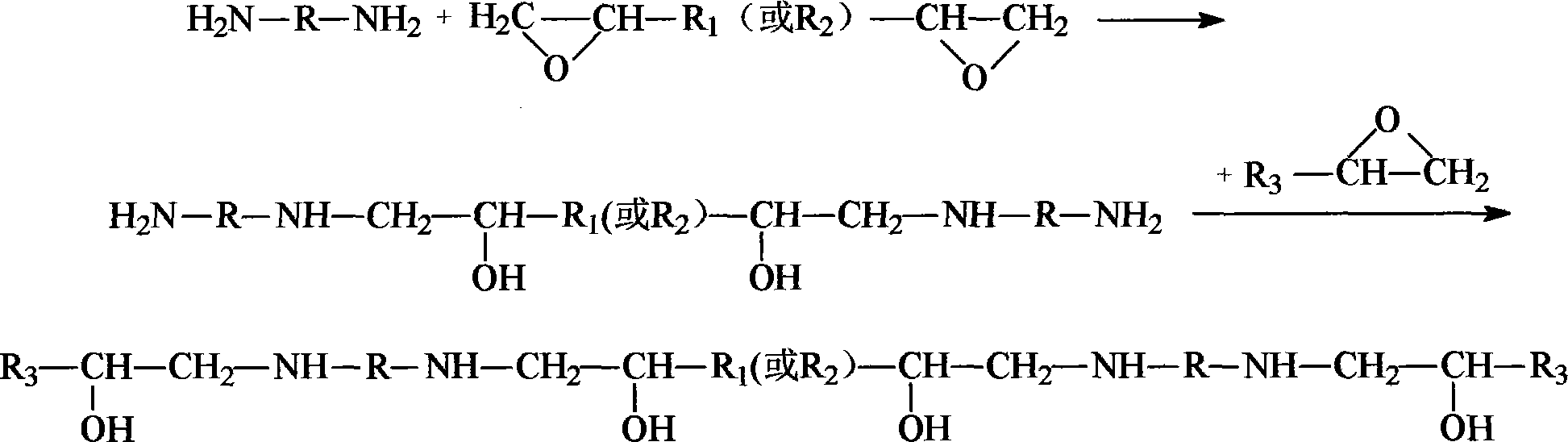

Self-emulsifying type aqueous latex of epoxy hardener, and preparation method

ActiveCN101050300AAvoid situations that require high temperaturesThe synthesis process is simple, safe and energy-savingEpoxyAdhesive

This invention relates to a method for preparing self-emulsifying waterborne epoxy curing agent emulsion, which is composed of: primary amine 7-20 wt.%, epoxy resin 12-27 wt.%, epoxy-terminated polyether 3-8 wt.%, epoxy active diluter 10-30 wt.%, and deionized water 35-60 wt.%. The method comprises: adding primary amine into a reactor, slowly dropping a mixture of epoxy resin and epoxy-terminated polyether, reacting at a certain temperature, slowly dropping monofunctional epoxy active diluter, reacting, adding water, and emulsifying to obtain white waterborne epoxy curing agent emulsion. The method has such advantages as simple process, low reaction temperature (below 100 deg.C), high safety and low energy consumption. The obtained waterborne epoxy curing agent emulsion has such advantages as low VOC content, high stability, high water resistance, high compatibility with epoxy resin, high impact resistance, good luster, high toughness and high adhesiveness, and can be used in paint, adhesive and polymer concrete.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

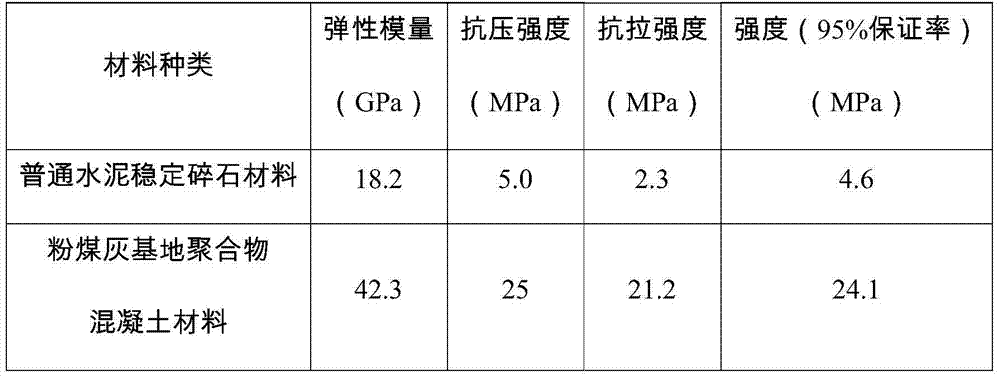

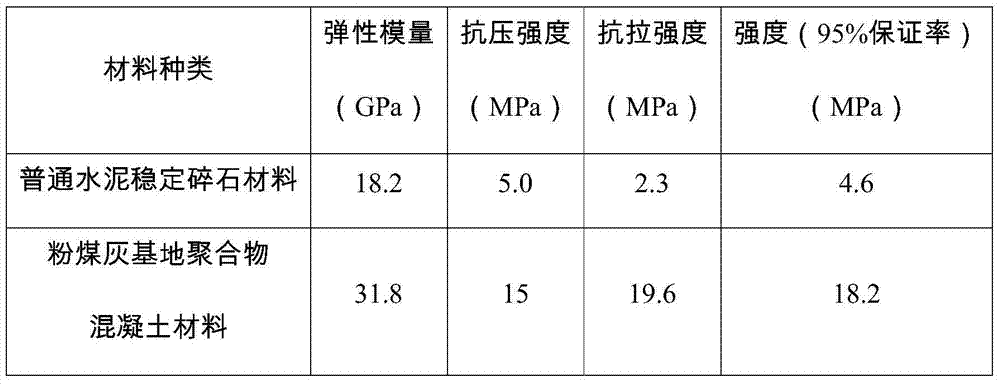

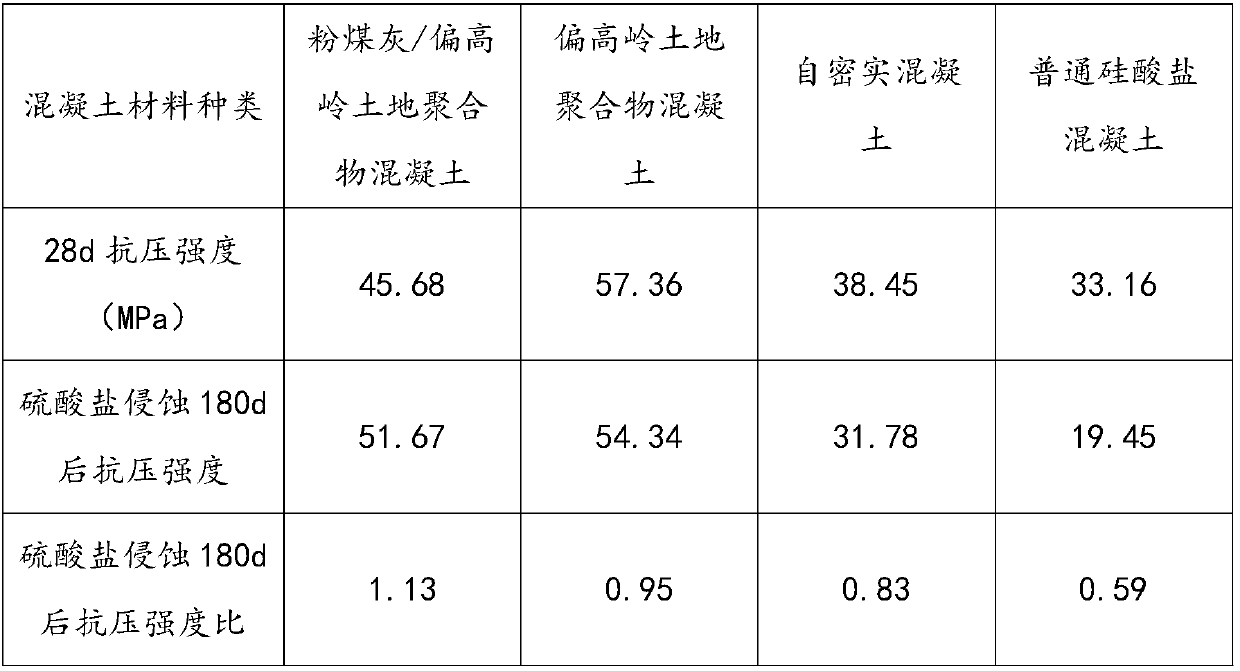

Flyash-based polymer concrete material and preparation method thereof

ActiveCN104496333APromote environmental protectionImprove mechanical propertiesPolymer sciencePolymer concrete

The invention discloses a flyash-based polymer concrete material and a preparation method and an application thereof. The flyash-based polymer concrete material comprises the following components in percentage by mass: 25%-45% of flyash, 0-15% of metakaolin, 10%-15% of cement, 0-5% of coal gangue and slag, 25%-35% of an alkali activator, 0.5%-1% of a retarder and 1%-5% of deionized water. An alkali-activated flyash-based polymer is adopted as a main gel material, so as to prepare an inorganic polymer concrete material; the polymer concrete material has the characteristics of high environmental protection property, good mechanical property and high early strength.

Owner:SHANGHAI PUDONG NEW AREA CONSTR GRP CO LTD

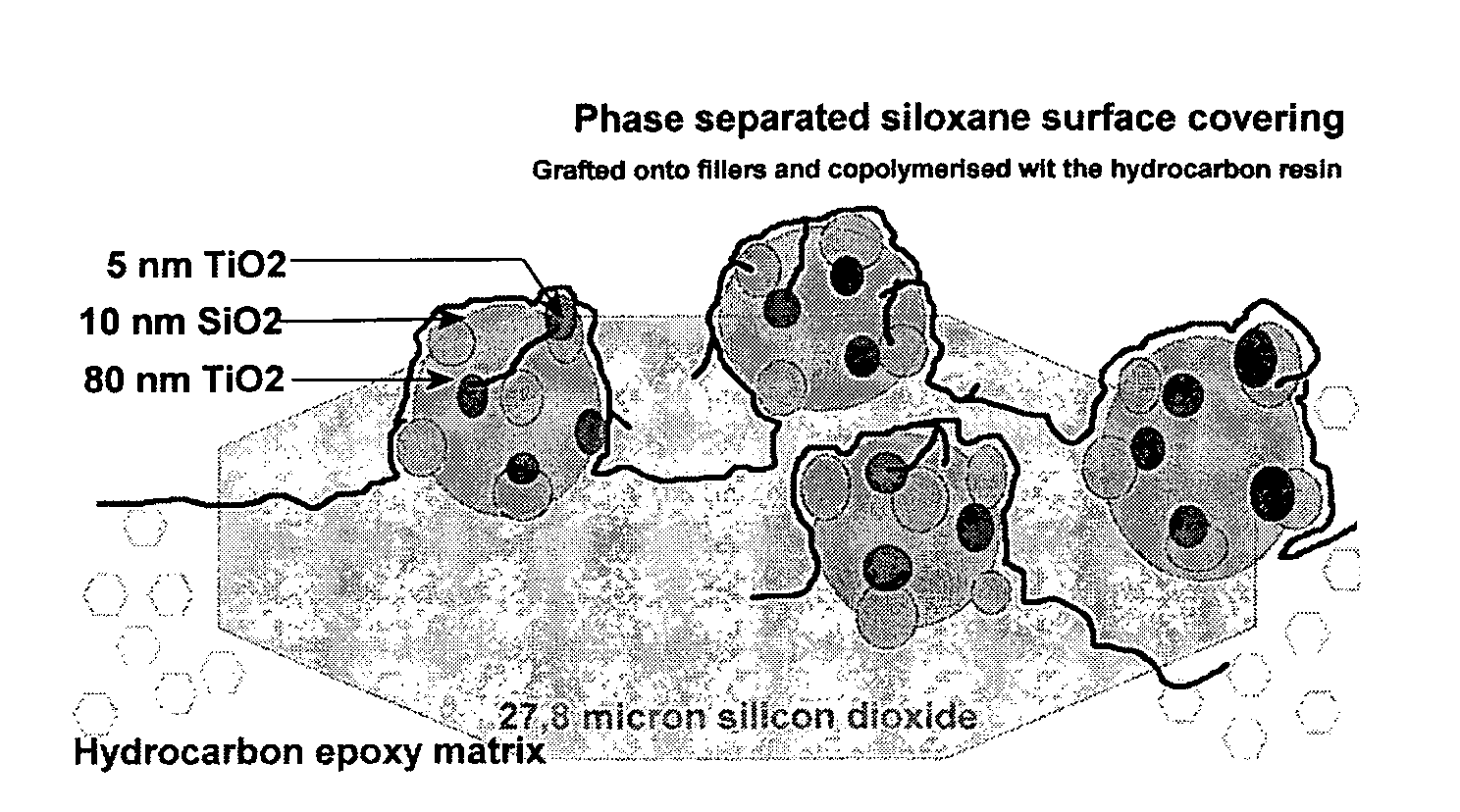

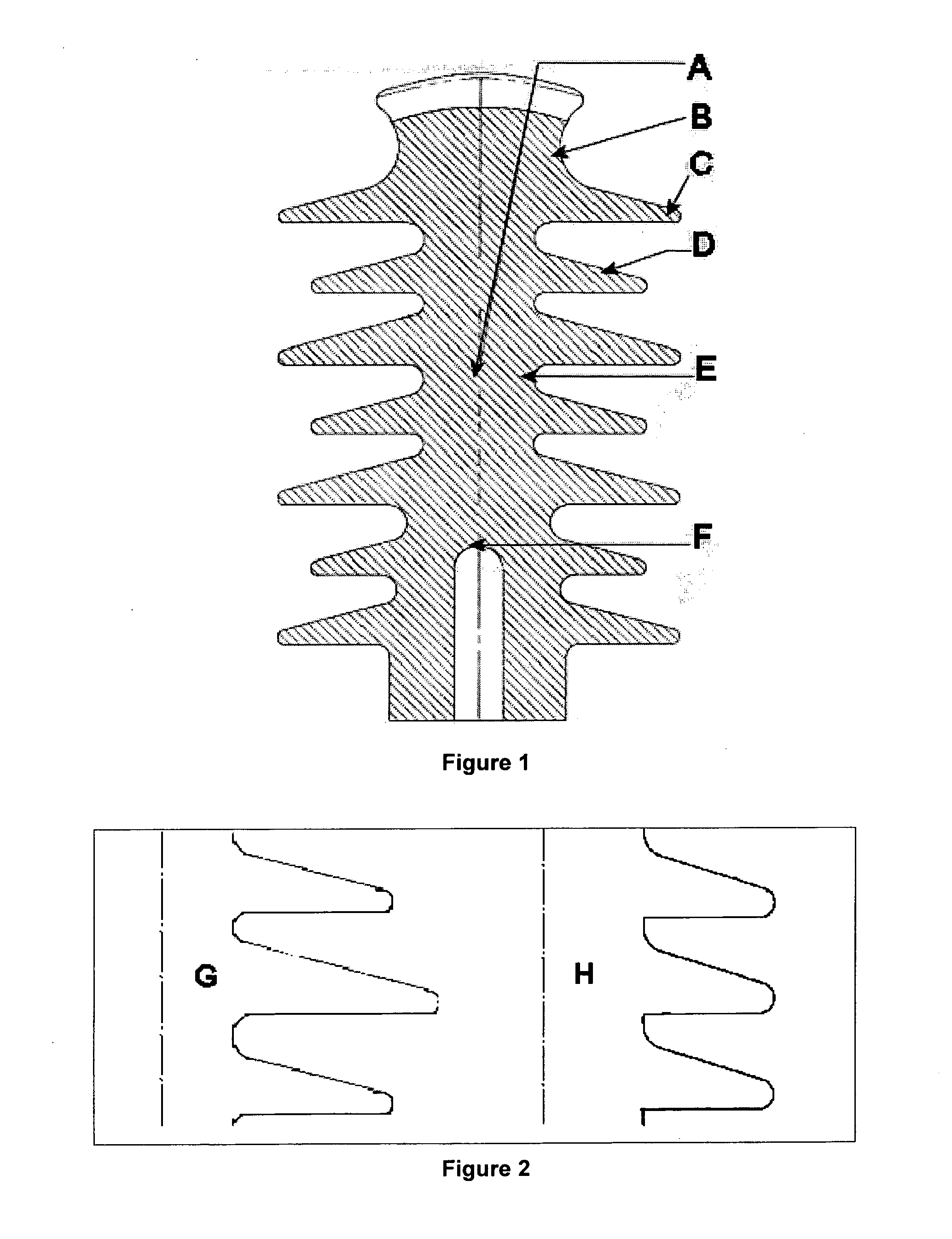

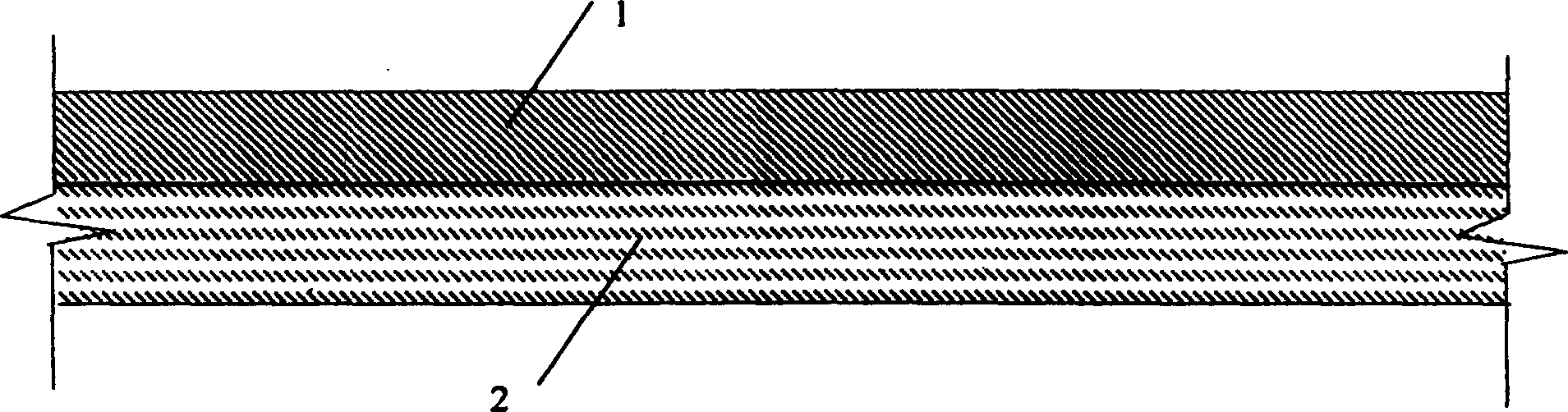

Polymeric High Voltage Insulator with a Hard, Hydrophobic Surface

InactiveUS20100326699A1Reduce weightLow costLiquid surface applicatorsElectric discharge heatingChemical reactionLow leakage

The present invention relates to phase separated siloxane-hydrocarbon copolymer surfaces which are hard and hydrophobic and can be superhydrophobic by the addition of nanoparticles. More specifically the siloxane oligomer / polymer precursor is terminated with (a) chemically reactive group(s). The bond between the siloxane moiety and the hydrocarbon functional moiety is a Si atom directly bonded to a carbon atom. It is applied (for example) to the entire surface of a fibre reinforced and void-free polymer concrete core with 60 to 88% polymeric and inorganic fillers for application as a high voltage insulator. The product has high mechanical strength, impact resistance and good electrical insulation properties. The coating provides good UV resistance, hydrophobicity and a hard self-cleaning surface for use as outdoor high voltage electrical insulator in areas of high pollution with low leakage currents when energised and can also be applied to other products.

Owner:NANONCI

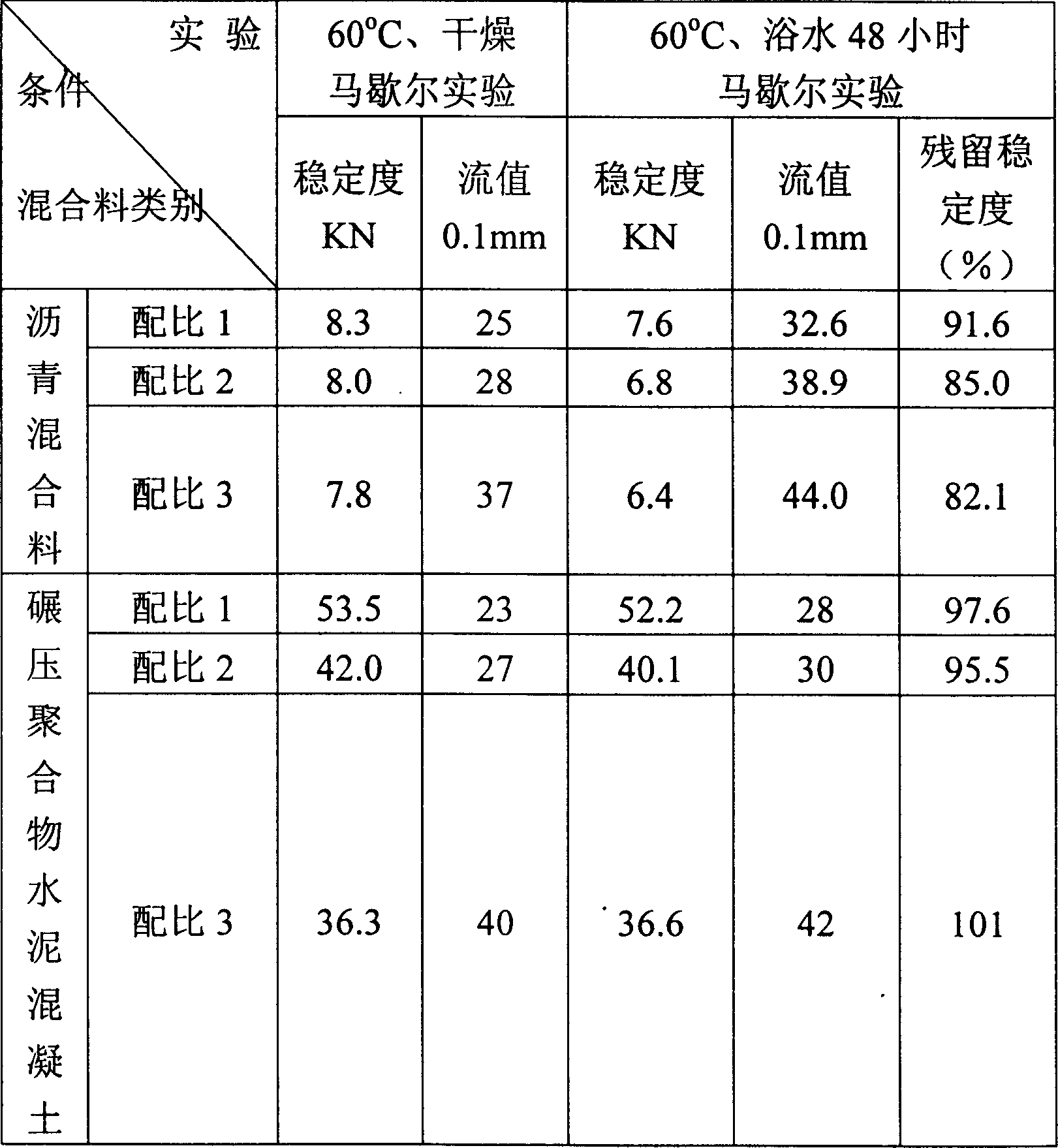

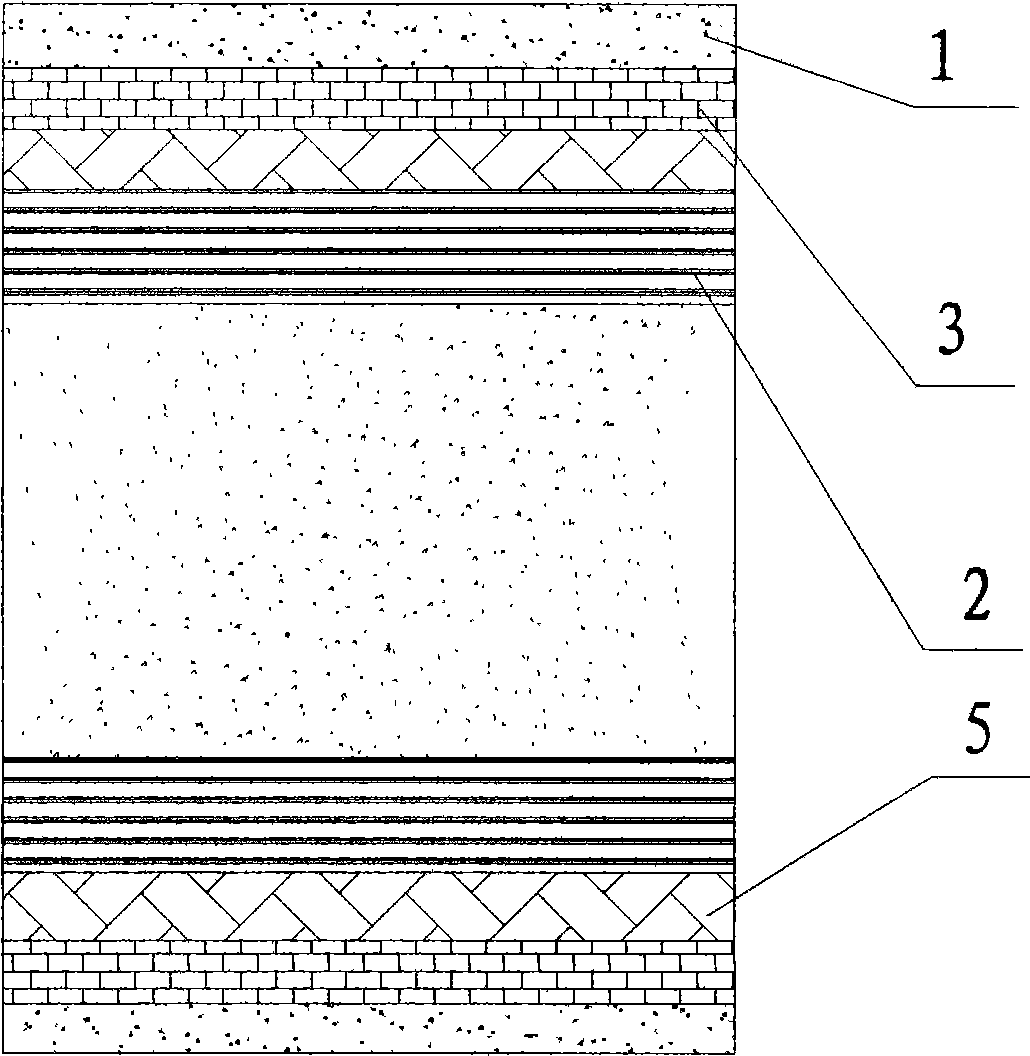

Road surface structure of rolled press polymer modified cement concrete and its constructure method

InactiveCN1598151AReduce dosageImprove economyIn situ pavingsRoller-compacted concretePolymer modified

The invention relates to a grinding polymer modification cement concrete pavement structure and its construction method which refers to pavement project and its construction method, as well as concrete material and its construction method. The invention utilizes slurry mixed by the polymer and cement as the binding agent to felt the macadam and sand, it is formed to grinding polymer concrete pavement structure by grinding technology. Granular material of the grinding concrete is felted firmly to the slurry after adding the polymer. After the grinding concrete is hard set, it will become high intensity, great deformability, great water resistance, great ageing resistance, great corrosion resistance, great temperature stability. According to the different condition, different kind polymer material and use level are used to adjust the deformability of the grinding polymer modification cement concrete to make it present rigidity or flexibility. The grinding polymer modification cement concrete pavement structure adopts grinding technology; its advantages are the construction is expediently, the use less of the polymer and great economical efficiency and wide adaptation surface; high intensity, great deformability, great water resistance, and crack resistance.

Owner:易志坚 +1

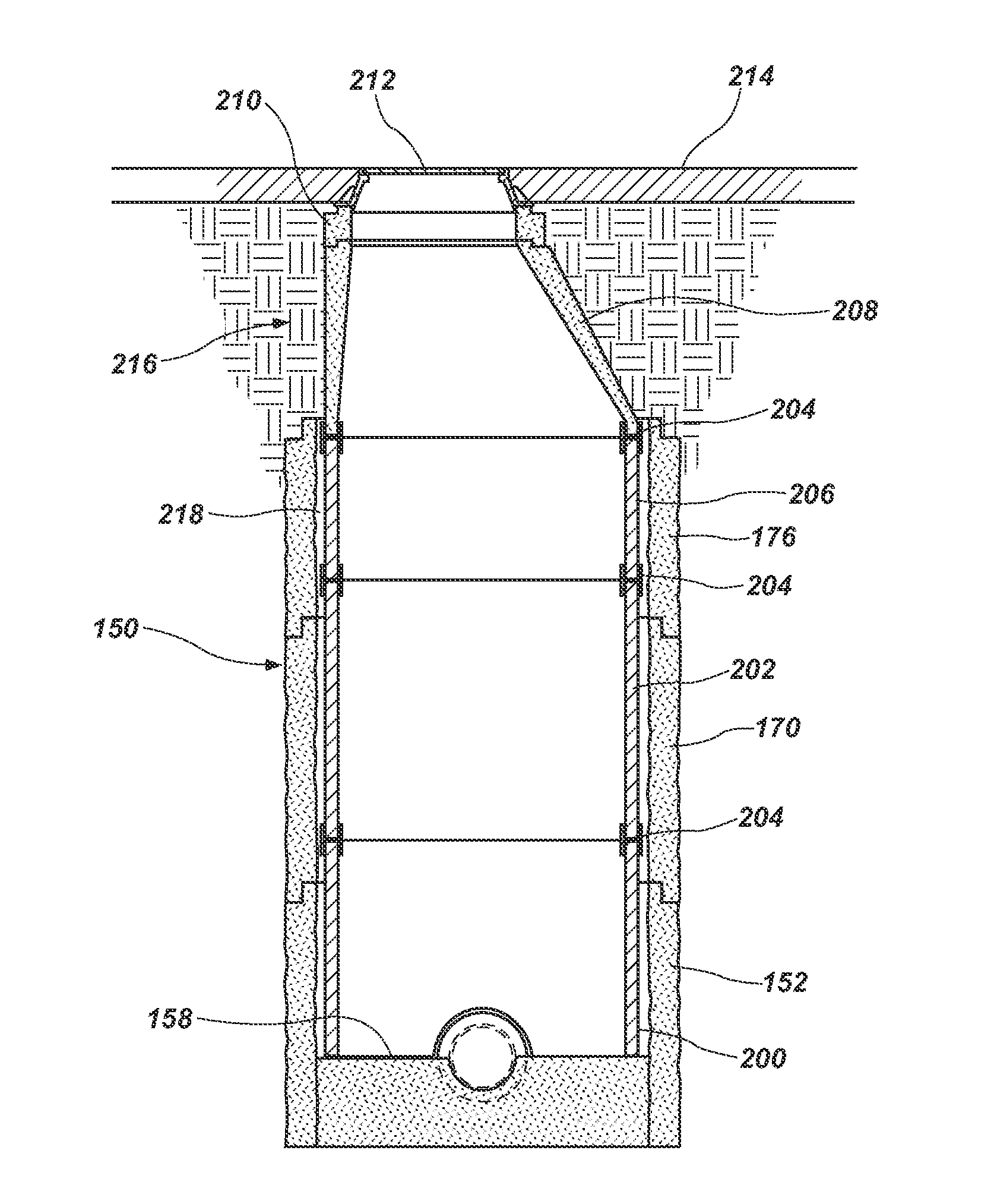

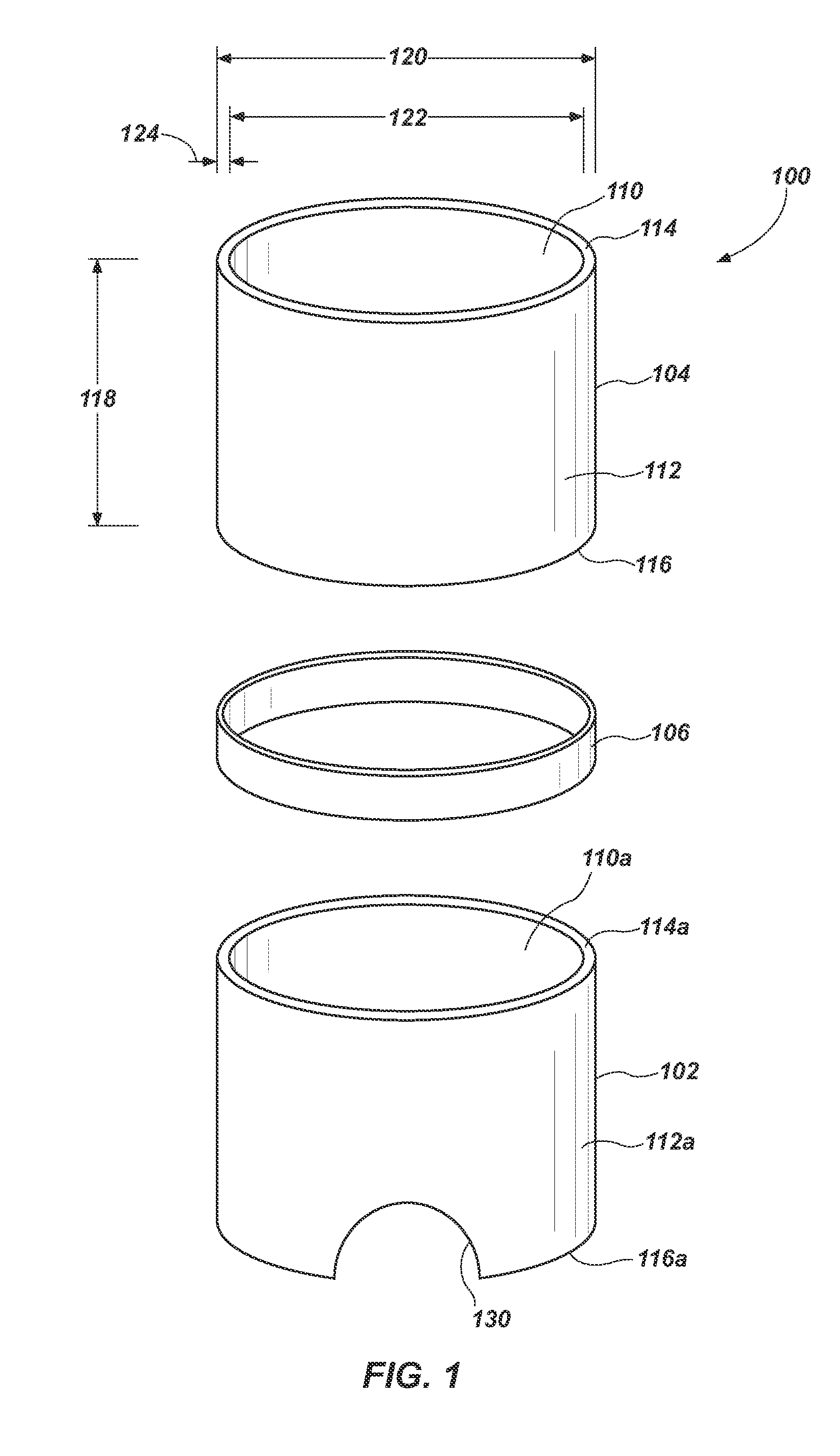

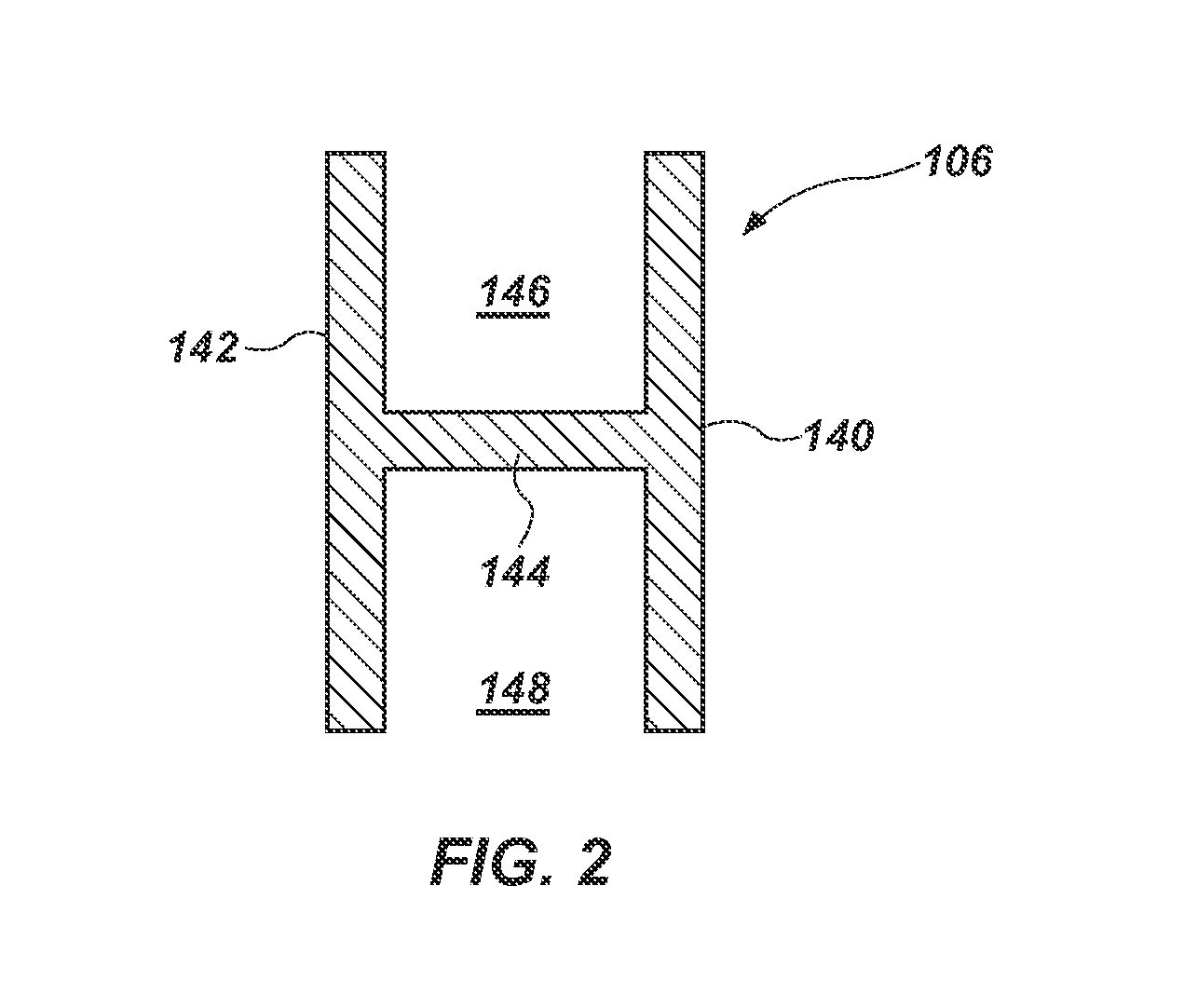

Rehabilitation of deteriorated manhole and other sewer structures

A new inner passageway through a pre-cast concrete structure damaged by corrosion may be formed by stackable inserts formed of polymer concrete. The inserts may be stacked in the old passageway through the pre-cast concrete structure such that an inner surface of the stacked inserts forms a new passageway through the pre-cast concrete structure. A grout may be poured between an outer surface of the stacked inserts and an inner surface of the pre-cast concrete structure forming the old passageway. The surfaces of the stackable inserts may have superior resistance to corrosive acids such that the need for future repair is greatly reduced. Suitable pre-cast concrete structures for rehabilitation include pre-cast concrete structures utilized in wastewater systems, including manholes and other similar structures. In this manner, the damaged pre-cast concrete structures do not need to be removed during the rehabilitation.

Owner:GENEVA POLYMER PROD

Strength controllable coal ash-based polymer concrete and preparation method thereof

The invention provides a strength controllable coal ash-based polymer concrete. The polymer concrete comprises a mixed solid phase and a mixed liquid phase, wherein the weight ratio of the mixed solid phase and the mixed liquid phase is 11:1, the mixed solid phase comprises the following components in parts by weight: 45-55 parts of coarse aggregate gravel, 13-33 parts of fine aggregate natural sand, 19-27 parts of coal ash, 0-8 parts of silica fume, and 0.05-0.12 part of sodium tripolyphosphate, and the mixed liquid phase comprises the following components in parts by weight: 67-75 parts of liquid sodium silicate for industrial use, and 25-33 parts of 10-18mol / L of sodium hydroxide solution. A preparation method for the coal ash-based polymer concrete is simple, has no toxicity and no contamination, and has low cost, and the raw material spreads all over the world and is expected to be used in fields such as corrosion resistant concrete construction, utilization of industrial wastes, rapid patching materials, high-strength high performance materials and the like. Furthermore, according to the coal ash-based polymer concrete, large amount of industrial waste coal ash can be efficiently used, so that the coal ash-based polymer concrete has great significance to conservation of energy and resources and environment protection. The invention also provides the preparation method of the coal ash-based polymer concrete.

Owner:WENZHOU UNIVERSITY

Light slat anti-crack construction method

InactiveCN101532312AGuaranteed installation qualitySolve the cracking of the board seamBuilding insulationsPolymer concreteAlong edge

A light slat anti-crack construction method is disclosed, to resolve a technical problem that slats are easy to crack during a construction process, with the following solutions according to the construction method, polymer concrete mortar is served as the jointing material, waterproof sizing material secondary raked joint is used at edge joints of slats, adhered with anti-crack fibre sheets, specifically, comprising the following steps: coating 10 mm of polymer concrete mortar sufficiently along edges on the contact surfaces between slats or slats and wall surface, assembling the slats by a low wedge top board method, with the polymer concrete mortar coated sufficiently at all joint seams, filling and scraping the wall joint seams with a waterproof sizing material twice, after the waterproof sizing material is solidified, coating a layer of 108 gum on the waterproof sizing material, and then adhering the 108 gum with alkaline-resisting glass fibre mesh, finally filing and leveling up grooves of the slats by the polymer concrete mortar. The invention is environment friendly, which resolves the problem effectively that the light slats are easy to crack, so as to guarantee installation quality of slats.

Owner:SHENZHEN CONSTR GRP

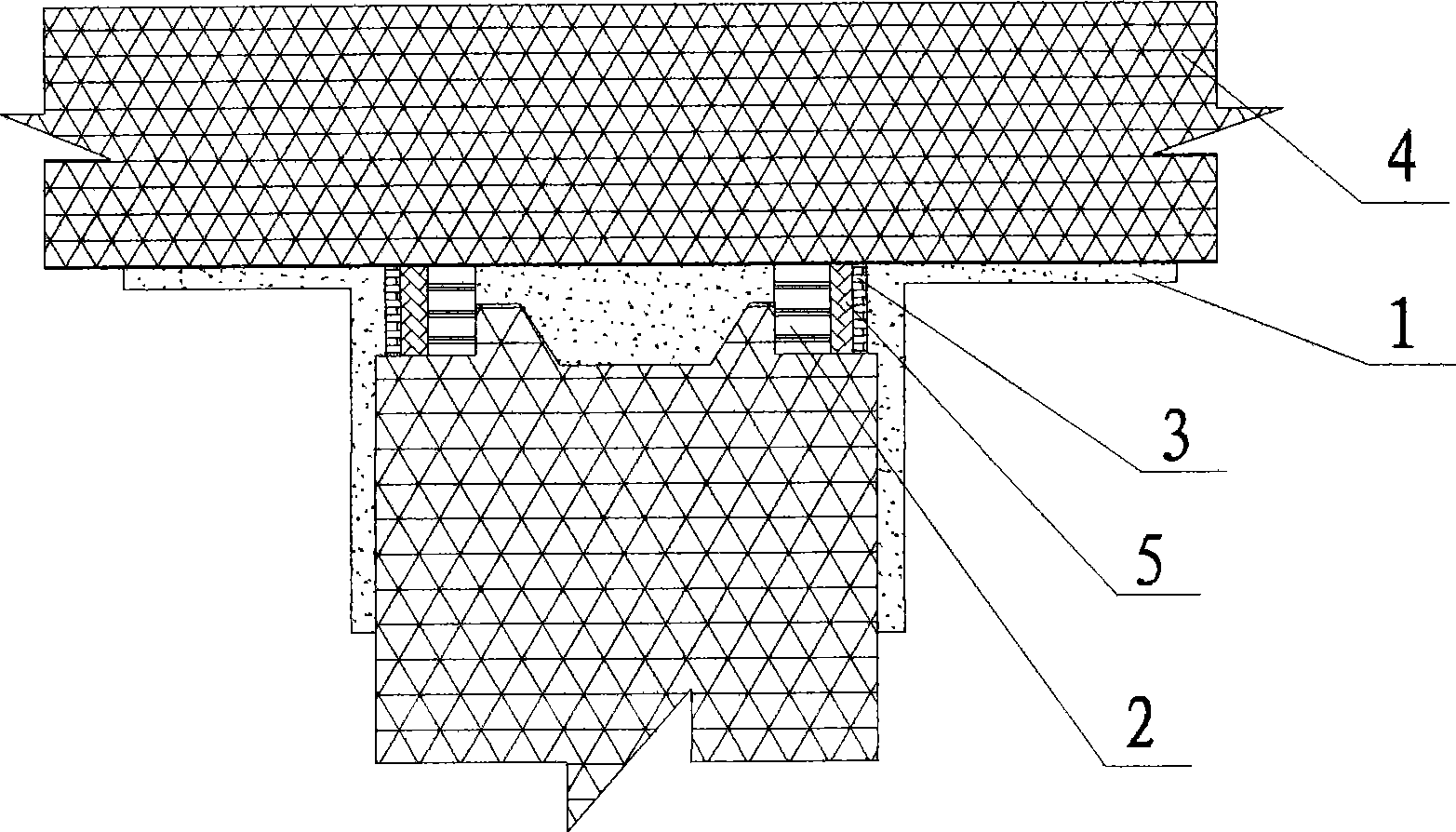

Anti-corrosion geopolymer concrete filling pile material as well as preparation method and construction process thereof

InactiveCN108675699AImprove liquidityDecreasing rheologyCement productionBulkheads/pilesFiberPolyvinyl alcohol

The invention discloses an anti-corrosion geopolymer concrete filling pile material, which is prepared from the following ingredients in parts by weight through preparation: 100 parts of metakaolin, 10 to 40 parts of fly ash, 150 to 250 parts of modified water-glass with the modulus number being 1.2 to 1.8, 400 to 600 parts of fine sand, 800 to 1500 parts of stone, 5 to 20 parts of polyvinyl alcohol fiber and 5 to 10 parts of boric acid, wherein the modified water-glass is prepared from 6 to 15 parts of water, 15 to 40 parts of sodium hydroxide and 129 to 195 parts of water-glass sold on the market. The invention also discloses a preparation method of the anti-corrosion geopolymer concrete filling pile material, and a construction process of the anti-corrosion geopolymer concrete filling pile material. The metakaolin base geopolymer-PVA fiber concrete filling pile material with good rheological property and anti-corrosion performance capable of being used for filling pile grouting construction can be prepared; the technical scheme has the advantages that the use is simple; the concrete material realizes the fast hardening and early strength; the construction is fast and continuous;the adaptability is high; the high efficiency of the materials can be realized; the material can be widely applied to the practical engineering of the filling pile in corrosive environment such as northwest salt and alkaline land engineering construction.

Owner:ZHEJIANG UNIV

Geopolymer cement

ActiveUS20150321954A1Accelerate strength growth rateHigh compressive strengthSolid waste managementCement productionSolid componentPolymer concrete

A solid component activator for use in a geopolymer cement containing a silico-aluminate material comprising a mixture of sodium silicate and sodium carbonate for activating the geopolymer cement by increasing reactivity of the silico-aluminate material in the geopolymer cement when forming geopolymer concrete.

Owner:CEMENT AUSTRALIA PTY

Method for producing polycyclic aromatic hydrocarbon sulfonate polymer concrete water reducing agent

InactiveCN101007719AImprove use valueNo anthracene coking phenomenonPolycyclic aromatic hydrocarbonSulfonate

The invention discloses a manufacturing method of polycyclic aromatic sulfonate polymer concrete dehydragent in the chemical manufacturing technique, which is characterized by the following: adopting anthracene slag and condensed sulfuric acid as raw material; sulfonating under 70-120 deg.c; hydrolyzing; condensing; neutralizing; improving receiving rate effectively.

Owner:JIANGDU RUNHUA CHEM

Novel thermal insulation and heat preservation building structure and construction technique

InactiveCN1594773ALow costImprove insulation effectCovering/liningsHeat proofingFiberFiberglass mesh

The present invention provides a novel thermal insulation and heat preservation structure and construction technique, the structure has wall body, a thermal insulation and heat preservation layer, a crack-resistant layer, a decorative layer. The construction technique has steps of subbase process, coating thermal insulation and heat preservation plasm, coating polymer concrete crack-resistant substrate, clinging mesh cloth, coating novel water-proof conserving liquid, decorative face processing, the subbase process method comprises steps of dabbing, watering, smoothing with normal concrete sand plasm or dabbing with polymer concrete sand plasm, the thermal insulation and heat preservation is molded with polystyrene particles and mineral having gelling property; the crack-resistant layer is that pressing alkali-proof fiberglass mesh cloth on the fiber polymer concrete plasm, then coating inleakage type elastic water-proof conserving liquid; the decorative layer is formed with flexible, water-proof lacquer putty and color dope. The structure has improved thermal insulation and heat preservation ability, wearing ability, and operation efficiency.

Owner:奥捷科技股份有限公司

Quick patching material for cement concrete pavement and preparation method thereof

The invention relates to a polymer concrete mortar for quick patching of cement concrete pavements and a preparation method thereof. The material is prepared in proportion by taking industrial waste flyash as a main raw material, a polyurethane-modified epoxy resin as a binder, a modified polyamine as a curing agent, and adding a right amount of an active dilution toughening agent. The specific proportion is accounted as: in parts by weight, 200 to 300 of flyash, 100 to 150 of polyurethane-modified epoxy resin, 100 to 150 of polyamine, 15 to 30 of a diluent, and 5 to 20 of an exciting agent. The patching material for cement concrete pavements prepared by the invention has the advantages of rapid hardening early strength (curing time: 10-40 min; compressive strength of 65-75 MPa), strong bonding power with cement concrete so that the construction can be performed in wet and low-temperature conditions, high cured strength, good toughness, smooth surface, and excellent abrasive resistance and shock resistance.

Owner:SHANGHAI JIAYUAN BUILDING MATERIAL

Composition of polymeric concrete

InactiveUS20080153942A1Good chemical resistanceImprove usabilityPolymer scienceMechanical resistance

This invention is related to a new composition of Polymeric Concrete which is characterized by the total elimination of Portland cement as an agglutinant or binding agent, and the total elimination of water as a catalyst or hardening agent. In particular, a Polymeric Concrete including i) 6.0 to 35% by weight of a polymerization or polycondensation resin; ii) 94.0 to 65.0 % by weight of loads or mechanical resistance elements; iii) optionally 0.5 to 5.0% by weight of a catalyst dissolved in dissolvent agents; iv) optionally 1.0 to 6.0 % by weight of an accelerator based on soap elaborated with non-hydrosoluble heavy metals dissolved in a dissolving agent; v) optionally 1.0 to 10.0% by weight of ultraviolet ray inhibitors dissolved in a dissolving agent; vi) optionally 1.0 to 15.0% by weight of flame combustion inhibitors dissolved in a dissolving agent; and vii) optionally 4.0 to 15.0% by weight integrated colors.

Owner:TEJADA JUAREZ NICOLAS FERNANDO

Compound activator and geopolymer cement concrete prepared from same

ActiveCN103172295ASuitable base stimulated activityReduce alkali chemical attackCement productionKaolin clayPolymer concrete

The invention provides a compound activator. The compound activator comprises triethanolamine, a naphthalene water reducer, quartz powder and lime milk. The invention further provides geopolymer cement concrete prepared from the compound activator. The geopolymer cement concrete comprises a binding material, an aggregate and the compound activator; by the geopolymer cement concrete per cubic meter, the addition amount of the binding material is 510-650kg, the addition amount of the aggregate is 1410-1550kg, the specific value of the addition amounts of the compound activator and the binding material is (0.22-0.35):1, the water-binder ratio is 0.35-0.37, and the sand ratio of the aggregate is 25-35%; and the binding material comprises one or more of metakaolin, slag powder and pulverized fuel ash, and the aggregate comprises sand and cobbles. The geopolymer cement concrete provided by the invention is low in cost, can be maintained at a normal temperature and has the advantages of high strength, high volume stability and durability, so that the geopolymer cement concrete can be widely applied to building fields such as civil engineering, highways and bridges instead of common Portland cement.

Owner:北京中联新航建材有限公司

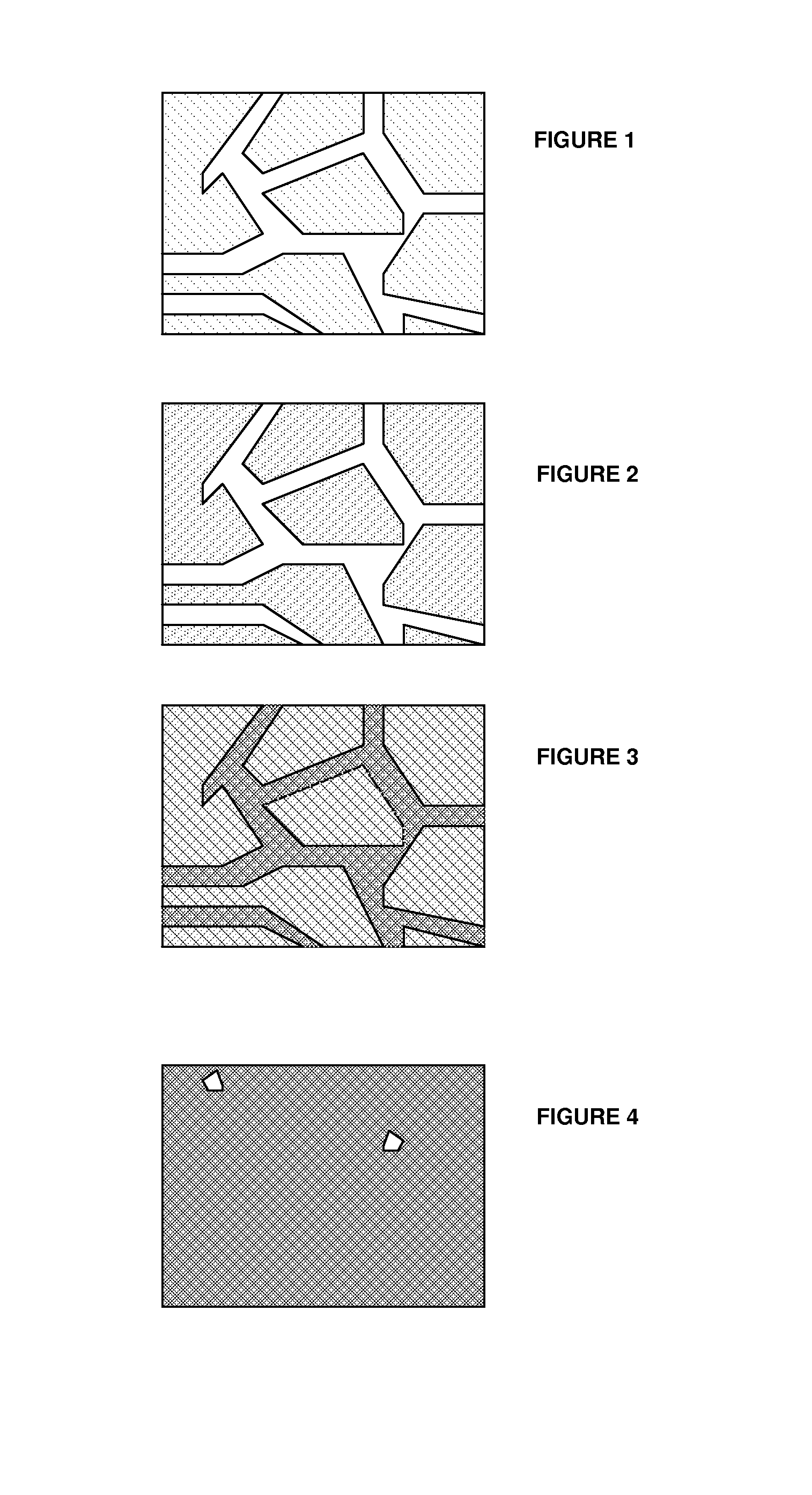

Alkali-activated slag geopolymer concrete and preparing method thereof

The invention provides alkali-activated slag geopolymer concrete. The geopolymer concrete is a compound powder cementing material is formed by slag powder and construction waste renewable micro powder under the priming action of a water glass solution of sodium hydroxide. The alkali-activated slag geopolymer concrete is prepared from, by weight, 150-210 parts of slag powder, 20-60 parts of construction waste renewable micro powder, 190-240 parts of water glass, 25-50 parts of solid sodium hydroxide, 400-700 parts of sand and 0-1600 parts of coarse aggregate. Being prepared from slag powder, construction waste renewable micro powder, water glass, solid sodium hydroxide, sand and coarse aggregate, the alkali-activated slag geopolymer concrete has the advantages of being high in early strength, high in durability, high temperature resistance, corrosion resistance and heat-insulating property and low in production energy consumption and is green building material low in cost and high in performance.

Owner:上海德滨环保科技有限公司

Phosphogypsum-base foaming concrete

The invention relates to a construction material, especially a phosphogypsum-base foaming concrete. The concrete is composed of the following components in parts by weight: 60 to 350 parts of water, 43.5 to 261 parts of phosphogypsum, 10 to 60 parts of fly ash, 10 to 60 parts of cement, 3 to 3.5 parts of quicklime, 0.01 to 0.02 part of water reducer, and 0.5 to 3.5 parts of foaming agent; wherein the particle size of fly ash is in a range of 5 [mu]m to 25 [mu]m, the cement is 325 slag cement, the water reducer is a naphthalene water reducer, and the foaming agent is a polymer concrete foaming agent. The weight of the concrete prepared according to the formula mentioned above is reduced by 30%, compared to that of the common solid non-foaming concrete. The 28-day compression resistant strength of the cement is in a range of 3.8 to 4.3 MPa. Moreover, the phosphogypsum and 325 slag cement are both industrial solid wastes, so the manufacturing cost of the cement is very low.

Owner:候姣姣

Geopolymeric concrete and preparation method thereof

The invention belongs to the field of concrete and particularly discloses geopolymeric concrete. The geopolymeric concrete is prepared from, by weight, 280-320 parts of mineral powder, 55-65 parts offly ash, 35-40 parts of silica fume, 220-240 parts of composite activator, 1.5-2 parts of water reducing agent, 0.8-1.2 parts of retarder, 665-692 parts of fine aggregates, 1200-1250 parts of coarse aggregates and 4.5-5.5 parts of fiber. According to the prepared geopolymeric concrete, alkaline waste liquor with high aluminum content, instantly soluble sodium silicate and sodium hydroxide are adopted to prepare the composite activator so that the dosage of the sodium hydroxide in the composite activator of the geopolymeric concrete can be greatly reduced, meanwhile, sodium metaaluminate in thewaste liquor can serve as active aluminium corrector or part of active aluminium raw material of a geopolymeric concrete system, and water in the waste liquor can serve as a water source of the concrete, so that the current preparation cost of the geopolymeric concrete is greatly reduced; in addition, the preparation method provides a new path for efficient resource utilization of the alkaline waste liquor with high aluminum content which is generated in the machining process of the aluminium alloy raw material.

Owner:成都宏基建材股份有限公司

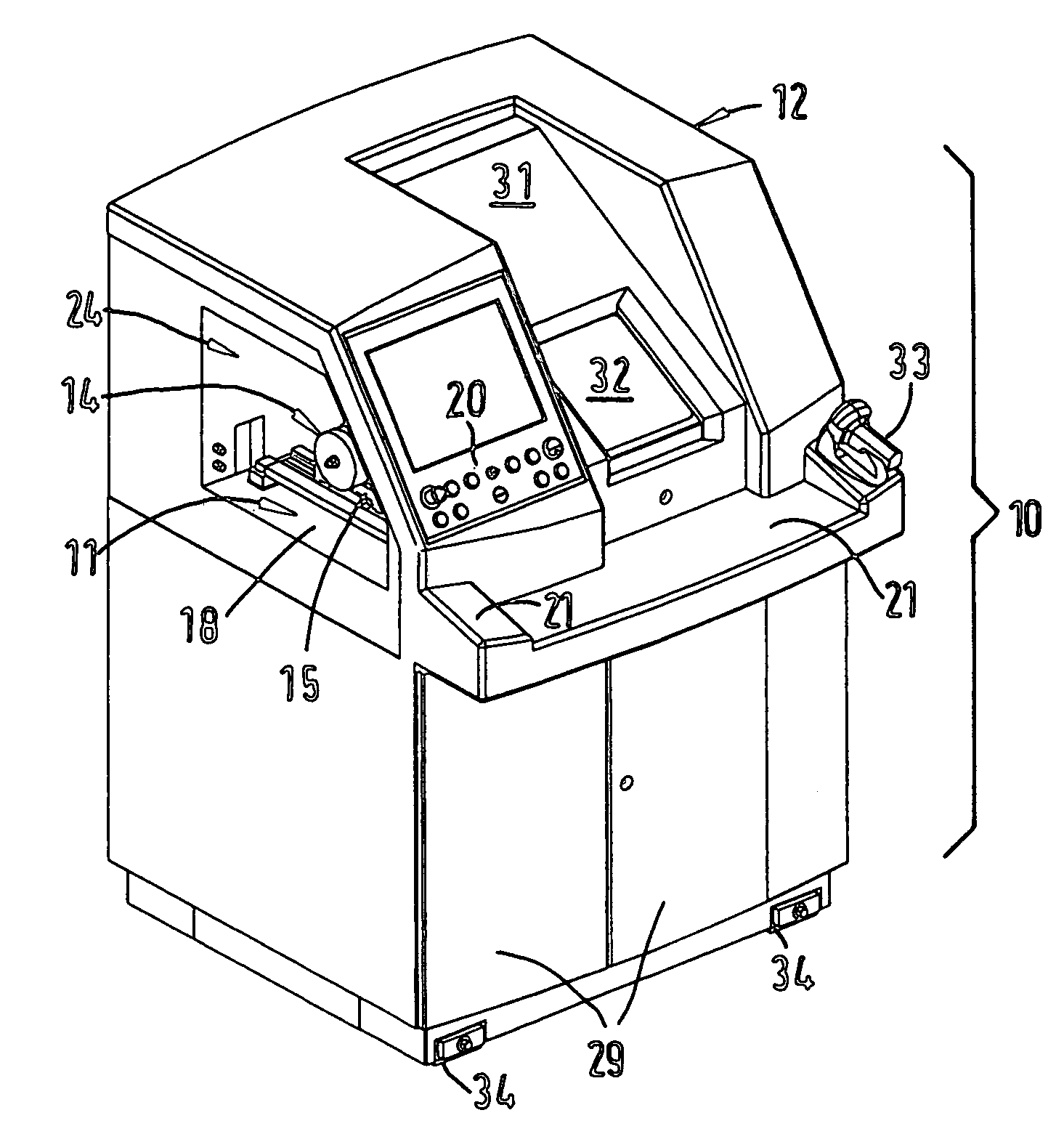

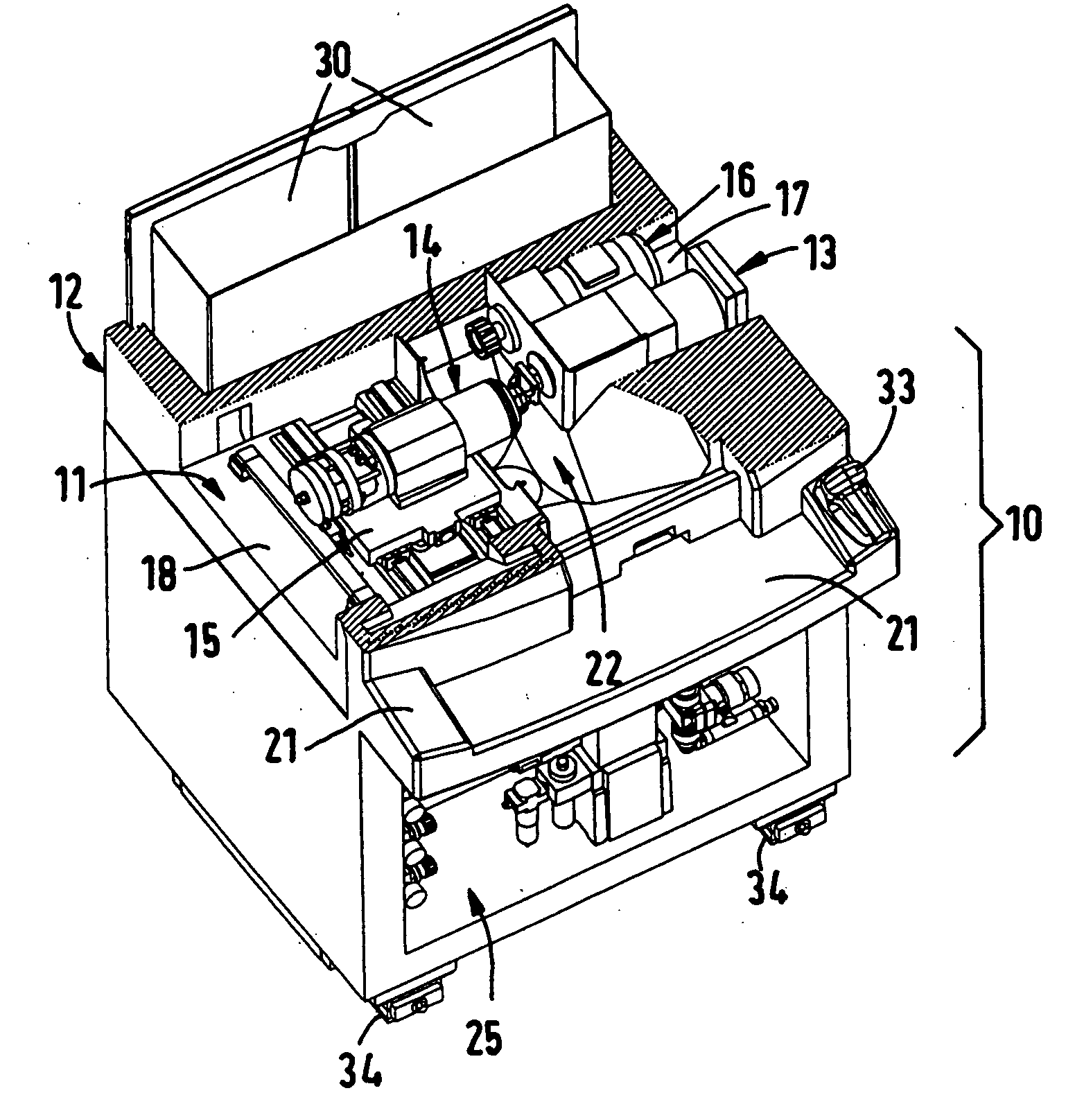

Lathe for machining optical workpieces

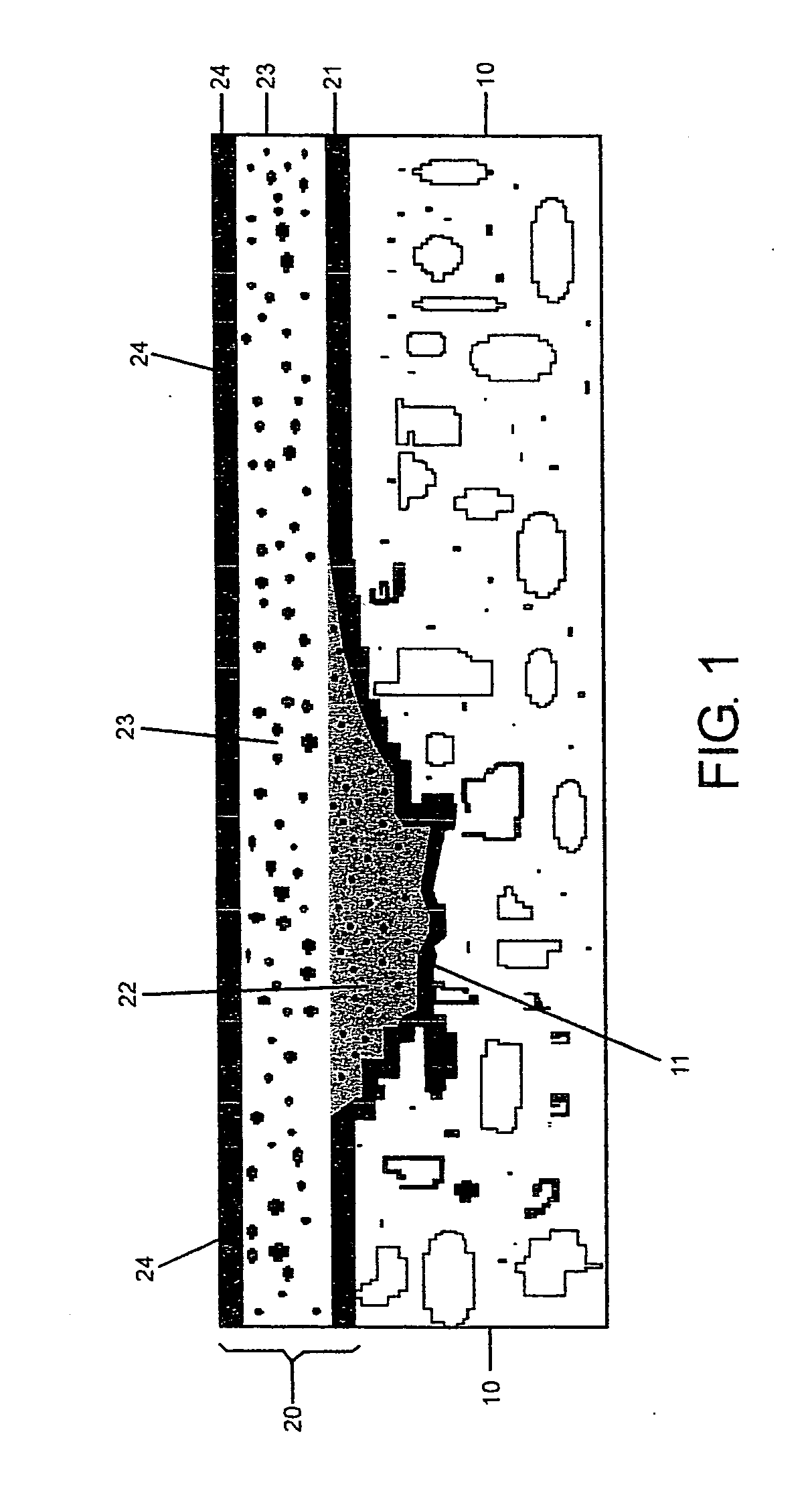

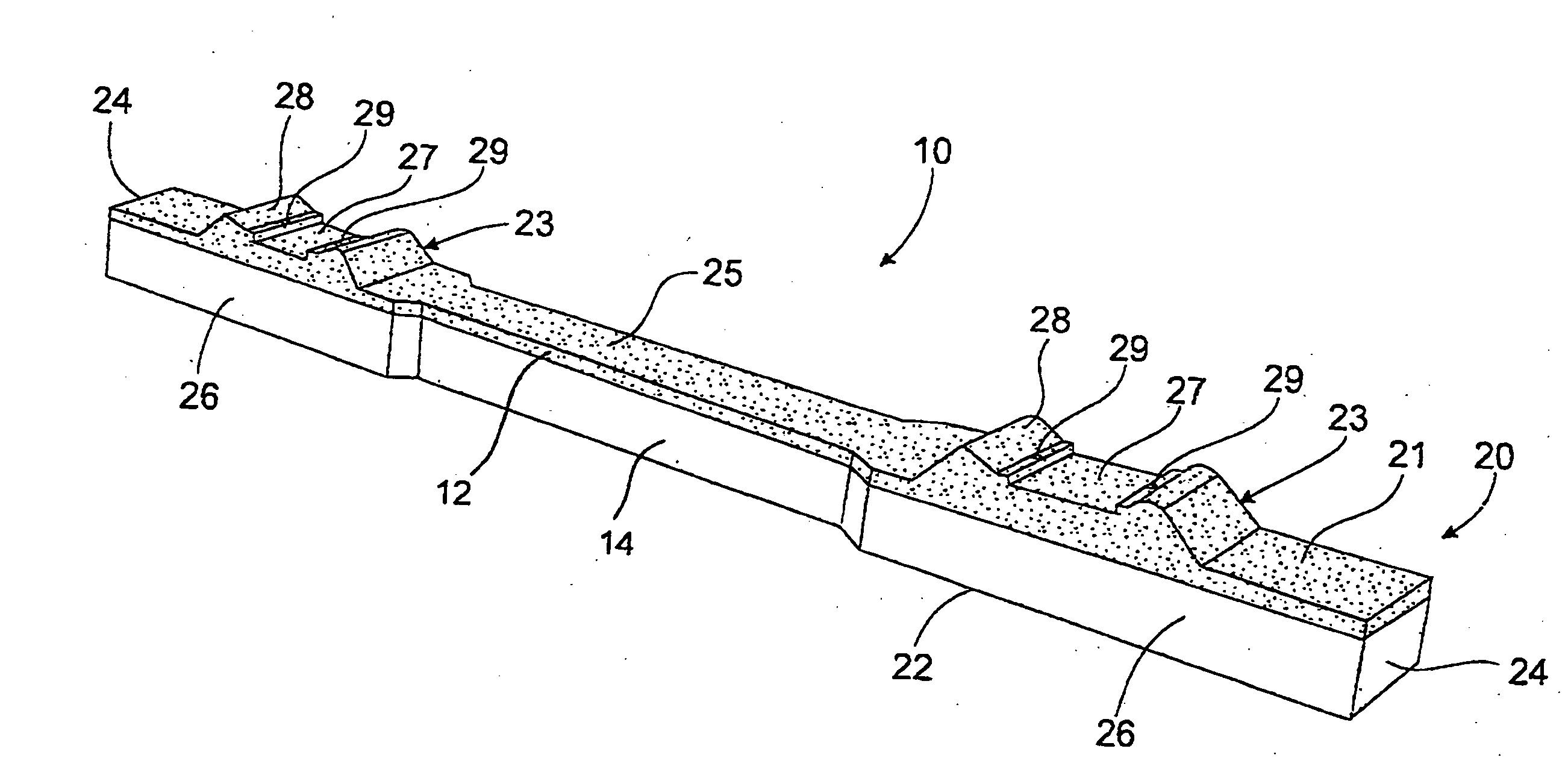

InactiveUS7278192B2Fast transmissionSimple and cost-effectiveLathesAutomatic/semiautomatic turning machinesCompact dimensionEngineering

A lathe for machining optical workpieces, in particular spectacle lenses, comprises a fast tool arrangement and a workpiece spindle arrangement. A machine frame is cast monolithically from polymer concrete and on and in which all the functional surfaces, functional spaces and other cutouts are formed to their exact dimensions during the casting process. The machine frame upper part cast in one piece simultaneously covers the fast tool arrangement and the workpiece spindle arrangement and thus the machine bed in the manner of a covering hood. The machine frame is of compact dimensions, has a very rigid oscillation-damping machine bed and, in comparison with the rapidly moving elements of the fast tool arrangement, has a very large mass with a high center of gravity, which prevents the transmission of disruptive oscillations from the fast tool movement to the machine bed and thus to the workpiece spindle arrangement. The lathe can be manufactured in a cost-effective manner and allows the production of any spectacle lens optical surfaces with extremely high dimensional accuracy and surface quality. The achievable optical surface quality allows direct polishing by means of flexible or adaptable polishing tools, as a result of which considerable savings are made in the subsequent process. If suitably equipped with a cutter spindle arrangement, edge machining operations on the spectacle lenses can be carried out.

Owner:SATISLOH GMBH

Polymeric Resin Composition For the Production of Coatings

InactiveUS20080194735A1Efficiently attachedLow costPlastic/resin/waxes insulatorsFilm/foil adhesivesPolymer resinPolymer concrete

Disclosed herein is a resin composition for the manufacture of coatings such as polymeric concretes, terrazzos and finishes, comprising: a) from 15 to 50% by weight of methyl methacrylate (MMA) monomer; b) from 25 to 75% by weight of a mixture of equal parts of polyester resins of: i) an isophthalic polyester resin; ii) an orthophthalic polyester resin; and iii) a neopentyl polyester resin; c) up to 8% by weight of an epoxy resin obtained from bisphenol A and epichlorohydrin; and d) up to 5% by weight of an aliphatic or aromatic polyurethane resin.

Owner:VERDUGO PEREZ JOSE ANGEL +1

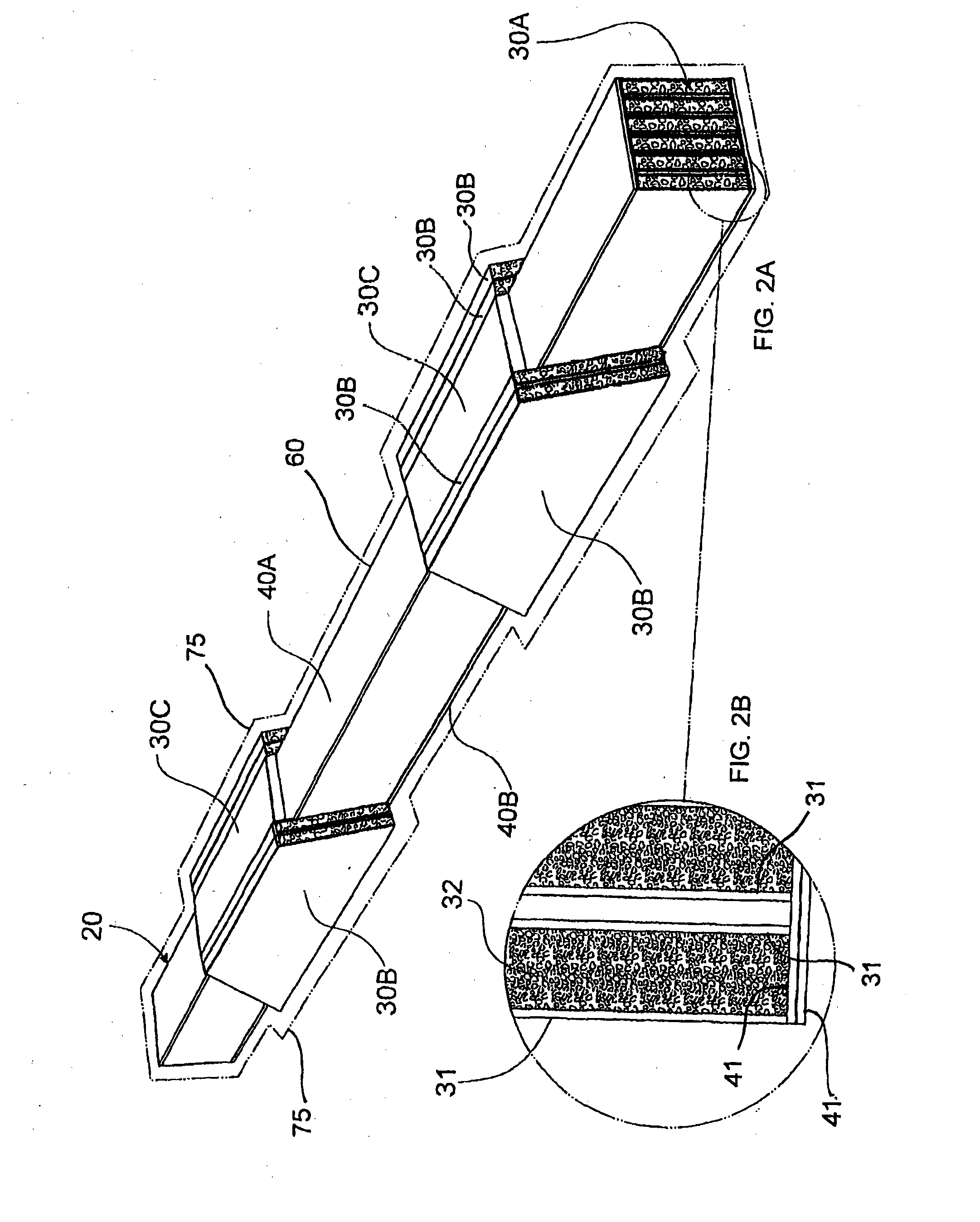

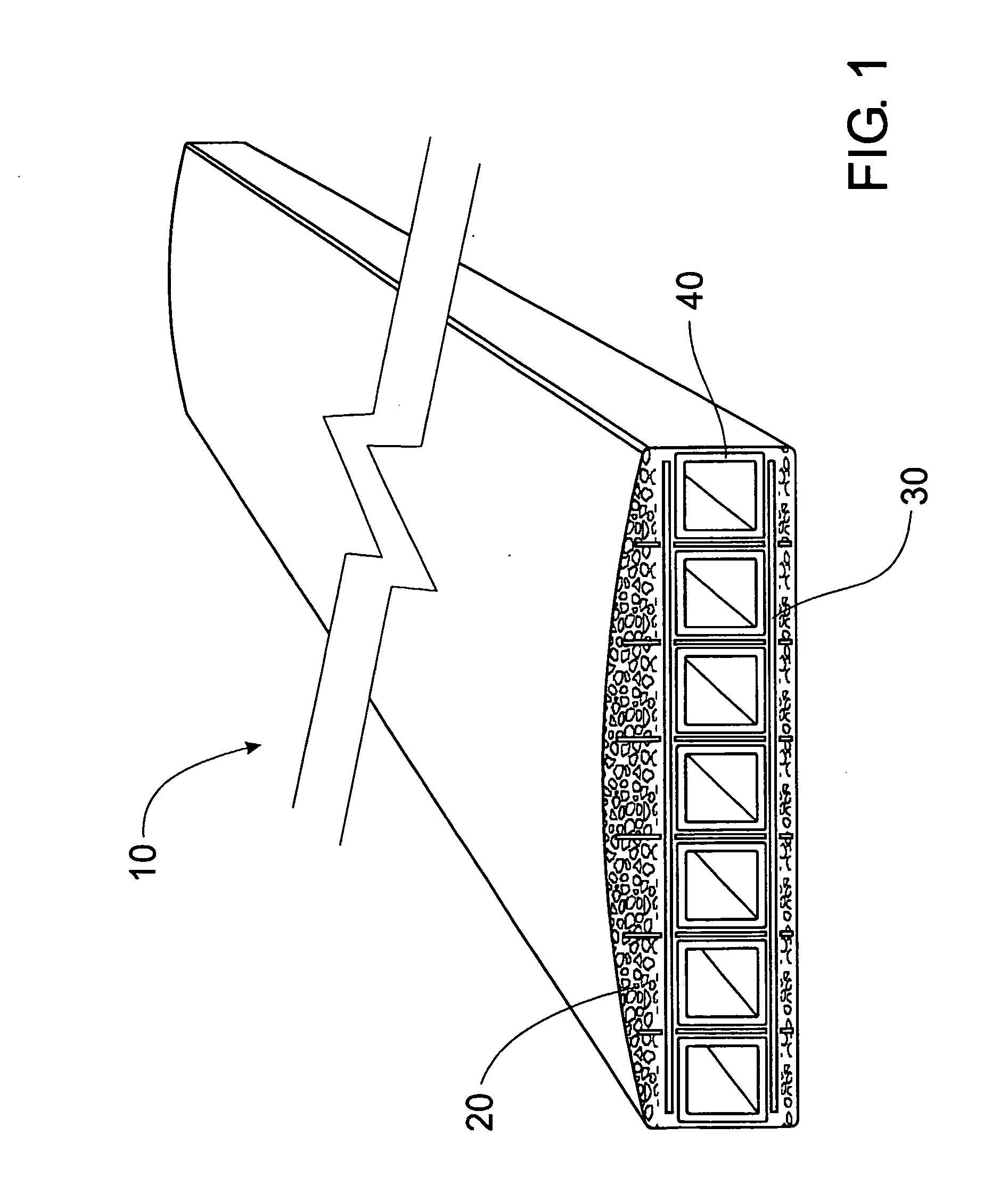

A Railway Sleeper

InactiveUS20150330031A1Produced cost-effectivelyLow production costBallastwaySynthetic resin layered productsPolymer resinPolymer concrete

A railway sleeper comprising a body having a top face on which railway rails are located and a bottom face for placement on a ground surface. The body is formed from a plurality of fibre composite sandwich panels plus a polymer concrete comprising an amount of polymer resin and an amount of filler. Each sandwich panel has a pair of fibre composite skins with a structural core material located therebetween. The fibre composite sandwich panels extend longitudinally within said body.

Owner:CARBONLOC

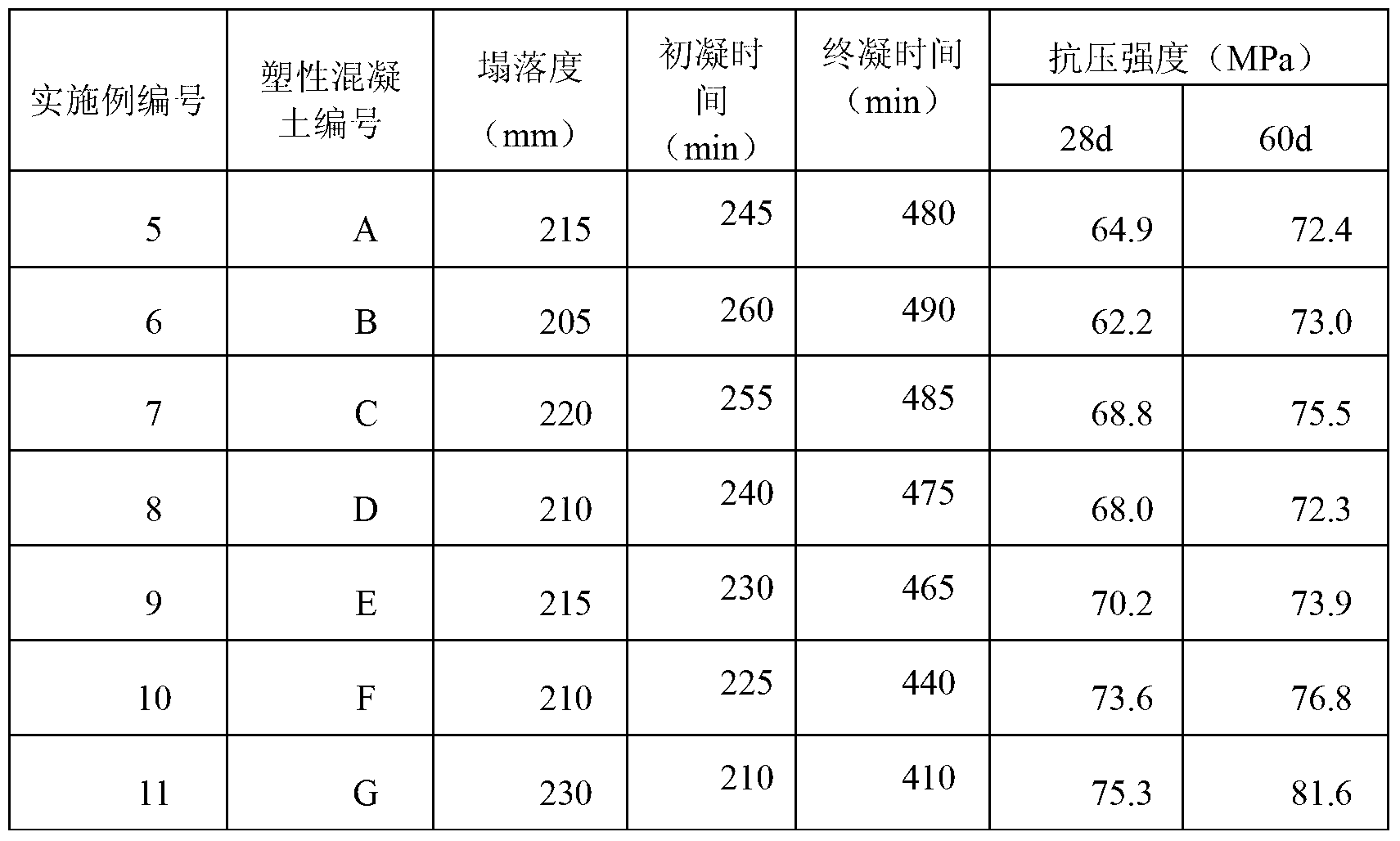

Bridge deck slab waterborne polyurethane polymer concrete and preparation method thereof

ActiveCN104876474ASusceptible to corrosion damage, the problem of low strength is solvedReduce repair costsSolid waste managementPolymer scienceSuperplasticizer

The invention provides bridge deck slab waterborne polyurethane polymer concrete and a preparation method thereof. The bridge deck slab waterborne polyurethane polymer concrete comprises the following raw material components: coarse aggregate, medium sand, coal ash, silica dust, a naphthalene water reducer, waterborne polyurethane and a silane coupling agent. The preparation method of the bridge deck slab waterborne polyurethane polymer concrete comprises the following steps: at room temperature, putting dried coarse aggregate, medium sand, coal ash and silica dust into a stirrer; then, adding waterborne polyurethane emulsion and stirring; and then adding the silane coupling agent and stirring; and finally adding the naphthalene water reducer and stirring. According to the preparation method, the waterborne polyurethane polymer is used for replacing concrete to serve as a cementing material, is mixed with aggregate and is added with coal ash, silica dust, the naphthalene water reducer and the silane coupling agent. The bridge deck slab waterborne polyurethane polymer concrete can be applied to a bridge deck structure which has a high requirement on durability or is difficult to repair and large in span.

Owner:HARBIN ENG UNIV

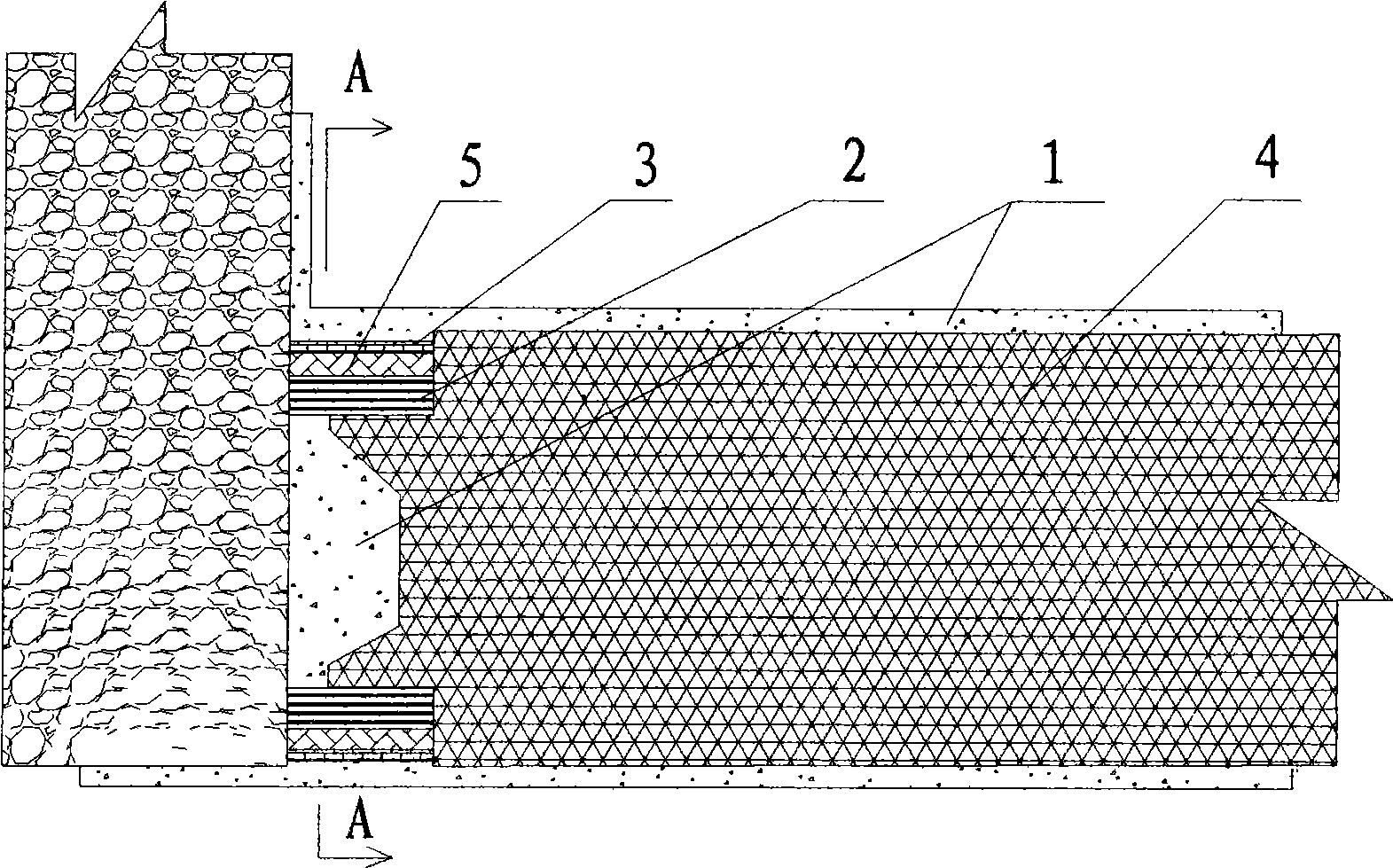

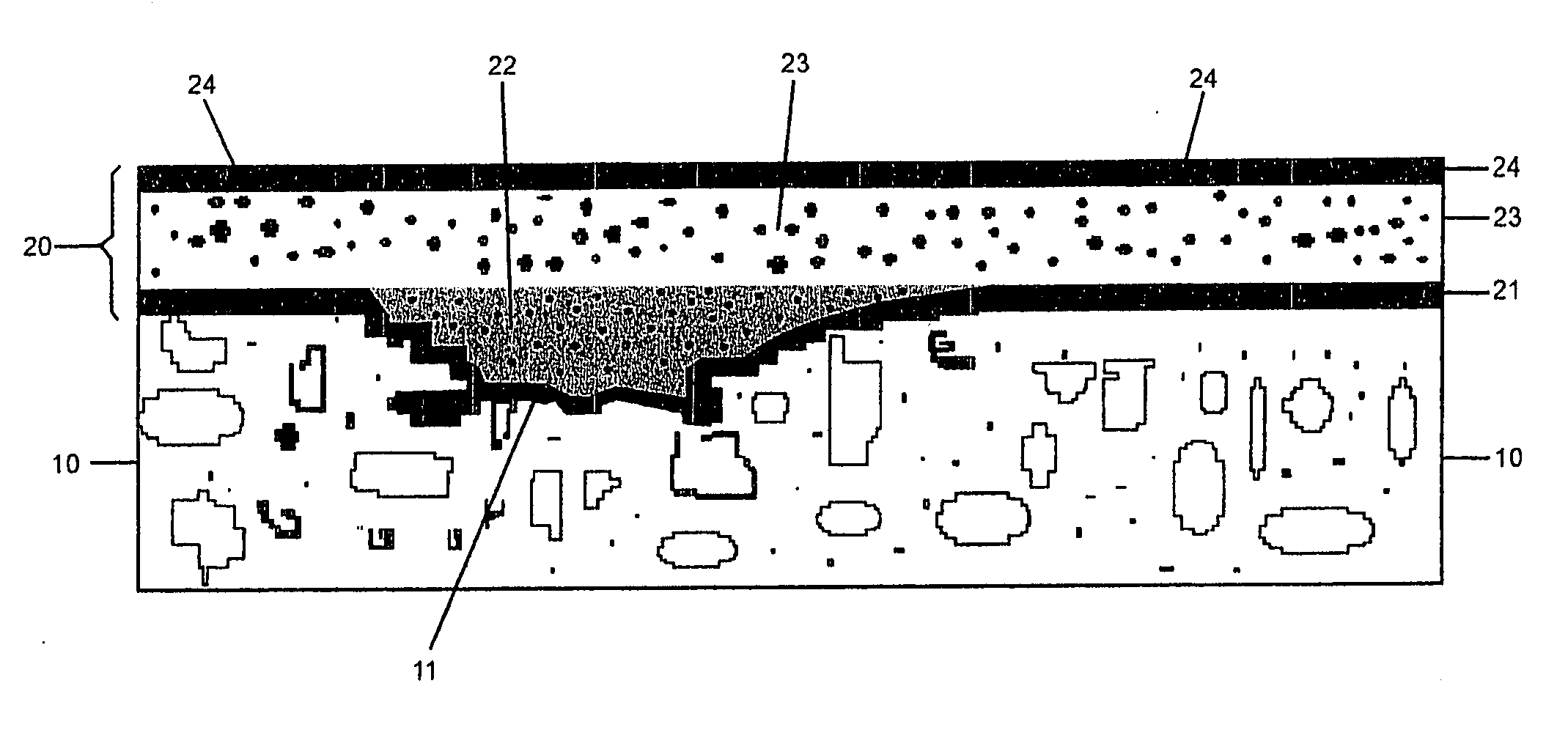

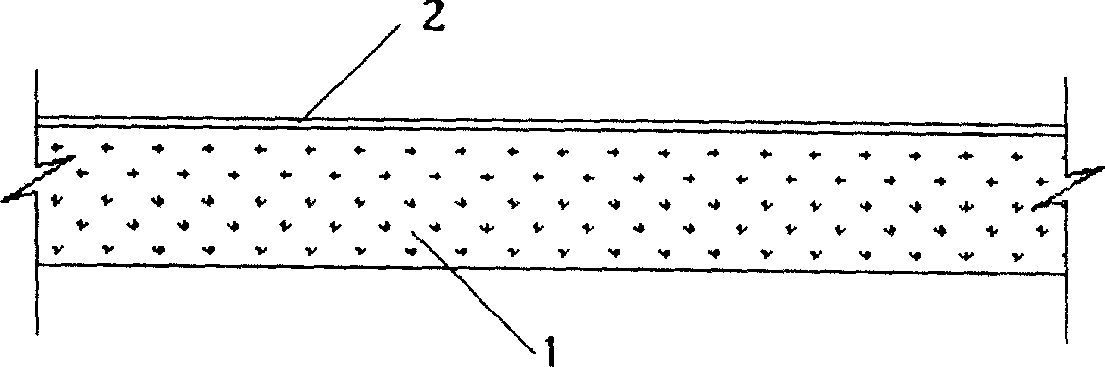

Color pavement formed by spraying on porous polymer concrete facing and construction method therefor

A colorful road plated with porous polymer concrete face and relative construction first mix polymer, broken stone and stuff uniformly to form polymer porous concrete material, lay to form polymer porous concrete face 1, mix uniformly the colorful face, and plate colorful face on the face of porous polymer concrete face layer 1 to form a colorful face layer 2, while the colorful face layer 2 is adhered with the porous polymer concrete face layer 1, to form a colorful road. The inventive road has high strength, better deformation property, abrasion resistance or the like, while the color can adjust via different fields.

Owner:易志坚

Lathe for machining optical workpieces

InactiveUS20060248697A1Simple and cost-effectiveAvoid spreadingLathesAutomatic/semiautomatic turning machinesCompact dimensionEngineering

A lathe for machining optical workpieces, in particular spectacle lenses, comprises a fast tool arrangement and a workpiece spindle arrangement. A machine frame is cast monolithically from polymer concrete and on and in which all the functional surfaces, functional spaces and other cutouts are formed to their exact dimensions during the casting process. The machine frame upper part cast in one piece simultaneously covers the fast tool arrangement and the workpiece spindle arrangement and thus the machine bed in the manner of a covering hood. The machine frame is of compact dimensions, has a very rigid oscillation-damping machine bed and, in comparison with the rapidly moving elements of the fast tool arrangement, has a very large mass with a high center of gravity, which prevents the transmission of disruptive oscillations from the fast tool movement to the machine bed and thus to the workpiece spindle arrangement. The lathe can be manufactured in a cost-effective manner and allows the production of any spectacle lens optical surfaces with extremely high dimensional accuracy and surface quality. The achievable optical surface quality allows direct polishing by means of flexible or adaptable polishing tools, as a result of which considerable savings are made in the subsequent process. If suitably equipped with a cutter spindle arrangement, edge machining operations on the spectacle lenses can be carried out.

Owner:SATISLOH GMBH

Colour functional road curb stone

ActiveCN1743554AGood water permeabilityNot easy to fall off and fadePaving gutters/kerbsTraffic signalsCalcium silicateFiber

This invention discloses a color function curbstone, which is a porous polymer concrete, the composition on weight is: white cement 200-500, stone 500-2000, ethane acetate multipolymer 10~200, inorganic pigment 0.5-20, n-butyl phthalate 0.5-90, aluminum silicate or silicon micro-powder 10-100, silicon sol 20-100, ageing fiber 0.5-10and water 70-200, which is good in pervious ability, anti-freeze and does not fade.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

Polymer concrete

InactiveUS20060014878A1Improve structural performanceImprove machinabilitySolid waste managementCeramic shaping apparatusPolymer resinPolymer concrete

A polymer concrete formulation comprising an amount of polymer resin; an amount of thixotrope; an amount of a light aggregate with a specific gravity less than that of the resin; and an amount of a heavy aggregate with a specific gravity larger than that of the resin.

Owner:THE UNIV OF SOUTHERN QUEENSLAND

Waterborne polyurethane polymer modified concrete for bridge deck slab and preparation method

The invention relates to waterborne polyurethane polymer modified concrete for a bridge deck slab and a preparation method. The waterborne polyurethane polymer modified concrete comprises the following components: ordinary silicate cement, pebbles, medium sand, coal ash, silicon ash, a naphthalene water reducer, waterborne polyurethane emulsion and water. The preparation method comprises the following steps: putting the dried pebbles, the ordinary silicate cement, the medium sand, the coal ash and the silicon ash into a stirring machine at a normal temperature, and stirring; adding the waterborne polyurethane emulsion, and stirring; adding the water, and stirring; finally, adding the naphthalene water reducer, and stirring. The invention provides the waterborne polyurethane polymer modified concrete for problems that an ordinary concrete bridge deck slab is likely to suffer from corrosion damage and low in strength. The polymer modified concrete can effectively solve the problem of high possibility of causing corrosion damage of the bridge deck slab in a complicated environment and greatly reduce the repair expense in an operation process. The polymer modified concrete can be applied to a bridge surface structure which is relatively high in durability requirement or is relatively difficult to repair and relatively large in span.

Owner:HARBIN ENG UNIV

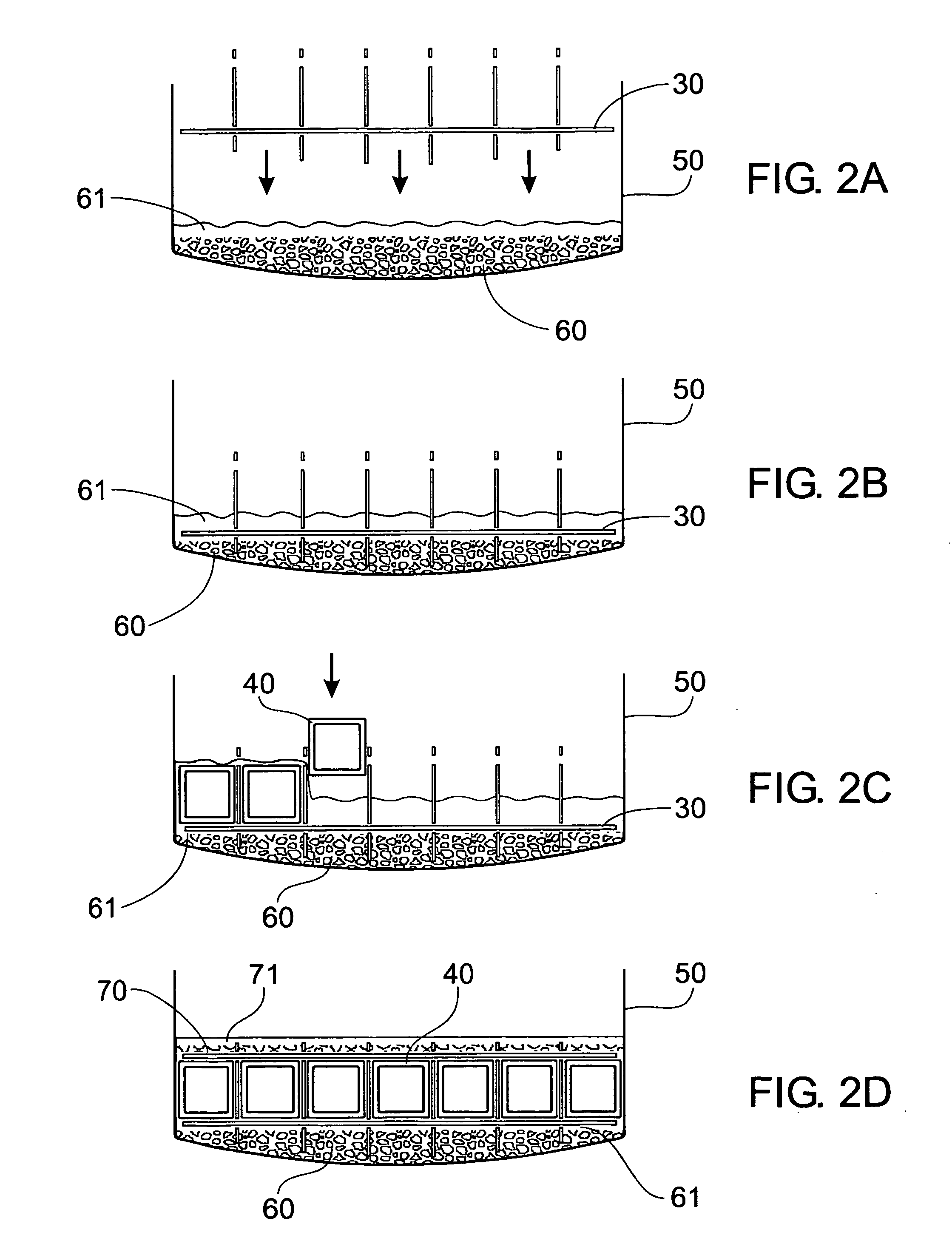

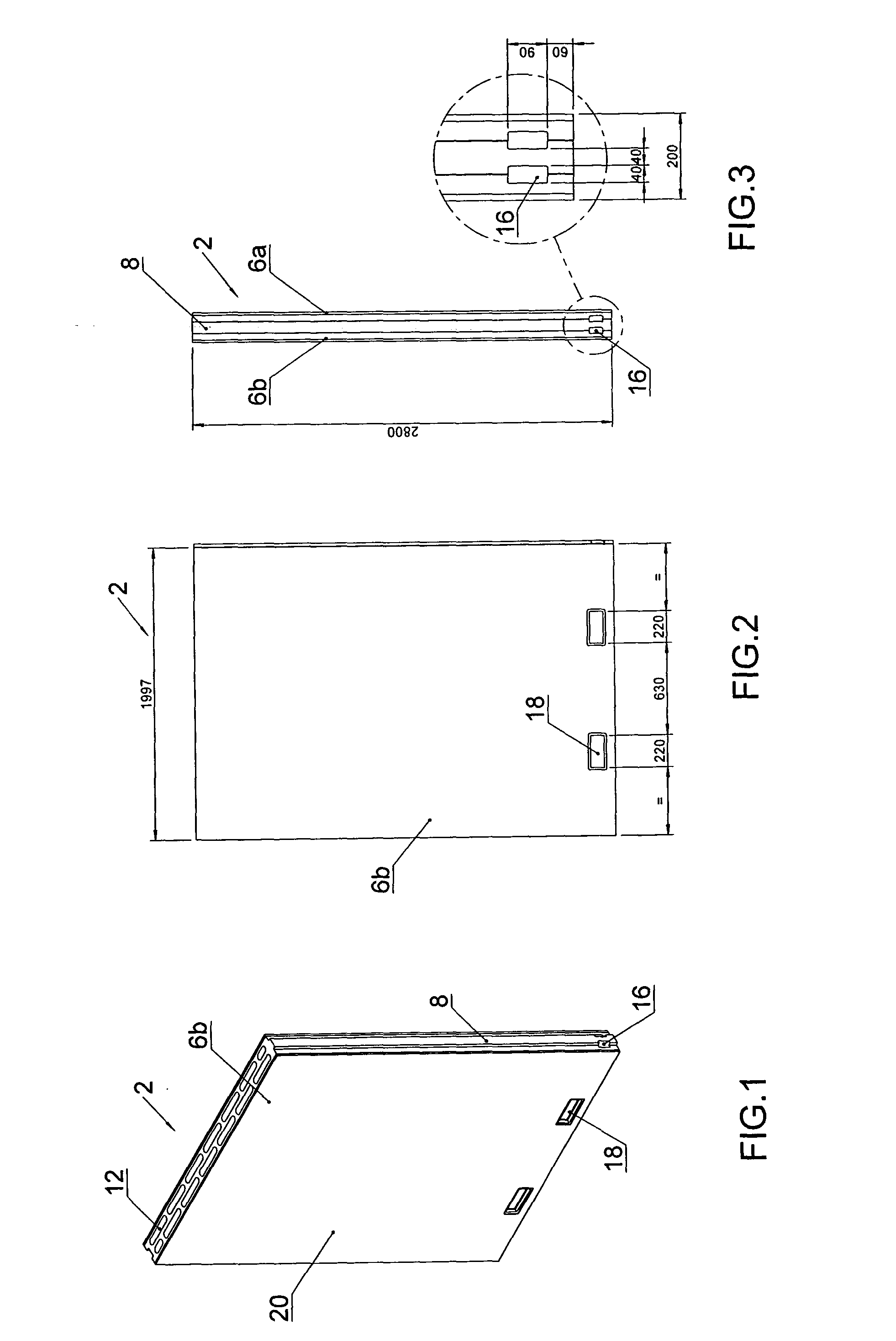

Building panel

ActiveUS20120159877A1Less-energy-intensiveReduce carbon dioxide emissionsRoof covering using slabs/sheetsRoof covering using tiles/slatesGeopolymerPolymer concrete

The present invention relates to a building panel. The building panel includes a core including first geopolymer concrete. One or more protective layers are located adjacent the core. Each protective layer includes second geopolymer concrete of greater density than the first geopolymer concrete. In one embodiment, passages are defined along which air can move within the core.

Owner:HALOK

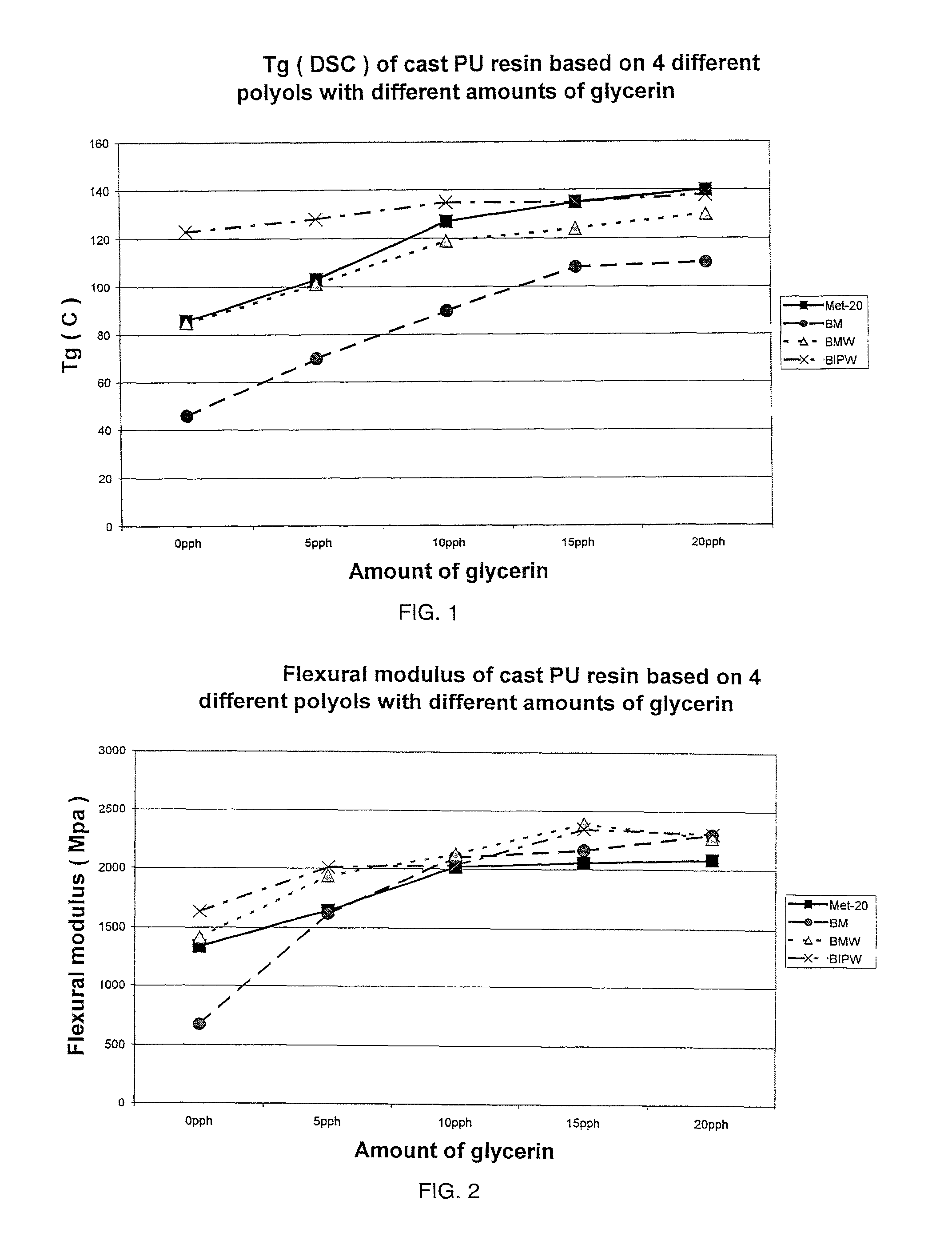

Polymer concrete and method for preparation thereof

InactiveUS7977424B2High hydroxyl valueImprove structural performanceSolid waste managementBuilding constructionsPolymer sciencePtru catalyst

A soy-based polyol is mixed with an isocyanate and aggregate to produce a soy-based polyurethane having superior mechanical properties. The aggregate composition may be varied to obtain different mechanical properties, as can the amount of resin. The resin may be crosslinked using a low molecular weight polyol, such as glycerine, to also improve structural performance. A catalyst may be added to accelerate curing time without reducing structural performance.

Owner:PETROVIC ZORAN +3

High damping vibration attenuation cement concrete

The invention relates to a high-damping cement concrete, comprising ordinary Portland cement, sand, water, polymer additive and additional water reducer and defoamer; the high-damping cement concrete is characterized in that the components and the weight proportions (in percentage terms) are as follows: 15%-18% of Portland cement, 25%-35% of medium sand, 45%-50% of gravel, 4.5%-8% of water, 4.5%-7.5 % of polymer additive, 0.02%-0.03% of water reducer, and 0.006-0.0075% of defoamer. The gravel size ranges from 5mm to 31.5mm. The polymer additive can be styrene-butadiene latex, acrylic copolymer emulsion or dispersible emulsion powder. By adopting the styrene-butadiene latex, acrylic copolymer emulsion or dispersible emulsion powder and other polymer additives as the modifier in the viscidity, the structural viscidity and inner friction performance of concrete material, the high-damping cement concrete disclosed in the invention achieves the same vibration damping characteristics as the existing polymer concrete and does not change the other properties of concrete, so that the project cost is greatly reduced and the high-damping cement concrete can be applied to engineering projects having system damping demand.

Owner:上海宝冶工程技术有限公司

Composite strengthening method through fiber-reinforced high-damping polymer concrete coated with carbon fiber cloth

InactiveCN106401204AImprove bearing capacityReduce cracking and spallingBuilding repairsAdhesiveConcrete beams

The invention discloses a composite strengthening method through fiber-reinforced high-damping polymer concrete coated with carbon fiber cloth. The composite strengthening method comprises the following steps that the outer surface of an original concrete beam is removed, and thus the structural layer is exposed to reach the aggregate face of the original concrete beam; paying off, drilling and hole cleaning are conducted on the aggregate face of the original concrete beam, shear pins are embedded in through anchor adhesive, and a reinforcing mesh is bound; after an interface agent is smeared on the aggregate face of the original concrete beam, a fiber-reinforced high-damping polymer concrete material is smeared to reach the designed thickness; and after maintenance, a binder is brushed on the surface of a fiber-reinforced high-damping polymer concrete reinforced layer, the carbon fiber cloth is pasted, and reinforcement of the original concrete beam is completed. According to the composite strengthening method, the good deformability and anti-seismic energy dissipation ability of the fiber-reinforced high-damping polymer concrete and superhigh strength of the carbon fiber cloth are used, thus the sectional dimension change is small, the influences on the structure clearance and the appearance are small, the overall anti-seismic property is good, the structure is simple, construction is convenient, and popularization is easy.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com