Silicon-aluminum polymeric material and preparation thereof

A technology of polymeric materials and silicon-aluminum, which is applied in the field of silicon-aluminum polymer materials and the preparation of silicon-aluminum polymer materials, can solve the problems of high cost of raw materials for silicon-aluminum polymer materials, and achieve the goal of increasing added value, low resource and energy consumption, and convenient source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

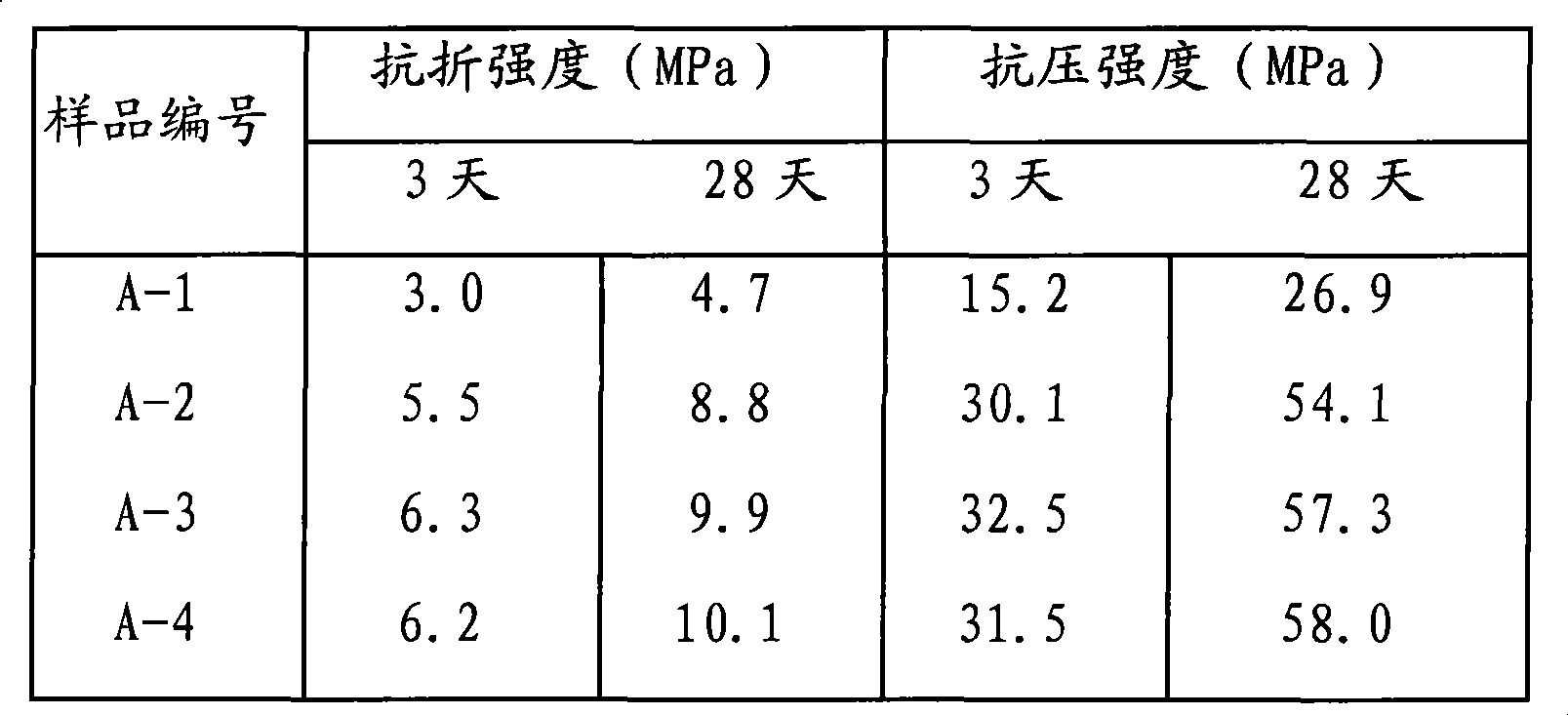

[0019] The bauxite tailings are ground in a ball mill, passed through an 80 μm sieve, and the sieved residue is less than 10.0%, and the obtained powder A-1.

[0020] The bauxite tailings were calcined at 800°C for 1.0, 1.5 and 2.0 hours respectively, and after naturally cooling down to room temperature, they were taken out and ground in a ball mill, passed through an 80 μm sieve, and the sieve residue was less than 10.0%, respectively to obtain powder A-2 , Powder A-3 and Powder A-4.

[0021] In order to verify the activity of the calcined bauxite tailings powder in this example, 85% by weight of powder A-1, powder A-2, powder A-3, and powder A-4 were used as raw materials, respectively mixed with 15% by weight of over 80 μm sieve residue is less than 10.0% of the slag powder, when the water-cement ratio is 0.45, the mortar ratio is 1:2.5 and the water glass content is 60% by weight (the water glass addition is based on its share of bauxite powder and slag powder Based on th...

Embodiment 2

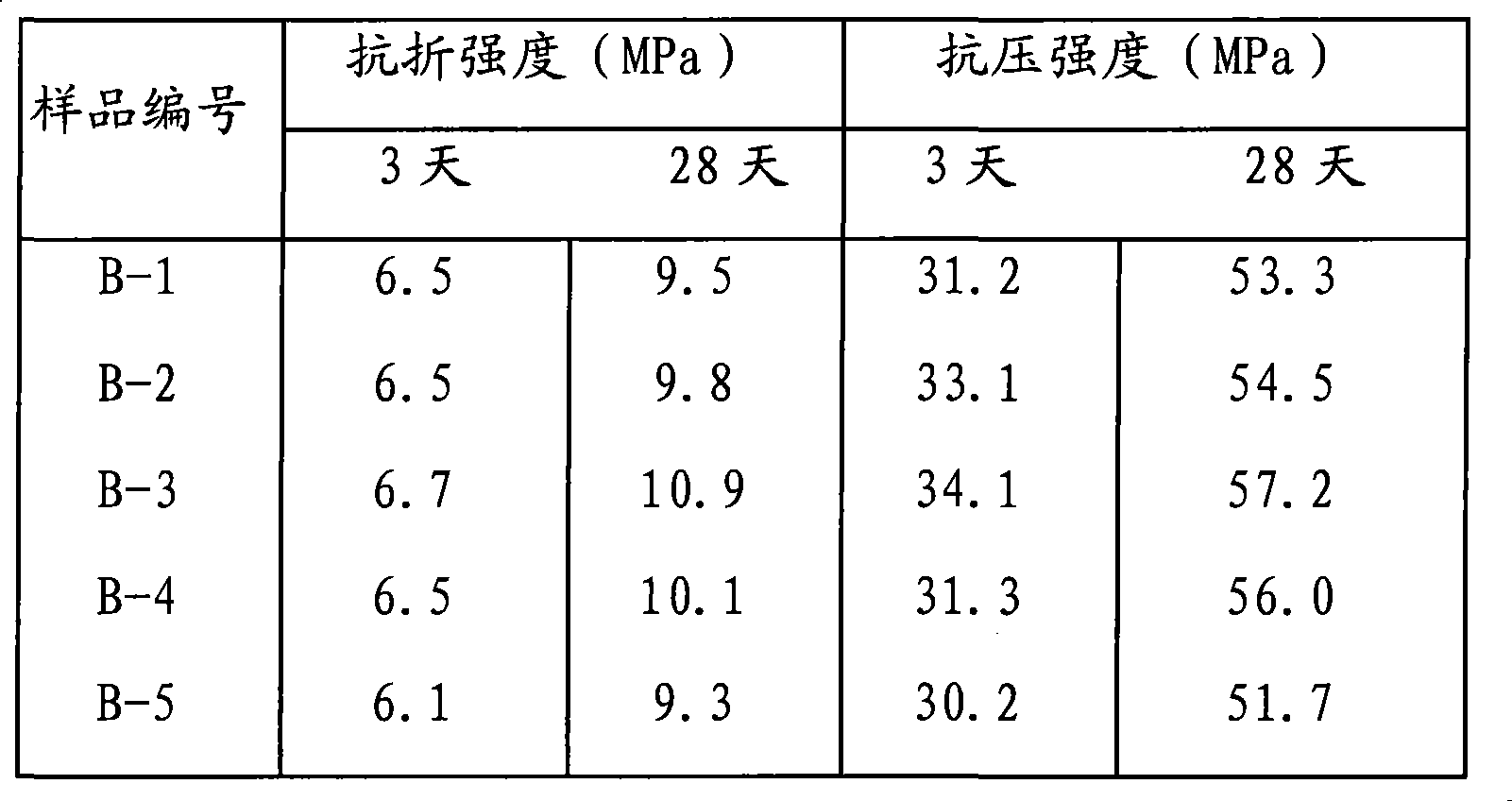

[0027] Add lime which accounts for 1% of the weight of the bauxite dressing tailings to the bauxite dressing tailings, and calcinate them at 800°C, 850°C, 900°C, 950°C and 1000°C for 1.5 hours, and cool down to room temperature naturally , take out and grind in a ball mill, pass through an 80 μm sieve, and the sieve residue is within the range of 10.0%, to obtain powder B-1, powder B-2, powder B-3, powder B-4 and powder B-5.

[0028] Using 75% by weight of powder B-1, powder B-2, powder B-3, powder B-4, and powder B-5 as raw materials, respectively mixed with 25% by weight of slag powder with a residue of less than 10.0% after passing through an 80 μm sieve , prepare silica-alumina polymer mortar under the condition that the water-cement ratio is 0.45, the cementitious sand ratio is 1:2.5 and the water glass dosage is 70% by weight (the water glass addition is based on the total weight of the above-mentioned powder), and with reference to The national standard GB / T17671-1999 s...

Embodiment 3

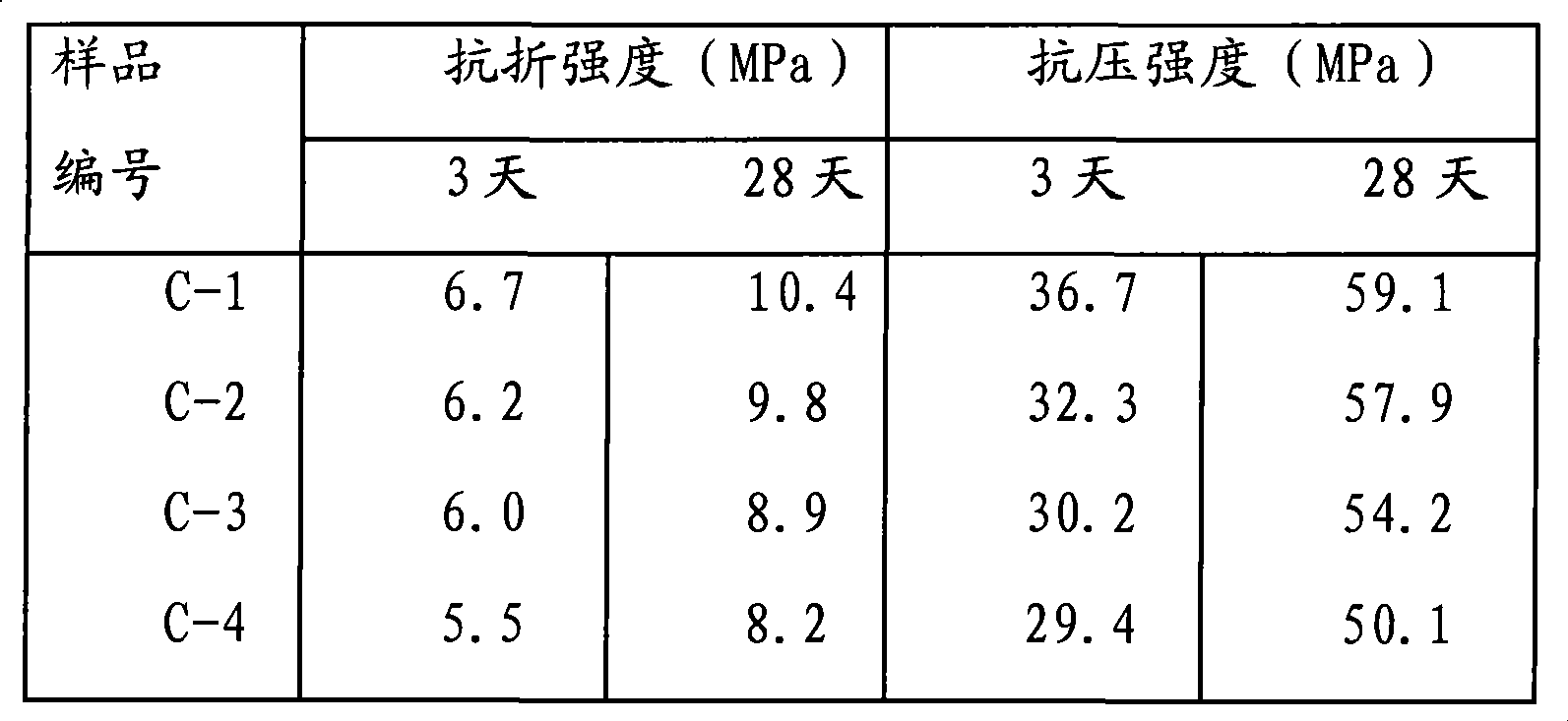

[0033] Add 20% of the weight of fly ash to the bauxite dressing tailings, calcinate at 850°C for 5 hours, cool down to room temperature naturally, take it out and grind it in a ball mill, pass through an 80μm sieve, and the sieve residue is less than 10.0% , to obtain powder.

[0034] Take 60 kg of the above-prepared powder and 40 kg of slag powder, and mix them uniformly to obtain powder C-1. Take 70 kg of the above-prepared powder and 30 kg of slag powder, and mix them uniformly to obtain powder C-2. Take 80 kg of the above-prepared powder and 20 kg of slag powder, and mix them uniformly to obtain powder C-3. Take 90 kg of the above-prepared powder and 10 kg of slag powder, and mix them uniformly to obtain powder C-4. Among them, the residue of slag powder passing through 80 μm sieve is less than 10.0%. Under the condition that the amount of water glass is 50% by weight (the amount of water glass added is based on the weight of the above-mentioned powder), the water-cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com