Complex plumbum, zinc, silver vulcanizing ore containing newboldite and pyrrhotite floatation method

A technology of pyrrhotite and sphalerite, applied in flotation, solid separation, etc., can solve the difficult problems of flotation and separation of lead-zinc sulfide ore, and achieve the effect of guaranteed grade and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

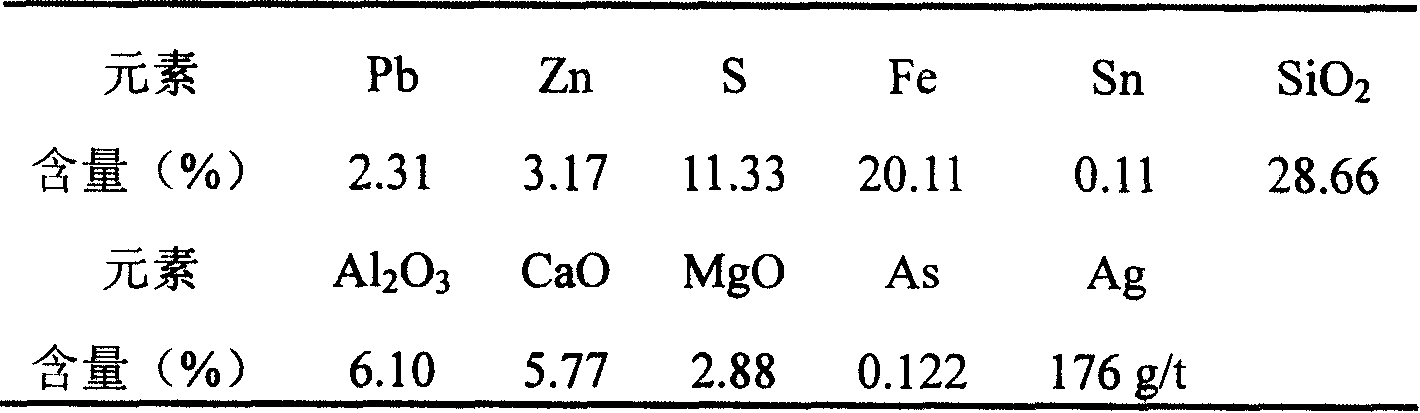

[0028] A complex lead-zinc-silver sulfide ore containing iron-bearing sphalerite and pyrrhotite in Yunnan. The main metal minerals of this ore are galena, sphalerite and pyrrhotite. The main gangue minerals are quartz, calcite and so on. The oxidation rate of lead in the ore is 11.87%, and the oxidation rate of zinc is 4.87%. The results of multi-element analysis of the ore are shown in Table 1.

[0029] Table 1 Multi-element analysis of raw ore

[0030]

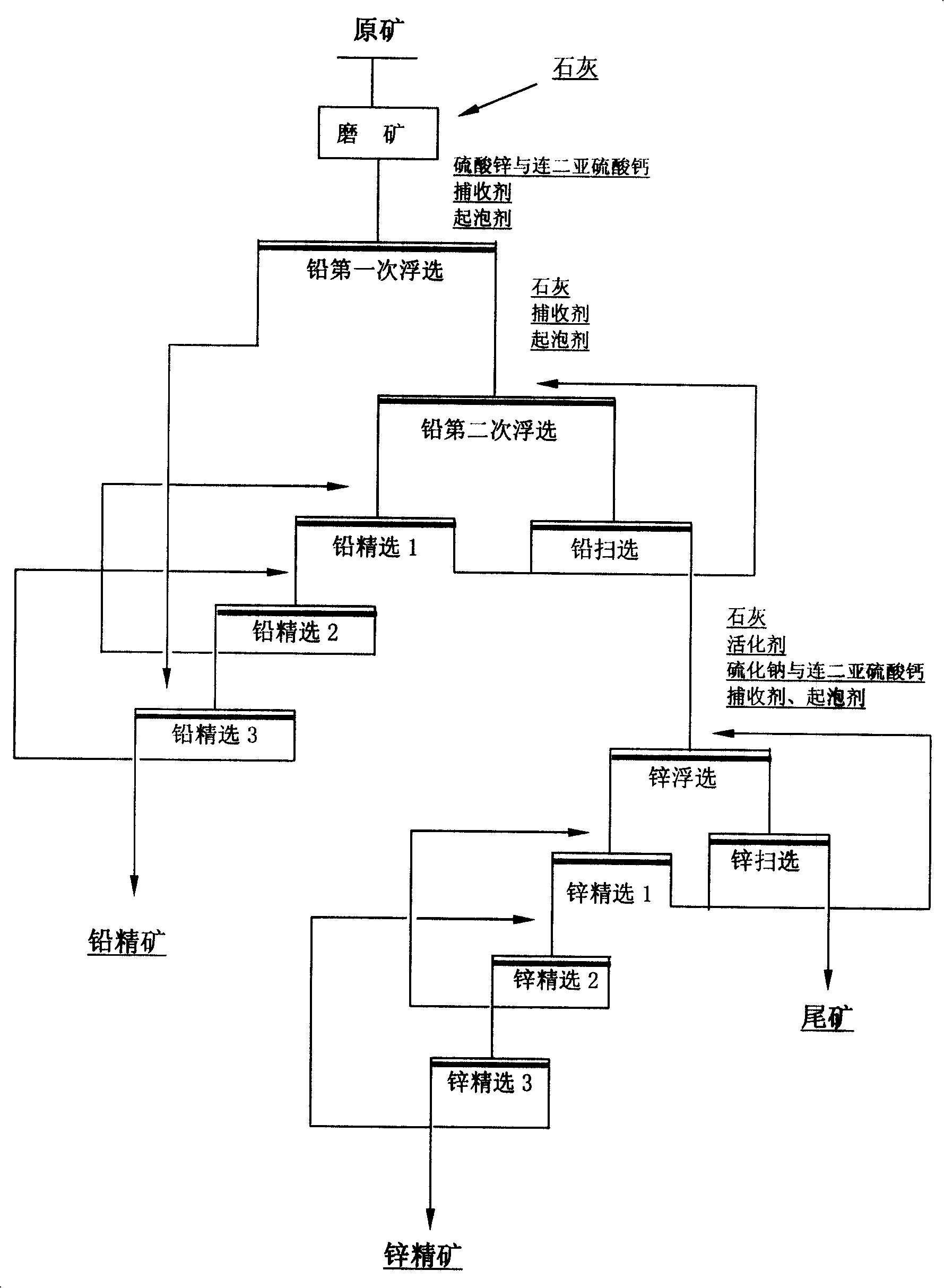

[0031] use as figure 1 Shown technological process, concrete technological parameter is as follows:

[0032] ① Grinding process: lime consumption is 1000g / t raw ore, and the particle size of the grinding overflow product is -0.074mm, accounting for 60%. The dosage is 800g / t raw ore, the slurry potential is kept at 320mV (relative to the hydrogen standard potential), and the slurry pH is 9.0.

[0033] ②The first flotation of lead: the flotation concentration is 30%, the dosage of sodium diethyldithioamidophosphate is 2...

Embodiment 2

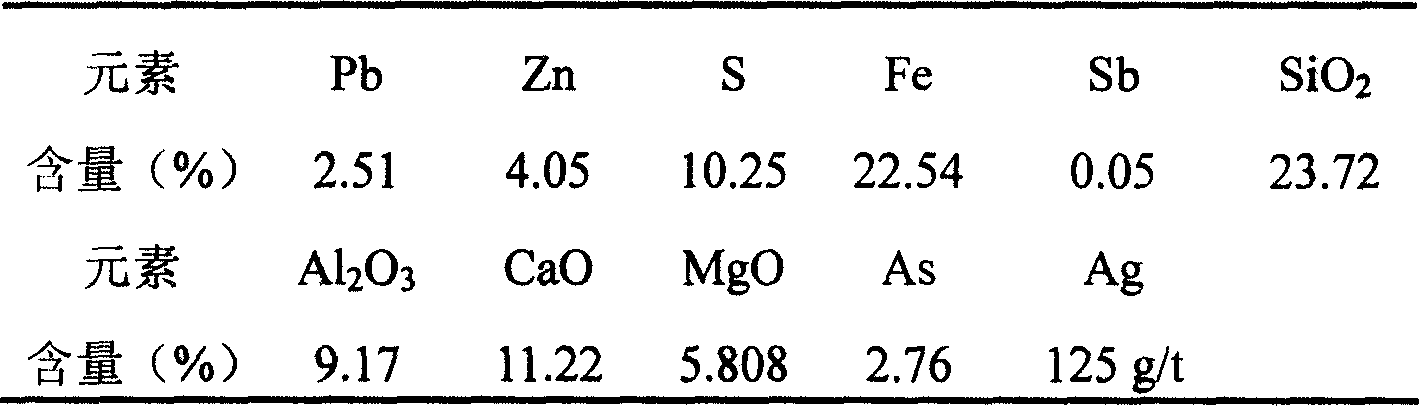

[0038] A complex lead-zinc-silver sulfide ore containing iron-bearing sphalerite and pyrrhotite in Inner Mongolia. The main metal minerals of this ore are galena, sphalerite, pyrrhotite, and arsenopyrite. The main gangue minerals are feldspar, quartz, calcite and so on. The oxidation rate of lead in the ore is 9.66%, and the oxidation rate of zinc is 5.31%. The results of multi-element analysis of the ore are shown in Table 2.

[0039] Table 2 Multi-element analysis of raw ore

[0040]

[0041] use as figure 1 The process flow is shown, and the specific process parameters are;

[0042] ① Grinding process: lime consumption is 1000g / t raw ore, and the particle size of the grinding overflow product is -0.074mm, which accounts for 75%; The dosage is 1000g / t, the pulp potential is kept at 280mV (relative to the hydrogen standard potential), and the pulp pH is 10.0.

[0043]②The first flotation of lead: the flotation concentration is 30%, the dosage of sodium diethyldithioami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com