Method for processing bauxite tailings by flocculating agent

A flocculant and bauxite technology, which is applied in the field of flocculant treatment of bauxite beneficiation tailings, can solve the problems of loose flocculation particles, high cost, and large dosage, and achieve fast settling speed, reduced dosage, and less dosage of chemicals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

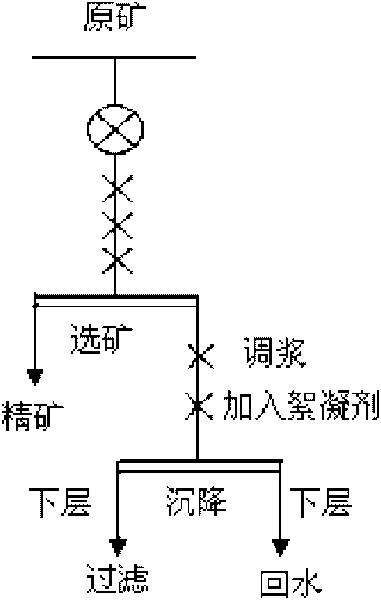

Image

Examples

Embodiment 1

[0026] This method was used to carry out the flocculation and settlement test on the selective flocculation tailings of bauxite in a mining area in Henan. The main minerals in the tailings are clay minerals. which contains Al 2 o 3 45.6%, SiO 2 33.65%, the ratio of aluminum to silicon is 1.35, and the pulp concentration is 3%.

[0027] Adjust the slurry with hydrochloric acid until the pH value is 3.0, and add 40 g / ton of 0.1% dimethyldiallyl ammonium chloride. Use a mechanical stirrer to stir for 3 minutes at a speed of 300 rpm, and allow the slurry to settle. It can be seen that a clear sedimentation interface is formed immediately, and the supernatant is clear. The settling speed can reach 35 mm / min. It can remove 80% of the water in the pulp.

Embodiment 2

[0029] This method was used to carry out the flocculation and sedimentation test on the washing sludge of an aluminum factory in Guangxi. According to phase analysis, the main components of the slime are diaspore 13.7, gibbsite 12.1 and kaolinite 47.4. The size of the minerals smaller than 0.010mm accounts for 76.64%.

[0030] Adjust the slurry with hydrochloric acid until the pH value is 5.5, and add 55 g / ton of dimethyldiallyl ammonium chloride with a concentration of 0.006% to the tailings slurry with a concentration of 5%. Use a mechanical stirrer to stir for 3 minutes at a speed of 300 rpm, and allow the slurry to settle. It can be seen that a clear sedimentation interface is formed immediately, and the supernatant is clear. The settling speed can reach 37 mm / min. It can remove 78% of the water in the pulp.

Embodiment 3

[0032] This method was used to carry out the flocculation and sedimentation test on the positive flotation tailings of an aluminum plant in Henan. The main minerals in the tailings are clay minerals. About 75% of them are extremely fine particles with a particle size of less than 0.020mm, including 20.79% of diaspore, 19.90% of kaolinite, 27.82% of illite, and 7.50% of pyrophyllite.

[0033] Use hydrochloric acid to adjust the slurry to pH 7.0, add 70 g / ton of dimethyldiallyl ammonium chloride with a concentration of 10% to the tailings slurry with a concentration of 5%, and 100 g / ton of polyaluminum ferric sulfate . Polyaluminum ferric sulfate was added before dimethyl and allyl ammonium chloride. Use a mechanical stirrer to stir for 3 minutes at a speed of 300 rpm, and allow the slurry to settle. It can be seen that a clear sedimentation interface is formed immediately, and the supernatant is clear. The settling speed can reach 30 mm / min. It can remove 75% of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com