Tailing dam damming method

A tailings dam and tailings technology, applied in the field of mine engineering, can solve problems such as the limited height of one-time dam body, frequent movement of tailings transportation and grading facilities, and difficulty in dam stacking in rainy seasons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

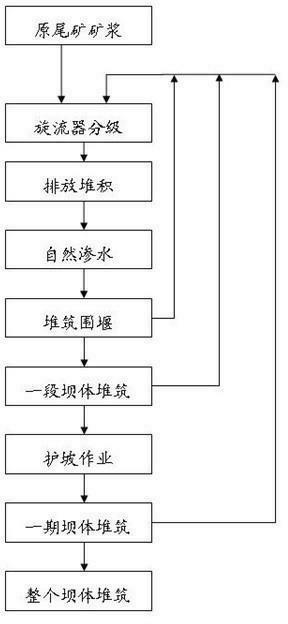

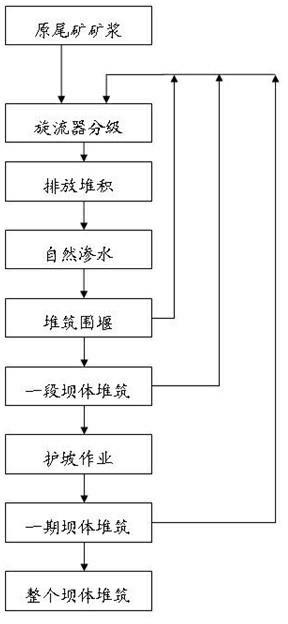

[0011] refer to figure 1 It can be seen that a kind of tailings dam construction method process step is: a: use the cyclone to classify the former tailings slurry to produce the coarse sand of the dam; When the sand cannot be naturally discharged and accumulated, stop the graded production and stack the coarse sand for 1 day, and discharge the original tailings slurry directly into the tailings pond, allowing the deposited coarse sand to seep naturally, so that the water content of the dam coarse sand is less than 20%; c: in the pile Build a cofferdam at the dam, enclose a space for continuing to pile up coarse sand, and repeat 8 times of classification-seepage-cofferdam operations to form a new dam body; d: repeat the above steps, and carry out slope protection operations for inner and outer slopes, so that The overall outer slope of the tailings dam is controlled at 1:3, and the first phase of the new dam is completed; e: Then the next phase of the dam is raised along the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com