Geopolymer cement material and preparation method thereof

A technology of geopolymeric cement and water glass, which is applied in cement production and other directions, and can solve the problems of single basic raw materials and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

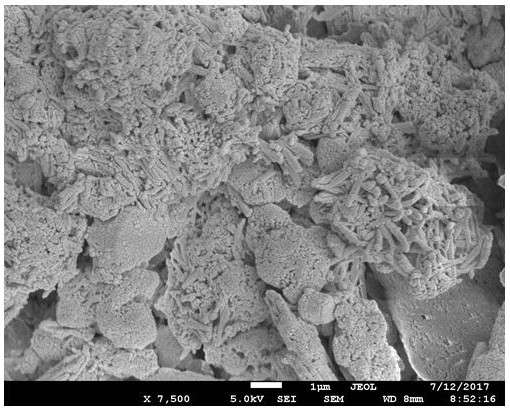

[0031] The spent FCC catalyst F was immersed in ammonium bicarbonate solution with a mass concentration of 10%. The mass ratio of ammonium bicarbonate solution to spent catalyst was 3:1. The material was dried at 100°C for 3 hours and calcined at 500°C for 2 hours to obtain pretreated spent FCC catalyst A; the SEM image of the obtained pretreated spent FCC catalyst A is shown in figure 1 . Depend on figure 1 It can be seen that columnar protrusions are formed on the surface of the spent catalyst.

[0032] The activator is composed of 10 parts by mass of NaOH mixed with 30 parts by mass of water glass, the original modulus of water glass is 3.2, and the modulus is adjusted to 1.8.

[0033] Take 18 parts of pretreated waste FCC catalyst A, 25 parts of metakaolin, 8 parts of slag, and 4 parts of water, and stir evenly, then add 25 parts of the above-mentioned activator, stir evenly, and obtain geopolymer cement material. Test the setting time of the well-mixed soil-polymer cem...

Embodiment 2

[0035] The spent FCC catalyst F was immersed in ammonium bicarbonate solution with a mass concentration of 15%. The mass ratio of ammonium bicarbonate solution to spent catalyst was 5:1. The material was dried at 110°C for 4 hours and calcined at 550°C for 3 hours to obtain the pretreated spent FCC catalyst B; the spent FCC catalyst B was observed with a scanning electron microscope, and columnar protrusions were formed on its surface.

[0036] The activator is composed of 15 parts by mass of NaOH mixed with 40 parts by mass of water glass, the original modulus of water glass is 3.2, and the modulus is adjusted to 1.6.

[0037] Take 12 parts of pretreated waste FCC catalyst B, 30 parts of metakaolin, 12 parts of slag, and 2 parts of water, and stir evenly, then add 30 parts of the above-mentioned activator, stir evenly, and obtain a geopolymeric cement material. Measure coagulation time and intensity with embodiment 1 method. The specific results are shown in Table 1.

Embodiment 3

[0039] The spent FCC catalyst F was immersed in ammonium bicarbonate solution with a mass concentration of 20%, and the mass ratio of ammonium bicarbonate solution to spent catalyst was 10:1, and transferred to a high-pressure container. The treatment time was 6 hours at 100°C, and the treated The material was dried at 120°C for 6 hours and calcined at 600°C for 4 hours to obtain the pretreated spent FCC catalyst C; the spent FCC catalyst C was observed with a scanning electron microscope, and columnar protrusions were formed on its surface.

[0040] Described activator is with embodiment 1.

[0041] Take 8 parts of pretreated waste FCC catalyst, 32 parts of metakaolin, 15 parts of slag, and 5 parts of water, and stir evenly, then add 25 parts of activator, stir evenly, and obtain geopolymer cement material. Measure coagulation time and intensity with embodiment 1 method. The specific results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com