Natural pyrrhotite biological filter and method for synchronously removing nitrate nitrogen and phosphorus out of water by using natural pyrrhotite biological filter

A biofilter and pyrrhotite technology, applied in biological treatment adjustment methods, chemical instruments and methods, biological water/sewage treatment, etc., can solve high treatment costs, low denitrification rate, complex microbial culture solution, etc. problem, to achieve high processing capacity, simple method and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

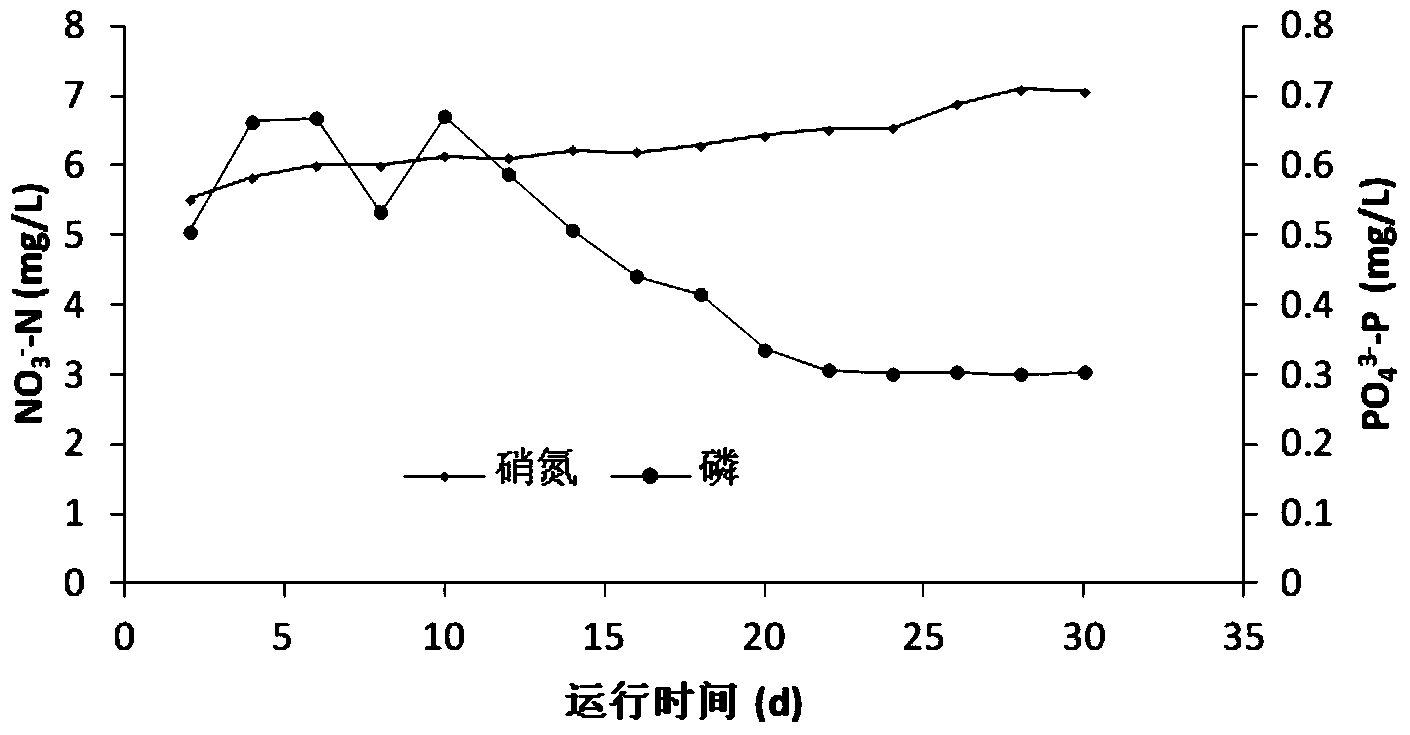

[0036] The treatment object is artificially prepared sewage composed of tap water, potassium dihydrogen phosphate and potassium nitrate, and the content of some pollutants is: NO 3 - -N27mg / L, PO 4 3--P6mg / L, water temperature 18°C. Its processing steps are:

[0037] (1) Preparation and construction of biofilter filler: prepare pyrrhotite into granular materials with a particle size between 2-20 mm; fill granular pyrrhotite into the reactor, and then rinse the reactor with clean water. The flushing can be stopped when the water out of the outlet is basically colorless; the measurement shows that the pH of the flushing water is 6, the bottom of the reactor is equipped with a water inlet, and the top is equipped with a water outlet; the reactor is a cylindrical reaction column with a height-to-diameter ratio of 3 ︰1. The cone is connected to the cylinder to facilitate even water in and out;

[0038] (2) Start-up of the biofilter: Mix anaerobic sludge and nutrient solution ...

Embodiment 2

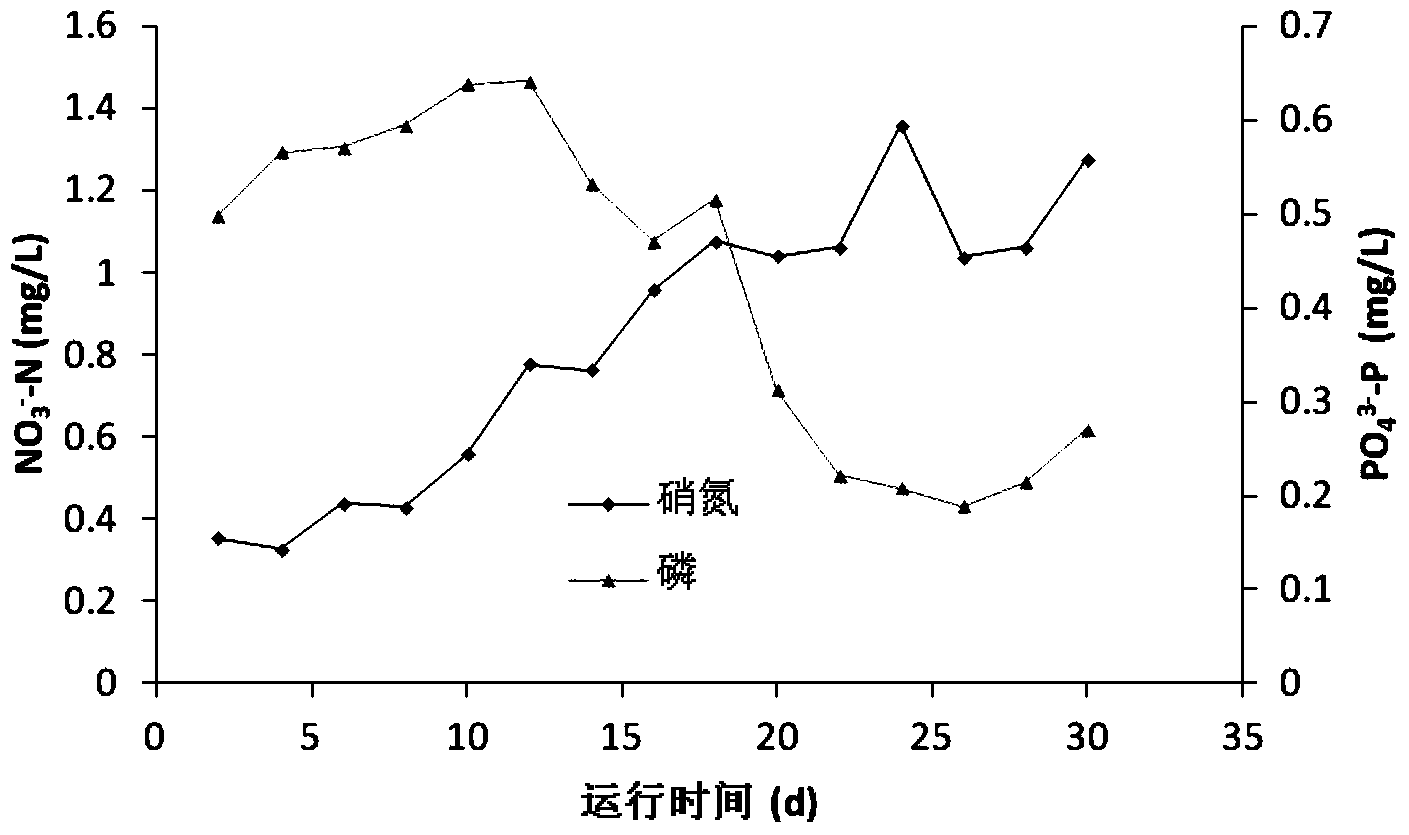

[0041] Same as Example 1, the difference is: the hydraulic retention time of the mixed nutrient solution is 24 hours during the start-up process of the biofilter in step (2). After the start-up, the reactor is pumped into the waste water to be treated, the hydraulic retention time is 24 hours, it runs for one month, and sampling analysis is performed every 2 days. The results are as follows: figure 2 shown. The final effluent nitrate nitrogen is stable at 1.13mg / L, phosphate phosphorus is stable at 0.22mg / L, the removal rate of nitrate nitrogen is 95.8%, and the removal rate of phosphorus is 96.3%.

Embodiment 3

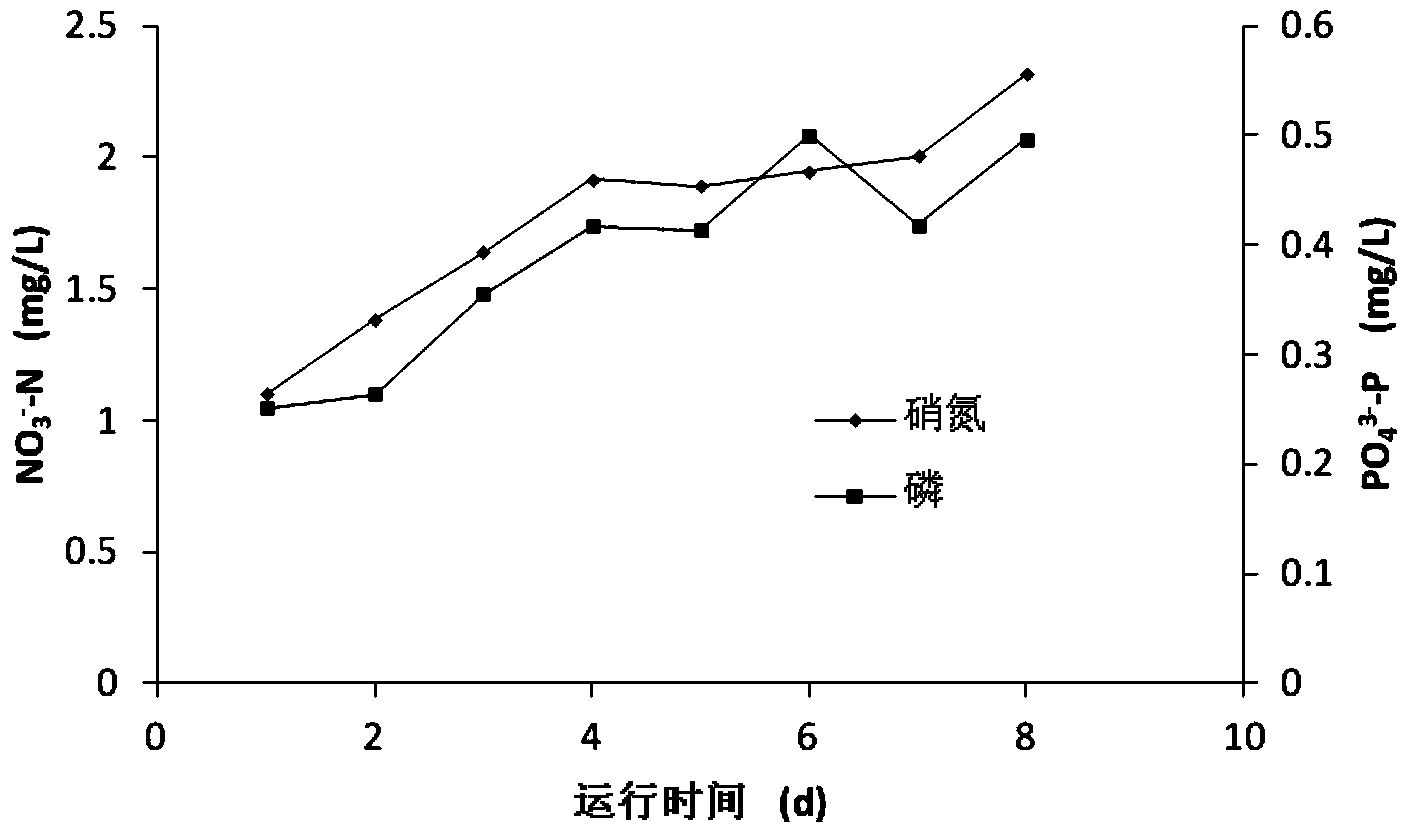

[0043] Same as Example 1, the difference is: the hydraulic retention time of the mixed nutrient solution during the start-up of the biofilter in step (2) is 20 hours. The external structure of the reactor is a cuboid, and the ratio of the length to the width of the cuboid is equal to 3:1.

[0044] The test water is artificially prepared sewage composed of tap water, potassium dihydrogen phosphate and potassium nitrate, NO 3 - -N28mg / L, PO 4 3- -P12mg / L, water temperature 18°C; pump the reactor after start-up into the waste water to be treated, the hydraulic retention time is 24 hours, run for one month, sample and analyze every 2 days, the results are as follows image 3 shown. The final effluent nitrate nitrogen is stable at 2.03mg / L, phosphate phosphorus is stable at 0.47mg / L, the removal rate of nitrate nitrogen is 92.8%, and the removal rate of phosphorus is 96.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com