Preparation method of straw phase change plate with phase change heat storage and insulation function

A phase change heat storage, straw board technology, applied in flat products, household appliances, manufacturing tools, etc., can solve the problem of low utilization rate of straw resources, achieve good durability, reduce supercooling, and prevent leakage loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Straw pretreatment: crush the straw with a hay cutter, and sieve through a 10 mm standard to obtain straw powder. o C to dry to less than 1% moisture content;

[0023] (2) Loading and packaging of phase change materials: at 40 o Prepare saturated Na at C 2 SO 4 solution, then in saturated Na 2 SO 4 Add borax and polyvinyl alcohol solution to the solution to obtain a phase-change mixed solution, and Na in the phase-change mixed solution 2 SO 4 :H 2 O: borax: the mass ratio of polyvinyl alcohol is 1:2:0.02:0.10. Add straw powder into the mixer, and add the phase-change mixture while stirring, so that the phase-change mixture and the straw are evenly mixed, and dry at room temperature to obtain the phase-change straw. The mass ratio of straw powder:phase-change mixture is 1:6 .

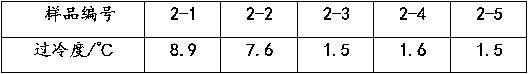

[0024] (3) Molding of straw plates: using geopolymer as the binder of phase-change straws, straw phase-change plates were prepared by compression molding. In the mixer, add the phase...

Embodiment 2

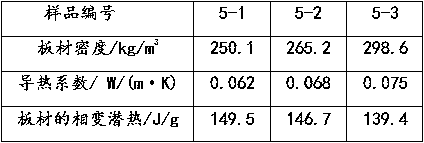

[0028] Design 5 groups of parallel experiments, the basic steps are the same as in Example 1, the difference is that the amount of nucleating agent borax is changed, other conditions are the same as in Example 1, and the influence of the amount of nucleating agent on the degree of phase transition supercooling is investigated. Among them, 1 group did not add borax (sample 2-1), and the other 4 groups experimented with Na 2 SO 4 :H 2 The mass ratio of O: borax: polyvinyl alcohol is 1:2:0.01:0.10 (sample 2-2), 1:2:0.02:0.10 (sample 2-3), 1:2:0.04:0.10 (sample 2) -4), 1:2:0.05:0.10 (sample 2-5).

[0029]

[0030] The experimental results show that the addition of nucleating agent borax can effectively reduce the supercooling degree of phase change materials.

Embodiment 3

[0032] Design 4 groups of parallel experiments, the basic steps are the same as in Example 1, the difference is that the amount of polyvinyl alcohol added is changed, and other conditions are the same as in Example 1, to investigate the effect of the amount of polyvinyl alcohol on the performance of the board. Among them, one group did not add polyvinyl alcohol (sample 3-1), and the other three groups experimented with Na 2 SO 4 :H 2 The mass ratio of O: borax: polyvinyl alcohol is 1:2:0.01:0.06 (sample 3-2), 1:2:0.01:0.10 (sample 3-3), 1:2:0.01:0.16 (sample 3 -4).

[0033] After 5 phase change cycles, the optical microscope observation found that the solid particles of sample 3-1 and 3-2 phase change materials increased significantly, and there was a phase separation phenomenon, while the plates of samples 3-3 and 3-4 after 100 phase change cycles The appearance did not change significantly.

[0034] The experimental results show that an appropriate amount of polyvinyl al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| latent heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com