Five-layer coverage forced reduction in-situ mineralization restorative method

A repair method and in-situ technology, applied in botany equipment and methods, restoration of contaminated soil, horticulture, etc., can solve heavy metal pollution of tailings ponds, water and soil loss of tailings ponds, and secondary environmental pollution that cannot be continuously and deeply repaired and other issues, to achieve the effect of reducing rainwater infiltration, low cost, and solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

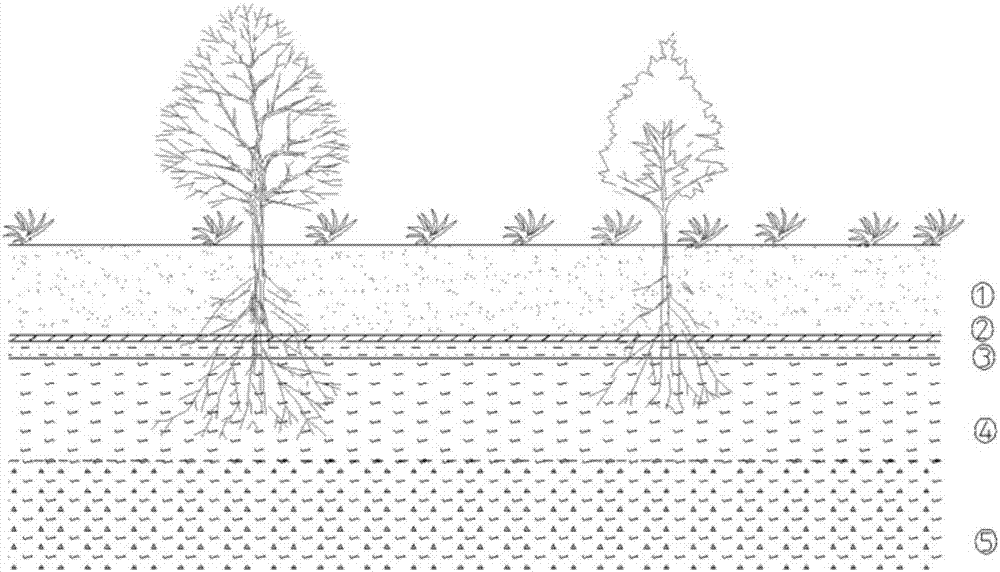

[0045] The five-layer structure from top to bottom in the five-layer covering strong reduction in-situ mineralization restoration method is as follows:

[0046] Non-polluted guest soil layer 1 is composed of non-polluted guest soil with a thickness of 20cm;

[0047] The clay sealing layer 2 is composed of cohesive soil and has a thickness of 5 cm;

[0048] Biomass reduction sealing layer 3, by weight percentage, includes 20% of straw and 80% of chicken manure, and its thickness is 5cm;

[0049] The main reaction layer 4, by weight percentage, includes 1% of steel slag powder, 1% of desulfurized gypsum, 2% of straw, 4% of chicken manure, and 92% of tailings, and its thickness is 30cm;

[0050] Raw tailings layer 5.

[0051] The steps of the five-layer covering strong reduction in-situ metallogenic restoration method to control heavy metal pollution in mines are as follows:

[0052] (1) 1% of steel slag powder, 1% of desulfurized gypsum, 2% of straw, and 4% of chicken manure ...

Embodiment 2

[0064] The five-layer structure from top to bottom in the five-layer covering strong reduction in-situ mineralization restoration method is as follows:

[0065] Non-polluted guest soil layer 1 is composed of non-polluted guest soil with a thickness of 25cm;

[0066] The clay sealing layer 2 is composed of bentonite and has a thickness of 2 cm;

[0067] Biomass reduction sealing layer 3, by weight percentage, includes bagasse 30%, pig manure 70%, and its thickness is 3cm;

[0068] The main reaction layer 4, by weight percentage, includes 0.5% of lime powder, 1% of phosphogypsum, 1% of bagasse, 2.5% of pig manure, and 95% of tailings, and its thickness is 25cm;

[0069] Raw tailings layer 5.

[0070] The steps of the five-layer covering strong reduction in-situ metallogenic restoration method to control heavy metal pollution in mines are as follows:

[0071] (1) 0.5% of lime powder, 1% of phosphogypsum, 1% of bagasse, and 2.5% of pig manure according to the main reaction laye...

Embodiment 3

[0084] The five-layer structure from top to bottom in the five-layer covering strong reduction in-situ mineralization restoration method is as follows:

[0085] Non-polluted guest soil layer 1 is composed of non-polluted guest soil with a thickness of 30cm;

[0086] The clay sealing layer 2 is composed of kaolin and has a thickness of 1 cm;

[0087] Biomass reduction sealing layer 3, by weight percentage, includes sawdust 10%, cow dung 90%, and its thickness is 5cm;

[0088] The main reaction layer 4, by weight percentage, includes fly ash powder 2%, lemon gypsum 4%, sawdust 0.5%, cow dung 3.5%, tailings 90%, and its thickness is 40cm;

[0089] Raw tailings layer 5.

[0090] The steps of the five-layer covering strong reduction in-situ metallogenic restoration method to control heavy metal pollution in mines are as follows:

[0091] (1) 2% of fly ash powder, 4% of lemon gypsum, 0.5% of sawdust, and 3.5% of cow dung according to the weight percentage of the main reaction lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com