Hydrothermal synthesis method of 4A molecular sieve from high-iron bauxite tailings

A high-iron bauxite and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, etc., can solve the problems of difficult utilization, environmental pollution, waste, etc., and achieve improved production efficiency, improved performance, Effect of reducing Fe2O3 content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

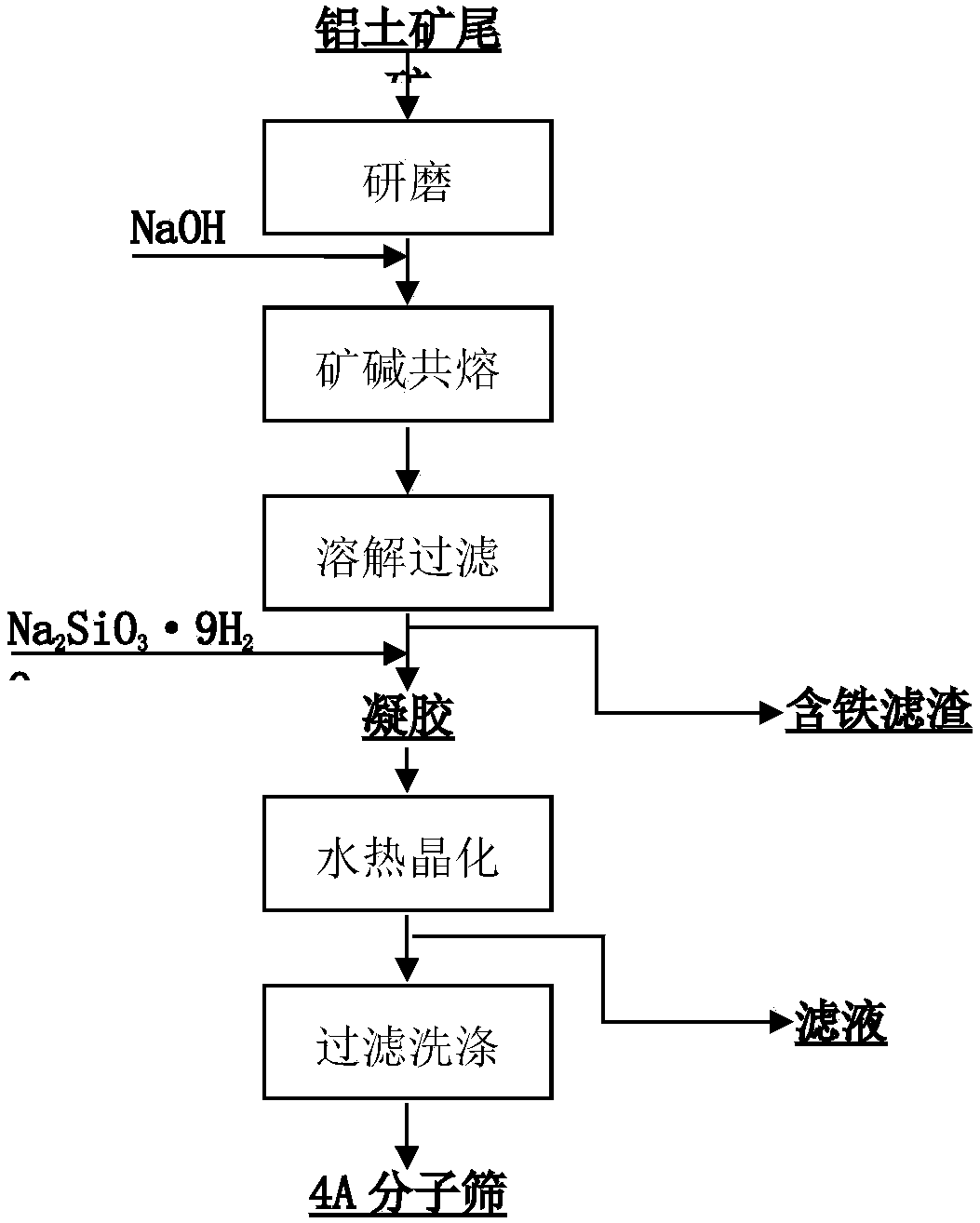

Method used

Image

Examples

Embodiment 1

[0026] The raw material of the present invention is Yuzhong bauxite tailings. The chemical composition of the bauxite tailings is shown in Table 1. The other main components are Al 2 O 3 , SiO 2 , Fe 2 O 3 , TiO 2 , K 2 O, the rest is crystal water, volatile matter and trace other impurities, such as Ca, S, Mg, Zr, Cr, Mn, etc.

[0027] Table 1: Main chemical composition table of bauxite tailings (%wt)

[0028]

[0029] The synthesis steps are:

[0030] (1) Ore-alkali eutectic: Take a certain amount of the above-mentioned tailings and solid NaOH, mix them and place them in a graphite crucible, and react in a muffle furnace. The ratio of ore to alkali is 1:0.75, heated to 400℃ for calcination and heat preservation 90min. The calcined product is ground to less than 30 μm.

[0031] (2) Preparation into glue: take 5g of mineral-alkali eutectic product and dissolve in 50mLH 2 In O, stir for 15 min at room temperature, filter to separate insolubles, and take the supernatant. Add 5g of sod...

Embodiment 2

[0036] The experimental raw materials are the same as in Example 1

[0037] The synthesis steps are:

[0038] (1) Ore-alkali eutectic: Take a certain amount of the above tailings and solid NaOH, mix them and place them in a graphite crucible, and react in a muffle furnace. The ratio of ore to alkali is 1:1, heated to 500℃ for calcination and heat preservation 60min. The calcined product is ground to less than 30 μm.

[0039] (2) Preparation into glue: take 5g of mineral-alkali eutectic product and dissolve in 50mLH 2 In O, stir for 15 min at room temperature, filter to separate insolubles, and take the supernatant. Add 5g of sodium silicate nonahydrate to the clear liquid, stir and mix well.

[0040] (3) Hydrothermal crystallization: the silicon-aluminum-containing gel described in step (2) is placed in a 100 mL hydrothermal kettle, heated at a constant temperature of 90°C, and the crystallization reaction is 6h-7h.

[0041] (4) Filtration and washing: filter after the crystallizatio...

Embodiment 3

[0043] The experimental raw materials are the same as in Example 1

[0044] The synthesis steps are:

[0045] (1) Ore-alkali eutectic: Take a certain amount of the above-mentioned tailings and solid NaOH, mix them and place them in a graphite crucible, and react in a muffle furnace. The ratio of ore to alkali is 1:1.5, and it is heated to 600°C for calcination and heat preservation. 30min. The calcined product is ground to less than 30 μm.

[0046] (2) Preparation into gel: take 5g of mineral-alkali eutectic product and dissolve in 50mL H 2 In O, stir for 15 min at room temperature, filter to separate insolubles, and take the supernatant. Add 5g of sodium silicate nonahydrate to the clear liquid, stir and mix well.

[0047] (3) Hydrothermal crystallization: the silicon-aluminum-containing gel described in step (2) is placed in a 100 mL hydrothermal kettle, and the crystallization reaction is heated at a constant temperature of 80° C. for 6-7 hours.

[0048] (4) Filtration and washing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com