Anti-corrosion geopolymer concrete filling pile material as well as preparation method and construction process thereof

A technology of geopolymers and cast-in-situ piles, applied in sheet pile walls, foundation structure engineering, cement production, etc., can solve problems such as degradation, poor use effect, and increased construction difficulty and cost, so as to achieve dense materials and contribute to antiseptic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

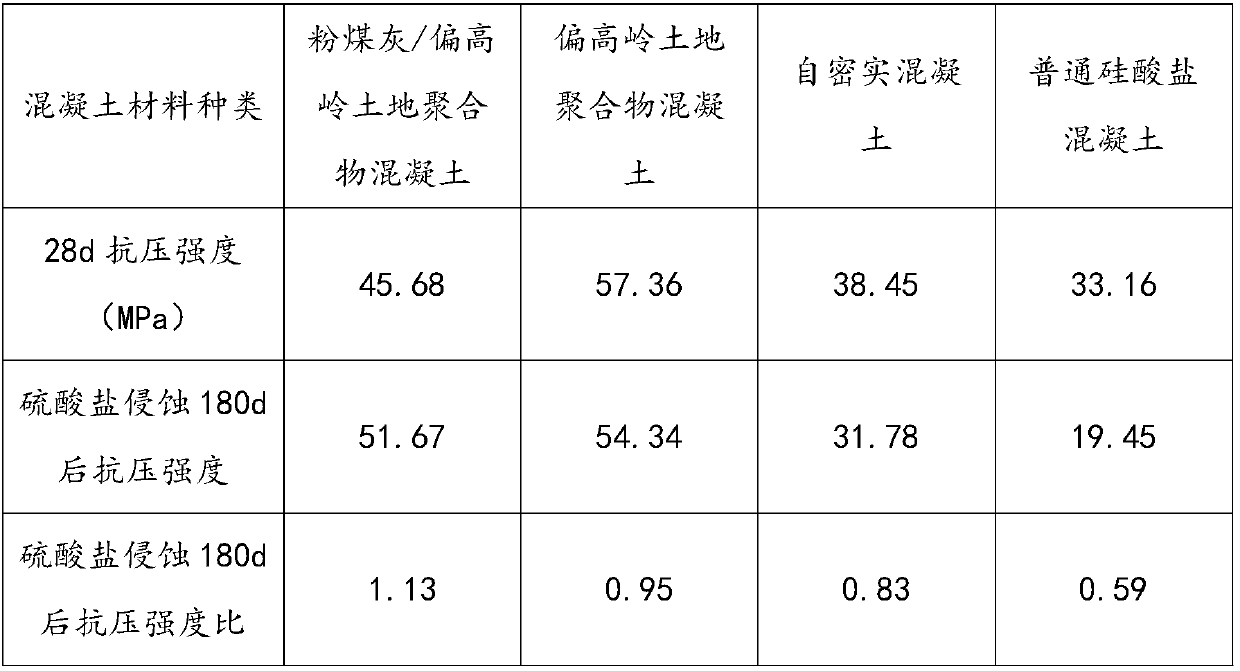

Examples

Embodiment 1

[0046] A corrosion-resistant geopolymer concrete pouring pile material, mainly used in the construction of marine island and reef projects, including the following components:

[0047] 100g of metakaolin, 20g of fly ash, 250g of modified water glass with a modulus of 1.4, 500g of fine sand, 1000g of stones, 20g of polyvinyl alcohol fiber, 8g of boric acid, wherein the modified water glass is composed of 20.97% water, It is prepared by 9.83% sodium hydroxide and 69.20% commercially available water glass. The silicon modulus of commercially available water glass is 2.2, and the effective solid content is 30%. Metakaolin is formed by calcination at 800°C, and its particle size is 0.1 -10μm; the fly ash is the first-class fly ash of industrial grade F in thermal power plants, and the particle size is 1-30μm; the fine sand is selected from type II, its fineness modulus is 1.6, and the particle size is about 250 μm; the stone is selected from type II River pebbles, the particle size...

Embodiment 2

[0059] A corrosion-resistant geopolymer concrete cast-in-situ pile material, mainly used in underwater construction engineering, including the following components:

[0060] 100g of metakaolin, 35g of fly ash, 250g of modified water glass with a modulus of 1.2, 600g of fine sand, 1600g of stones, 15g of polyvinyl alcohol fiber, 5g of boric acid, wherein the modified water glass is composed of 5.29% water, It is prepared by 11.76% sodium hydroxide and 82.95% commercially available water glass. The silicon modulus of commercially available water glass is 2.2, and the effective solid content is 30%. Metakaolin is formed by calcination at 800°C, and its particle size is 0.1 -10μm; the fly ash is the first-class fly ash of industrial grade F in thermal power plants, and the particle size is 1-30μm; the fine sand is selected from type II, its fineness modulus is 1.6, and the particle size is about 250 μm; the stone is selected from type II River pebbles, the particle size of the sto...

Embodiment 3

[0072] A corrosion-resistant geopolymer concrete pouring pile material is mainly used in the construction of saline-alkali land in Northwest China, including the following components:

[0073] 100g of metakaolin, 40g of fly ash, 250g of modified water glass with a modulus of 1.5, 400g of fine sand, 800g of stones, 10g of polyvinyl alcohol fiber, 10g of boric acid, wherein the modified water glass is composed of 27.27% water, It is prepared by 8.10% sodium hydroxide and 64.63% commercially available water glass. The silicon modulus of commercially available water glass is 2.2, and the effective solid content is 30%. Metakaolin is formed by calcination at 900°C, and its particle size is 0.1 -10μm; the fly ash is the first-class fly ash of industrial grade F in thermal power plants, and the particle size is 1-30μm; the fine sand is selected from type II, its fineness modulus is 1.6, and the particle size is about 250 μm; the stone is selected from type II River pebbles, the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com