Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1244results about "Gatherer machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

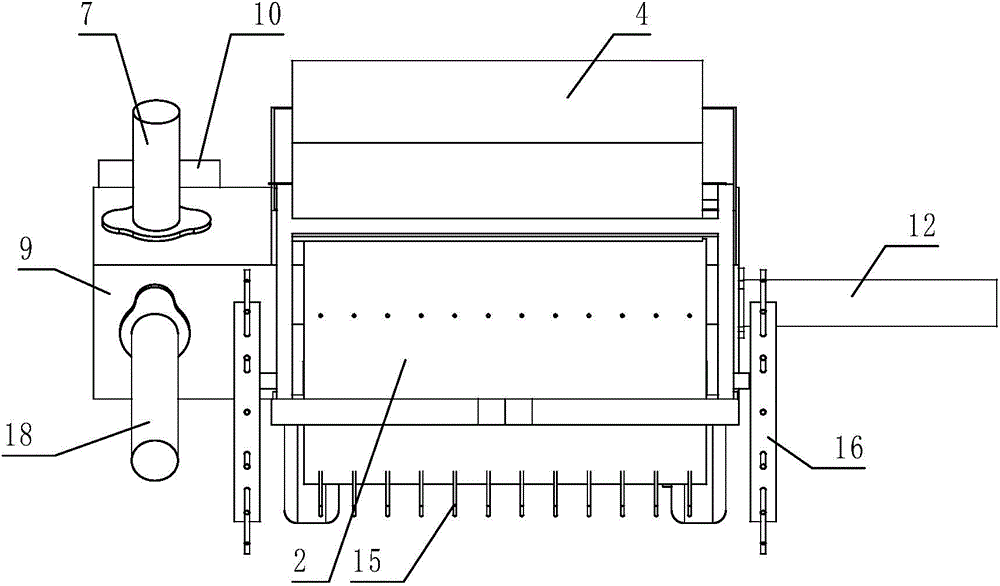

Residual film recovery device and residual film recovery machine formed by same

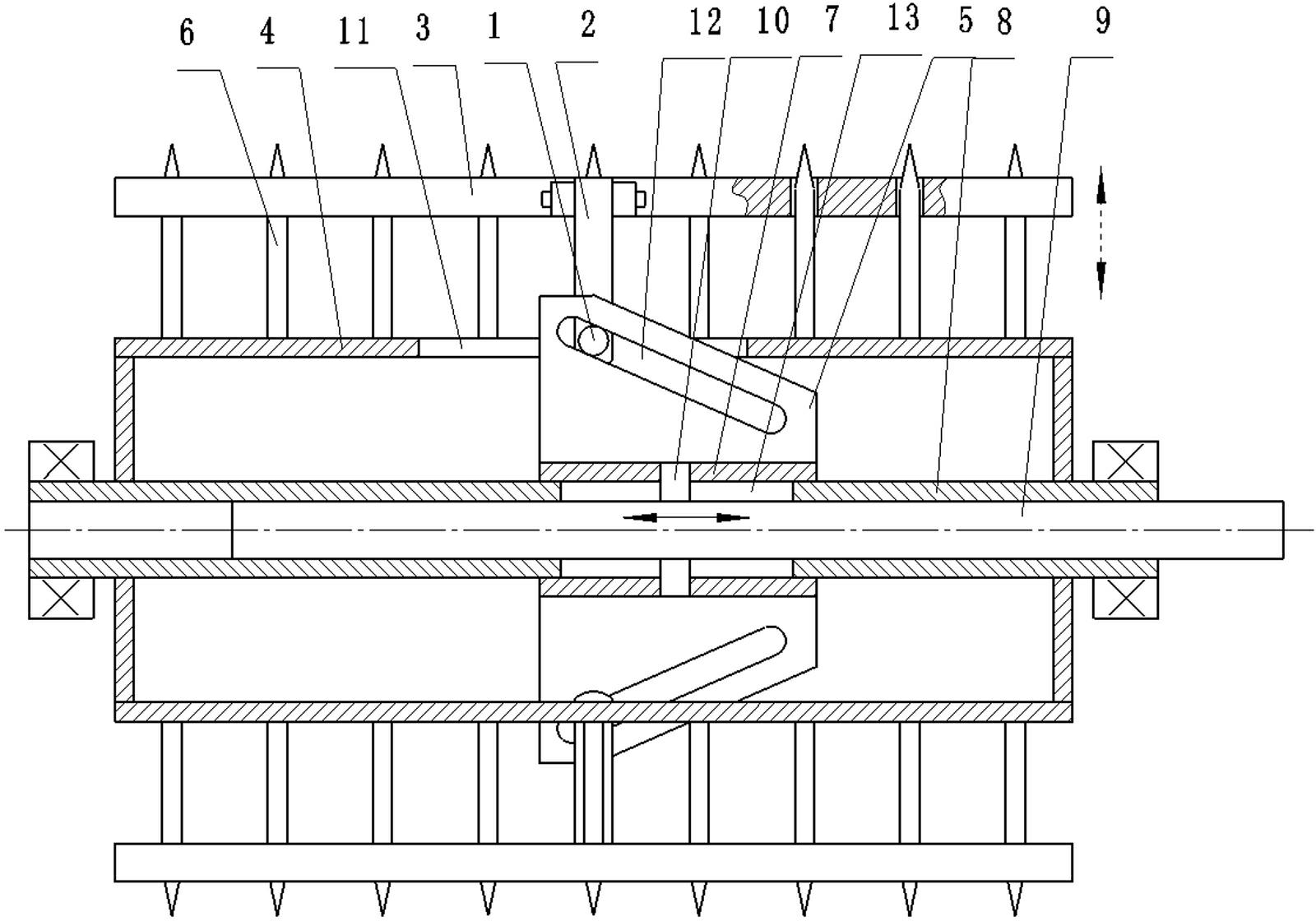

The invention discloses a residual film recovery device and a residual film recovery machine formed by the same. The residual film recovery device comprises a cylindrical hollow roller (4). The periphery of the outer wall of the roller (4) is provided with fingered picking teeth (6). Film withdrawing sliding blocks (3) are arranged on the picking teeth (6). The roller (4) is provided with a hollow shaft (8). A sliding sleeve (7) and chute plates (5) are arranged on the hollow shaft (8). Push-pull connecting rods (2) are arranged between the chute plates (5) and the film withdrawing sliding blocks (3). The residual film recovery device can be applied to various farmland operation machinery to form the residual film recovery machine or a combined land preparation operation machinery. Compared with the prior art, the residual film recovery device and the residual film recovery machine have simple structures and good operation effect; the problem of eliminating wound residual films and plant straws in the operating process is solved; the operation is ensured to be normally carried out; the residual film recovery device can be applied onto various residual film recovery machines and can also be integrated onto other combined land preparation operation machineries or similar operation machineries.

Owner:新疆石河子离合器厂

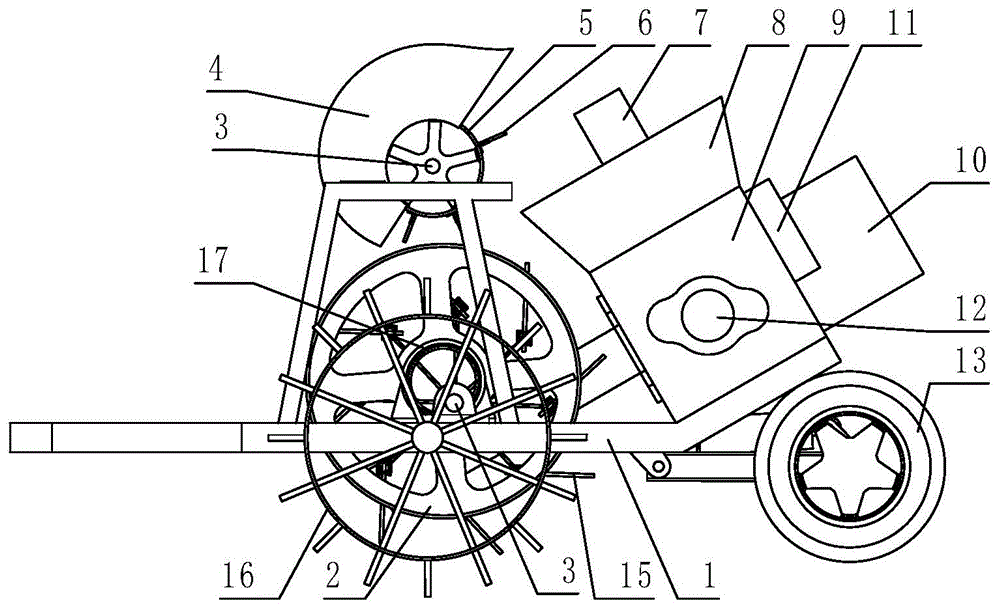

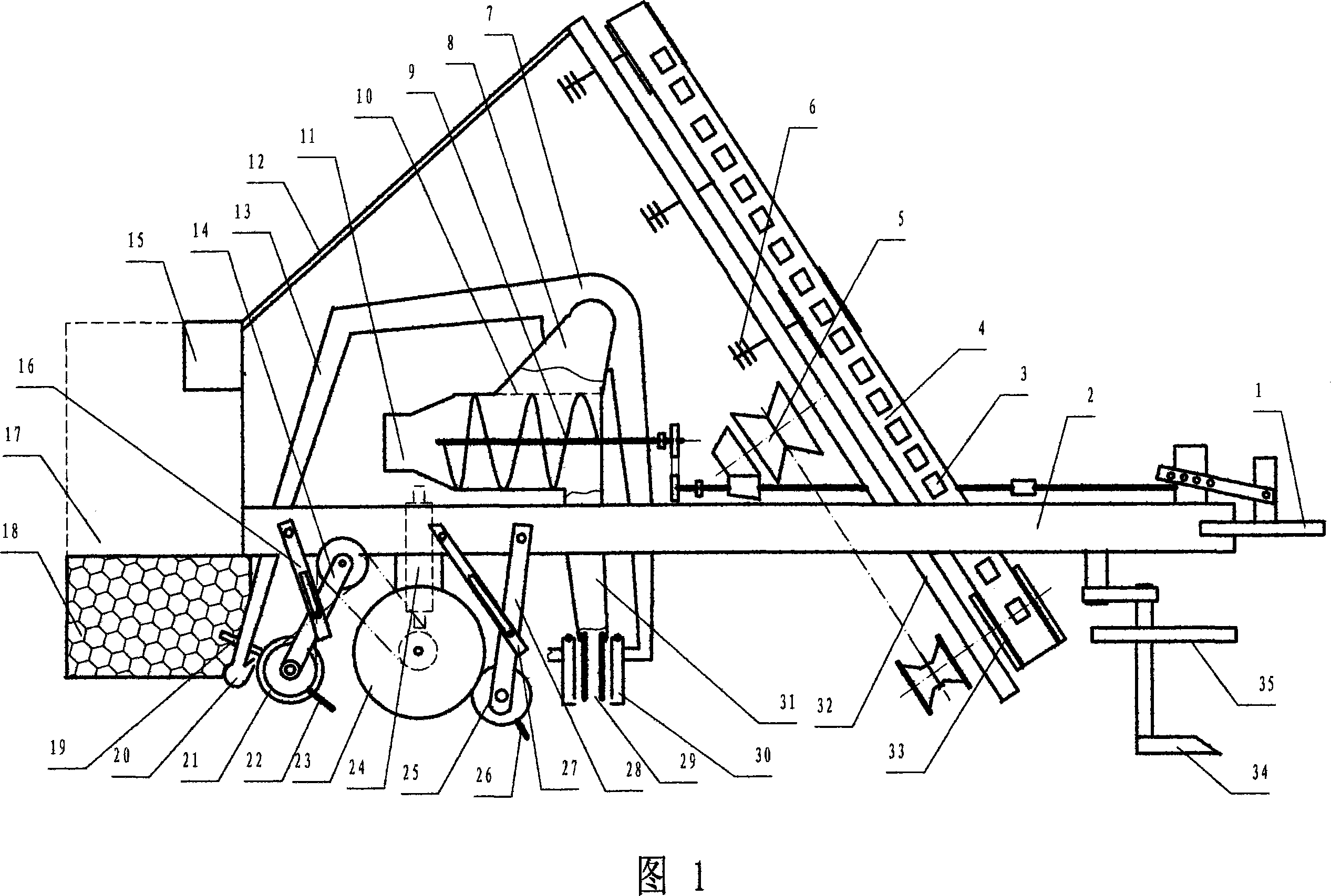

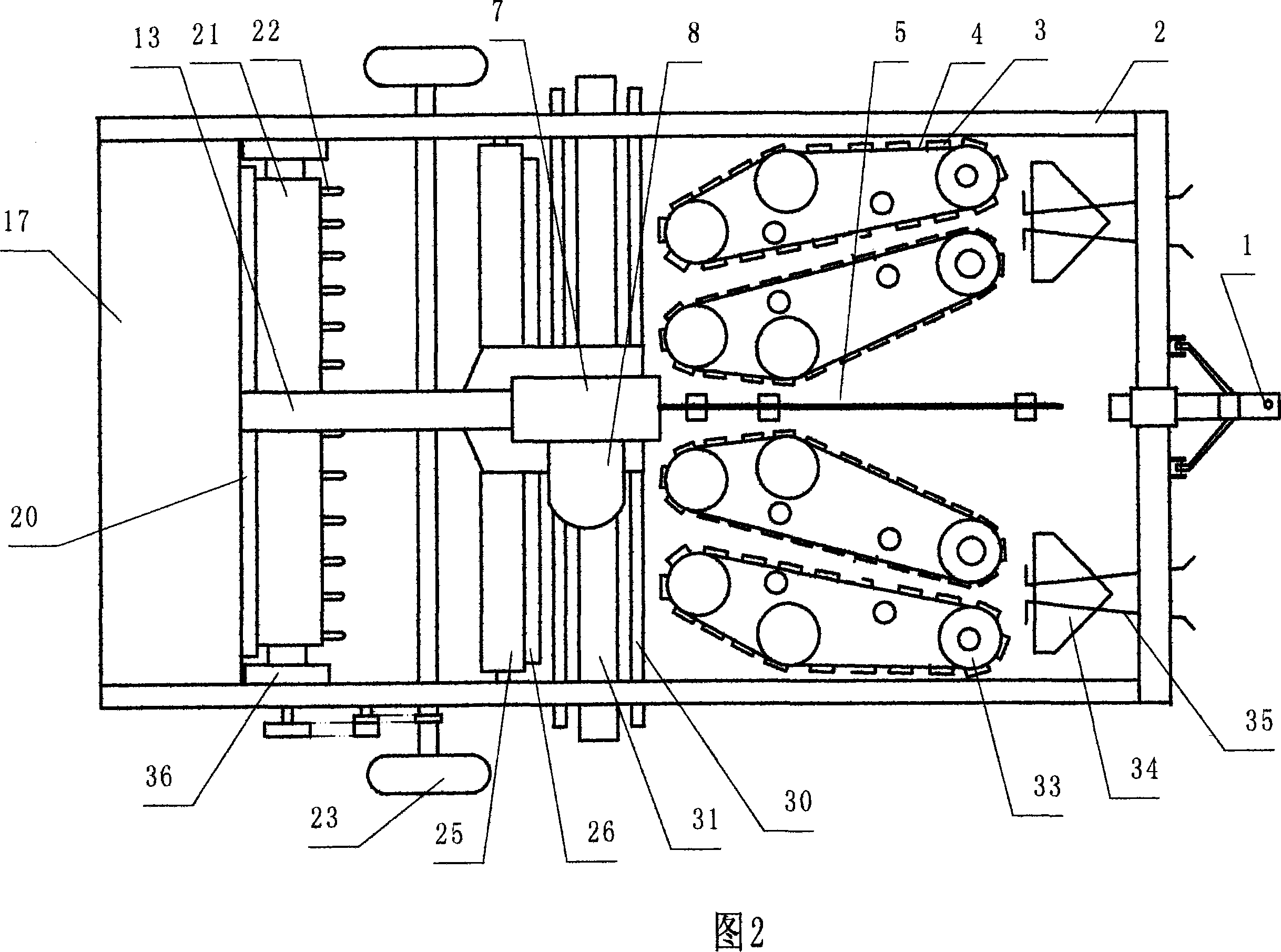

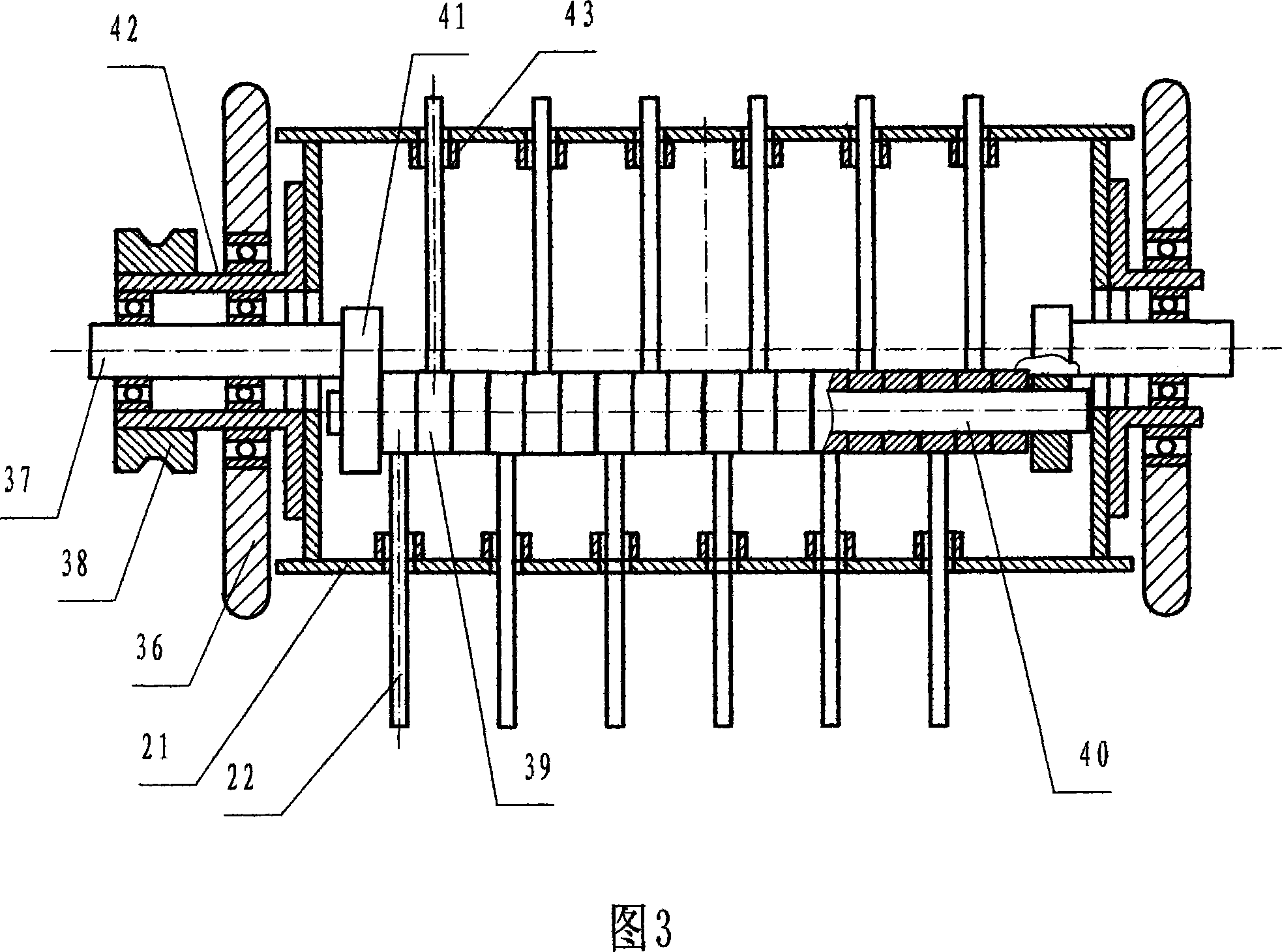

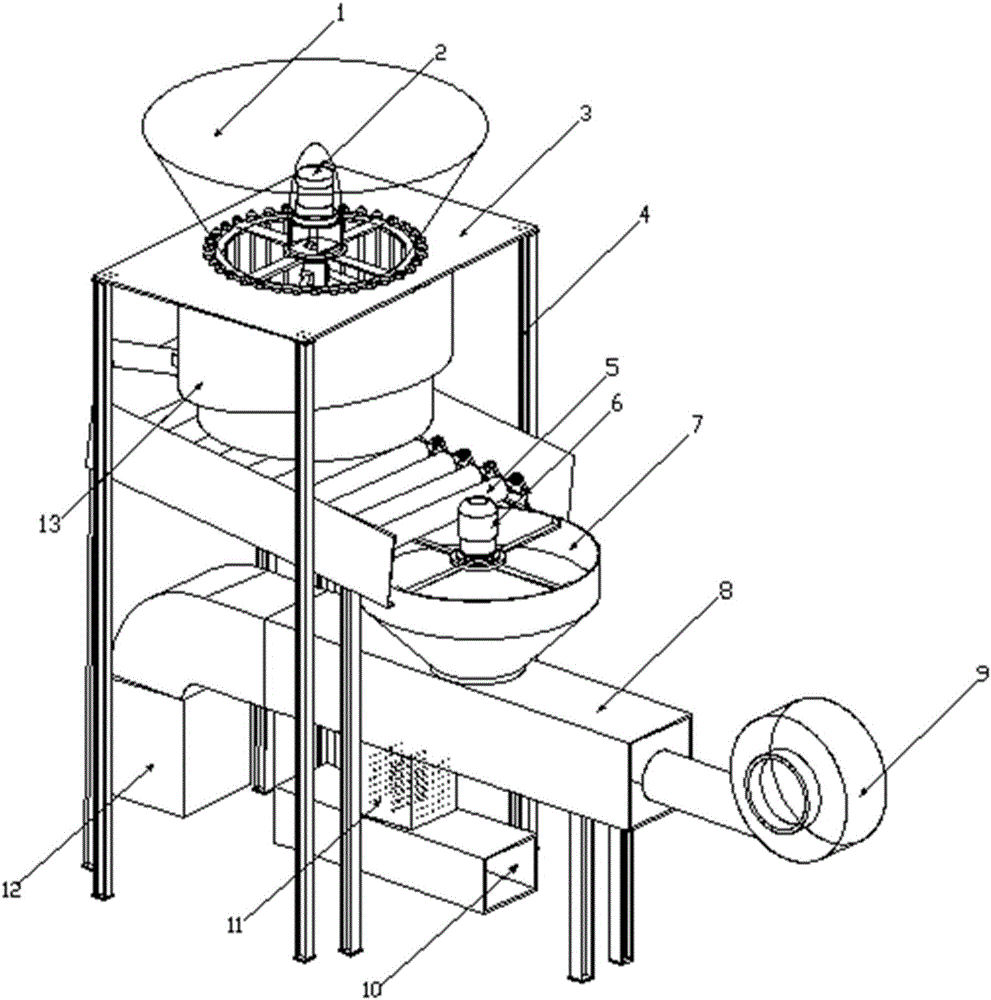

Deep plastic film residue screening and recycling machine

InactiveCN104186042AReach the effect of recyclingAchieve the purpose of collectionGatherer machinesAgricultural engineeringPlastic film

The invention relates to the technical field of agricultural machinery, in particular to a deep plastic film residue screening and recycling machine matching with a four-wheel tractor in use. The deep plastic film residue screening and recycling machine is hung on the four-wheel tractor through a connecting frame, the entire deep plastic film residue screening and recycling machine uses a left side plate and a right side plate for connection and land wheels as supports, a transmission is fixedly on a transmission support fixed on the rear side of the connecting frame and in power connection with the four-wheel tractor through a spline connecting shaft, a first driving chain wheel is fixed to the middle of a transmission main shaft of the transmission, and a second driving chain wheel is fixed on the outer side of the right side plate of the right end of the transmission main shaft; an exhaust inlet and a centrifugal fan are fixed in the rears of the left side plate and the right side plate through a fan support frame; a collection box is fixed at the rear ends of the left side plate and the right side plate through a collection box support frame. The deep plastic film residue screening and recycling machine is simple in structure, easy to operate, convenient to use and clean and thorough in plastic film recycling and is a satisfactory agricultural machine for protection of cultivated land.

Owner:青海林丰农牧机械制造有限公司

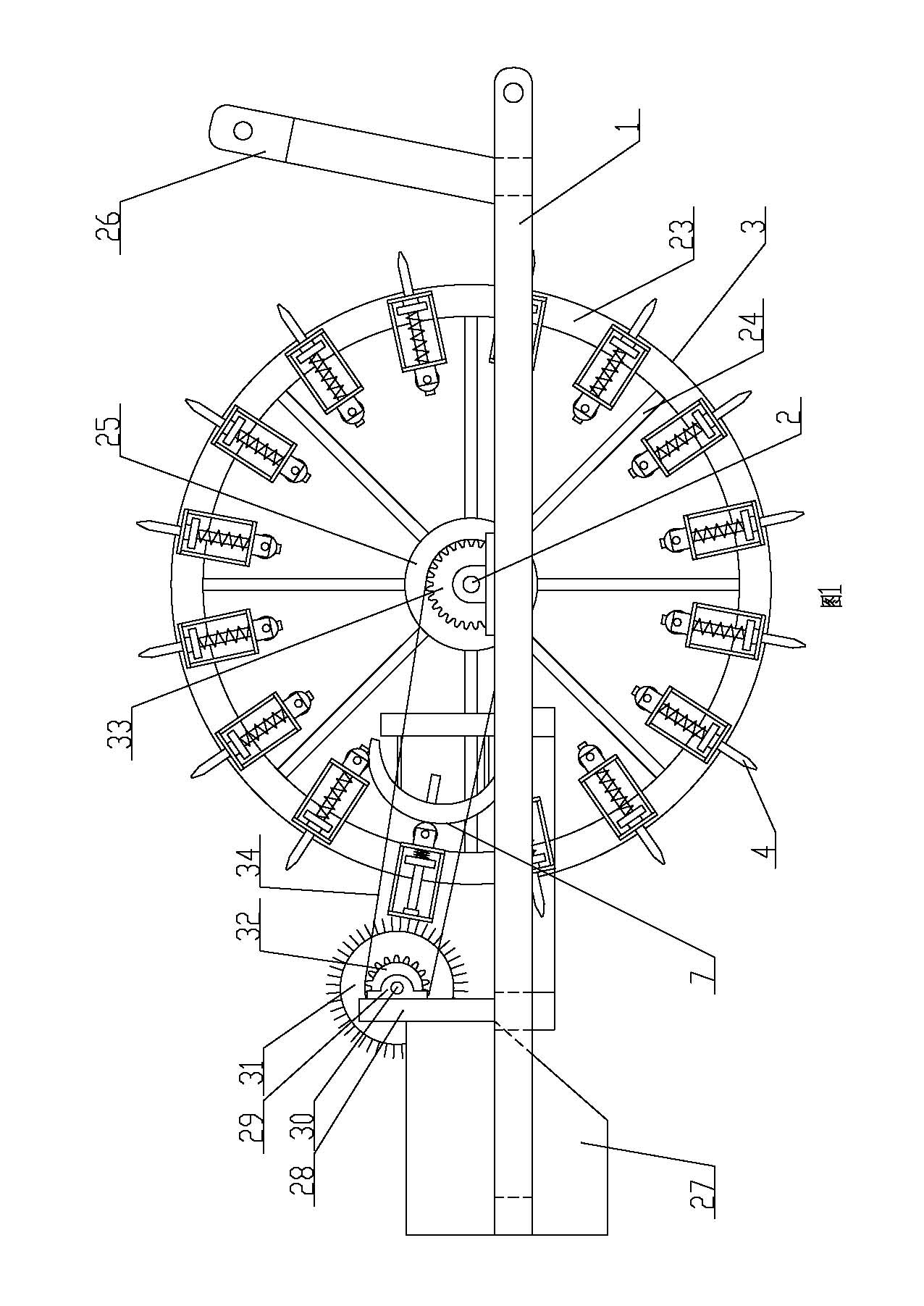

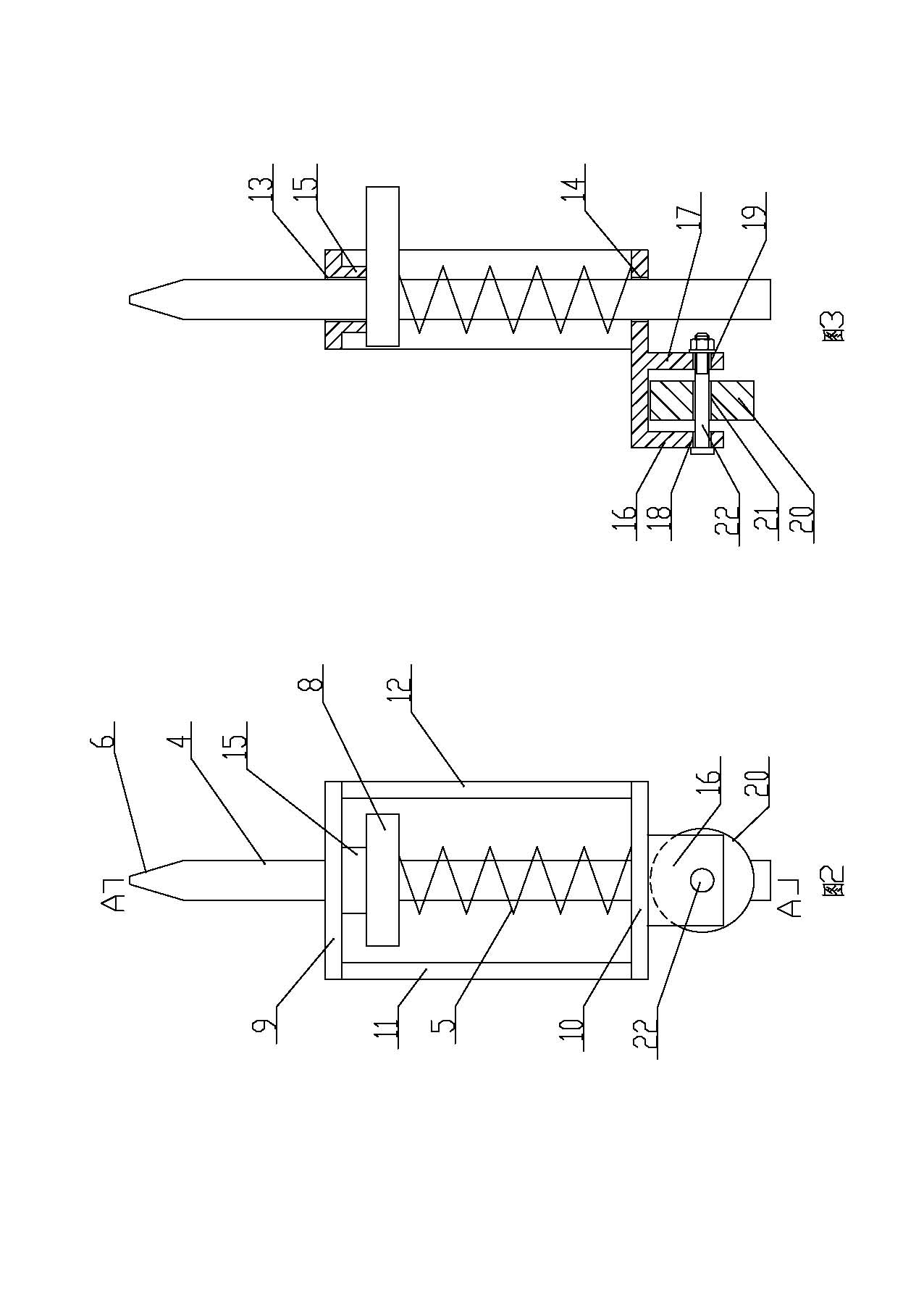

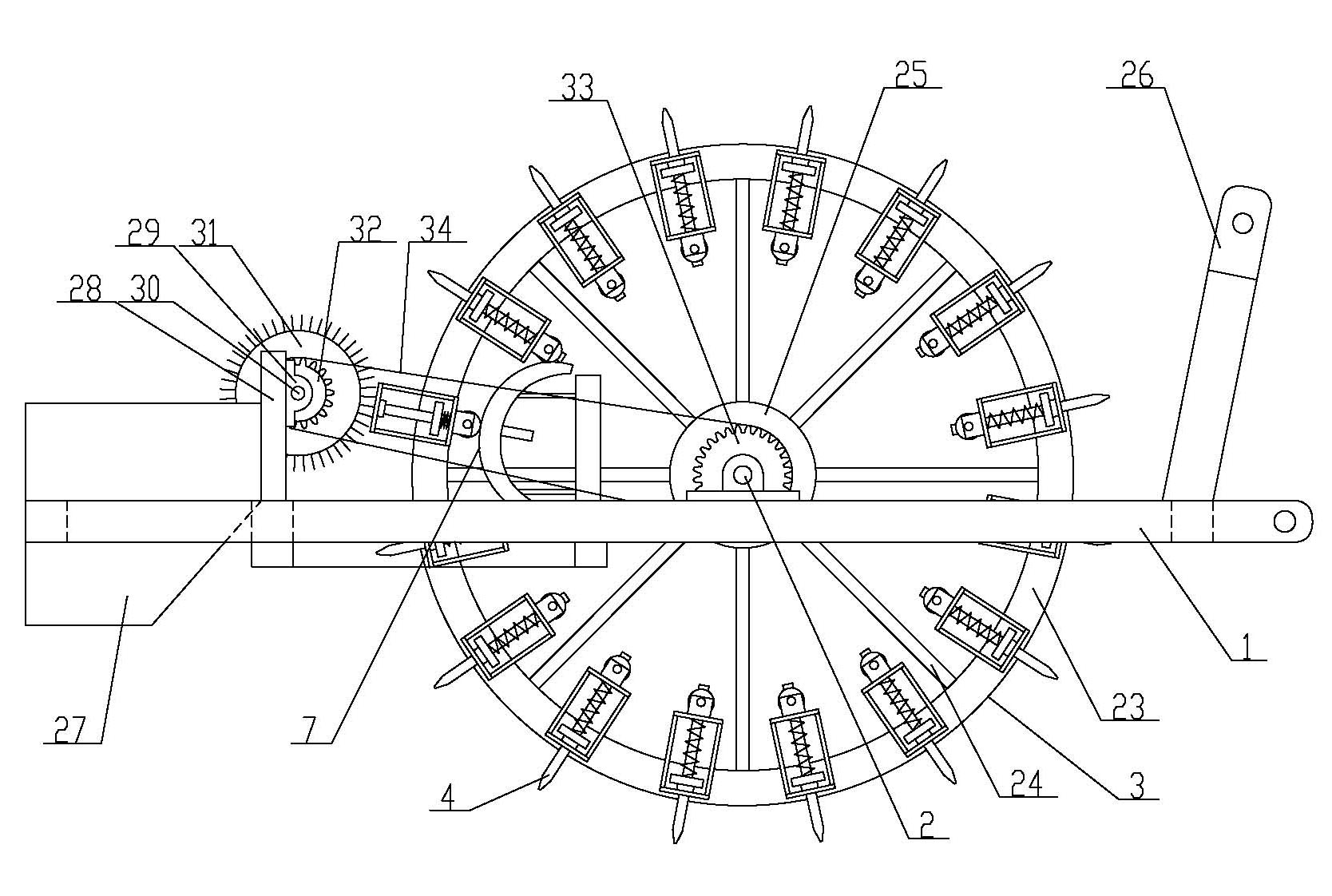

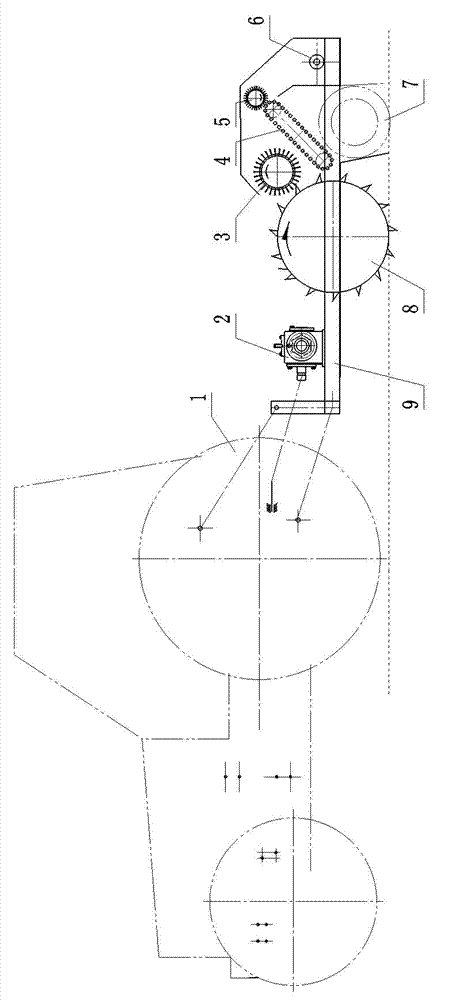

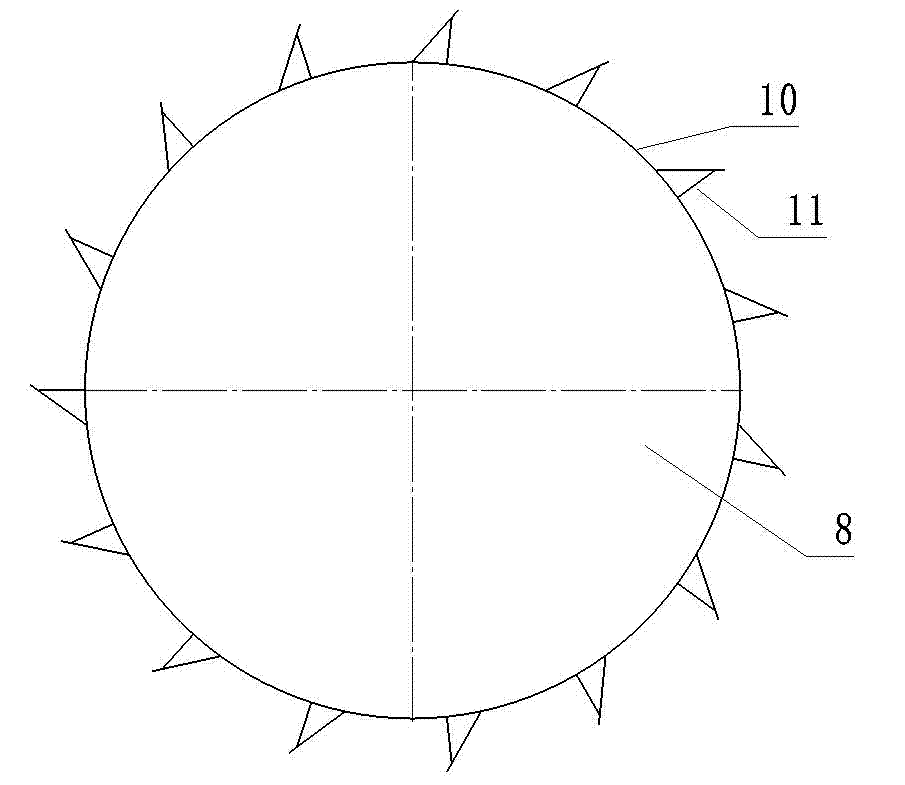

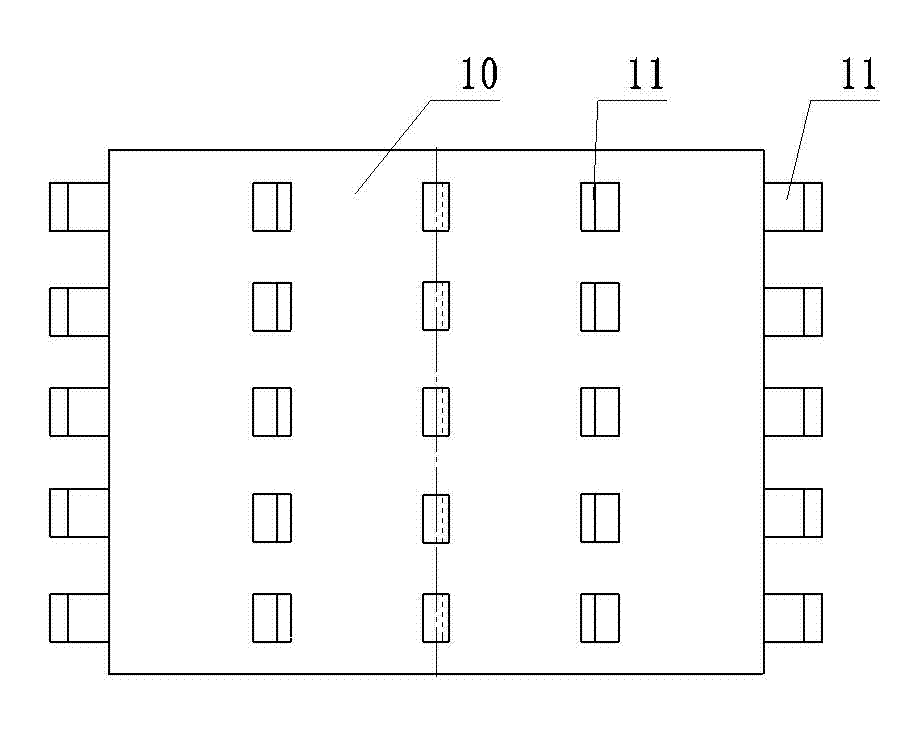

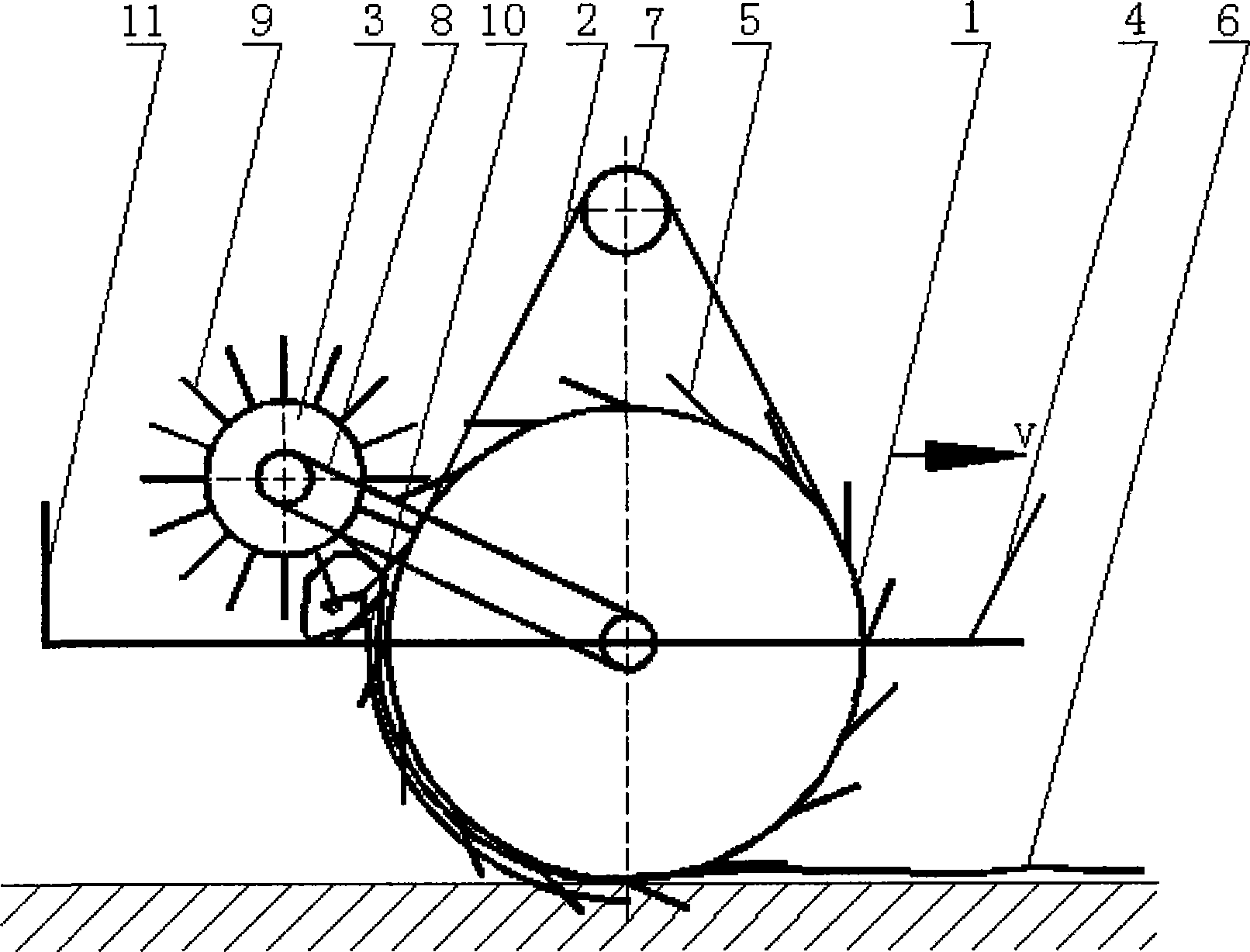

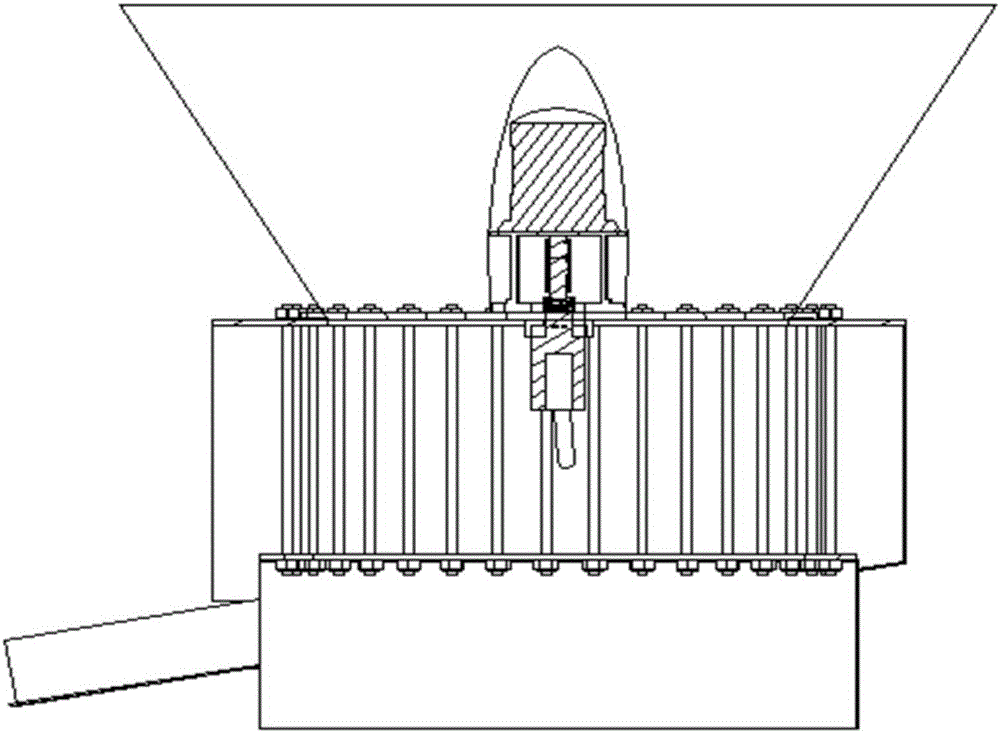

Remnant film picker

InactiveCN101933415ACompact and reasonable structureEasy to useGatherer machinesAgricultural engineeringCam

The invention relates to the technical field of remnant agricultural film recycle devices, in particular to a remnant film picker which comprises a machine frame, a spindle, picking wheels and spike-type pickers, wherein the spindle is installed on the machine frame and can rotate, at least one picking wheel is installed on the spindle, at least two spike-type pickers are arranged at intervals close to the edge of the picking wheel, each spike type picker comprises a picker shell, spike teeth and a compression spring, and a cam is fixedly arranged on the machine frame behind the spindle and can drive the picker shells to move towards the outside of the picking wheel so that the tooth points of the spike tooth can completely return into the picker shells. The remnant film picker has the advantages of reasonable and compact structure, convenient use; the picking wheel is used for driving the spike teeth to rotate to pick remnant films up, the cam is used for driving the picker shells to move relative to the spick teeth to remove the remnant films on the spick teeth, a film removing brush roll is used for sending the remnant films into a film collection box; and thus, the remnant film picker has the characteristics of safety, labor saving, convenience and high efficiency.

Owner:张朝书

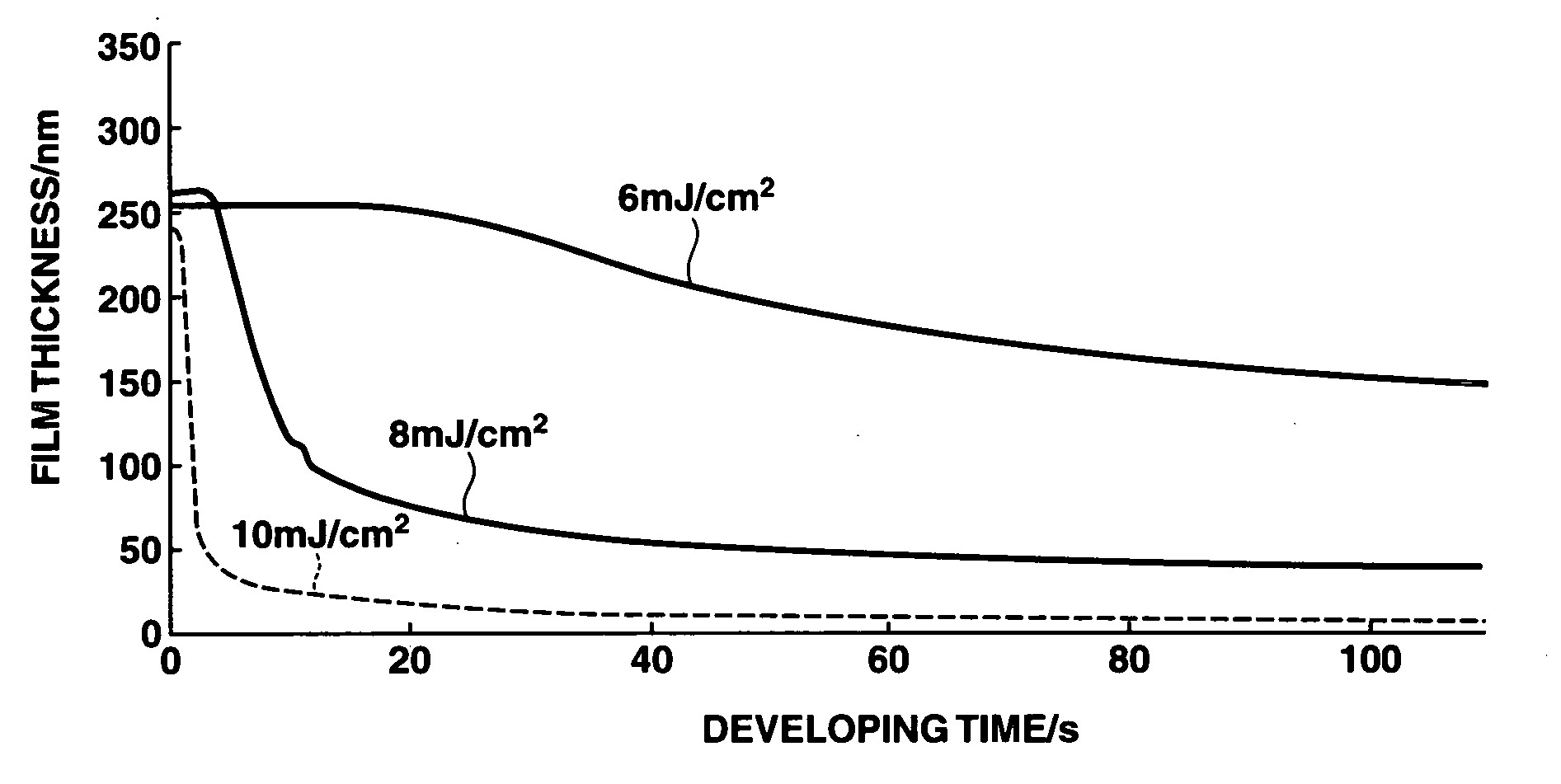

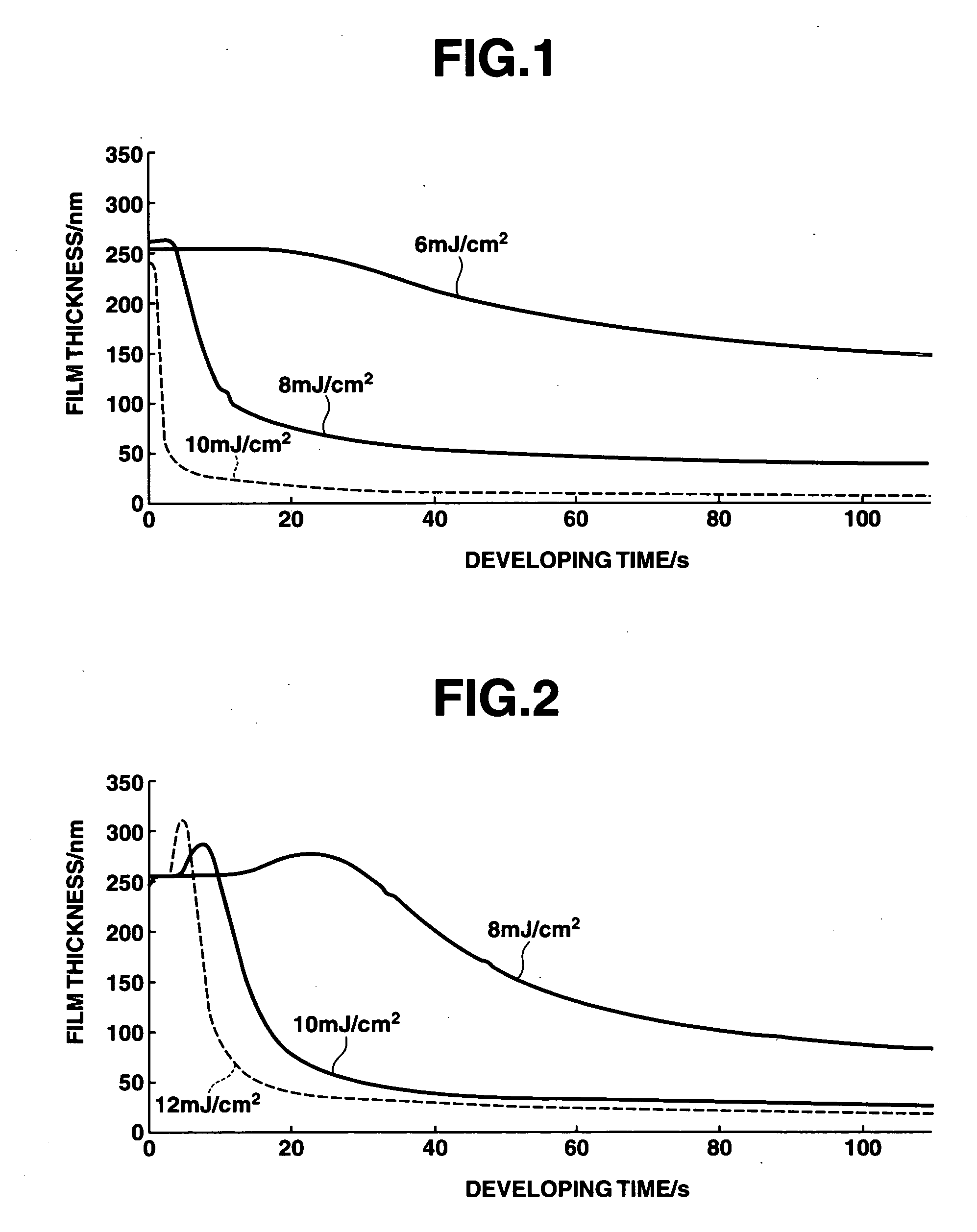

Positive resist compositions and patterning process

ActiveUS20050227174A1Minimal line edge roughnessHigh sensitivityAgricultural machinesRadiation applicationsMeth-Leaving group

A polymer which is obtained from a combination of (meth)acrylate having a bridged ring lactone group and (meth)acrylate having an acid leaving group with a hexafluoroalcohol group is used as a base resin to formulate a positive resist composition which when exposed to high-energy radiation and developed, exhibits a high sensitivity, a high resolution, and a minimal line edge roughness due to controlled swell during development. The composition also has excellent dry etching resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Floating synchronous curl-up film roller type seedling plastic film collector

InactiveCN101911865AAvoid secondary pollutionHigh yieldGatherer machinesWebs handlingAgricultural engineeringWheel cylinder

The invention provides a floating synchronous curl-up film roller type seedling plastic film collector which is characterized by comprising a stand. The middle part of the stand is rotatably connected with a land axle, two land wheels are respectively fixed at both ends of the land axle, a soil shaking mechanism is rotatably connected to the stand arranged above the land axle, a gripper-shaped film loosening mechanism is fixed on the stand arranged behind the soil shaking mechanism, two adjustable break shovels are respectively arranged at both sides of the front end of the stand, two U-shaped brackets are respectively fixed at both sides of the back end of the stand, a curl-up film roller is supported in the two U-shaped bracket through a curl-up film roller axle, a tension spring is respectively connected between each end of the curl-up film roller axle at the outer side of the two U-shaped brackets and the stand, a wheel cylinder which is driven by the curl-up film roller through friction is arranged below the curl-up film roller, extension ends at both ends of the wheel cylinder are rotatably connected to the stand, the extension end at one end is connected with a side land axle through a wheel cylinder transmission mechanism, and the extension end at the other end is connected with the soil shaking mechanism through a soil shaking transmission mechanism. The film curling speed of the invention is consistent with the advancing speed of a machine, thereby efficiently avoiding the phenomena of film tearing and breaking and ensuring normal continuous work of the machine.

Owner:CHINA AGRI UNIV

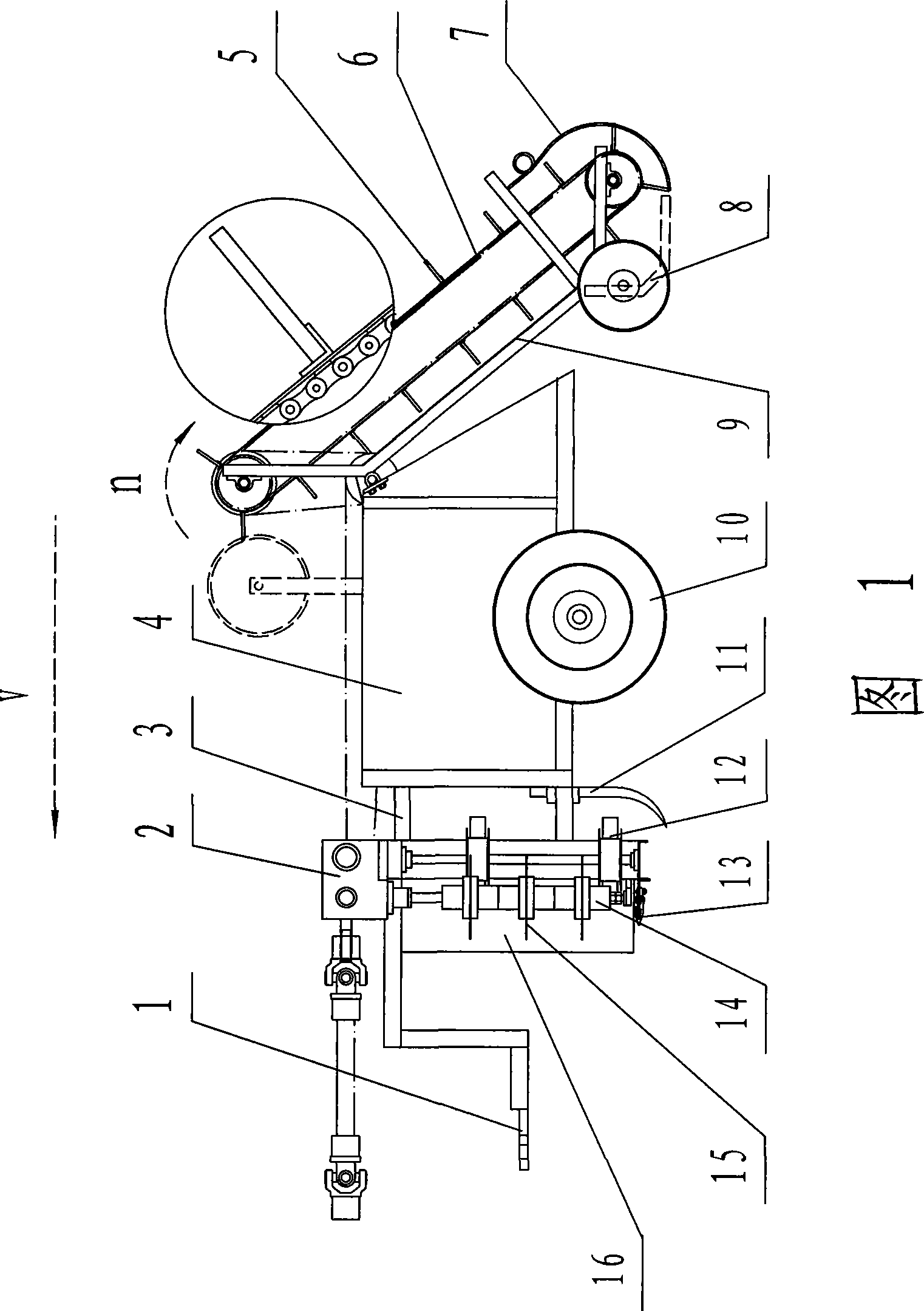

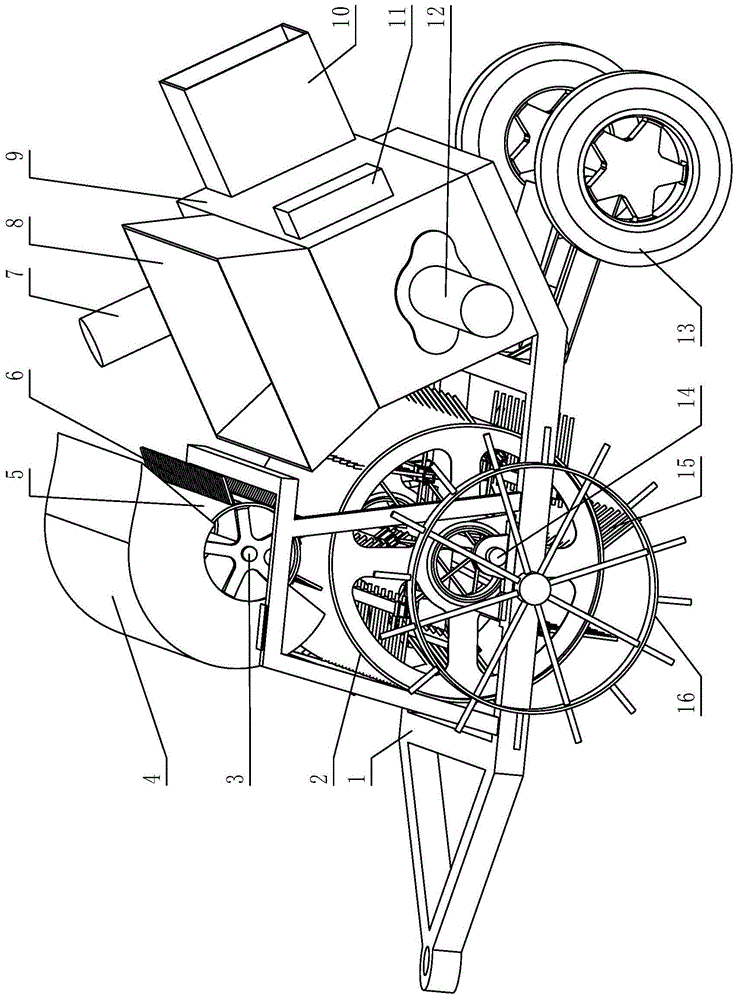

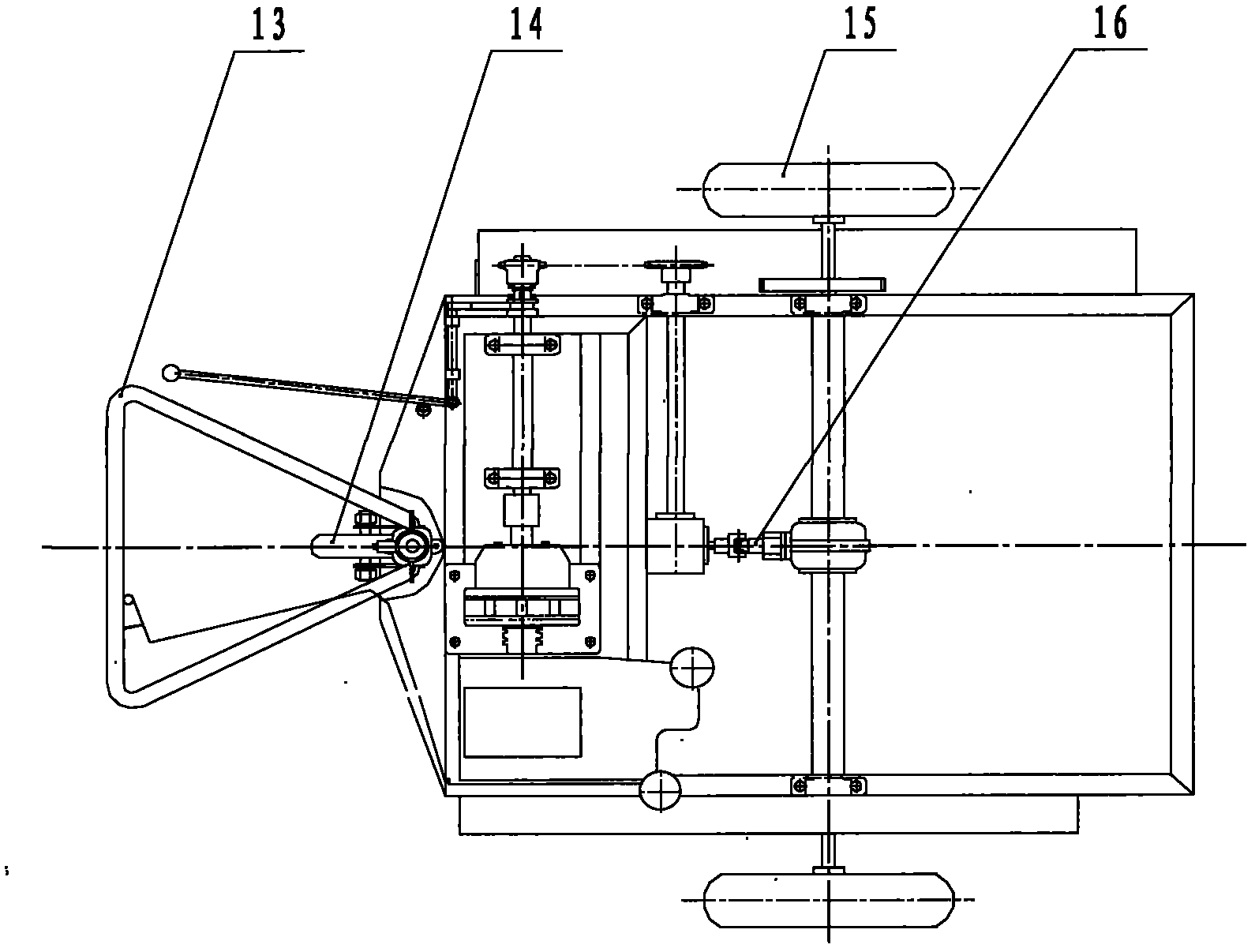

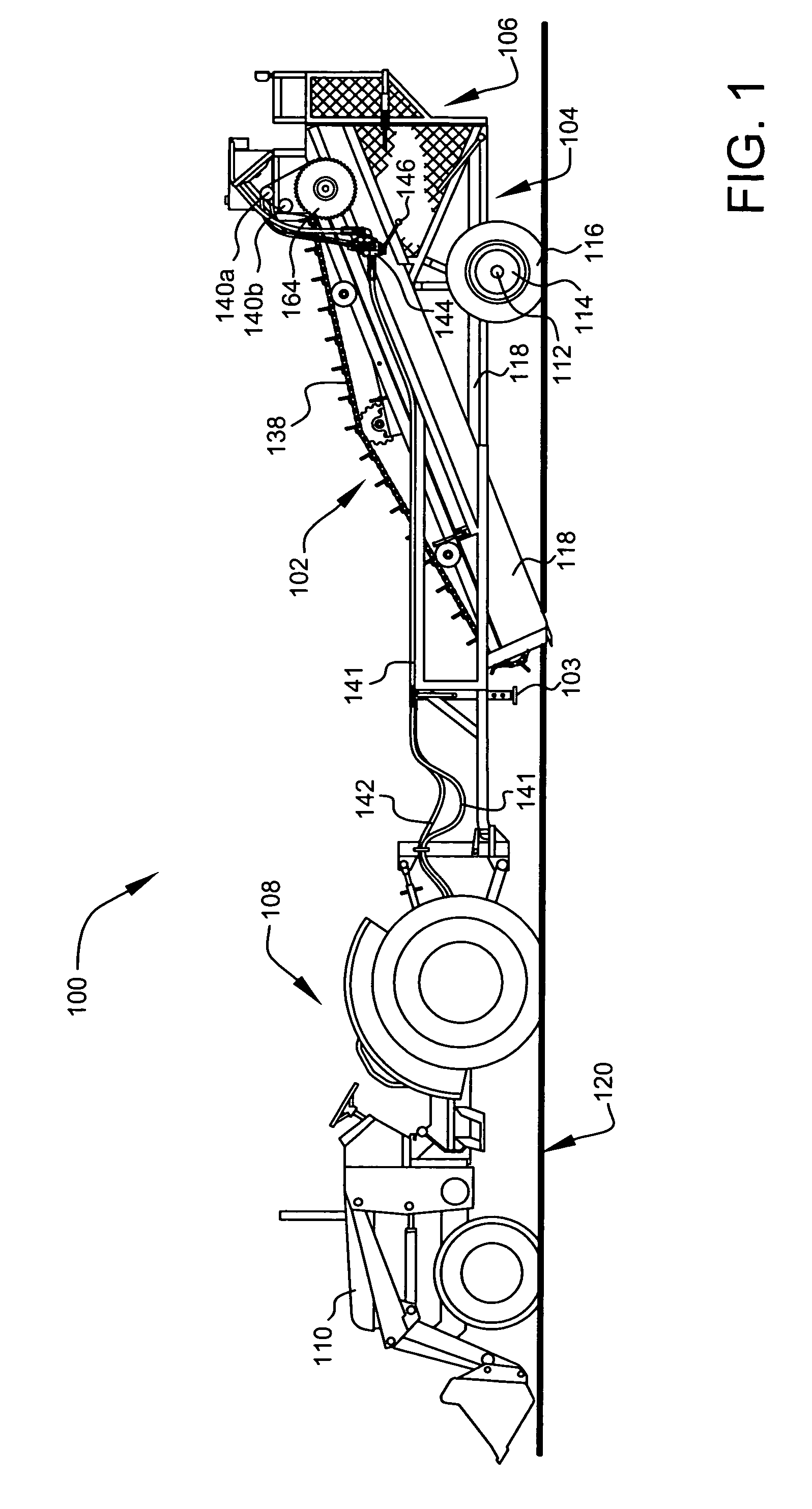

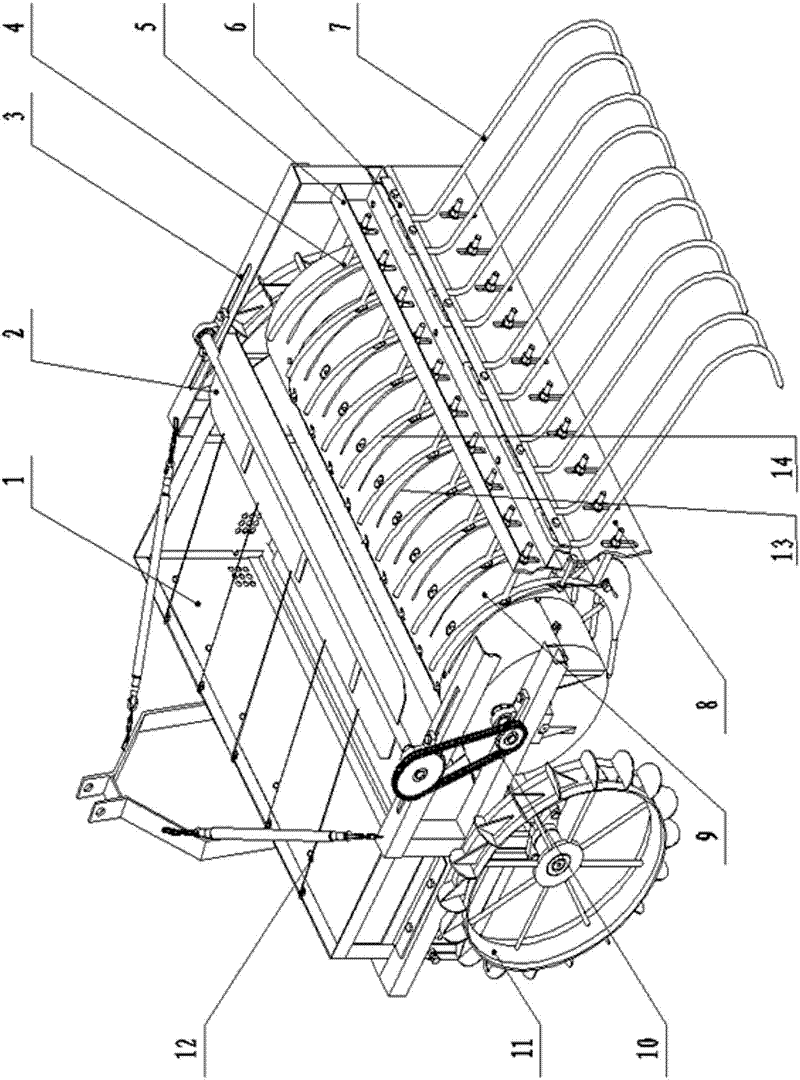

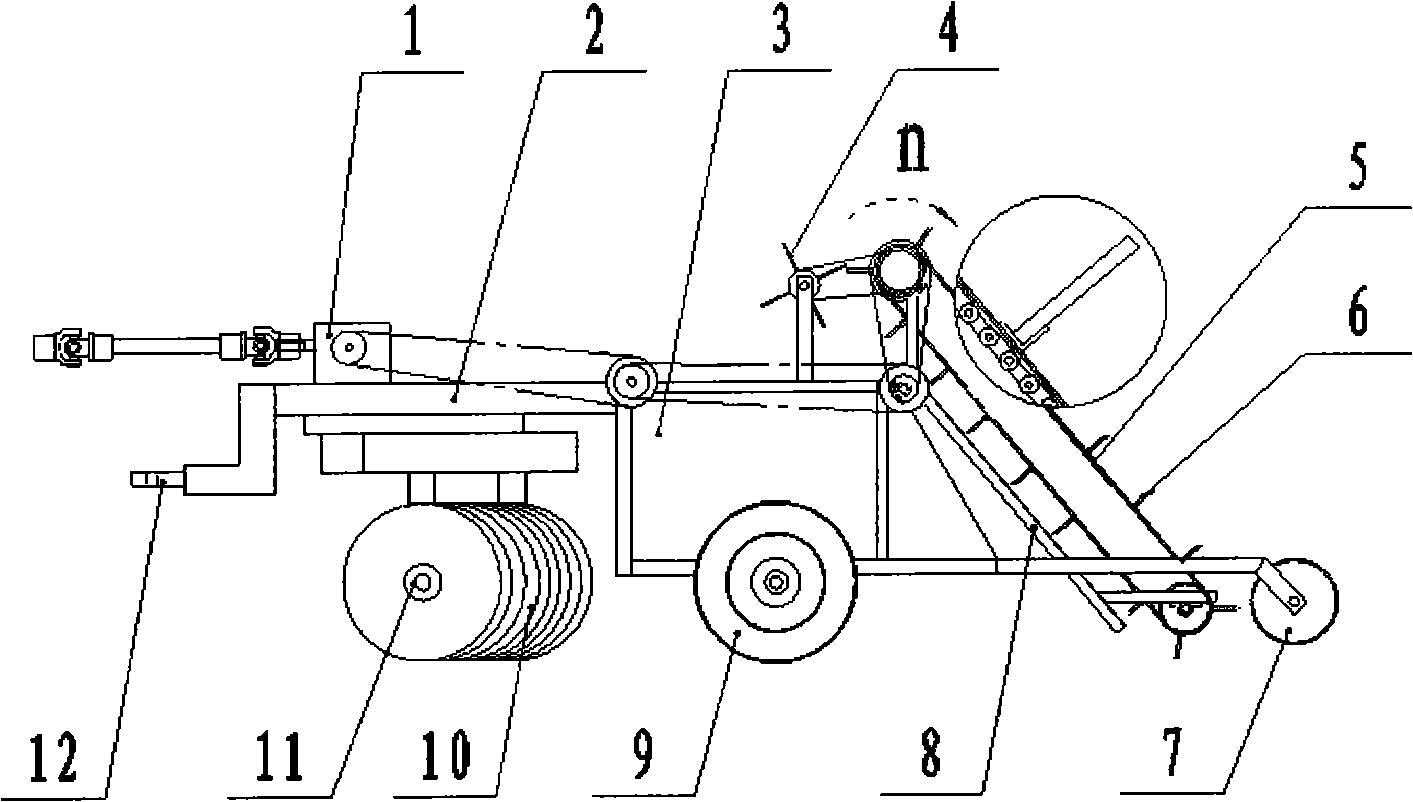

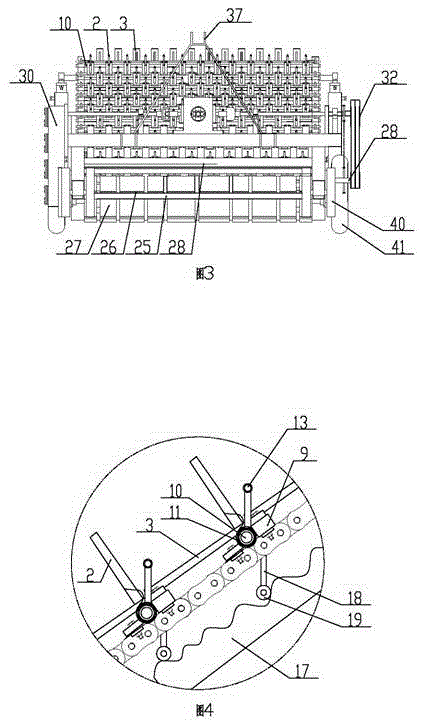

Stalk crushing returning and residual plastic film recovery combined machine

The invention relates to a machine used for the combined operation of chopping crop straws and returning farmland and recycling residual films on the ground surface. The machine comprises a traction unit (1), a transmission system (2), a frame (3), a residual film box (4), a land wheel (10), a scarifier tyne (11), a straw chopping device and a residual film recycling device; the straw chopping device consists of a reciprocating cutterbar (13), a transverse conveying belt (12), a disc type chopper (14), a protection hood (16) and a transmission device; wherein, the residual film recycling device is arranged at the back of the residual film box and consists of a chain harrow (6), an elastic gear (7) for raking the film, a bottom board (9) and a feeler wheel (8); a gear rod (5) is arranged on the chain harrow, and the elastic gear (7) for raking the film is arranged at the back side of the residual film recycling device. The machine can finish the two operations of returning the straws to the farmland and recycling the residual films, has the advantages of high operation speed, clean residual film recycling, small energy consumption and film-rod separation; moreover, the residual films are hard to twist working parts; therefore, the demands of chopping the straws and recycling the residual films can be met.

Owner:SHIHEZI UNIVERSITY

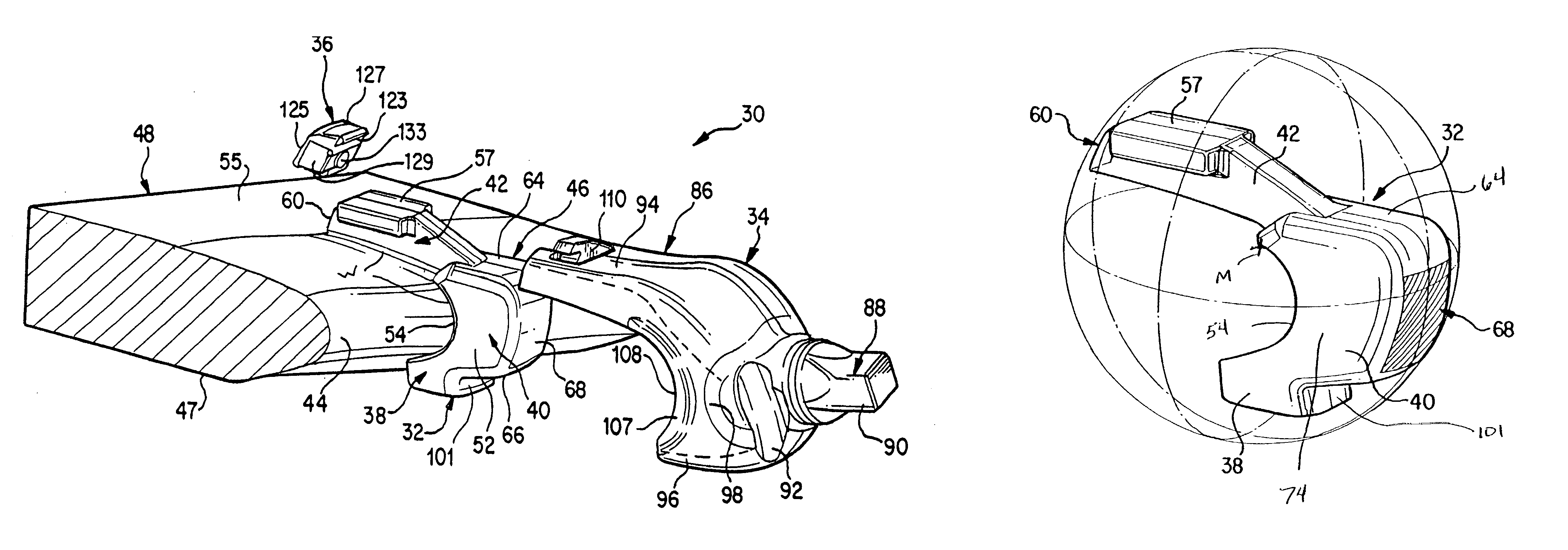

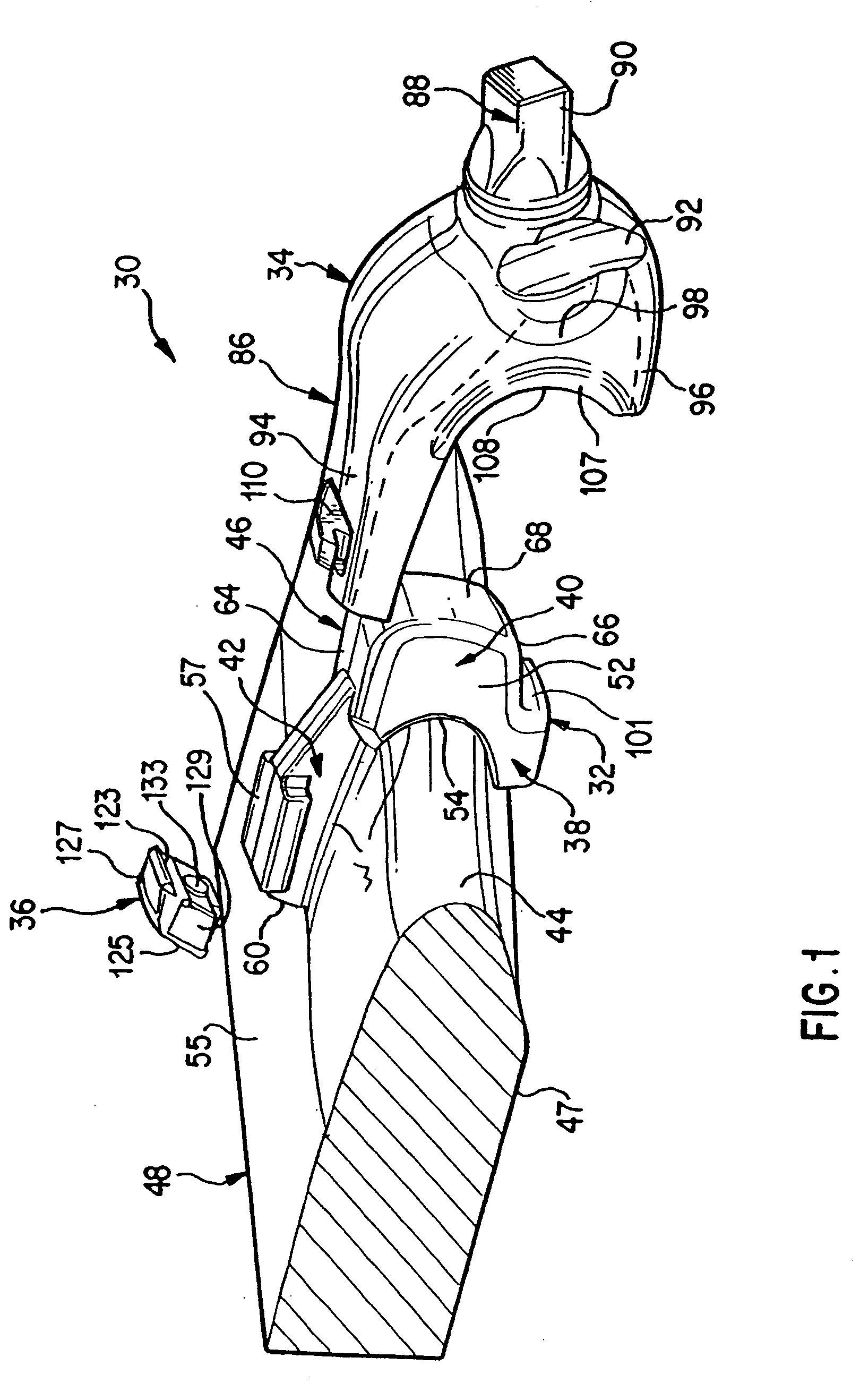

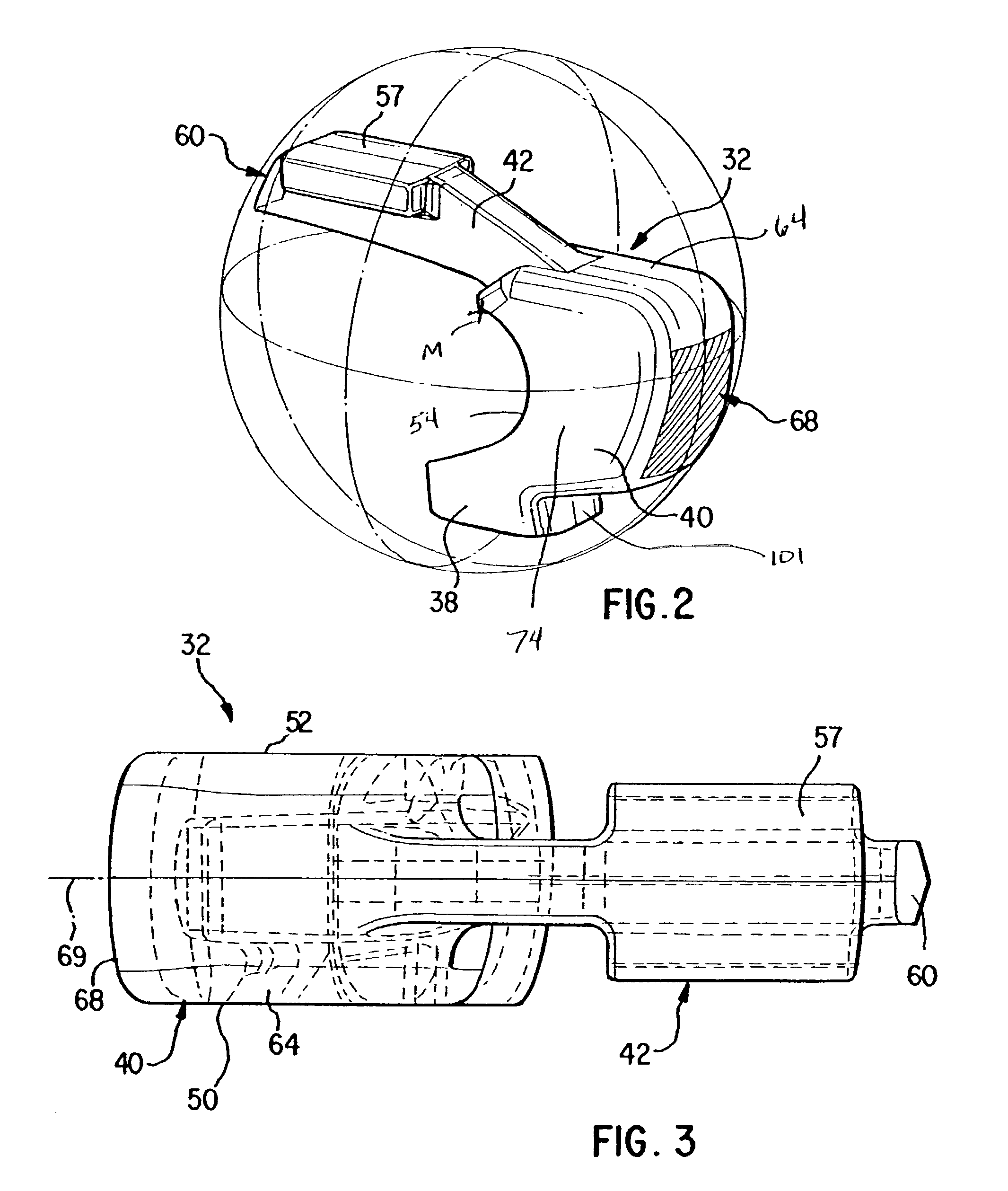

Assembly for securing a wear member to an excavator

InactiveUS7165347B2Easy and accurate and quick mannerPrecise positioningMechanical machines/dredgersRod connectionsEngineeringBearing surface

Owner:ESCO CORP

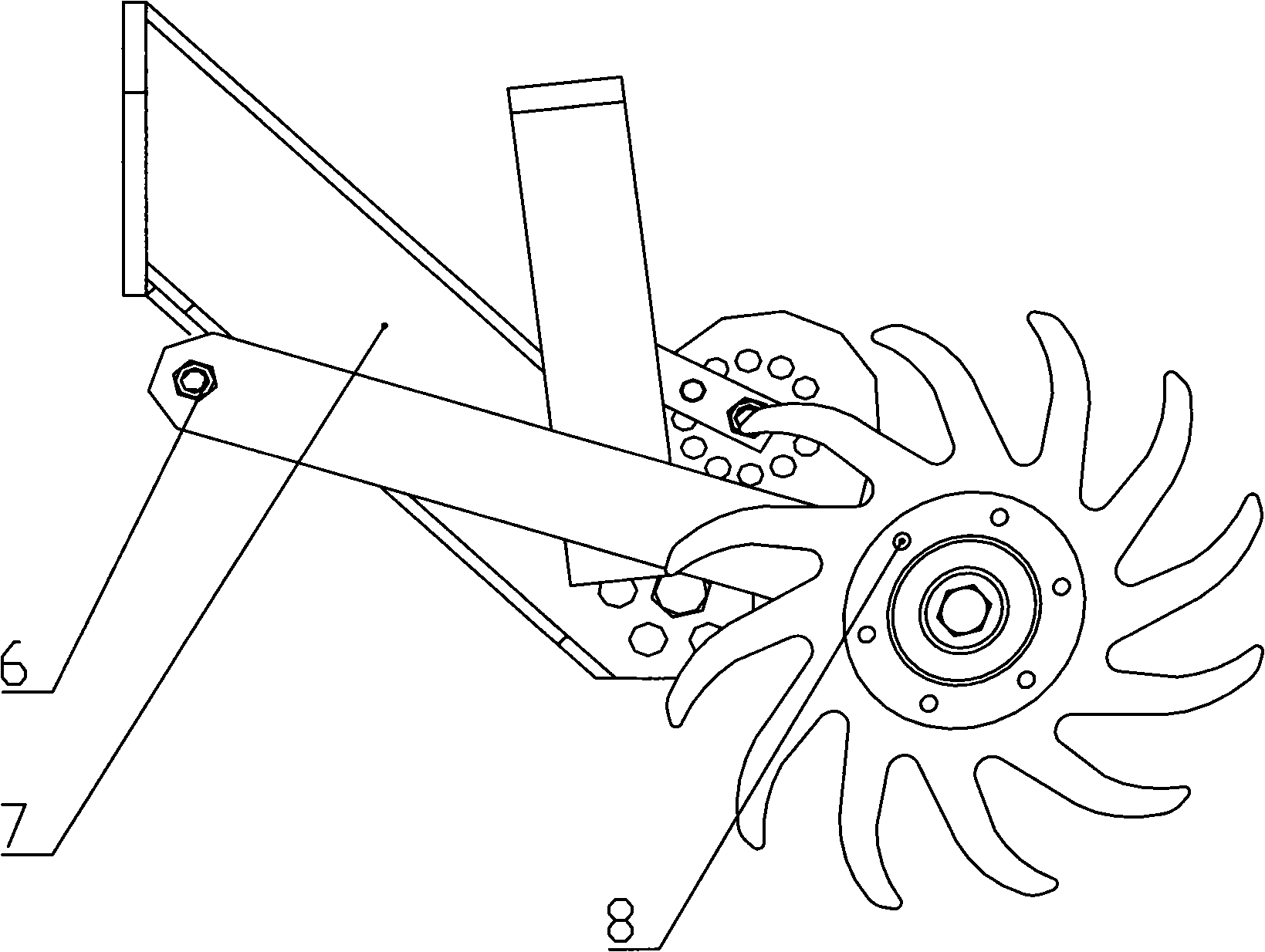

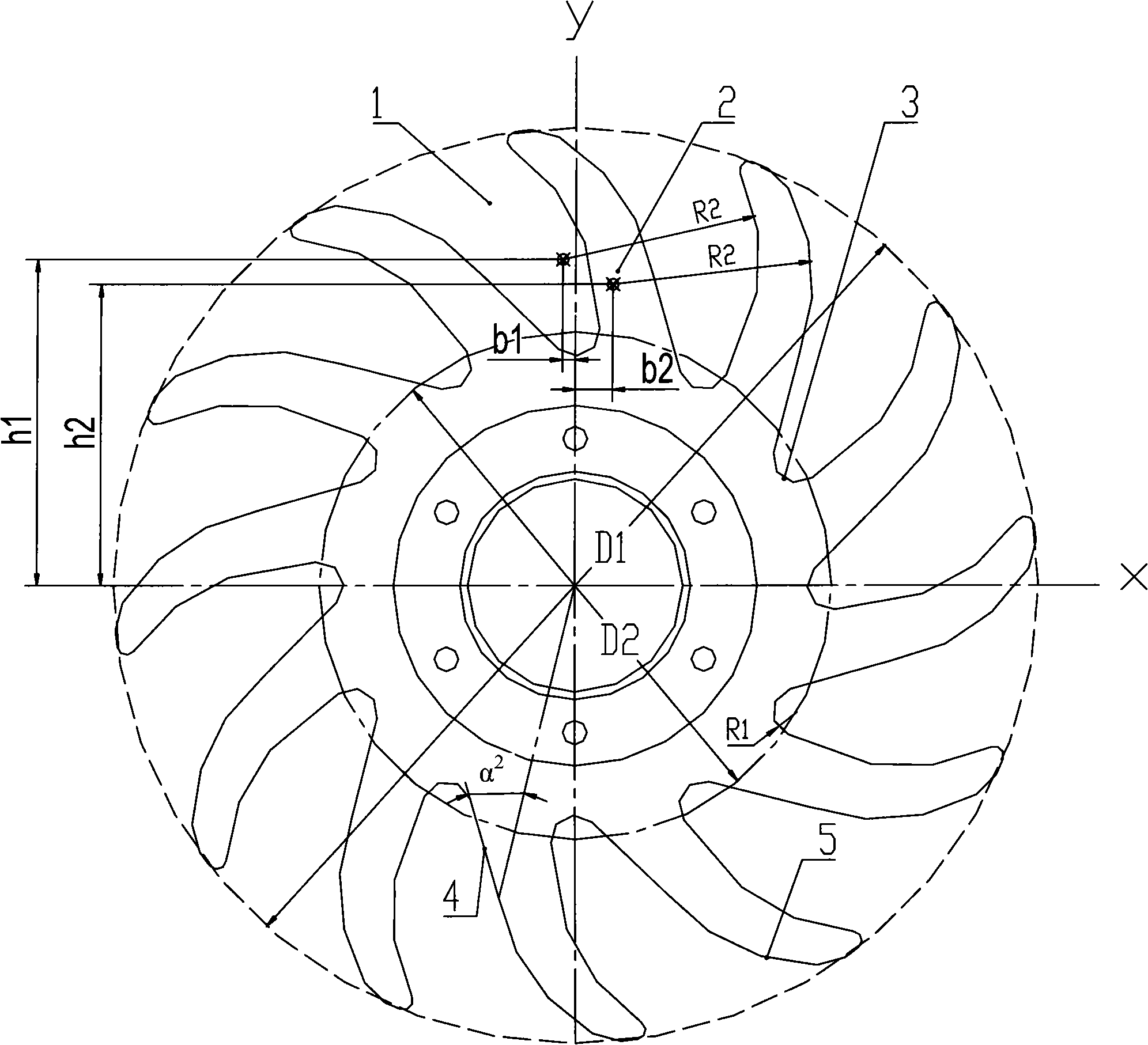

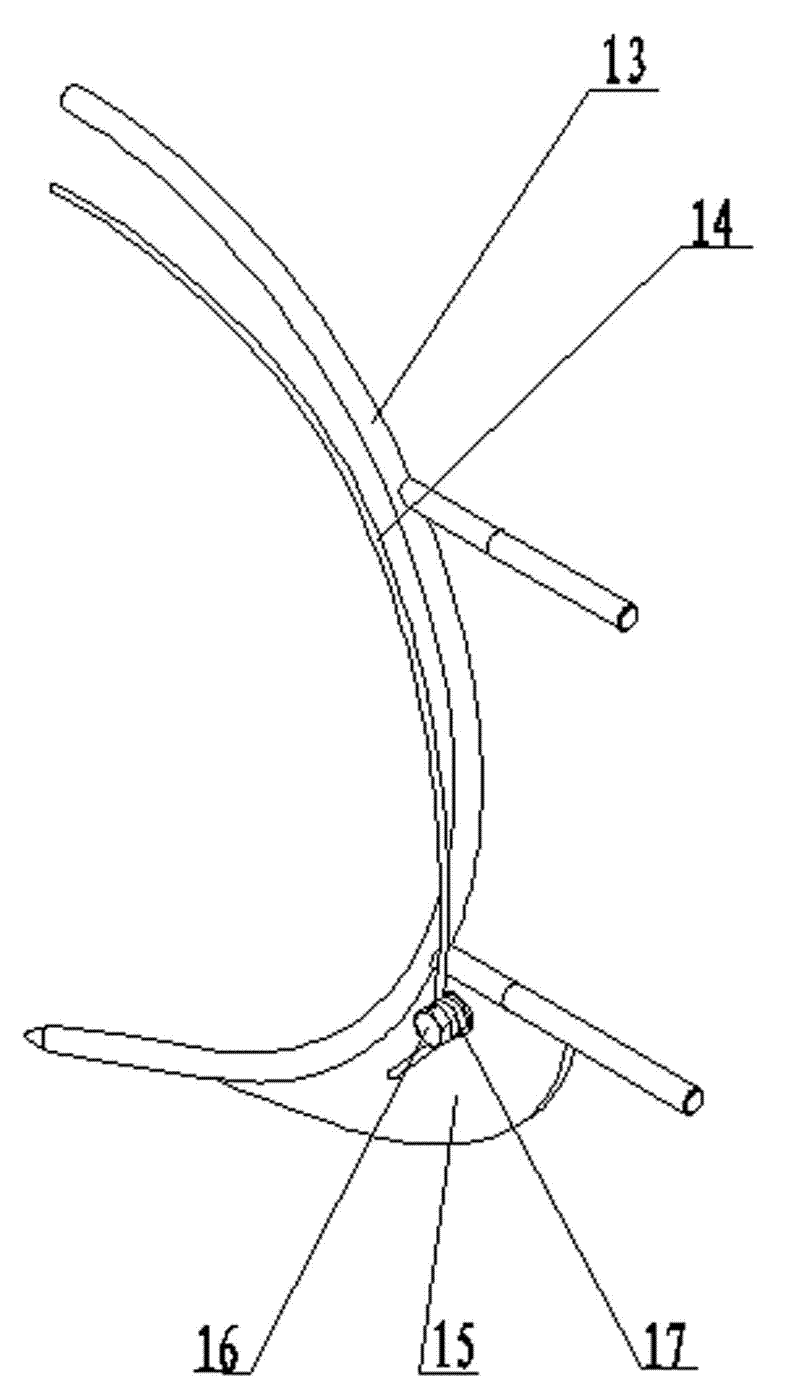

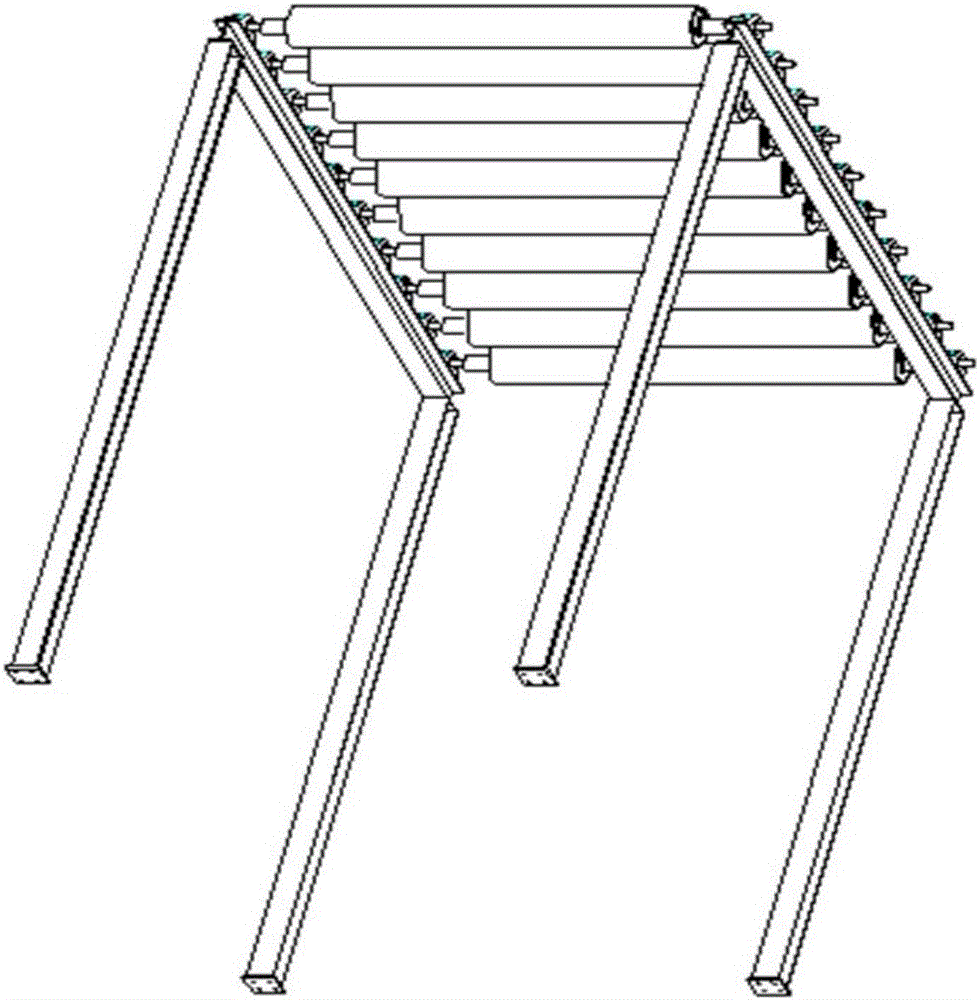

Profiling claw type floating stubble, grass cleaning mechanism

The invention relates to a row cleaner for agricultural no-tillage planting machinery, especially to a biomimetic claw type floating stubble and grass clearing mechanism. The invention is intended to resolve the problems of effect on normal seeding operation and seeding quality or the like because of the winding, accumulation and clog on a colter by a mass of stalks and weeds coated on the protective cropland surface. The floating row cleaner mainly comprises a pair of finger-shaped grass-poking wheels connected with the ground, an installation rack for convergent arms, a cam for regulating depth and a lower limiting arm, wherein the finger-shaped grass-poking wheels are key parts. The pair of finger-shaped grass-poking wheels forming splay with each other is mounted on installation rack for convergent arms, wherein the centers of the pair of finger-shaped grass-poking wheels of the front ends converge at a point and are not interfered with each other. The middle of each finger-shaped grass-poking wheel is provided with a round disk whose circumference is distributed with a plurality of finger-shaped teeth uniformly. The plurality of teeth are radially distributed, line parts of the finger-shaped teeth form a certain angle with the radial line in radial direction of the round disk, and extend to the outer circle from arc.

Owner:JILIN UNIV

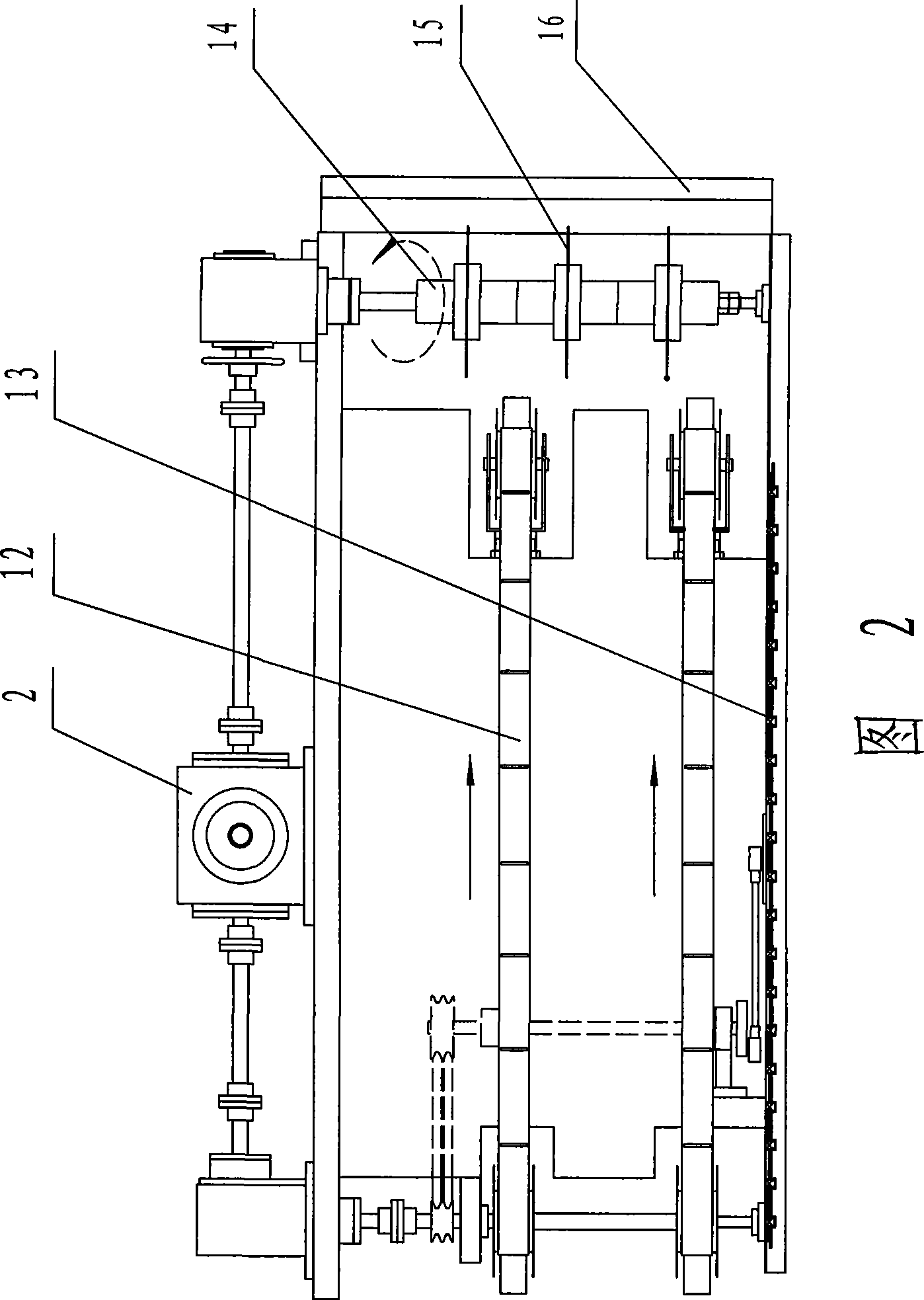

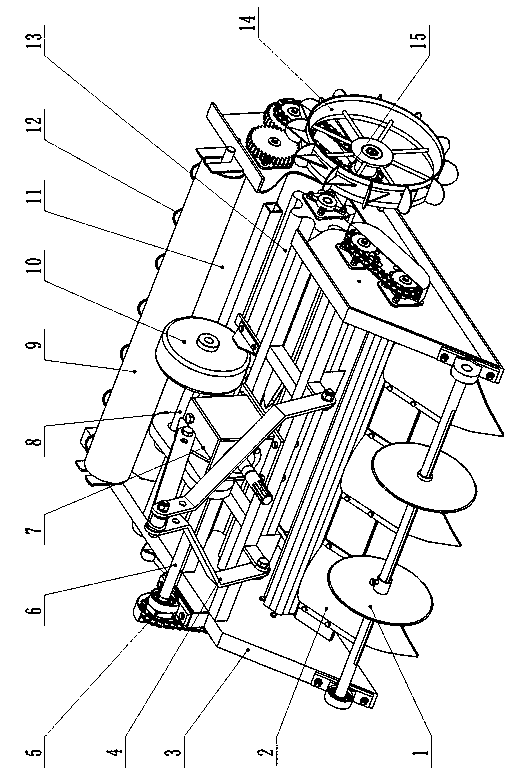

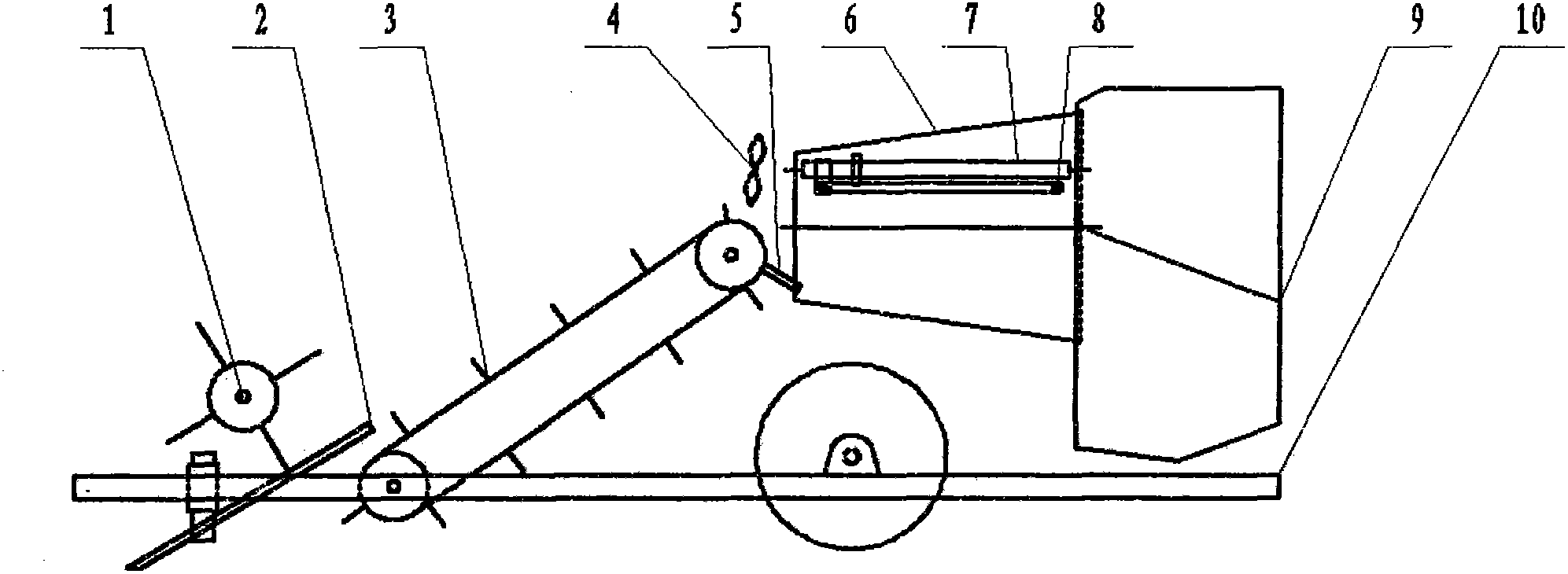

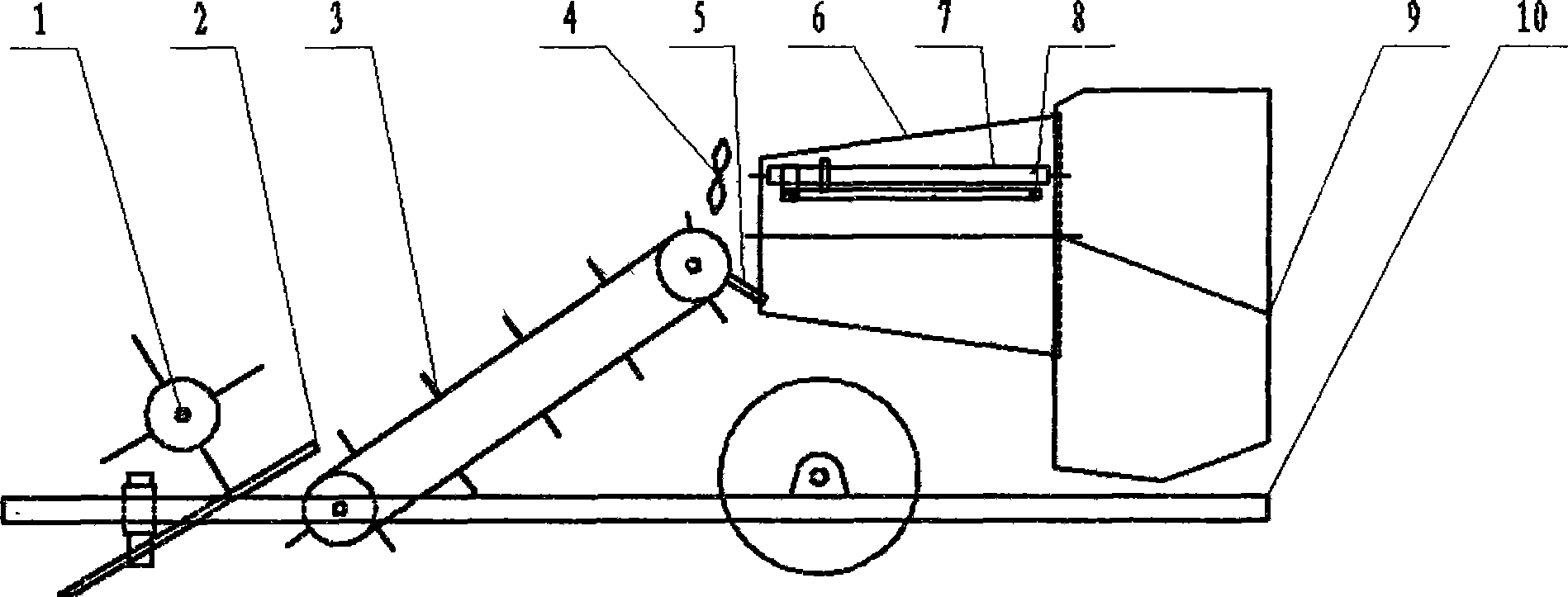

Machine for picking up, cleaning up and packaging residual film

InactiveCN103650674AClean up thoroughlyImprove work efficiencyGatherer machinesIntegrated operationsEarth surface

The invention relates to an agricultural machine, in particular to a machine for picking up, cleaning up and packaging residual film. The machine for picking up, cleaning up and packaging the residual film is used for recovery and packaging integrated operation of the residual film on the surface of farmland. The machine for picking up, cleaning up and packaging the residual film comprises a rack, a transmission device and a traveling wheel. The machine for picking up, cleaning up and packaging the residual film is characterized in that a film lifting roller is arranged on the front portion of the rack, a film brushing roller A is arranged on the obliquely-rear portion of the film lifting roller, a residual film cleaning-up device is arranged behind the film lifting roller, a film brushing roller B is arranged at the position, close to the tail end, of the residual film cleaning-up device, and a residual film packaging device is arranged behind the residual film cleaning-up device and the film brushing roller B. According to the machine for picking up, cleaning up and packaging the residual film, various procedures such as film gathering, picking-up operation, residual film cleaning-up operation, film separation and residual film packaging can be accomplished through one-time operation, especially, the residual film cleaning-up device is used for carrying out cleaning-up operation on the residual film, the residual film can be thoroughly cleaned up, operating efficiency is improved, the machine for picking up, cleaning up and packaging the residual film has the advantages of being simple in structure and low in manufacturing cost, and the requirement of the agricultural technology for mechanical film recovery and packaging after the autumn harvest can be met.

Owner:XINJIANG KESHEN AGRI EQUIP SCI&TECH DEV

Farmland plastic film residue recycling and packaging combined operating machine

InactiveCN104541620AReduce pollutionEasy to storeLoadersGatherer machinesHydraulic cylinderFixed frame

The invention relates to a farmland combination operating machine, and particularly relates to a farmland plastic film residue recycling and packaging combined operating machine capable of picking and packaging earth surface agricultural films and performing combined operation. The farmland plastic film residue recycling and packaging combined operating machine comprises a rack, a drive system and a walking wheel, wherein the rack is provided with a picking mechanism, a demolding mechanism and a packaging mechanism; ground wheels are arranged below the rack; the picking mechanism structurally comprises a roller, elastic teeth and an elastic tooth fixing framework; the roller is in a hollow cylindrical shape; the wall of the roller is provided with a bar-shaped hole; the demolding mechanism structurally comprises a demolding roller, a scraping plate and an arc outer cover; the packaging mechanism structurally comprises a rectangular packaging box body, a hydraulic oil cylinder I, a hydraulic oil cylinder II and a hydraulic oil cylinder III. The farmland plastic film residue recycling and packaging combined operating machine is compact and reasonable in structure, can perform picking and packaging combined operation on the earth surface agricultural films, and is economic and practical.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

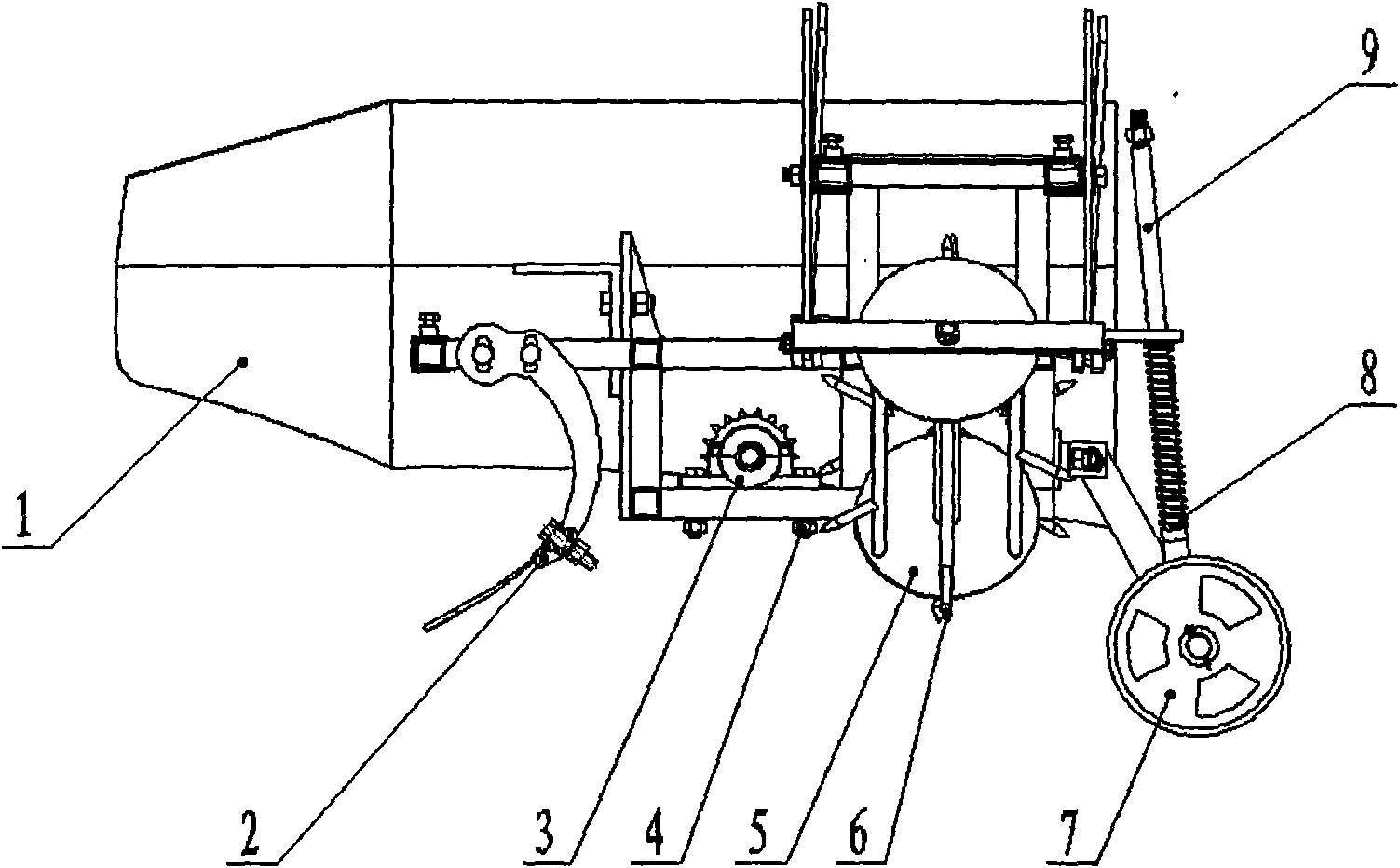

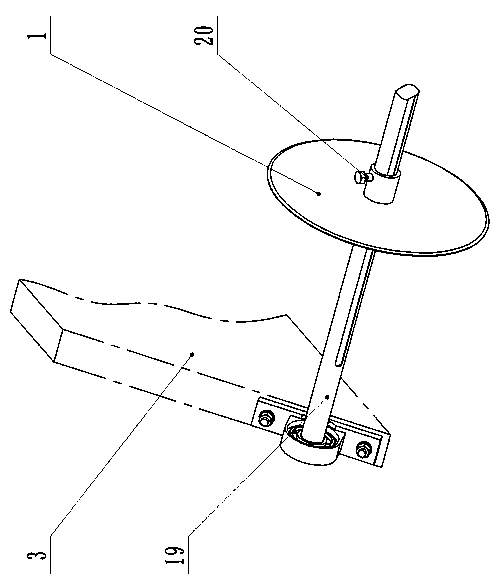

Mini type mulching film recovery machine of tobacco in seedling stage

InactiveCN101658087ASolve the problem of working at a height that cannot enter the groundSolve the problem of profiling and picking filmGatherer machinesDrive wheelGear wheel

The invention relates to a mini type mulching film recovery machine of tobacco in seedling stage, which mainly comprises a seedling protective plate (1), a depth limiting land wheel (7), a break shovel (2), a stander (11), a large chain wheel (13), a small chain wheel (17), a gear wheel (18), a pinion (22), a film rolling roll (15), a universal joint (16), a position horizontal adjusting rod (20)of the film rolling roll and an angle vertical adjusting rod (25) of the film rolling roll. The gear wheel (18) and the pinion (22) are meshed to make the film rolling roll (15) and a driving wheel toreversely rotate to roll the film, so earth rolling is avoided; the inclined angle of the film rolling roll (15) can be adjusted by the universal joint (16), the angle vertical adjusting rod (25) ofthe film rolling roll and the position horizontal adjusting rod (20) of the film rolling roll according to the inclined angle of a tobacco ribbing surface; and the film rolling roll (15) is always well attached to the inclined plane of tobacco ribbing by the depth limiting land wheel (7) under the action of a depth limiting spring (8). The small tobacco seedling stage mulching recovery machine isused for recovering mulching films of seedling-stage tobacco planted in ridge culture, belongs to field tending machinery and is also suitable for recovering mulching films of cotton and other flat planting crops.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Self-propelled stall cleaning apparatus

A self-propelled stall cleaning apparatus has a frame assembly, one pair of drive wheels, a motor attached to the assembly for driving the drive wheels and a motor driven collector head. The collector head has a pivoting fork with tines for collecting manure and debris. The fork picks up the manure and debris and tosses it onto a sifting conveyor. The sifting conveyor separates the manure from the bedding and delivers the manure to a lift conveyor which drops the manure into a collection bin. The collection bin is moveable from a stowed position to a dumping position.

Owner:CLARK LOUISE KLEMM

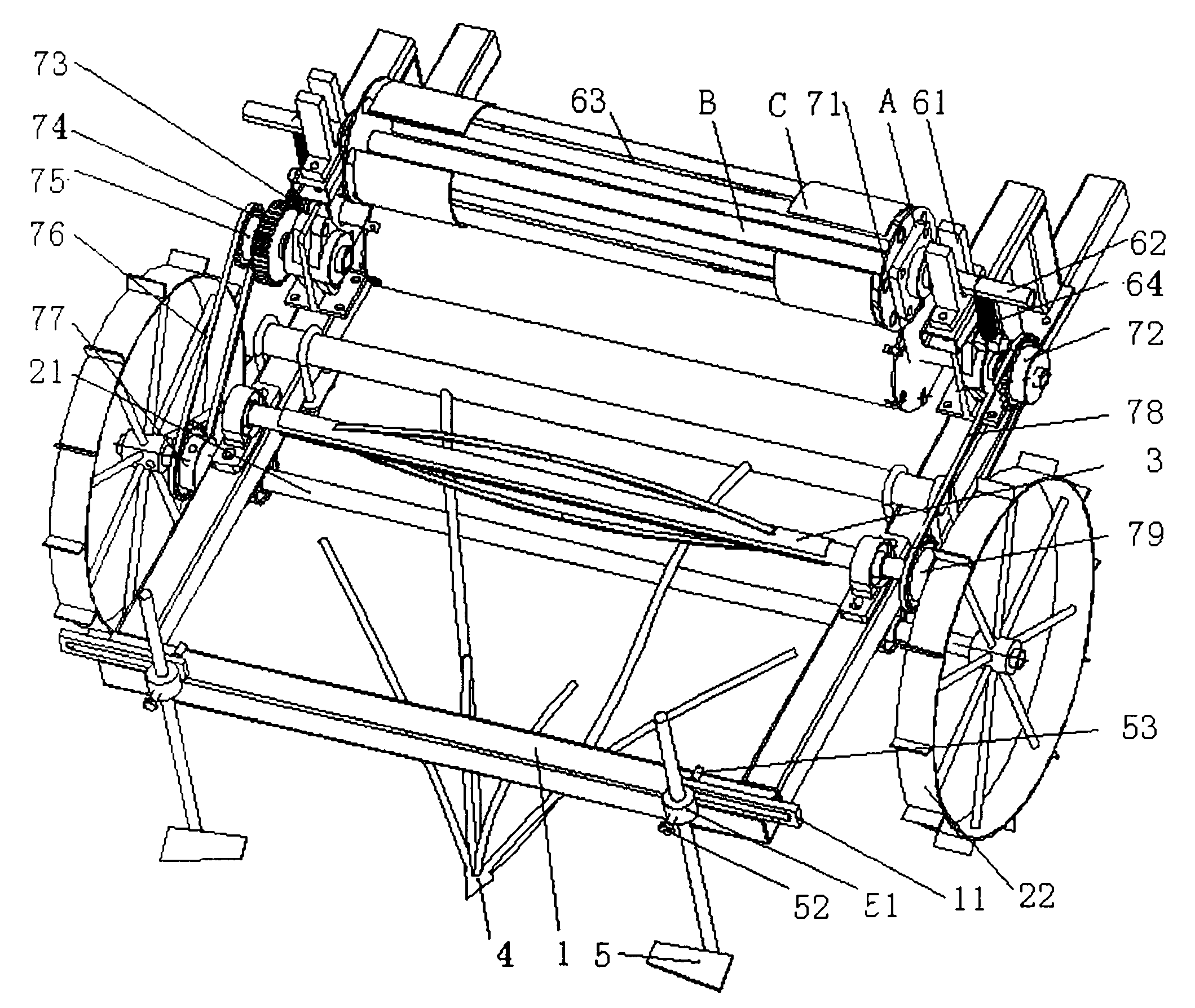

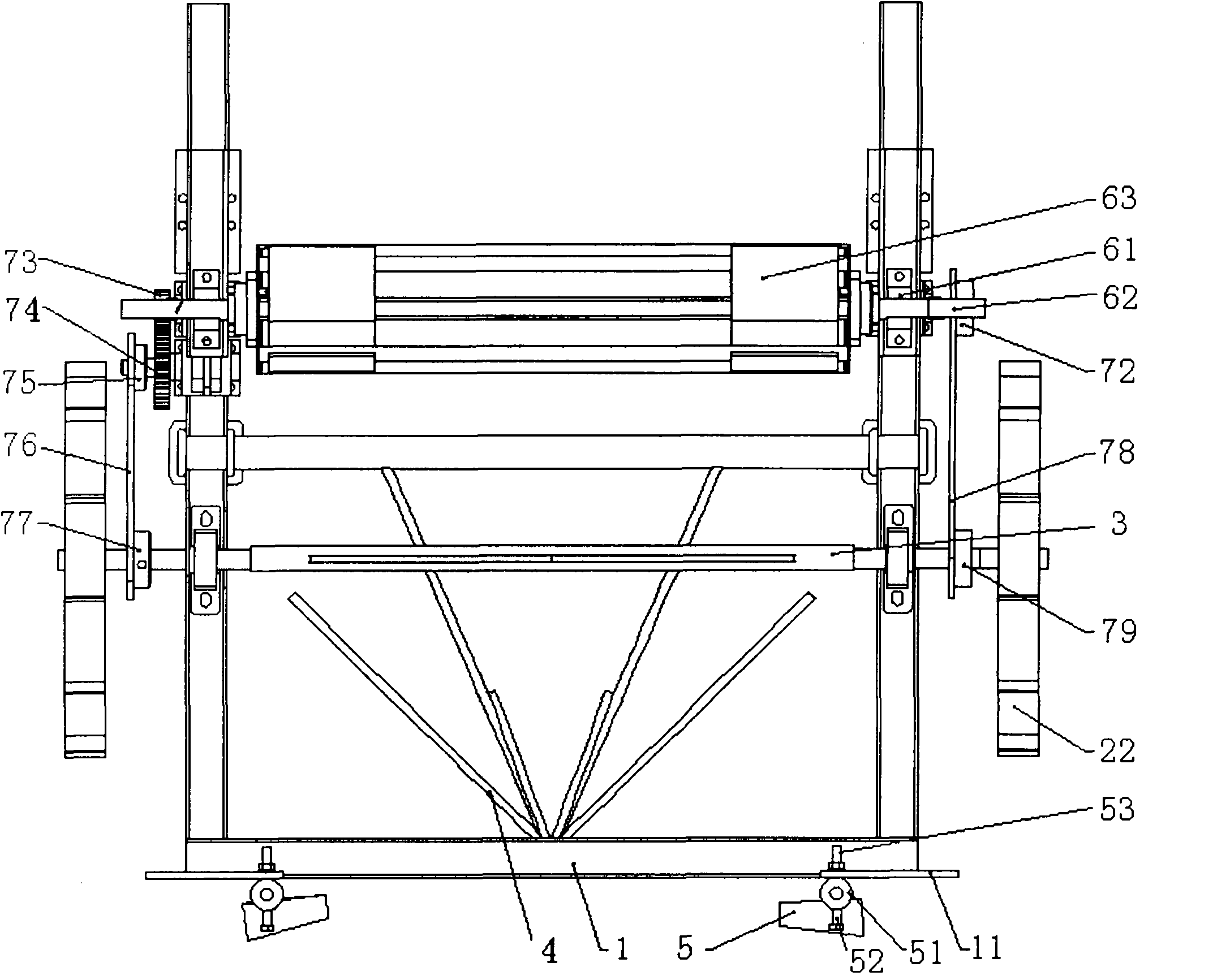

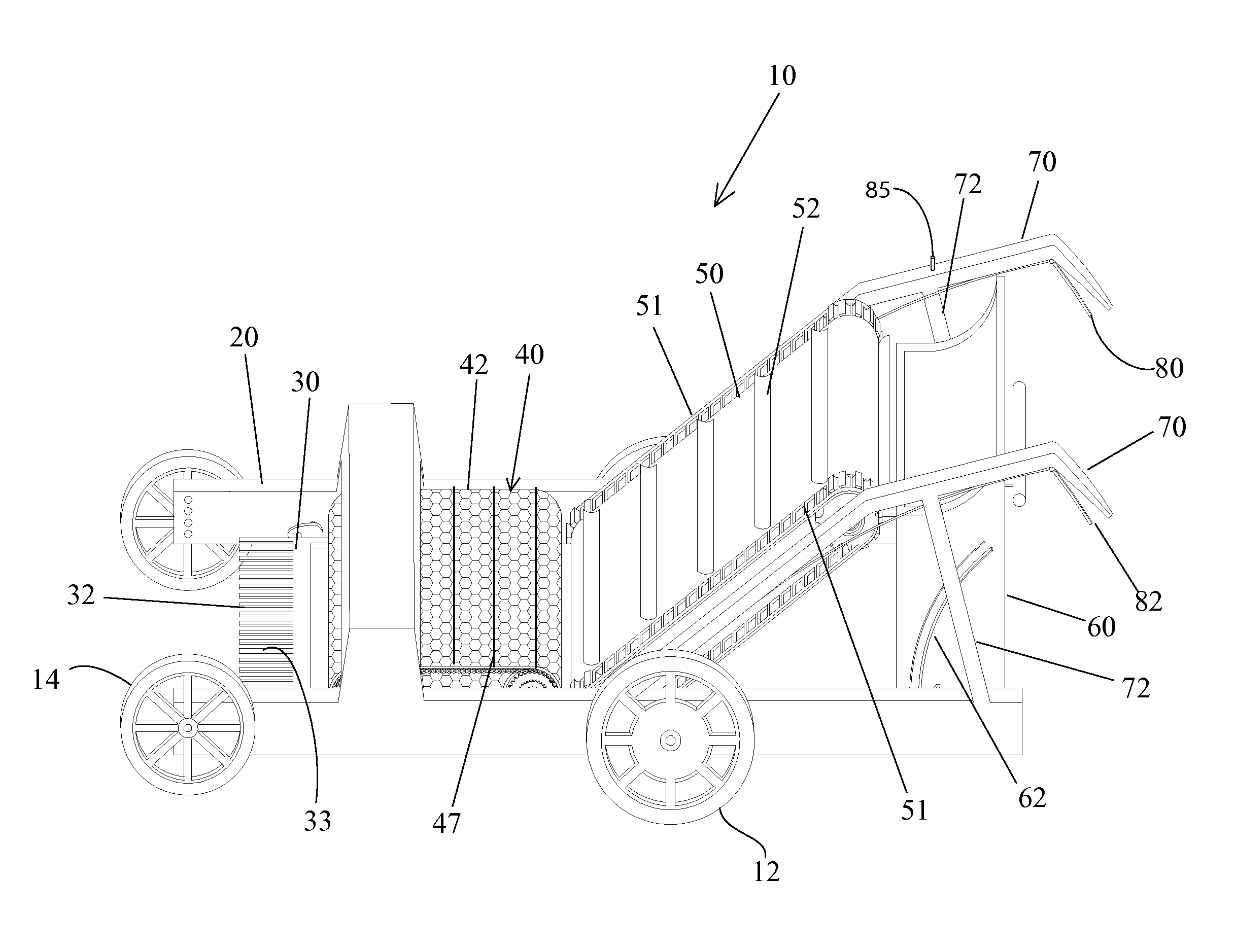

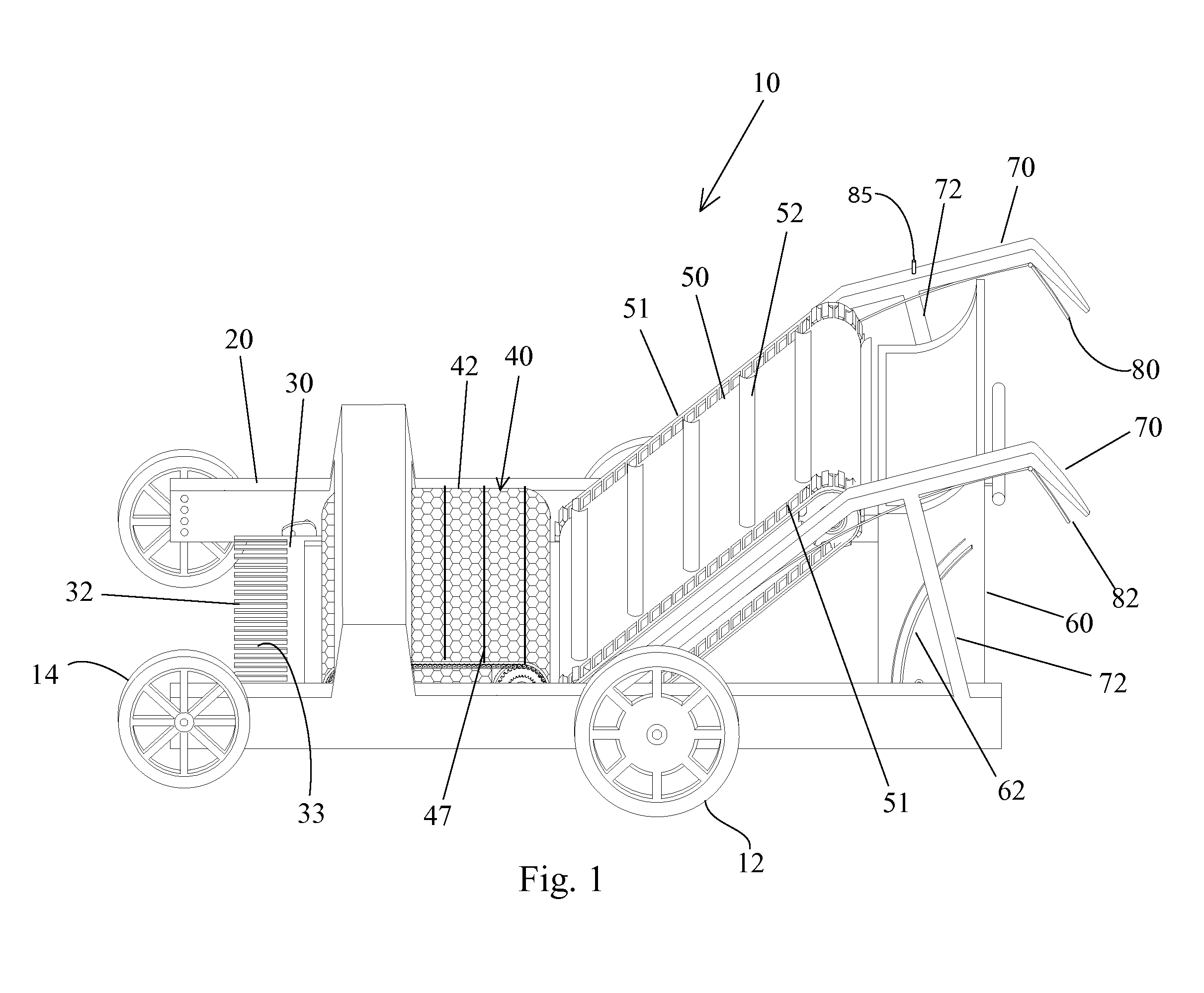

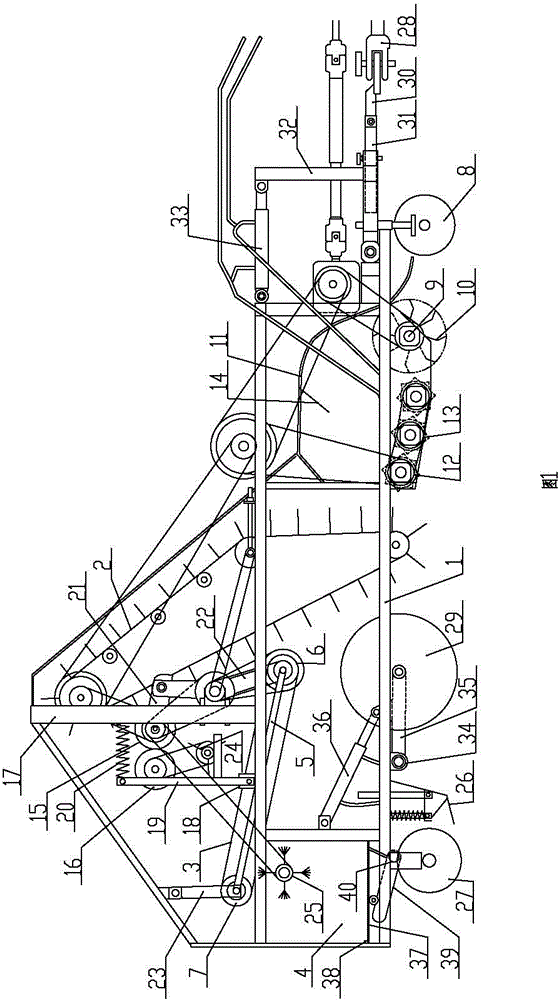

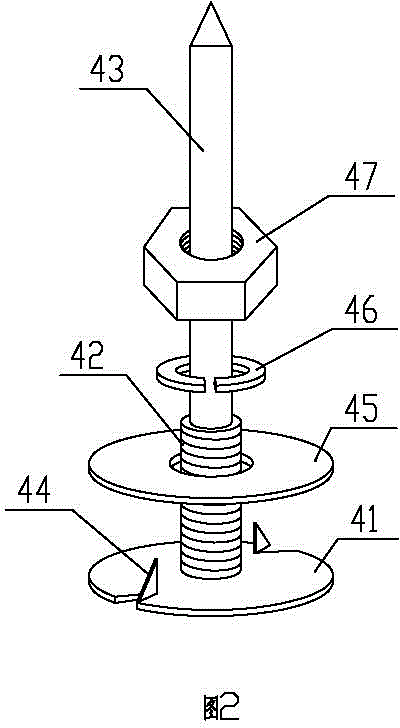

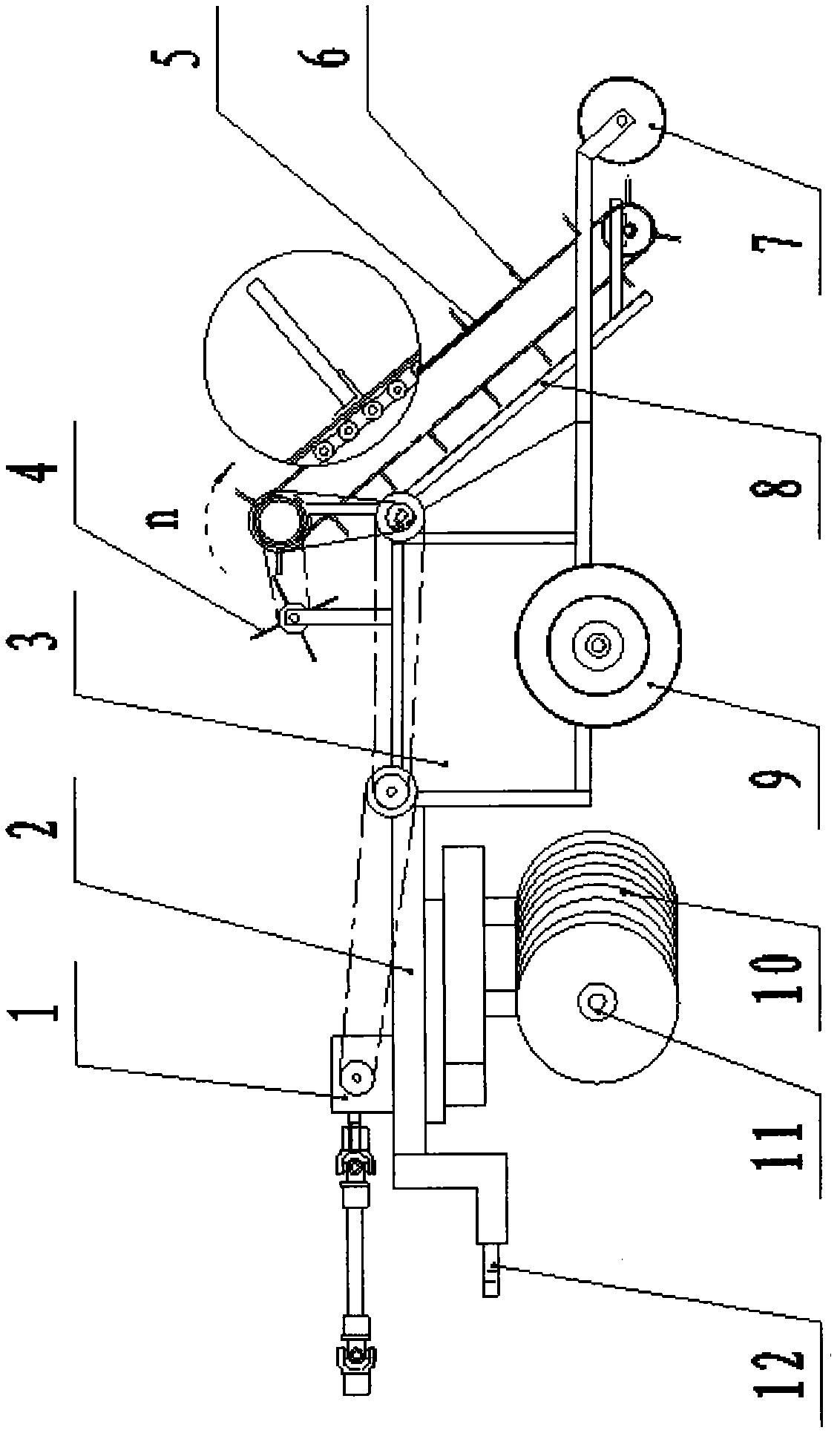

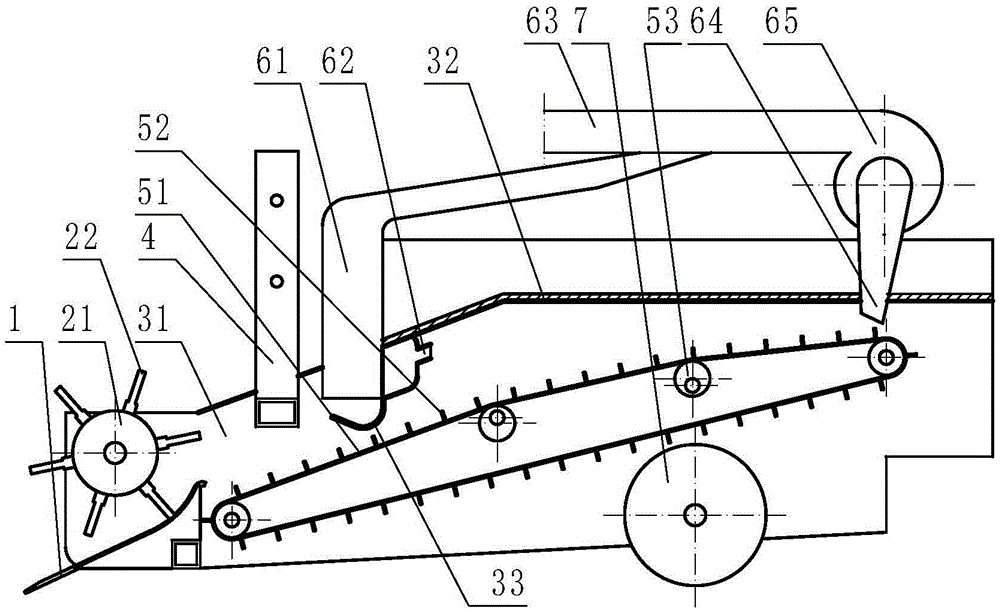

Film-cutting removing and film-lifting winding type mulching film picking machine

ActiveCN103749015AMeet the requirements of picking operationsWon't breakGearingGatherer machinesUltimate tensile strengthMechanical engineering

The invention relates to the technical field of machines for collecting and picking waste mulching films in a farm, in particular to a film-cutting removing and film-lifting winding type mulching film picking machine. The film-cutting removing and film-lifting winding type mulching film picking machine comprises a rack, a suspension bracket installed on the rack, land wheels installed on the two sides of the rack and a transmission mechanism. A film cutting mechanism is installed below the front of the rack. A film lifting mechanism is arranged on the portion, at back of the film cutting mechanism, of the rack. A shaking soil-removing conveying mechanism is arranged at back of the film lifting mechanism and installed in the middle of the rack. A mulching film winding mechanism is arranged above the back of the rack and located at back of the shaking soil-removing conveying mechanism. The film-cutting removing and film-lifting winding type mulching film picking machine can complete the operations of film cutting, film lifting, film surface debris removing, mulching film collecting and the like at a time, complete the multiple working procedures of film cutting, film lifting, grass and straw removing, soil shaking-off and the like at a time in a combination mode, reduce labor intensity, reduce operation cost and effectively improve work efficiency.

Owner:WUWEI GUANGDA IND & TRADE

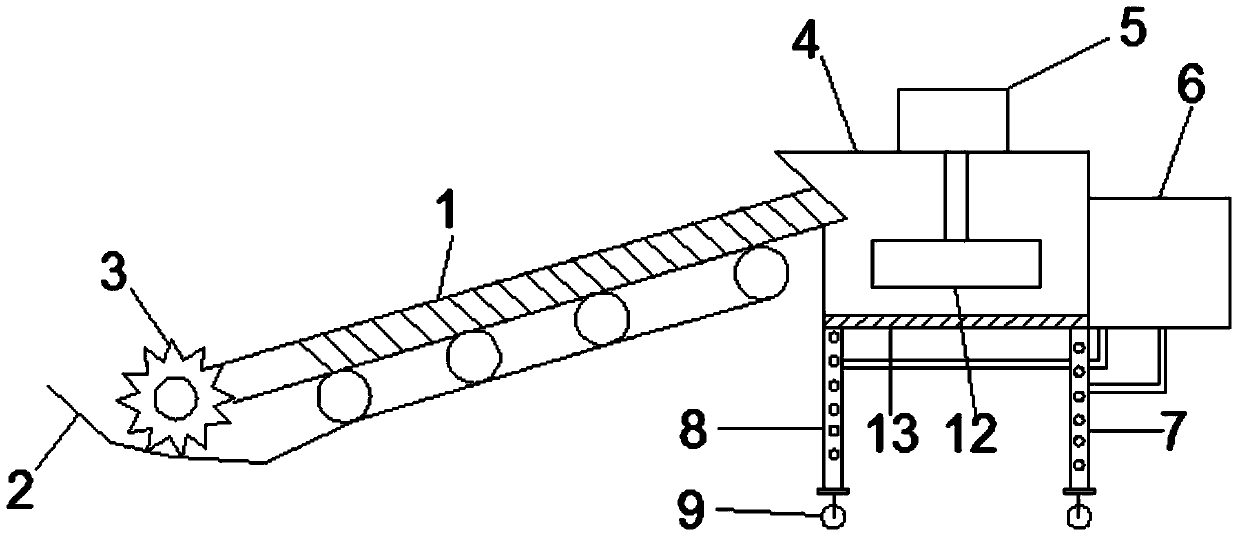

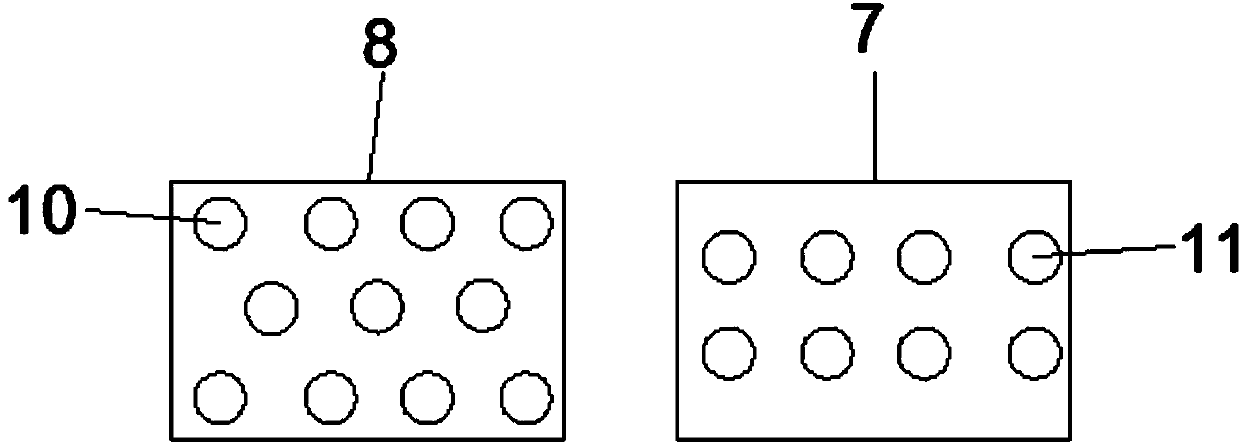

Field plastic film residue recycling machine

ActiveCN104137670AReduce carryImprove cleaning efficiencyGatherer machinesPlastic filmAgricultural machinery

The invention relates to the technical field of agricultural machinery, in particular to a field plastic film residue recycling machine. The field plastic film residue recycling machine comprises a machine frame, a soil digging device, a spike tooth conveying belt, a conveying mesh belt, a collecting box and a power assembly. The soil digging device is arranged below the front portion of the machine frame. The spike tooth conveying belt is arranged on the portion, behind the soil digging device, of the machine frame. The upper portion of the spike tooth conveying belt inclines in the mode that the front part is downward and the rear part is upward. A mesh belt installation frame is arranged on the portion, located behind the spike tooth conveying belt, of the machine frame. A front mesh belt installation device and a rear mesh belt installation device are installed on the mesh belt installation frame. According to the field plastic film residue recycling machine, the structure is reasonable and compact, use is convenient, soil is dug out by the soil digging device and are thrown onto the spike tooth conveying belt, small plastic film residues in soil can be completely recycled, soil blocks and the plastic film residues are conveyed to the conveying mesh belt through the spike tooth conveying belt, and the plastic film residues and soil can be effectively separated through the conveying mesh belt; in this way, soil carrying volume of the recycled plastic film residues can be greatly reduced. The field plastic film residue recycling machine has the advantages that the plastic film residue removing efficiency is high, the recycling effect is good, and multiple purposes are achieved through the one machine.

Owner:喀什富农农机技术开发有限公司

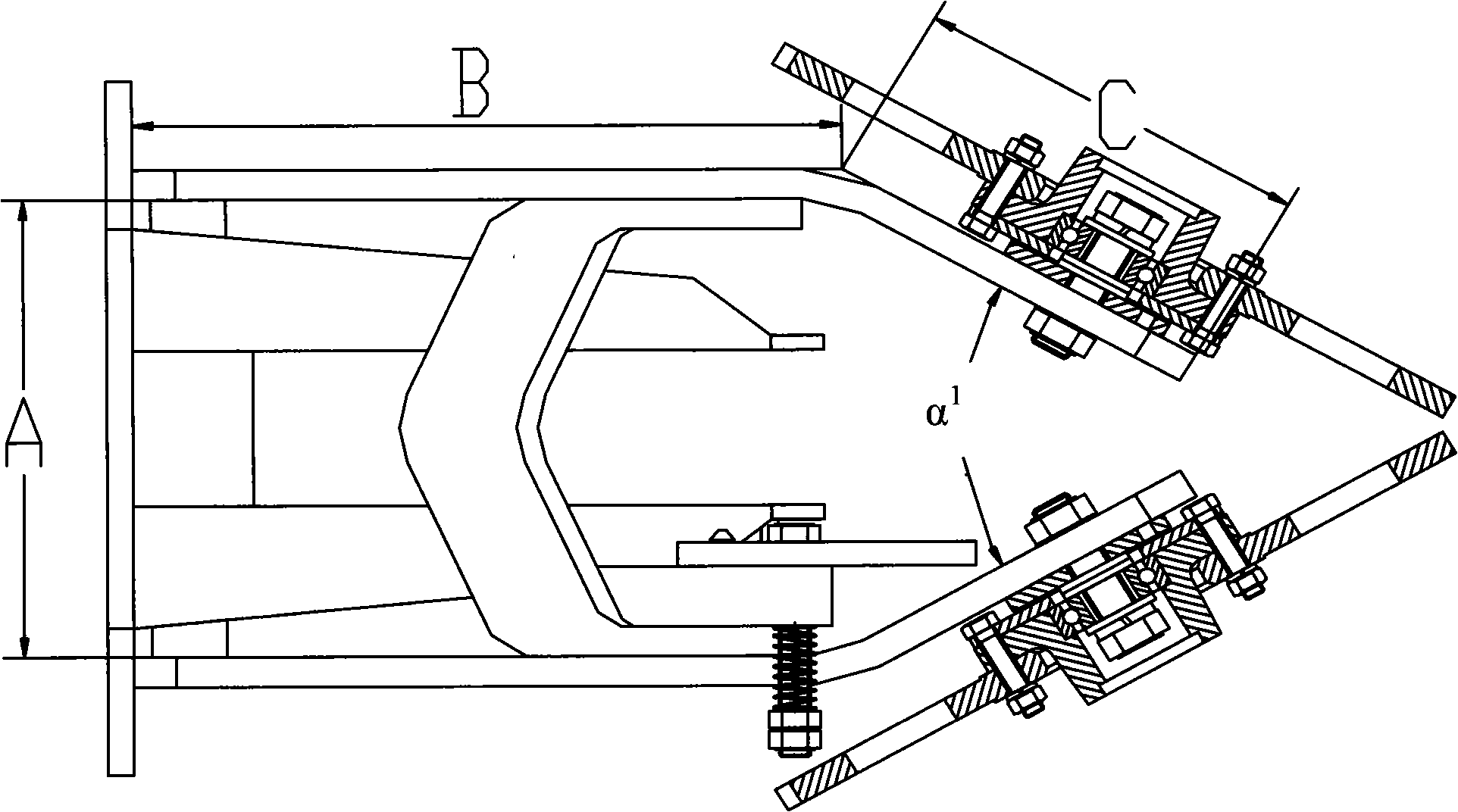

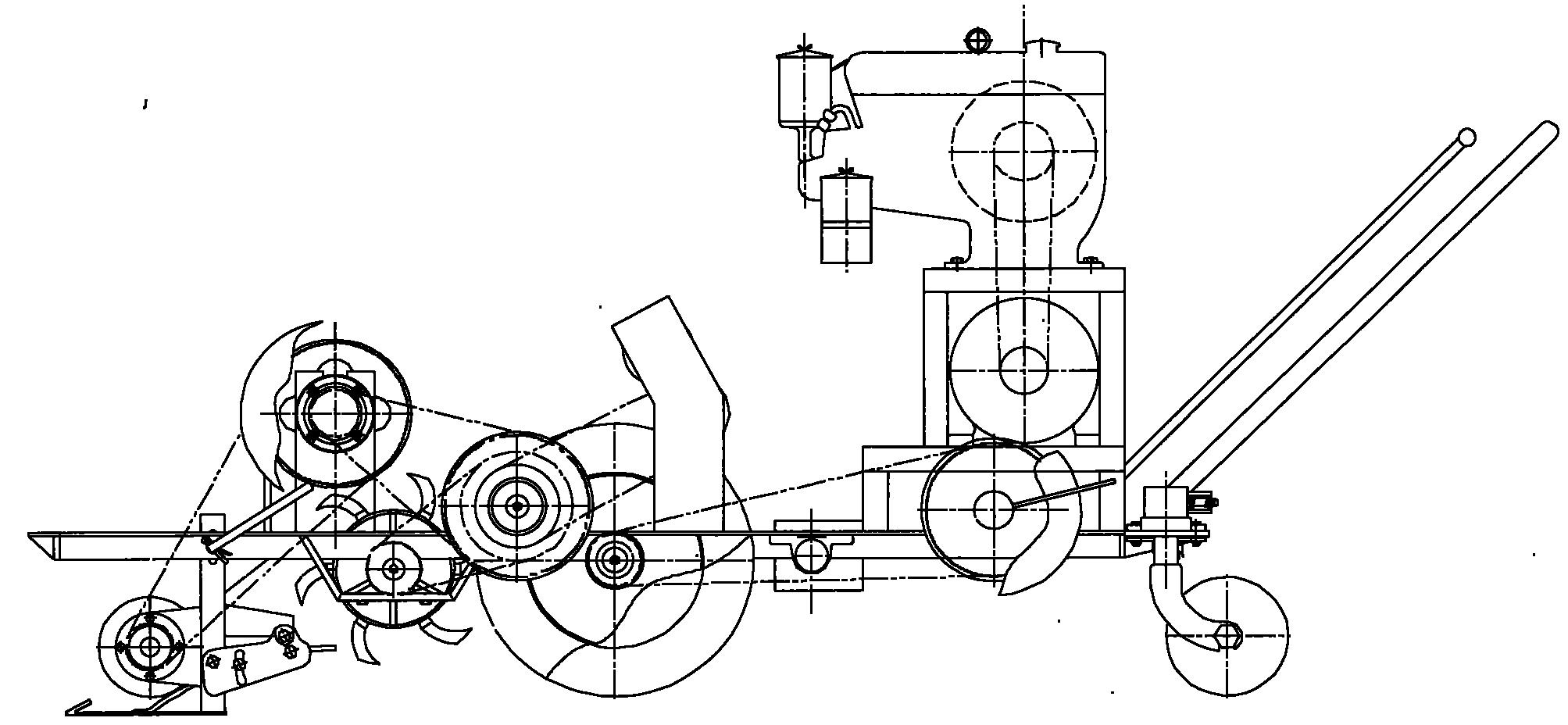

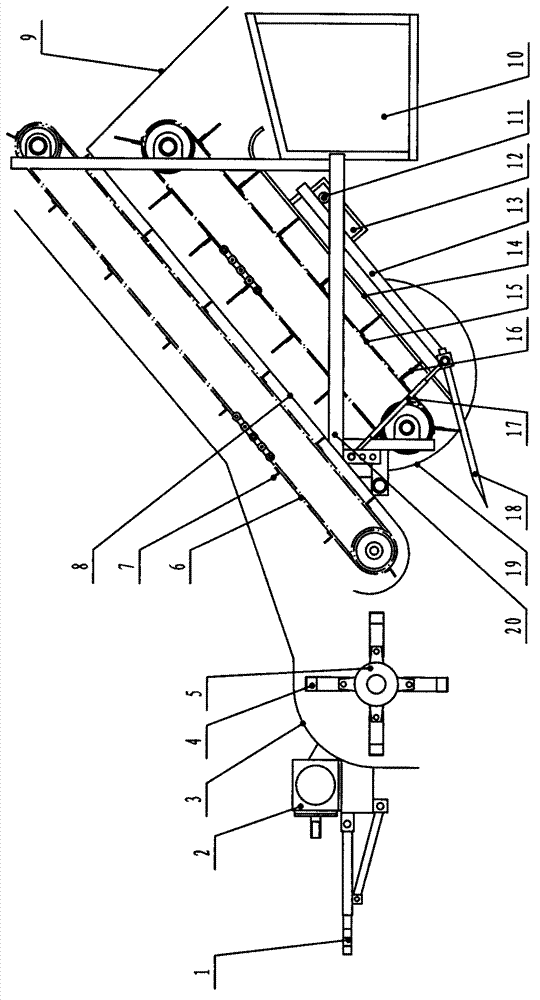

Self-propelled onion mulching film recoverer

The invention relates to a miniature self-propelled onion mulching film recoverer comprising a power device, a speed reducer, a power clutch device, a travelling chassis, a stand, a transmission system, a scarifying and film-lifting device, a soil-clearing device, a film-lifting device, conveying bridges and a film-coiling device. The recoverer adopts a rectangular frame structural form based on a three-wheeled self-propelled chassis, the power device of the whole machine is arranged at the rear-upper part of the machine body, the devices and the mechanisms at all parts of the machine are jointed together through the transmission system, the scarifying and film-lifting device is mounted at the foremost of the machine body, the soil-clearing device is mounted above the scarifying and film-lifting device through bearing seat plates at both ends and arranged at the rear-upper side of the soil-clearing device, the film-lifting device comprising four film-lifting wheels are arranged on thestand, the four groups of conveying bridges which are arranged at a certain inclined angle and close to the rear-upper side of the film-lifting device are fixed in the middle of the stand, and the film-coiling device is mounted at the lower-rear part of the machine body. In the on-site operation, the onion mulching film is lift by a film lifter in the front of the machine, residue soil on the surface of the mulching film is removed by the soil-clearing device, and the four film-lifting wheels of the film-lifting device continuously lift toward the rear-upper side of the machine so that the mulching film enters the conveying bridges, is rolled by a film-pressing mechanism above the conveying bridges and is conveyed toward the film-coiling device at the rear-lower side of the machine, and finally, the mulching film is continuously wound on a film-coiling roller of the film-coiling device so as to finish the recovery operation process of the mulching film.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

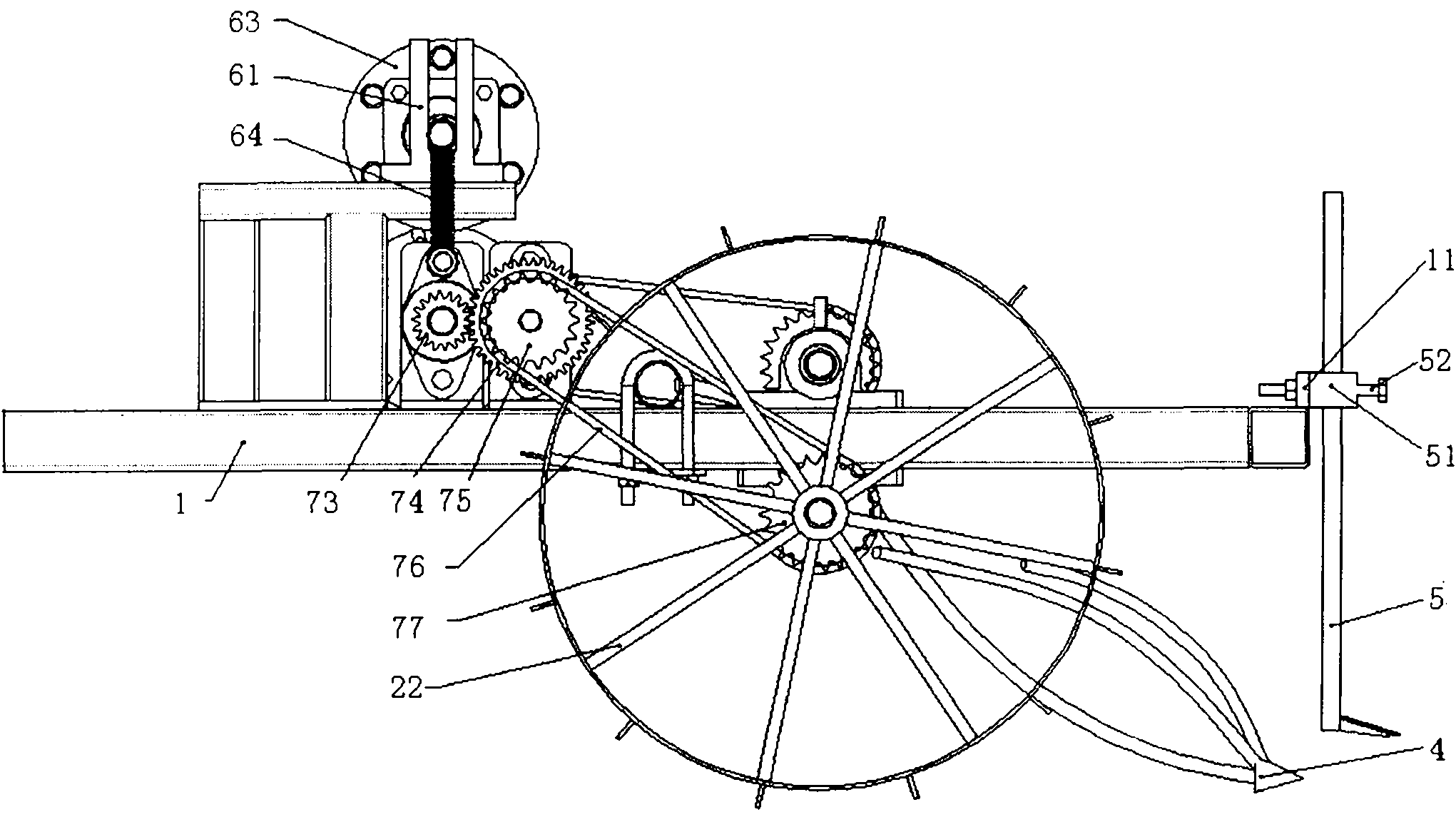

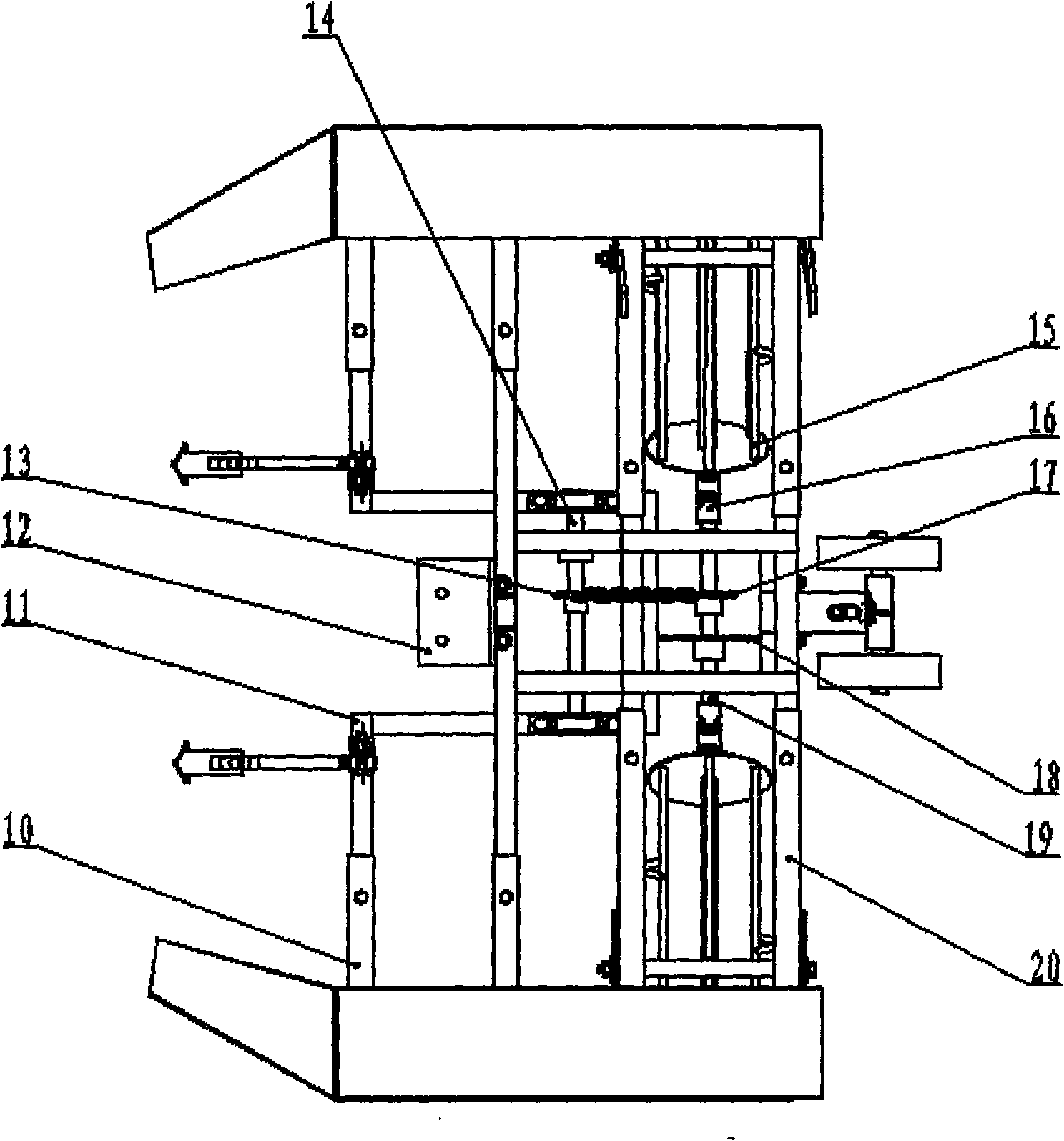

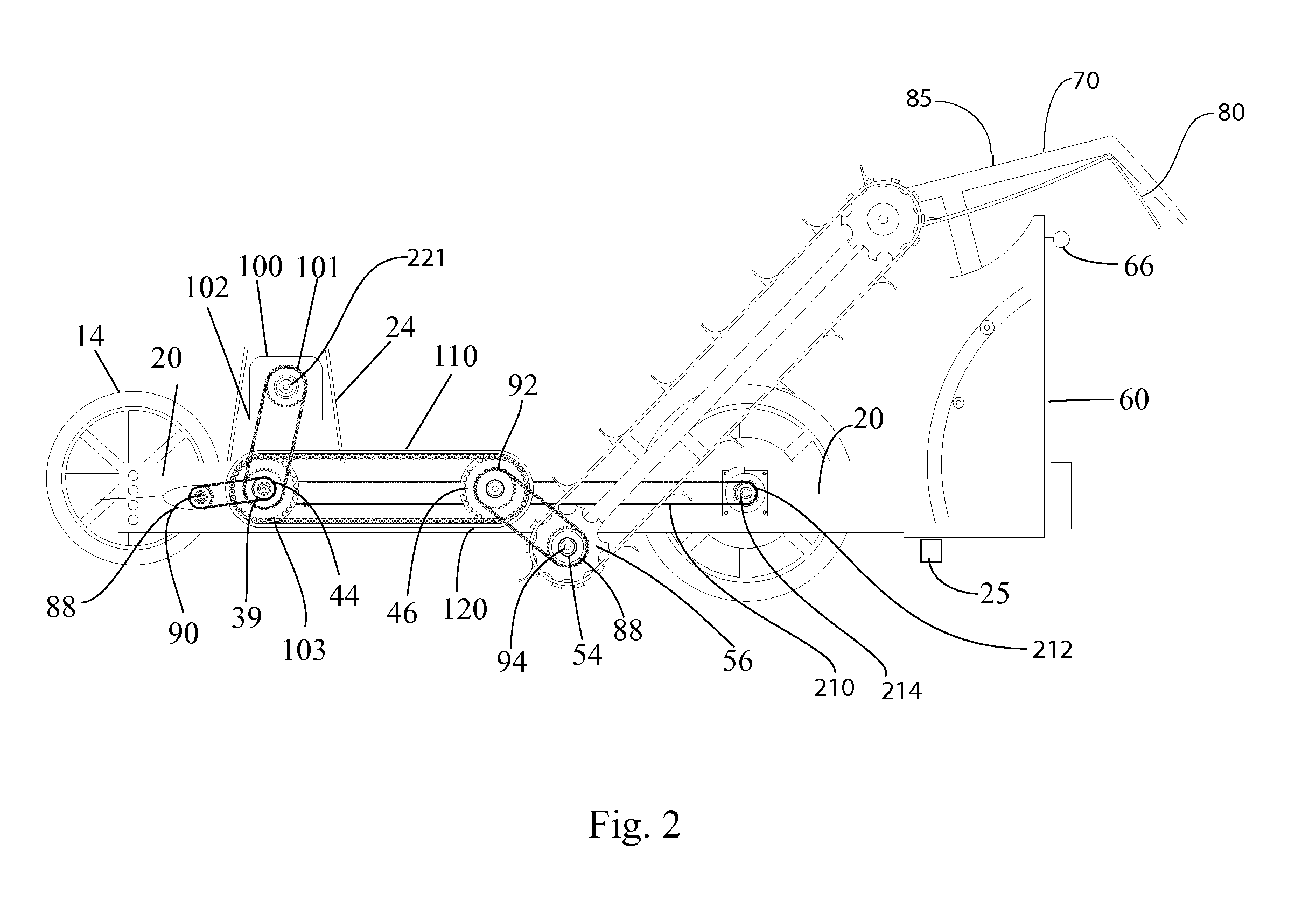

Clamping type residual membrane recovering machine

InactiveCN102144438AHigh recovery rateMeet recycling requirementsGatherer machinesSprocketMembrane configuration

The invention relates to a clamping type residual membrane recovering machine, belonging to the field of agricultural machinery. The machine comprises a traction device, a drive system, a residual membrane box, an earth wheel and a residual membrane recovering device, wherein the residual membrane recovering device consists of a clamping type residual membrane picking wheel, a sprocket rake type residual membrane transporting device, a baseboard, a membrane removing wheel and a contour wheel; the clamping type residual membrane picking wheel consists of a chain wheel, four rows of clamps, a push rod, a clamp bracket, a restoring spring, a baffle block and a cam wheel; the lower end of each clamp is provided with a shifting fork; a plurality of rows of rack bars are arranged on the sprocket rake type residual membrane transporting device; the residual membrane recovering device is arranged at the back side of the residual membrane box in a hinging way; a clamping type residual membranepicking mechanism is arranged at the lower end of the residual membrane recovering device; a contour earth wheel is arranged at the back side of the lower end of the residual membrane recovering device; the baseboard is arranged at the lower side of the sprocket rake type residual membrane transporting device; and the membrane removing wheel is arranged at the upper end of the residual membrane recovering device. The clamping type residual membrane recovering machine is fast in work speed, can be used for recovering small pieces of the residual membrane, is high in residual membrane recovering rate, and can be used for meeting the residual membrane recovering requirement.

Owner:SHIHEZI UNIVERSITY

Soil separating systems

InactiveUS7841422B1Reduced feature requirementsAvoid problemsLiftersTopping machinesEngineeringConveyor belt

A towable apparatus adapted for the separation of rock, stones, or debris from topsoil, having a stationary, non-vibrating sifting screen. A hydraulically powered conveyor belt with paddles pushes the soil across the sifting screen. The system provides features to assist prevention of machine jamming by large debris. A method of use is also disclosed.

Owner:CHAVEZ JOSEPH J +1

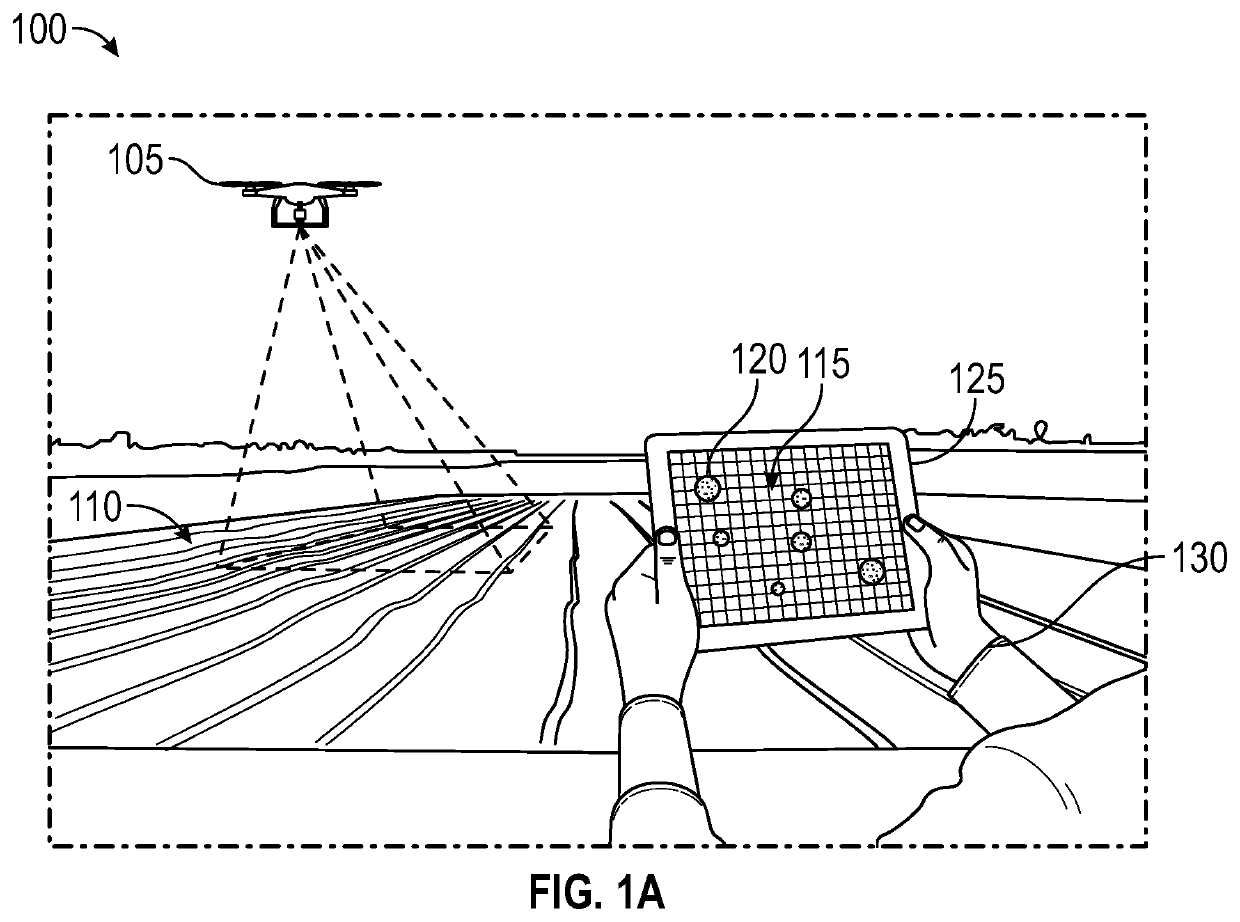

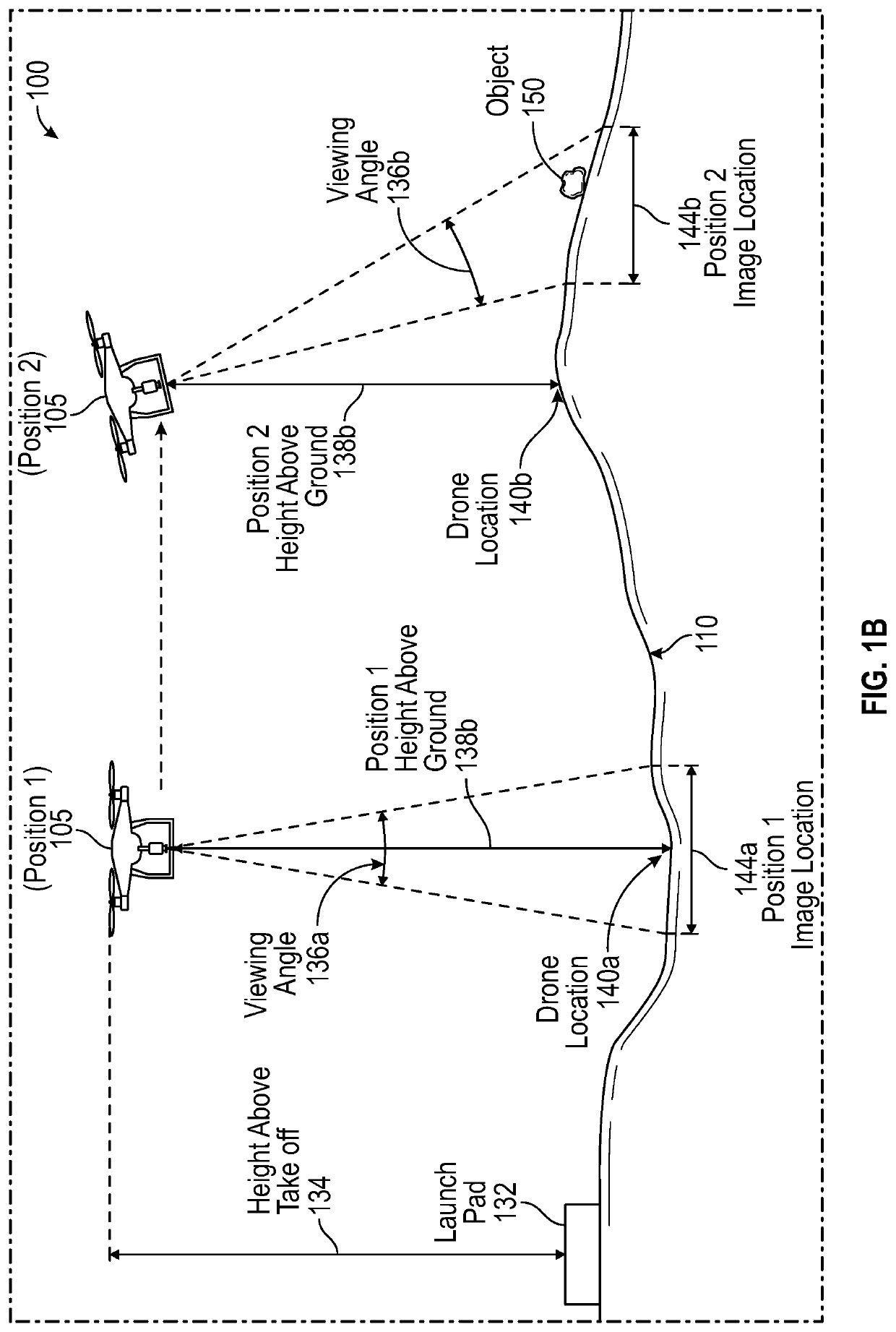

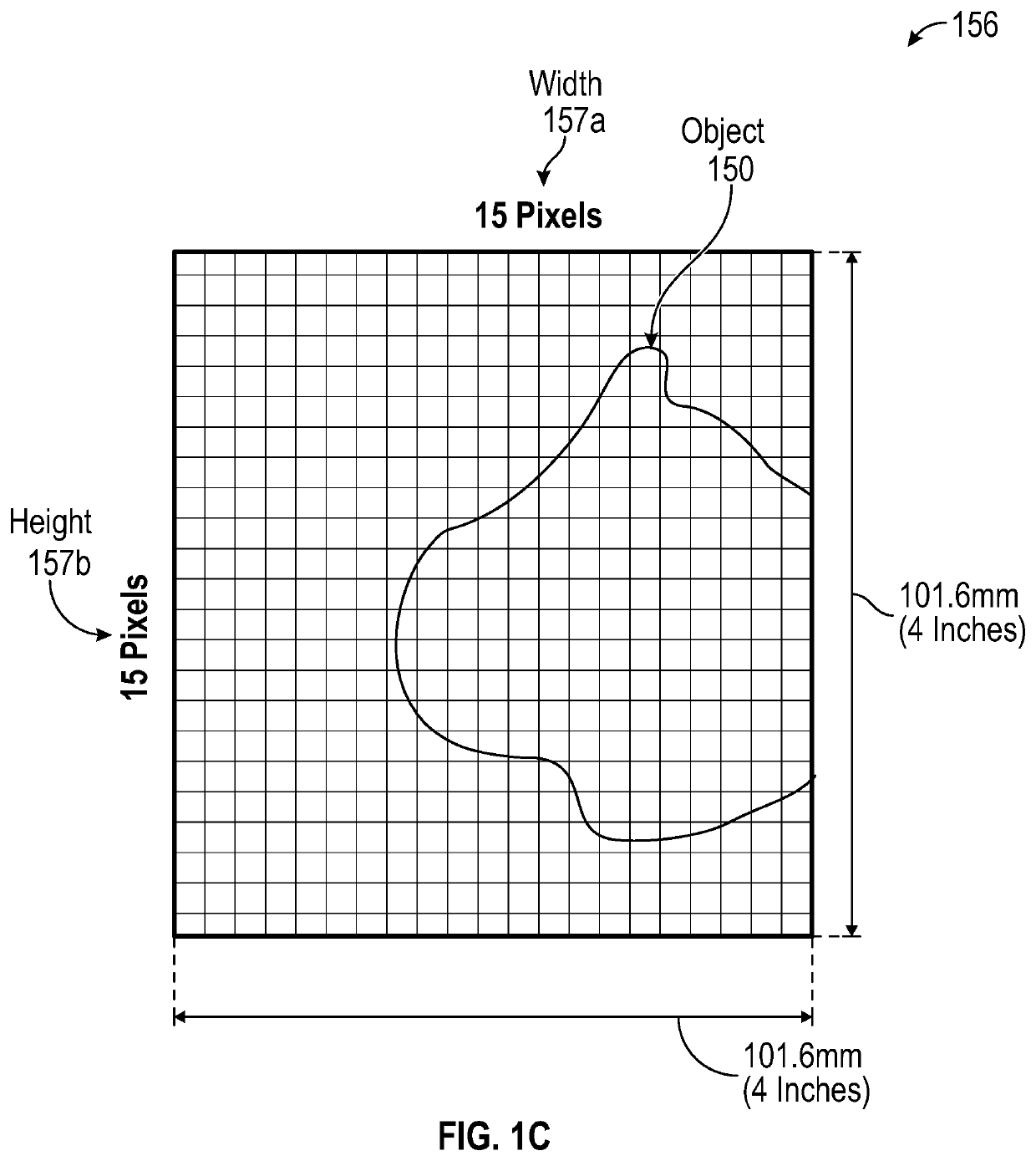

Object identification and collection system and method

PendingUS20200020093A1Reduce distortion problemsImage enhancementImage analysisComputer graphics (images)Collection system

An object identification and collection method is disclosed. The method includes employing an image-collection vehicle to capture first images of a target geographical area, identifying one or more objects in the first images, and guiding an object-collection system over the target geographical area toward the one or more identified objects. The method further includes determining object information for each of the identified objects and guiding the object-collection system based on the object information. The method may further include capturing second images of the ground relative to the object-collection system as the object-collection system is guided toward the one or more identified objects, identifying a target object in the second images, and instructing the object-collection system to pick up the target object.

Owner:TERRACLEAR INC

Residual film recycling machine

The invention relates to a residual film recycling machine, which comprises a driving wheel arranged on a machine frame, a film collection box, a film combing mechanism, a pickup and a transmission mechanism. The film collection box is arranged in the front of the machine frame. The pickup is arranged at the rear of the film collection box. An arched film lifter is arranged at the rear of the pickup. The arched film lifter in the invention is provided with a main film-lifting tooth and an auxiliary film-lifting tooth; the main film-lifting tooth and the auxiliary film-lifting tooth are matched so as to lift a film; therefore, the residual film recycling rate is increased; the rotary direction of the pickup is adjusted so that the mechanisms are simplified, and the working resistance of machines and tools is reduced; the film collection box is installed in the front of the pickup so that potential safety hazards resulted from difficult lifting or raising of a tractor because of weight increasing of residual films, weeds and crop branches and leaves in the film collection box can be avoided; to prevent the residual films from being wound on the film combing mechanism, film-eliminating elastic teeth are installed on the frame of the film collection box; simultaneously, a set of drill rakes is additionally arranged at the rear of the machines and tools; the residual films which are not picked up by the pickup are secondarily picked up; the residual film recycling rate is ensured; and the working efficiency is increased.

Owner:庆阳市前进机械制造有限公司

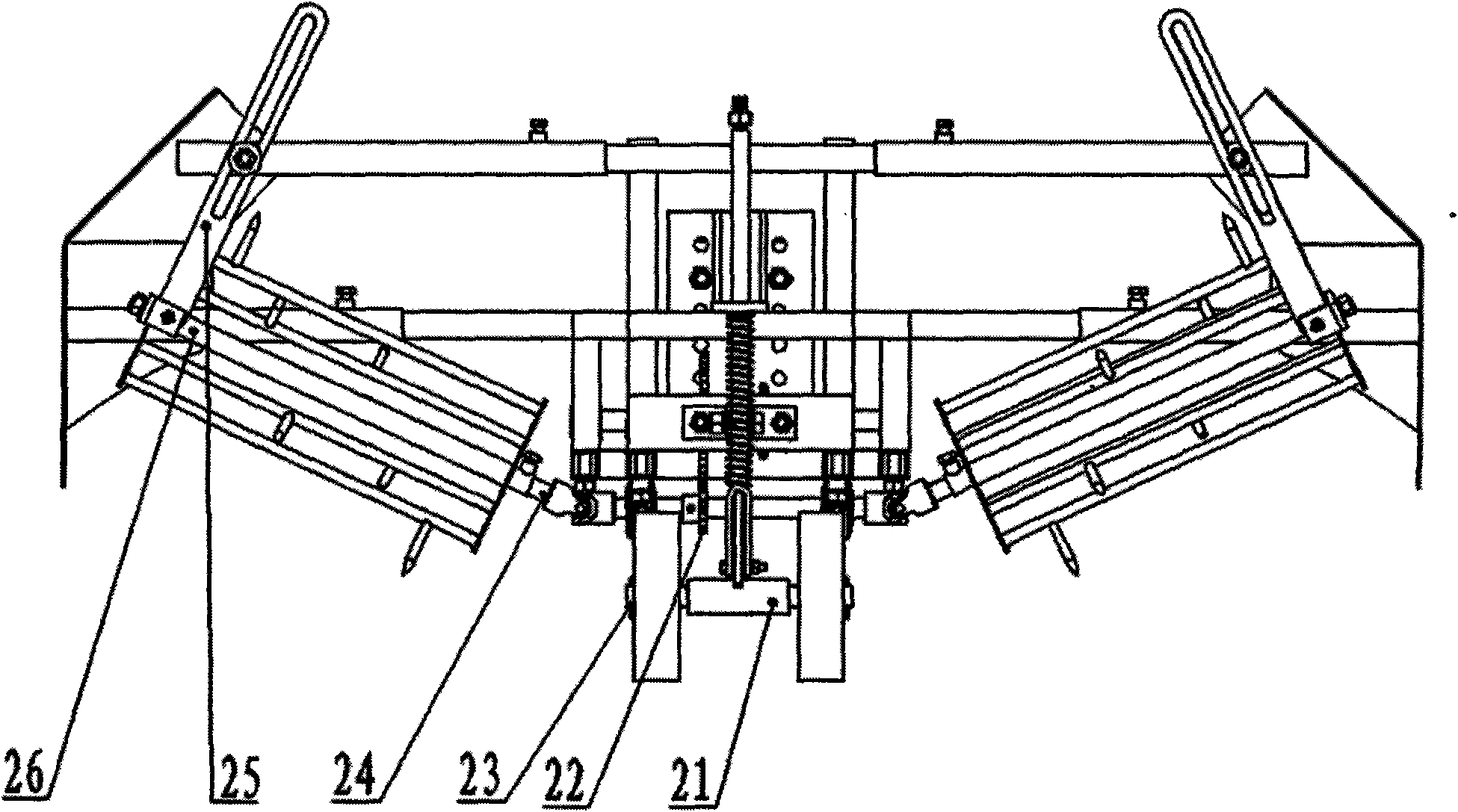

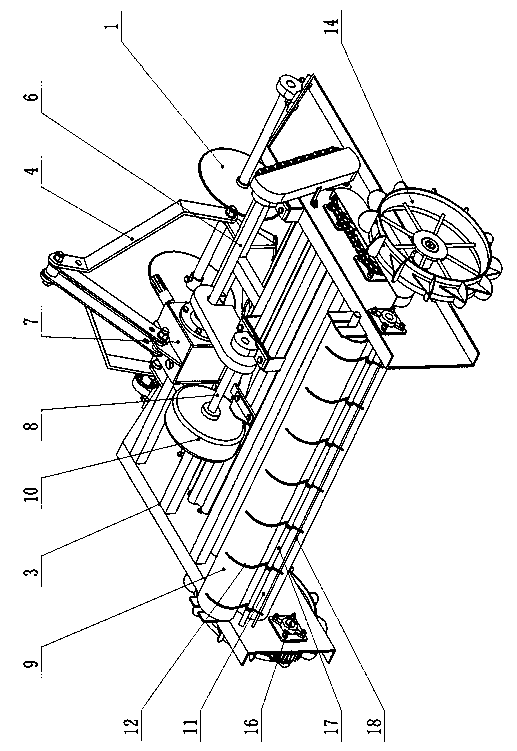

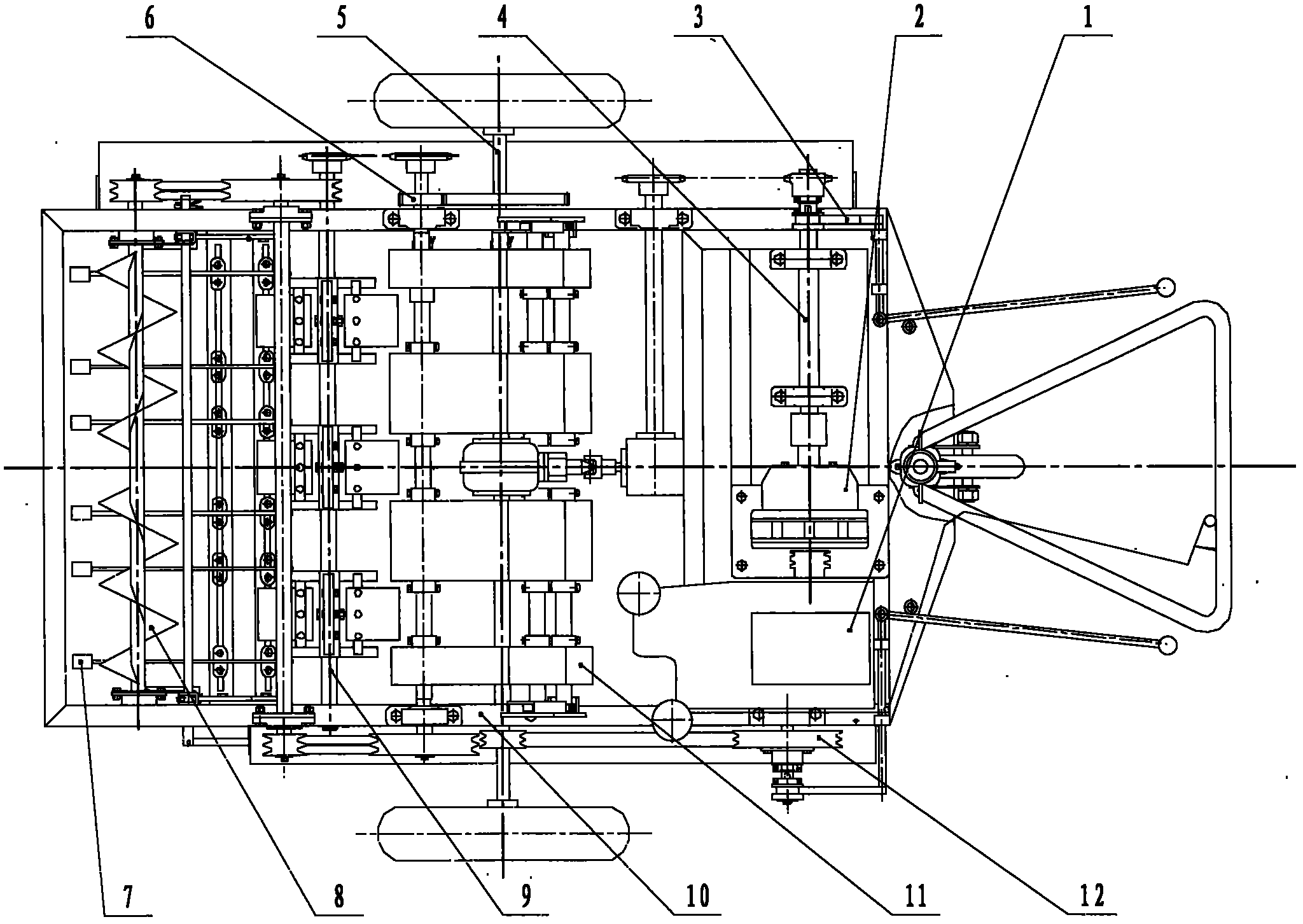

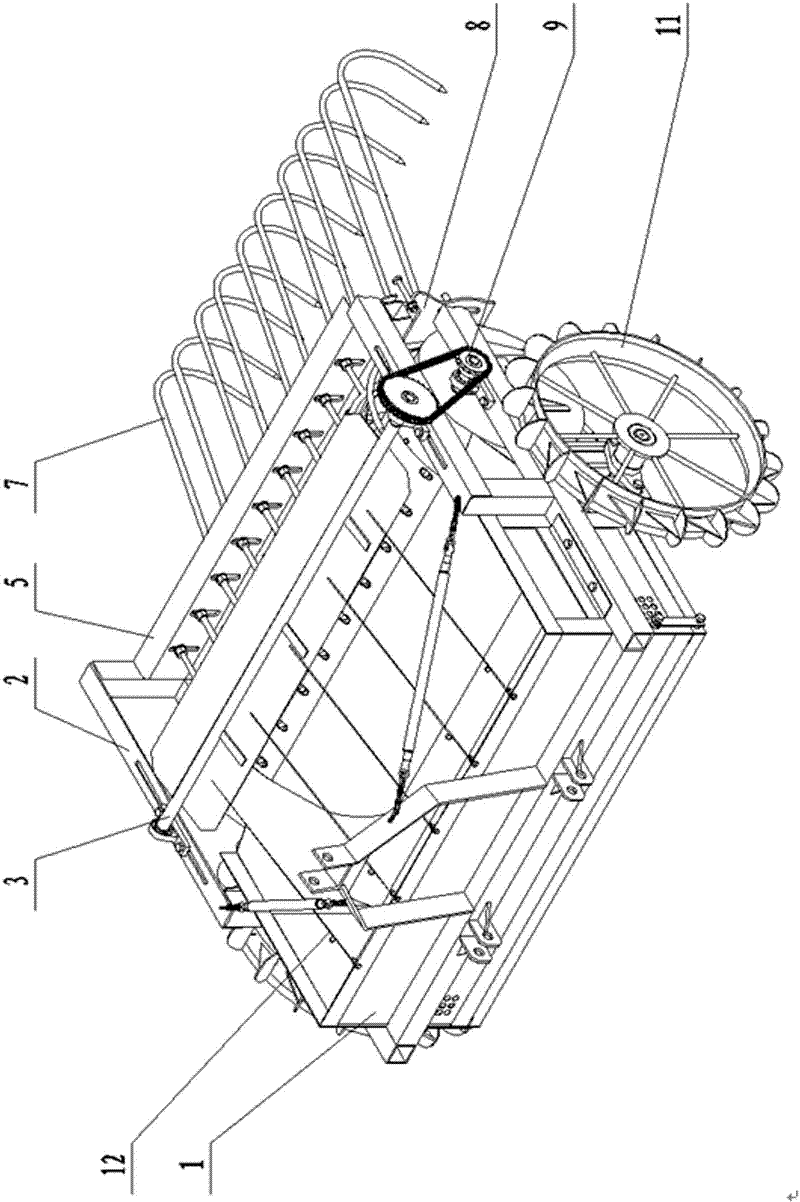

Land preparation and residual plastic film recycling combined machine

InactiveCN102144439AHigh recovery rateMeet recycling requirementsSpadesPloughsCircular discAgricultural engineering

The invention relates to a land preparation and residual plastic film recycling combined machine, belonging to the field of agricultural machinery and comprising a traction device, a frame, a transmission system, a soil turning device, a residual plastic film box, land wheels, a residual plastic film recycling device and a pressing roller; the combined machine is characterized in that the traction device is installed at the front side of the soil turning device; the residual plastic film box is arranged at the rear side of the soil turning device; the residual plastic film recycling device is arranged at the rear side of the residual plastic film box in a hinging manner; the pressing roller is installed at the rear side of the residual plastic film recycling device; the soil turning device consists of a plurality of disk harrow plates; the residual plastic film recycling device consists of a sprocket harrow, a film removing wheel and a soleplate; the sprocket is provided with ratches; and the soleplate is arranged at the lower side of the sprocket harrow and has a certain gap with the ratches. The land preparation and residual plastic film recycling combined machine disclosed by the invention has good land preparation effect, high working speed, can pack up the residual plastic films on the land surface with high recycling rate for the residual plastic films and can meet requirements of seedbed preparation and residual plastic film recycling treatment.

Owner:SHIHEZI UNIVERSITY

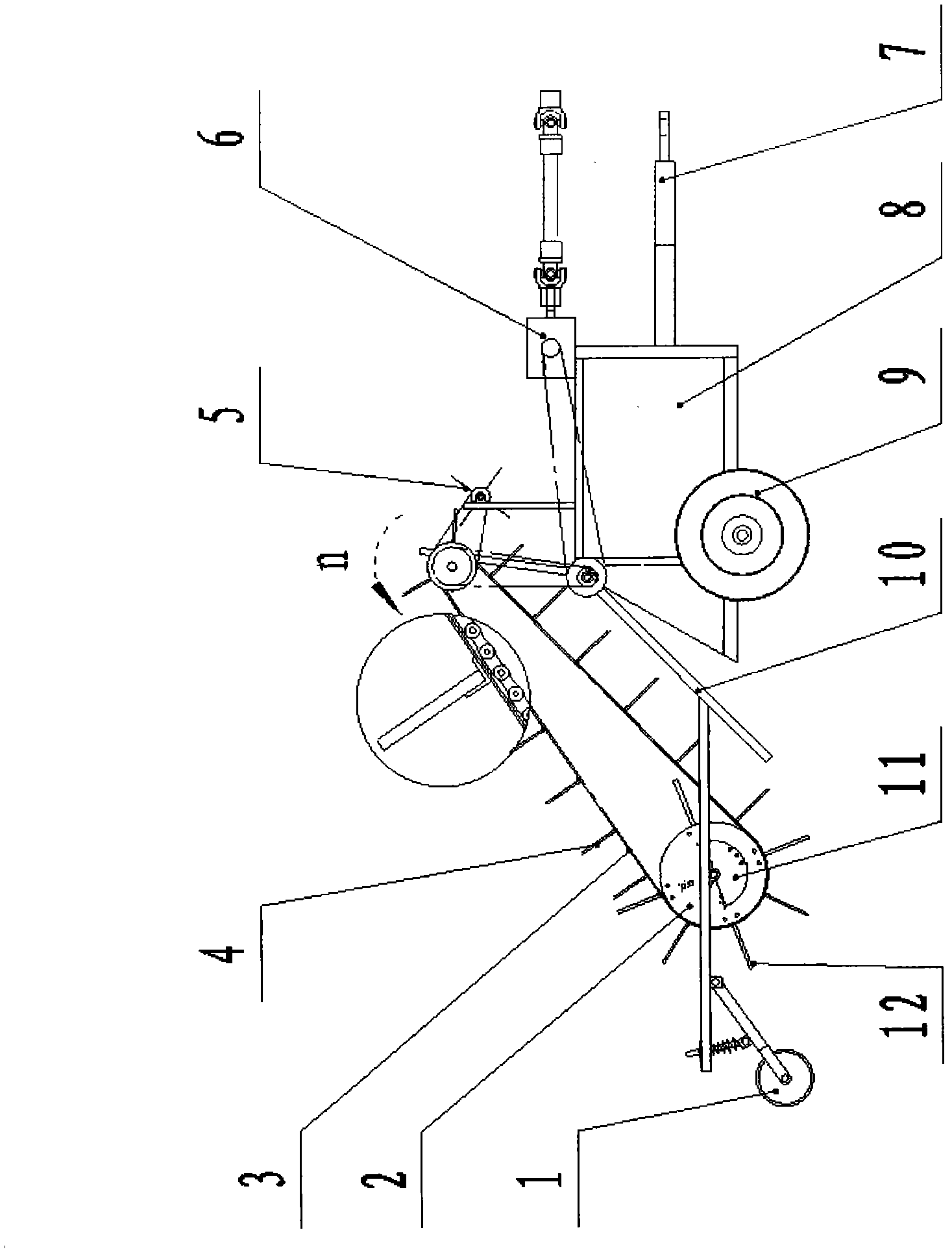

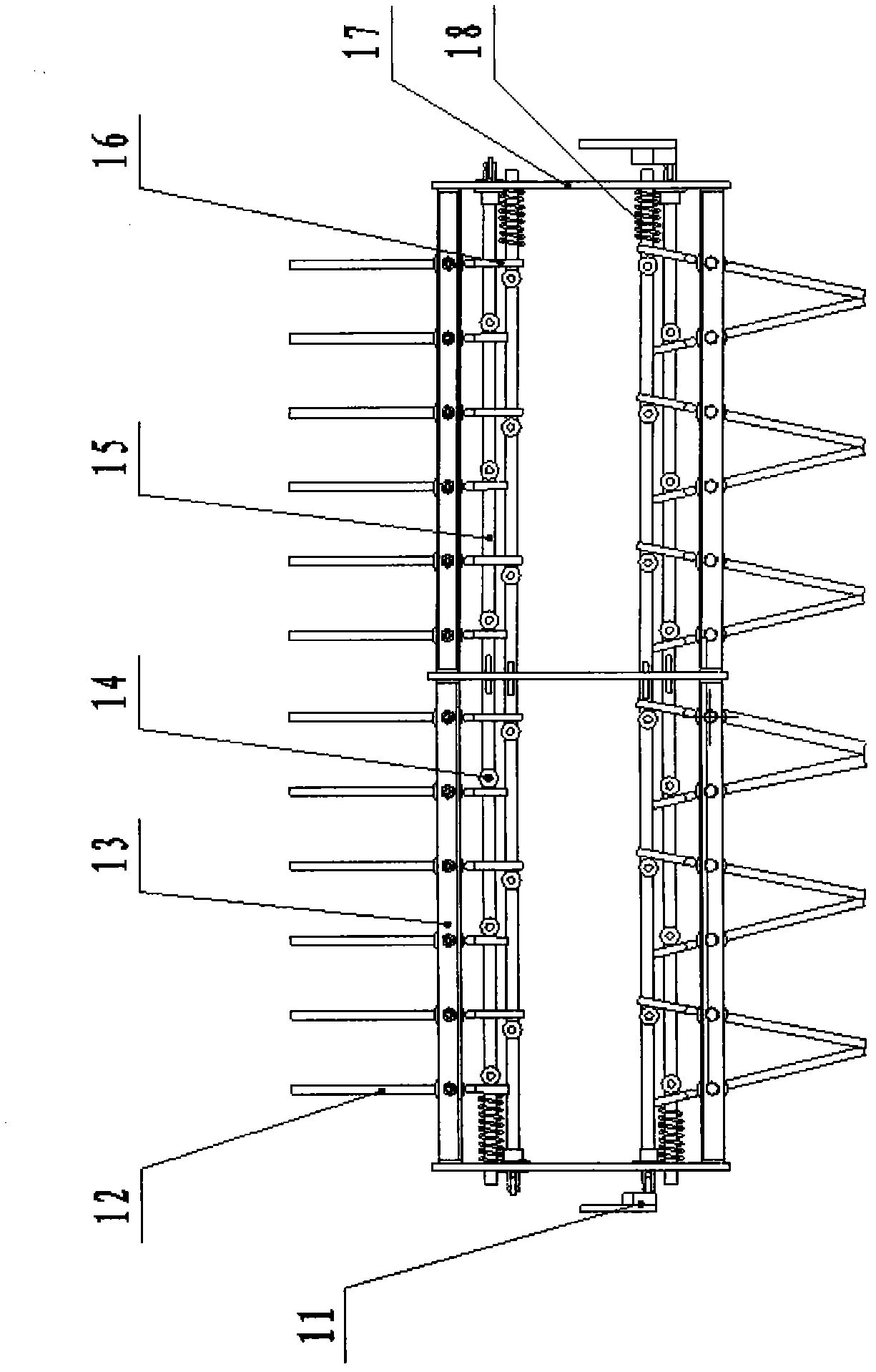

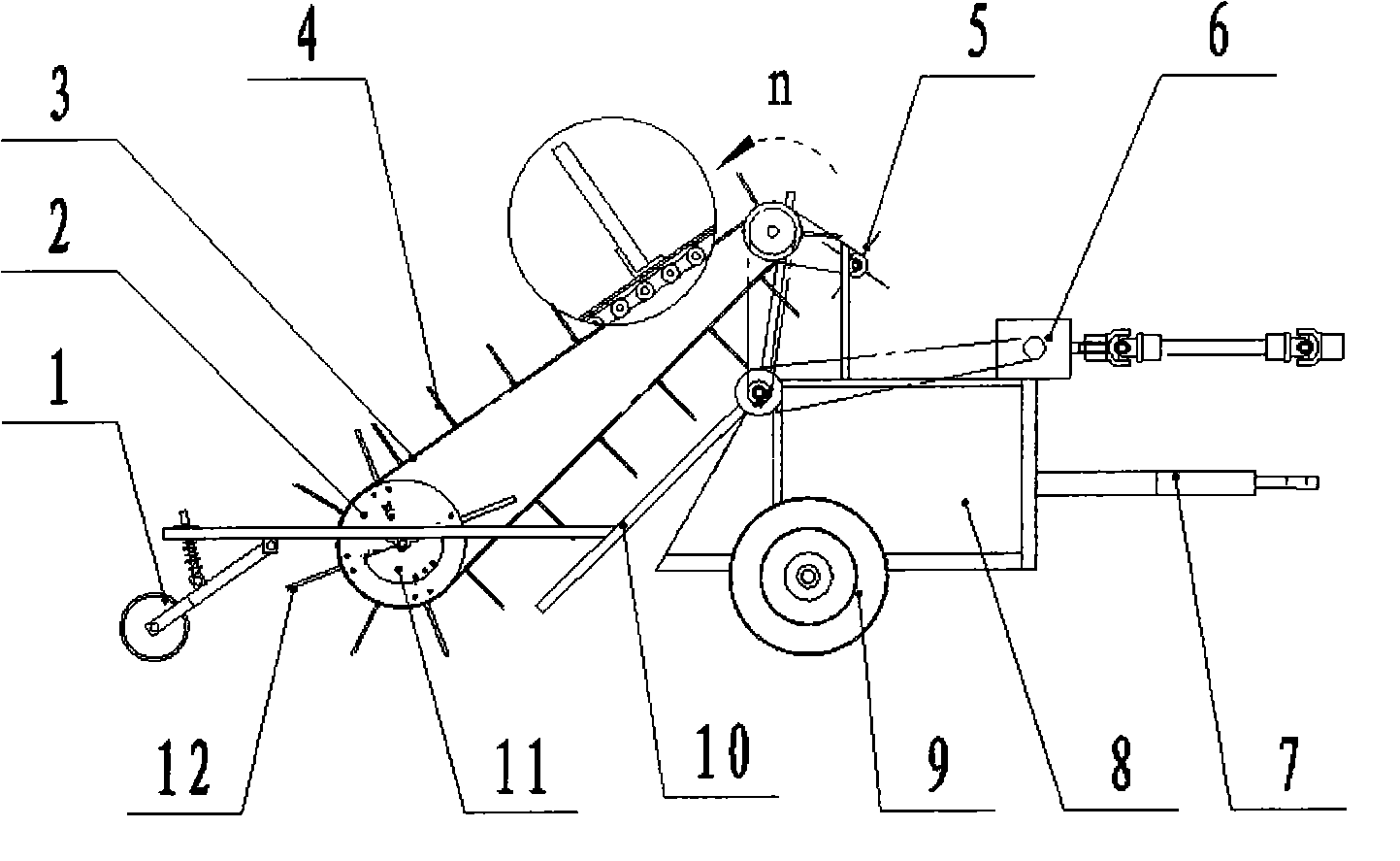

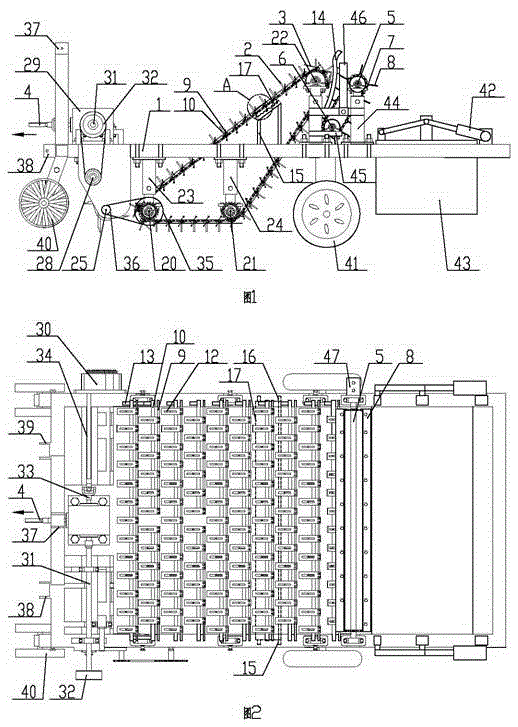

Novel straw smashing and film residue recycling machine

InactiveCN102726136ARecycle cleanNot easy to tangleCrop conditionersMowersMechanical engineeringImpurity

The invention relates to a novel straw smashing and film residue recycling machine comprising a traction device (1), a transmission system (2), a frame (20), a film residue box (10), a land wheel (19), a straw smashing device, a straw feeding device and a film residue recycling device, wherein the straw smashing device is composed of a cutter shaft (5), a blade (4) and a shield (3); the straw feeding device is composed of a straw conveying chain (6), a scraper (7), a base plate (8) and a tail plate (9); the film residue recycling device is composed of a film residue feeding chain (15), a film scraper (16), a film lifting rack and a suspension rod (17); and the film lifting rack is composed of a film lifting tooth (18), a grid bar (14), a frame (13) and a slide rail (12). The novel straw smashing and film residue recycling machine is simple in structure, high in operation speed, good in ground profiling capability, clean in film residue recycling, and low in impurity content in the recycled film residue; besides, the film residue is not easy to intertwine around a working component; and therefore, the machine is capable of meeting the requirements of straw smashing and film residue recycling.

Owner:SHIHEZI UNIVERSITY

Machine for recycling mulch film during seedling stage

InactiveCN101496464AGuaranteed to work continuouslyHigh yieldGatherer machinesAgricultural engineeringSeedling

The invention relates to a seedling period mulching film recovering machine. The seedling period mulching film recovering machine is characterized in that: the seedling period mulching film recovering machine comprises a film raising wheel, a film obstructing and unloading flat belt and a film unloading wheel; the film raising wheel is designed into a wheel type and is fixedly arranged on a machine frame on both sides of crop seedlings; a plurality of film raising teeth are circumferentially arranged on the outer ring of the film raising wheel, and each film raising tooth has the same dip angle design; a pulley is fixedly arranged on the machine frame above the central line of the film raising wheel, the film raising wheel is taken as the other pulley, and the film obstructing and unloading flat belt is arranged between the film raising wheel and the pulley; the film unloading wheel is fixedly arranged on the machine frame on the rear upside of the film raising wheel and is connected with the film raising wheel through a driving chain; and a plurality of film scraping plates are circumferentially arranged on the outer ring of the film unloading wheel at the same angular intervals and are in contact with the film raising teeth and the film unloading flat belt. The seedling period mulching film recovering machine is characterized by simple structure, low power consumption, high film raising rate, low seedling hurting rate, low price, excellent performance, and the like. The seedling period mulching film recovering machine is suitable for being applied to and generalized in the recovery of seedling period mulching films of various crops.

Owner:CHINA AGRI UNIV

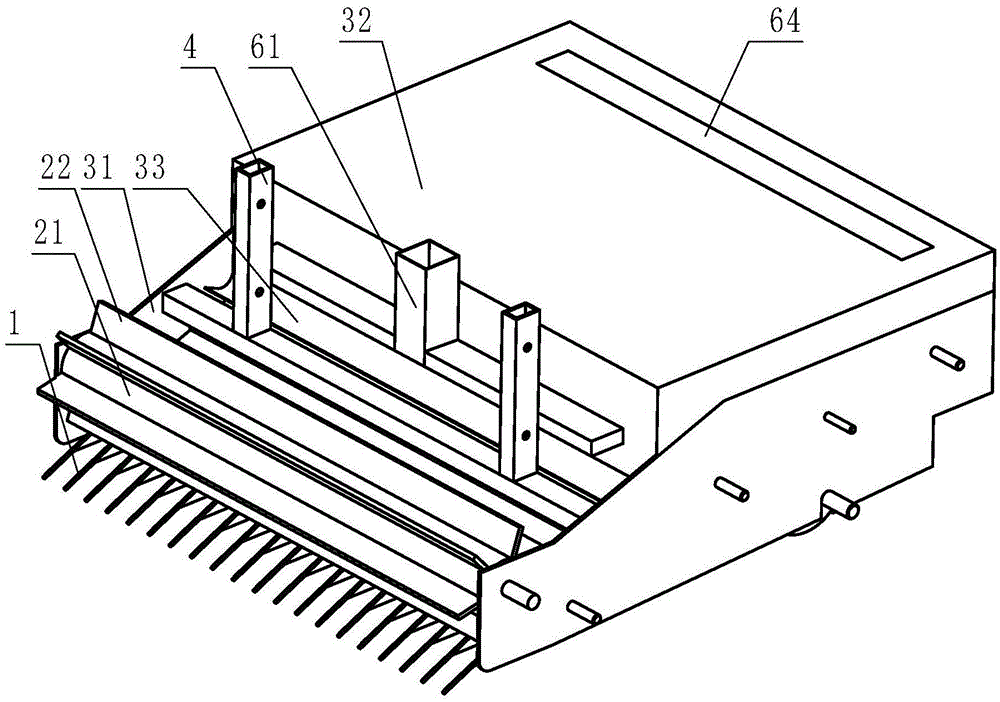

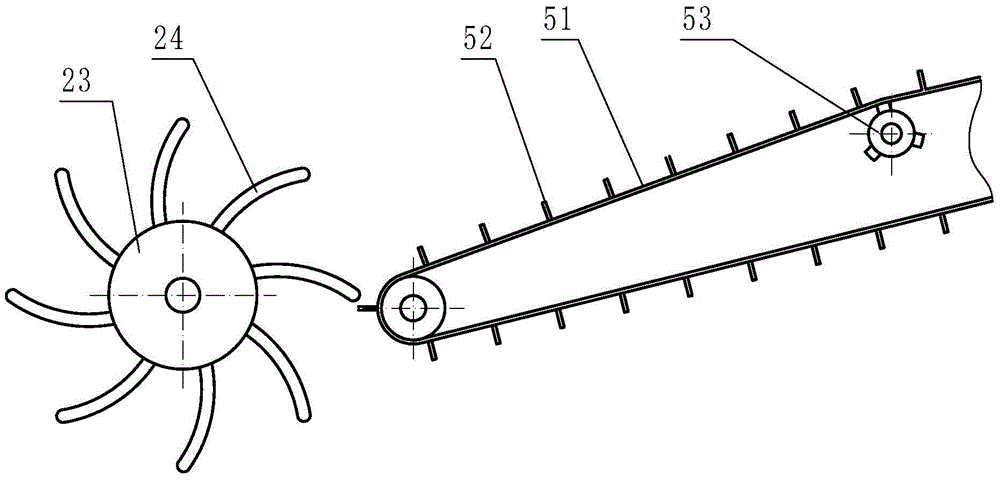

Vibration throwing pneumatic type mulch recycling operation method and machine

InactiveCN105409361AImprove recycling effectAchieve cleanupGatherer machinesPositive pressureEngineering

The invention discloses a vibration throwing pneumatic type mulch recycling operation method and machine. The machine comprises a main frame (31), a traction or suspension rack (4) and a transmission mechanism and is characterized in that a ploughing mechanism and a vibration conveying mechanism are sequentially arranged on the main frame from front to back; the vibration conveying mechanism comprises a conveying belt (51); vibrators (53) are arranged on the lower portion of the upper belt body of the conveying belt (51); a cover (32) is arranged above the vibration conveying mechanism; a positive-pressure blowing nozzle (62) and a corresponding negative-pressure induced draft nozzle (64) are arranged in the space formed between the cover (32) and the conveying belt (51); and the ploughing mechanism is of an elastic claw type or rotary tillage type. Compared with the prior art, the vibration throwing pneumatic type mulch recycling operation machine has the advantages that mulch fragments in soil are first cleaned by the ploughing mechanism and thrown to the vibration conveying mechanism; the vibration conveying mechanism vibrates to separate the soil-mulch mixture; and the mulch fragments can be picked up and collected by the positive-pressure blowing nozzle and the corresponding negative-pressure induced draft nozzle, so that the mulch fragments in the soil can be cleaned, the workload of soil processing can be lowered greatly, and the mulch recycling effect can be increased.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Soil screening remediation device

InactiveCN104170550AImprove repair effectEfficient removalSoil lifting machinesGatherer machinesChemical storageSoil treatment

The invention relates to the technical field of agricultural devices, in particular to a soil screening remediation device. The soil screening remediation device comprises a soil conveying belt, a soil taking shovel is mounted at the front end of the soil conveying belt, the rear end of the soil conveying belt is connected with a soil treatment tank, a film adsorption mechanism is mounted in the soil treatment tank, a screening device is mounted under the film adsorption mechanism, and a chemical spraying device is mounted below the spraying device and connected with a chemical storage tank through a delivery pipe. Through the soil screening remediation device, processes of soil turning, crushing, screening, chemical spraying, remediation and the like can be performed simultaneously, screening effect is good, mulching films and solid impurities can be removed effectively, and separation efficiency is high; the soil screening remediation device is simple in structure, chemical spraying holes in the chemical spraying device are arranged alternatively, chemical and soil are mixed more uniformly, time for soil impurity removal and remediation is short, and the remedied soil can be kept soft and highly breathable within a long time.

Owner:DANYANG BAODE ECOLOGICAL AGRI & FORESTRYDEV

High-voltage electrostatic absorptive film collector

InactiveCN102668747AMeet the agricultural requirements for separation and extractionMeet and adapt to the requirements of the film harvesting operationGatherer machinesEngineeringHigh pressure

The invention relates to a high-voltage electrostatic absorptive film collector, which belongs to agricultural machinery. A cone-shaped cage type rotary drum and a double-layered collecting tank which are communicated with each other are installed successively in the rear of a circular rotary conveyor belt assembly on a frame. A high-voltage electrostatic absorber is assembled in the cone-shaped cage type rotary drum, wherein the high-voltage electrostatic absorber is located above a centre line of the cone-shaped cage type rotary drum and is parallel to the centre line. A film scrapping assembly is sleeved on the high-voltage electrostatic absorber. A draught fan assembly is installed above the rear end of the circular rotary conveyor belt assembly and in front of the cone-shaped cage type rotary drum. A joining plate is configured between the rear end of the circular rotary conveyor belt assembly and the front end of the cone-shaped cage type rotary drum. An assistant soil scrapping plate is assembled above a shovel stubble and film collecting assembly. The high-voltage electrostatic absorptive film collector provided by the invention meets the agricultural requirements of isolating and extracting films, stubbles, soils and impurities and has the advantages of novel and reasonable structural design, good operational quality and high efficiency.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

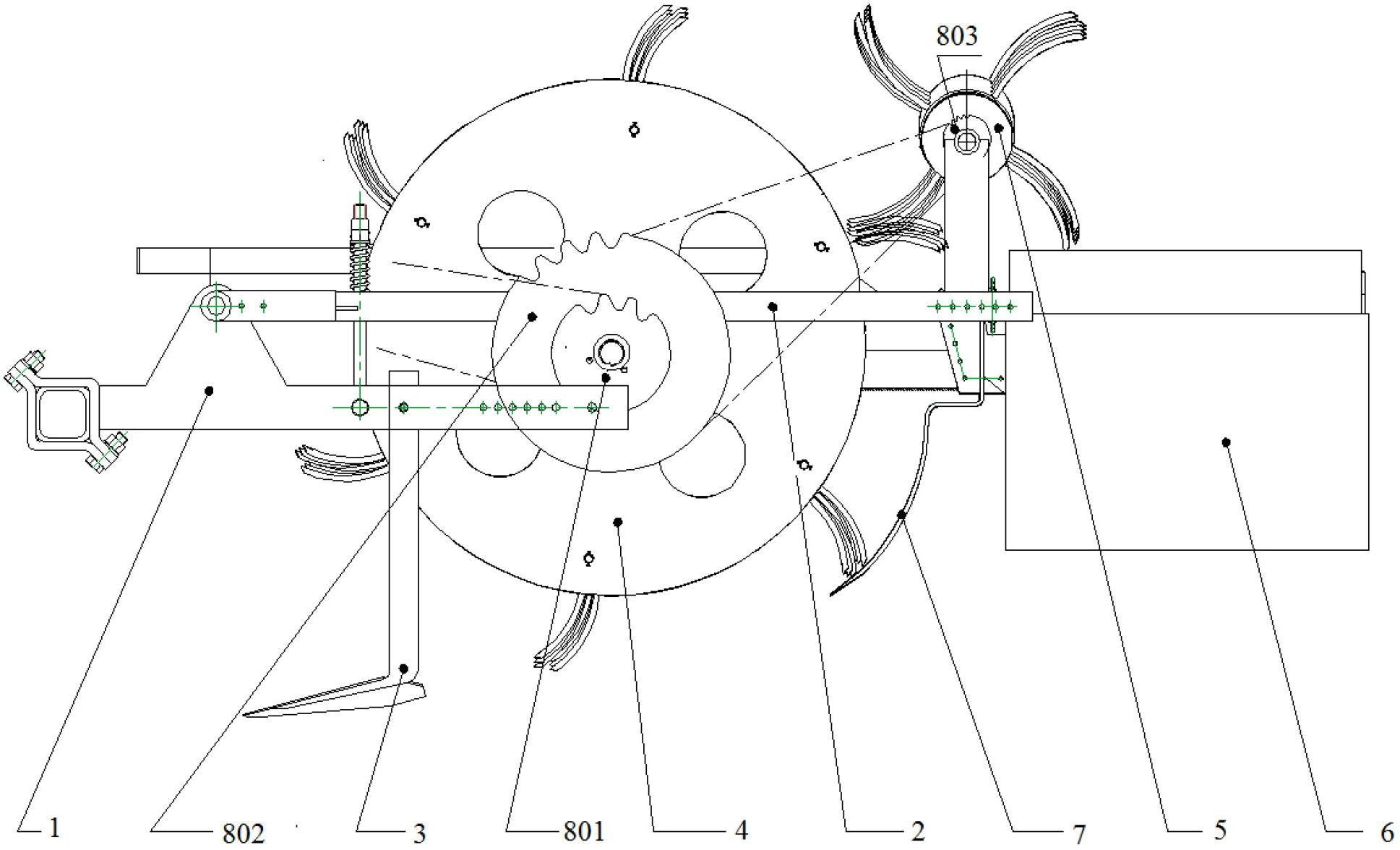

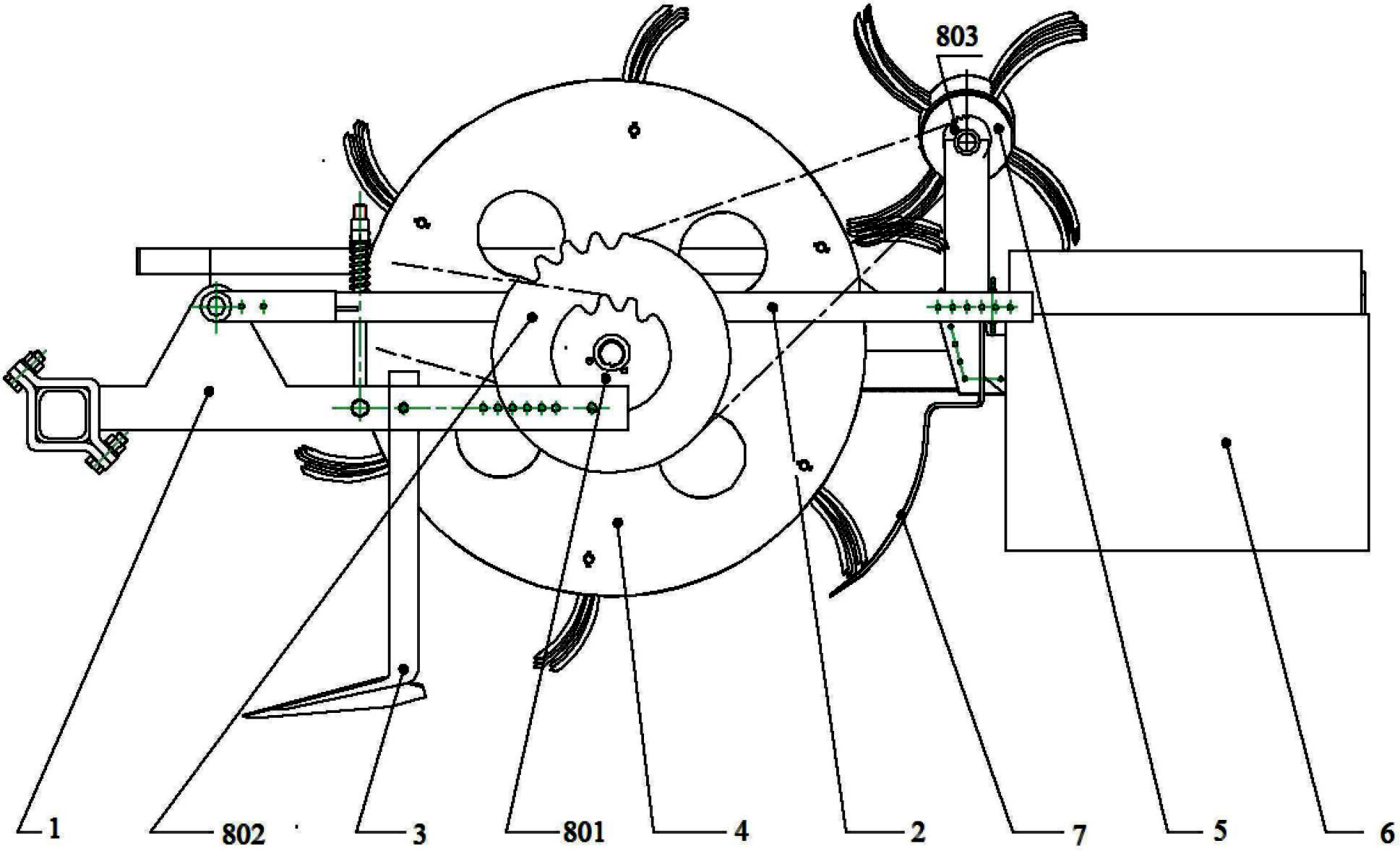

Film-picking and film-unloading mechanism for residual film recovery of straight-rod crops

InactiveCN102668939AReasonable configurationSimple structureGatherer machinesPlant protective coveringsDrive shaftEngineering

The invention belongs to the field of minitype agricultural machinery, and in particular relates to a film-picking and film-unloading mechanism for residual film recovery of straight-rod crops. A frame is connected with a profiling frame; a break shovel is arranged under the middle of the frame; a film-picking component and a film-unloading component are arranged in parallel on the profiling frame according to front and back positions; a first transmission wheel and a second transmission wheel which synchronously move are arranged on a drive shaft of the film-picking component; a third transmission wheel is arranged on a drive shaft of the film-unloading component; the first transmission wheel is connected with a traction mechanism through a chain; the second transmission wheel and the third transmission wheel are driven by the chain; film-rising shovels are arranged behind the film-picking component and on the profiling frame under the film-unloading component; and a film collection box is arranged at the rear end of the profiling frame. The mechanism is reasonable in arrangement, simple in structure and reliable in film-picking and film-unloading, low in cost and is convenient and feasible, and is convenient to mount and repair; and moreover, the mechanism can continuously operate, and the film can be picked cleanly.

Owner:CHINA AGRI UNIV

Recovery separator of cotton stalk and membrane

InactiveCN101032202AImprove cleaning rateIncrease productivityGatherer machinesAgricultural engineeringMembrane configuration

The cotton stalk and residual film recovering and separating machine includes walking wheels, a drawing carriage, a frame, a driving mechanism, a hydraulic mechanism, a cotton stalk collector and a residual film collector. The cotton stalk collector includes cotton stalk collecting box, a root cutting shovel, a cotton stalk holding plate and a cotton stalk drawing conveyer. The residual film collector includes a residual film collecting box, a blower and a cylinder with film picking shaft and film picking rod, and a guide plate extending into residual film collecting box. Compared with available technology, the present invention has the advantages of high production efficiency, high residual film collecting rate and capacity of separating cotton stalk and residual film.

Owner:吴春林 +1

Film release plate type agricultural film recovery machine

ActiveCN105580517AImplement automatic cleanupImprove the effective recovery rateGatherer machinesAgricultural engineering

The invention relates to the technical field of agricultural mulching film recovery machinery, in particular to a film release plate type agricultural film recovery machine. The film release plate type agricultural film recovery machine comprises a machine frame, a soil digging device and a film release plate type nail band device. The soil digging device capable of digging out a residual film is arranged under the front portion of the machine frame, the film release plate type nail band device capable of conveying the residual film is installed on the machine frame, the front portion of the film release plate type nail band device is obliquely arranged in the direction that the front portion is lower than the rear portion, and film picking spike teeth are evenly distributed on the outer side of the film release plate type nail band device. The film release plate type agricultural film recovery machine is reasonable and compact in structure and convenient to use, digs out residual films through the soil digging device, collects the residual films through the film picking spike teeth, remarkably reduces the probability that the residual films are wound or hung on the spike teeth, achieves automatic removal of the residual films on the film picking spike teeth, saves the time and labors, remarkably improves the effective recovery rate of the residual films, prolongs the service life of equipment and has the advantages of being safe, simple, convenient and efficient and capable of saving labors.

Owner:张朝书

Beach-cleaning system for separating litter from sand, trailer incorporating same, and method of using same

A box-shaped beach-cleaning trailer is configured to be loaded with, and collectively carry beach-cleaning equipment and a litter collection station. The beach-cleaning equipment are towed by a vehicle to collect litter on the sands. The litter collected by the beach-cleaning equipment is collected in the litter collection station. The trailer includes a pair of rail members disposed on upper edges of the respective opposite side wall portions such that the rail members face each other with an opening therebetween. A sieve unit is detachably mounted on the rail members, and is configured to move a back-and-forth direction along the rail members. The sieve unit is moved in a back-and-forth direction manually; or by using a driving mechanism including a drive wheel, a driven wheel, and a connecting rod arranged between the sieve unit and the driven wheel, for separating colleted litter of various sizes from sand.

Owner:HONDA MOTOR CO LTD

A device and a method used for separating light thin film from plants through breaking

InactiveCN105940785ACompact structureReduce manufacturing costGrain treatmentsGatherer machinesEngineeringElectrostatic attraction

The invention provides a device and a method used for separating light thin film from plants through breaking. The device comprises a centrifugal separation mechanism, a roller conveying mechanism, a breaking and winnowing mechanism and an electrostatic attraction mechanism, which are arranged from top to bottom successively. The centrifugal separation mechanism firstly performs mud shaking to remove big soil particles; small soil particles roll among rollers of the roller conveying mechanism and are removed; the breaking and winnowing mechanism breaks a mixture of plants and thin film and performs winnowing according to the characteristic that the specific gravities of the plants and the thin film are different to primarily remove thin film mixed with the plants; the electrostatic attraction mechanism performs deep attraction on the plants subjected to winnowing to further remove thin film mixed with the plants. The device can perform breaking and separating on thin film mixed with plants, is especially suitable for collecting mulching film and peanut vines separately, and is low in manufacture cost and convenient to operate.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com